Submitted:

25 July 2023

Posted:

26 July 2023

You are already at the latest version

Abstract

Keywords:

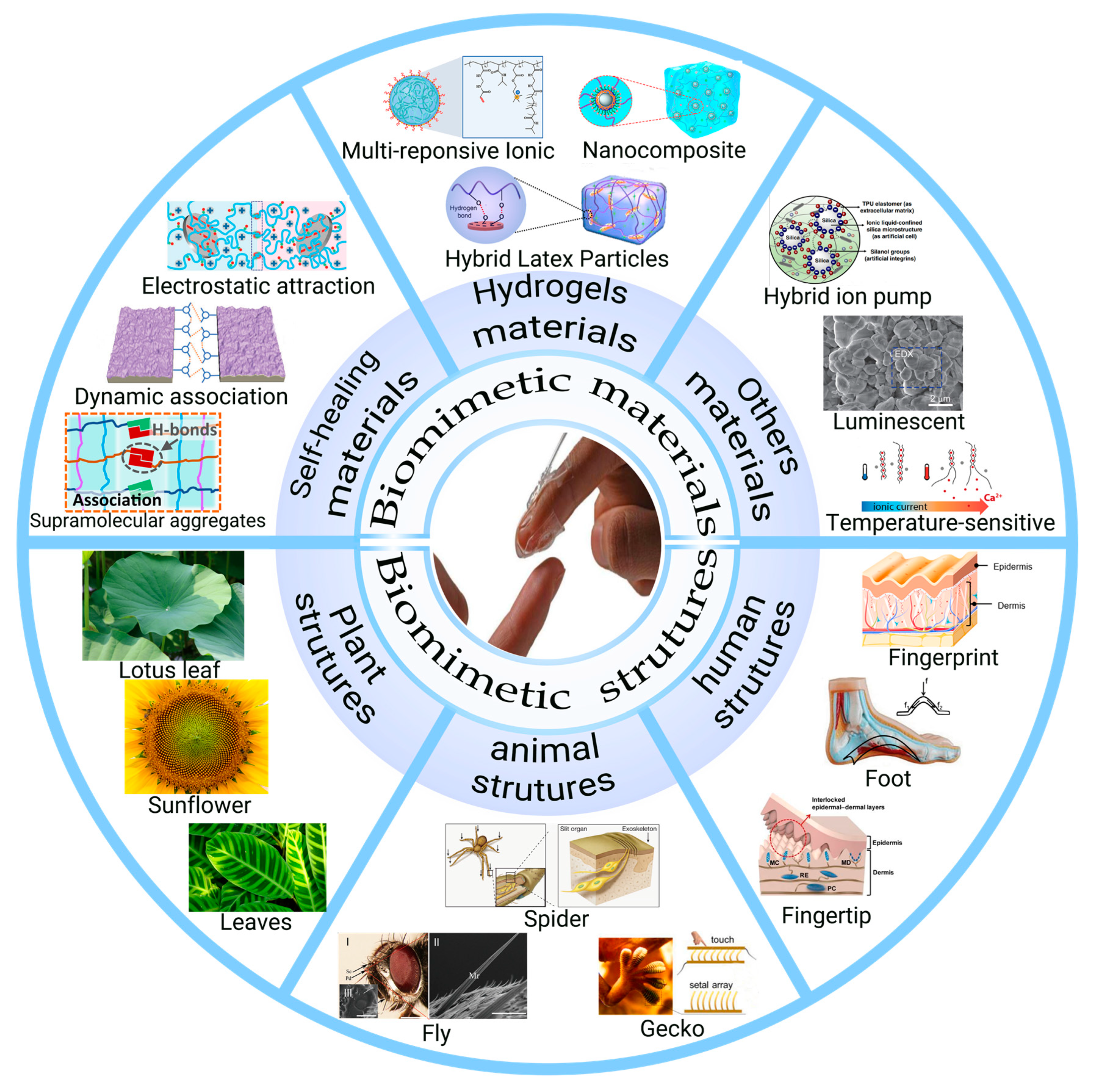

1. Introduction

2. Bioinspired materials for construction of flexible touch sensors

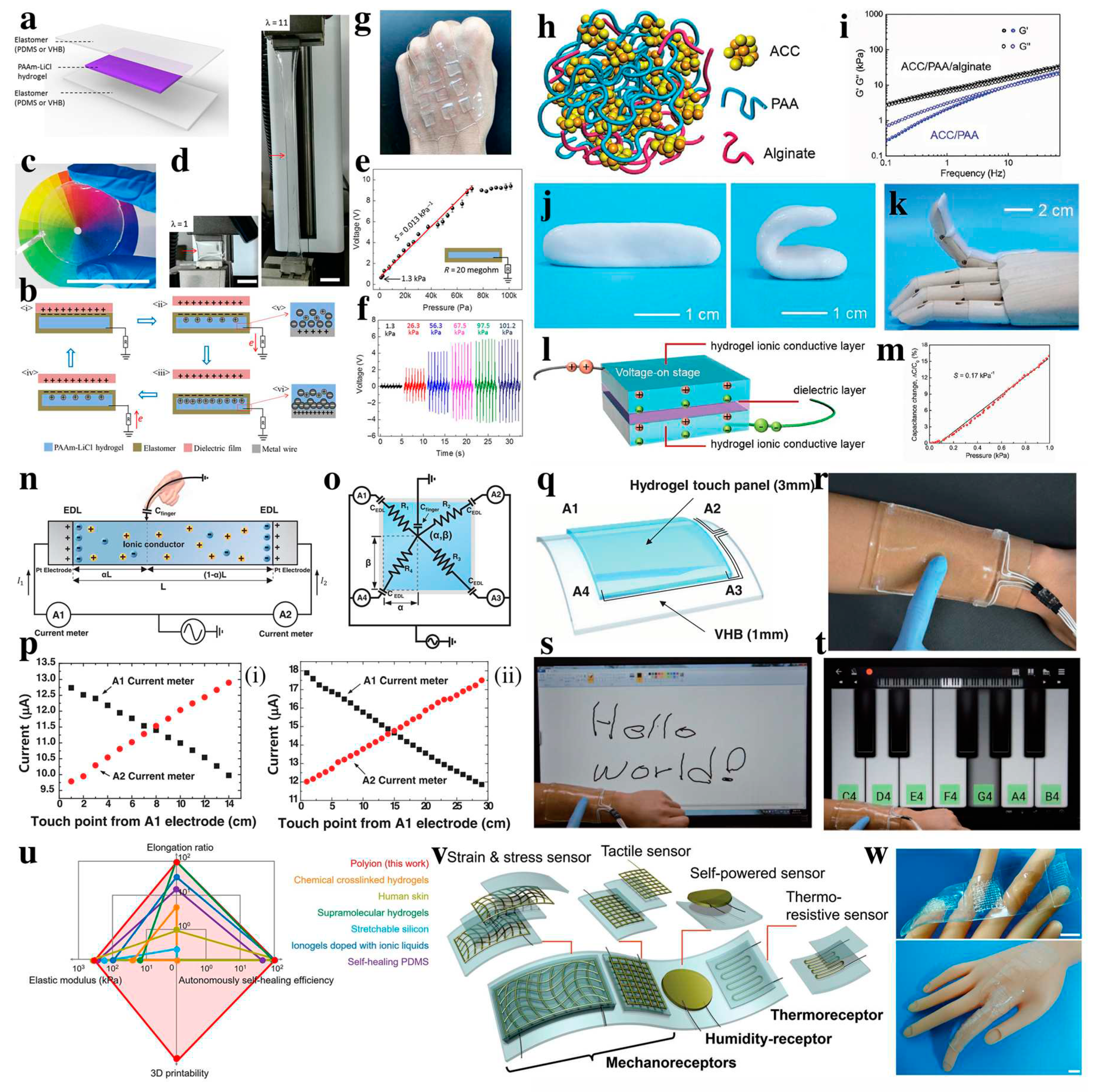

2.1. Touch sensors based on hydrogel materials

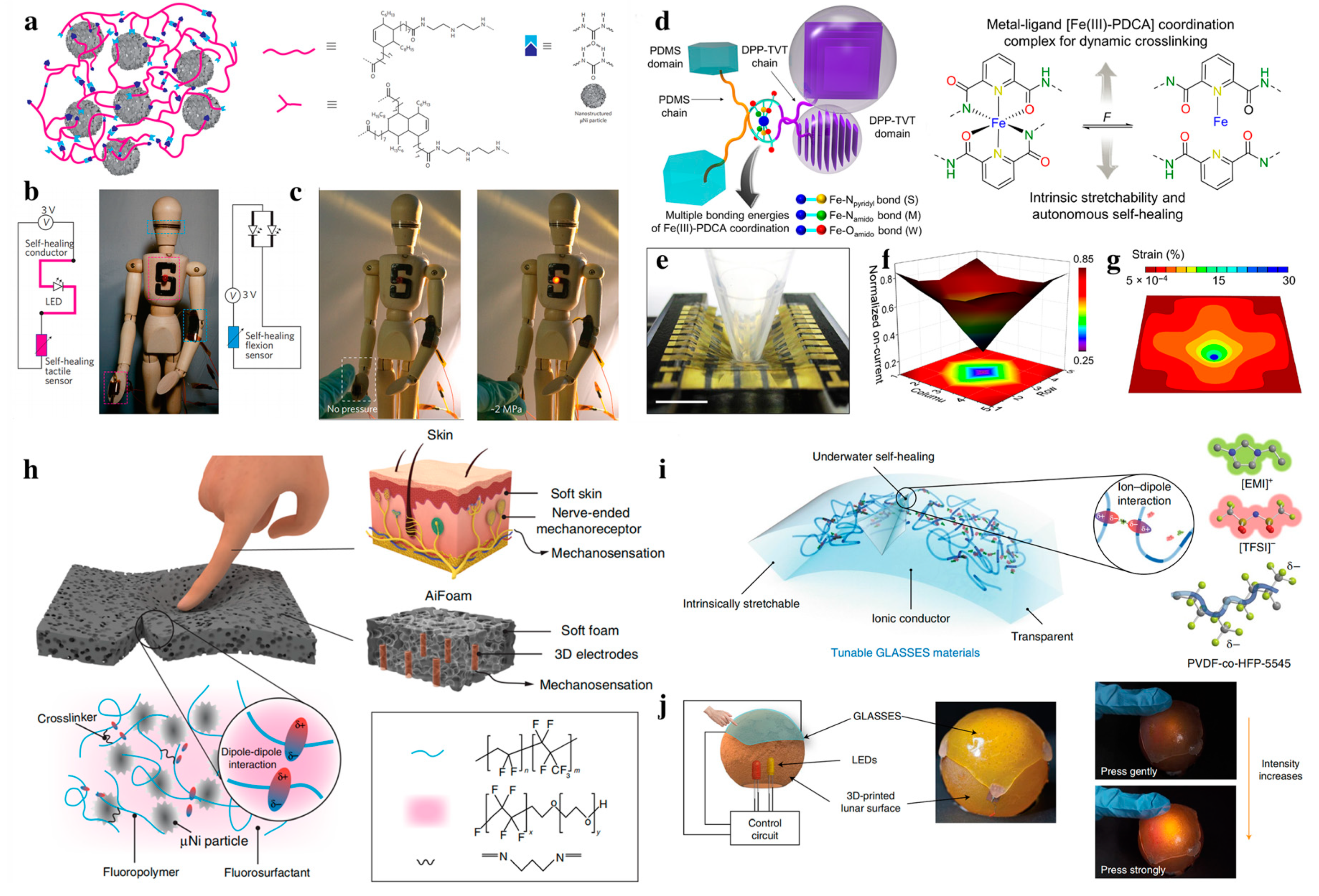

2.2. Touch sensors based on self-healing materials

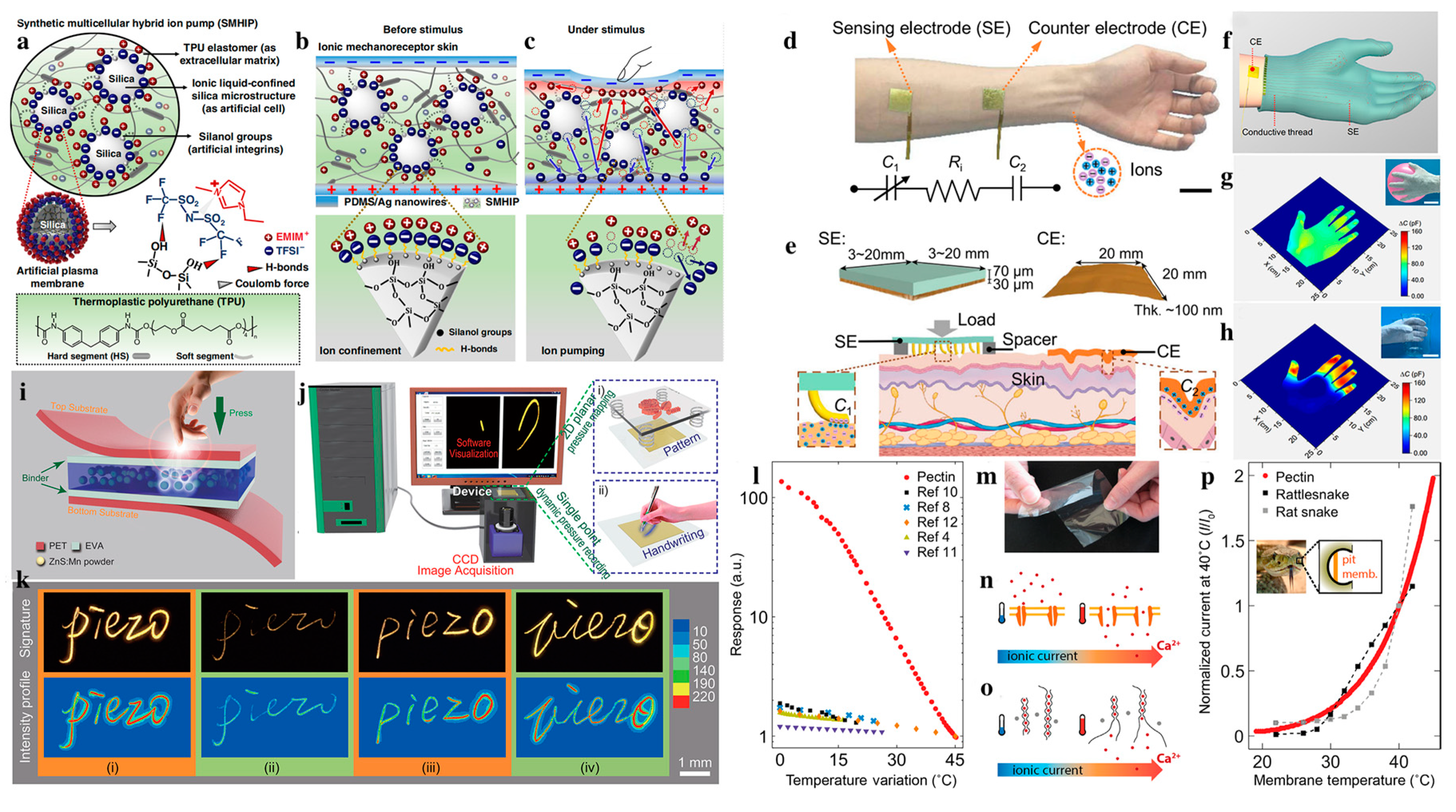

2.3. Touch sensors based on other bionic materials

3. Bioinspired structures for construction of flexible touch sensors

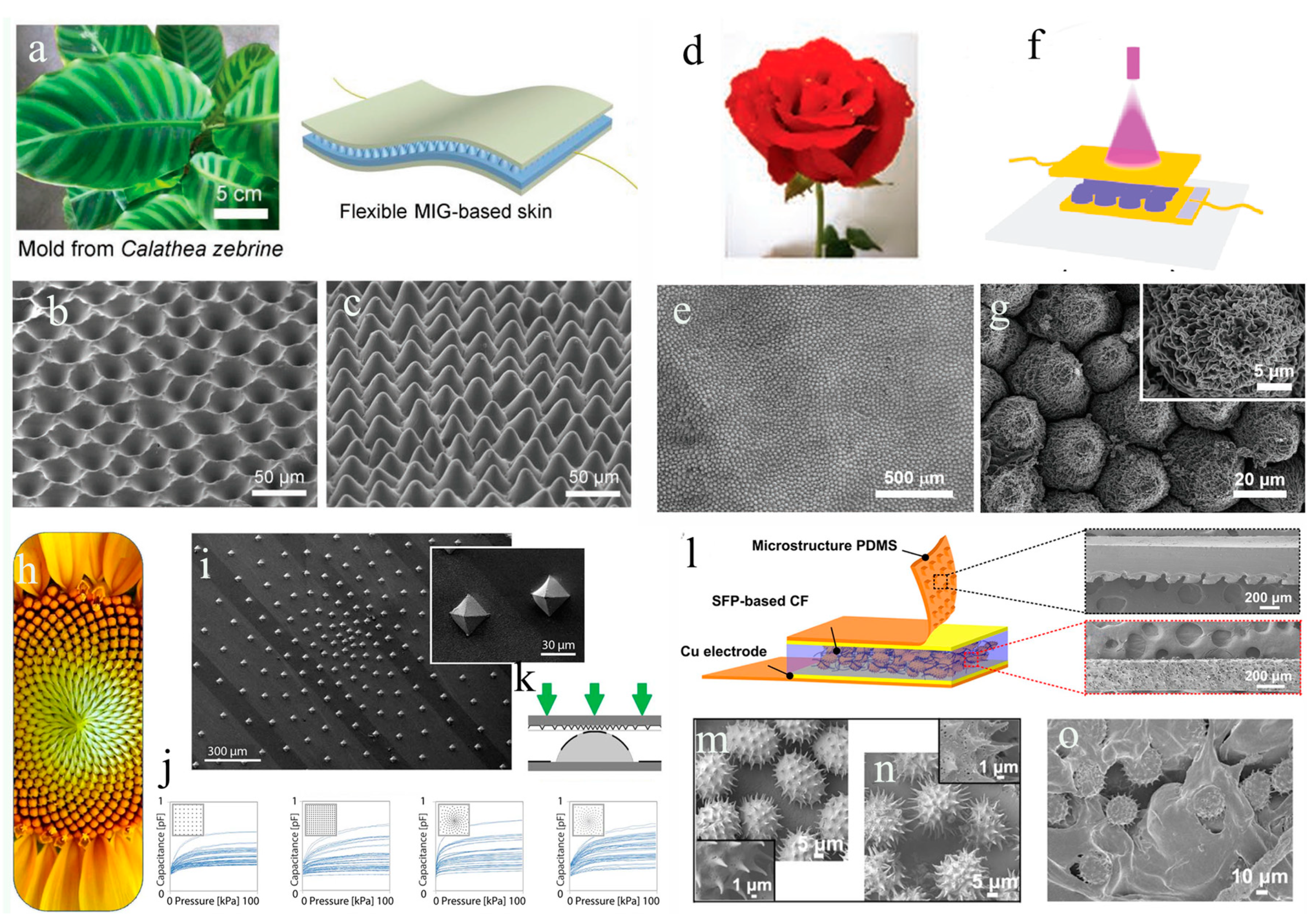

3.1. Biomimetic plant structures

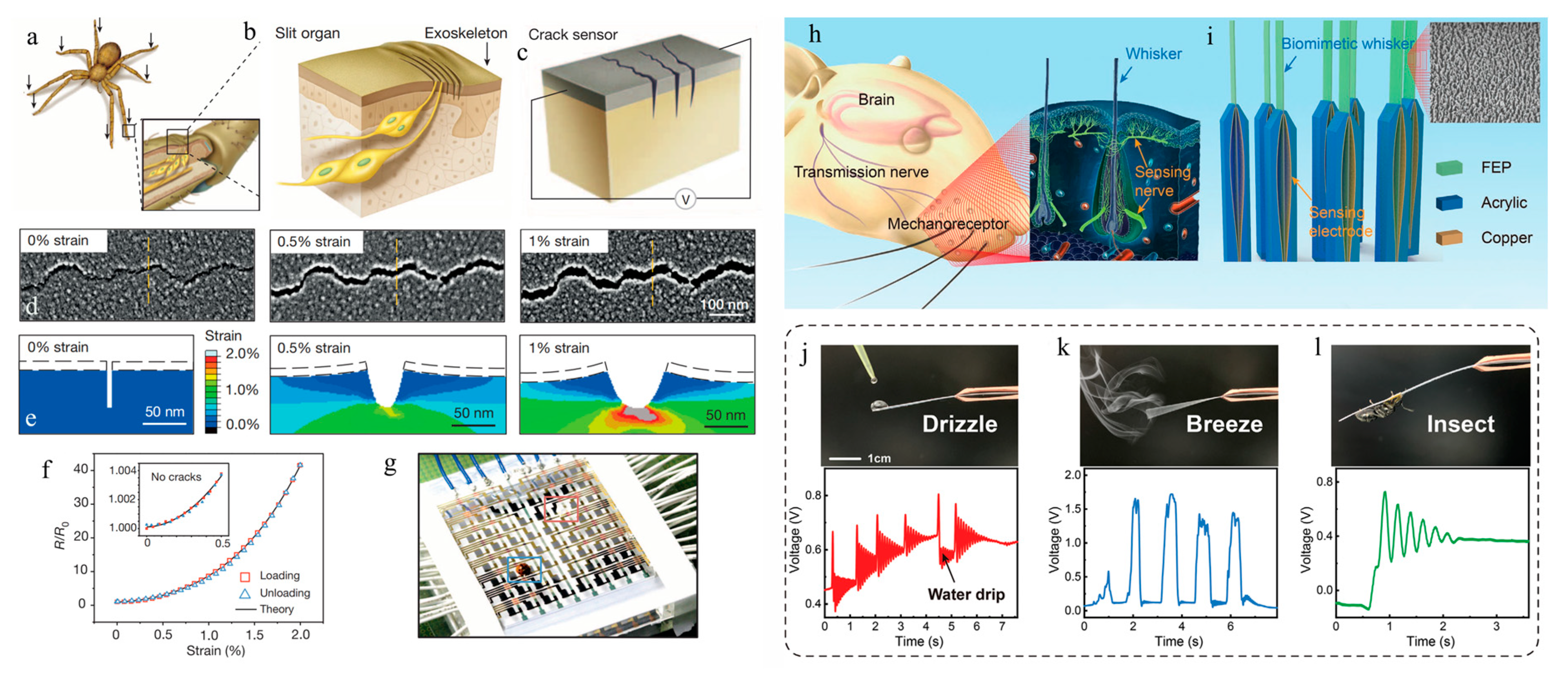

3.2. Biomimetic animal structures

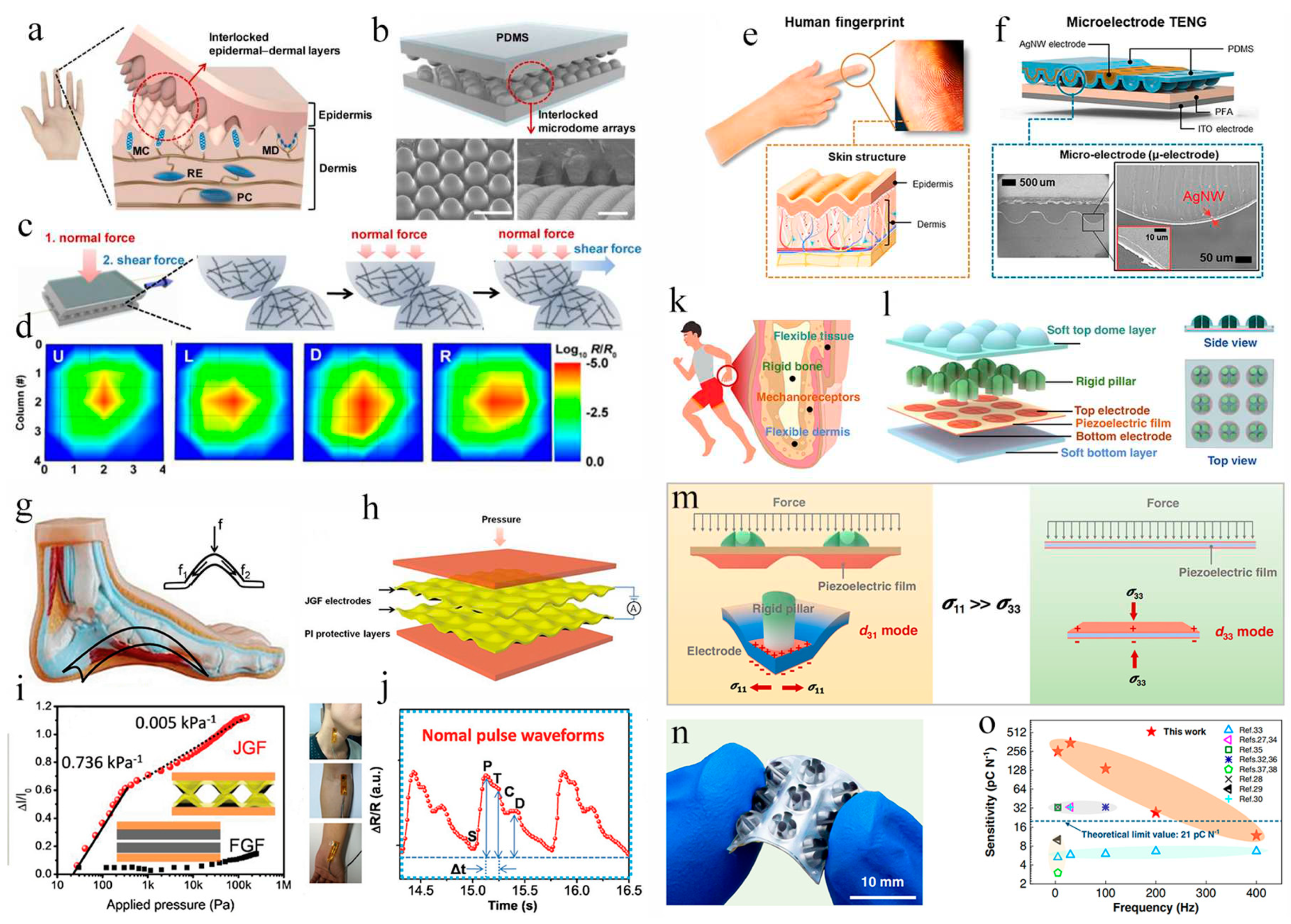

3.3. Bionic human structures

4. Conclusion and outlook

References

- Chen, S.; Jiang, K.; Lou, Z.; Chen, D.; Shen, G. Recent Developments in Graphene-Based Tactile Sensors and E-Skins. Advanced Materials Technologies 2018, 3, 1700248. [CrossRef]

- Lu, N.; Kim, D.-H. Flexible and Stretchable Electronics Paving the Way for Soft Robotics. Soft Robotics 2014, 1, 53-62. [CrossRef]

- Cha, Y.; Seo, J.; Kim, J.-S.; Park, J.-M. Human–computer interface glove using flexible piezoelectric sensors. Smart Materials and Structures 2017, 26, 057002. [CrossRef]

- Peng, X.; Dong, K.; Ye, C.; Jiang, Y.; Zhai, S.; Cheng, R.; Liu, D.; Gao, X.; Wang, J.; Wang, Z.L. A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators. Sci Adv 2020, 6, eaba9624. [CrossRef]

- Xiong, Y.; Shen, Y.; Tian, L.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C.-P. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring. Nano Energy 2020, 70, 104436. [CrossRef]

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv Mater 2016, 28, 4373-4395. [CrossRef]

- Tang, X.; Wu, C.; Gan, L.; Zhang, T.; Zhou, T.; Huang, J.; Wang, H.; Xie, C.; Zeng, D. Multilevel Microstructured Flexible Pressure Sensors with Ultrahigh Sensitivity and Ultrawide Pressure Range for Versatile Electronic Skins. Small 2019, 15, e1804559. [CrossRef]

- Xu, H.; Lv, Y.; Qiu, D.; Zhou, Y.; Zeng, H.; Chu, Y. An ultra-stretchable, highly sensitive and biocompatible capacitive strain sensor from an ionic nanocomposite for on-skin monitoring. Nanoscale 2019, 11, 1570-1578. [CrossRef]

- Majumder, S.; Mondal, T.; Deen, M.J. Wearable Sensors for Remote Health Monitoring. Sensors (Basel) 2017, 17. [CrossRef]

- Lee, Y.; Myoung, J.; Cho, S.; Park, J.; Kim, J.; Lee, H.; Lee, Y.; Lee, S.; Baig, C.; Ko, H. Bioinspired Gradient Conductivity and Stiffness for Ultrasensitive Electronic Skins. ACS Nano 2021, 15, 1795-1804. [CrossRef]

- He, Z.; Chen, W.; Liang, B.; Liu, C.; Yang, L.; Lu, D.; Mo, Z.; Zhu, H.; Tang, Z.; Gui, X. Capacitive Pressure Sensor with High Sensitivity and Fast Response to Dynamic Interaction Based on Graphene and Porous Nylon Networks. ACS Appl Mater Interfaces 2018, 10, 12816-12823. [CrossRef]

- Sharma, S.; Chhetry, A.; Zhang, S.; Yoon, H.; Park, C.; Kim, H.; Sharifuzzaman, M.; Hui, X.; Park, J.Y. Hydrogen-Bond-Triggered Hybrid Nanofibrous Membrane-Based Wearable Pressure Sensor with Ultrahigh Sensitivity over a Broad Pressure Range. ACS Nano 2021, 15, 4380-4393. [CrossRef]

- Chen, M.; Li, K.; Cheng, G.; He, K.; Li, W.; Zhang, D.; Li, W.; Feng, Y.; Wei, L.; Li, W.; et al. Touchpoint-Tailored Ultrasensitive Piezoresistive Pressure Sensors with a Broad Dynamic Response Range and Low Detection Limit. ACS Appl Mater Interfaces 2019, 11, 2551-2558. [CrossRef]

- Jiang, W.; Li, H.; Liu, Z.; Li, Z.; Tian, J.; Shi, B.; Zou, Y.; Ouyang, H.; Zhao, C.; Zhao, L.; et al. Fully Bioabsorbable Natural-Materials-Based Triboelectric Nanogenerators. Adv Mater 2018, 30, e1801895. [CrossRef]

- Elsayes, A.; Sharma, V.; Yiannacou, K.; Koivikko, A.; Rasheed, A.; Sariola, V. Plant-Based Biodegradable Capacitive Tactile Pressure Sensor Using Flexible and Transparent Leaf Skeletons as Electrodes and Flower Petal as Dielectric Layer. Advanced Sustainable Systems 2020, 4. [CrossRef]

- Chakraborty, P.; Guterman, T.; Adadi, N.; Yadid, M.; Brosh, T.; Adler-Abramovich, L.; Dvir, T.; Gazit, E. A Self-Healing, All-Organic, Conducting, Composite Peptide Hydrogel as Pressure Sensor and Electrogenic Cell Soft Substrate. ACS Nano 2019, 13, 163-175. [CrossRef]

- Ahmed, A.; Zhang, S.L.; Hassan, I.; Saadatnia, Z.; Zi, Y.; Zu, J.; Wang, Z.L. A washable, stretchable, and self-powered human-machine interfacing Triboelectric nanogenerator for wireless communications and soft robotics pressure sensor arrays. Extreme Mechanics Letters 2017, 13, 25-35. [CrossRef]

- Zhou, K.; Dai, K.; Liu, C.; Shen, C. Flexible conductive polymer composites for smart wearable strain sensors. SmartMat 2020, 1, e1010. [CrossRef]

- Liu, C.; Huang, N.; Xu, F.; Tong, J.; Chen, Z.; Gui, X.; Fu, Y.; Lao, C. 3D Printing Technologies for Flexible Tactile Sensors toward Wearable Electronics and Electronic Skin. Polymers (Basel) 2018, 10, 629. [CrossRef]

- Wang, Z.; Zhou, Z.; Wang, S.; Yao, X.; Han, X.; Cao, W.; Pu, J. An anti-freezing and strong wood-derived hydrogel for high-performance electronic skin and wearable sensing. Composites Part B: Engineering 2022, 239, 109954. [CrossRef]

- Wang, J.; Qian, S.; Yu, J.; Zhang, Q.; Yuan, Z.; Sang, S.; Zhou, X.; Sun, L. Flexible and Wearable PDMS-Based Triboelectric Nanogenerator for Self-Powered Tactile Sensing. Nanomaterials (Basel) 2019, 9, 1304. [CrossRef]

- Mahata, C.; Algadi, H.; Lee, J.; Kim, S.; Lee, T. Biomimetic-inspired micro-nano hierarchical structures for capacitive pressure sensor applications. Measurement 2020, 151, 107095. [CrossRef]

- Kim, D.; Park, J.; Kim, Y.T. Core–Shell and Helical-Structured Cylindrical Triboelectric Nanogenerator for Wearable Energy Harvesting. ACS Applied Energy Materials 2019, 2, 1357-1362. [CrossRef]

- Cui, M.; Hou, T.; Tong, J.; Xin, Y.; Zhou, X.; Liang, W. Flexible Piezoelectric Tactile Sensor With Cilia-Inspired Structures Based on Electrospun PVDF/Fe3O4 Nanofibers. IEEE Sensors Journal 2022, 22, 24430-24438. [CrossRef]

- Wang, S.; Xiao, P.; Liang, Y.; Zhang, J.; Huang, Y.; Wu, S.; Kuo, S.-W.; Chen, T. Network cracks-based wearable strain sensors for subtle and large strain detection of human motions. Journal of Materials Chemistry C 2018, 6, 5140-5147. [CrossRef]

- Deng, J.; Kuang, X.; Liu, R.; Ding, W.; Wang, A.C.; Lai, Y.C.; Dong, K.; Wen, Z.; Wang, Y.; Wang, L.; et al. Vitrimer Elastomer-Based Jigsaw Puzzle-Like Healable Triboelectric Nanogenerator for Self-Powered Wearable Electronics. Adv Mater 2018, 30, e1705918. [CrossRef]

- Wang, C.; Yu, Y.; Yuan, Y.; Ren, C.; Liao, Q.; Wang, J.; Chai, Z.; Li, Q.; Li, Z. Heartbeat-Sensing Mechanoluminescent Device Based on a Quantitative Relationship between Pressure and Emissive Intensity. Matter 2020, 2, 181-193. [CrossRef]

- Chen, S.; Wu, N.; Lin, S.; Duan, J.; Xu, Z.; Pan, Y.; Zhang, H.; Xu, Z.; Huang, L.; Hu, B.; et al. Hierarchical elastomer tuned self-powered pressure sensor for wearable multifunctional cardiovascular electronics. Nano Energy 2020, 70, 104460. [CrossRef]

- Wang, Y.; Wu, H.; Xu, L.; Zhang, H.; Yang, Y.; Wang, Z.L. Hierarchically patterned self-powered sensors for multifunctional tactile sensing. Sci Adv 2020, 6, eabb9083. [CrossRef]

- Qin, Y.; Zhang, X.; Zheng, A.; Xia, Q. Bioinspired Design of Hill-Ridge Architecture-Based Iontronic Sensor with High Sensibility and Piecewise Linearity. Advanced Materials Technologies 2021, 7. [CrossRef]

- Xia, S.; Zhang, Q.; Song, S.; Duan, L.; Gao, G. Bioinspired Dynamic Cross-Linking Hydrogel Sensors with Skin-like Strain and Pressure Sensing Behaviors. Chemistry of Materials 2019, 31, 9522-9531. [CrossRef]

- Song, S.; Zhang, C.; Li, W.; Wang, J.; Rao, P.; Wang, J.; Li, T.; Zhang, Y. Bioinspired engineering of gradient and hierarchical architecture into pressure sensors toward high sensitivity within ultra-broad working range. Nano Energy 2022, 100. [CrossRef]

- Amoli, V.; Kim, J.S.; Jee, E.; Chung, Y.S.; Kim, S.Y.; Koo, J.; Choi, H.; Kim, Y.; Kim, D.H. A bioinspired hydrogen bond-triggered ultrasensitive ionic mechanoreceptor skin. Nat Commun 2019, 10, 4019. [CrossRef]

- Song, Z.; Li, W.; Bao, Y.; Wang, W.; Liu, Z.; Han, F.; Han, D.; Niu, L. Bioinspired Microstructured Pressure Sensor Based on a Janus Graphene Film for Monitoring Vital Signs and Cardiovascular Assessment. Advanced Electronic Materials 2018, 4. [CrossRef]

- Gao, G.; Yang, F.; Zhou, F.; He, J.; Lu, W.; Xiao, P.; Yan, H.; Pan, C.; Chen, T.; Wang, Z.L. Bioinspired Self-Healing Human-Machine Interactive Touch Pad with Pressure-Sensitive Adhesiveness on Targeted Substrates. Adv Mater 2020, 32, e2004290. [CrossRef]

- Di Giacomo, R.; Bonanomi, L.; Costanza, V.; Maresca, B.; Daraio, C. Biomimetic temperature-sensing layer for artificial skins. Sci Robot 2017, 2, eaai9251. [CrossRef]

- Wei, P.; Chen, T.; Chen, G.; Liu, H.; Mugaanire, I.T.; Hou, K.; Zhu, M. Conductive Self-Healing Nanocomposite Hydrogel Skin Sensors with Antifreezing and Thermoresponsive Properties. ACS Appl Mater Interfaces 2020, 12, 3068-3079. [CrossRef]

- Wang, X.; Zhang, H.; Yu, R.; Dong, L.; Peng, D.; Zhang, A.; Zhang, Y.; Liu, H.; Pan, C.; Wang, Z.L. Dynamic pressure mapping of personalized handwriting by a flexible sensor matrix based on the mechanoluminescence process. Adv Mater 2015, 27, 2324-2331. [CrossRef]

- Lee, S.; Park, J.-W. Fingerprint-inspired triboelectric nanogenerator with a geometrically asymmetric electrode design for a self-powered dynamic pressure sensor. Nano Energy 2022, 101. [CrossRef]

- Li, T.; Luo, H.; Qin, L.; Wang, X.; Xiong, Z.; Ding, H.; Gu, Y.; Liu, Z.; Zhang, T. Flexible Capacitive Tactile Sensor Based on Micropatterned Dielectric Layer. Small 2016, 12, 5042-5048. [CrossRef]

- Boutry, C.M.; Negre, M.; Jorda, M.; Vardoulis, O.; Chortos, A.; Khatib, O.; Bao, Z. A hierarchically patterned, bioinspired e-skin able to detect the direction of applied pressure for robotics. Sci Robot 2018, 3. [CrossRef]

- Yang, M.; Cheng, Y.; Yue, Y.; Chen, Y.; Gao, H.; Li, L.; Cai, B.; Liu, W.; Wang, Z.; Guo, H.; et al. High-Performance Flexible Pressure Sensor with a Self-Healing Function for Tactile Feedback. Adv Sci (Weinh) 2022, 9, e2200507. [CrossRef]

- Qiu, Z.; Wan, Y.; Zhou, W.; Yang, J.; Yang, J.; Huang, J.; Zhang, J.; Liu, Q.; Huang, S.; Bai, N.; et al. Ionic Skin with Biomimetic Dielectric Layer Templated from Calathea Zebrine Leaf. Advanced Functional Materials 2018, 28. [CrossRef]

- Pang, Q.; Wu, K.; Jiang, Z.; Yang, F.; Shi, Z.; Gao, H.; Zhang, C.; Hou, R.; Zhu, Y. Nanostructured ionic hydrogel with integrated conductivity, stretchability and thermal responsiveness for a high-performance strain and temperature sensor. Biomater Sci 2023, 11, 3603-3615. [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Lee, Y.; Ha, M.; Jung, Y.; Lim, H.; Kim, S.Y.; Ko, H. Tactile-direction-sensitive and stretchable electronic skins based on human-skin-inspired interlocked microstructures. ACS Nano 2014, 8, 12020-12029. [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.Y.; Kim, T.I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222-226. [CrossRef]

- Sun, F.; Liu, L.; Liu, T.; Wang, X.; Qi, Q.; Hang, Z.; Chen, K.; Xu, J.; Fu, J. Vascular smooth muscle-inspired architecture enables soft yet tough self-healing materials for durable capacitive strain-sensor. Nat Commun 2023, 14, 130. [CrossRef]

- Zhang, Y.; Ye, S.; Cao, L.; Lv, Z.; Ren, J.; Shao, Z.; Yao, Y.; Ling, S. Natural Silk Spinning-Inspired Meso-Assembly-Processing Engineering Strategy for Fabricating Soft Tissue-Mimicking Biomaterials. Advanced Functional Materials 2022, 32, 2200267. [CrossRef]

- Xu, S.; Liu, T.; Mu, Y.; Wang, Y.F.; Chi, Z.; Lo, C.C.; Liu, S.; Zhang, Y.; Lien, A.; Xu, J. An organic molecule with asymmetric structure exhibiting aggregation-induced emission, delayed fluorescence, and mechanoluminescence. Angew Chem Int Ed Engl 2015, 54, 874-878. [CrossRef]

- Brochu, A.B.; Craig, S.L.; Reichert, W.M. Self-healing biomaterials. J Biomed Mater Res A 2011, 96, 492-506. [CrossRef]

- Pu, X.; Liu, M.; Chen, X.; Sun, J.; Du, C.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Ultrastretchable, transparent triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and tactile sensing. Sci Adv 2017, 3, e1700015. [CrossRef]

- Lei, Z.; Wang, Q.; Sun, S.; Zhu, W.; Wu, P. A Bioinspired Mineral Hydrogel as a Self-Healable, Mechanically Adaptable Ionic Skin for Highly Sensitive Pressure Sensing. Adv Mater 2017, 29. [CrossRef]

- Kim, C.C.; Lee, H.H.; Oh, K.H.; Sun, J.Y. Highly stretchable, transparent ionic touch panel. Science 2016, 353, 682-687. [CrossRef]

- Lei, Z.; Wang, Q.; Wu, P. A multifunctional skin-like sensor based on a 3D printed thermo-responsive hydrogel. Materials Horizons 2017, 4, 694-700. [CrossRef]

- Xue, Z.; Song, H.; Rogers, J.A.; Zhang, Y.; Huang, Y. Mechanically-Guided Structural Designs in Stretchable Inorganic Electronics. Adv Mater 2020, 32, e1902254. [CrossRef]

- Zhao, F.; Shi, Y.; Pan, L.; Yu, G. Multifunctional Nanostructured Conductive Polymer Gels: Synthesis, Properties, and Applications. Acc Chem Res 2017, 50, 1734-1743. [CrossRef]

- Wang, Z.; Cong, Y.; Fu, J. Stretchable and tough conductive hydrogels for flexible pressure and strain sensors. J Mater Chem B 2020, 8, 3437-3459. [CrossRef]

- Caccavo, D.; Cascone, S.; Lamberti, G.; Barba, A.A. Hydrogels: experimental characterization and mathematical modelling of their mechanical and diffusive behaviour. Chem Soc Rev 2018, 47, 2357-2373. [CrossRef]

- Zhang, C.; Wu, B.; Zhou, Y.; Zhou, F.; Liu, W.; Wang, Z. Mussel-inspired hydrogels: from design principles to promising applications. Chem Soc Rev 2020, 49, 3605-3637. [CrossRef]

- Wang, Z.; Li, H.; Tang, Z.; Liu, Z.; Ruan, Z.; Ma, L.; Yang, Q.; Wang, D.; Zhi, C. Hydrogel Electrolytes for Flexible Aqueous Energy Storage Devices. Advanced Functional Materials 2018, 28, 1804560. [CrossRef]

- Sarwar, M.S.; Dobashi, Y.; Preston, C.; Wyss, J.K.; Mirabbasi, S.; Madden, J.D. Bend, stretch, and touch: Locating a finger on an actively deformed transparent sensor array. Sci Adv 2017, 3, e1602200. [CrossRef]

- Sun, J.Y.; Keplinger, C.; Whitesides, G.M.; Suo, Z. Ionic skin. Adv Mater 2014, 26, 7608-7614. [CrossRef]

- Cao, Y.; Tan, Y.J.; Li, S.; Lee, W.W.; Guo, H.; Cai, Y.; Wang, C.; Tee, B.C.K. Self-healing electronic skins for aquatic environments. Nature Electronics 2019, 2, 75-82. [CrossRef]

- Jin, H.; Huynh, T.P.; Haick, H. Self-Healable Sensors Based Nanoparticles for Detecting Physiological Markers via Skin and Breath: Toward Disease Prevention via Wearable Devices. Nano Lett 2016, 16, 4194-4202. [CrossRef]

- Tee, B.C.; Wang, C.; Allen, R.; Bao, Z. An electrically and mechanically self-healing composite with pressure- and flexion-sensitive properties for electronic skin applications. Nat Nanotechnol 2012, 7, 825-832. [CrossRef]

- Oh, J.Y.; Son, D.; Katsumata, T.; Lee, Y.; Kim, Y.; Lopez, J.; Wu, H.C.; Kang, J.; Park, J.; Gu, X.; et al. Stretchable self-healable semiconducting polymer film for active-matrix strain-sensing array. Sci Adv 2019, 5, eaav3097. [CrossRef]

- Guo, H.; Tan, Y.J.; Chen, G.; Wang, Z.; Susanto, G.J.; See, H.H.; Yang, Z.; Lim, Z.W.; Yang, L.; Tee, B.C.K. Artificially innervated self-healing foams as synthetic piezo-impedance sensor skins. Nat Commun 2020, 11, 5747. [CrossRef]

- Qi, M.; Yang, R.; Wang, Z.; Liu, Y.; Zhang, Q.; He, B.; Li, K.; Yang, Q.; Wei, L.; Pan, C.; et al. Bioinspired Self-healing Soft Electronics. Advanced Functional Materials 2023, 33, 2214479. [CrossRef]

- Khatib, M.; Zohar, O.; Saliba, W.; Haick, H. A Multifunctional Electronic Skin Empowered with Damage Mapping and Autonomic Acceleration of Self-Healing in Designated Locations. Adv Mater 2020, 32, e2000246. [CrossRef]

- Zhu, P.; Du, H.; Hou, X.; Lu, P.; Wang, L.; Huang, J.; Bai, N.; Wu, Z.; Fang, N.X.; Guo, C.F. Skin-electrode iontronic interface for mechanosensing. Nat Commun 2021, 12, 4731. [CrossRef]

- Jin, M.L.; Park, S.; Lee, Y.; Lee, J.H.; Chung, J.; Kim, J.S.; Kim, J.S.; Kim, S.Y.; Jee, E.; Kim, D.W.; et al. An Ultrasensitive, Visco-Poroelastic Artificial Mechanotransducer Skin Inspired by Piezo2 Protein in Mammalian Merkel Cells. Adv Mater 2017, 29, 1605973. [CrossRef]

- Wu, W.; Wang, Z.L. Piezotronics and piezo-phototronics for adaptive electronics and optoelectronics. Nature Reviews Materials 2016, 1, 16031. [CrossRef]

- Bhargava, R.N.; Gallagher, D.; Hong, X.; Nurmikko, A. Optical properties of manganese-doped nanocrystals of ZnS. Phys Rev Lett 1994, 72, 416-419. [CrossRef]

- Webb, R.C.; Bonifas, A.P.; Behnaz, A.; Zhang, Y.; Yu, K.J.; Cheng, H.; Shi, M.; Bian, Z.; Liu, Z.; Kim, Y.S.; et al. Ultrathin conformal devices for precise and continuous thermal characterization of human skin. Nat Mater 2013, 12, 938-944. [CrossRef]

- Ha, M.; Lim, S.; Cho, S.; Lee, Y.; Na, S.; Baig, C.; Ko, H. Skin-Inspired Hierarchical Polymer Architectures with Gradient Stiffness for Spacer-Free, Ultrathin, and Highly Sensitive Triboelectric Sensors. ACS Nano 2018, 12, 3964-3974. [CrossRef]

- Li, X.; Fan, Y.J.; Li, H.Y.; Cao, J.W.; Xiao, Y.C.; Wang, Y.; Liang, F.; Wang, H.L.; Jiang, Y.; Wang, Z.L.; et al. Ultracomfortable Hierarchical Nanonetwork for Highly Sensitive Pressure Sensor. ACS Nano 2020, 14, 9605-9612. [CrossRef]

- Kang, S.; Lee, J.; Lee, S.; Kim, S.; Kim, J.-K.; Algadi, H.; Al-Sayari, S.; Kim, D.-E.; Kim, D.; Lee, T. Highly Sensitive Pressure Sensor Based on Bioinspired Porous Structure for Real-Time Tactile Sensing. Advanced Electronic Materials 2016, 2. [CrossRef]

- Guo, Y.; Guo, Z.; Zhong, M.; Wan, P.; Zhang, W.; Zhang, L. A Flexible Wearable Pressure Sensor with Bioinspired Microcrack and Interlocking for Full-Range Human-Machine Interfacing. Small 2018, 14, e1803018. [CrossRef]

- Wang, K.; Lou, Z.; Wang, L.; Zhao, L.; Zhao, S.; Wang, D.; Han, W.; Jiang, K.; Shen, G. Bioinspired Interlocked Structure-Induced High Deformability for Two-Dimensional Titanium Carbide (MXene)/Natural Microcapsule-Based Flexible Pressure Sensors. ACS Nano 2019, 13, 9139-9147. [CrossRef]

- Chou, H.H.; Nguyen, A.; Chortos, A.; To, J.W.; Lu, C.; Mei, J.; Kurosawa, T.; Bae, W.G.; Tok, J.B.; Bao, Z. A chameleon-inspired stretchable electronic skin with interactive colour changing controlled by tactile sensing. Nat Commun 2015, 6, 8011. [CrossRef]

- Yu, S.; Li, L.; Wang, J.; Liu, E.; Zhao, J.; Xu, F.; Cao, Y.; Lu, C. Light-Boosting Highly Sensitive Pressure Sensors Based on Bioinspired Multiscale Surface Structures. Advanced Functional Materials 2020, 30. [CrossRef]

- Wang, L.; Jackman, J.A.; Tan, E.-L.; Park, J.H.; Potroz, M.G.; Hwang, E.T.; Cho, N.-J. High-performance, flexible electronic skin sensor incorporating natural microcapsule actuators. Nano Energy 2017, 36, 38-45. [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1-8. [CrossRef]

- Hunt, J.; Bhushan, B. Nanoscale biomimetics studies of Salvinia molesta for micropattern fabrication. J Colloid Interface Sci 2011, 363, 187-192. [CrossRef]

- Zhao, T.; Li, T.; Chen, L.; Yuan, L.; Li, X.; Zhang, J. Highly Sensitive Flexible Piezoresistive Pressure Sensor Developed Using Biomimetically Textured Porous Materials. ACS Appl Mater Interfaces 2019, 11, 29466-29473. [CrossRef]

- Shi, J.; Wang, L.; Dai, Z.; Zhao, L.; Du, M.; Li, H.; Fang, Y. Multiscale Hierarchical Design of a Flexible Piezoresistive Pressure Sensor with High Sensitivity and Wide Linearity Range. Small 2018, 14, e1800819. [CrossRef]

- Guo, R.; Yu, Y.; Zeng, J.; Liu, X.; Zhou, X.; Niu, L.; Gao, T.; Li, K.; Yang, Y.; Zhou, F.; et al. Biomimicking Topographic Elastomeric Petals (E-Petals) for Omnidirectional Stretchable and Printable Electronics. Adv Sci (Weinh) 2015, 2, 1400021. [CrossRef]

- Qin, D.; Xia, Y.; Whitesides, G.M. Soft lithography for micro- and nanoscale patterning. Nat Protoc 2010, 5, 491-502. [CrossRef]

- Choo, S.; Choi, H.-J.; Lee, H. Replication of rose-petal surface structure using UV-nanoimprint lithography. Mater Lett 2014, 121, 170-173. [CrossRef]

- Wei, Y.; Chen, S.; Lin, Y.; Yang, Z.; Liu, L. Cu–Ag core–shell nanowires for electronic skin with a petal molded microstructure. Journal of Materials Chemistry C 2015, 3, 9594-9602. [CrossRef]

- Yang, X.; Zhao, Y.; Xie, J.; Han, X.; Wang, J.; Zong, C.; Ji, H.; Zhao, J.; Jiang, S.; Cao, Y.; et al. Bioinspired Fabrication of Free-Standing Conducting Films with Hierarchical Surface Wrinkling Patterns. ACS Nano 2016, 10, 3801-3808. [CrossRef]

- Nisoli, C. Spiraling solitons: A continuum model for dynamical phyllotaxis of physical systems. Phys Rev E Stat Nonlin Soft Matter Phys 2009, 80, 026110. [CrossRef]

- Mannsfeld, S.C.; Tee, B.C.; Stoltenberg, R.M.; Chen, C.V.; Barman, S.; Muir, B.V.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat Mater 2010, 9, 859-864. [CrossRef]

- An, J.; Chen, P.; Wang, Z.; Berbille, A.; Pang, H.; Jiang, Y.; Jiang, T.; Wang, Z.L. Biomimetic Hairy Whiskers for Robotic Skin Tactility. Adv Mater 2021, 33, e2101891. [CrossRef]

- Pohlmann, K.; Grasso, F.W.; Breithaupt, T. Tracking wakes: the nocturnal predatory strategy of piscivorous catfish. Proc Natl Acad Sci U S A 2001, 98, 7371-7374. [CrossRef]

- Yang, Y.; Chen, J.; Engel, J.; Pandya, S.; Chen, N.; Tucker, C.; Coombs, S.; Jones, D.L.; Liu, C. Distant touch hydrodynamic imaging with an artificial lateral line. Proc Natl Acad Sci U S A 2006, 103, 18891-18895. [CrossRef]

- Severson, K.S.; Xu, D.; Yang, H.; O’Connor, D.H. Coding of whisker motion across the mouse face. Elife 2019, 8. [CrossRef]

- Bechert, D.W.; Bruse, M.; Hage, W.; Meyer, R. Fluid mechanics of biological surfaces and their technological application. Naturwissenschaften 2000, 87, 157-171. [CrossRef]

- Bhushan, B.; Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog Mater Sci 2011, 56, 1-108. [CrossRef]

- Gao, H.; Wang, X.; Yao, H.; Gorb, S.; Arzt, E. Mechanics of hierarchical adhesion structures of geckos. Mech Mater 2005, 37, 275-285. [CrossRef]

- Fratzl, P.; Barth, F.G. Biomaterial systems for mechanosensing and actuation. Nature 2009, 462, 442-448. [CrossRef]

- Hossl, B.; Bohm, H.J.; Rammerstorfer, F.G.; Mullan, R.; Barth, F.G. Studying the deformation of arachnid slit sensilla by a fracture mechanical approach. J Biomech 2006, 39, 1761-1768. [CrossRef]

- Laboy-Juarez, K.J.; Langberg, T.; Ahn, S.; Feldman, D.E. Elementary motion sequence detectors in whisker somatosensory cortex. Nat Neurosci 2019, 22, 1438-1449. [CrossRef]

- Zhang, J.; Yao, H.; Mo, J.; Chen, S.; Xie, Y.; Ma, S.; Chen, R.; Luo, T.; Ling, W.; Qin, L.; et al. Finger-inspired rigid-soft hybrid tactile sensor with superior sensitivity at high frequency. Nat Commun 2022, 13, 5076. [CrossRef]

- Chen, H.; Song, Y.; Guo, H.; Miao, L.; Chen, X.; Su, Z.; Zhang, H. Hybrid porous micro structured finger skin inspired self-powered electronic skin system for pressure sensing and sliding detection. Nano Energy 2018, 51, 496-503. [CrossRef]

- Zhu, H.; Jin, Z.; Bai, H.; Cao, J.; Dong, X.; Zhong, Y.; Dai, S.; Cheng, G.; Yuan, N.; Ding, J. Flexible, high-sensitive and multifunctional wearable sensor based on the dual bioinspired spinosum microstructure of carbon nanotube/carbon black-coated polydimethylsiloxane film. Measurement 2023, 207. [CrossRef]

- Cauna, N. Nature and functions of the papillary ridges of the digital skin. Anat Rec 1954, 119, 449-468. [CrossRef]

- Li, R.X.; Ip, A.; Sanz-Miralles, E.; Konofagou, E.E. Noninvasive Evaluation of Varying Pulse Pressures in vivo Using Brachial Sphymomanometry, Applanation Tonometry, and Pulse Wave Ultrasound Manometry. Artery Res 2017, 18, 22-28. [CrossRef]

- Yang, T.; Jiang, X.; Zhong, Y.; Zhao, X.; Lin, S.; Li, J.; Li, X.; Xu, J.; Li, Z.; Zhu, H. A Wearable and Highly Sensitive Graphene Strain Sensor for Precise Home-Based Pulse Wave Monitoring. ACS Sens 2017, 2, 967-974. [CrossRef]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat Mater 2016, 15, 937-950. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).