Submitted:

24 July 2023

Posted:

25 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Preparation of MgB2 wires

2.2. Strain Calculation using ToF Method

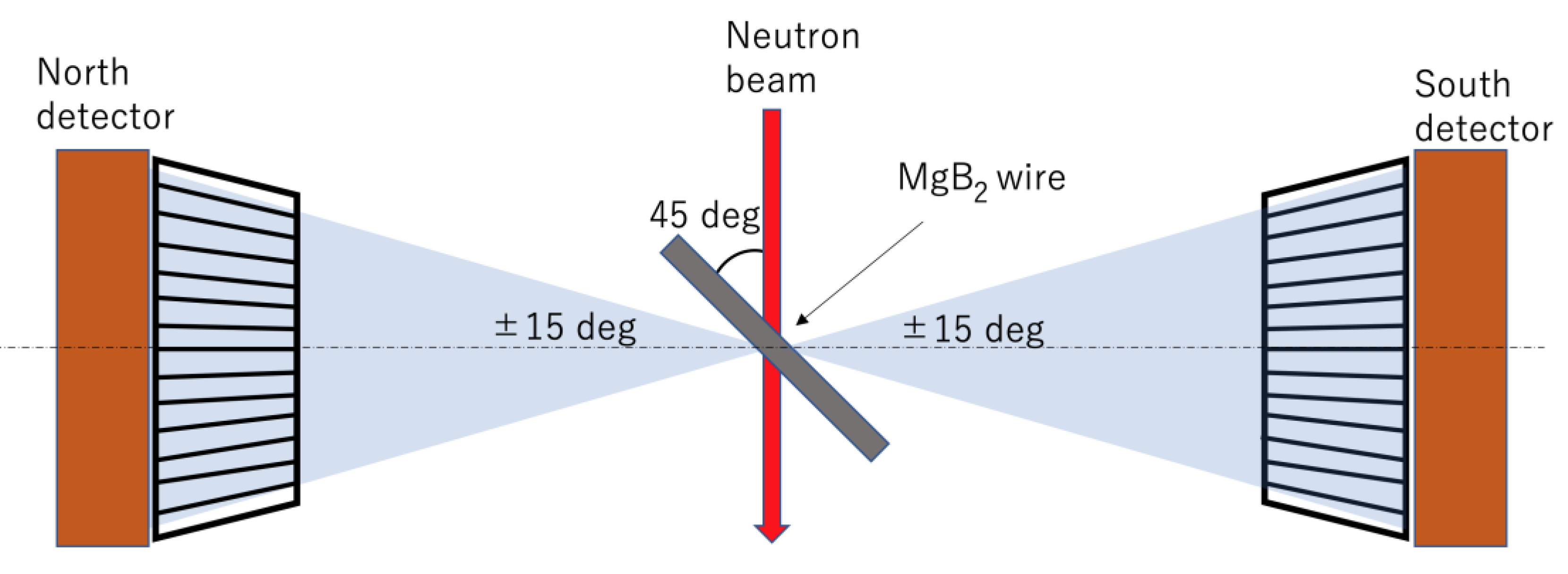

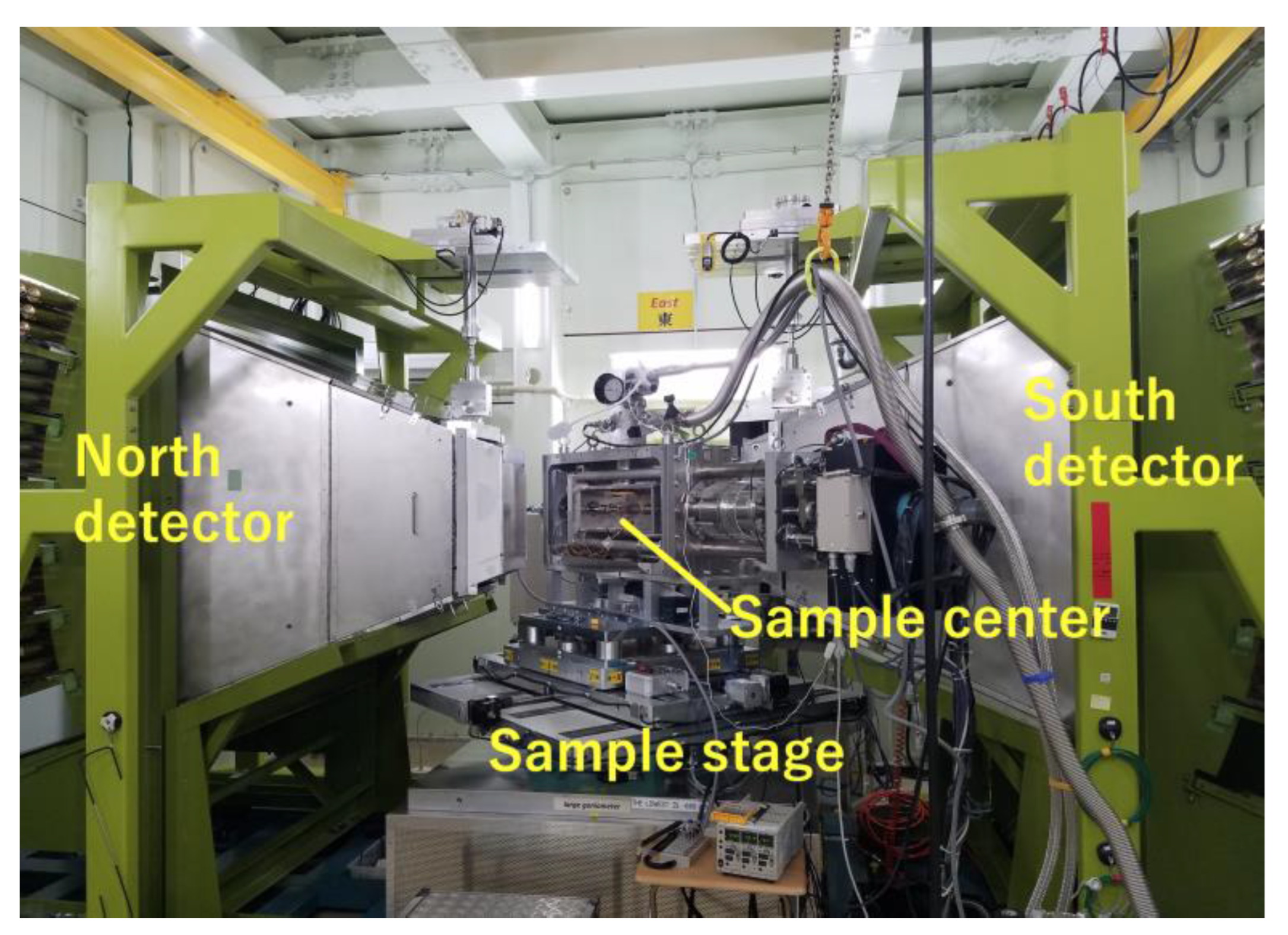

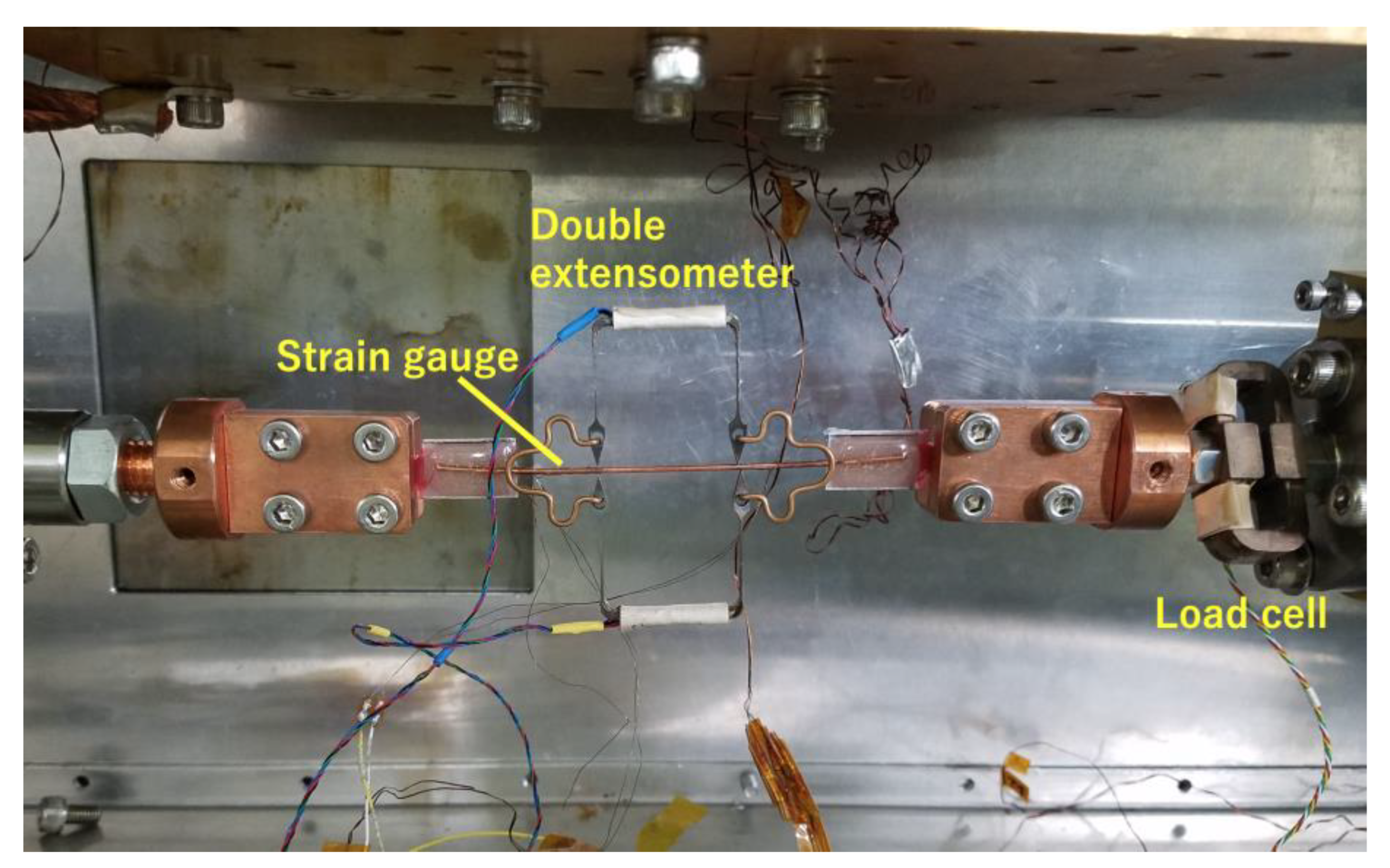

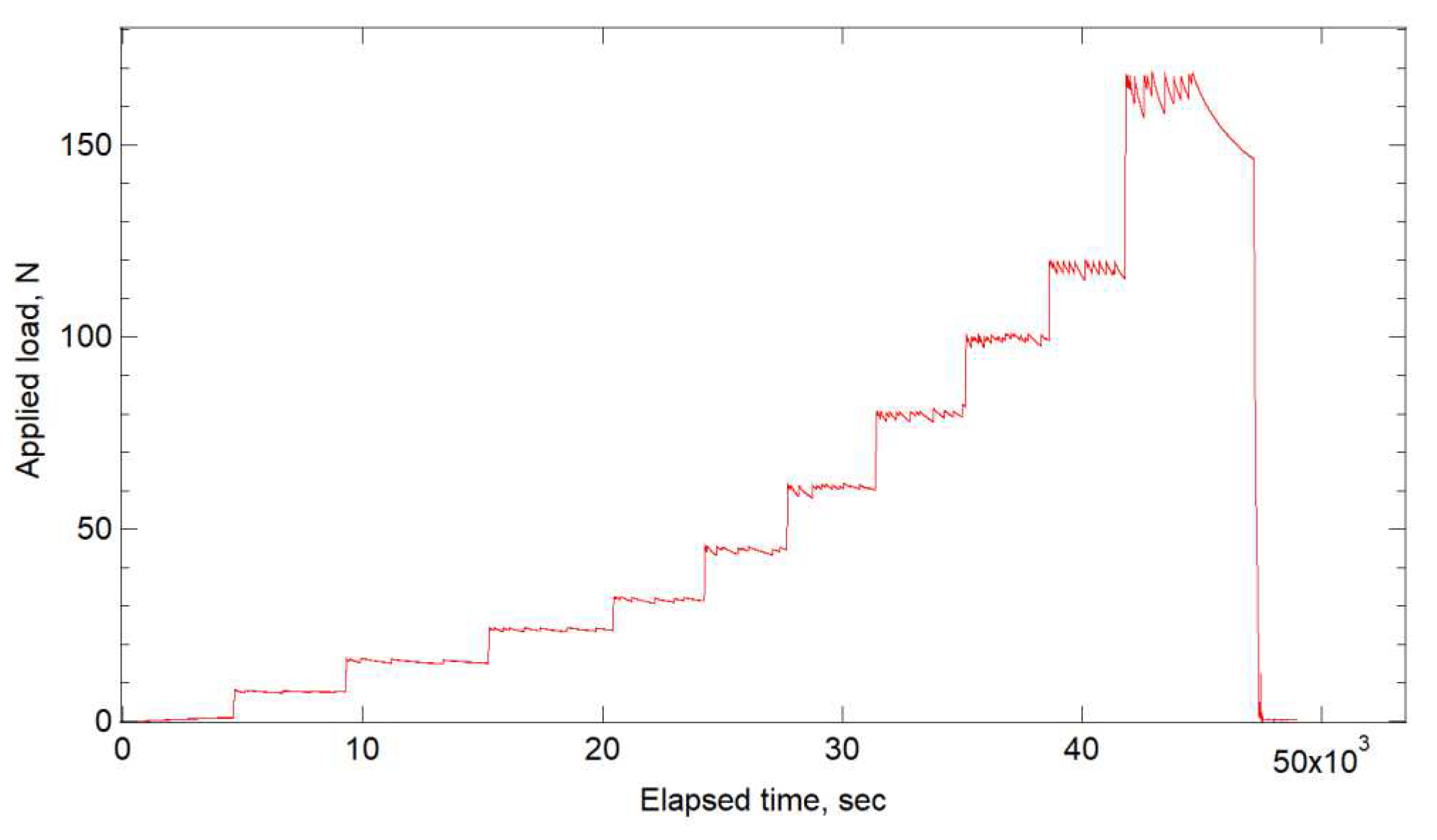

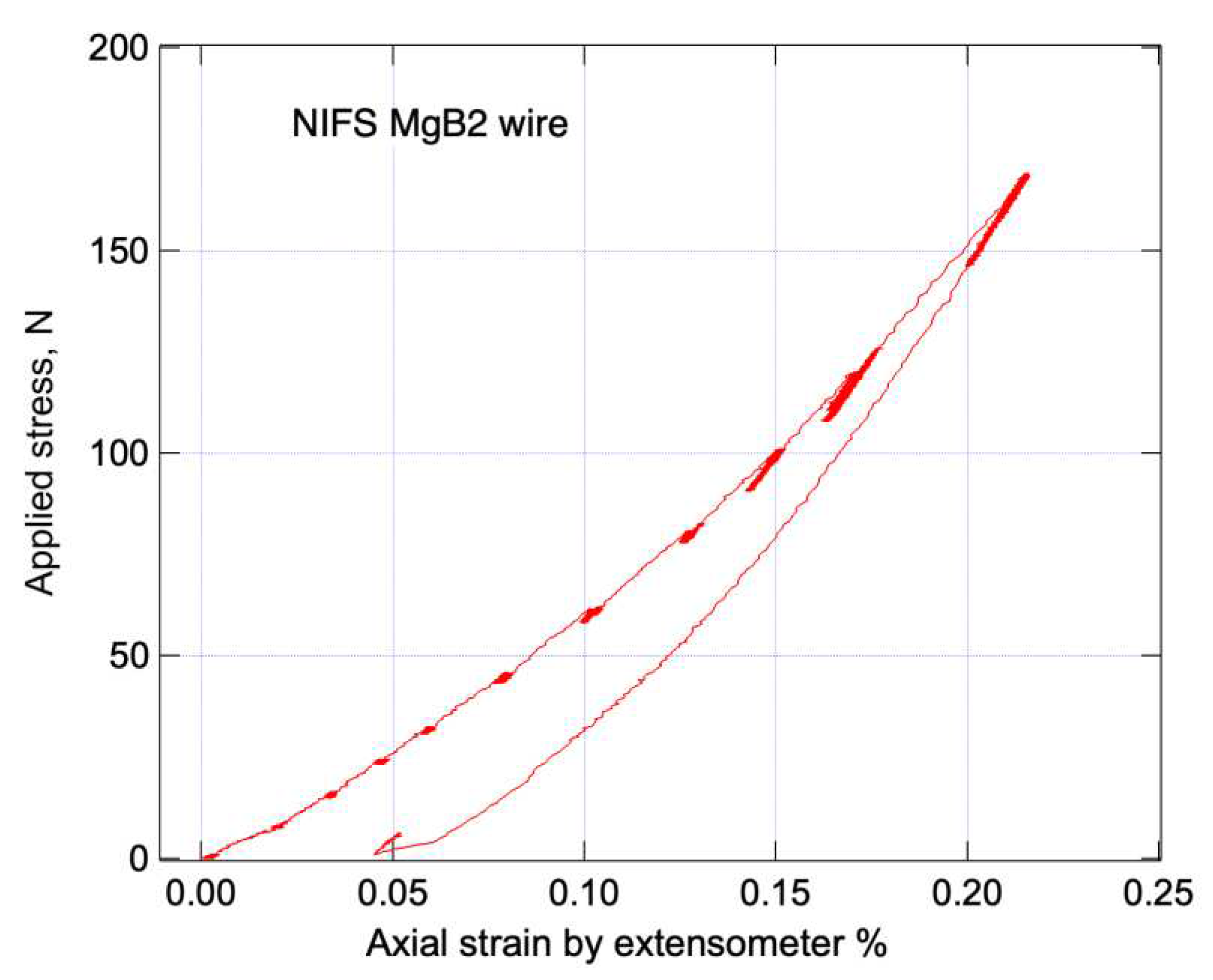

2.3. In situ strain measurement under tensile teset and equipment

3. Results

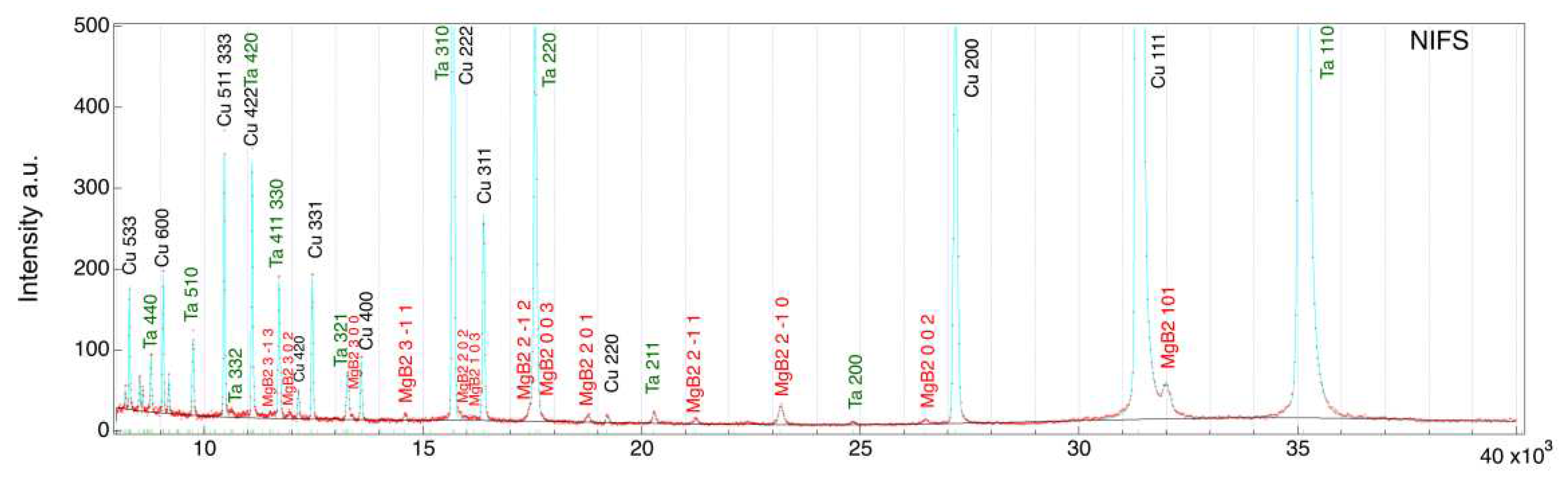

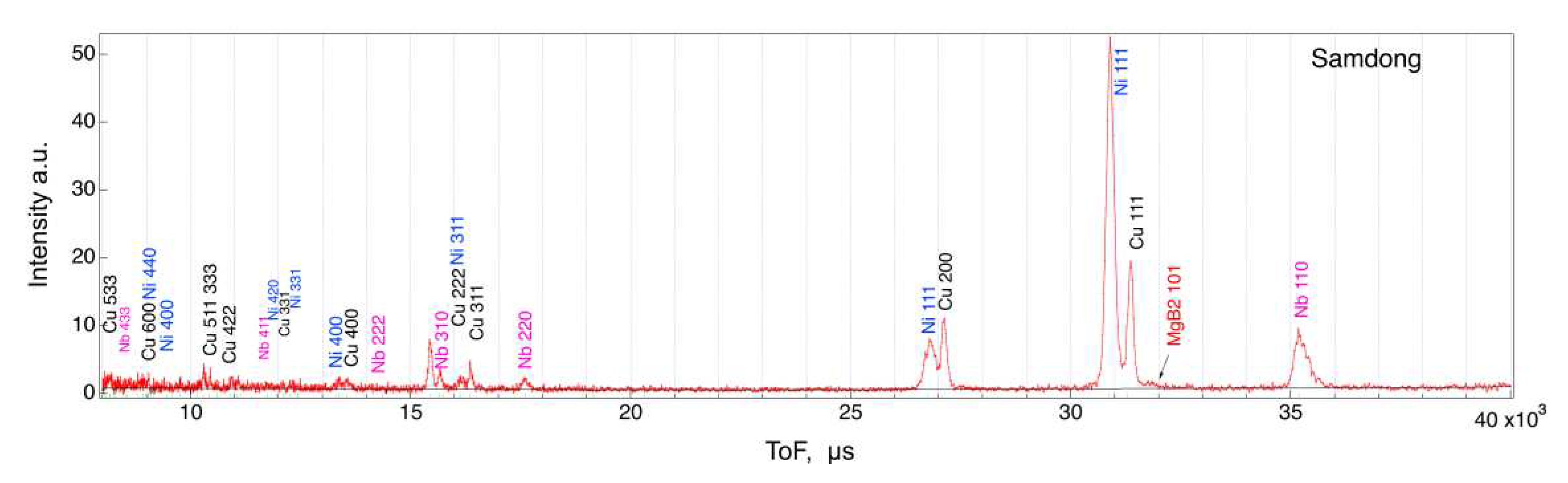

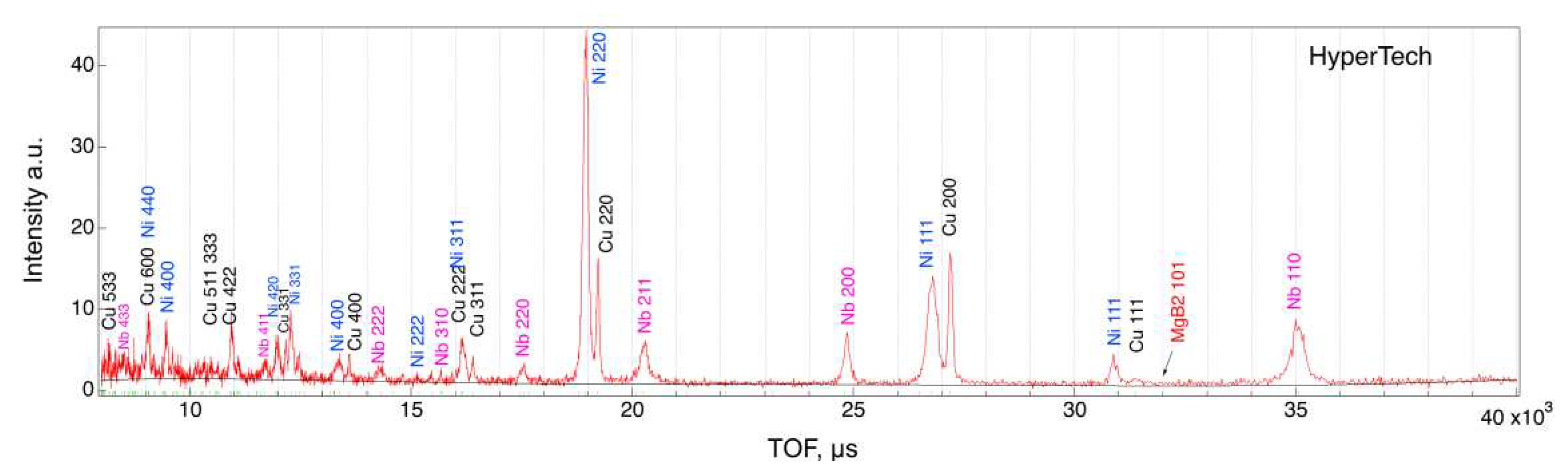

3.1. Diffraction histogram by ToF method

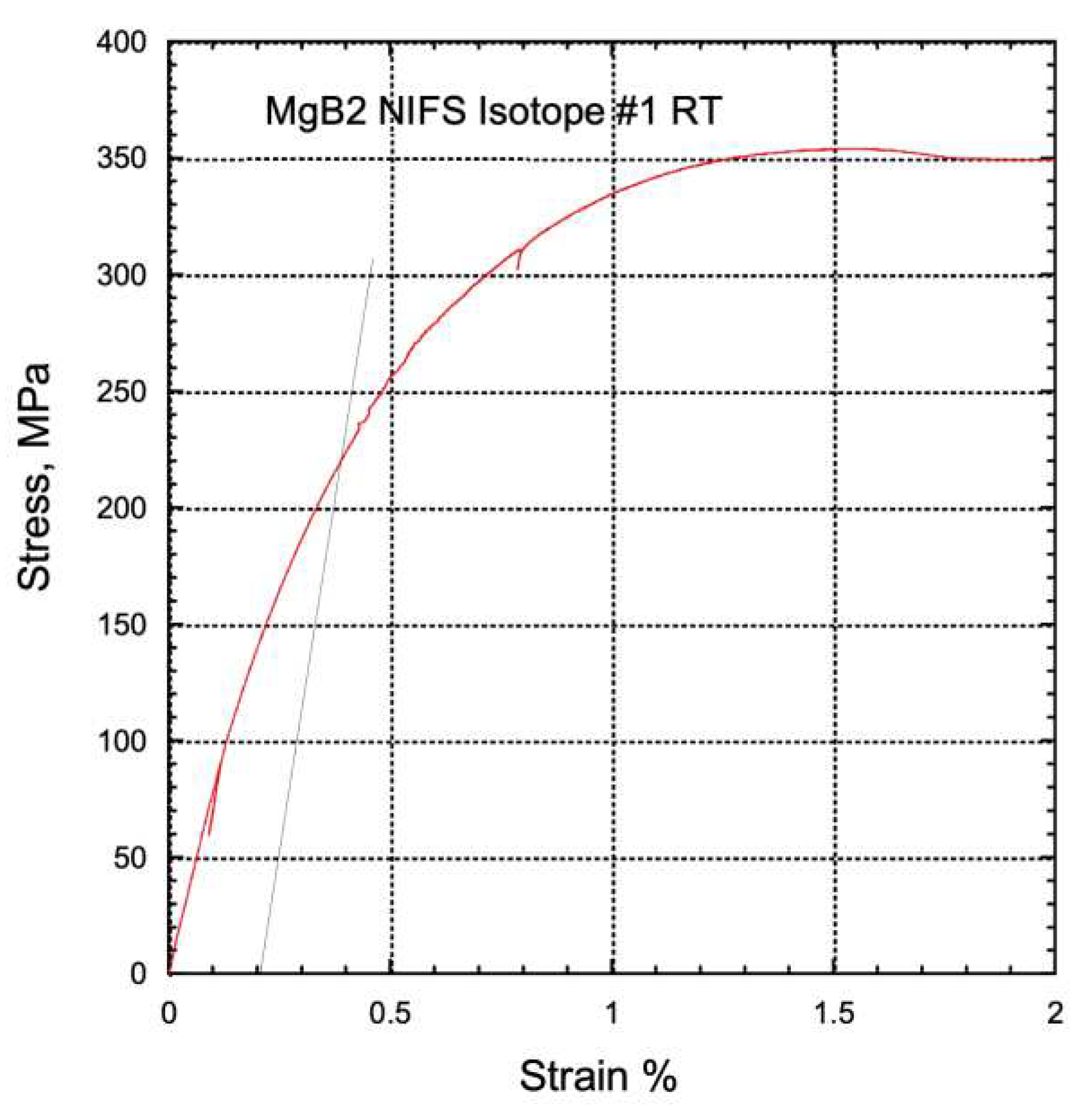

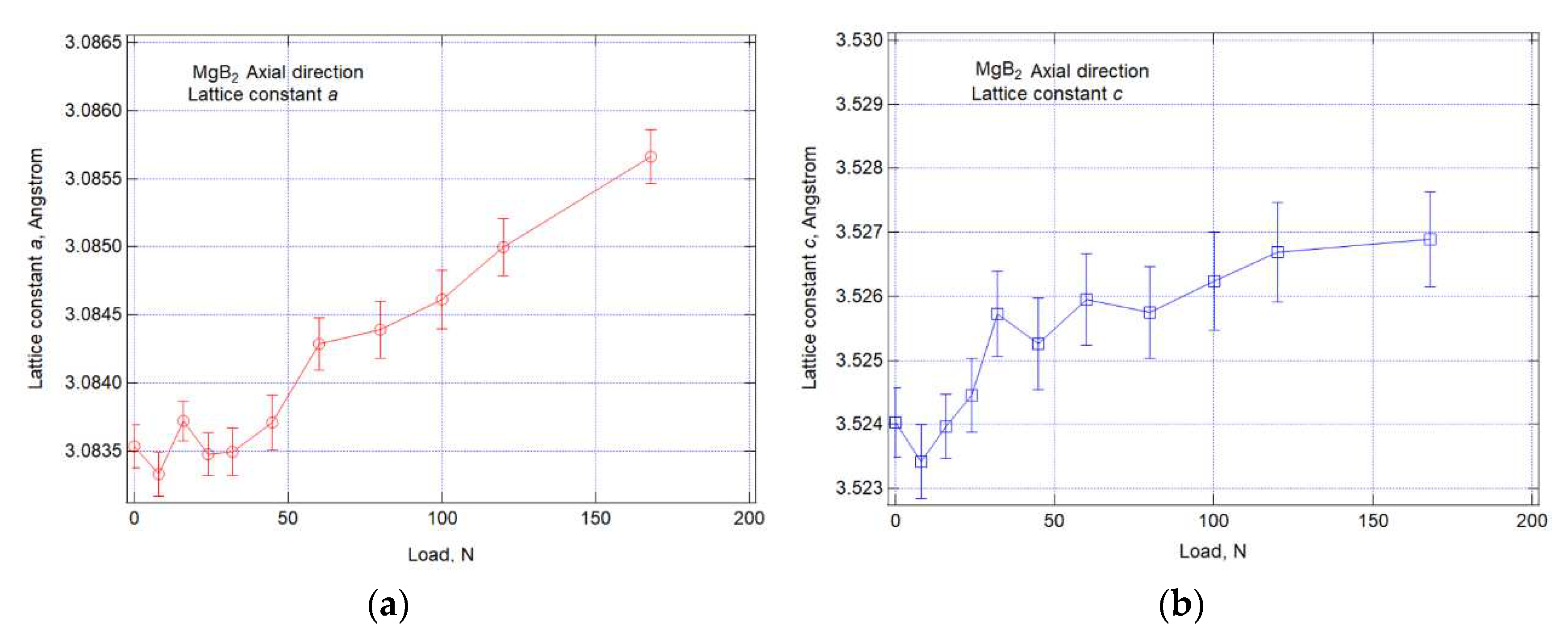

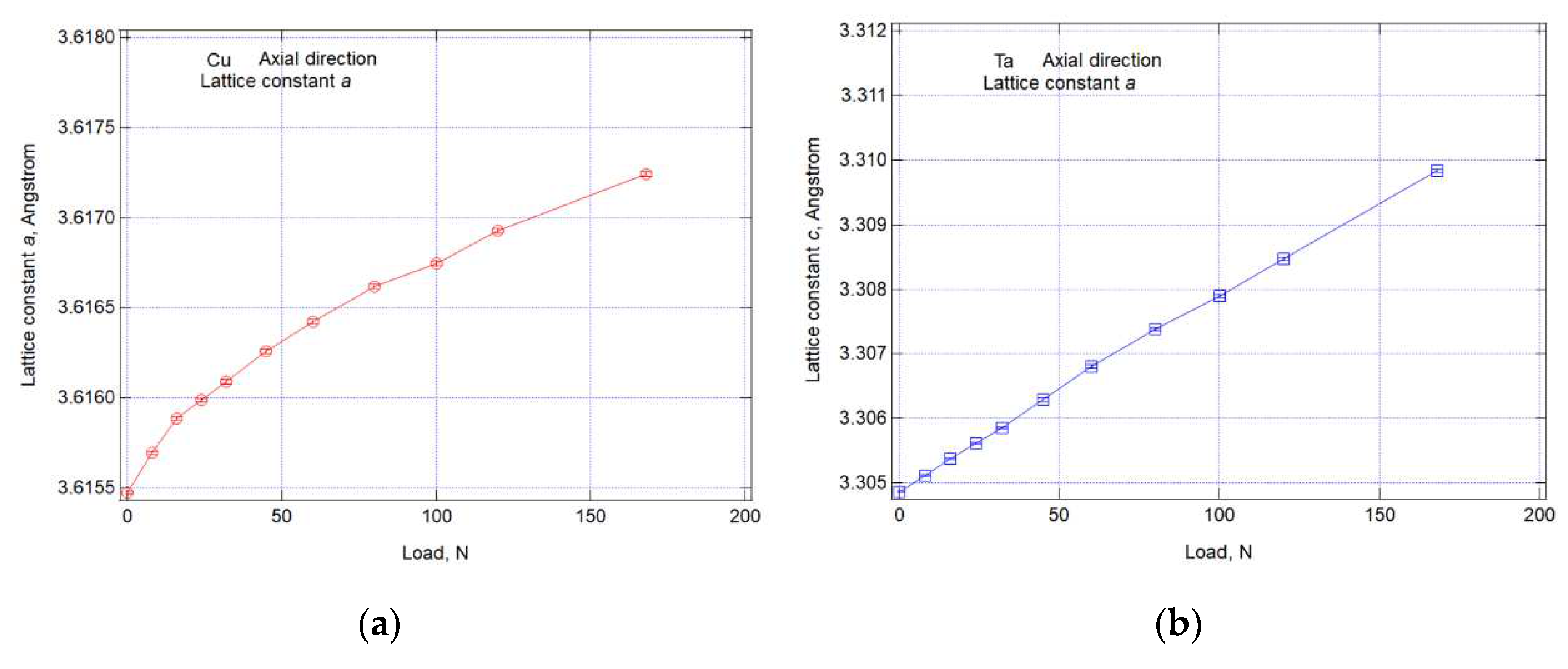

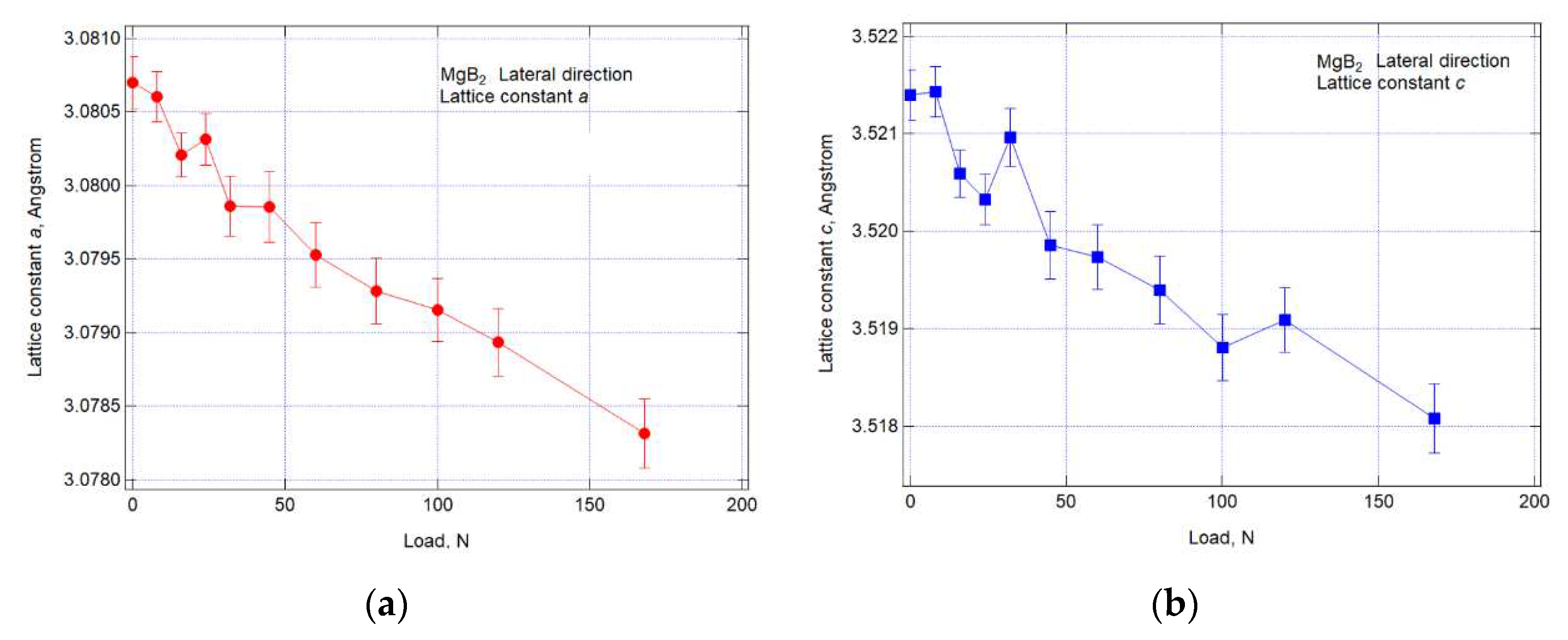

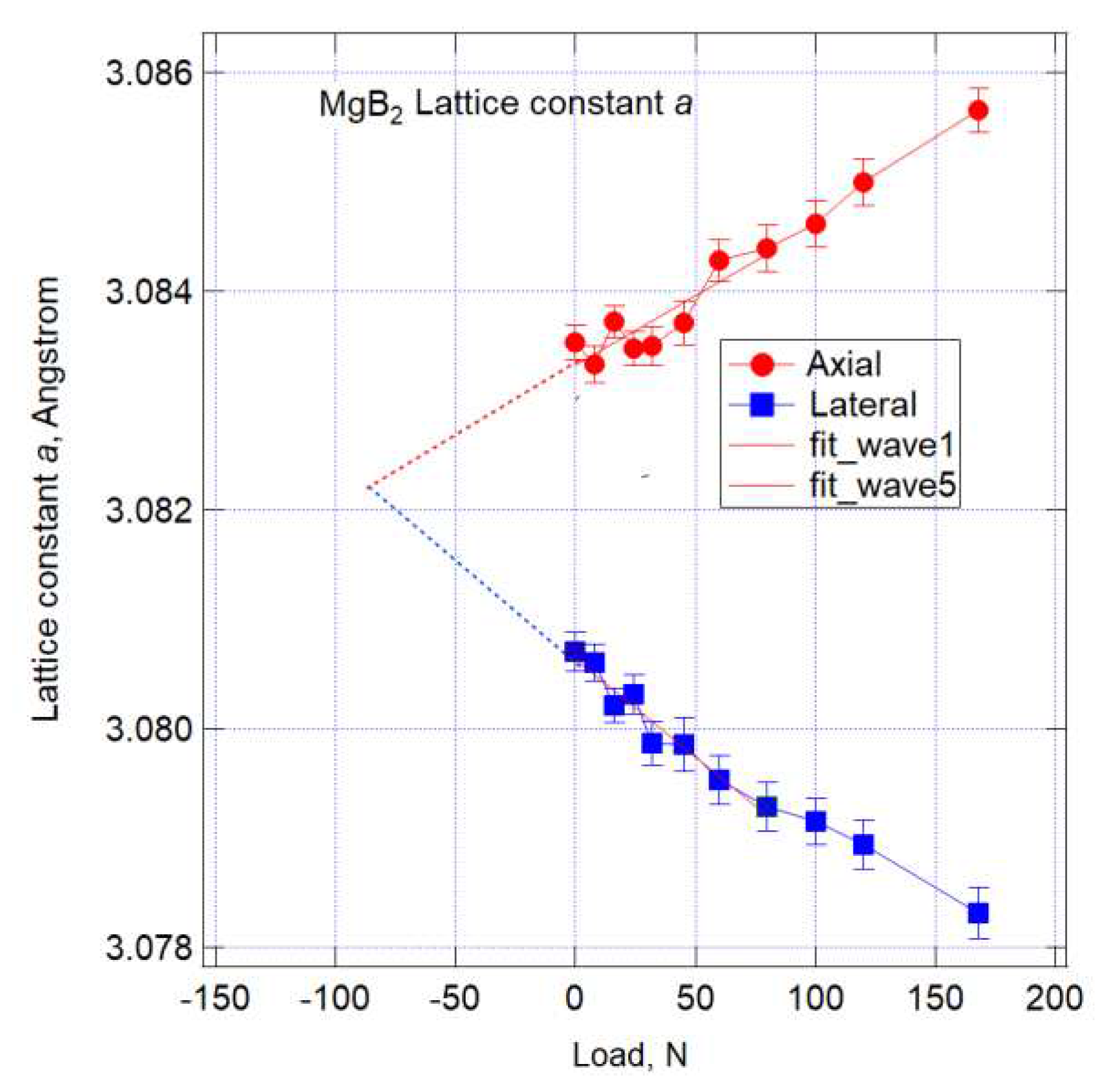

3.2. Strain measurement under tensile loadings

4. Discussion

5. Conclusions

- (1)

- Neutron scattering experiments on 11B enriched MgB2 wire have shown sufficient diffraction peaks of MgB2. Rietveld analysis of each phase allowed optimization of the lattice constants using approximately all peaks.

- (2)

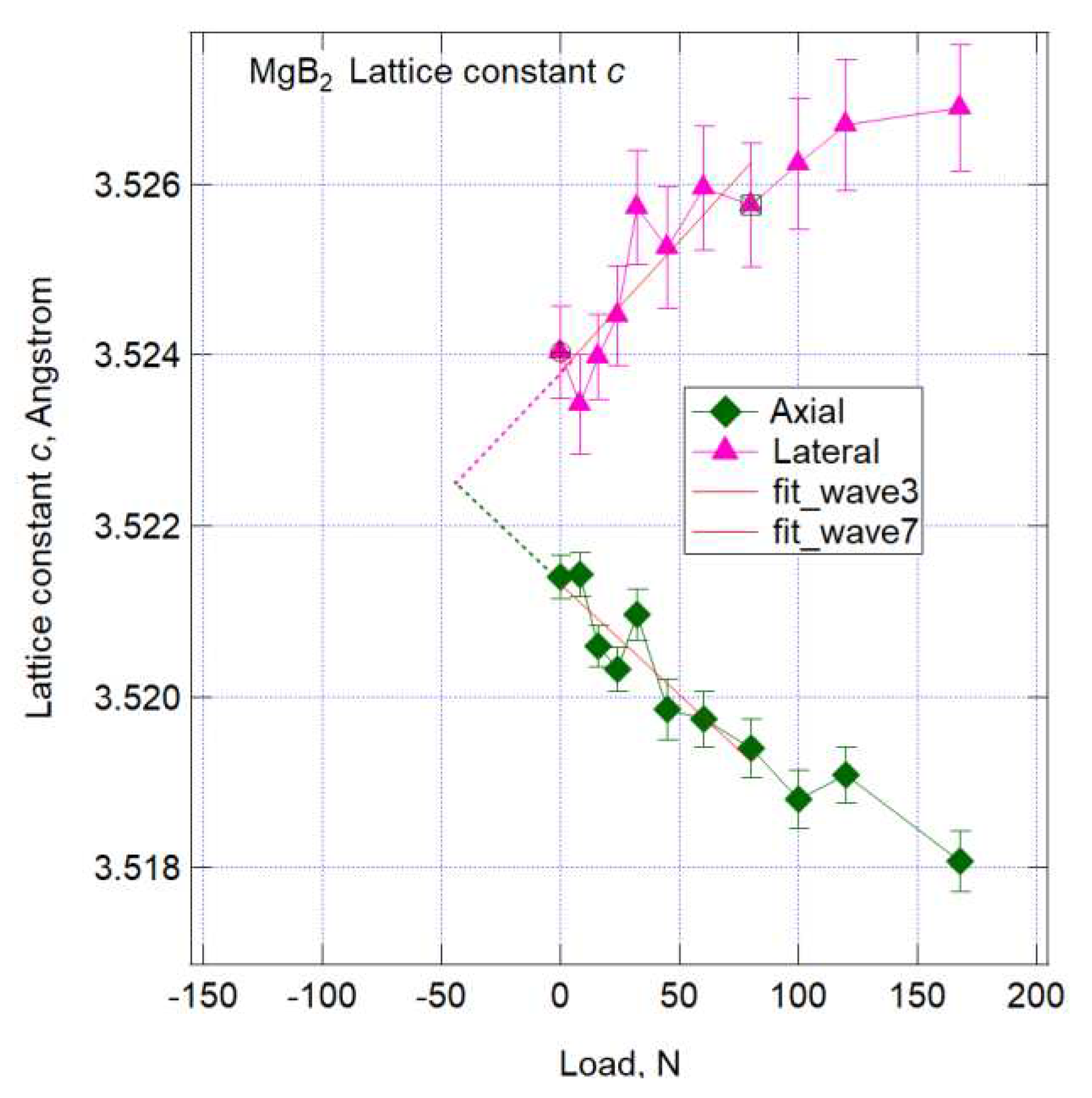

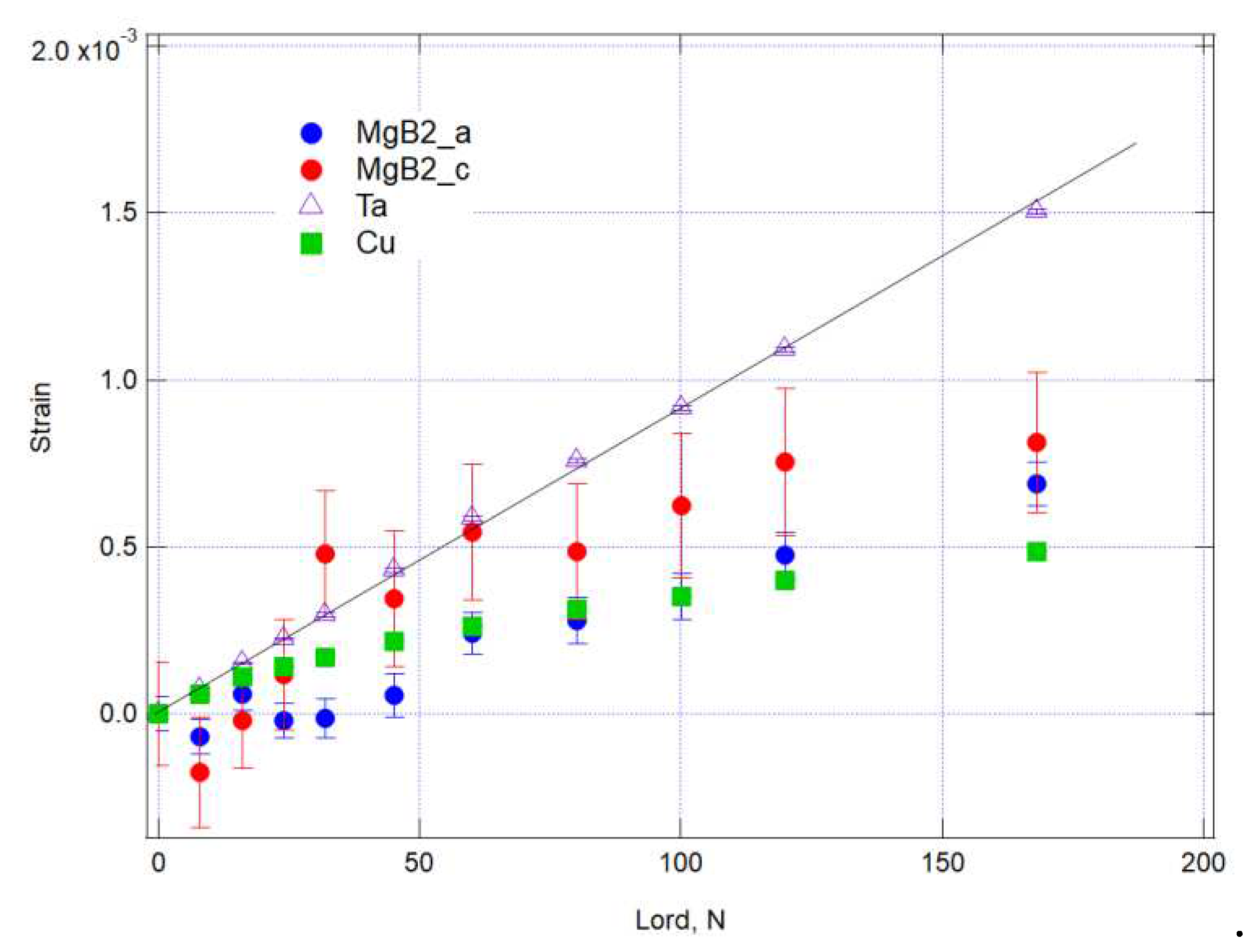

- This allowed to obtain previously unreported changes in load and strain of MgB2 wires under tensile load at room temperature. The difference in lattice constants between axial and lateral directions strongly suggests that the residual stress or strain at room temperature is tensile.

- (3)

- The ratio of the change in lattice constant to load in the axial and lateral directions was close, indicating that the axial strain may be relaxing.

- (4)

- About 2 types of commercially conventional practical MgB2 wire, scattering experiments were performed for 7200 sec but no analyzable MgB2 peaks were obtained. This suggests that it is almost impossible to obtain diffraction of MgB2 in neutron scattering experiments for boron with natural ratio isotopes.

Acknowledgments

References

- Nagamatsu, J.; Nakagawa, N.; Muranaka, T.; Zenitani, Y.; Akimitsu, J. Superconductivity at 39 K in magnesium diboride. Nature 2001, 410, 63–64. [Google Scholar] [CrossRef]

- Ballarino, A; Flükiger, R; Status of MgB2 wire and cable applications in Europe. J. Phys. Conf. Ser. 2017, 871, 012098.

- Marino, I,; Pujana, A.; Sarmiento, G.; Sanz, S.; Merino, J.M.; Tropeano, M.; Sun, J.; Canosa, T.; Lightweight MgB2 superconducting 10 MW wind generator. Supercond. Sci. Technol. 2016, 29, 024005.

- Tanaka, H.; Suzuki, T.; Kodama, M.; Koga, T.; Watanabe, H.; Yamamoto, A.; Michizono, S. Performance of MgB2 superconductor developed for high-efficiency klystron applications . IEEE Trans, Appl. Supercond. ,2020 30-4, 6200105. [CrossRef]

- Choi, Y.; Park, D.; Li, Y.; Tanaka, H.; Lee, E.; Bascuñán, J.; Iwasa, Y. Persistent-mode operation and magnetization behavior of a solid nitrogen-cooled MgB2 small-scale test coil towards a tabletop 1.5-T osteoporosis MRI. Supercond. Sci. Technol. 2020, 33, 1018.

- Sykes, A.; Costley, A.E.; Windsor, C.G.; Asunta, O.; Brittles ,G.; Buxton, P.; Chuyanov, V; Connor J.W.; Gryaznevich, M.P.; Huang, B.; Hugill, J.; Kukushkin, A.; Kingham, D.; Langtry, A.V.; McNamara, S.; Morgan, J.G.; Noonan, P.; Ross, J. S. H.; Shevchenko, V.; Slade, R.; Smith, G.; Compact fusion energy based on the spherical tokamak. Nucl. Fusion. 2018, 58 016039. [CrossRef]

- Leslie, M.; Ito, T.; Aizawa, K.; Arima, H. ; Start-Ups Seek to Accelerate Path to Nuclear Fusion. Engineering 2021, 8, 6–8. [Google Scholar]

- Ekin, W. J.; Chapter “Strain Effects in Superconducting Compounds”, Advances in Cryogenic Engineering Materials, 1984, Volume 30.

- Osamura, K.; Machiya, S.; Tsuchiya, Y.; Suzuki, H. Internal Strain and Mechanical Properties at Low Temperatures of Surround Cu Stabilized YBCO coated conductor, IEEE Transaction on Applied Superconductivity 2010 20 1532-1536. [CrossRef]

- Osamura, K.; Machiya, S.; Tsuchiya, Y.; Suzuki, H. ; Force free strain exerted on a YBCO layer at 77 K in surround Cu stabilized YBCO coated conductors, Supercond. Sci. Technol. 2010, 23, 045020–045026. [Google Scholar] [CrossRef]

- Oguro, H.; Awaji, S.; Nishijima, G.; Takahashi, K.; Watanabe, K.; Machiya, S.; Suzuki, H.; Tsuchiya, Y.; Osamura, K. Residual strain measurement using neutron diffraction for practical Nb3Sn wires under a tensile load. Supercond. Sci. Technol. 2010, 23-2, 025034. [CrossRef]

- Osamura, K.; Machiya, S.; Ochiai, S.; Osabe, G.; Yamazaki, K.; Fujikami. J.; High strength / high strain tolerance DI-BSCCO tapes by means of pre-tensioned lamination technique. IEEE Trans. on Appl. Superconductivity 2013, 6400504-7. [Google Scholar]

- Hishinuma, Y.; Kikuchi, A.; Shimada, Y.; Kashiwai, T, Hata, S.; Yamada, S.; Muroga, T.; Sagara, A.; Development of MgB2 superconducting wire for the low activation superconducting magnet system operated around core D-T plasma. Fusion Eng. Des. 2015, 98-99, 1076-1080. [CrossRef]

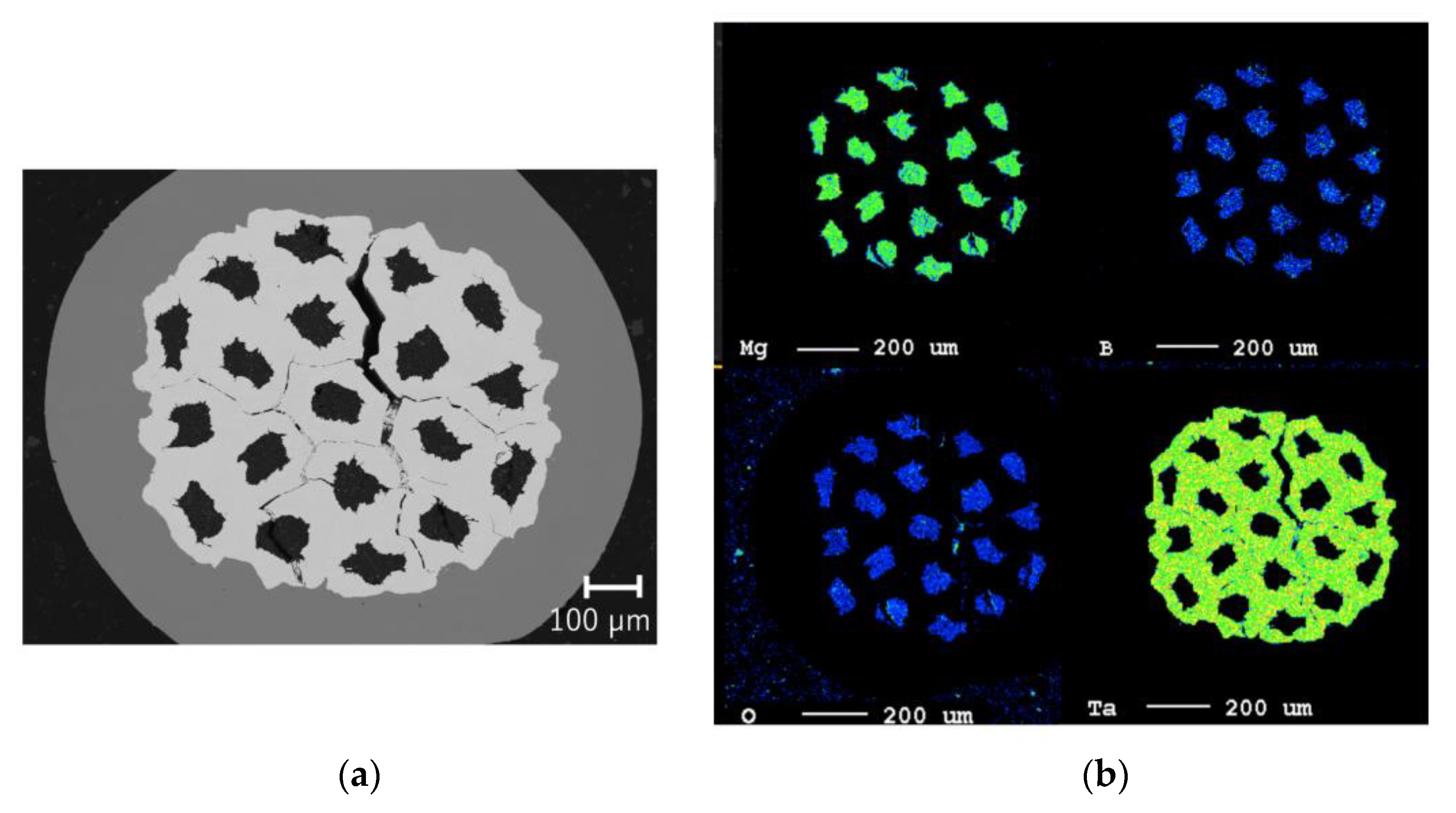

- HISHINUMA, Y.; SHIMADA, Y.; HATA, S.; TANAKA, T.; KIKUCHI, A. Superconducting Properties and Microstructure of In-situ Cu Addition Low Activation MgB2 Multifilamentary Wires Using Different Boron-11 Isotope Powders. Teion Kogaku. 2022, 57-1, 32-38 (in Japanese).

- Cheng, F.; Liu, Y.; Ma, Z.; Li, H.; Shahriar, M.; Hossain, A. ; Superior critical current density obtained in Mg11B2 low activation superconductor by using reactive amorphous 11B and optimizing sintering temperature. Journal of Alloys. Comp. 2015, 650, 508–513. [Google Scholar] [CrossRef]

- Mooring, F.P.; Monahan, J.E.; Huddleston, C.M. Neutron cross sections of the boron isotopes for energies between 10 and 500 keV. Nuclear Phys. 1966, 82-1, 16-32. [CrossRef]

- Harjo, S.; Ito, T.; Aizawa, K.; Arima, H. ; Current Status of Engineering Materials Diffractometer at J-PARC. Mater. Sci. Forum 2013, 681, 443–448. [Google Scholar] [CrossRef]

- Kikuchi, A; Yoshida, Y; Iijima, Y; Banno, N; Takeuchi, T.; Inoue, K; The synthesis of MgB2 superconductor using Mg2Cu as a starting material. Supercond. Sci. Technol. 2004, 17, 781-785.

- Jin. X.; Nakamoto, T.; Harjo, S; Hemmi, T; Umeno, T.; Ogitsu, T.; Yamamoto, A.; Sugano, M.; Aizawa, K.; Abe, J.; Gong, W.; Iwahashi, T; Development of a cryogenic load frame for the neutron diffractometer at Takumi in Japan Proton Accelerator Research Complex, Rev. Sci. Instrum. 2013 84-6, 063106.

- Nyilas, A.; Strain sensing systems tailored for tensile measurement of fragile wires. Supercond. Sci. Tech. 2005, 18-12 S409. [CrossRef]

- Oishi, R.; Yonemura, M.; Nishimaki, Y.; Torii, S.; Hoshikawa, A.; Ishigaki, T.; Morishima, T.; Mori, K.; Kamiyama, T. Rietveld analysis software for J-PARC. Nuclear Instruments and Methods in Physics Research Section A. 2009, 600-1, 94-96.

- Sugano, M.; Machiya, S.; Osamura, K.; Adachi, H.; Sato, M.; Semerad, R. Prussei, W. The direct evaluation of the internal strain of biaxially textured YBCO film in a coated conductor using synchrotron radiation. Supercond. Sci. Technol. 2009, 22-1, 015002. [CrossRef]

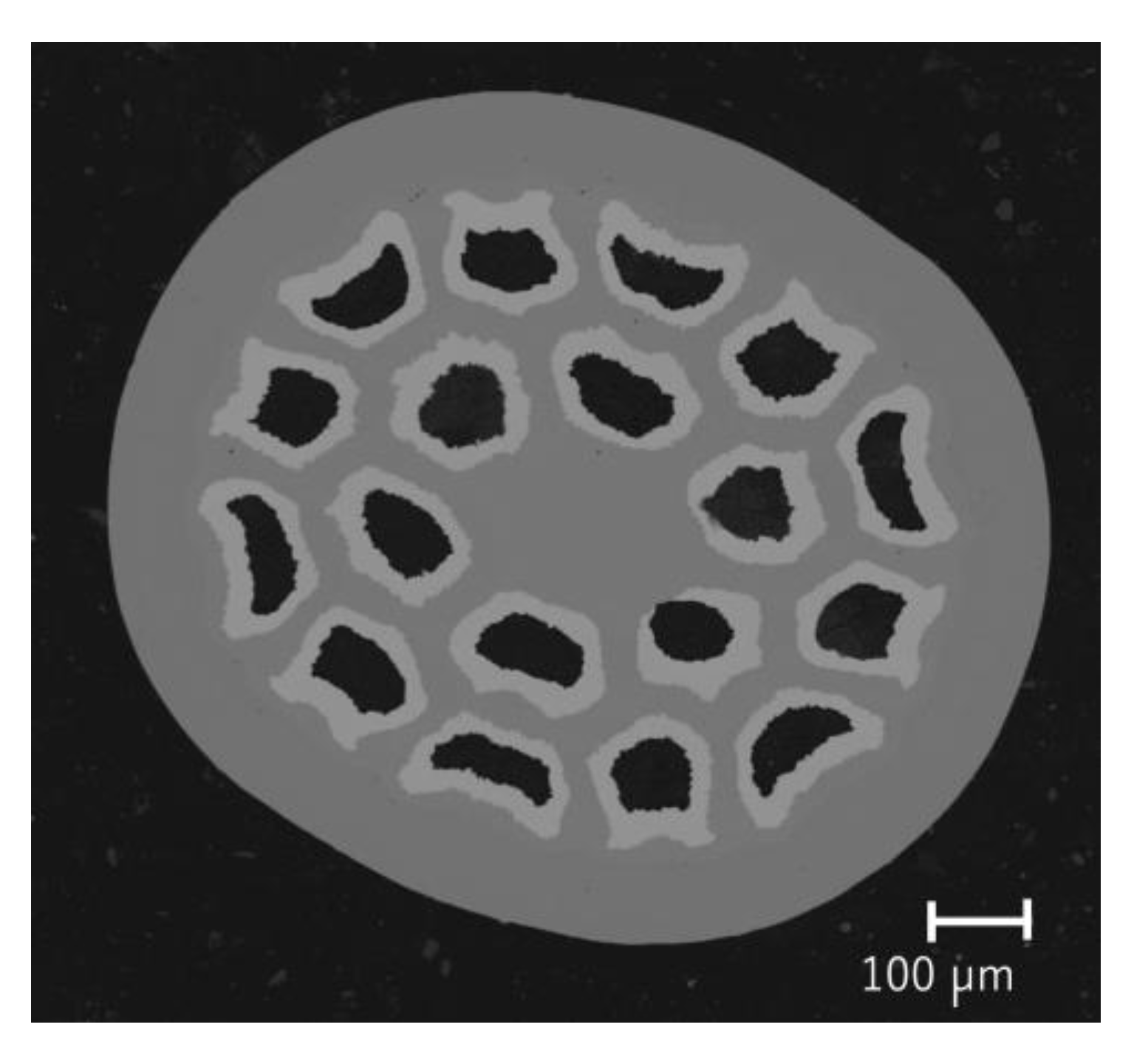

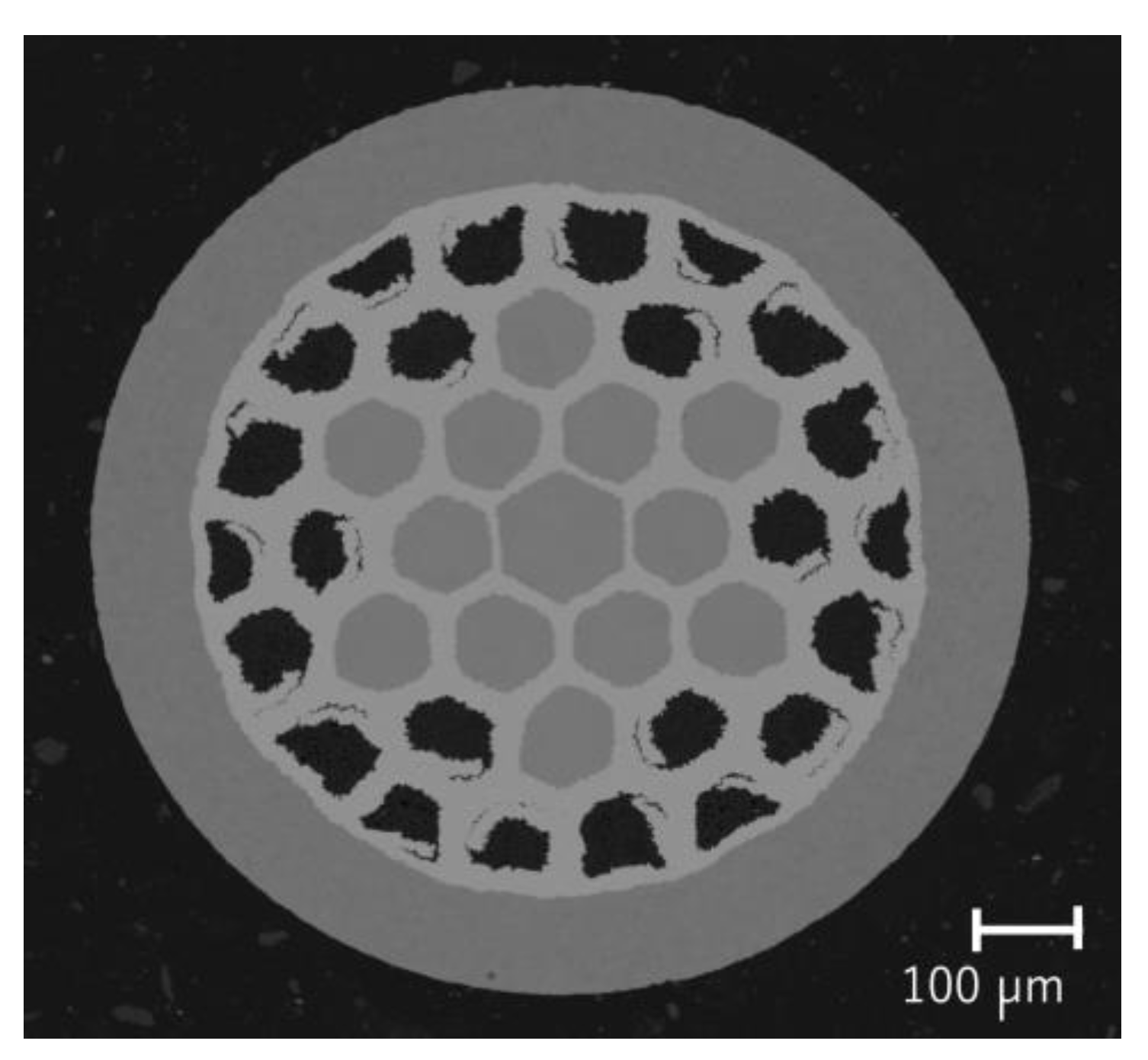

| Manufacturer | Filament | Filament2 | Inner-sheath | Matrix | Outer-sheath |

|---|---|---|---|---|---|

| Samdong | MgB2(0.132) | Nb(0.165) | Cu(0.320) | Ni-Cu-Fe alloy(0.382) | |

| Hypertech | MgB2(0.099) | Cu(0.149) | Nb(0.369) | Ni-Cu-Fe alloy(0.382) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).