1. Introduction

The digital era is the revolution that the world is experiencing today after mechanization, electrification, and automation. The term industry 4.0; which characterizes the new industrial revolution known as digitalization; was born in 2011 and was launched in Germany (Kagermann et al., 2013; Rojko, 2017). This new revolution integrates digitized technologies such as the Internet of Things, big data, additive manufacturing, cloud computing, cyber-physical systems (CPS) and many others. These digital technologies have been proved as an adequate solution to improve the development, productivity, and competitiveness of the company (Rojko, 2017; Relich, 2017).

The global recession of recent years has changed the overall view of the industrial sector. Industrial production today is conducted by global competition and the need to rapidly adapt production to market demand as it is constant evolution. These requirements can only be achieved through radical advances in current manufacturing technology.

In 2011, the German Government has given birth to a new section called Industry 4.0, considered the fourth industrial revolution (Kagermann et al., 2013; Weyer et al., 2015; Motyl et al., 2017; Grieco et al., 2017; Wagner et al., 2017). The goal is to achieve computerization and interconnection in traditional industry. According to several authors (MacDougall, 2014; McKinsey Digital, 2015; Deloitte AG, 2015), Industry 4.0 can be considered as a production of cyber-physical systems (CPS), based on a heterogeneous integration of data and knowledge and can be summarized as an interoperable, integrated, adapted, optimized manufacturing process, service oriented that correlates with algorithms, Big Data (BD) and high technologies such as the Internet of Things (IoT), industrial automation, cybersecurity (CS), cloud computing (CC) or intelligent robotics. (Gallab et al., 2021; Gallab et al., 2022; Naciri et al., 2022) have summarized these technologies in more detail and listed research that addresses them further.

Because of its many benefits, reliability, and convenience, companies are increasingly interested in this revolution. In addition, to making production more efficient, precise, and varied, Industry 4.0 eases the load on operators by avoiding repetitive tasks, thereby reducing errors due to weariness and increasing their profitability (Koch et al., 2014; Pereira et al., 2017; Mamad, 2018; Yasanur, 2018; Waibel et al., 2018).

Before talking about Industry 4.0, industrial manufacturing went through three revolutions, the first having started with mechanization in the 1800s, the next was sparked by electrification and mass production, while the third is characterized through the introduction of microelectronics and automation ensuring flexibility at the production level, where a variety of products are manufactured on flexible production lines with programmable machines. However, such production systems do not yet have flexibility regarding the quantity of production.

Triggered by the trend towards digitization, the fourth industrial revolution is the first to be announced even before its development. This is Industry 4.0 which offers a whole new approach to problem solving (Rojko, 2017).

In fact, 76% of manufacturers either have a smart factory initiative underway or are working on its formulation, and more than half of manufacturers (56%) have invested $ 100 million or more on digital companies. However, only 14% of companies have been able to successfully have smart factories. In addition, only 6% of manufacturers have reached an advanced stage of digitization of production processes with large profits (Capgemini, 2017).

In this context and to better facilitate the choice for companies and help them to make decisions, this work aims to specify for each sector the most appropriate technologies to put in place to achieve the fixed profits and generate benefits.

Indeed, and according to a study carried out by Capgemini Digital Transformation Institute in 2017 showed that industrial manufacturing achieved 20% of the profits by involving in the intelligent industry, and 19% for the automotive sector, 18% energy & utilities and 17% for aerospace and defense, etc. The expected gains for these companies are: On-time delivery; Quality and Scrap; Capex & Inventory, Material, Logistics and Transportation; Labor cost; overall productivity.

The objective of this paper is to help companies select the best digital technologies and with respect to the chosen criteria, especially when quantitative data are unavailable and the decision is to be made by experts. To deal with the uncertainty of experts’ knowledges and opinions a TOPSIS method under hesitant fuzzy information was adopted. To the best of our knowledge, this is the first study using Hesitant fuzzy MCDM for technologies 4.0 selection in automotive industry. Other works such as the work of (Soni et al., 2022) has developed a hesitant fuzzy-based technology selection framework limited to choose the suitable technologies for Sustainable Supply Chain Finance for Small and medium enterprises (SME). This work addresses some applications of hesitant fuzzy logic. Nevertheless, the existing literature review does not address a generic technology selection model and more specifically for the automotive sector. The model we propose is not only based on the hesitant fuzzy but combined with a multi-criteria method.

This paper is structured as follows: the 2nd section proposes the methodology to follow. The third exposes TOPSIS method under hesitant fuzzy information. The 4th presents the sectoral assessment of industrial companies in Morocco. The 5th section discusses the results, followed by the sensitivity analysis. Finally, some conclusions are provided.

2. The proposed Methodology

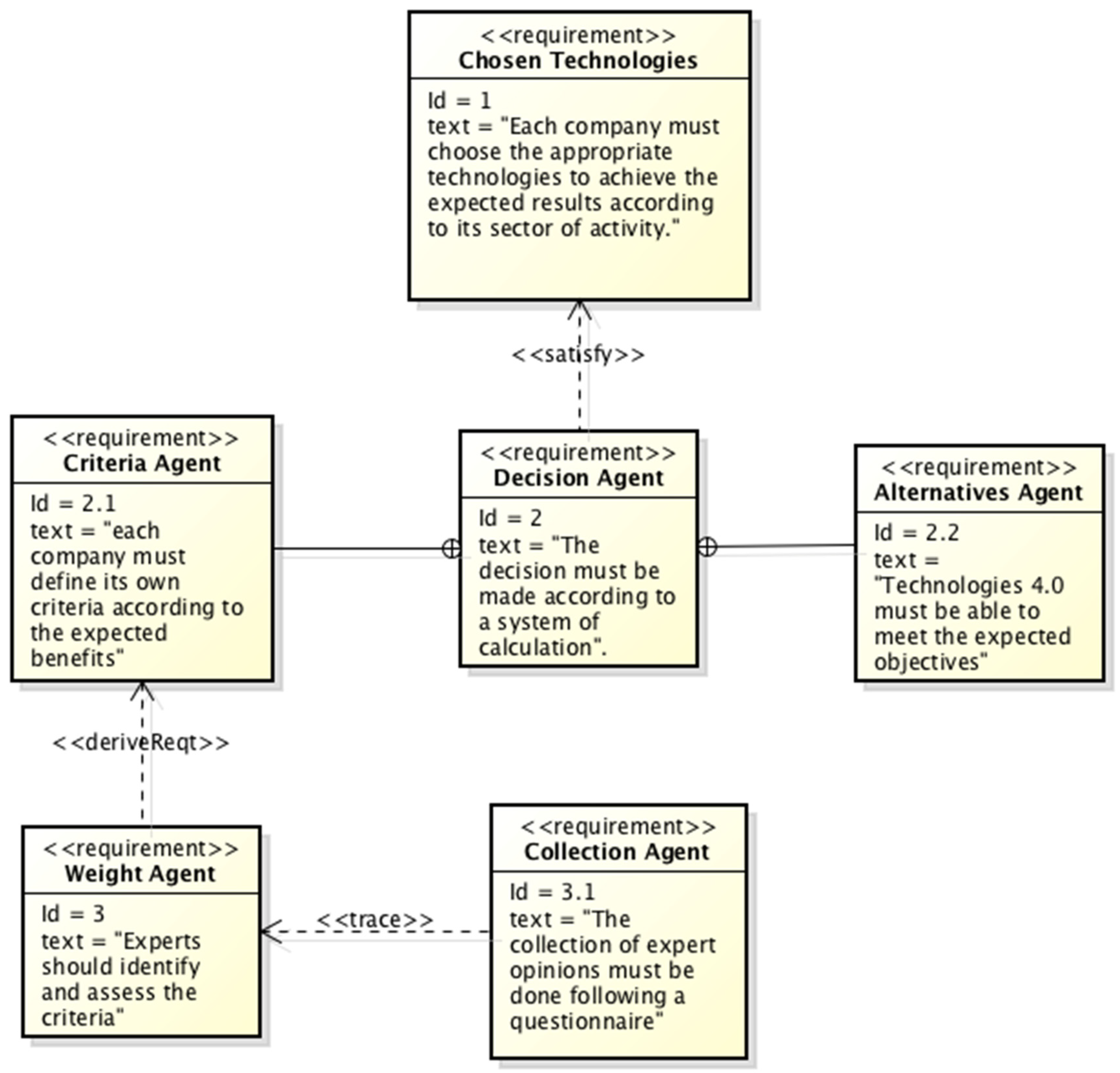

This work presents firstly a generic model based on the Multi-Agent Approach, allowing any company, whatever its sector of activity, to choose the right digital technologies appropriate to its activity and guaranteeing the achievement of expected goals.

Figure 1 illustrates a model of the proposed system. This system is made up of agents, their goal is to work in interaction to make the right classification decisions.

The agents of this system are:

- -

Criteria Agent: choose the criteria that the company seeks to achieve;

- -

Alternatives Agent: the possible alternatives of technologies that the company plans to implement to achieve the said objectives;

- -

Weight Agent: allows to assign and grant a weight to each criterion based on the opinions of experts;

- -

Collection Agent: using the DELPHI method, this agent collects data based on a well-prepared and distributed questionnaire;

- -

Decision Agent: this agent uses the TOPSIS method coupled under hesitant fuzzy logic approach to classify technologies according to defined criteria.

The proposed model will allow each company to choose the appropriate 4.0 technologies for its activity and in order to achieve its own objectives. Based on the criteria set, according to its experts and using a questionnaire, the decision agent will classify the technologies (alternatives) according to their importance and using a decision-making model. This model is developed by combining the multi-criteria method with fuzzy logic.

3. TOPSIS method under hesitant fuzzy information

3.1. Hesitant fuzzy set (HFS)

In group decision making, it may be difficult for different DMs to specify a single value for the membership of an element to a given set. For instance, three decision makers can suggest three different membership degrees and . HFSs developed by Torra (Torra, 2010) allow to deal with such a situation as it allows the membership degree to be represented by a set of possible values . Hesitant fuzzy set provides a richer representation of uncertain and imprecise information.

Definition 1. A hesitant fuzzy set (HFS) A is defined as follows:

where

is a hesitant fuzzy element (HFE) or hesitant fuzzy number (HFN) composed of a set of membership degrees in

denoting the possible membership degrees of the element

to A. The hesitant fuzzy number can be simply expressed as

. When

, the hesitant fuzzy set is reduced into a simple fuzzy set.

Definition 2. Let be three HFNs, the following operations are defined:

- 1)

- 2)

- 3)

Definition 3. The score function of a HFN

is given as

where

is the number of elements in

.

Let and be two HFEs:

- 1)

If , then

- 2)

If , then

- 3)

, then

This score functions allow the comparison between HFNs.

Definition 4. Let be two HFNs and , some operations are defined as the following:

- 1)

- 2)

- 3)

- 4)

Definition 5. Let

be two HFNs,

the number of elements in

and

, the hesitant Hamming distance between

is defined as:

where

and

are the kth smallessed value in

and

respectively.

According to (Xia and Xu, 2011) the elements of and should be arranged in an increasing order. In addition, when the number of elements of and are different, the HFN with the minimum number of elements should be extended by adding its minimum value until it has the same size as the one with the maximum number of elements.

To support decision making, several models and tools were developed. One such well known example is Multi-Criteria-Decision Makin (MCDM). It refers to making decisions with respect to more than one criterion via a scientific approach (Gal et al., 2013). The main idea of MCDM is that breaking a problem down into sub-parts (alternatives, criteria ...), and then establishing the priority among the choices is a comprehensive way to understand it mathematically.

3.2. Hesitant Fuzzy TOPSIS

This study adopt the Technique for Order Preference by Similarity to an Ideal Solution (TOPSIS) under hesitant fuzzy information as MCDM approach. TOPSIS is a very flexible technique, easy to understand and has a sound mathematical concept compared to other many MCDM approaches (Hwang and Yoon, 1981; Shih et al., 2007). The ultimate goal of TOPSIS is to choose the alternative with the shortest distance from the positive ideal solution and the farthest distance from the negative ideal solution. TOPIS method has been widely extended to include information under different fuzzy representation such as traditional fuzzy set, interval number, interval valued fuzzy set, intuitionistic fuzzy set and interval valued intuitionistic fuzzy set (Chase, 1981; Chen, 2015; Chen and Tsao, 2008). A large variety of TOPSIS and its fuzzy variants are summarized by (Cevik et al., 2014).

Hesitant fuzzy TOPSIS (Xu and Zhang, 2013) is one of the popular extensions of TOPSIS method. Its main idea is to deal with MCDM problems under hesitant fuzzy information (Chen, 2000; Cables et al., 2012; Xu and Zhang, 2013; Yue, 2014; Zeng and Xiao, 2018). The literature highlighted several successful applications of Hesitant fuzzy sets in solving MCDM problems (Palczewski and Sałabun, 2019). Zeng and Xiao (2018) designed a new modified TOPSIS method under hesitant fuzzy environment. Its advantages and practical applications were also highlighted. (Senvar et al., 2016) used hesitant fuzzy TOPSIS in order to select the optimal location for a new hospital in Istanbul. (Cevik Onar et al., 2014) integrated interval type 2 fuzzy set and a Hesitant fuzzy TOPSIS in order to select strategic decisions. (Zhang et al., 2015) designed a new approach based on TOPSIS and linear programming to deal with hesitant fuzzy information in MCDM problems. (Sun et al., 2018) suggested a modified version of TOPSIS method that is able to deal with negative values. The new method is based on new correlation coefficient between hesitant fuzzy sets.

Let

be a set of alternatives to be evaluated with respect to a set of criteria

and let

be the weight vector of all criteria. A hesitant fuzzy decision matrix is given by:

where

is a HFN that represents the evaluation of the alternative

with respect to the criterion

according to the decision makers.

As per (Xu and Zhang, 2013), the TOPSIS method under hesitant fuzzy information can be summarized by the following steps:

Step 1: Determine the hesitant positive ideal solution (HPIS)

and the hesitant negative ideal solution (HNIS)

:

where

where

is the kth smallest value in

Step 2: Calculate the separation measure

of each alternative from the HPIS and HNIS, respectively using hesitant Hamming distance:

where

denotes the weight of jth criterion

Step 3: Calculate the relative closeness coefficient

of each alternative to the Hesitant ideal solution:

The Alternatives are then ranked according to values. The best alternative is that with the highest value.

4. Sectoral assessment of industrial companies in Morocco

A questionnaire was delivered to collect the needed data for this study. A study carried out by (Gallab et al., 2021), processes the data obtained from this questionnaire.

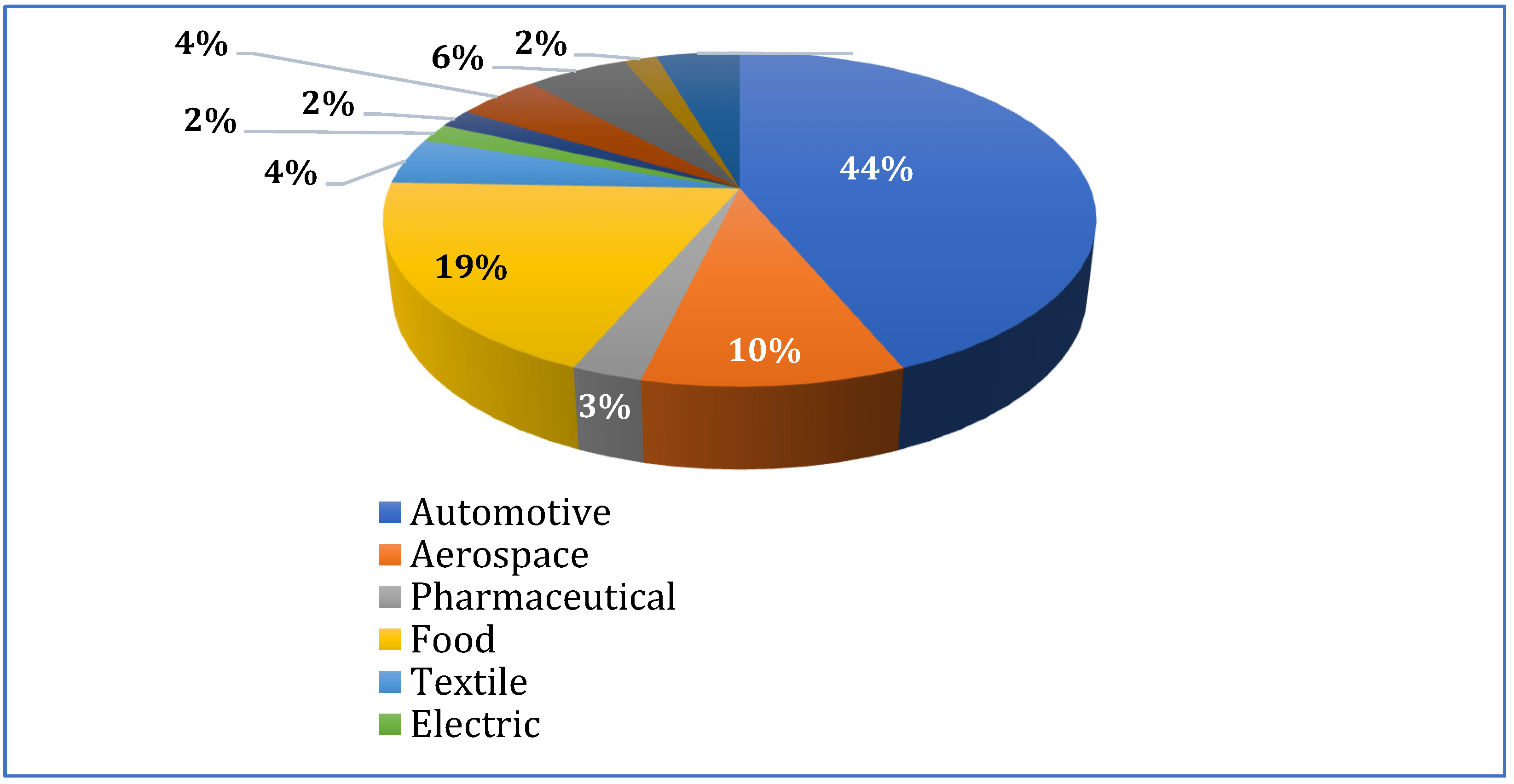

Figure 2 represents the distribution of industrial sectors in Morocco. The sectors: Automotive with 44%, Agri-food (19%), and Aerospace (10%) are the major industrial sectors in Morocco, which proves and reinforces the data presented by the ministry (Ministry of Industry, Trade, Green Economy and Digital, 2018).

According to these studies, the automotive sector is considered the 1st sector in Morocco. The 1st construction hub on the continent, with a wide platform for the production and export of motor vehicles of renowned foreign groups. Regarding the aviation sector, it is a sector that begins to know considerable development in the country. International companies start to settle in 15 years and the sector has more than 140 companies in 2018 (Ministry of Industry, Trade, Green Economy and Digital, 2018). The agri-food sector, is a pillar sector and represents one of the key sectors in the Moroccan economy. It is the country’s leading which balances domestic and international demand. It brings together 29% of Moroccan industrial companies (Moroccan Investment Development Agency, 2017).

The objective of this study is therefore, to specify and classify the appropriate technologies in the automotive sector to monitor the era of industry 4.0 and to make industries intelligent. The aim of adopting this new revolution is to generate more profits by increasing productivity and minimizing costs, to better structure the organization of the company, and to secure this data.

From the questionnaire and the collected results, we could know the most used technologies in each sector, the benefits gained, and the expected benefits by implementing the appropriate technologies for each sector. We also held with experts and rated the importance of each benefit according to each sector.

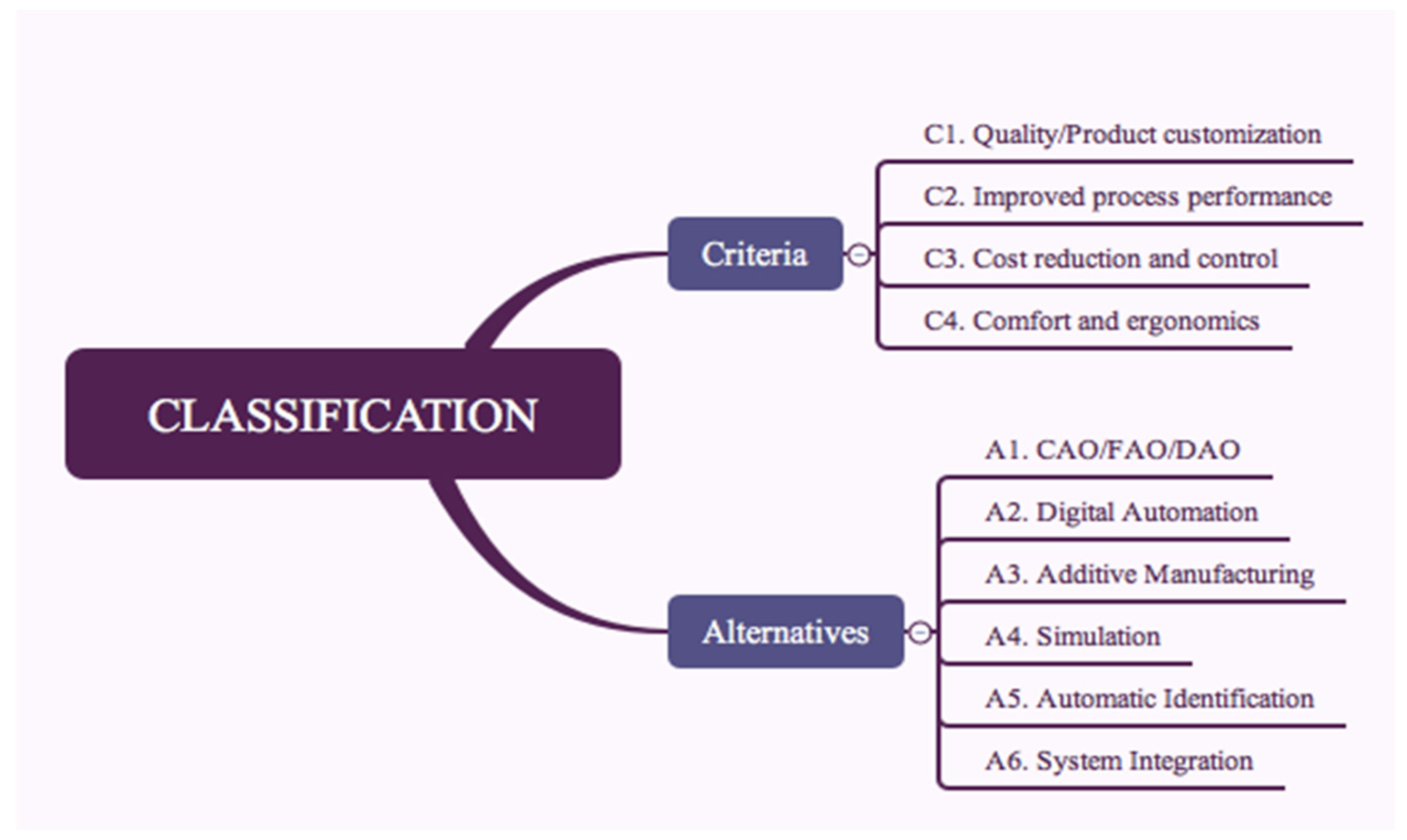

5. Results and Discussions

The TOPSIS method with hesitant fuzzy numbers is implemented to select 4.0 technologies for companies in Moroccan automotive sector. To collect the necessary data, a questionnaire was addressed to five experts in the field considering their positions, experiences, and academic background. They are asked to give scores in [0,1] to each technology with respect to the different criteria (

Figure 3). Experts are also asked to rate the importance (

) of each criterion. The obtained weights of each criterion are averaged. To ensure that

, the weights of the four criteria are then normalized. The obtained hesitant fuzzy decision matrix and the weight vector of all criteria are shown in

Table 1. It worth noting that when the number of the different membership degrees in a hesitant fuzzy element

is less than five, we add the minimal degree until reaching 5 elements. Here we suppose that decision makers are pessimistic.

The hesitant positive ideal solution and the hesitant negative ideal solutions are as follows:

The obtained results of the study are presented in

Table 2.

The findings suggest that simulation (A4) is the most desirable technology among the studied alternatives, followed by CAO/FAO/DAO (A1), Automatic identification (A5) and Digital Automation (A2) respectively. Finally, additive manufacturing (A3) ranked fifth followed by System Integration (A6).

For Cloud Computing, IOT, CPS are base technologies that ensure connectivity and intelligence to other ones (Frank et al., 2019, Masood and Sonnatag, 2020; Gallab et al., 2021). Thus, they are not taken into account in the classification of technologies.

Therefore, the question that should be asked first is what the added value can bring this technology. The answer to this question allows to find the right technology with the desired added value.

Indeed, the implementation of 4.0 has reformed the industry. For the automotive sector is already a pioneer sector; seeking continuous performance, improvement in productivity and quality; integrate long before the prerequisites of Industry 4.0 (Toyota Production System), and new implemented companies follow automatically this revolution.

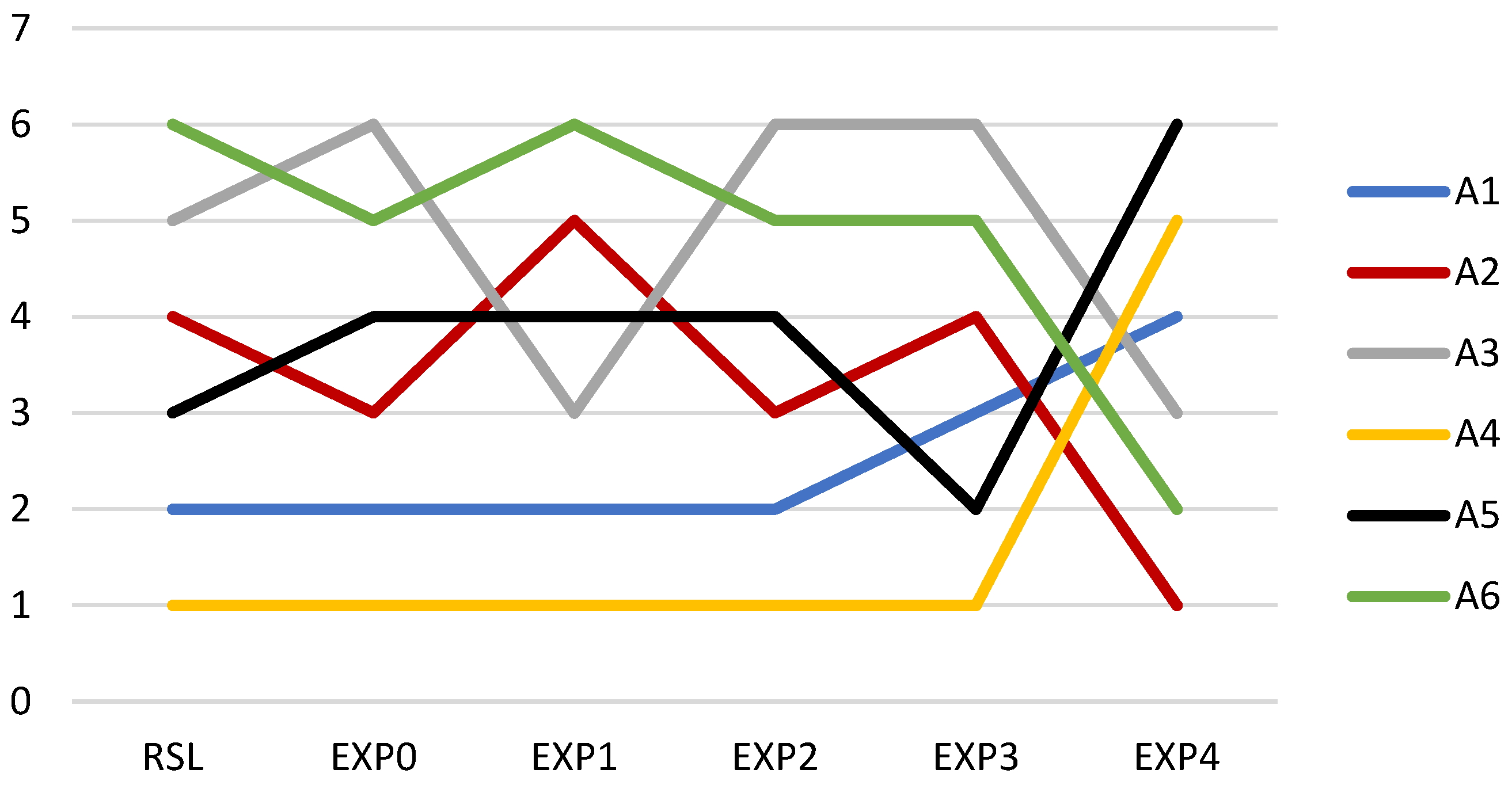

In order to assess the impact of the criteria weights on the obtained results, a sensitivity analysis was also performed. We analyzed five scenarios. In the first one (EXP0) we supposed that all criteria have the some wights (

). In the second one (EXP1) we considered the first criterion as the most important (

) while the other criteria are supposed with some importance (

). In the third scenario, the second criterion is supposed the most important (

) while the weights of other criteria are supposed equal (

). In the fourth scenario, the third criterion is set as the most important

while the wights of other criteria are supposed equal

. Finally, in last scenario the fifth criterion is set to be the most important

and other criteria as considered with the some wights

. The obtained results are shown in

Figure 4.

We can notice that simulation (A4) and CAO/FAO/DAO (A1) were placed on the top of the ranking in the majority of scenarios, which demonstrate their great importance compared to other technologies. We also noted that the findings changed dramatically when the importance of comfort and ergonomics is increased (EXP4). That can be explained by the fact that the impact of analyzed technologies on this factor is not very clear.

6. Conclusions

Regarding the transition of companies from conventional proceedings to digitalization of operations and due to the necessity of choosing the best technologies of this digitalization in various industries sectors, technologies 4.0 selection has become a challenging concept toward the management of the company. Meanwhile, there are so many developed approaches to aid decision-makers in determining the most technique that allows achieving the desired benefits by using MCDM techniques. There are some significant findings that can help decision-makers to find the relevant technology for their activities. The availability and reliability of data plays a vital role in this decision. Therefore, decision-makers should clearly define their selection criteria.

The use of TOPSIS as a technique of Multi-Criteria Decision Making (MCDM) approach combined with the hesitant fuzzy logic and the knowledge of industrial companies’ experts, help decision-makers for ranking technologies according to chosen criteria. This approach allows to make decision more accurately and facilitates the companies’ integration into this digital revolution. More specifically, this study aimed to help Moroccan automotive companies accurately select the best 4.0 technologies, especially in the absence of quantitative data and when the decision is to be made based on the experts’ knowledges. The adopted approach allows dealing with the hesitancy of decision-makers and the uncertainty and subjectivity of their opinions.

For future research, this study can be extended to include other sectors such as aviation and agri-food. The proposed framework can also be used as a benchmark to measure the relevance of each technology in several activities.

References

- Cables, E.; García-Cascales, M.S.; Lamata, M.T. The LTOPSIS: An alternative to TOPSIS decision-making approach for linguistic variables. Expert Systems with Applications 2012, 39, 2119–2126. [Google Scholar] [CrossRef]

- Capgemini Digital Transformation Institute. Smart Factories, How can manufacturers realize the potential of digital industrial revolution. Smart Factory Survey. 2017.

- Ceruti, A.; Marzocca, P.; Liverani, A.; Bil, C. Maintenance in aeronautics in an Industry 4.0 context: The role of Augmented Reality and Additive Manufacturing. Journal of Computational Design and Engineering 2019, 6, 516–526. [Google Scholar] [CrossRef]

- Cevik Onar, S.; Oztaysi, B.; Kahraman, C. Strategic decision selection using hesitant fuzzy TOPSIS and interval type-2 fuzzy AHP: A case study. International Journal of Computational intelligence systems, 2014, 7, 1002–1021. [Google Scholar] [CrossRef]

- Chase, R.B. The customer contact approach to services: Theoretical bases and practical extensions. Operations research 1981, 29, 698–706. [Google Scholar] [CrossRef]

- Chen, T.Y.; Tsao, C.Y. The interval-valued fuzzy TOPSIS method and experimental analysis. Fuzzy sets and systems 2008, 159, 1410–1428. [Google Scholar] [CrossRef]

- Chen, C.T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy sets and systems, 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Chen, T.Y. The inclusion-based TOPSIS method with interval-valued intuitionistic fuzzy sets for multiple criteria group decision making. Applied Soft Computing, 2015, 26, 57–73. [Google Scholar] [CrossRef]

- Deloitte, AG.; 2015. Industry 4.0. Challenges and solutions for the digital transformation and use of exponential technologies. 45774A Deloitte Zurich Switzerland. 2015.

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing Companies. International Journal of Production Economics 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Gal, T.; Stewart, T.; and Hanne, T. ; 2013. Multicriteria decision making: Advances in MCDM models, algorithms, theory, and applications, volume 21. Springer Science &Business Media.

- Gallab, M.; Bouloiz, H.; Kébé, A.S.; Tkiouat, M. Opportunities and Challenges of the Industry 4. 0 in industrial companies: A Survey on Moroccan firms. Journal of Industrial and Business Economics 2021, 48, 413–439. [Google Scholar] [CrossRef]

- Gallab, M.; Mouhib, Z.; Naciri, L.; Kebe, S.A.; Nali, M.; Di Nardo, M. Aeronautics 4.0: Modeling and Simulation of a smart tool. ACM publisher. 2022. [Google Scholar] [CrossRef]

- Gorris, L.; Yoe, C. Risk Assessment: Principales, Methods, and Applications. Encyclopedia of Food Safety, 2014, 1, 65–72. [Google Scholar]

- Grieco, A.; Caricato, P.; Gianfreda, D.; Pesce, M.; Rigon, V.; Tregnaghi, L.; Voglino, A. An Industry 4.0 Case Study in Fashion Manufacturing. Procedia Manuf. 2017, 11, 871–877. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple attribute decision making: Methods and application. Springer, Berlin. Retrieved from https://www.springer.com/gp/ book/9783540105589. 1981. [Google Scholar]

- Kagermann, H.; Wahlster, W.; Helbig, J. 2013. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. Final report of the Industrie 4.0 WG.

- Koch, V.; Kuge, S.; Geissbauer, R.; Schrauf, S. 2014. Industry 4.0: Opportunities and challenges of the industrial internet. Tech. Rep. TR 2014-2, PWC Strategy GmbH, United States, New York City, New York (NY).

- MacDougali, W. 2014. Industrie 4.0-smart manufacturing for the future. Germany trade & invest (GTA).

- Mamad, M. Challenges and Benefits of Industry 4.0: An overview. International Journal of Supply and Operations Management (IJSOM). 2018, 5, 256–265. [Google Scholar]

- Masood, T.; Sonnatag, P. Industry 4.0 adoption challenges and benefits for SMEs. Computer Industry 2020, 121, 103261. [Google Scholar] [CrossRef]

- McKinsey and Company., 2015. Industry 4.0: How to navigate digitization of the manufacturing sector. Tech. rep., McKinsey and Company, New York City, New York (NY).

- Ministry of Industry, Trade, Green Economy and Digital, Morocco, 2018. http://www.mcinet.gov.ma.

- Moroccan Investment Development Agency, Morocco, 2017. http://www.invest.gov.ma.

- Motyl, B.; Baronio, G.; Uberti, S.; Speranza, D.; Filippi, S. How will Change the Future Engineer’s Skills in the Industry 4.0 Framework? A questionnaire Survey, Procedia Manuf. 2017, 11, 1501–1509. [Google Scholar] [CrossRef]

- Naciri, L.; Mouhib, Z.; Gallab, M.; Nali, M.; Abbou, R.; Kebe, A. Lean and industry 4.0: A leading harmony. Procedia Computer Science 2022, 200, 394–406. [Google Scholar] [CrossRef]

- Palczewski, K.; Sałabun, W. The fuzzy TOPSIS applications in the last decade. Procedia Computer Science, 2019, 159, 2294–2303. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4. 0 concept, Procedia Manufacturing 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Peukert, C.; Pfeiffer, J.; Meißner, M.; Pfeiffer, T.; Weinhardt, C. Shopping in Virtual Reality Stores: The Influence of Immersion on System Adoption. Journal of Management Information Systems. [CrossRef]

- Pichery, C. Sensitivity Analysis. Encyclopedia of Toxicology 2014, volume 3, pp 779-780. 36 Issue 3, p755-788. 34p.

- Possingham, H.P.; McCarthy, M.A.; Lindenmayer, D.B. Population Viability Analysis. Encyclopedia of Biodiversity 2013, 210–219. [Google Scholar]

- Relich, M. The impact of ICT on labor productivity in the EU. Information technology for development. 2017, 23, 706–722. [Google Scholar] [CrossRef]

- Rojko, A. ; 2017. Industry 4.0 Concept: Background and Overview. ECPE European Center for Power Electronics e.V.; iJIM ‒ Vol. 11, No. 5, Nuremberg, Germany.

- Senvar, O.; Otay, I.; Bolturk, E. Hospital site selection via hesitant fuzzy TOPSIS. IFAC-PapersOnLine, 2016, 49, 1140–1145. [Google Scholar] [CrossRef]

- Shih, H.S.; Shyur, H.J.; Lee, E.S. An extension of TOPSIS for group decision making. Mathematical and Computer Modelling, 2007, 45, 801–813. [Google Scholar] [CrossRef]

- Soni, G.; Kumar, S.; Mahto, R.; Mangla, S.K.; Mittal, M.L.; Lim, W.M. A decision-making framework for Industry 4.0 technology implementation: The case of FinTech and sustainable supply chain finance for SMEs. Technological Forecasting & Social Change 2022, 180, 121686. [Google Scholar] [CrossRef]

- Sun, G.; Guan, X.; Yi, X.; Zhou, Z. An innovative TOPSIS approach based on hesitant fuzzy correlation coefficient and its applications. Applied Soft Computing 2018, 68, 249–267. [Google Scholar] [CrossRef]

- Torra, V. Hesitant fuzzy sets. International Journal of Intelligent Systems 2017, 25, 529–539. [Google Scholar] [CrossRef]

- Waibel, M.W.; Steenkamp, L.P.; Moloko, N.; Oosthuizen, G.A. Investigating the Effects of Smart Production Systems on Sustainability Elements. Procedia Manufacturing 2017, 8, pp. 731–737. [Google Scholar] [CrossRef]

- Wagner, T.; Herrmann, C. and Thiede, S. Industry 4.0 Impacts on Lean Production Systems. ScienceDirect. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0 – Standardization as the crucial challenge for highly modular, multi-vendor production systems. IFAC-Papers On-Line 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Xia, M.; Xu, Z. Hesitant fuzzy information aggregation in decision making. International journal of approximate reasoning 2011, 52, 395–407. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, X. Hesitant fuzzy multi-attribute decision making based on TOPSIS with incomplete weight information. Knowledge-Based Systems 2013, 52, 53–64. [Google Scholar] [CrossRef]

- Yasanur, K. Sustainability impact of digitization in logistics. 15th Global Conference on Sustainable Manufacturing Procedia Manufacturing. 2018, 21, 782–789. [Google Scholar]

- Yue, Z. TOPSIS-based group decision-making methodology in intuitionistic fuzzy setting. Information Sciences 2014, 277, 141–153. [Google Scholar] [CrossRef]

- Zeng, S.; Xiao, Y. A method based on TOPSIS and distance measures for hesitant fuzzy multiple attribute decision making. Technological and Economic Development of Economy, 2018, 24, 969–983. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, A.; Wu, Y. A hesitant fuzzy multiple attribute decision making method based on linear programming and TOPSIS. IFAC-PapersOnLine, 2015, 48, 427–431. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).