Submitted:

19 July 2023

Posted:

19 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3.1. Materials

3.2. Sample preparation

3.3. Test and characterization

3. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xi Jinping. A Decisive Victory in Building a Moderately prosperous Society in all Respects and Striving for the Great Victory of Socialism with Chinese Characteristics for a New Era: A Report to the 19th National Congress of the Communist Party of China. Theoretical learning, 2017(12):4-25.

- Hu, Y.; Li, K.; Zhang, B.; Han, B. Strength Investigation and Prediction of Superfine Tailings Cemented Paste Backfill Based on Experiments and Intelligent Methods. Materials 2023, 16, 3995. [Google Scholar] [CrossRef] [PubMed]

- Cui Lisheng, Fu Ximing. Comprehensive development and application of dolomite ore. China Powder Industry, 2006, (2): 30-34.

- Zhang, T.; Shi, X.; Wang, Q.; Peng, W. Comprehensive Evaluation of the Performance and Benefits of SSA–GGBS Geopolymer Mortar. Materials 2023, 16, 4137. [Google Scholar] [CrossRef] [PubMed]

- Panda B, Paul S C, Hui L J, et al. Additive manufacturing of geopolymer for sustainable built environment. Journal of Cleaner Production, 2017, 167: 281-288. [CrossRef]

- Kamal, Abdelli, Mahfoud, et al. Influence of the pozzolanic reactivity of the Blast Furnace Slag (BFS) and metakaolin on mortars. Energy Procedia, 2017. [CrossRef]

- Kathirvel P, Kaliyaperumal S. Influence of recycled concrete aggregates on the bending properties of reinforced alkali activated slag concrete. Construction & Building Materials, 2016, 102(JAN.15PT.1):51-58. [CrossRef]

- Han Dan, Che Yunxuan, Song Peng, et al. Preparation and mechanical properties of metakaolin base polymer. Sichuan Cement, 2014, 000(005):120-123.

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Cheng T W, Chiu J P. Fire-resistant geopolymer produce by granulated blast furnace slag. Minerals Engineering, 2003, 16(3):205-210. [CrossRef]

- Cohen, E.; Peled, A.; Bar-Nes, G. Dolomite-based quarry-dust as a substitute for fly-ash geopolymers and cement pastes. J. Clean. Prod. 2019, 235, 910–919. [Google Scholar] [CrossRef]

- Yip, C.K.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S. Carbonate mineral addition to metakaolin-based geopolymers. Cem. Concr. Compos. 2008, 30, 979–985. [Google Scholar] [CrossRef]

- M. Szybilski, W. M. Szybilski, W. Nocuń-Wczelik. The effect of dolomite additive on cement hydration. Procedia Engineering, 2015, 108: 193-198. [CrossRef]

- Mikhailova, O.; Yakovlev, G.; Maeva, I.; Senkov, S. Effect of Dolomite Limestone Powder on the Compressive Strength of Concrete. Procedia Eng. 2013, 57, 775–780. [Google Scholar] [CrossRef]

- Aizat, E.A.; Al Bakri, A.M.M.; Liew, Y.M.; Heah, C.Y. Chemical composition and strength of dolomite geopolymer composites. 2017. [Google Scholar] [CrossRef]

- Yin Suhong. Study on alkali induced gelling and grouting materials of carbonate ore. Guangzhou: South China University of Technology, 2004.

- Wang Jing, ZHANG Yaojun, Wang Yachao. Preparation of fly ash and slag base polymer toughened by asphalt and polypropylene fiber. Bulletin of the Chinese Ceramics, 2013, 32(007):1432-1437.

- Wang Chang’an, Wu Yuliang, Guo Minyi, et al. Development and application of emulsified asphalt and its emulsifier. Guangzhou Chemistry, 2006, 031(001):54-60.

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Liu Leping, Cui Xuemin, Kuang Peizhang, et al. A geopolymer/emulsified asphalt composite and its preparation method, CN103232182A[P].

- J. Davidovits. Properties of geopolymer cements. First international conference on alkaline cements and concretes. Kiev, Ukraine: Kiev State Technical University, 1994, 1: 131-149.

- J. Davidovits. Geopolymers: inorganic polymeric new materials. Journal of Thermal Analysis and calorimetry, 1991, 37(8): 1633-56. [CrossRef]

- Liu Leping, Tan Hua, Deng Jiaxi, Kuang Peizang, He Yan. Properties and reaction mechanism of slag base polymer dry powder materials. Journal of Wuhan University of Technology,2014,36(06):36-40.

- Wang, H.; Li, H.; Yan, F. Synthesis and mechanical properties of metakaolinite-based geopolymer. Colloids Surfaces A: Physicochem. Eng. Asp. 2005, 268, 1–6. [Google Scholar] [CrossRef]

- Lin, W.; Zhou, F.; Luo, W.; Song, T.; Li, H. Alkali-activated dolomite and its outstanding mechanical strength. Mater. Lett. 2020, 270, 127682. [Google Scholar] [CrossRef]

- Lin, W.; Zhou, F.; Luo, W.; You, L. Recycling the waste dolomite powder with excellent consolidation properties: Sample synthesis, mechanical evaluation, and consolidation mechanism analysis. Constr. Build. Mater. 2021, 290, 123198. [Google Scholar] [CrossRef]

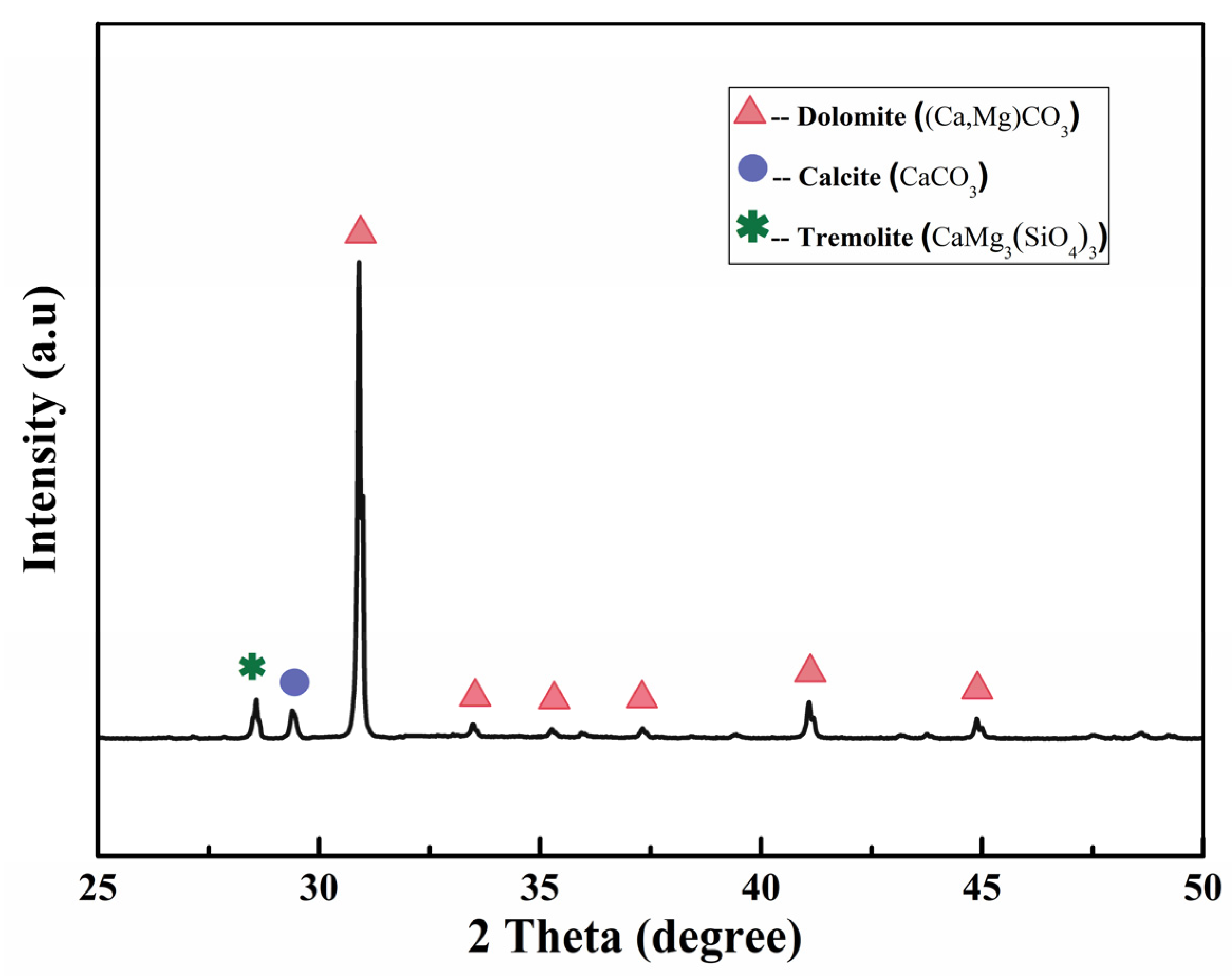

| CO2 | CaO | MgO | SiO2 | Al2O3 | Fe2O3 | Na2O | K2O | P2O5 |

|---|---|---|---|---|---|---|---|---|

| 45.22 | 24.31 | 24.11 | 5.58 | 0.53 | 0.19 | 0.03 | 0.02 | 0.01 |

| Name | Asphalt | Water | Emulsifier |

|---|---|---|---|

| JY-C2 | 48 | 51.10 | 0.90 |

| Types | Ion Species | pH | Angler Viscosity | Storage Stability (%) | Cohesion (N·m) |

|---|---|---|---|---|---|

| Medium breaking | cation | 2.98 | 10.95 | 0 | 1.28 |

| DAC | SAC [21] | |||||

|---|---|---|---|---|---|---|

| Compressive Strength (C) | Bending Strength (F) | C/F Ratio |

Compressive Strength (C) | Bending Strength (F) | C/F Ratio |

|

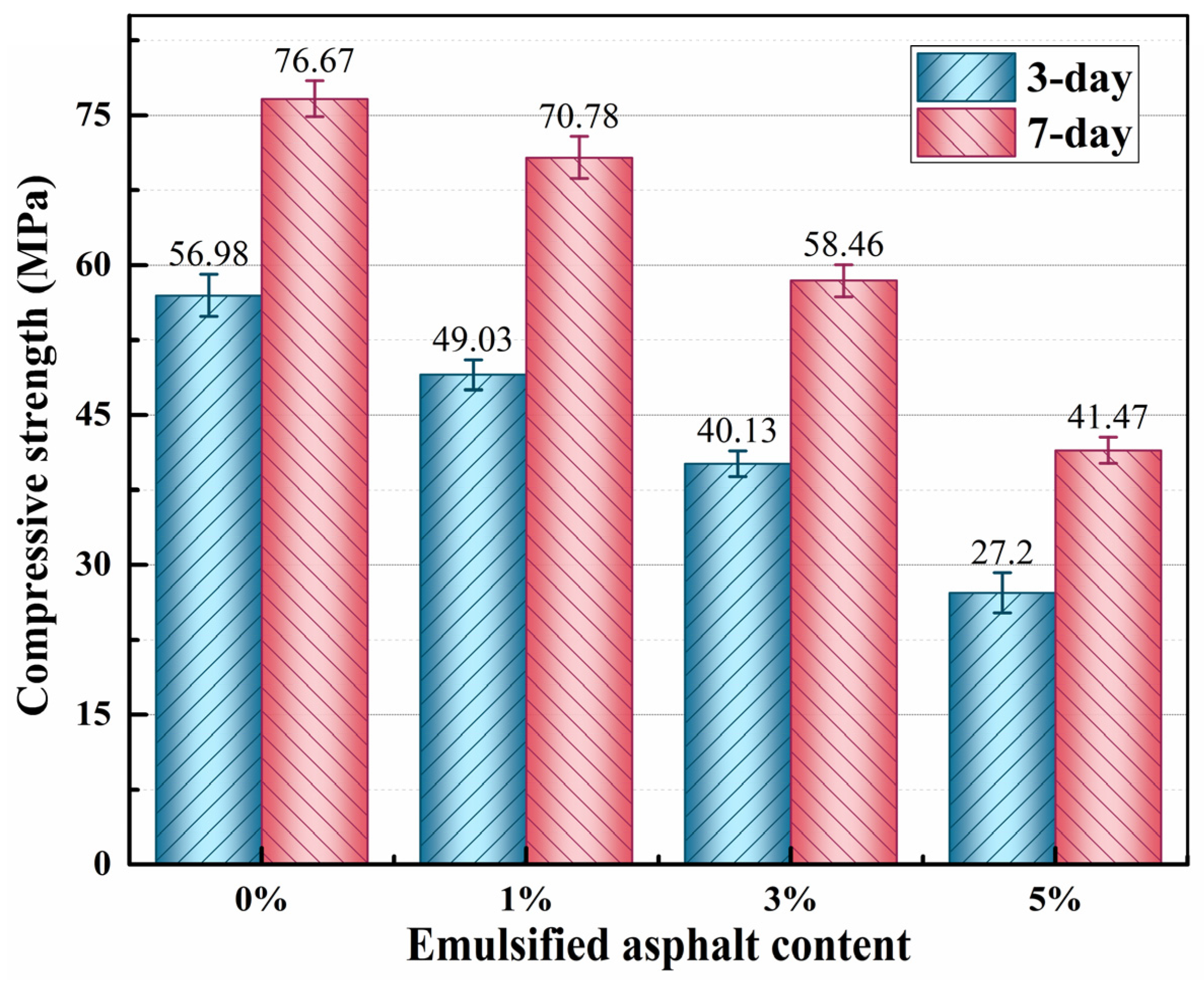

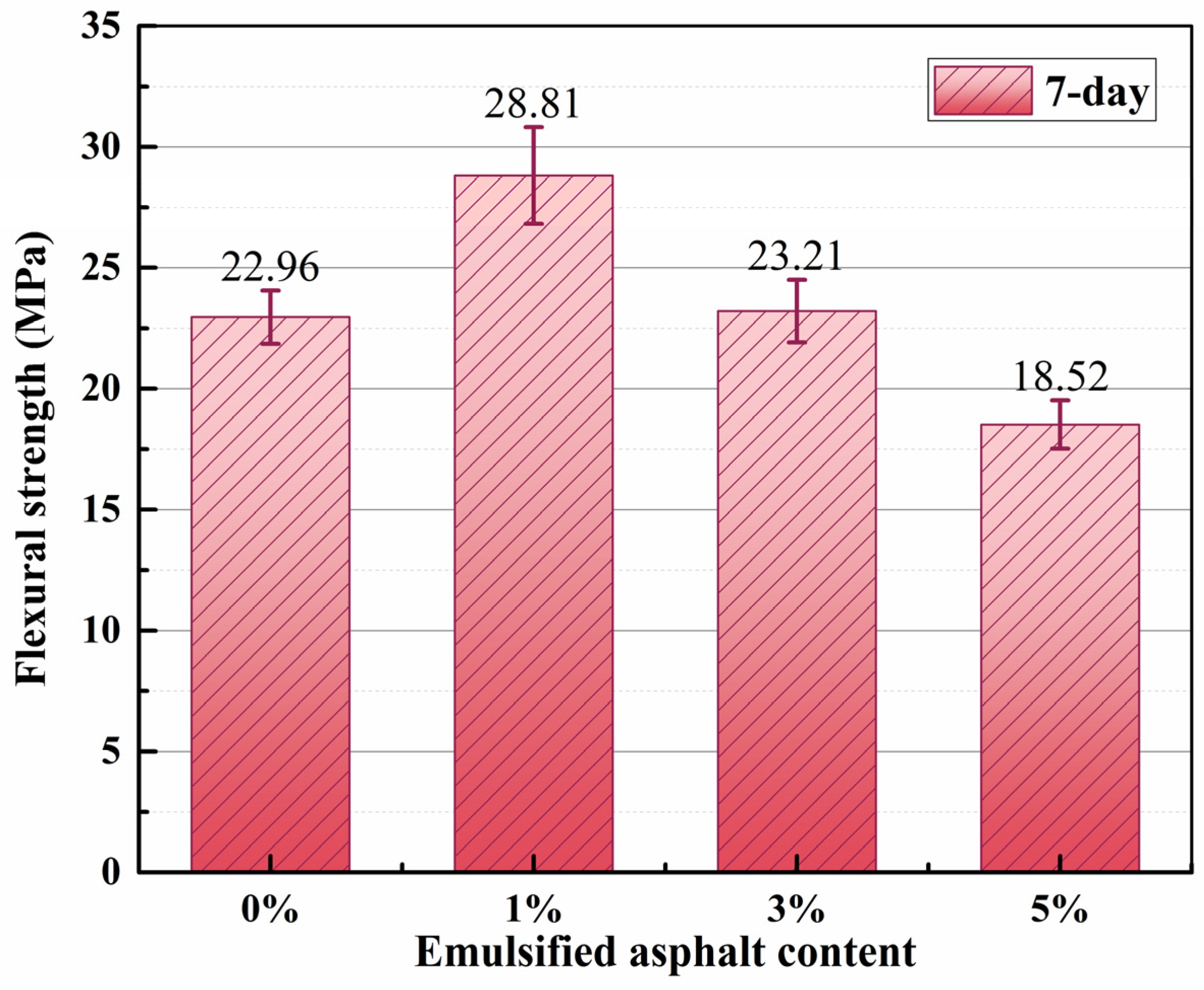

| Group 1 | 58.46 | 23.21 | 39.70% | 58.7 | 11.8 | 20.10% |

| Group 2 | 60.35 | 23.61 | 39.12% | 60.7 | 13.8 | 22.73% |

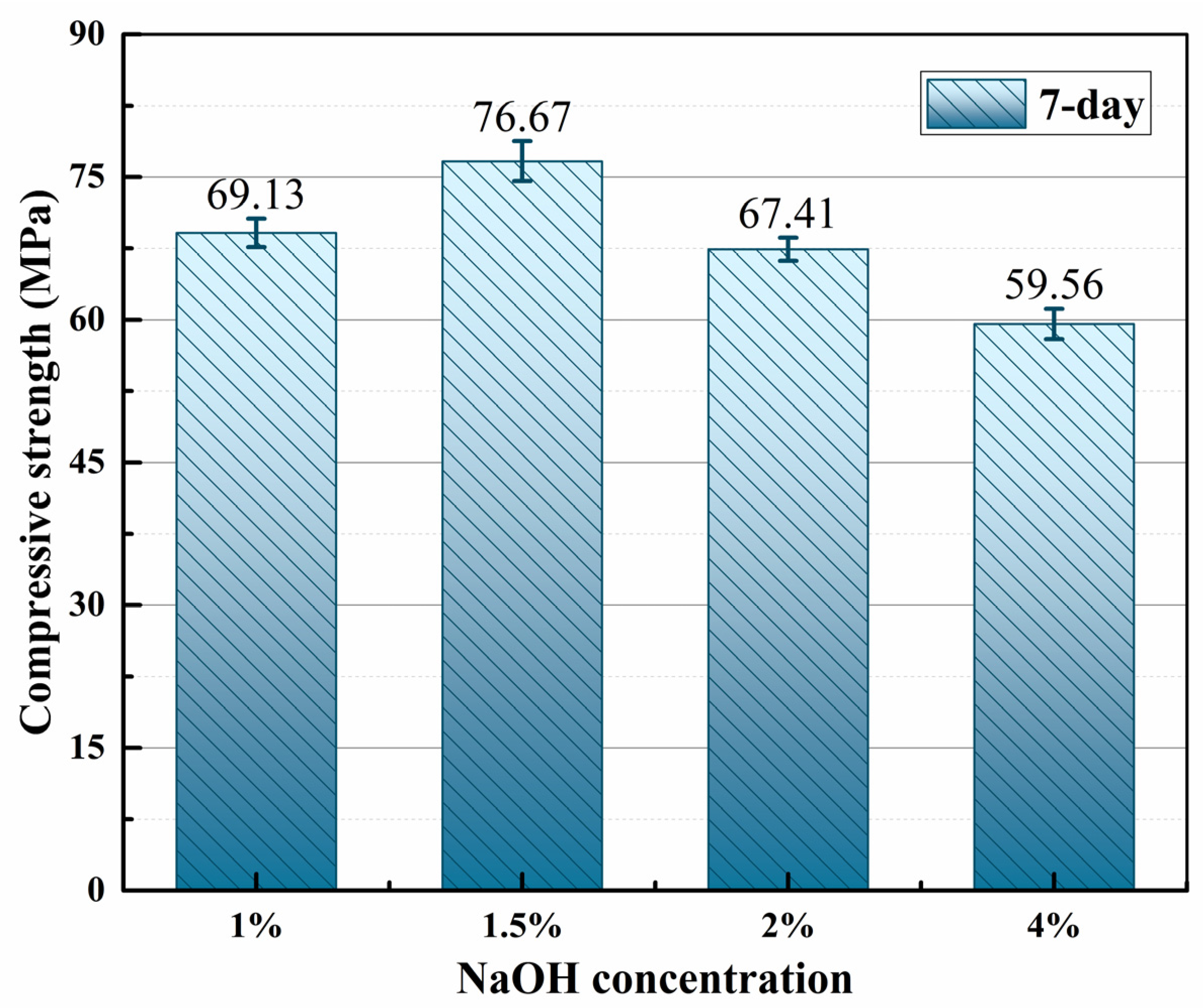

| Group 3 | 76.67 | 22.96 | 29.95% | 76.9 | 10.5 | 13.65% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).