1. Introduction

“One of the greatest challenges in the use of nuclear energy is the highly radioactive waste which is generated during power production. It must be dealt with safely and effectively. While technical solutions exist, including deep geological repositories, progress in the disposal of radioactive waste has been influenced, and in many cases delayed, by public perceptions about the safety of the technology. One of the primary reasons for this is the long life of many of the radioisotopes generated from fission, with half-lives on the order of 100,000 to a million years. Problems of perception could be reduced to an essential degree if there were a way to burn or destroy the most toxic long-lived radioactive wastes during the production of energy.” [

1]

This excerpt taken from Victor Arkhipov, a consultant in the IAEA division of nuclear power and fuel cycle, highlights the importance of technological approaches for nuclear waste management, not only from a technical point of view, but also from the view of the public perception of nuclear technologies. This statement has not lost its validity even if it was published in the IAEA Bulletin number 39 back in 1997. A very recent study [

2] has again highlighted, that an improved technical solution for waste management is what people hope for and expect to be delivered from the nuclear community to make nuclear more attractive, in addition to the fear around misuse of nuclear materials, environmental pollution, through releases or accidents. Here, the new research and innovation work created through the iMAGINE approach provide new, interesting opportunities for significantly improved solutions for a future final disposal [

3].

Partitioning and Transmutation (P&T) is the waste management strategy which has been developed to answer this expectation. P&T attracted much attention in the research in the 1990ies and the following decade.in In Europe, it led to the large integrated research programme EUROTRANS [

4] and its follow-ups. These projects delivered the demonstrations for the technological steps required for transmutation of transuranics and were supported by research on partitioning in the programmes NEWPART (FP-4), PARTNEW (FP-5) and EUROPART (FP-6) [

5]. These projects successfully delivered the lab scale demonstration of P&T technologies, but the follow-up challenge is now, to establish P&T technologies on an industrial scale for successful delivery [

6]. Currently, nuclear waste management research on an industrial scale is only being undertaken in Russia [

7] and is mainly based on the principles proposed through EUROTRANS. Another, much more far reaching, future approach could be based on the operation of innovative reactors directly on SNF without prior reprocessing [

8]. This leads to the first research question: “Are the aims and objectives of P&T achievable without prior partitioning”

The 2

nd challenge after direct SNF-based operation is the integration of already reprocessed material into the waste management strategy. The re-dissolution of vitrified waste was already discussed in the acatech study on P&T in Germany in 2012 to 2014 [

9,

10], but it was not followed up in detail due to the limited effect of only removing Am and Cm with the remaining material reconditioned again in borosilicate glass. The situation has now changed due to the possibility of reverse reprocessing in the iMAGINE system which allows new approaches of dealing with waste [

3]. This leads to the second research question “What could be done if reprocessing has already taken place and ‘the soup’ still contains minor actinides, either as liquid or already conditioned in boron silicate glass. Can this situation be improved?”

The problem will be tackled through long term operational analysis based on the modelling approach and the staggered start-up of the clean up, as developed and described in [

11]. The calculations will be used to investigate and understand the effect of different feed streams with increased fission product content on reactor operation and criticality. Finally, the accumulation of transuranic elements inside the core will be analysed.

2. Code, Model and Methods

The codes and methods description has already been provided in several publications [

11,

12,

13]. However, it is adapted to the specifics of this study and it is essential for a general understanding. The HELIOS code system version: HELIOS 2.03 with the internal 173 group library [

14] has been used for these simulations. HELIOS is a 2D spectral code with wide unstructured mesh capabilities and a transport solver based on the collision probability method [

15] and the Method of Characteristics [

16]. The general model is based on the EVOL benchmark configuration [

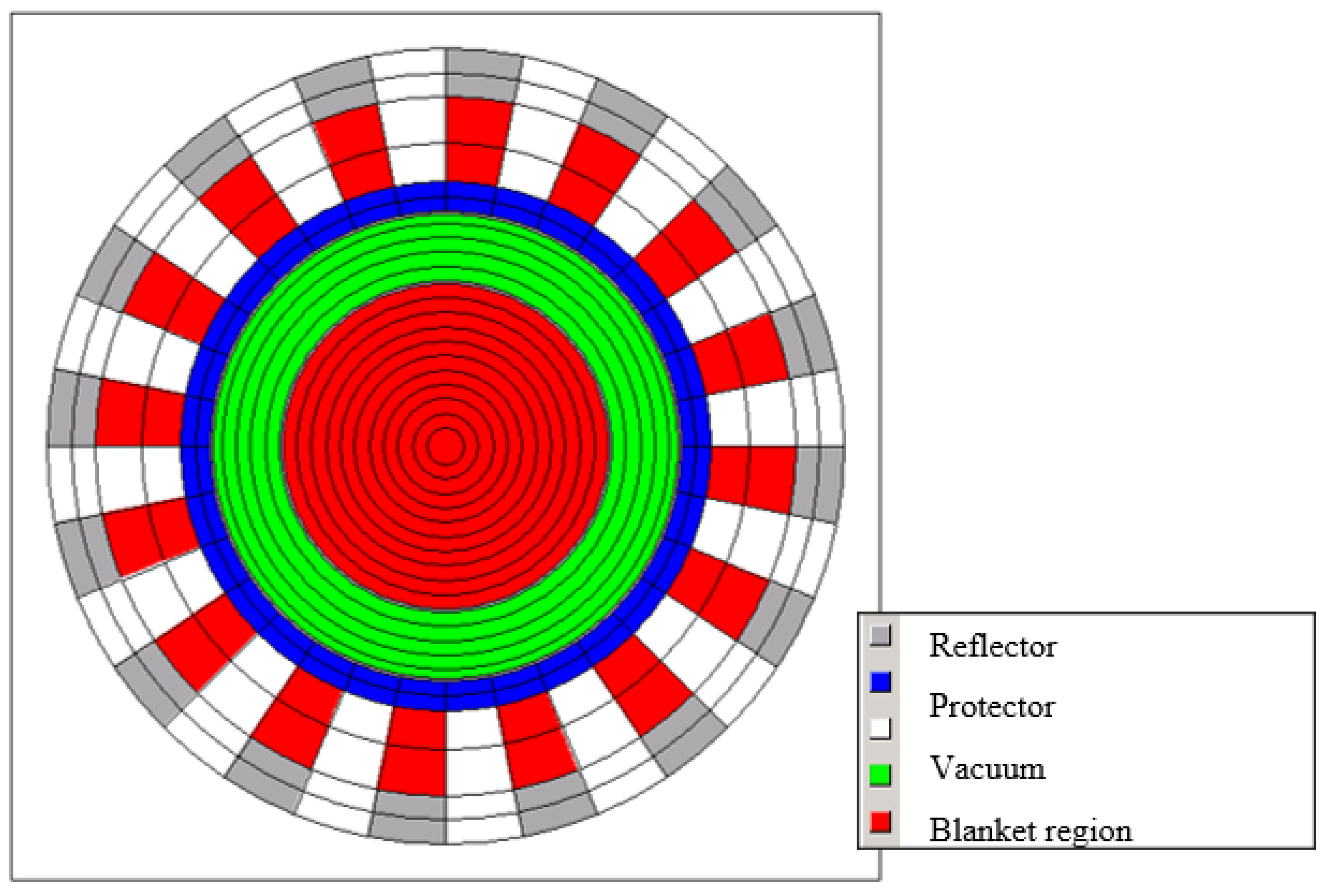

17] which is transferred to a volume corrected 2D HELIOS model (see

Figure 1). The model has been adopted to reproduce the 3D structure and the relations between different materials as closely as possible. Furthermore, the benchmark model has been extended to additionally represent the outer structures and the 16 heat exchanger pipe arrangement for a better representation of the real geometry. Leakage in the third dimension is introduced into the calculation through the insertion of a buckling correction available in HELIOS (BSQ: 0.00002). This value has been fixed by a comparison of 2D and 3D calculations within the EVOL benchmark exercises [

18]. Using this setting, a multiplication factor (k) of ~1.005 is required for a pseudo 3D k

eff of 1.0. The leakage in radial direction is directly modelled through vacuum boundary conditions.

The salt system chosen for iMAGINE is based on NaCl-UCl

3-UCl

4 with the eutectic composition 42.5%–17.0%–40.5%. A detailed discussion on the data of the salt system and the rationale behind the choice is given in [

19]. The blanket area is filled with sodium, while the protector is based on B

4C. The reference model has a core of radius 287.5 cm and a U-235 enrichment of 11.06%.

The composition for the SNF feed as well as for the additional feed of vitrified waste material is calculated, based on light water reactor fuel with an average burnup of 50 GWd/tHM using HELIOS. The model is based on the 4.5% enriched fuel configuration of the NEA MOX benchmark [

20].

The HELIOS code is an industrial standard software which is designed to perform the neutron transport calculations, the burnup calculations, and if requested the cross-section preparation for core simulators. Originally, the HELIOS code was written for the simulation of solid structured fuel assemblies, thus the possibility of online refueling and online reprocessing was not foreseen. To deal with these special features required for the simulation of molten salt reactor operation a PYTHON script has been developed [

12], which is based on the special features of the HELIOS package.

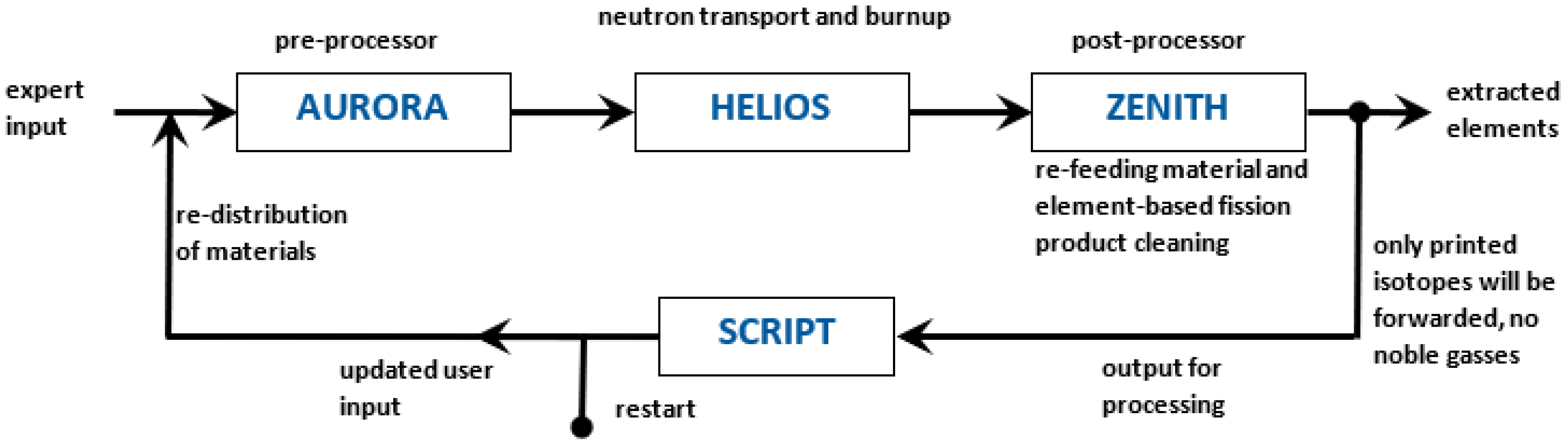

All input data, which does not change during the whole reactor operation, is stored in a so-called expert input. The changing material configuration is fed into the system through a user input which is re-written in every cycle using a PYTHON script. Within each of the cycles 5 burnup steps are calculated through HELIOS. The expert input and the updated user input are merged in the pre-processor AURORA [

21], which creates the updated input for the HELIOS run used for the determination of the neutron flux distribution and based on this the burnup of different materials. The results are finally evaluated at the end of each cycle in the post-processor ZENITH [

22]. On the one hand, here it is decided which elements are reduced or increased and to what extent. On the other hand, new user input is also created in ZENITH using the information about the isotopes to be fed back into the next cycle. These are finally used to create the input for the next cycle with the help of the PYTHON script (see

Figure 2). Theoretically, it would be possible to simulate a molten salt reactor precisely by using small time steps in this calculation loop.

In a real MSR two different time scales for the salt cleanup can be observed based on two different processes, the helium bubbling for gaseous and volatile fission products with a comparably short acting time, and the online salt cleanup for the dissolved fission products with a significantly longer acting time. To improve the modelling of both procedures, a new strategy has been developed based on the use of a burnup of 10 GWd/tHM per cycle (using five burnup steps in HELIOS), coinciding with a full removal of gaseous and volatile fission products (the elements 18, 35, 36, 53, 54, 85 are not carried forward through ZENITH) after each initiation of a Python cycle. The dissolved fission products can be removed based on a variable cleaning efficiency providing the opportunity to set this efficiency or the share of salt to be cleaned elementwise for all considered elements.

The use of the described process has already been validated and used in several peer-reviewed publications [

12,

13,

23,

24]. Meanwhile, the modelling and simulation quality will be significantly improved due to the new code version and the increased computational power which allow now the use of the 173 energy group cross section set instead of the 47 group set in the earlier publications.

However, due to the characteristics of HELIOS, some approximations still have to be accepted. There is no fuel salt movement, thus an undesired burnup distribution arises during each of the calculation cycles, while the materials are only re-distributed when a new user input is defined. HELIOS is an LWR code and an LWR spectrum is used for the weighting of the master libraries inside each energy group. However, this error will be significantly reduced compared to earlier publications, since the number of energy groups is tripled, thus the width of each energy group has significantly reduced. Comparisons with other codes in the EVOL benchmark [

18], in a fast reactor isotope accumulation test against SERPENT [

25], as well as comparisons with SCALE/POLARIS [

19,

26] have shown good agreement. This is what is currently available in terms of modelling techniques and solvers; therefore, to verify the reliability of the results, a real reactor physics experiment for molten salt reactors would be required as discussed in [

26].

The approximations and the use of the HELIOS code package seem to be adequate for the approximation level required for this kind of long-term investigation of isotope accumulation to support the development of a clean-up system. The results of the influence of different elements on the system criticality have been evaluated in earlier publications [

27,

28] and a detailed comparison to SCALE/Polaris is given in [

11]. However, recent studies have shown a significant difference between SCALE/Polaris and HELIOS in studies on the effect of Cl-37 enrichment [

29].

This study will investigate the use of iMAGINE approach for a technology-based management of nuclear waste following the aims and objectives of P&T. For this a long-term operation based on a staggered initiation of the clean-up system, as developed in [

11], will be used as the reference case and the evolution of transuranic elements Pu, Am, and Cm will be discussed for this reference case and for different scenarios which will lead to higher insertion of transuranic elements.

3. Results

As already mentioned, long term operational analysis based on the modelling approach and the staggered startup of the cleanup in the way it was developed and analyzed in [

11]. The aim of the investigation is to provide an understanding whether the iMAGINE approach will be able to fulfil the expectations on delivering a highly innovative waste management strategy without the demand for prior reprocessing. The two main points are: a) the direct operation on SNF from light water reactors, and; b) additionally use the system to treat already vitrified wastes from reprocessing to burn the minor actinides and to use the reverse reprocessing approach to allow improved handling of the fission products.

Basis for all investigations provided here is the analysis of different potential feed streams

Clean, depleted uranium tailings (tailings)

spent nuclear fuel without reprocessing (SNF)

an increased amount of fission products that would be in the reactor system when the already separated fission products would be added to perform a kind of P&T operation on already vitrified leftovers of previous reprocessing approaches (SNF+FP)

These streams will be fed into the reactor after the start-up to understand the influence of the feed on the long-term evolution of the core. The simulations will be used to get a first understanding of the effects of an increased fission product feeding into a reactor during operation by investigating core criticality and the concentrations of the elements to be transmuted, Pu, Am, and Cm as well as Tc as a representative fission product where the accumulation and the effect of the salt clean-up can be observed. The results will be used to draw conclusions on a potential optimization for a potential future operational scheme.

3.1. The reference case study

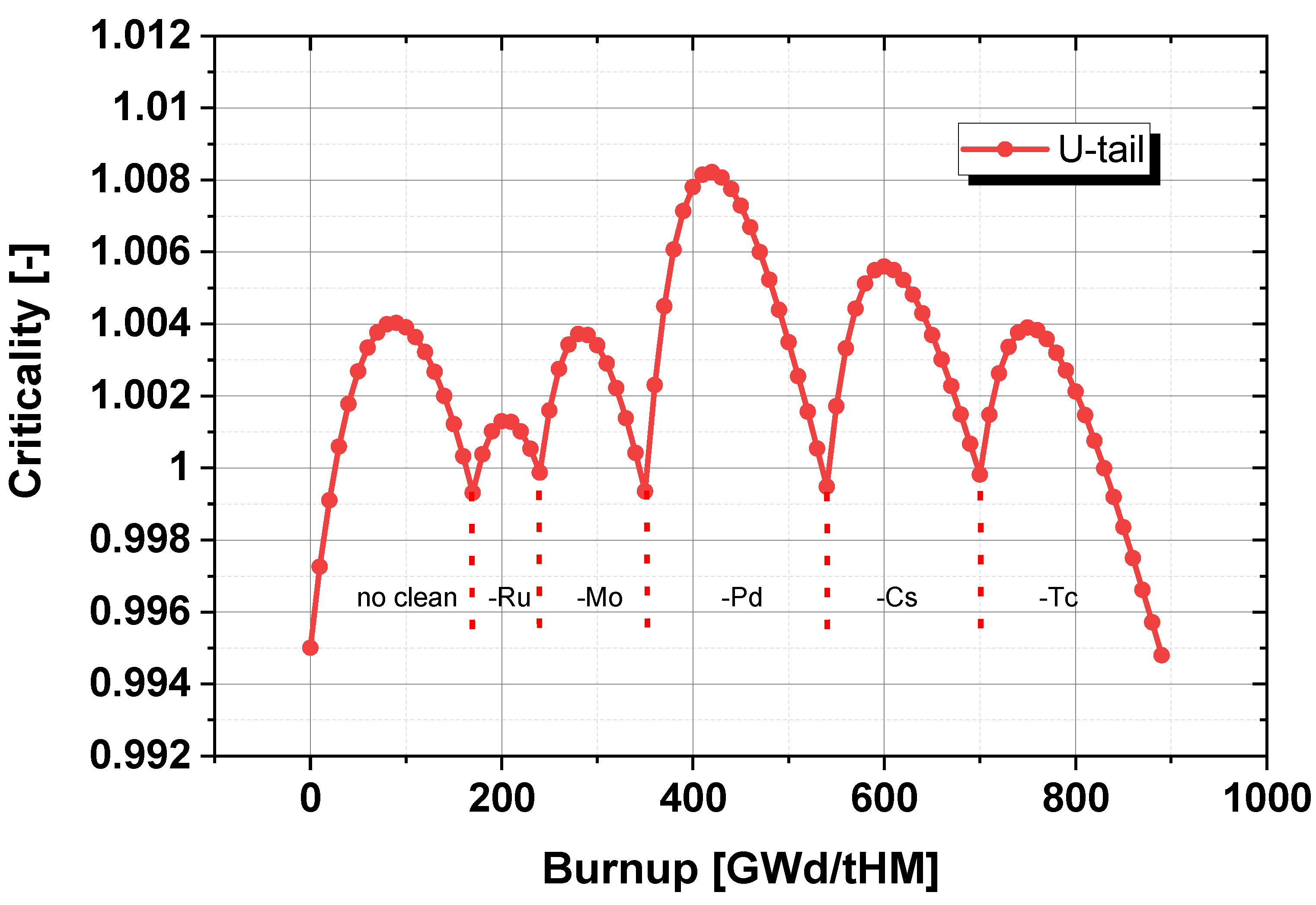

The evolution of the system criticality over burnup is given in

Figure 3 for the staggered initiation of the clean-up of different fission product elements as shown in the bottom of the figure. The aim of the scheme is to balance the reactivity of the core for an extended period only through the clean-up initiation without relying on active control measures, like control rods, as well as to assure for the simulation to limit the effect of the k

eff normalization on the results of breeding in a molten salt system [

11]. The idea behind the staggered clean-up approach is to allow studies on the long term behaviour of a potential self-sustained iso-breeding molten salt reactor system with different feed streams as described above (tailings, SNF, SNF+FP) to get a deeper understanding of the effect of feeding very small material amounts over a long time on the long-term changes in composition and criticality.

The feed stream with depleted uranium tailings has been chosen as the reference case for this study (see

Figure 3). Also, it is one of the easiest envisaged operational modes in which U238, already transmuted into fissile Pu239, is replaced after every burnup cycle using the U238 from clean tailings in the feed stream. The feeding stream is optimized to ensure a constant amount of U238 within the core within a reasonable accuracy after each 10 GWd/tHm cycle. This is essential to balance the amount of breeding material available as basis for the iso-breeding. The clean-up of a certain additional element is activated every time when the system criticality falls below 1. In this case 20% of the whole salt amount is cleaned after every 10 GWd/tHM cycle and the choice of the elements to be separated follows the priority list as previously developed [

11]. Applying this staggered approach allows reactor operation until ~900 GWd/tHM is extracted, related to the initial load, compared to ~200 GWd/tHM without clean-up.

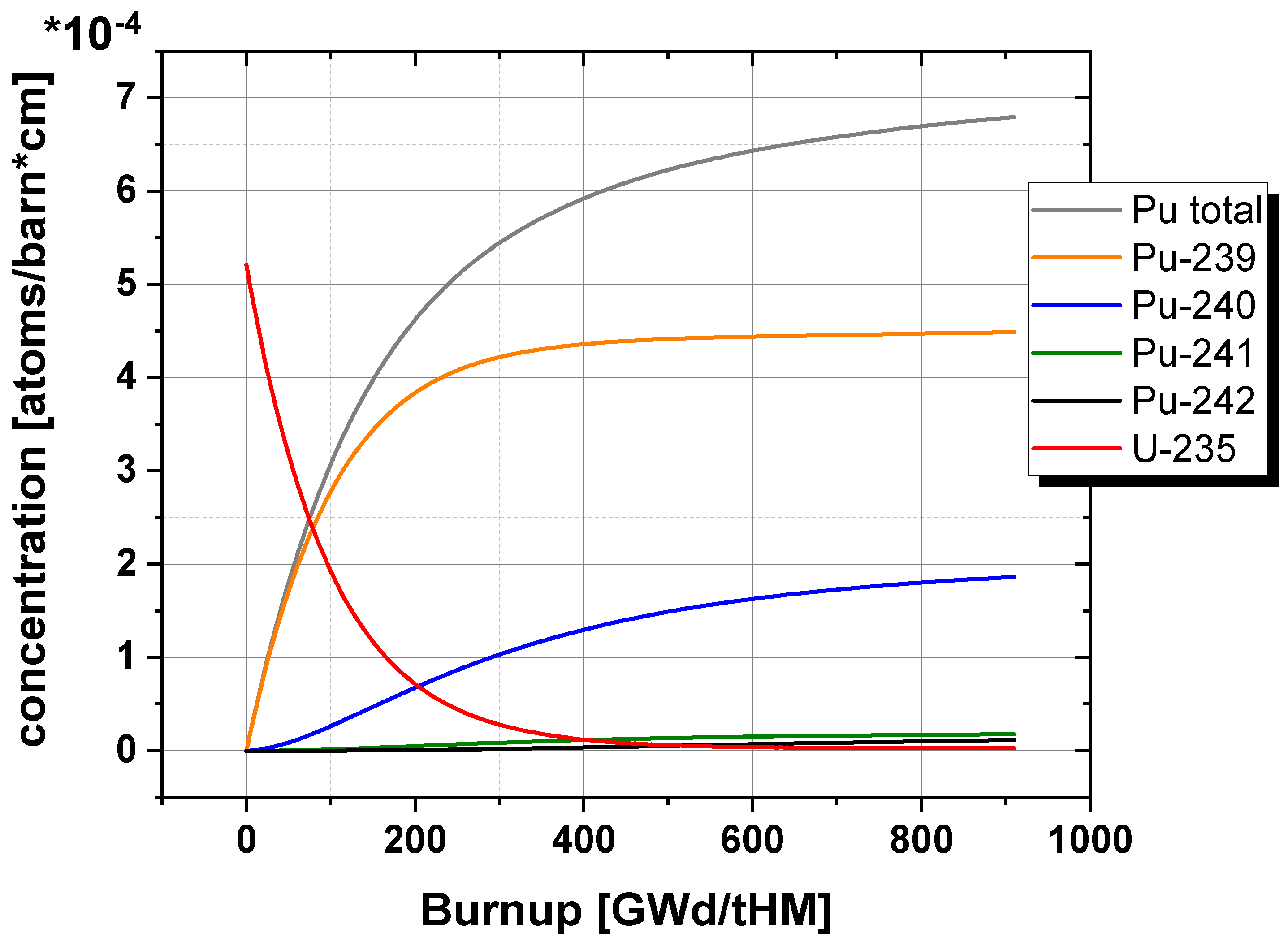

For a more detailed analysis of the changes of the isotopic contents of TRU materials, the contents in the core are analysed in the following,

Figure 4,

Figure 5 and

Figure 6. As already described, the initial core is based on enriched Uranium. The initial U-235 content decreases rapidly due to reactor operation, see

Figure 4 and is replaced by Pu-239 as main fissile material at a burnup of ~75 GWd/tHM. The amount of U235 continues to decrease beyond this point and becomes almost negligible at a burnup of ~500 GWd/tHM. At this time, the amount of Pu239 in the system also attains a steady state with an equilibrium between breeding and burning being approached. It is important to highlight here that only a negligible amount of fissile material, besides the U235 required for reactor start-up, has been inserted into the system. All fissile material is produced in-situ through internal breeding within the system. This process is supported by continuous replenishment of U238 through the feed stream to maintain a constant amount of fertile material in the system. The creation of the higher Pu isotopes starts with some time delay, since these isotopes are formed out of material which has to be bred first. At the end of the observation period of ~900 GWd/tHM, the Pu-240 production has slowed down significantly along with the total Pu content, but an asymptotic value has not yet been achieved. The production of Pu-241 and Pu-242 is on a very small level. The final Pu vector is Pu-239, 67%; Pu-240, 28%; Pu-241, 3%; and Pu-242, 2% at 900 GWd/tHM.

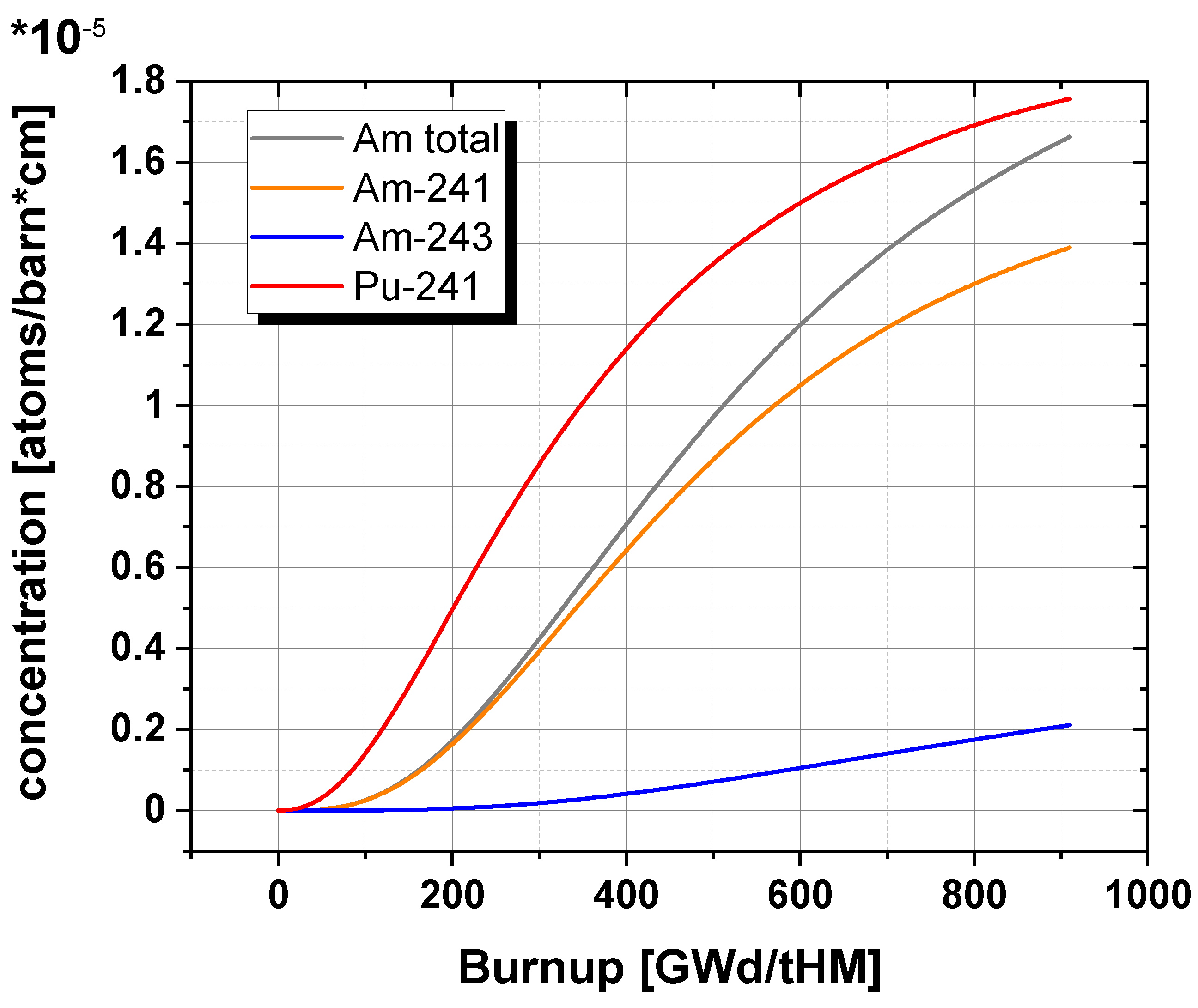

The Americium production (see

Figure 5) follows a similar long-term structure as the higher Pu build up, but with even longer time delays since a substantial amount of the precursor isotope has to be bred first. The overall Americium quantity at the end of the observation period is less than 3% of the total Pu content in the fuel salt. Am-241 is mainly formed though the decay of Pu-241 – thus the amount is slightly dependent on reactor power since there is the competition between Pu-241 fission and β

-decay with a half-life of ~14 years. The delay in Am-241 production from the precursor Pu-241 is clearly observed in

Figure 5. The small amount of Am243 is formed mainly through the rapid beta decay of Pu243 (half-life of 5h) which is itself formed through neutron capture in Pu242. Am243 may also be formed due to neutron capture in Am241 and Am242m, but with a significantly lower contribution. Total Am production has reached a point of inflection at ~600 GWd/tHM Indicating that an asymptotic value will be achieved, although this would require a much longer operational time.

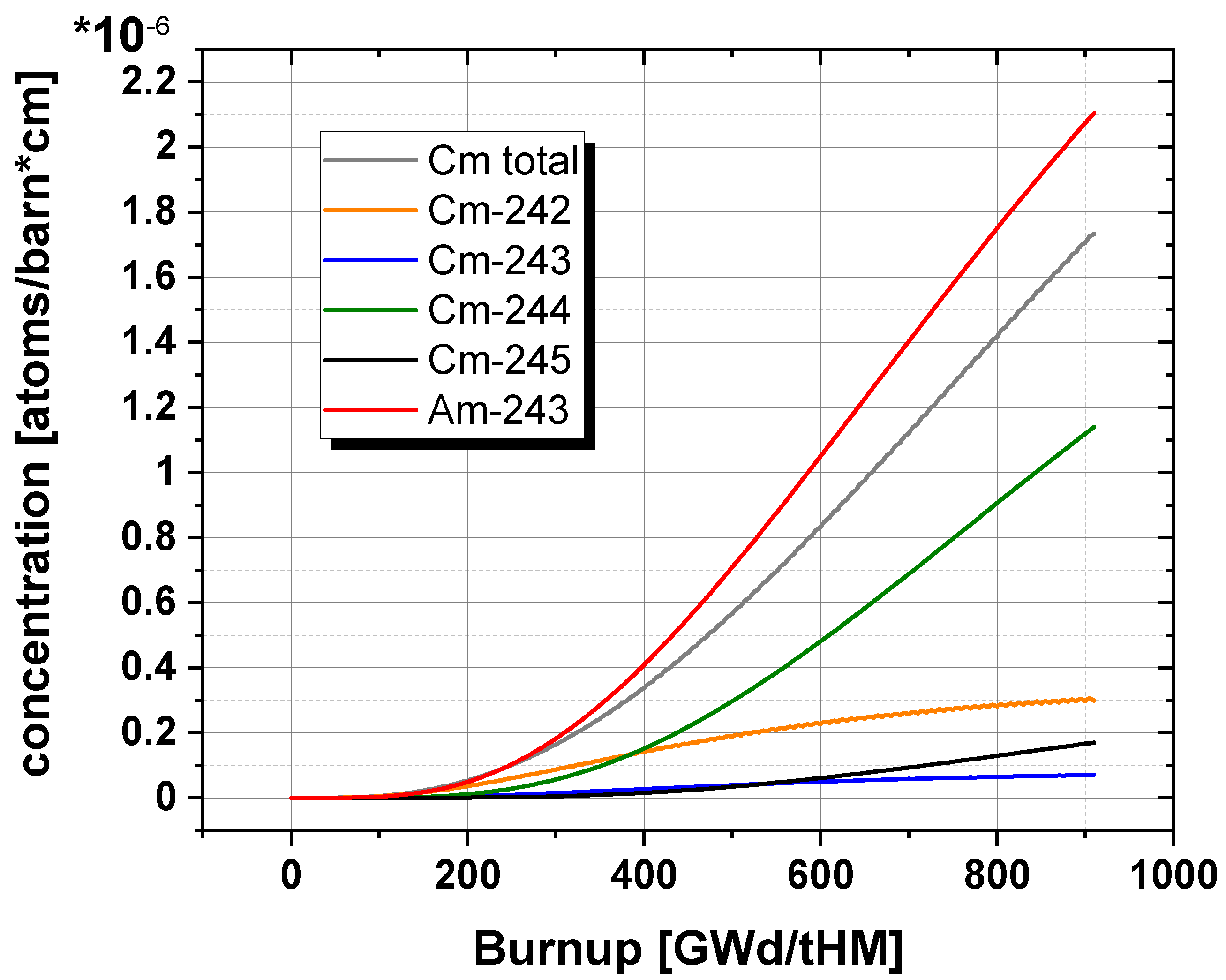

The Curium formation in the core is 10 times lower than the Americium formation, see

Figure 6. The leading isotopes are Cm-244 and Cm-242. Cm-242 is mainly formed through neutron capture in Am-241 creating Am-242 (16h half-life), followed by a beta decay to either Cm-242 or through electron capture to Pu-242 (marginal path). Cm-244 is mainly formed through neutron capture in Am-243 and the following decay of Am-244 with a small half-life of only 10h. The delay of the formation of the leading isotope Cm-244 compared to the precursor isotope Am-243 is clearly observable. The Cm-242 production has already reached a clear point of inflection at about 500 GWd/tHM and has got almost asymptotic, while the Cm-244 still accumulates following the trend of Am-243. In general, the Cm-production has not reached a point of inflection during the observation period, mainly due to the still increasing amounts of Cm-244 and Cm-245. To observe the long-term behaviour and to assess a potential asymptotic behaviour a significantly longer observation period would be required.

However, an important fact is that due to the reverse reprocessing all these TRU isotopes will stay in the core and will not require handling like in traditional P&T systems with solid fuel and external reprocessing. This new approach will help to reduce the radiation exposure to workers unlike the multi recycling scheme required in the manufacturing of fuel for conventional solid-fuelled systems [

7].

3.2. Parametric study of different fission product contents

The basis for the simulation is given by the case with SNF feed as calculated, based on light water reactor fuel with an average burnup of 50 GWd/tHM using HELIOS. The use of SNF (black line with squares) instead of tailings (red line with circles) as feed leads to a slightly longer potential operation. The system achieves higher criticality in the first operational period without salt clean-up (see

Figure 7). This effect is due to the higher share of fissile material in the SNF feed (~ 1% Pu and ~1% U-235) as compared to ~0.3% U-235 in tailings. Obviously, this observed difference is mainly important in the first operational stage without salt clean-up, since the following steps do not show major differences anymore. However, it is an interesting outcome that the effect of the fissile material added seems to be stronger than the effect of adding the fission products contained in the SNF. The main reason is that most FPs have significantly higher absorption XS in the thermal neutron spectrum as compared to fast spectrum. Thus, the fission products have a much stronger poisoning effect in light water reactors than in the iMAGINE system.

Next, a higher amount of FPs is inserted into the system while keeping the amount of fertile and fissile materials (uranium and plutonium) in the feed stream as unchanged. The idea is to model two feed streams with different amounts of vitrified waste by only increasing the amount of fission products in the SNF by 2 and 5 times. This model assures a ‘conservative approach’ bringing all fission products and minor actinides into the core. In this way, it is not considered that gaseous and volatile fission products are only contained to a small share in the vitrified waste, while the major share has to be handled in a different way in the reprocessing plant. However, the effect will be limited to the first calculation cycle since all gaseous and volatile fission products will anyway be released at the end of each 10 GWd/tHM cycle.

The insertion of double the amount of fission products (blue line with triangles) has a minor overall effect compared to the case using tailings. However, compared to the case of SNF feed, it becomes clear that the increased amount of fission products has mainly a strong effect in the first stage before the clean-up is activated. The long-term effect is very limited. This can be explained by the overall increase of the amount of fission products in the core as well as with the effect of the clean-up which reduces not only the fission products created through the burnup, but also the fission products which are inserted in addition.

Inserting 5 portions of fission products (green lines with diamonds) has a very strong influence in the first operational period and even does not allow the reactor to get critical in the averaged criticality analysis per cycle. In general, the insertion of such a large amount of fission products significantly penalizes the operation reducing the total burnup by ~20% from 910 GWd/tHM to 720 GWd/tHM compared to the SNF case. However, it is clear that the reactor could still be operated with such a high fission product load, which confirms that the insertion of larger amounts of fission products, eg through the feeding of dissolved vitrified waste would be possible as waste management method. On the one hand this offers the opportunity to burn minor actinides which have not been separated previously in reprocessing; on the other hand, the approach will allow the use of reverse reprocessing method with the opportunity of the elementwise separation of fission products leading to new possibilities for conditioning of the waste streams.

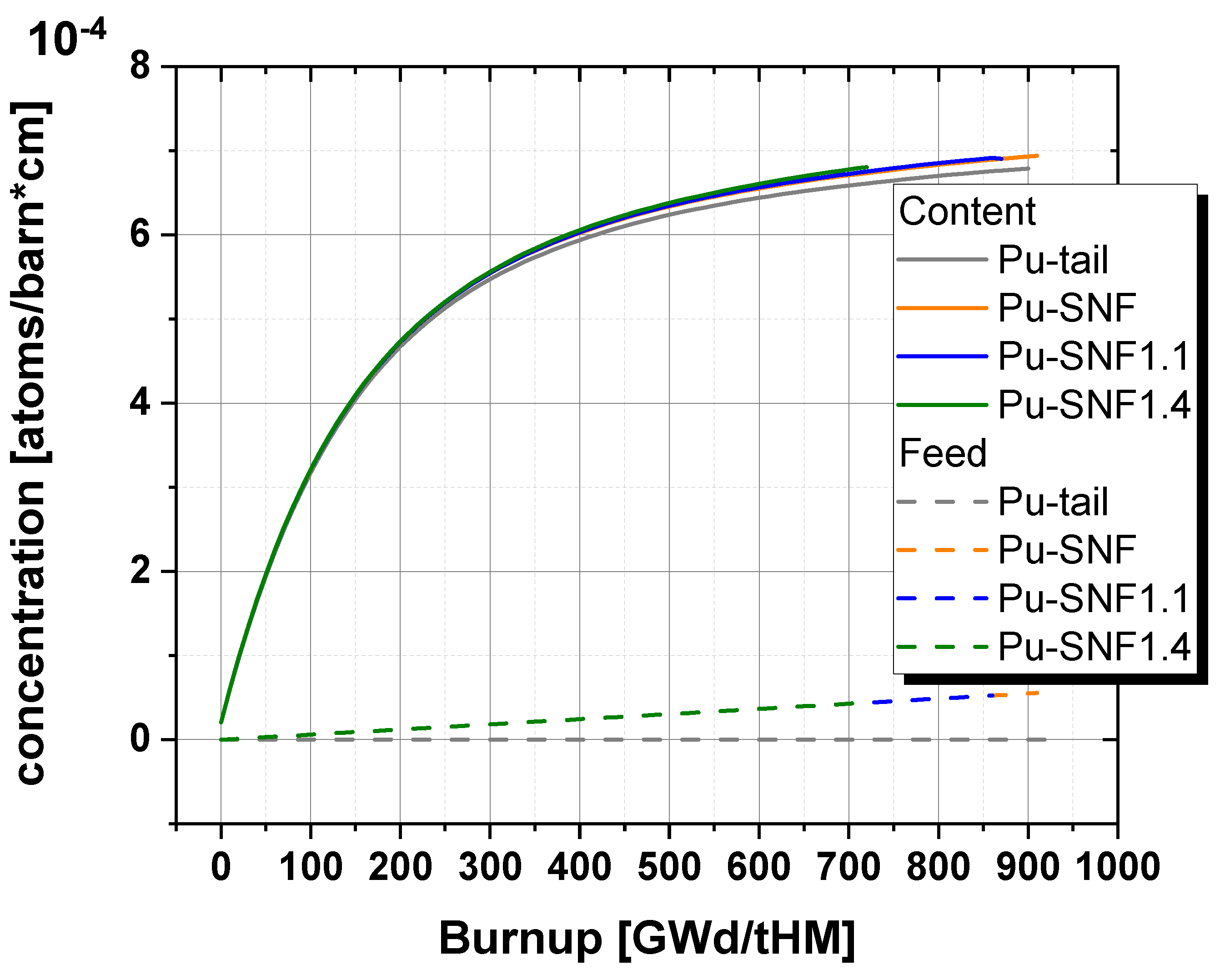

The comparative analysis of the plutonium accumulation,

Figure 8, shows that the Pu concentration in the core depends only weakly on the different feed scenarios. The Pu content in the scenario with the tailings feed is slightly lower, while feeding the largest amount of fission products will deliver a marginally higher Pu content. However, there is no real effect on the overall tendency of the increase in the Pu amount and the formation of an almost asymptotic concentration at the end of the observation period. The amount of Pu fed (dashed lines) is identical in all SNF cases, which verifies the correct implementation of the model for the fission product feed.

The analysis of the Pu management shows that the amount resident in the system is in all cases slightly higher than in the reference case. However, in all SNF feeding cases the overall Pu amount is slightly reduced compared to the reference case with tailings feed. The inserted Pu amount consists of the Pu fed into the system and the Pu bred in the system. The Pu reduction is calculated using Eq. (1). Obviously, the difference between the slightly higher Pu concentration at the end of the observation period is lower than the amount of Pu fed into the system through the SNF feed. The results indicate that some small amount of Pu burning is achieved in the SNF fed scenarios. The different amounts of fission products have only a very marginal effect.

Table 1.

Detailed analysis of the Pu management based on feeding and the amount resident at the end of the observation period.

Table 1.

Detailed analysis of the Pu management based on feeding and the amount resident at the end of the observation period.

| |

Pu-tail [atoms/barn*cm] |

Pu-SNF

[atoms/barn*cm] |

Pu-SNF1.1

[atoms/barn*cm] |

Pu-SNF1.4

[atoms/barn*cm] |

| Amount fed |

0.00E+00 |

5.56E-05 |

5.26E-05 |

4.40E-05 |

| Amount resident |

6.79E-04 |

6.94E-04 |

6.90E-04 |

6.81E-04 |

| Pu reduction |

|

-6% |

-6% |

-6% |

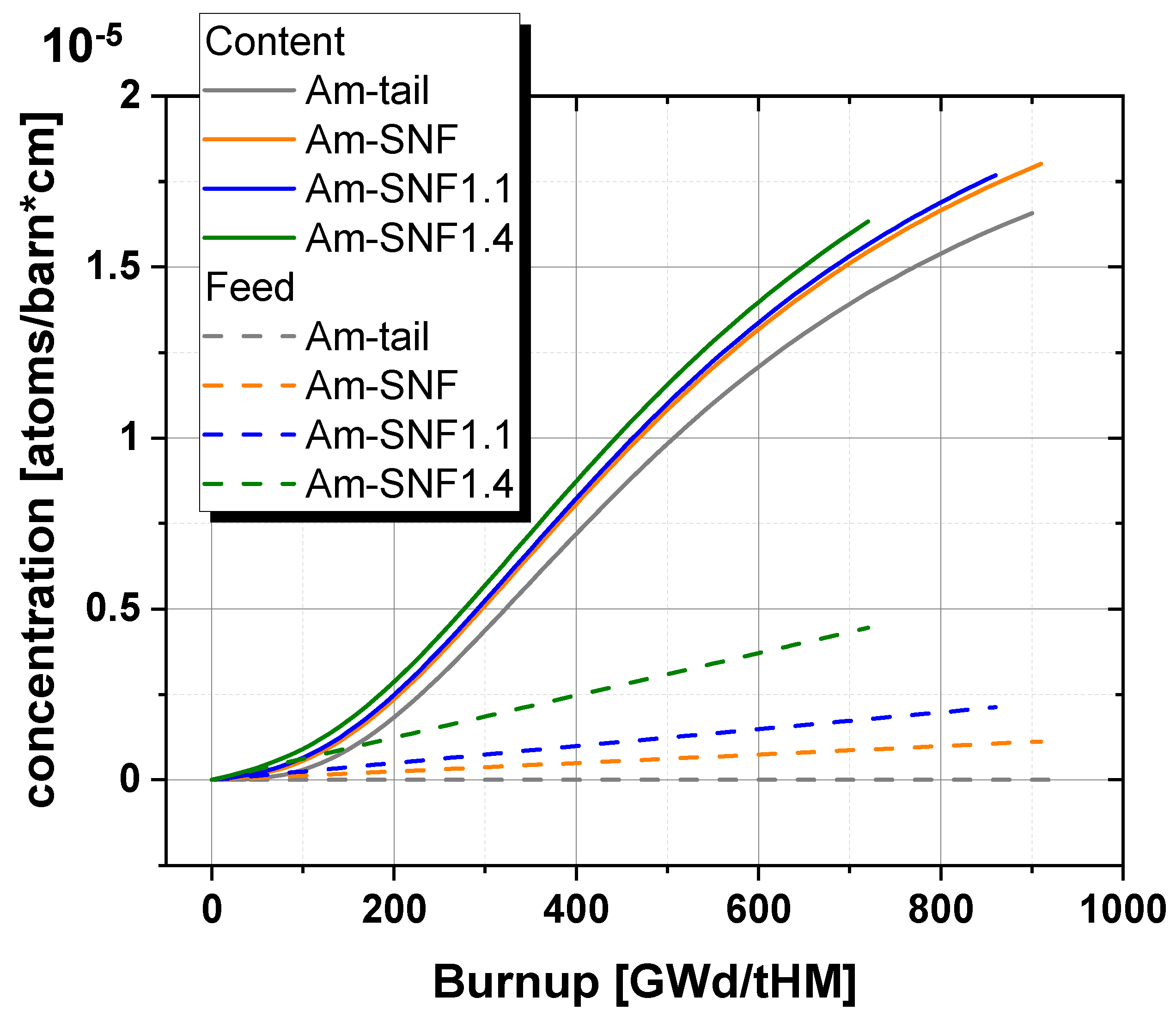

The comparative analysis of the Americium content in the core,

Figure 9, shows that the general tendency of the accumulation of Am is only slightly influenced through the feed. This indicates that the Am concentration in the core is mainly driven by the operation of the reactor and the breeding processes. Increasing the Am amount in the core through the feed leads to a slightly higher concentration, but the effect is smaller than the increase due to operation. The Am feed is indicated through the dashed lines. It is already apparent from these lines that the inserted amount of Am is larger than the difference the concentration appearing in the core over the observations period.

A more detailed analysis of the Am management,

Table 2, confirms this observation for the cases with higher fission product feed, but this is not the case for the unmodified SNF feed. The amount resident at the end of the observation period depends on the operational time and the amount of Am fed into the system leading to the lowest resident amount for the SNF 1.4 case.

Figure 9 supports here the understanding, the lowest amount is obviously a result of the shorter observation period, while the concentration is highest through the whole period. The overall Am change is calculated using Eq. (1). The higher Am content is because the increased Pu content in the SNF feed case leads to a higher breeding of Am, since the SNF contains greater amounts of higher Pu isotopes as precursor. Especially in the beginning since a fully developed LWR Pu vector at 50 GWd/tHM is inserted while the clean configuration based on enriched Uranium will initially be Pu free. In the tailings-based system the breeding will start at a lower average mass of the Pu isotopes (see the delay in the Am concentration for the tailings fed case). The breeding process creates only Pu-239 in the first time period of operation, the formation of higher Pu isotopes requires a longer irradiation time, see

Figure 4. In the cases of higher loads of Am through the feeding stream, Am reduction takes place and the reduction efficiency increases with increased Am concentration which coincides with the observation that have been made in a large number of P&T studies delivered in the past [

30,

31,

32].

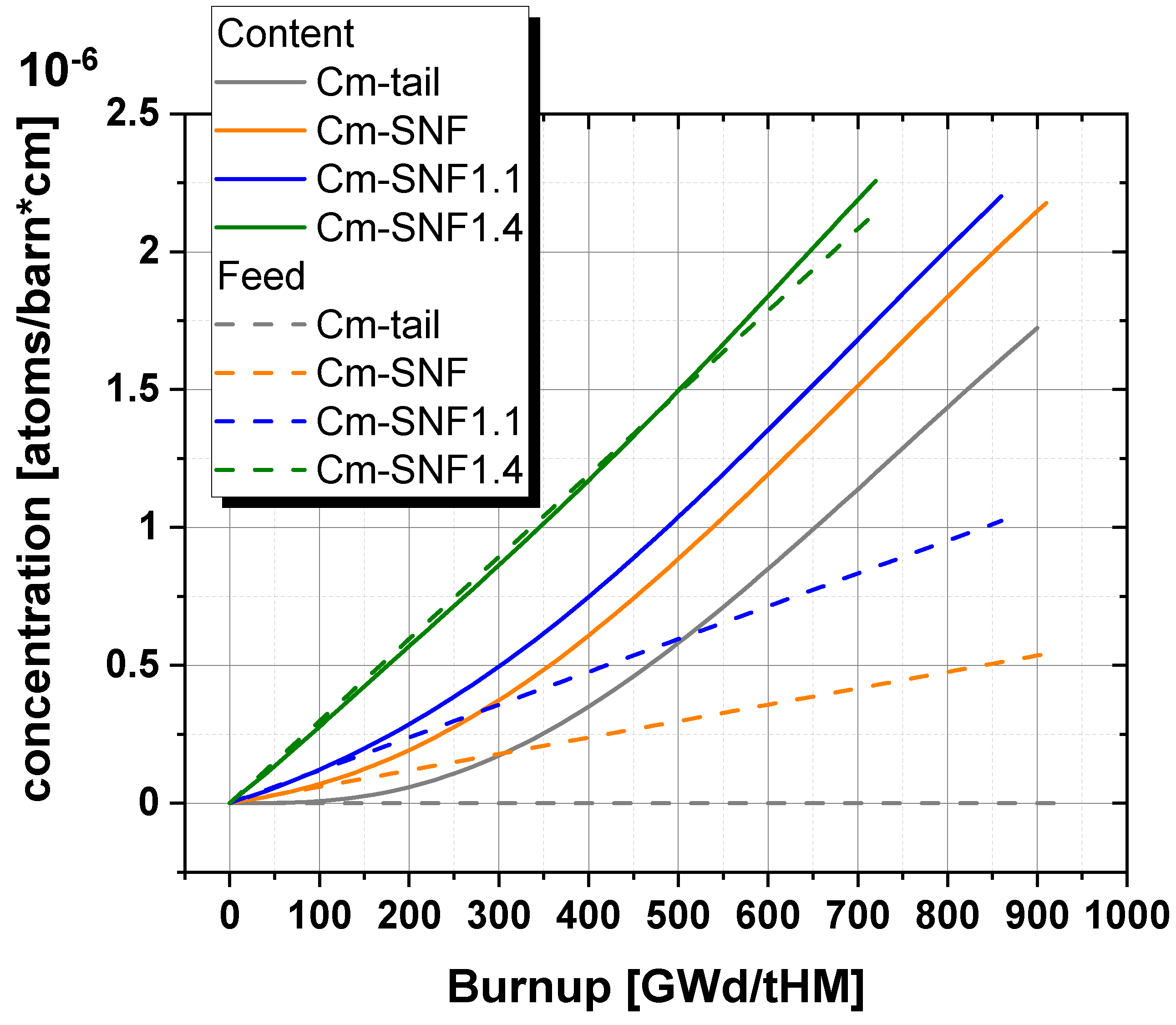

The Cm content over the observation period is rising for all cases, see

Figure 10. No saturation level is achieved and the concentration of Cm in the salt is still growing almost linearly at the end of the observation period. However, there is a clear difference between the base case where no Cm is fed into the core and all other cases. In all cases, Cm is bred inside the core from neutron capture reactions in Am - this means the production is strongly dependent on the Am content in the core and thus delayed in a clean core where the Am has to be bred first. However, the delay in the increase of the Cm concentration is much more pronounced than for Am, compare

Figure 9 and

Figure 10. It gets obvious in the other cases, that the rapid increase in the Cm concentration at the beginning is caused by the feed through the SNF and additionally through the ‘vitrified’ waste, see the identical gradient of the concentration (solid lines) and the content inserted through the feed (dashed lines) up to 100 GWd/tHM. The massive insertion of Cm in the SNF 1.4 scenario and the almost identical slope of the feed and the content indicates that efficient burning takes place when the concentration is high enough.

A more detailed analysis of the Cm management and the concentrations as well as the feed is given in

Table 3. The overall Cm change is calculated using Eq. (1). The concentration of Cm in the system (amount resident) at the end of the observation period increases by 27%, 28% and 31%, respectively for the scenarios with increased Cm feed. Obviously, the feeding amount is more influential in the case of Cm on the amount resident than the breeding process. However, the higher the feed, the greater is the amount of Cm which is transmuted during the operation of the reactor. In the scenario with the highest Cm feed, almost all material added through the feeding process is already burnt at the end of the observation period, which indicates a successful transmutation process, even if the concentration is still increasing. The cases with the lower feed support some transmutation, but the process is not yet efficient enough due to the low amount of Cm added.

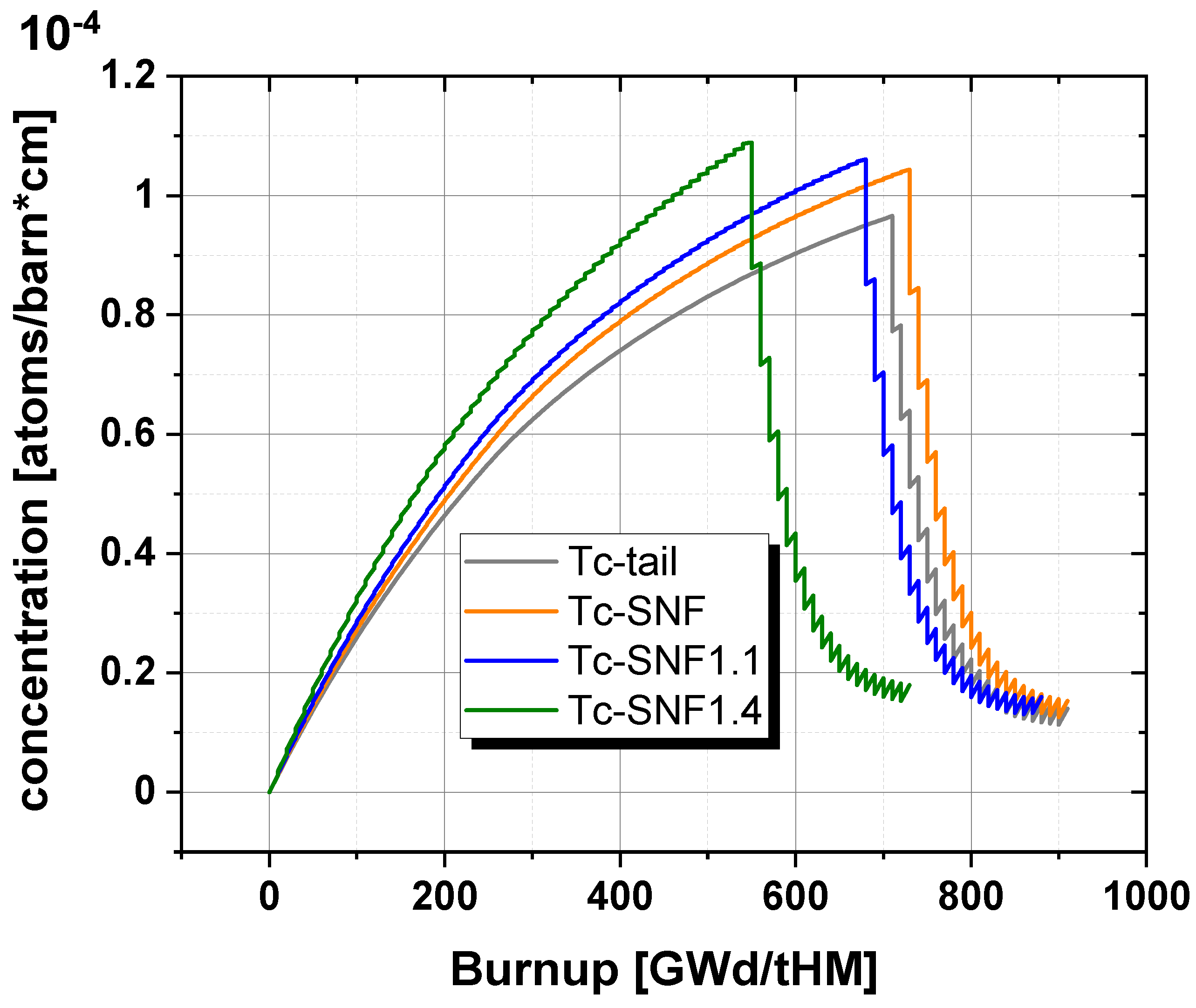

In the final step, the effect of the different scenarios on fission product accumulation and salt clean-up is evaluated using technetium as representative fission product, see

Figure 11. The initial analysis indicates that the amount of all fission products inserted through the feeding stream is small compared to the accumulation of Tc which is created due to reactor operation One of the main reasons is that the LWR fuel which is inserted through the feed stream has a limited burnup of ~50GWd/tHM, much lower than the overall burnup in the fuel over the observation period. A more important observation for the long-term operation is that the asymptotic value of Tc after activation of the salt clean-up seems to be only marginally influenced by the feed. This confirms the expectation that the effect of the higher amount of fission products in the feed stream will be almost completely balanced through the clean-up system. This effect is interesting since it could lead to the conclusion that it would promising to start with a comparably high fission product load while initiating the clean-up system earlier and using the fission products as a removable poison. These could be siphoned off when the reactor physics demands the removal of a specific fission product to reduce the number of different fission products to be tackled in the clean-up system in early operation stage.

4. Conclusions

Nuclear waste management, through partitioning and transmutation has been researched since the 1990ies. Currently, the general agreement is that partitioning of minor actinides is a pre-requisite for the process. The results shown in this paper confirm that it is possible to achieve the aims of P&T without prior partitioning in the innovative iMAGINE system. However, it is certainly ‘less efficient’ since the high concentration of MAs, required for efficient burning, are impossible to obtain in a short time. The amounts of MA inserted mainly stay in the system until their concentrations are high enough to reach a steady state. These high concentration levels have not been achieved in this study which just shows that this proposed nuclear waste management approach will be a long-term effort when it is accomplished without partitioning/separation technologies. However, none of the analyses contradicts this effort – the key points are a) when the technology for treating the waste is possible and reliable, the time horizon will not be a major concern b) the waste management is now linked into energy production instead of requiring dedicated costly facilities, thus creating opportunities to deliver waste management with a promising economic basis c) the waste management is now associated with massive and long-term energy production by extracting all energy content of the mined Uranium, thus unlocking a precious, practically inexhaustible energy resource through smart technology development.

From a reactor physics point, it has been demonstrated that the reactor can be kept critical even with the insertion of massive amounts of already separated FPs – either vitrified or the so-called “soup” in countries with active reprocessing programmes. Long-term self-sustained reactor operation has been demonstrated through modelling & simulation for a system started with enriched Uranium for all investigated cases. After the initial start-up based on enriched Uranium, the system is sufficiently robust to operate on an SNF feed or even a feed stream with additional FPs from already reprocessed waste

The required chemical processes for the dissolution of vitrified material, as well as the effects on the reactor chemistry would have to be investigated in detail. However, this has to be weighed against the opportunities: a) getting the minor actinides re-inserted into the reactor and burnt on the long term without partitioning; and b) the opportunity to open the way for improved conditioning or even, re-use of some materials due to the reverse reprocessing leading to an elementwise sorted waste stream as well as the materials captured in the off-gas treatment.

It has been demonstrated that burning of the minor actinide isotopes is accelerated with increasing amounts of previously separated waste inserted. This could be used as an optimization scheme, the insertion could be very high in the beginning, as a kind of ‘burnable absorber’ when the Pu production is strong. The subsequent initiation of the clean-up system at a later stage will then reduce the effect of the inserted fission products which will free additional criticality reserve to keep the core stable. In addition, this strategy of an increased initial load will help to improve the burning rate of the trans-plutonium isotopes due to the correlation between the reduction rates and the amounts of Cm and Am resident in the core. Thus, an early insertion would be beneficial to achieve high burning rates without the demand for partitioning.

The general conclusion is, the objectives of P&T are achievable without prior partitioning – this is a ground-breaking result; however, it will take significantly long operation times, which does not seem to be problematic as long as energy production based on nuclear power production is continued. In the case of a phase out decision, this strategy would not really be promising. In this case a much more efficient transmutation scenario would have to be envisaged as already discussed several years ago for Germany [

12].

Author Contributions

Conceptualization, Bruno Merk; Data curation, Anna Detkina and Lakshay Jain; Investigation, Omid Noori-kalkhoran; Methodology, Bruno Merk and Lakshay Jain; Resources, Bruno Merk, Omid Noori-kalkhoran and Dzianis Litskevich; Software, Dzianis Litskevich; Validation, Anna Detkina and Greg Cartland-Glover; Writing – original draft, Bruno Merk; Writing – review & editing, Lakshay Jain and Greg Cartland-Glover.

Acknowledgment

The lead author wants to thank The Royal Academy of Engineering for the funding through their Chair in Emerging Technology scheme, grant number CiET2021\161, which made this work possible.

References

- Arkhipov, V. Future nuclear energy systems: Generating electricity, burning wastes. IAEA BULLETIN, 39/2/1997, 1997. 2015. Available online: https://www.iaea.org/sites/default/files/publications/magazines/bulletin/bull39-2/39204783033.pdf (accessed on 27 February 2015).

- Merk, B.; Litskevich, D.; Detkina, A.; Noori-kalkhoran, O.; Jain, L.; Derrer-Merk, E.; Aflyatunova, D.; Cartland-Glover, G. iMAGINE—Visions, Missions, and Steps for Successfully Delivering the Nuclear System of the 21st Century. Energies 2023, 16, 3120. [Google Scholar] [CrossRef]

- Merk, B.; Detkina, A.; Litskevich, D.; Patel, M.; Noori-kalkhoran, O.; Cartland-Glover, G.; Efremova, O.; Bankhead, M.; Degueldre, C. A First Step towards Zero Nuclear Waste—Advanced Strategic Thinking in Light of iMAGINE. Energies 2022, 15, 7209. [Google Scholar] [CrossRef]

- Knebel J.; et al. IP EUROTRANS: A European Research Programme for the Transmutation of High Level Nuclear Waste in an Accelerator Driven System. Actinide and Fission Product Partitioning & Transmutation Eighth Information Exchange Meeting Las Vegas, Nevada, USA 9-11 November 2004, 2004. Available online: http://www.oecd-nea.org/pt/docs/iem/lasvegas04/11_Session_V/S5_01.pdf (accessed on 10 June 2013).

- C. Madic, B. Boullis, P. Baron, F. Testard, M.J. Hudson, J.-O. Liljenzin, B. Christiansen, M. Ferrando, A. Facchini, A. Geist, G. Modolo, A.G. Espartero, J. De Mendoza, Futuristic back-end of the nuclear fuel cycle with the partitioning of minor actinides. J. Alloys Compd. 2007, 444–445. [Google Scholar] [CrossRef]

- Merk, B. Litskevich, D., Peakman, A., & Bankhead, M. The Current Status of Partitioning & Transmutation and How to Develop a Vision for Nuclear Waste Management. Atw-Int. J. Nucl. Power 2019, 64, 261–266.

- A. Khaperskaya, Khomyakov Yu, Shadrin A, Feinberg O.,Conceptual approaches and the main directions of R & D on partitioning and transmutation of minor actinides and long-lived fi ssion products in the Russian Federation State atomic energy corporation “Rosatom”, Manchester, 15th International Exchange Meeting on Partitioning and Transmutation 2 October 2018, Manchester.

- Merk, B., Litskevich, D., Bankhead, M.; Taylor, R. J. An innovative way of thinking nuclear waste management - Neutron physics of a reactor directly operating on SNF. PLoS ONE 2017, 12. [CrossRef]

- acatech (Ed.): Partitioning and Transmutation of Nuclear Waste. Opportunities and Risks in Research and Application (acatech POSITION PAPER), Munich 2014.

- Ortwin Renn (Hrsg.), Partitionierung und Transmutation Forschung – Entwicklung – Gesellschaftliche

Implikationen acatech STUDIE Dezember 2013.

- Merk, B.; Detkina, A.; Litskevich, D.; Noori-Kalkhoran, O.; Cartland-Glover, G. A HELIOS-Based Dynamic Salt Clean-Up Study for iMAGINE. Appl. Sci. 2022, 12, 8748. [Google Scholar] [CrossRef]

- Merk B, Litskevich D. Transmutation of All German Transuranium under Nuclear Phase Out Conditions - Is This Feasible from Neutronic Point of View? PLoS One 2015, 10, e0145652. [Google Scholar] [CrossRef]

- Merk, B., Rohde, U., Glivici-Cotruta, V., Litskevich, D.; Scholl, S. On the Use of a Molten Salt Fast Reactor to Apply an Idealized Transmutation Scenario for the Nuclear Phase Out. PLOS ONE 2014, 9. [CrossRef]

- HELIOS2 Methods Manual (version 2.03.01), Studsvik, SSP-11/452 Rev 6, January 12, 20214.

- Villarino EA, Stammler RJJ, Ferri A. and Casal JJ. HELIOS: angularly dependent collision probabilities. Nuclear Science and Engineering 1992, 112.

- C.A. Wemple, H-N.M. Gheorghiu , R.J.J. Stamm’ler , E.A. Villarino 2008) Recent Advances in the HELIOS- 2 Lattice Physics Code, International Conference on the Physics of Reactors “Nuclear Power: A Sustainable

57 Resource”, Interlaken, Switzerland, September 14-19, 2008.

- Evaluation and Viability of Liquid Fuel Fast Reactor System EVOL, DELIVERABLE D2.1, Design

parameters definition for most stable salt flux, rev 3 30/04/2012.

- M. Brovchenko et al., Neutronic benchmark of the molten salt fast reactor in the frame of the EVOL and MARS collaborative projects, EPJ Nuclear Sci. Technol. 2019, 5, 2. [CrossRef]

- B. Merk, A. Detkina, S. Atkinson, D. Litskevich, G. Catland-Glover: Evaluation of the Breeding Performance of a NaCl-UCl-Based Reactor System, Energies 2019, 12, 3853. [CrossRef]

- OECD/NEA AND, U.S. NRC PWR MOX/UO2 CORE TRANSIENT BENCHMARK Tomasz Kozlowski and Thomas J. Downar Purdue University West Lafayette, Indiana U.S.A. Final Specifications, Revision. 2 December 2003. Available online: https://www.oecd-nea.org/upload/docs/application/pdf/2020-10/mox_benchmark_specifications_2003.pdf (accessed on 5 June 2023).

- AURORA USER MANUAL, Studsvik, SSP-11/451 Rev 8, January 12, 2021.

- ZENITH USER MANUAL, Studsvik, SSP-11/460 Rev. 5, December 8, 2020.

- Merk, B.; Litskevich, D. On the Burning of Plutonium Originating from Light Water Reactor Use in a Fast Molten Salt Reactor-A Neutron Physical Study. ENERGIES 2015, 8, 12557–12572. [Google Scholar] [CrossRef]

- Merk B, Litskevich D. A disruptive approach to eliminating weapon-grade plutonium – Pu burning in a molten salt fast reactor. PLoS ONE 2018, 13, e0201757. [CrossRef]

- Rachamin R, Wemple C, Fridman E (2013) Neutronic analysis of SFR core with HELIOS-2, Serpent, and

DYN3D codes. Annals of Nuclear Energy 2013, 55. [CrossRef]

- A. Detkina, D. Litskevich, M. Drury, B. Merk (2022) Zero Power Experiment for Molten Salt Reactor -- Code

Verification and Validation Request, International Conference on Physics of Reactors 2022, Pittsburgh,

United States.

- B Merk, D Litskevich, R Gregg, AR Mount. « Demand driven salt clean-up in a molten salt fast reactor–Defining a priority list ». PloS ONE 2018, 13, e0192020.

- Merk, B.; Detkina, A.; Litskevich, D.; Drury, M.; Noori-kalkhoran, O.; Cartland-Glover, G.; Petit, L.; Rolfo, S.; Elliott, J.P.; Mount, A.R. Defining the Challenges—Identifying the Key Poisoning Elements to Be Separated in a Future Integrated Molten Salt Fast Reactor Clean-Up System for iMAGINE. Appl. Sci. 2022, 12, 4124. [Google Scholar] [CrossRef]

- Claude Degueldre, Bruno Merk (2023) Use of chloride-37 in Molten Salt Fast Reactor for ecological and

economical reasons, submitted to Progress in Nulear Energy.

- Jaag, S. , and Kiefhaber, E. Americium incineration - Challenge in plutonium burning and minor actinide transmutation. United States: N. p., 1999. Web.

- Bruno Merk, Moderating Material to Compensate the Drawback of High Minor Actinide Containing Transmutation Fuel on the Feedback Effects in SFR Cores. Science and Technology of Nuclear Installations 2013, 2013, 172518. [CrossRef]

- Gulevich, A.V. , Eliseev, V.A., Klinov, D.A. et al. Possibility of Burning Americium in Fast Reactors. At Energy 2020, 128, 88–94. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).