1. Introduction

During the last few years, the concept of manufacturing is changing so deeply as to be called "the fourth industrial revolution". The 21st century saw the start of this revolution in Hannover, Germany, which continues to outpace the digital revolution. However, let's take into account that every machine and system in the Fourth Industrial Revolution uses digital objects and is made up of numbers (0 and 1). We can refer to this time period as "The Age of Digital Objects". Implementing novel manufacturing techniques and the mechanisation of the sector by steam-powered equipment during the 18th and 19th centuries helped promote capital accumulation. Periodic changes from that era are known as an industry revolution. The First Industrial Revolution (which took place in the United Kingdom) represents a fundamental shift from the agricultural economy to manufacturing. The establishment of factories using electrical energy and mass production signalled the beginning of the second phase of this fundamental revolution. Information and communication technology (ICT) systems were adapted for industrial operations in the late 1960s, which aided in the automation of production (Fargnoli, 2020).

We are currently in the fourth stage of this revolution. This Revolution saw the acceleration of mechanical processes through the use of software and new technologies like artificial intelligence (AI), internet of things (IoT), and full-scale robotics of self-driving and unmanned vehicles; so, it brought a dramatic decrease in the human element's contribution while increasing the speed with which production was made by making very large calculations. The development of the internet, software, and hardware technologies paved the path for the creation of interoperable, communicable, and responsive objects.

Industry 4.0 is the digitisation and automation of manufacturing environments as well as the parallel development of a digital supply chain that supports products, their business context, order selection, delivery, retail, and even potential customers (Hsu, 2022), so the term "Industry 4.0" refers to the fourth industrial revolution, a new wave of technology-driven industrial production that promises to revolutionise the way manufacturing is done.

It is based on a new generation of mobile Internet technologies, faster and more adaptable characteristics of the Internet, and the creation of intelligent industrial robots through the development of equipment connected to this global network. Robots, smart readers (sensors), unmanned vehicles, and other devices that we can categorise as components of each component and interact with online (Di Nardo, 2020).

For a clear overview of the current state of industrial development, many advantages and disadvantages of Industry 4.0 can be listed. Advantages:

- (1)

In a smart factory, manufacturing is demand-driven and always incorporates efficient supply chain management and production planning to make the best use of already available resources or outsource services. The waste of valuable raw materials and the likelihood of producing dangerous by-products during mass production are both reduced by optimal resource management. As a result, the system is more productive, and the entire production process is more economical and sustainable.

- (2)

The smart manufacturing system's adaptable production lines and intelligent machinery make the entire setup fault-tolerant and resilient to any malicious event or probable failure. For the goal of strategy and decision-making in the future, data gathered from numerous sources that include the status of the ongoing processes, machine condition, and/or real-time updates on market demand and customer feedback is kept and evaluated. The CPS also keeps track, monitors, diagnoses, forecasts, and takes proactive actions or upgrades itself to control the entire industrial system based on these data saved in an enterprise's cloud. These technology developments give the production under Industry 4.0 a resilient and dynamic nature.

- (3)

Smart manufacturing operates with complete autonomy and self-regulation; little to no manual intervention is required. This eliminates human mistakes and their negative effects on production, planning, and design. The work of the engineers and management staff in calculation and decision-making is reduced with less reliance on humans. Additionally, it frees workers from tedious, dangerous, and tough routine activities while reducing the cost of labour for such professions. As a result, smart production with minimal human participation enhances workplace satisfaction and preserves good working relations between employees and employers.

- (4)

Smart products are developed optimally in a flexible production environment by assembling smart workpieces. They are then thoroughly evaluated in labs to ensure product safety throughout the product life cycle. These items interact with their surroundings, can communicate their statuses during their whole existence, and can be recognised by the RFID tags that have been applied to them. They can also store data, perform calculations, handle errors, and perform self-maintenance. These goods are of the highest quality, fully customisable, and can satisfy the needs of both businesses and the market.

- (5)

A smart manufacturing system has more influence over consumers than suppliers and manufacturers. Here, products are created purely in response to customer requests and comments. The manufacturers are committed to delivering a high-quality final product in a shorter amount of time and with acceptable value, ensuring the customer's happiness. Even customers can change the variety or number of their orders at the last minute. The smart factory offers easy access and consistently upholds high after-sales services, product maintenance, and customer support standards. Once customers discard them, the products can be recycled.

Disadvantages:

- (1)

Need for intelligent decision-making, enabling smart types of machinery capable of making a decision on their own.

- (2)

For a reliable, effective operation that is run continuously, 24x7 connectivity is required. 5G is a technology that intends to meet the demands of Industry 4.0 for high-speed M2M communication.

- (3)

Industrial Big Data Handling.

- (4)

Appropriate control methods enable interaction between cybernetic and physical parts.

- (5)

For security reasons, Industry 4.0 applications for smart factories can benefit from encryption and authorisation, software verification, high-confidence software and systems certification, and high-fidelity simulation. Additionally, the important operating instructions must be notified to and acknowledged by the relevant person before execution, and the sensitive information must be stored in the company's own cloud storage space. To prevent assaults like denial of service (DoS), deception attacks, anomaly-based infiltration, etc., that have a major negative impact on society and directly cause property damage, appropriate preventative measures should be performed.

- (6)

Furthermore, the managerial challenges are those related to the initial investment, as traditional factories' infrastructure is unsuitable for smart factories, and the unavailability of skilled workers is needed for smart production. (Sinha, 2020)

In conclusion, Industry 4.0 is set to revolutionise the way manufacturing is done. Making use of advanced technologies will enable manufacturers to improve efficiency, reduce costs, and improve the environment. With the help of Industry 4.0, manufacturers will be able to stay competitive in an ever-changing world.

However, Industry 4.0 is only the beginning. Industry 5.0 is expected to be the next revolution and is set to bring even more advanced technologies and automation to the factory floor. Industry 5.0 will build on the advances of Industry 4.0 and focus on developing advanced artificial intelligence and machine learning technologies. This will enable manufacturers to automate more complex processes, allowing them to further reduce costs and improve efficiency in appliances with resilience 4.0.

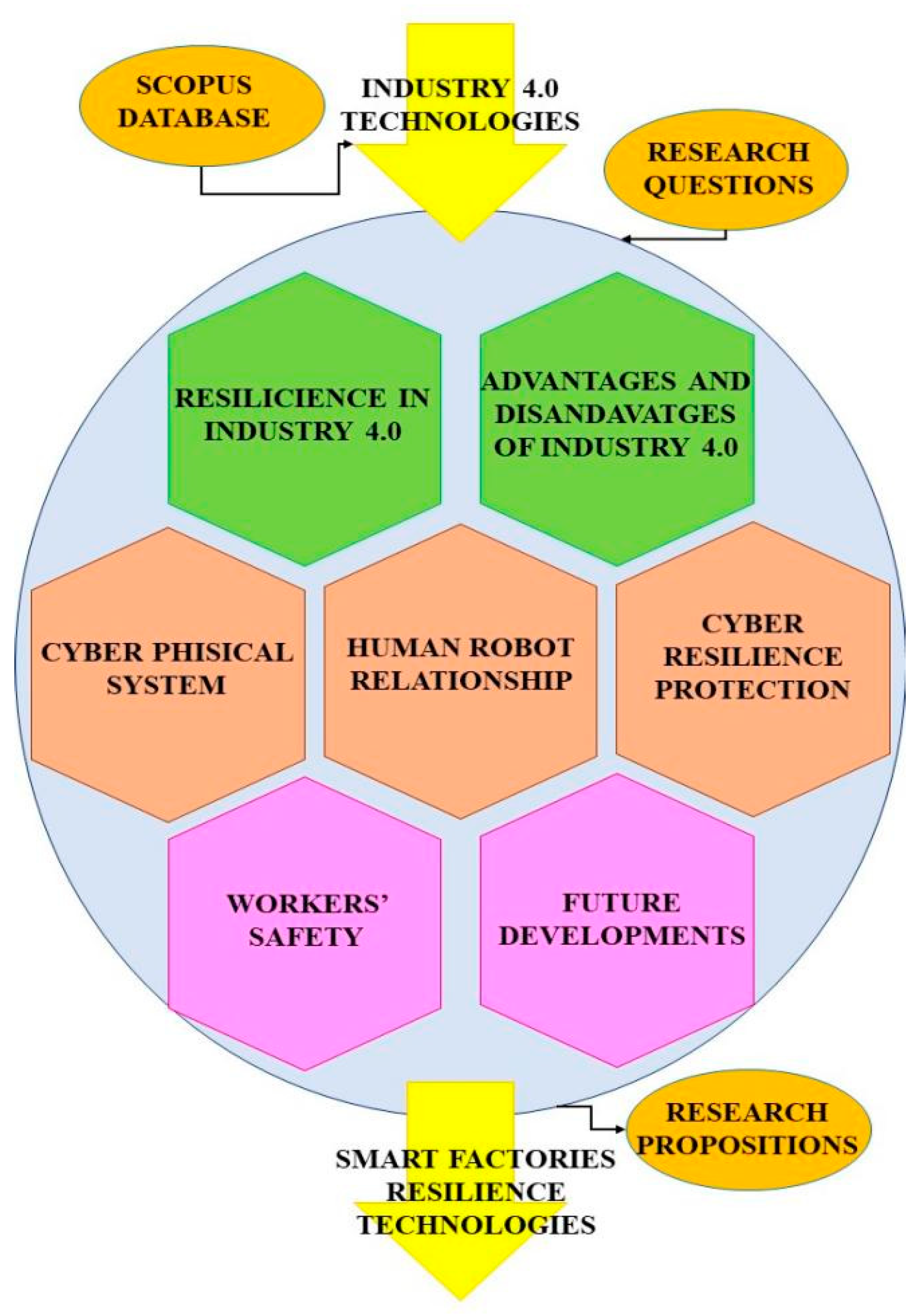

This research interest is, therefore, to serve as a referential to develop adaptive skills and overcome adverse situations, as, with "The Age of Digital Objects", comes the necessity to expand the limits and have the ability to react effectively, all while maintaining a strong level of stability. For this, a bibliographic study was first held, and several articles were analysed and then merged with the most relevant keywords selected to come up with below research questions that will serve as input to the literature review:

RQ1: What is the role of resilience in the digital industry?

RQ2: What are cyber systems’ responsibilities in the digital industry?

RQ3: In the human-robot interface of the Digital Industry, what function does safety play?

RQ4: What are the foundational elements of the digital industry, and how will it evolve in the future?

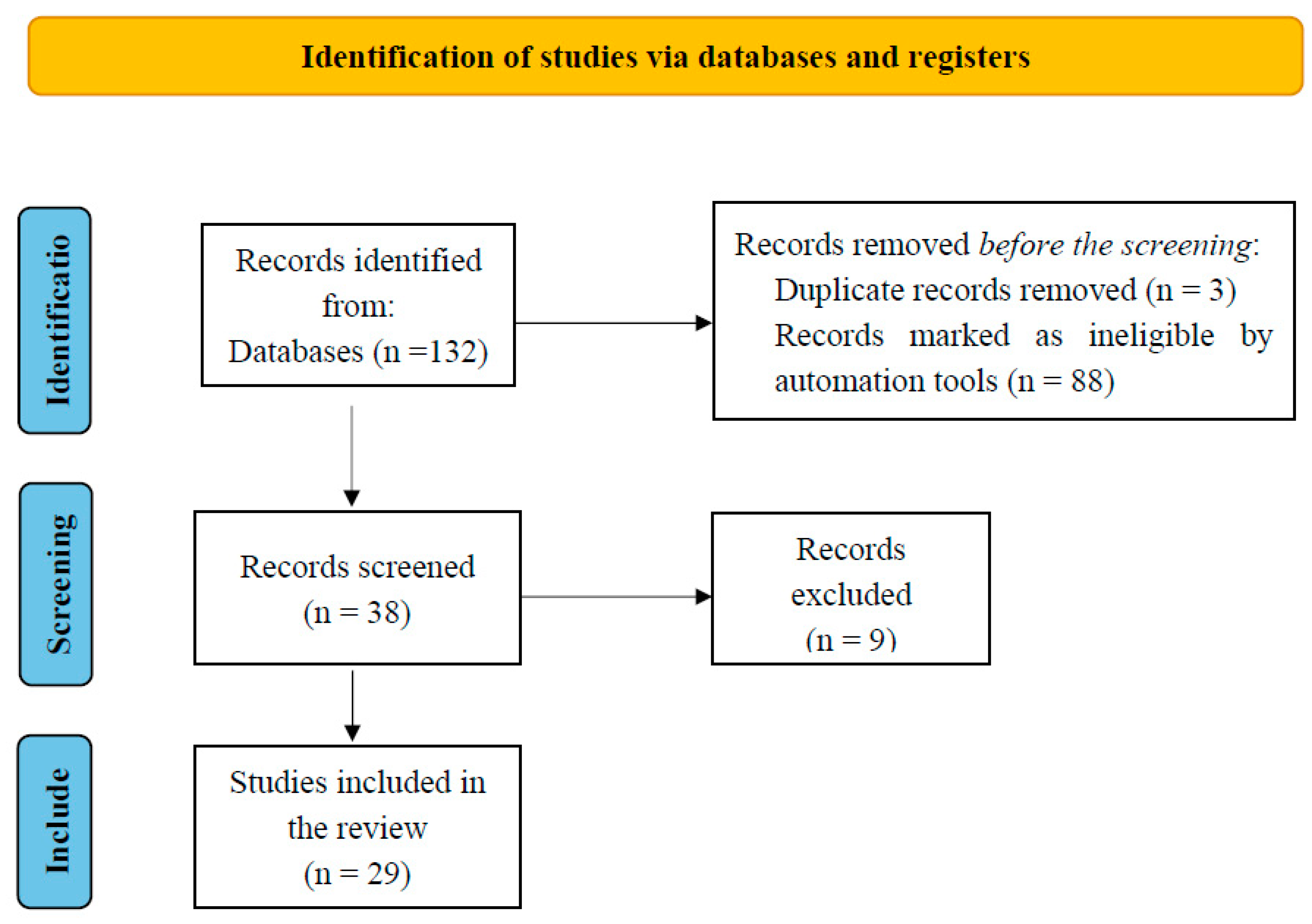

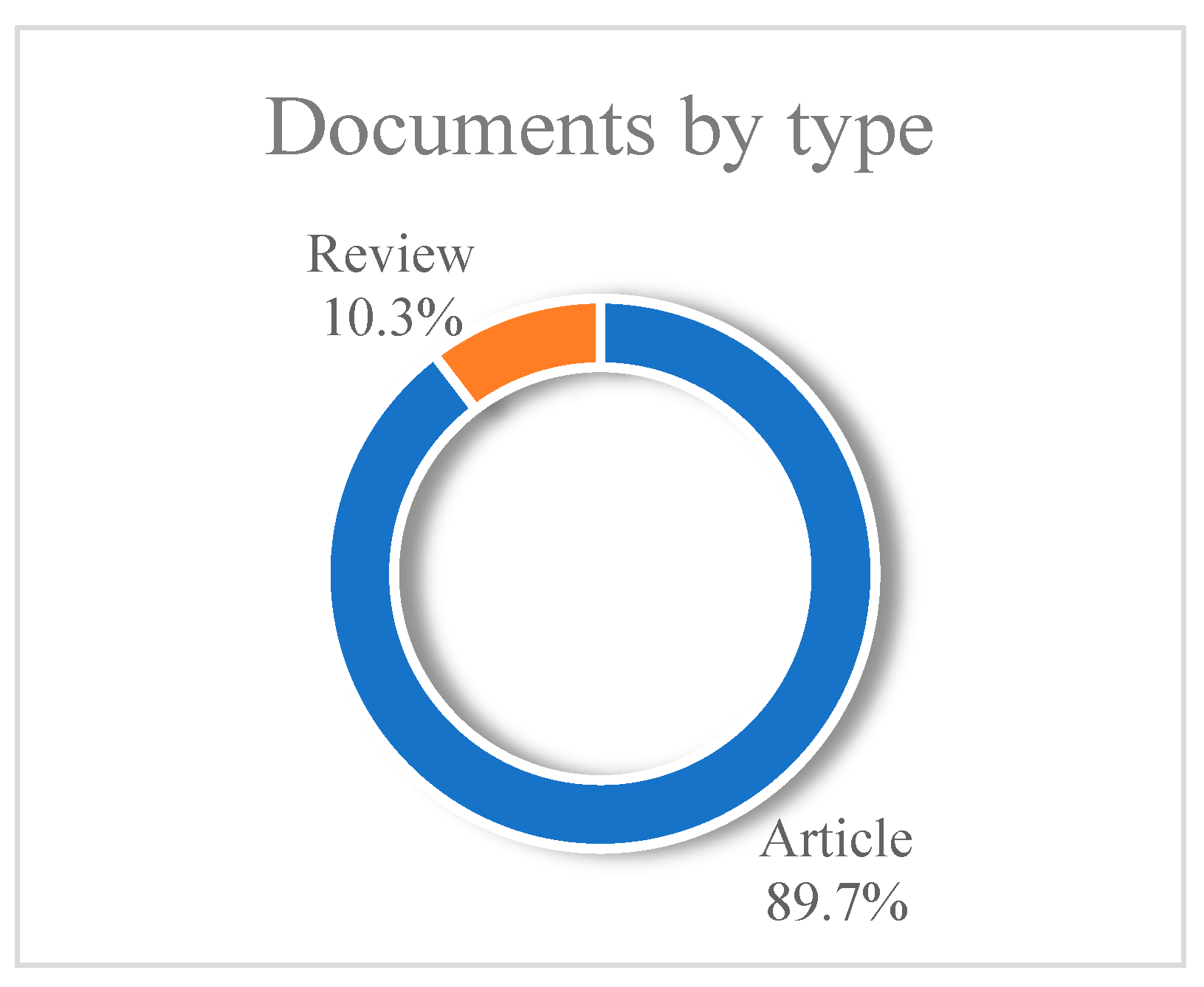

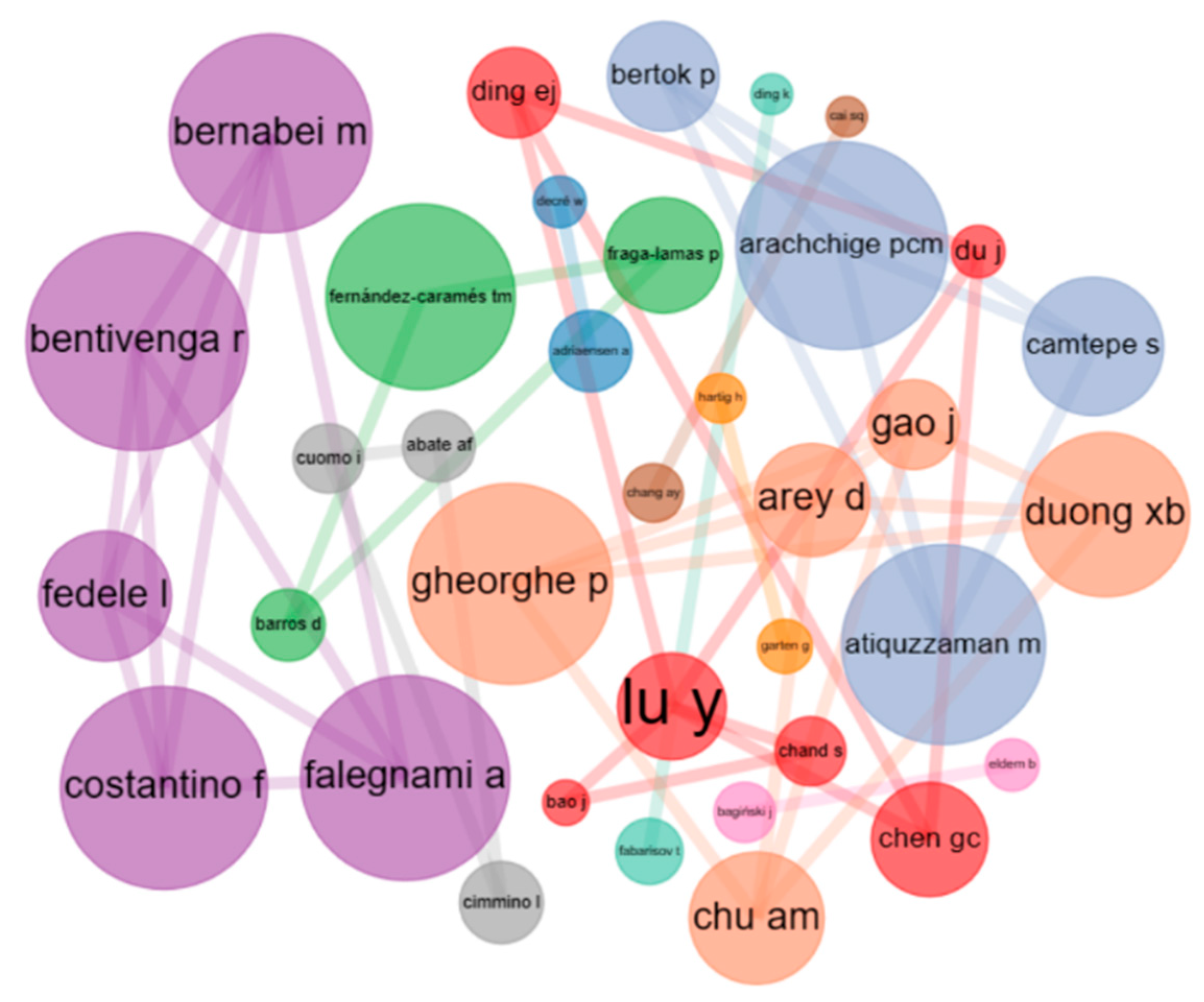

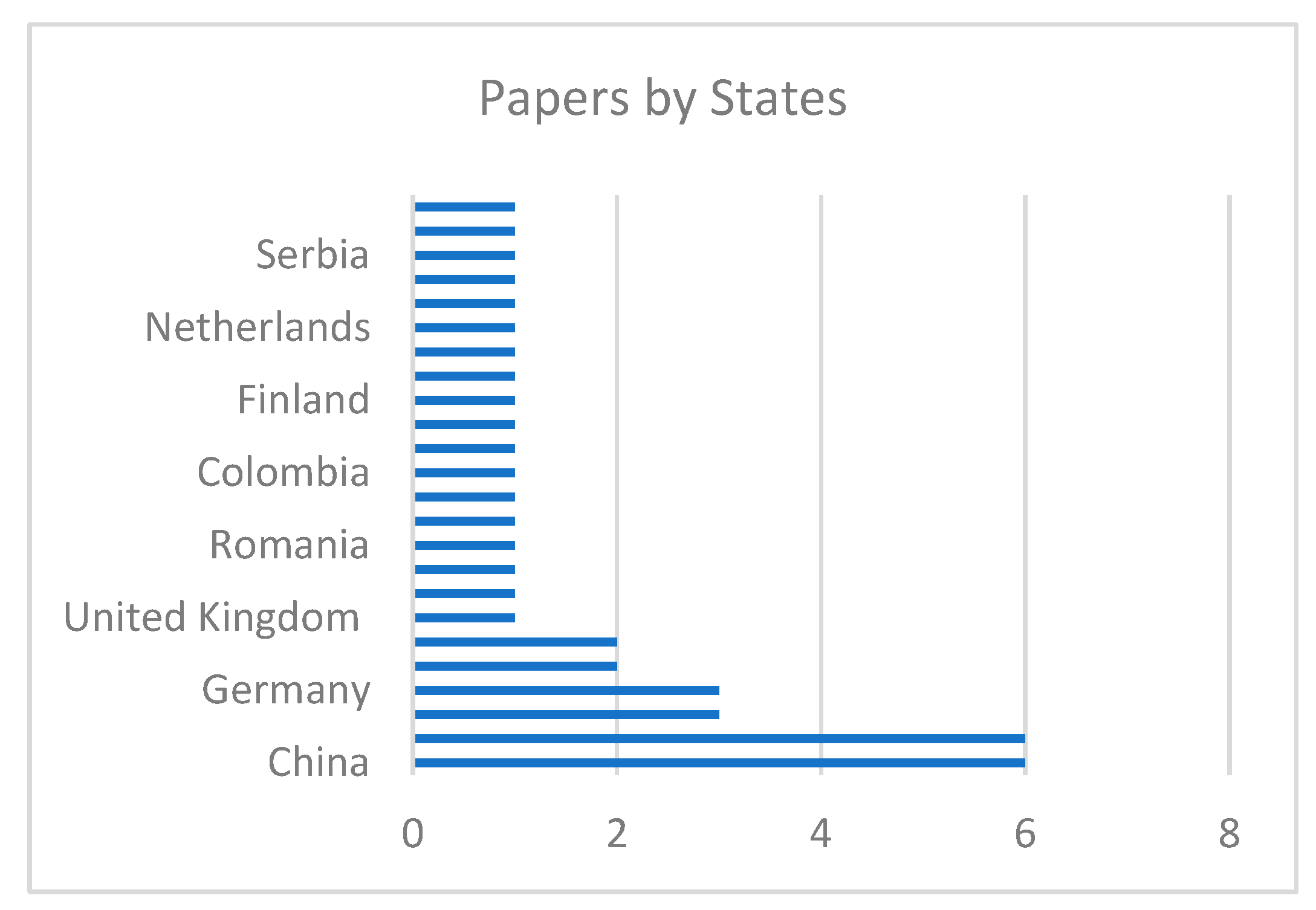

The authors performed a systematic literature review and followed a review protocol of published articles and reviews. This literature review on the selected keywords in the digital age will synthesise existing knowledge, identify gaps and provide useful information for researchers, practitioners and policy-makers.

4. Thematic Analysis

4.1. Resilience in Industry 4.0

The capacity of a business to resist external shocks or disturbances in the social, economic, or political environment and to adapt to new circumstances is known as entrepreneurial resilience. To achieve this, businesses must be able to remain stable in the face of outside forces, revert to their initial condition, or adopt a new equilibrium. As a result, they can tolerate outside pressures and long-term market survival. Resilience is the capacity to adapt swiftly to keep the ability to act and, if required, fundamentally rethink structures and processes. Robustness, on the other hand, is the ability of firms to face change without modifying their structure. Anyone who thinks a restoration to the pre-crisis system is necessary and that the current difficulties have mostly been resolved is fundamental. Anyone who thinks the current difficulties have been mostly resolved and that going back to the pre-crisis system is the way to go is utterly erroneous and unprepared for the next catastrophe. Resilience is a continuous strategic effort for company management to maintain long-term sustainability, not a one-time solution to a problem. Only resilient businesses are ready for the impending catastrophe. (Fabarisov, 2020)

The Fourth Industrial Revolution is being fuelled by several factors that will influence its course, including:

Mobile Devices: Using mobile devices, particularly smartphones and tablets, is one of life's essential activities. These gadgets will become a larger part of daily life in the future. Applications that allow users to control several devices and systems from a mobile device remotely will be created, simplifying life even further. From this point forward, it is possible to forecast that mobile phones and mobile computers will have identical concepts and that practically anything may be done on a mobile device without a traditional computer (Efe, 2020).

Networking and Internet Technologies: By moving faster and larger data from one location to another, IPv6 (6th Edition IP protocol) makes it very simple and quick to get over computer networks' bottlenecks. Moving enormous data, big video, and big music swiftly and easily, especially across networks and the internet, will now be considered normal. Nearly every piece of technology can be connected to the internet and use it for communication. We will live in a network society if it is legal.

Cloud computing systems: As the number of computing systems and devices used in daily life rises, storing the data generated by these systems and devices will become one of the largest difficulties. This issue will need to be resolved, and cloud computing technologies will need to be used for comprehensive, resilient, complete, and dependable data storage. The data in the cloud is of enormous value in terms of usability, especially given that it is always accessible and that it is never lost or corrupted.

Big data is the outcome of automated processes that have amassed a volume of data that is too large to be managed without the aid of automated software and machines. As time passes, it will become increasingly necessary to collect more data and ensure that it can be accessed securely from any location. In-depth work will be needed, particularly for the collecting, processing, and presentation of data in huge systems like e-government. Processing the acquired data will increase the significance of the precisely needed data mining in this approach. One of the most crucial components of data mining will be the identification and analysis of the data with the necessary attributes [

15]. In this field have been introduced a type particular of a system called a system of the system (SOS) since they refer to associations of operational and managerial independent software-intensive systems, which are occasionally dispersed across several contexts. Software-intensive, information, embedded, and ultra-large systems are examples of SoS—systems whose components are other systems. High-level missions that can’t be accomplished by any system alone are accomplished through collaboration between the constituent systems.

Additionally, they must be built to connect diverse systems, enabling interoperation, communication, coordination, cooperation, and, most often, transparent collaboration. Media Arch is a type of SOS's architecture (Garcès, 2019).

Artificial intelligence and Industrial Robots: As the usage of robots in various industries and industries grows quickly, robots can communicate with one another and directly contribute to production. Robots with artificial intelligence will interact and collaborate with one another at every level of the production process in this approach. Given the changing conditions and demands, it is clear that, in the future, robots will dominate every production sector due to diverse applications of artificial intelligence. advanced algorithms for making decisions.

Three-Dimensional Printers: Unlike conventional printers, three-dimensional printers enable the rapid production of any industrial product. Even today, many parts of purchased products come with three-dimensional drawings of the parts. These designs can be used to build spare parts and make needed changes to the parts. The usage of humans to realise their goals and be surprised will grow as a result of the development of three-dimensional printers. In industry, 3D printers are commonly employed. Ford used 3D printers to manufacture numerous parts when developing the 2017 Mustang in the United States. due to the fact that production can be done more cheaply. These printers are becoming more and more crucial for the manufacture of prototypes and replacement parts. In internal logistical procedures where robots are involved, RFID (Radio Frequency Identification) technologies are used.

Raw materials are transported from trucks to production by autonomous forklifts, and DoS (denial of service) assaults against these frequencies run the danger of upsetting the supply chain.

In industrial automation and control systems, the usage of sensors has advanced significantly. Sensors automatically create a maintenance work order for critical concerns, including the equipment's need for maintenance. Hackers can try to impede the operation of robots in a smart factory by interfering with the SIEM (Security Information and Event Management) and security systems, which can cause false alarms and reduce the danger of hackers.

The future goal is to get closer to the idea of "smart factories," which are factories that are equipped with advanced automation, robotics, big data and analytics, and the Internet of Things (IoT). Industry 4.0 is expected to change the way manufacturing is done, from the way that goods are designed and produced to how the factory itself is managed and operated (Le,2020). By connecting machines, production lines, warehouses, and other elements of the factory environment to the Internet, it will be possible to gain real-time insights into production processes and identify areas where efficiency can be improved. This will enable manufacturers to streamline processes, reduce costs, and increase productivity. In addition to improved efficiency, Industry 4.0 is expected to offer a number of other benefits. For example, the use of data and analytics will enable more accurate forecasting of demand and production. This will enable manufacturers to better meet customer needs and reduce inventory costs. Furthermore, by making use of the latest advances in robotics and automation, it will be possible to reduce the need for manual labour, resulting in a safer and more efficient working environment. Finally, Industry 4.0 is expected to have a positive impact on the environment. By reducing the need for manual labour, it will reduce the amount of energy and resources required for production. Furthermore, by making use of the latest technologies, manufacturers can reduce their reliance on harmful chemicals and other pollutants. These technologies make it possible for intricate supply chain systems to be linked, and as these linkages develop, they will help to optimise production or operations (Gupta, 2020).

4.2. Cyber-physical system

Industry 4.0 is increasingly developing cyber-physical systems that innovate industrial engineering and traditional control systems with the deployment of advanced technological paradigms such as IoT, machine learning and artificial big data with the goal of making factories more efficient and with greater manufacturing innovation with a higher degree of self-awareness and self-configuration. There is currently a push toward the adoption of the Fog Paradigm to improve all engineering applications that reach real-time execution with high reliability, such as minimising communication errors, and toward the cloud for all applications that require high raw computing powers (O'Donovan, 2019). The introduction of these changes involves a phase of adaptation of present systems as particular engineering applications require a combination of computational power and latency for which it is required to develop both the hardware and software of the cyber-physical system. The goal of industrial cyberphysics is to ensure efficiency and performance in line with Industry 4.0 requirements while managing control applications that require real-time decision-making processes. Although cloud interfaces have generally been utilised to facilitate the deployment of cyber-physical systems, there are real limits in terms of consistency, dependability, and external risk factors (such as broadband outages). Although the computing capability of the fog interface is also constrained, these limits might be lessened by inventive design and engineering. The cloud's inconsistent real-time performance, on the other hand, is not indicative of the topology or architecture that underlies it. Therefore, industrial cyber-physical systems enabling Industry 4.0 engineering applications and scenarios would seem more naturally adapted to the decentralisation, flexibility, and consistency offered by fog computing (O'Donovan, 2019). Moreover, Industry 4.0 saw the introduction of the ICS (industrial control system). In this field, cyber-attacks may result in disruptive effects, such as large societal and financial losses and, in fact, it has been presented a unified architectural approach from the viewpoints of ICS security-related technologies, ICS threats, and ICS procedures to proactively handle the security issue of ICSs (Zhou, 2021)

A Cyber-Physical System (CPS) (Sinha, 2020) is the combination of the physical world with the cyber world. Research has demonstrated the existence of a hardware/software framework that supports run-time resilience for cyber-physical systems, using digital twins and failure models to improve operation, integration, maintenance and recoverability for many application scenarios, particularly for contexts such as intelligent cities and industrial IoT (Parri, 2021). CPS are large, interconnected, complex, heterogeneous and networked systems whose operations are tracked, coordinated, controlled and integrated by components that interact with the physical world through computing, transmission and other means. Unlike traditional stand-alone embedded systems, CPS is based on the networking of multiple devices. In other words, CPS is a modernised version of the embedded system that can send and receive data over a wired or wireless network, enabling on-demand search, access, exploration and/or recovery of information and resources, as well as intelligent analysis, use and linking, allowing anyone to perform automated diagnostics and tasks anywhere, anytime. Cyber-Physical Production Systems (CPPS) are being developed to apply CPS to industrial production systems. CPPS is the combination of a conventional production system with intelligent equipment, information storage and fast processors. This enables production facilities to communicate, act and control each other independently through adaptive networks. This enhances core production processes in terms of decentralised decision-making, industrial added value, supply chain and lifecycle management, manufacturing technology and resource consumption. Cyber-physical human-centric (CPHS) has evolved to meet the goals of complex industrial plants to be human-centric, resilient and sustainable (Fraga-Lamas, 2022). In manufacturing processes that rely on collaborative robots and large machines, it allows for improved operator safety and traceability. The proposed use case focuses on a factory floor where human proximity sensing is used to determine when a machine should or should not be running in order to use resources more efficiently and prevent accidents or incidents involving such machines. A CPHS proposal uses a hybrid edge computing architecture and intelligent fog computing nodes that analyse thermal images and take industrial safety actions. Experiment results show that in the chosen real scenario, the algorithm developed for CPHS is capable of quickly and accurately detecting the human presence (in less than 10 ms with 97.04% accuracy) using low-powered equipment such as Raspberry Pi 3B and providing an efficient solution (a good trade-off among efficiency, robustness, and performance) that could be implemented in many Industry 5.0 applications.

4.3. Cyber resilience protection

Risks associated with working in industrial environments are compounded by the trend toward Industry 4.0. In such dynamic contexts, approaches are required to analyse Safety Communication (SC) (Digmayer, 2022). Individual SC averages and quantitative evaluation metrics are the main topics of current investigations. This essay suggests a qualitative method for the SC analysis through which a process chain in an engineering firm may be looked at. The findings show that SC is implemented as a sophisticated network of communication channels (Lackorzynski, 2021). This system's flaws cause a variety of issues at the level of both workplaces and process chains. SC does not adhere to Industry 4.0 standards because of a lack of digitisation. These involve producing digital SC material, enhancing businesses' resistance to new risks, and preparing content for current SC media in accordance with work contexts and related activities (Lu, 2020). The strategies currently in use, developed for a long time with criteria of reliability and safety, as well as productivity and production quality, appear outdated in the last ten years or so. Global manufacturing operations today have more demanding standards than ever before, including things like transaction security and privacy. Manufacturing control is not a new concept, but the integration of distributed manufacturing facilities and the complete control of the production processes in these facilities is a current research topic, which is denoted with terms such as virtual factories, cloud manufacturing, industrial 4.0, industrial IIoT, and more recently, manufacturing based on software-defined networks (SDN) (Radu, 2019). SDN is a network architecture that decouples the network data from the control system in the world of computer networks. According to the requirements of each individual application, the SDN architecture assigns all data control to a logically centralised, software-programmable control plane. In terms of security, anyone with a computer running network control software could potentially take over your entire network. The integrated modelling environment proposed in this study for SDN applications addresses virtual manufacturing system assurance through cybersecurity and resilience methods (Babiceanu, 2019).

Particularly advanced and winking at Industry 5.0 may be the implementation of an additional system that has privacy Preserving as its goal using Machine learning systems. A proposed architecture called PriModChain can be utilised for trustworthy sharing and machine learning in an IIoT setting (Arachchige, 2020). The practicality of the framework has been examined in terms of privacy, security, dependability, safety, and resilience.

4.4. Human-robot relationship

Recent advancements in manufacturing technology, often known as Industry 4.0, aim to create Smart Factories with more automated supply networks and production lines. In this instance, the main idea behind the fourth Industrial Revolution (I4.0) is the incorporation of cutting-edge technologies into workplace environments and business processes which call for paradigms that have a significant impact on both people and technology. The adoption of technological innovation is beneficial for businesses because it guarantees major benefits, such as those related to costs, technology, management, etc., and it enables employers to improve employee safety. (Bertoncel, 2019)

Although new procedures, innovative technology, different types of workplaces, social or managerial transformation, as well as the fact that "new scientific understanding permits a long-standing problem to be classified as a risk" are all sources of new emerging risks. One illustration of this is the risk to working conditions posed by new tools that necessitate cutting-edge safety evaluation techniques. According to the EU Agency for Safety and Health at Work's expert prognosis on Named Entity Recognition (NER) (Adriaensen, 2019), workers experience more mental and emotional strain due to the difficulty of new knowledge, the renovation of work methods they cause, and poorly designed human-apparatus boundaries.

However, this important development does not completely merge with the requirement for human operators; on the contrary, it necessitates their participation in a hybrid task-execution process in collaboration with robots. For the future of factories where humans and robots work side by side closely in shared workspaces, creating safe environments for human operators is essential.

Collaborative applications face high risks due to the ambiguity of human behaviour and, subsequently, the actual implementation of operations. Currently, some new technologies are able to transform the informal and goal-oriented description of a human-robot collaboration application into a logic model, taking into account many important teamwork factors, such as work cell layouts, robot kinematics, operator characteristics, interactions between robots and operators in tasks, and their corresponding risk estimates.

Therefore, it is essential for a thorough safety investigation to develop a model that sees humans as more than just an operational element and simulates their mistaken behaviour.

In particular, it is extremely important to concentrate on formal models that replicate the most typical human errors that can happen while carrying out manufacturing tasks; doing so enables the detection (and correction) of hazardous situations that might go unnoticed if a purely functional model of humans is used. (Askarpour, 2019)

These topics are extensively studied everywhere. By virtue of the opening of many small- and medium-sized enterprises (SMEs) that not only represent a large potential market for robotics across a variety of industries but also face similar challenges in the global market, including the need for rapid reconfiguration of their production systems, improved safety, smaller production runs, and lower costs.

The use of advanced robots in manufacturing is in fact spreading throughout business. Previously utilised mostly in large, high-tech manufacturing facilities, robots are now more widely used by a variety of manufacturing organisations, including small- and medium-sized enterprises (SMEs) that aren't necessarily involved in the high-tech sector. As a result, workplaces where humans and robots coexist are frequently physically divided, which limits their flexibility and efficiency.

Collaborative robots are typically installed in shared spaces and put through a variety of tests that gauge their effectiveness and performance in relation to human safety criteria for robotic systems that can reduce the chances of relevant low-level injuries. (Dede, 2021)

4.5. Workers’ safety

The constant adoption of new technologies in the workplace calls for paradigms that have a significant impact on both people and technology. The adoption of technological innovation is beneficial for businesses because it guarantees major benefits, such as those related to technology, efficiency, administration, etc., and it enables employers to improve employee safety. Technological advancements necessitate consideration of risks to workers. Indeed, it is important to highlight new risks of injury, new potential causes of illness or new hazards caused by innovative activities and procedures.

For instance, new risks for injuries, new potential sources of diseases, or new dangers brought on by new practices or activities should all be considered.

This paragraph indicates that there is no comprehensive overview of the unique risks associated with the application of novel technologies in production systems. So, in order to study various technologies and identify the particular risks associated with the technical solutions under consideration, a precise analysis was conducted. The implementation of technologies, such as IoT, Cloud, and Artificial Intelligence, characterises the industry 4.0 transformation process (Bertoncel, 2019).

These modern technologies are a big invention that has the potential to fundamentally alter how we work. However, it is challenging to independently examine all the technologies in terms of new risks for the employees due to the creation of an underpinning level constructed with several innovative solutions, each of which is defined with a variety of features. Workers' health and safety risks are not only related to the abovementioned technologies; rather, they should be examined in light of the particular technological solution used in each situation. For this reason, the study that has been presented has only looked at the technologies that pose a serious risk to the health and safety of workers. In light of this, eight technology categories were established: additive manufacturing, AGV, augmented reality/virtual reality, exoskeleton, robot/cobot, and smart mobile wearable devices.

The risk factors identified for each technology have been categorised according to ISO 12100:2010 (Safety of machinery - General principles for design - Risk assessment and mitigation), and two additional risk categories - Organisational Risks and Psychological Risks - have been integrated to provide a broad set of norms for the context being analysed. Organisational hazards occur when risk is associated with policies, processes, standards and organisational solutions that are unrelated to the actions of the worker. The connection between the worker and digital technologies and their subjective view of their work are the sources of psychological risks. In addition, the risk categories of 12100:2010 have been renamed as follows to provide a broader and more thorough reference in this context: Chemical and biological replaced the category "Materials and substances", while the category "Environment" was renamed "Work environment and microclimate". (Costantino, 2022).

For example, research shows several sensors to monitor various physical and behavioural biometric parameters. This is made possible by the combination of multiple biometric traits with the assistance of machine learning technologies working in conjunction with various types of sensors (Abate, 2022). The author's approach is simple to execute in a large-scale smart factory, and experiments employing COTS hardware have demonstrated how it will further the adoption of Industry 4.0.

The authors present evidence that their suggestion can greatly increase operator safety while averting fatal collisions. By using various smart devices, it is therefore possible to gain a thorough understanding of how operators operate and prevent a number of injuries when operating industrial machinery. Industry 4.0 adoption is accelerated by experiments using hardware that is readily available off the market to show how the concept can be easily implemented in a large-scale smart plant. Additionally, the use of lightweight approaches shows that multibiometric system integration is possible without the use of high-performance hardware, enabling businesses to keep costs low while implementing these new technologies.

While one of the major disruptive events of the previous 20 years, the COVID-19 pandemic demonstrated the susceptibility of multinational manufacturing corporations to their supply networks and operations. It proved that big businesses undervalue the requirement for resilient and sustainable operations. Due to a variety of factors, the pandemic's worldwide impact is enormous for supply chains that are interrupted. For example, Wuhan, the epicentre of the COVID-19 outbreak, is home to numerous large manufacturing firms where suppliers of auto parts and semiconductors to major automakers like General Motors, Hyundai, Toyota, Volkswagen, Honda, etc. are concentrated. Additionally, any disruptions in China and India had an impact on businesses around the world. The effects of disruptive occurrences, such as a shortage of raw materials, delivery delays, a lack of replacement parts, a reduction in labour capacity, etc., directly affect operations. Additionally, (Eldem,2022) created a model to assess how a pandemic might affect the supply chain network and production resilience. It is clear that the COVID-19 scenario presents a chance for the creation of a flexible and resilient manufacturing process to maintain the organisations' social, environmental, and economic sustainability. These procedures help the organisation's financial situation. As a result, the best techniques for both socioeconomic development and environmental preservation were merged. The detrimental effects of the tragedy on business operations and industrial policy are causing worry among experts, governments, corporate executives, and legislators. As a result, businesses are seeking to solve the problems and difficulties related to the three components of sustainability. As a result, numerous initiatives have been made to alter businesses, including those that concern employee well-being, healthcare communication tactics that are effective, workers safety, smart working circumstances, and capability development. These are a few of the social sustainability programs that organisations have implemented to lessen the COVID-19's effects and maintain social sustainability.

The management and execution of work tasks has recently undergone a rapid transformation thanks to the introduction of new technology. Building Information Modeling (BIM) is being used more frequently to enhance the performance of different tasks, particularly in the construction industry. With this in mind, and given that the construction industry remains one of the most dangerous workplaces, several studies have suggested that BIM is an essential process for effectively improving workplace safety. In this perspective, (Fargnoni, 2020) examine contemporary studies on the application of BIM to increase building site security. The study found that design for safety with BIM, dynamic visualisation and feedback had a more legitimate research direction. More BIM practices are required, according to the study's findings, particularly in the areas of safety education and training, using BIM to improve the climate and resilience of safety, and creating quantitative risk analysis to better support security management.

A future proposal in the era of the IoT, in industrial settings, sensors, actuators, and smart objects are used to manage all aspects and activities of a factory, from routinely available systems, such as lighting, production, and automation systems, to critical systems, such as safety and fire protection systems that detect structural integrity. In critical and emergency situations, such as wildfires and other disaster-inducing events, it is critical to seek assistance and resources from third parties, particularly nearby entities, in order to respond to the emergency as soon as possible. This also applies to smart services such as fire management and building evacuation, which should be made resilient in the face of similar catastrophic events. As a result, there is an Industry 4.0 initiative where a system can monitor the progression of flames and protect each district area from power outages or disconnections. (Tricomi, 2021)

5. Future developments

While many companies around the world are still trying to adapt to the principles of Industry 4.0, others are already looking towards the future as they have started the transition to Industry 5.0. Within this paradigm, Cyber-Physical Human-centred Systems (CPHS) have emerged to harness the capabilities of operators. In order to achieve the goals of complex production systems, CPHS is based on three salient points: human-centricity, resilience and sustainability. (Fraga-Lamas, 2022)

In particular, about human-centricity, it was discussed how Lean Thinking can contribute to the 5.0 Society and Industry 5.0. In the area of sustainability, efforts are made not to waste water and raw materials. Human potential that is unrealised is another sort of waste. This waste is a result of operators' suggestions, inventiveness, and original ideas being not capitalised. Now that technology is all around us and encourages creativity more than ever, creative people are even more needed. Technology can also restrict actions and stifle innovation. Because of this, the adoption of technology must be carefully thought out and justified. When technology is effectively integrated, creativity and the potential of the individual can be completely unlocked. (Alves, 2022)

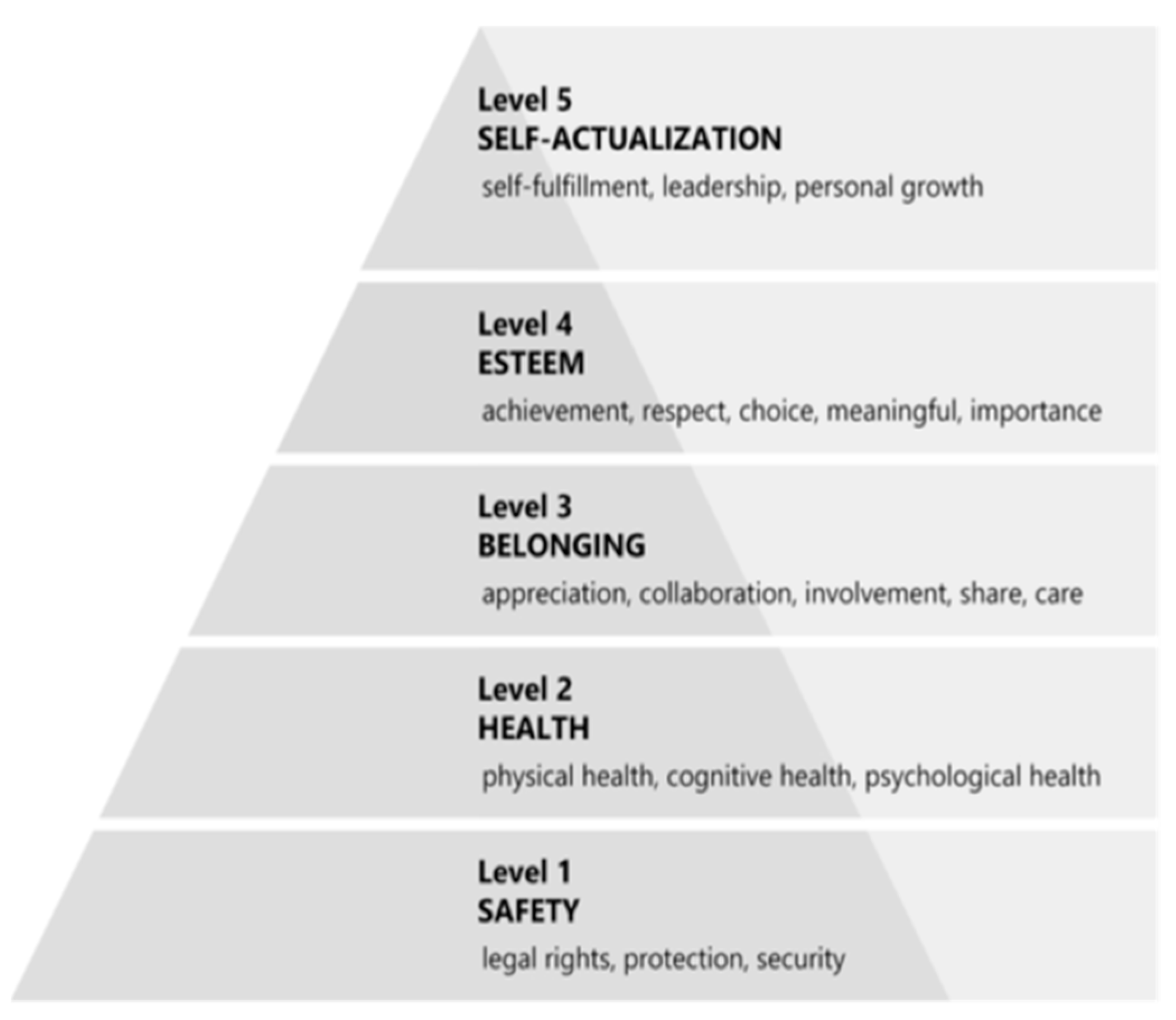

The requirements Industry 5.0 has sparked formal discussions about the need for manufacturing to be human-centric, with the wellbeing of industry workers at the centre of manufacturing processes rather than system-centric, with only efficiency and quality improvement and cost reduction as its driving forces. As a fundamental contribution to the knowledge of workers' needs, an “Industrial Human Needs Pyramid” was created to define and classify human needs and motivations in production. (

Figure 8). (Lu, 2022)

The pyramid's five tiers, from the base to the top, depict the progression from ensuring fundamental human safety to promoting personal development:

Level 1: Safety. The first thing an industrial environment should achieve is physical safety. A combination of isolation and reactive protection between machines and humans is used in today's protective techniques. Adaptive planning and execution of safe human-machine interactions are required as the protection mechanism must go from reactive protection to proactive protection, where the environment can sense and forecast workers' behaviour.

Level 2: Health. Healthy working conditions are Level 2 needs. Physical health at this level refers to a setting that reduces unsafe motions, postures, or working patterns that result in long-term musculoskeletal injury. The production environment should also offer high-value jobs to promote worker engagement while decreasing cognitive stress to keep workers psychologically healthy.

Level 3: Belonging. This level begins to respond to a worker's social characteristics. Because we are a social species, cooperation is essential for our survival and development. The term "belongingness" describes the psychological need people have to connect with others, affiliate with groups, and feel linked. Friendship, intimacy, trust, acceptance, receiving and giving affection, and admiration are a few examples of belonging requirements.

Level 4: Esteem. Esteem needs include self-assurance, courage, conviction in oneself, social and personal acceptance, and respect from others. One of the key steps to obtaining self-actualisation is meeting these requirements. Although esteem is an internal trait, humans are influenced by outside forces, such as peer validation and approval.

Level 5: Self-actualisation. Self-actualisation refers to realising personal potential, seeking personal growth and peak experience. The worker at this level views their job largely as a means of achieving personal fulfilment. They have a feeling of purpose that they naturally incorporate into their daily operations, embrace themselves and others, and maintain deep and lasting relationships.

7. Conclusion

We are in the era of Industry 4.0, and the companies are undergoing a significant structural operational transformation and overcoming many challenges to adapt manufacturing in a smart and environmentally friendly way to meet the demand for affordable, customised, and high-quality products on a global scale.

The intelligent artefacts can communicate with each other and rearrange and reorganise themselves to produce diverse customised items in a flexible and sustainable manner. Research has shown that responsiveness is the most crucial factor and that high service levels, cost-cutting, recovery, safety standards, and working conditions are the most crucial criteria for each of their respective elements (Nayeri, 2023). Moreover, "Industrial Big data" may be obtained from a sizable number of smart things that are dispersed geographically and transmitted to the cloud. The "gold" for Industry 4.0 may be in the proper big data analysis and processing. Data-based virtual manufacturing enables system-wide coordination, prediction, and control, resulting in greater system performance, increased production efficiency, higher-quality products, lucrative business growth, and more. The typical labour patterns and norms used in traditional industries will therefore alter, evolve, or maybe go entirely out of style. As a result, there is an increased need for a workforce that is specifically skilled and trained, which will increase the likelihood that new jobs of all kinds will be created. (Hsu, 2022) This technological process, however, must also be accompanied by an advancement in security.

Indeed, in order to protect the user, future technical advancements should focus on integrating safety systems and systems for detecting workplace and worker circumstances. It should also be mentioned that developing risks include psychological elements in addition to physical and physiological ones. In order to close the gap in employee health and safety, policing terms of specific 4.0 technology adoption, it has been demonstrated how digital innovation within manufacturing systems can help companies improve the safety and well-being of workers as well as production. Thus, projecting companies towards the fifth industrial revolution.