1. Introduction

In recent years, in order to meet the needs of high-speed penetration in modern war, various types of aircraft have higher and higher engine power and faster and faster flight speed, which makes the infrared radiation characteristics of various types of aircraft caused by thermal and aerodynamic heating in the process of high-speed flight more and more obvious. The high infrared radiation characteristics of various types of aircraft are easy to be found by enemy detection equipment such as infrared thermal imager and destroyed by infrared guided weapons in wartime [

1]. In view of this, low infrared emissivity materials which can effectively reduce the infrared radiation characteristics of various types of aircraft have received extensive attention from many scholars [

2,

3,

4,

5,

6,

7]. Among all kinds of low infrared emissivity materials reported, resin/metal composite coatings, which are composed of various resin matrix and flake metal pigments, have obvious comparative advantages in low emissivity, engineering application performance, multi-spectrum compatibility, cost and convenience [

8,

9,

10,

11,

12], and have been developed rapidly. It has a broad application prospect in the field of infrared stealth of various aircraft. However, the low infrared emissivity resin/flake metal composite coating reported at present mainly uses polyurethane (PU), epoxy resin and other strong polar resins as the main film forming materials [

13,

14,

15]. The main advantage of the low infrared emissivity coating prepared by the above resin matrix is that it has good mechanical properties. However, the strong polar groups such as isocyanate group, carbonyl group and epoxy group present in large quantities in the molecular structure of the resin matrix easily make the prepared low emissivity coating have high surface energy, so it cannot show good hydrophobic properties. Thus, the coating encountered a new bottleneck problem in terms of anti-pollution [

16]. It is an effective way to solve the above problems to make the above low infrared emissivity coating have good hydrophobic properties through certain technical means [

17,

18].

Coatings with prominent hydrophobic properties have broad application prospects in the fields of self-cleaning, corrosion resistance and oil-water separation [

19,

20]. In the process of coating preparation, the super-hydrophobic properties of the coating are mainly achieved by reducing the surface energy of the coating and constructing micro and nano rough structures [

21,

22]. In the early stage, our research group used polydimethylsiloxane (PDMS) as a low surface energy resin matrix, flake Al powder as a low emissivity functional pigment, and nano-SiO

2 as a micro-nano rough structural modifier, a low emissivity coating with outstanding hydrophobic properties was preliminarily prepared [

23]. However, the emissivity of the coating reaches 0.661, while the mechanical properties are poor, especially the adhesion strength and impact strength are very low, so there is still a large room for improvement from the engineering application requirements. In view of this, by optimizing the composition and interface structure of the coating, it is of great practical significance to reduce the emissivity of the coating and improve the mechanical properties of the coating on the basis of ensuring that the coating has good hydrophobic properties. In this paper, polyurethane modified by hydrogen-containing silicone oil (HCSO) is used as resin matrix, and coating additives such as dispersant, adhesion enhancer and defoamer are used to modify the coating interface, so as to further optimize the low emissivity and mechanical properties of the coating on the premise of ensuring the coating has good hydrophobic properties.

2. Materials and methods

2.1. Materials

Nano-SiO2 (purity 99.5 wt%, particle size 30±5 nm), Al powders (solid content 67 wt%, flake, particle size 20–30 µm), PU (liquid, solid content 50 wt%), hydrogen-containing silicone oil (HCSO, liquid, solid content 96 wt%), medium molecular weight sodium polycarboxylate anionic surfactant was used as dispersant (analytically pure), 2-hydroxyethyl methacrylate phosphate was used as adhesion enhancer (analytically pure), dimethylsilicone oil was used as defoamer (analytically pure), and tinplate substrate (12 cm×5 cm, thickness 0.3 mm) were purchased from Nanjing Sidier Paint Limited Company, China. All reagents were analytical grade and were used as received without further treatment.

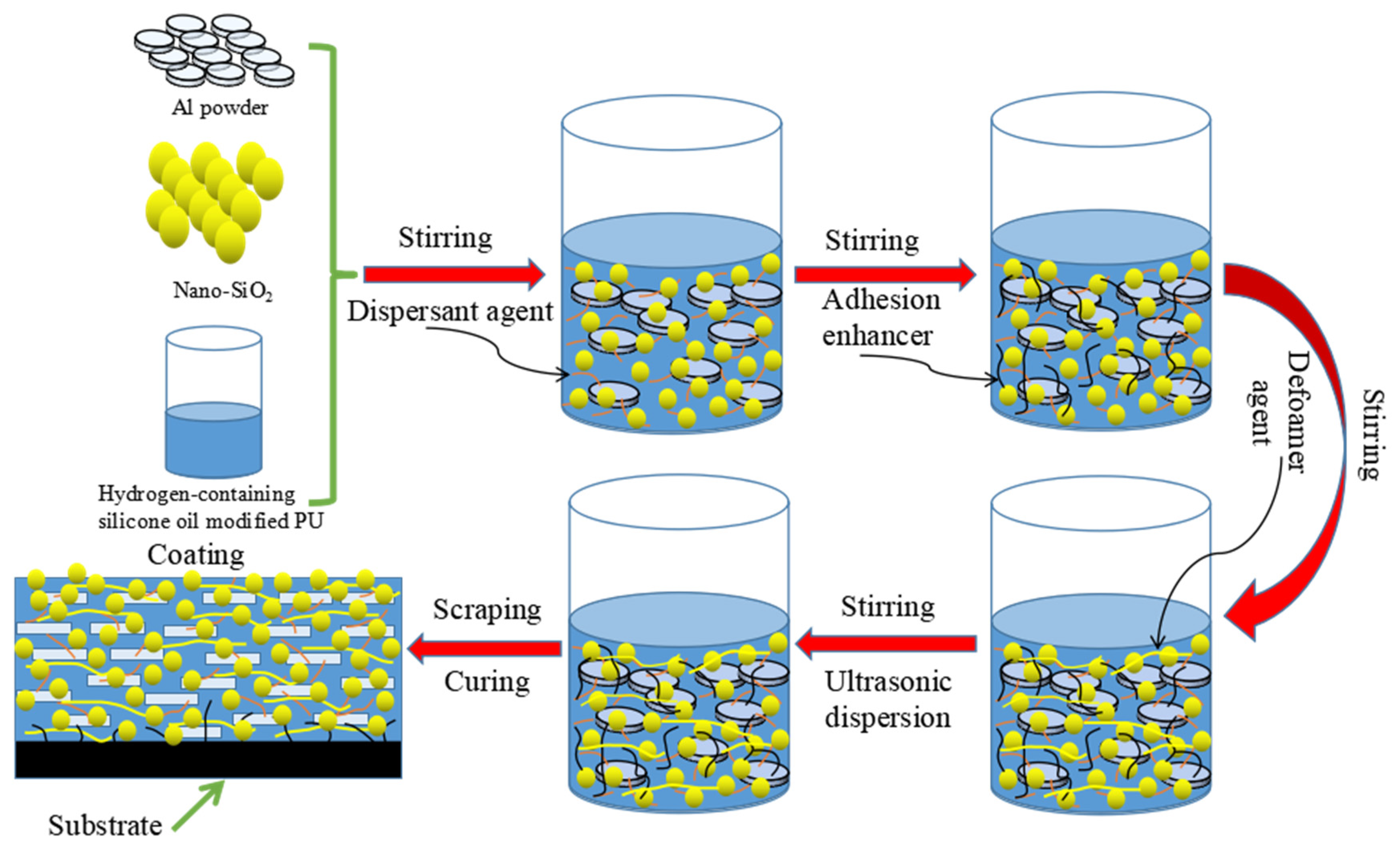

2.2. Preparation of the coating

Take the tinplate plate (12cm×5cm×0.3mm) as the coated substrate, sand it so that its surface has obvious rough marks, and then wipe the surface of the substrate with a disposable paper towel dipped in an appropriate amount of anhydrous ethanol. The modified resin was obtained by mixing HCSO and polyurethane with a mass ratio of 2:8, and the resin matrix was used as an adhesive to prepare a hydrophobic low infrared emissivity coating. The mass ratio of Al powder and nano SiO

2 is fixed at 6:4, and an appropriate amount of the modified resin and functional fillers (Al powder + nano SiO

2) are weighed in a disposable plastic cup with a mass ratio of 6:4. After adding an appropriate amount of anhydrous ethanol, stir and disperse evenly with a glass rod until there are no obvious particles in the paint. Then the ultrasonic wave with the frequency of 25 KHz is used to disperse the paint for 10 minutes, so that the paint is uniform and fine. The paint was coated on the tinplate by glass rod scraping, dried at room temperature for 3 h, and cured in an oven at 80

oC for 3 h to obtain the coating sample, and then characterized the properties. On the basis of the above basic formula samples, the dispersant was added by 1%, 3%, 5%, 7% (mass fraction) of the total filler content, and the effect of dispersant on the comprehensive properties of the coating was studied. On the basis of the above optimal amount of dispersant, the adhesion enhancer was added according to 2%, 3%, 4%, 5% (mass fraction) of the total resin matrix, and the influence of adhesion enhancer on the comprehensive properties of the coating was studied. Then, on the basis of the optimal amount of adhesion enhancer, the defoamer was added according to 1%, 3%, 5% (mass fraction) of the total resin matrix, and the effect of the defoamer on the comprehensive properties of the coating was studied. The preparation process of hydrophobic HCSO modified PU/Al composite coating with low infrared emissivity is shown in

Figure 1.

2.3. Characterization

The surface morphology of the coating were characterized via scanning electron microscopy (SEM, JSM-6510 LV, Japan Electronics Corporation). The Infrared emissivity (8~14 μm) of the coating was measured using IR-2 infrared emissometer (Shanghai Institute of Technological Physics). The glossiness of the coating was measured using mirror glossiness tester (JKGZ-60, Tianjin Jingkelian Material Testing Machine Co., Ltd.). The water contact angle (WCA) of the coating was measured using contact angle meter (JC2000D7, Shanghai Zhongchen Digital Technology Equipment Co., Ltd.). A 3 μL water droplet was formed on the surface of the coating by manual sampling method. The WCA of the water droplet was measured by the software of the instrument. The adhesion strength of the coating was evaluated by using QFZII circle-cut tester (China) according to China National Standard GB 1720-79(89). The impact strength of the coating was evaluated by using QCJ impact strength tester (China) according to China National Standard GB 1732-93.

3. Results and discussion

3.1. Effect of dispersant on coating performance

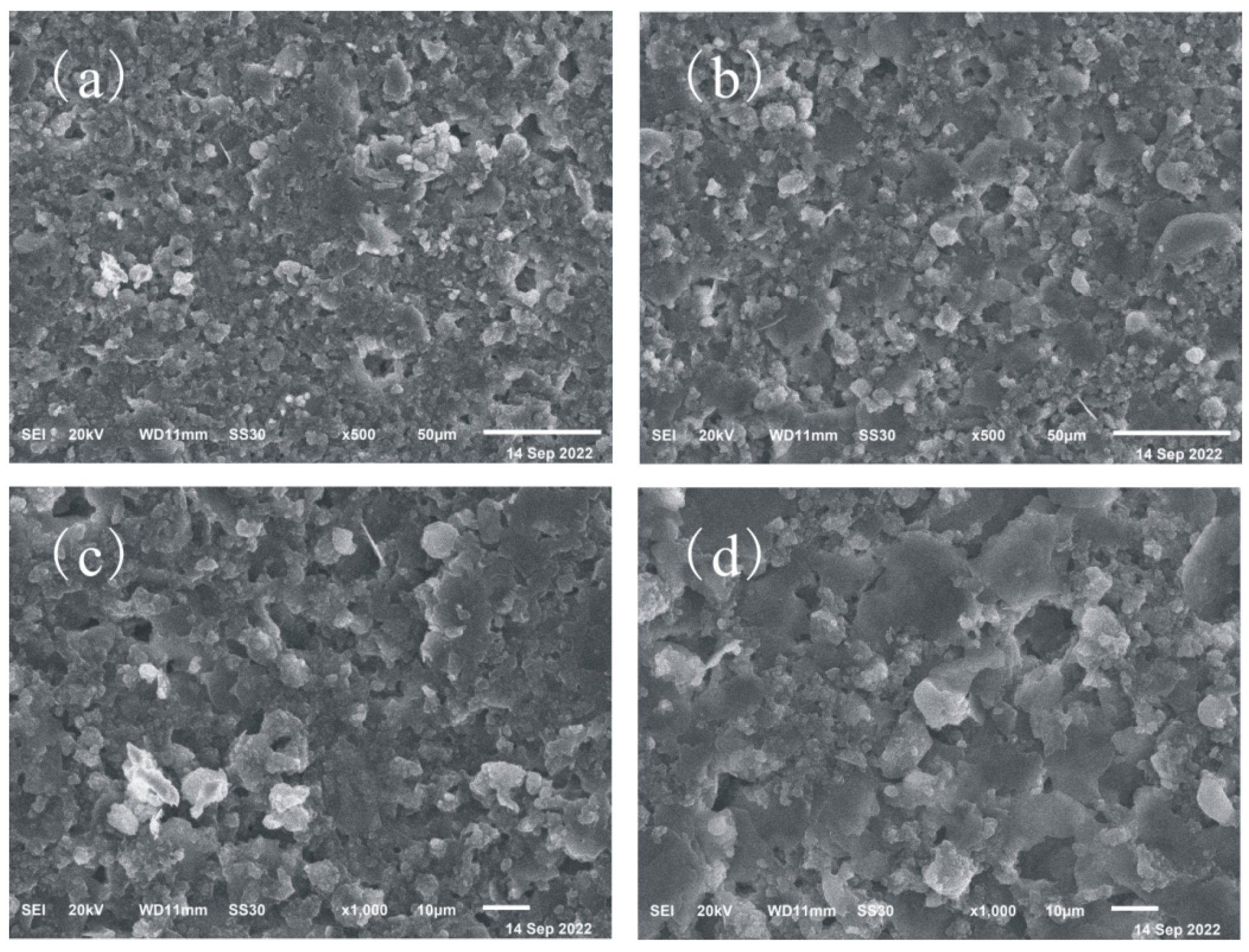

The SEM images of the coatings with different amounts of dispersant are shown in

Figure 2. It can be seen that when a certain amount of dispersant is added to the coating, the dispersion state of flake Al powder and nano-SiO

2 particles in the coating is obviously improved. The characteristics of flake Al powder on the coating surface are more obvious, and the agglomeration characteristics of nano-SiO

2 are reduced to a certain extent. In addition, the addition of dispersants to the coating does not have a negative effect on the regularity of the coating surface. The more obvious characteristics of flake Al powder on the surface of the coating is conducive to strengthening the reflection of the coating on infrared light, which is expected to make the coating show relatively low emissivity [

12]. The increase of the dispersion state of nano-SiO

2 in the coating is conducive to the formation of more obvious micro-nano papilloid structure on the surface of the coating, which is conducive to strengthening the hydrophobic property of the coating [

22].

The optical and mechanical properties of the coating with different amounts of dispersant are shown in

Table 1. It can be seen that with the increase of the amount of dispersant added to the coating, the infrared emissivity of the coating generally shows a downward trend. On the contrary, the glossiness of the coating generally showed an upward trend. When the amount of dispersant added in the coating increases to 3 wt%, the infrared emissivity of the coating can be reduced to 0.535, which is 8.55% lower than the original emissivity (0.585). The corresponding glossiness of the coating can be increased from 3.0 to 4.8. However, the coating has polar glossiness characteristics under different amounts of dispersant. The above performance indexes can make the coating have good infrared and visible compatible stealth performance. The change of properties is mainly caused by the micro-structure of the coating. By modifying the coating with dispersant, the dispersion state of flake AL powder in the coating can be more uniform, and the characteristics of flake Al powder on the surface of the coating are more obvious, thus strengthening the reflection intensity of the coating to infrared light, and then reducing the infrared emissivity of the coating [

12]. The increase of glossiness of the coating is also caused by the obvious characteristics of flake Al powder in the coating. However, a large number of micro-nano rough structures composed of nano-SiO

2 particles in the coating make the overall roughness of the coating high, which can keep the polar glossiness of the coating [

22]. Good mechanical properties are the basic requirements for the application of a stealth coating. Therefore, we tested the adhesion strength and impact strength of the coating under different amounts of dispersant, and the results are listed in

Table 1. It can be seen that with the increase of the amount of dispersant added to the coating, the adhesion strength and impact strength of the coating have been significantly improved. When the amount of dispersant in the coating increases to 5 wt%, the adhesion strength and impact strength of the coating can be improved from grade 5 and 10 kg.cm before modification to grade 2 and 20 kg.cm after modification, respectively.

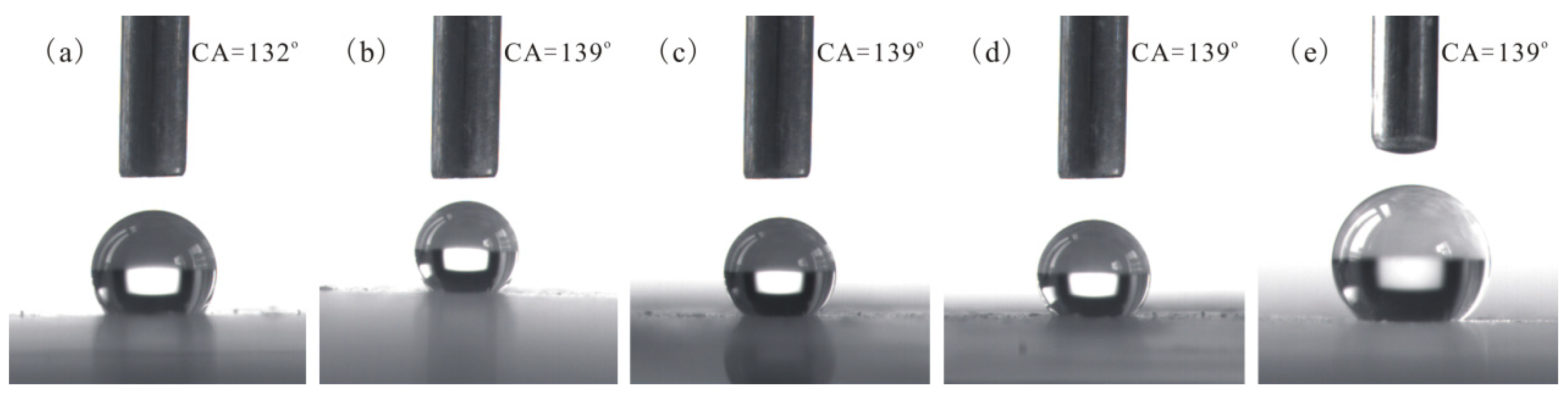

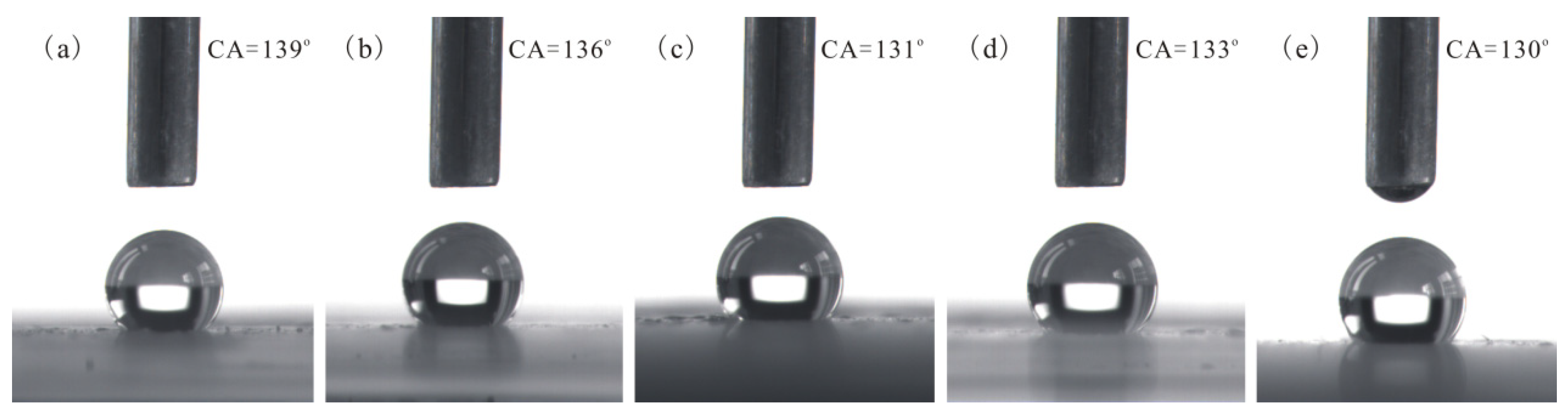

Figure 3 shows the WCAs of the coatings with different amounts of dispersant. It can be seen that adding 1 wt% dispersant to the coating can increase the WCA of the coating from 132

o before modification to 139

o after modification, and continue to increase the dispersant, the WCA of the coating is basically stable. The above results show that adding a small amount of dispersant to the coating can obviously improve the hydrophobic property of the coating. Considering the infrared emissivity, glossiness, and mechanical properties of the coating, the optimal addition amount of dispersant in the coating is 5 wt%.

3.2. Effect of adhesion enhancer on coating performance

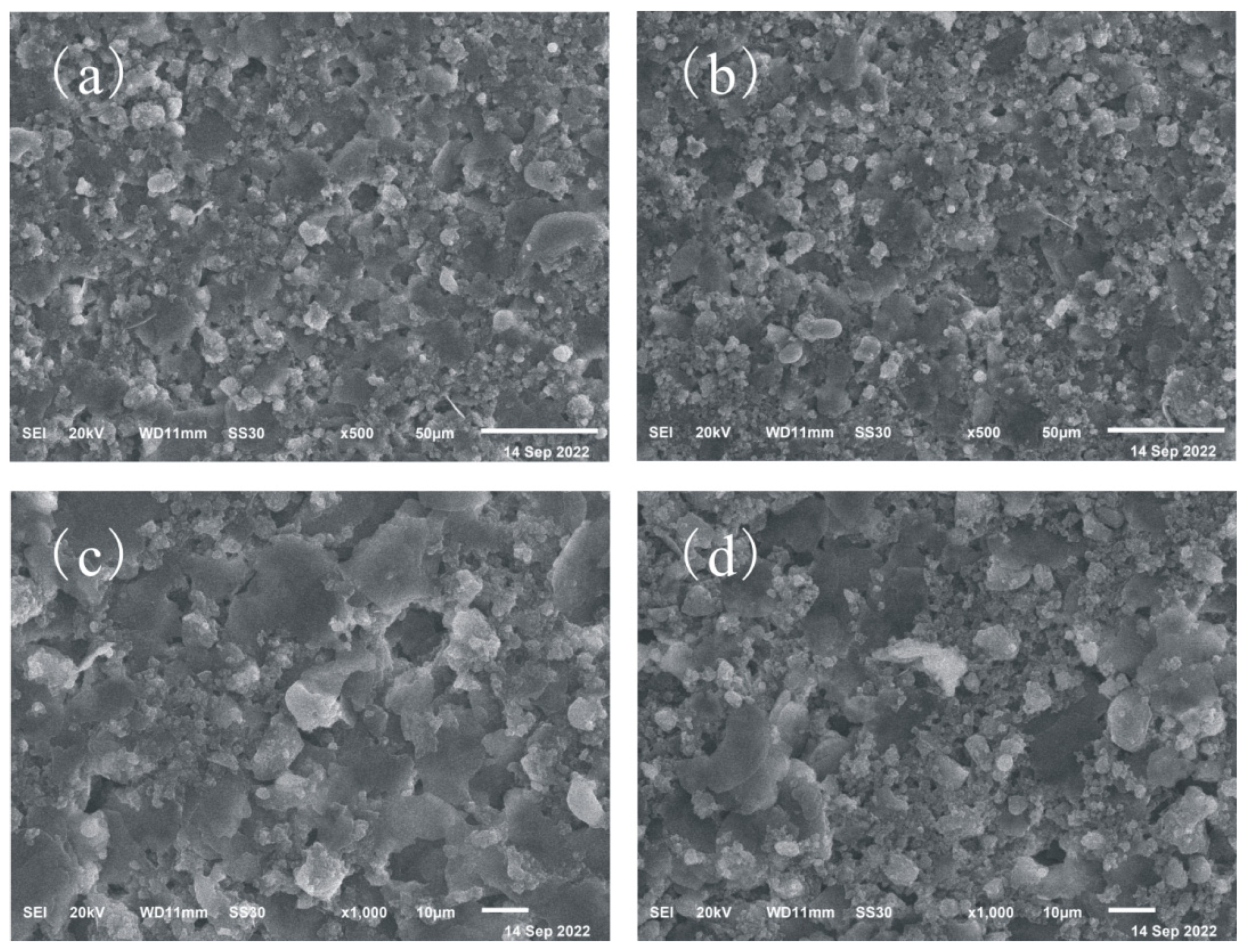

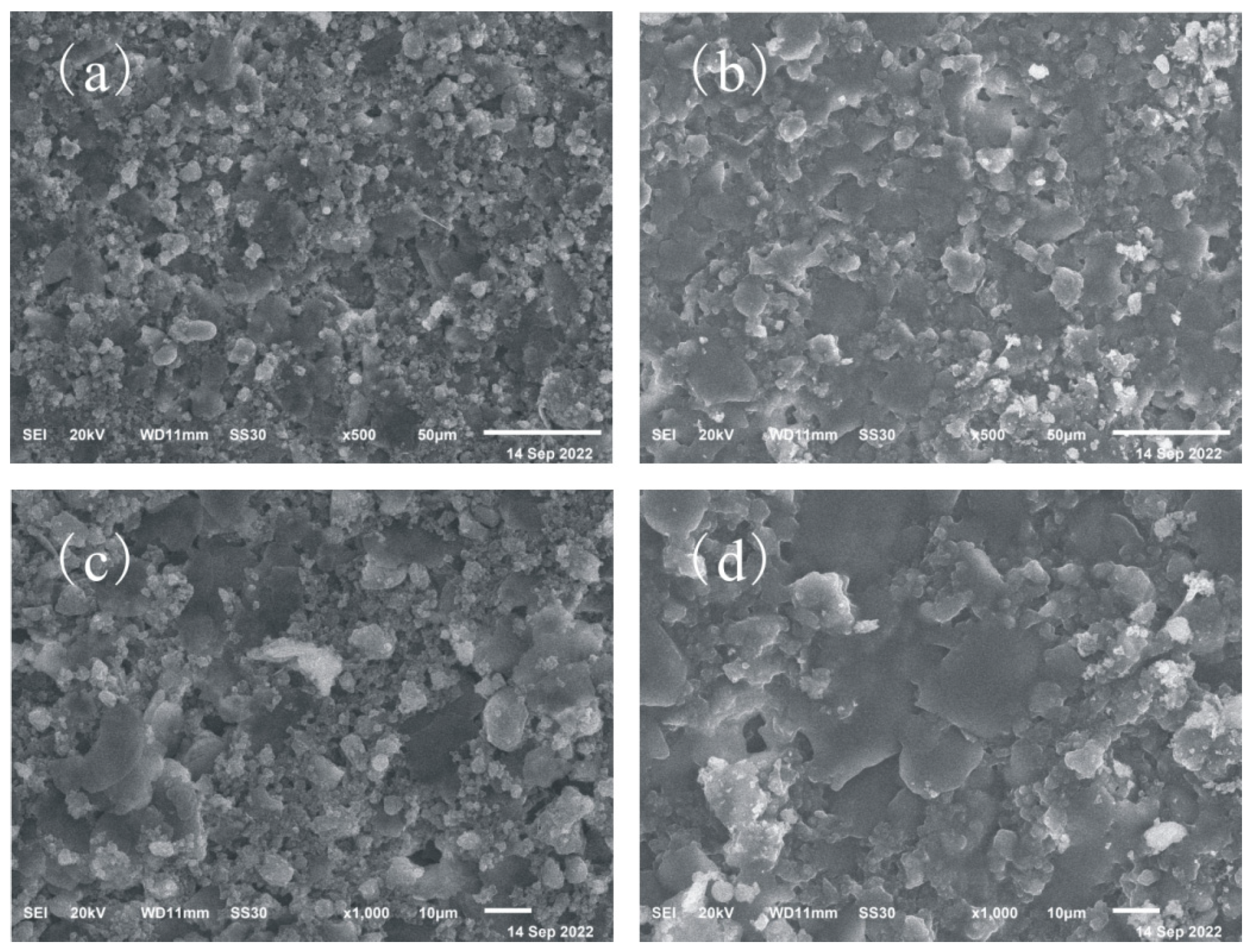

In order to further improve the mechanical properties of the coating, the effects of adhesion enhancer on the properties of the coating were studied based on the addition amount of dispersant was fixed at 5 wt%. The SEM images of the coatings with different amounts of adhesion enhancer are shown in

Figure 4. It can be seen that the addition of adhesion enhancer has little effect on the micro-structure of the coating. Before and after the modification of the adhesion enhancer, the distribution state of flake Al powder and nano-SiO

2 in the coating almost did not change, and the surface of the coating still maintained a relatively regular surface state. These micro-structure states are conducive to the coating to maintain relatively stable optical and hydrophobic properties.

The optical and mechanical properties of the coating with different amounts of adhesion enhancer are shown in

Table 2. It can be seen that the infrared emissivity of the coating decreases slightly with the increase of the amount of adhesion enhancer added in the coating. The infrared emissivity of the coating decreased slightly from 0.538 before modification to 0.508 after modification when the addition amount of adhesion enhancer increased to 3 wt%. The glossiness of the corresponding coating has no obvious change rule with the change of the amount of adhesion enhancer added in the coating. The glossiness of the coating can be adjusted in a small range of 5.0 to 6.1, it still maintains a very low gloss characteristic. The main reason is that the adhesion enhancer used in this paper has special bridging characteristics. One end of its molecular structure contains strong polar groups such as hydroxyl, which can be fused with functional fillers with high surface energy in the coating. The other end of its molecular structure contains weakly polar groups such as phosphate groups, which can be fused with the resin matrix with low surface energy in the coating. The bonding strength between the resin matrix and the functional pigment in the coating is obviously enhanced through the bridging action of the adhesion enhancer, and the regularity of the coating is enhanced, so that the emissivity of the coating is reduced [

12]. However, the adhesion enhancer has little effect on the surface state of the coating, so the glossiness of the coating is almost unchanged. In addition, the adhesion enhancer also has an obvious promoting effect on the mechanical properties of the coating. When the addition amount of adhesion enhancer in the coating is 4 wt%, the adhesion strength and impact strength of the coating can be increased from grade 2 and 20 kg.cm before modification to grade 1 and 30 kg.cm after modification, respectively. The main reason is that the adhesion enhancer can significantly enhance the bonding strength between the resin matrix and the substrate, and the bonding strength between the resin matrix and the functional fillers through the bridging action, so that the mechanical properties of the coating can be significantly improved.

Figure 5 shows the WCAs of the coatings with different amounts of adhesion enhancer. It can be seen that the WCA of the coating decreases with the increase of the adhesion enhancer in the coating. The main reason is that there are more strong polar groups such as hydroxyl group on the molecular structure of the adhesion enhancer, which can increase the surface energy of the coating surface, thus reducing the hydrophobicity of the coating.

3.3. Effect of defoamer on coating performance

In order to further improve the mechanical properties of the coating, the effect of defoamer on the properties of the coating was studied. The SEM images of the coating with different amounts of defoamer are shown in

Figure 6. It can be seen that the addition of defoamer in the coating has a very obvious effect on the surface structure of the coating. When a small amount of defoamer is added to the coating, the original pores of the coating are obviously reduced, and the regularity and surface state of the coating are obviously improved. Moreover, the addition of did not change the horizontal orientation state of flake Al and the dispersion state of nano-SiO

2 in the coating. The above micro-structure characteristics are conducive to further improving the mechanical properties of the coating on the premise of maintaining low emissivity and good hydrophobicity.

The optical and mechanical properties of the coating with different amounts of defoamer are shown in

Table 3. It can be seen that the addition of defoamer in the coating has a significant effect on the emissivity of the coating. The emissivity of the coating shows a gradual increasing trend with the increase of the amount of defoamer added in the coating. Which can be increased from 0.508 when the defoamer content is 0 wt% to 0.582 when the defoamer content is 5 wt%. The main reason is that the molecular structure of the defoamer of dimethylsilicone oil has a large number of silico-oxygen bonds which can produce strong absorption in the middle infrared band. Therefore, adding defoamer to the coating can enhance the absorption of infrared light and increase the emissivity of the coating [

12]. In addition, the glossiness of the coating can be less than 5.0 under the conditions of different amounts of defoamer, which reflects the outstanding low gloss characteristics of the coating. Due to the modification of the coating by defoamer, the porosity in the coating is obviously reduced and the regularity is obviously increased, so the mechanical properties of the coating can be significantly improved. When the amount of defoamer added to the coating is 1 wt%, the impact strength of the coating can be increased from 30 kg.cm before modification to 40 kg.cm after modification (

Table 3).

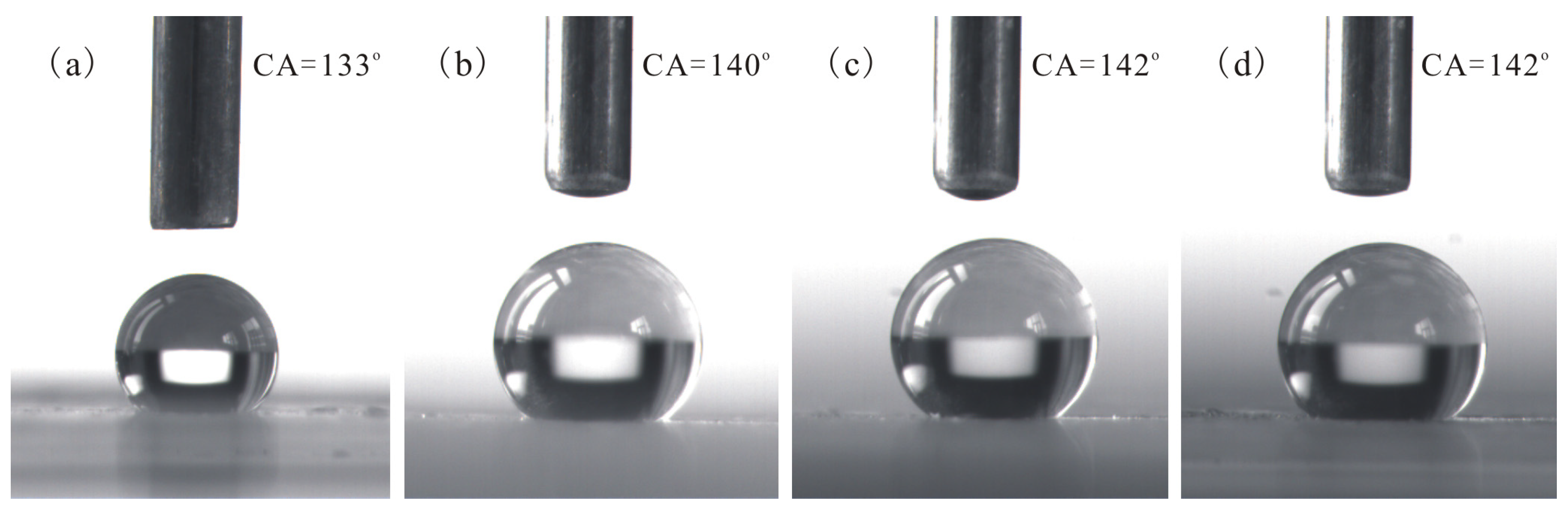

Figure 7 shows the WCAs of the coatings with different amounts of defoamer. It can be seen that the WCA of the coating can be significantly increased after the coating is modified with defoamer, the hydrophobicity of the coating can be obviously improved. When the amount of defoamer added in the coating is 1 wt%, the WCA of the coating can be significantly increased from 133

o before modification to 140

o after modification. The main reason is that the defoamer used in this paper is dimethylsilicone oil, which has the characteristics of low surface tension and low surface energy. Therefore, after adding a small amount of defoamer to the coating, the surface energy of the coating can be reduced, and the hydrophobicity of the coating can be increased [

21].

4. Conclusions

On the basis of hydrogen-containing silicone oil modified PU/Al composite coating, the dispersion state of various fillers in the coating is improved by dispersant, the interface structure of the coating is improved by adhesion enhancer, and the porosity of the coating is reduced by defoamer. Finally, a low infrared emissivity composite coating with good mechanical properties and hydrophobic properties is prepared. Polycarboxylate anionic dispersant can significantly enhance the dispersion of filler particles in the coating, thus reducing the emissivity of the coating and improving the hydrophobic property. The interface structure between the resin matrix and fillers, and the interface structure between the resin matrix and the metal substrate can be obviously improved by the adhesion enhancer. Thus, the bonding strength between the resin matrix and the fillers, and the bonding strength between the resin matrix and the tinplate substrate can be enhanced. Then the adhesion strength and impact strength of the coating can be significantly improved. Adding a small amount of defoamer to the coating can significantly reduce the pores in the coating, so that the impact strength of the coating can be significantly improved.

Author Contributions

Conceptualization, methodology, validation, resources, writing—review and editing, W.Z.; data management and supervision, X.L.; formal analysis and investigation, D.L. All authors have read and agreed to the published version of the manuscript.

Funding

This project was sponsored by the National Natural Science Foundation of China (61705029) and Key Project of Scientific Research Plan of Higher Education in Anhui Province (2022AH051121).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that there is no conflict of interest.

References

- Ma, D.; Xie, Y.; Wang, L.; Peng, Y.; Yin, Y.; Wang, X.; Liu, B.; Zhang, G.; Zhu, L.; Xu, D. Layered La2Zr2O7 flexible fibrous membrane for super thermal insulation and infrared stealth. Chem. Eng. J. 2023, 468, 143488. [Google Scholar] [CrossRef]

- Lyu, J.; Liu, Z.W.; Wu, X.H.; Li, G.Y.; Fang, D. Nanofibrous kevlar aerogel films and their phase-change composites for highly efficient infrared stealth. ACS Nano 2019, 13, 2236–2245. [Google Scholar] [CrossRef] [PubMed]

- Phan, L.; Walkup IV, W.G.; Ordinario, D.D.; Karshalev, E.; Jocson, J.M.; Burke, A.M.; Gorodetsky, A.A. Reconfigurable infrared camouflage coatings from a cephalopod protein. Adv. Mater. 2013, 25, 5621–5625. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.J.; Wang, W.; Yu, X.; Xu, H.; Zhong, Y.; Sui, X.; Zhang, L.; Mao, Z. Preparation of ZnO:(Al, La)/polyacrylonitrile (PAN) nonwovens with low infrared emissivity via electrospinning. Mater. Lett. 2015, 143, 120–123. [Google Scholar] [CrossRef]

- Solovyev, A.A.; Rabotkin, S.V.; Kovsharov, N.F. Polymer films with multilayer low-E coatings. Mat. Sci. Semicon. Proc. 2015, 38, 373–380. [Google Scholar] [CrossRef]

- Wang, L.; Xu, G.; Liu, C.; Hou, H.; Tan, S. Surface-modified CeO2 coating with excellent thermal shock resistance performance and low infrared emissivity at high-temperature. Surf. Coat. Tech. 2019, 357, 559–566. [Google Scholar] [CrossRef]

- Zhang, W.G.; Lv, D.D. Preparation and characterization of Ge/TiO2 one-dimensional photonic crystal with low infrared emissivity in the 8-14 μm band. Mater. Res. Bull. 2020, 124, 110747. [Google Scholar] [CrossRef]

- Chen, X.T.; Zhou, M.; Zhao, Y.; Gu, W.H.; Wu, Y.; Tang, S.L.; Ji, G.B. Morphology control of eco-friendly chitosan-derived carbon aerogels for efficient microwave absorption at thin thickness and thermal stealth. Green Chem. 2022, 24, 5280–5290. [Google Scholar] [CrossRef]

- Zhou, H.P.; Yu, M.J.; Zhu, M.N.; Zheng, Q.; Xu, Y. Difunctional composite coatings with low infrared emissivity and electrostatic dissipation property. Infrared Phys. Techn. 2021, 113, 103609. [Google Scholar] [CrossRef]

- Luo, H.; Zhang, X.; Huang, S.; Shan, D.; Liao, C. Infrared emissivity and microwave transmission behavior of flaky aluminum functionalized pyramidal-frustum shaped periodic structure. Infrared Phys. Techn. 2019, 99, 123–128. [Google Scholar] [CrossRef]

- Yu, H.J.; Xu, G.Y.; Shen, X.M. Low infrared emissivity of polyurethane/Cu composite coatings. Appl. Surf. Sci. 2009, 255, 6077–6081. [Google Scholar] [CrossRef]

- Zhang, W.G.; Xu, G.Y.; Ding, R.Y. Microstructure, optimum pigment content and low infrared emissivity of polyurethane/Ag composite coatings. Physica B 2013, 422, 36–39. [Google Scholar] [CrossRef]

- Yan, X.X.; Xu, G.Y. Influence of silane coupling agent on corrosion-resistant property in low infrared emissivity Cu/polyurethane coating. Prog. Org. Coat. 2012, 73, 232–238. [Google Scholar] [CrossRef]

- Liu, Z.; Ban, G.; Ye, S.; Liu, W.; Liu, N.; Tao, R. Infrared emissivity properties of infrared stealth coatings prepared by water-based technologies. Opt. Mater. Express 2016, 6, 3716–3724. [Google Scholar] [CrossRef]

- Zhang, W.G.; Ma, Z.W.; Lv, D.D.; Luo, J.W.; Li, J. An ultra-low infrared emissivity composite coating with outstanding mechanical properties and salt water resistance. Infrared Phys. Techn. 2022, 126, 104351. [Google Scholar] [CrossRef]

- Fantucci, S.; Serra, V. Investigating the performance of reflective insulation and low emissivity paints for the energy retrofit of roof attics. Energ. Buildings 2019, 182, 300–310. [Google Scholar] [CrossRef]

- Pawar, P.G.; Xing, R.; Kambale, R.C.; Kumar, A.M.; Liu, S.; Latthe, S.S. Polystyrene assisted superhydrophobic silica coatings with surface protection and self-cleaning approach. Prog. Org. Coat. 2017, 105, 235–244. [Google Scholar] [CrossRef]

- Satapathy, M.; Varshney, P.; Nanda, D.; Mohapatraa, S.S.; Beherab, A.; Kumar, A. Fabrication of durable porous and non-porous superhydrophobic LLDPE/SiO2 nanoparticles coatings with excellent self-cleaning property. Surf. Coat. Tech. 2018, 341, 31–39. [Google Scholar] [CrossRef]

- Ye, X.X.; Gui, Y.W.; Ke, L.; Gao, K.Y.; Huang, X.; Shi, B. Fabrication of 3D porous superhydrophobic sponges using plant polyphenol-Fe3+ complexes as adhesive and their applications in oil/water separation. Golloid. Surface. A 2018, 551, 9–16. [Google Scholar] [CrossRef]

- Li, C.; Sun, Y.; Cheng, M.; Sun, S.; Hu, S. Fabrication and characterization of a TiO2/polysiloxane resin composite coating with full-thickness super- hydrophobicity. Chem. Eng. J. 2018, 333, 361–369. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, X.; Yan, Y.; Qian, T.; Wang, T.; Sun, J.; Jin, Q. Facile fabrication of a PDMS @ stearic acid-Al(OH)3 coating on lignocellulose composite with superhydrophobicity and flame retardancy. Appl. Surf. Sci. 2018, 450, 387–395. [Google Scholar] [CrossRef]

- Liu, Y.; Li, S.; Zhang, J.; Wang, Y.; Han, Z.; Ren, L. Fabrication of biomimetic superhydrophobic surface with controlled adhesion by electrodeposition. Chem. Eng. J. 2014, 248, 440–447. [Google Scholar] [CrossRef]

- Zhang, W.G.; Zheng, M.Y.; Lv, D.D. Preparation and performance characterization of superhydrophobic low infrared emissivity composite coating. Surf. Techn. 2020, 49, 105–111. (In Chinese) [Google Scholar]

Figure 1.

Schematic for the preparation of the coating.

Figure 1.

Schematic for the preparation of the coating.

Figure 2.

SEM images of coatings with different amounts of dispersant, (a)(c) 0 wt%, (b)(d) 5 wt%, (c) and (d) are partial magnified images of (a) and (b).

Figure 2.

SEM images of coatings with different amounts of dispersant, (a)(c) 0 wt%, (b)(d) 5 wt%, (c) and (d) are partial magnified images of (a) and (b).

Figure 3.

WCAs of coatings with different amounts of dispersant, (a) 0 wt%, (b) 1 wt%, (c) 3 wt%, (d) 5 wt%, (e) 7 wt%.

Figure 3.

WCAs of coatings with different amounts of dispersant, (a) 0 wt%, (b) 1 wt%, (c) 3 wt%, (d) 5 wt%, (e) 7 wt%.

Figure 4.

SEM images of coatings with different amounts of adhesion enhancer, (a)(c) 0 wt%, (b)(d) 4 wt%, (c) and (d) are partial magnified images of (a) and (b).

Figure 4.

SEM images of coatings with different amounts of adhesion enhancer, (a)(c) 0 wt%, (b)(d) 4 wt%, (c) and (d) are partial magnified images of (a) and (b).

Figure 5.

WCAs of coatings with different amounts of adhesion enhancer, (a) 0 wt%, (b) 2 wt%, (c) 3 wt%, (d) 4 wt%, (e) 5 wt%.

Figure 5.

WCAs of coatings with different amounts of adhesion enhancer, (a) 0 wt%, (b) 2 wt%, (c) 3 wt%, (d) 4 wt%, (e) 5 wt%.

Figure 6.

SEM images of coatings with different amounts of defoamer, (a)(c) 0 wt%, (b)(d) 1 wt%, (c) and (d) are partial magnified images of (a) and (b).

Figure 6.

SEM images of coatings with different amounts of defoamer, (a)(c) 0 wt%, (b)(d) 1 wt%, (c) and (d) are partial magnified images of (a) and (b).

Figure 7.

WCAs of coatings with different amounts of defoamer, (a) 0 wt%, (b) 1 wt%, (c) 3 wt%, (d) 5 wt%.

Figure 7.

WCAs of coatings with different amounts of defoamer, (a) 0 wt%, (b) 1 wt%, (c) 3 wt%, (d) 5 wt%.

Table 1.

Optical and mechanical properties of coatings with different amounts of dispersant.

Table 1.

Optical and mechanical properties of coatings with different amounts of dispersant.

| Amounts of dispersant/wt% |

Emissivity |

Glossiness |

Adhesion strength/grade |

Impact strength/kg.cm |

| 0 |

0.585 |

3.0 |

5 |

10 |

| 1 |

0.583 |

4.3 |

5 |

10 |

| 3 |

0.535 |

4.8 |

3 |

15 |

| 5 |

0.538 |

5.0 |

2 |

20 |

| 7 |

0.541 |

5.4 |

2 |

20 |

Table 2.

Optical and mechanical properties of coatings with different amounts of adhesion enhancer.

Table 2.

Optical and mechanical properties of coatings with different amounts of adhesion enhancer.

| Amounts of adhesion enhancer/wt% |

Emissivity |

Glossiness |

Adhesion strength/grade |

Impact strength/kg.cm |

| 0 |

0.538 |

5.0 |

2 |

20 |

| 2 |

0.520 |

5.6 |

2 |

20 |

| 3 |

0.508 |

5.7 |

1 |

25 |

| 4 |

0.508 |

5.0 |

1 |

30 |

| 5 |

0.511 |

6.1 |

1 |

30 |

Table 3.

Optical and mechanical properties of coatings with different amounts of defoamer.

Table 3.

Optical and mechanical properties of coatings with different amounts of defoamer.

| Amounts of defoamer/wt% |

Emissivity |

Glossiness |

Adhesion strength/grade |

Impact strength/kg.cm |

| 0 |

0.508 |

5.0 |

1 |

30 |

| 1 |

0.527 |

4.3 |

1 |

40 |

| 3 |

0.563 |

4.7 |

1 |

40 |

| 5 |

0.582 |

4.8 |

1 |

40 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).