1. Introduction

After the first electrified railways began operating in the United States, corrosion problems were noticed on underground pipes and cables that ran near the railway line. At first, it was thought that the chemical composition of the soil caused this corrosion damage. However, it was soon concluded that soil chemistry cannot cause such serious degradation problems, and after some investigation, it was determined that the current leaking from the running rails (“stray current”) was the main cause of the corrosion problem [

1,

2]. These early electrified railways were not isolated from the ground and did not use rail joint bonding, both contributing to stray current leakage into the ground.

Today, railways in urban areas are operated at DC with voltages that are mostly in the lower range, namely 600V–750V [

3]. There are several systems that operate at voltages of 750V–1500V, usually suburban commuter and city railways. Power is supplied by Traction Power Stations (TPS) to the vehicles via catenary/third rail and pantographs/current collector, and in most cases rails are used as the return current path [

4,

5]. When traction current flows back to the TPS, the longitudinal electrical resistance of the rails causes a voltage drop and thus a difference of potential between the rails and the ground. This rail potential is variable along the track and is generally lowest at the TPS [

6]. Due to inadequate insulation of the return circuit from the ground, current leaks from the rails and reaches TPSs via other parallel paths. This current is referred to as stray current [

7,

8].

Where stray current leaks from metallic structures, corrosion and damage, overheating, arcing, and fires can occur. In an extreme case signaling and communications systems with low noise immunity can be disrupted, endangering people and equipment inside and outside the track or train [

9,

10]. In case of proximity between DC and AC railways, when the signaling system of the latter uses DC relays, stray current from the DC system may couple and cause serious interference [

11,

12,

13].

For corrosion to occur on an electrically continuous metal structure two conditions must be met: the metal must have a different potential on its surface, i.e., anodic and cathodic parts, and the metal must be in contact with an electrolyte. Due to the potential difference between the metal and the conductive electrolyte, electrochemical corrosion occurs. At the anode, iron is oxidized, releasing ferrous ions into the electrolyte, which results in the dissolution or loss of metal [

14], as shown in reaction (

1). The cathodic reaction varies with the type of electrolyte. Reaction () represents the reaction that occurs in a neutral or alkaline electrolyte and reaction () occurs in an acidic electrolyte [

2]. The electrochemical cell is set up between anodic and cathodic sites.

Stray current corrosion is an electrochemical process involving anodic and cathodic reactions occurring simultaneously, caused by external voltage sources [

15,

16]. Stray current corrosion occurs at the point where current leaves a conductor and passes into an electrolyte. Urban railways are a common source of stray current because of the longitudinal rail resistance in combination with large traction current intensity, and low rail-to-ground insulation resistance

[

17]. The dynamic nature of the stray current generated by DC traction systems is due to the changes in the potential between rail and ground in the track. These variations are influenced by the acceleration and deceleration of transit vehicles and by the number and location of vehicles in the system [

18,

19,

20].

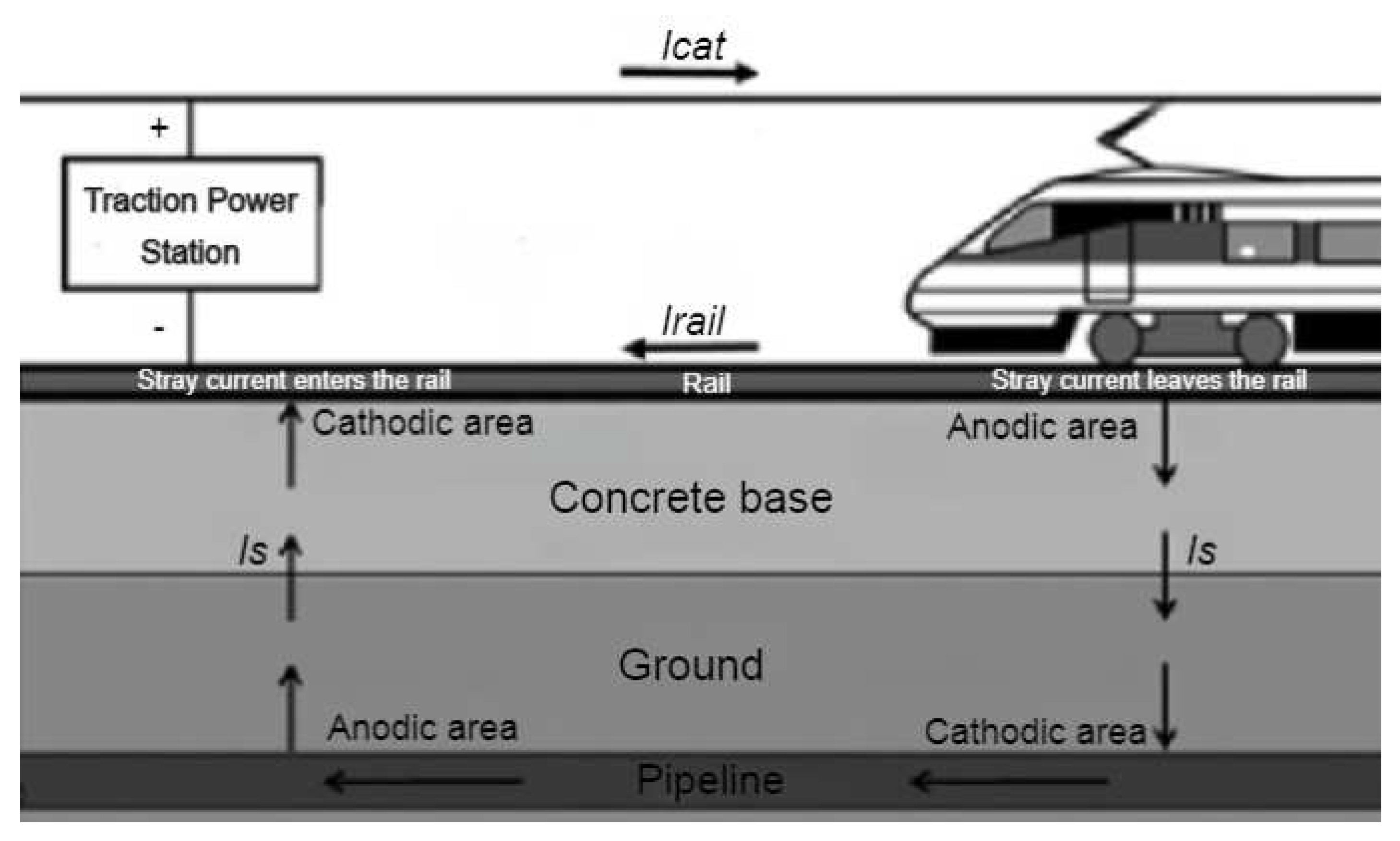

The current leaks from the rail to the ground due to potential (voltage) between the rail and ground caused by vehicle movement on the rails. This voltage drop forces the current to leak from the rail and flow into the ground or into an underground metallic structure [

21]. Two areas can be identified in relation to stray currents: the cathodic area is where the current enters the metallic structure from the ground, and the anodic area occurs where the current leaves the metal and enters the electrolyte. In an anodic region, dissolution of the metal occurs, and the metal loss can be calculated using Faraday’s Law [

22]. The stray current circuit for a concrete track slab is schematically shown in

Figure 1.

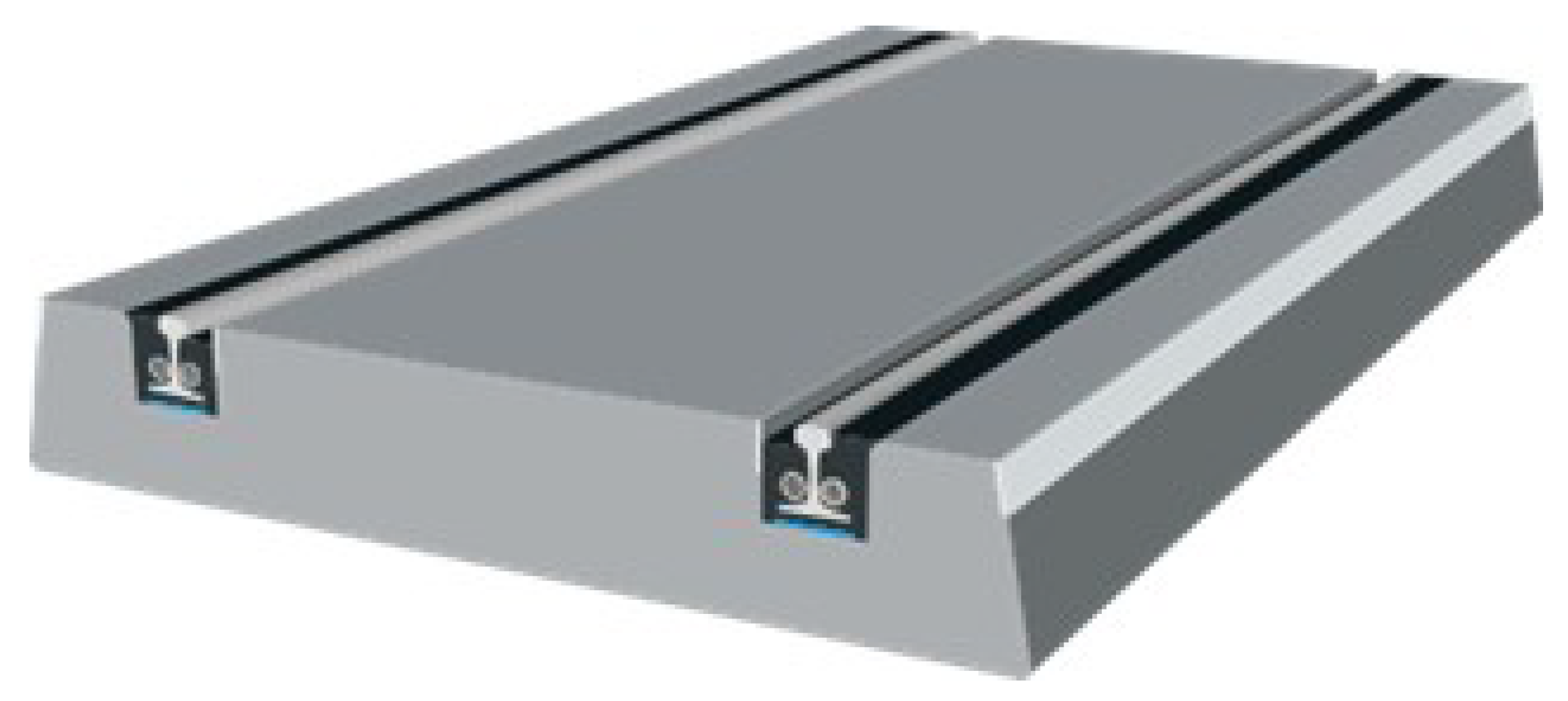

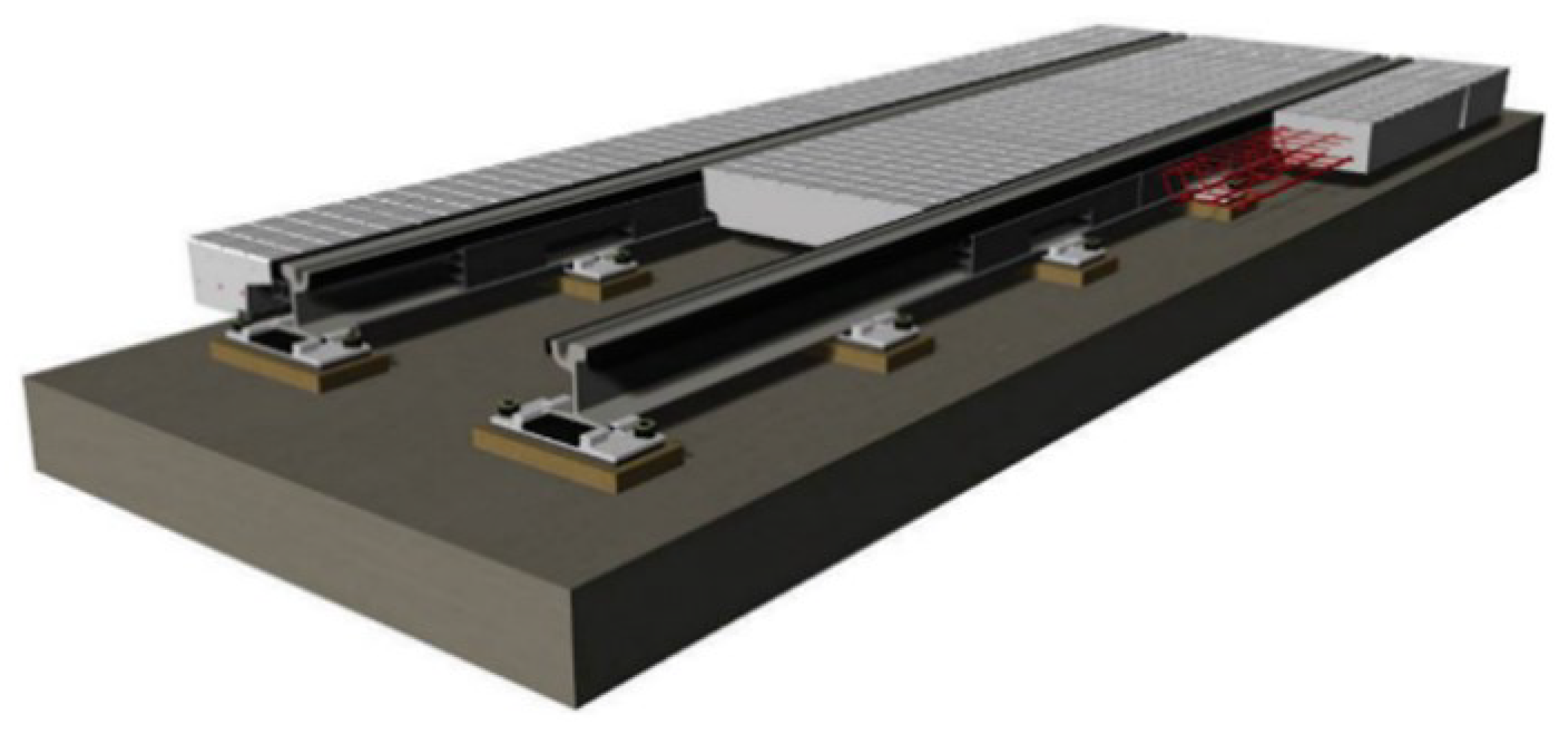

The amount of stray current generated by rail transit systems depends largely on the type of track, the insulation of the rail, the insulation of the fastening system, the maintenance of the track, the distances between TPSs, the grounding systems of the track, the types of vehicles and driving style, etc [

6,

17]. Corrosion is noticed on rails and fastening system components on many urban railway tracks worldwide and is a topic of a significant amount of research. If rails are completely insulated (as in tracks with continuously fastened rails, where elastic material provides continuous rail support and isolation, see

Figure 2), corrosion of the rail is in principle prevented. But in the tracks with discretely laid and fastened rails (shown in

Figure 3), it is hard to completely insulate the rail and fastening systems so corrosion processes are inevitable. When tracks are located in the coastal and marine environment or built on street sections (where salt mix is used to prevent freezing during the winter), these harmful conditions increase corrosion rate. Also, sunlight, relative humidity, temperature, and atmosphere largely affect corrosion [

24]. Wet conditions are especially pronounced in tunnels and in closed formations.

The most common type of corrosion in urban railway tracks is stray current induced corrosion, where direct current leaks from the rail and metallic components of the fastening system to the supporting structure, through accumulated soil and water, resulting in large material losses for the rail and fastening system [

2].

Corrosion forms of rail tracks can be divided into general corrosion, which normally takes place on large rail surfaces and localized corrosion. The typical form of localized corrosion on rail is crevice corrosion and in most cases, it can be noticed between the elastic clip and rail foot or rail foot and elastic rail pad, where the accumulation of corrosive media including chloride ions and maybe microbes can easily take place, initiating crevice corrosion [

24]. The rail foot has the thinnest cross-section and is the only part of the rail that comes into contact with the fastening system, so thinning of the rail foot due to corrosion processes can be very dangerous [

24,

26]. According to [

27] corrosion typically causes very intricate defect shapes growing in unpredictable directions and forming sharp angles and corrosion pits. These defects cause stress concentrations under loading which can accelerate crack initiation and causes fatigue failure [

28].

The effects of stray current on rail and fastening system components are discussed in [

29], where several rail samples fastened to the concrete base using different types of fastening systems were immersed in water and stressed by applying a DC voltage, simulating unfavorable conditions when water remains in the track due to inadequate track drainage. It was concluded that stray current causes localized damage to the rails and fastening system components, particularly the clips. The thinning of their cross-section occurs at the points with the highest stress concentrations due to traffic load (as analyzed in [

30]), so it is inevitable that the clips break during the service life, which means that the rail is no longer fastened to the base. When such a break occurs on a closed track formation built on street section where road and rail vehicles share the same driving surface, it is not noticed until the track is opened, so traffic safety may be compromised.

A track corrosion survey in subway tunnels was carried out and analyzed in [

31], where corrosion severity was rated on a numerical scale for rails and components of the fastening system. In this paper, the presence of stray currents was also evaluated by using the Lateral Gradient Technique (LGT). The potential was measured between the embedded reinforcement and the concrete surface. Corrosion has been found to be most severe where the soil has accumulated and bridges the electrical insulation between the rail, or fasteners, and the concrete surface.

In conclusion, corrosion can cause severe degradation of the rails and the fastening system. For this reason, it is essential to immediately prevent corrosion and stray current when building or reconstructing track systems.

Some operators have recognized the danger that stray current poses to the infrastructure and set out in their guidelines the parameters that must be adhered to in order to reduce and control stray current phenomena and thus extend the service life of the track system.

This work proceeds through existing guidelines and prescriptions in

Section 2, commented for completeness, adequacy and effectiveness, and then goes into the details of suggested measures to adopt during design, discussed in

Section 3.

Section 4 provides recommendations on which measures to apply when building tracks with continuously fastened rails and which to apply when building tracks with discretely supported and fastened rails. Main conclusions are presented in

Section 5.

2. Overview of Guidelines and Standards for Stray Current Limitation

The most important measures to reduce stray current on track structures are to increase the track-to-ground resistance

(sometimes expressed in terms of conductance

) and reduce the designed longitudinal electrical resistance

of the running rails [

10,

32]. Track-to-ground resistance

can also be expressed as rail-to-ground resistance

, where:

[

33].

Because of the many different types of track structures, there are no uniform measures to achieve a high value. Some operators have defined limit values for and established guidelines on how to achieve and maintain such values. In this section an analysis of the guidelines applied to different infrastructures is carried out and providing a general overview of the typical requirements.

According to the standard EN 50122-2 [

34] the most important parameters for the magnitude of stray currents are:

conductance per length of the tracks and the other parts of the return circuit;

the distance between TPSs;

the longitudinal resistance of the running rails, when used for the traction return current flow;

spacing of cross bonds.

In the EN 50122-2 it is stated that experience has proven that there is no damage in the tracks over a period of 25 years if the average stray current per length does not exceed mA/m of a single track line. According to this standard, if the following values of rail-to-ground conductance per length are not exceeded during the system’s lifetime, it is not necessary to conduct further investigations:

where

indicates the track potential, having subtracted the off potential (usually negligible, as discussed in [

35]).

In the design guidelines for the new LRT in Edmonton, Canada [

36], it is required at Chapter 13 the designer to prepare a stray current mitigation plan and a stray current survey for the new track construction. The stray current mitigation plan must specify stray current control requirements, identify infrastructure to be considered in the stray current design, and include verification and validation requirements. The purpose of the stray current survey is to establish a baseline for the prevailing stray current phenomena prior to construction. The primary focus of the stray current design should be mitigating the stray current at the source: where a large

cannot be achieved, additional measures to protect adjacent conductive structures must be considered. The suggested measures are the use of high-insulation materials for the track and protective coatings for isolation from ground for conductive structures as possible victims of stray current.

We can say that high values can be achieved by using high-resistivity ballast materials with adequate drainage, grading, and appropriately designed insulating track fastening devices. An insulating resin bed or an insulating inter-layer between the track and the bearing system, such as a rail boot, must be provided for closed track. Adequate drainage, both on the surface and in the substructure, is required to avoid water stagnation that could affect the rail insulation.

Also the guidelines produced for the Valley Metro project in Arizona [

37] set forth a set of requirements for stray current and corrosion protection: minimum

values are indicated for different types of track systems, and they are altogether presented in

Table 1 at the end of the section. For ballasted track and direct fixation track construction, the minimum

is 500

per 1000 ft (

m) and for the embedded track is 250

per 1000 ft (

m), recognizing as commonplace a larger leakage for embedded tracks laid down with traditional construction systems. However, the guideline requires that all embedded rails must be encased in insulating boots extended to the top of the concrete on both rail sides to prevent stray currents.

The design criteria for the Central Corridor LRT in Minnesota [

38] also address corrosion control measures, clarifying the necessity of control at the source under all normal operating conditions, rather than attempting to mitigate the harmful effects on other transit facilities and underground structures. Not only, as obvious, direct or indirect electrical connections between the positive and negative traction circuits and the ground are forbidden, but TPS separation is required so that track voltage does not exceed 50 V during normal operation. This 50 V, in contrast to a commonly accepted 60 V or higher for railway applications [

39] was commented in [

40] as commonplace when electrical safety prevails on stray current protection and 50 V is enforced in particular in the US as a safety measure at the workplace. Limits on track-to-ground voltage are also specified in the standard EN 50122-1 [

39], where the allowable values are much higher than traditionally allowed in North America. The higher track-to-ground voltage results in a higher stray current for the same track-to-ground resistance, which must be taken into account when determining rail-to-ground resistance that the track must meet.

The level of stray current is also required to be checked by simulation against suitable

values, distinguishing the various types of track and rail fixation systems and having determined local soil resistivity values distributed along the alignment (every 500 ft (

m) for the first meters of soil depth). Another requested result of the simulations should be the expected soil potential gradient values. The different track construction types have specific

requirements: 250

per 1000 ft (

m) for direct fixation track construction and 100

per 1000 ft (

m) for embedded and ballasted track (also reported in

Table 1 below). To allow reaching the necessary

values, appropriate insulating track fastening devices should be used, such as insulated sleeper plates, insulated rail clips, direct fasteners, rail boots, or other approved methods.

In [

41] it is observed that the degree of insulation between the rails and the ground is necessarily a compromise between the need to control step and touch voltages and the need to limit stray current leakage. The isolation level between the ground and the rails is required to be at least 10

/km for the tunnel and 2

/km for the open area of a single-track section under normal operating conditions (not too different from the prescribed limits in the EN 50122-2 [

34]).

These guidelines consider an overall approach for stray current protection and monitoring at the track, including at least the following:

isolation or control of all possible stray current leakage paths to minimize stray current effect on the system and adjacent structures;

detection and monitoring of stray currents;

stray current collection system.

A general prescription is given to experimentally verify insulation level of each track section during design.

The stray current management guide [

42] provided by UK Tram (a non-profit association of tramways, metros and other similar mass transit systems of the former Great Britain), remains on the same lines indicating good track insulation and low track voltage as the two key factors to reduce stray current. The former can be achieved by frequent feeding points reducing TPS separation and the distance over which the return current must flow. However, reducing the TPS separation incurs a significant financial impact. This is one of the problems with the relatively high voltage limits that can cause shock hazards and stray current is usually a secondary problem.

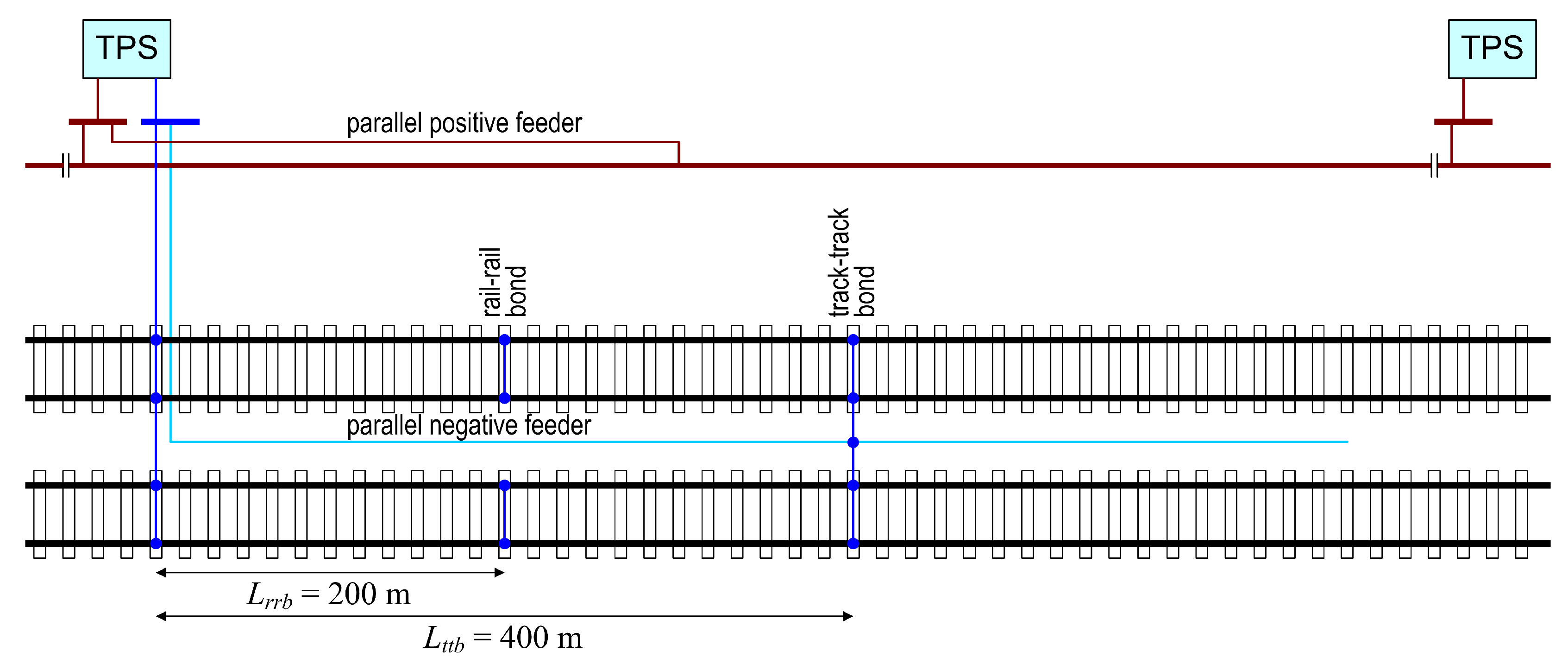

Rails should be continuously welded, and frequent cross-bonding between rails should be provided, providing multiple parallel paths for the return current, making maximum availability of return conductor capacity and additionally ensuring redundancy in case of a failed bond, or rail discontinuity.

The prescription for the advisable separation of rail-to-rail and track-to-track bonding points is 200 m and 400 m, respectively, and this aspect will be discussed later in

Section 3.5. The actual adequate spacing for each type of bond should be an outcome of a rail potential study and must be determined during the design phase of the track construction. The measures to increase the rail-to-ground resistance depend on the type of track. These provisions mainly concern the insulation of the fastening systems, the use of intermediate layers, the use of concrete sleepers, ensuring a clean and well-drained ballast, etc.

Also, NASA and the US Dept. of Transportation [

43] considered the problem of stray current and its control almost 50 years ago, focusing in particular on preventing the worsening of stray current levels in older systems, when stray current control was not part of the design. The suggested approach is first and foremost to clean and maintain the track and to monitor its conditions:

special attention should be given to track cleanliness: debris and dirt should not be allowed to accumulate on the track;

any corrosion damage should be investigated immediately, by measuring local stray current and measures should be taken to control it;

several maintenance procedures should be followed: tests should be carried out in cooperation with third parties (e.g. utilities and structures owners) to ascertain undue impact on underground metallic structures

Tests were prescribed to be conducted with owners of third-party structures to ensure that operation of the transit system does not affect potentially exposed underground conductive structures. The structure impressed potential should be observed to evaluate stray current conditions and the effectiveness of cathodic protection systems. However, no clear prescription with limits or reference levels was given, and this is a general weak point of corrosive situation assessment: limit values in fact depend on the type of soil, the environmental conditions, and also the type of metal the structure is made of.

Table 1.

Allowed value of track-to-ground resistance in defined in the analyzed guidelines.

Table 1.

Allowed value of track-to-ground resistance in defined in the analyzed guidelines.

| Type of the |

Valley Metro, |

Central

Corridor LRT, |

Dubai Metro, |

| track construction |

Phoenix, AZ [37] |

Minneapolis, MN [38] |

UAE [41] |

| Ballasted track |

1.64 |

0.33 |

– |

| Embedded track |

0.82 |

0.33 |

– |

| Direct fixation track |

1.64 |

0.82 |

– |

| Track in tunnel |

– |

– |

0.01 |

| Track in open area |

– |

– |

0.002 |

3. Measures for Reducing Stray Current When Designing New Track Corridors

When designing new track corridors in urban areas or when the track reconstruction is planned, stray current prevention should be anticipated. When determining corridors for new tracks, consideration must also be given to the location of existing buried metallic infrastructures that could be affected by stray currents. Suppose pipelines are laid parallel to planned track construction: in this case the severity of stray current will depend on the distance between the pipeline and the track because the electrical resistance of the soil through which the current flows increases with distance. If the pipeline is laid perpendicular to the planned track, the stray current severity is determined by the smallest distance between the pipeline and the track which is analyzed in [

18].

Due to limited space and many underground infrastructures, it is almost impossible to define a new corridor for track construction in such a way that stray currents do not endanger nearby metallic structures, so limit values must be identified. The amount of track leakage current and the way it is distributed at the interface between the rails and infrastructure highly depends on the construction technique, the interfacing elements and suitable isolation techniques, such as non-conductive pads and bituminous layers [

12], which is defined by the type of the track.

The location of the tracks also affects the value of the stray currents. For example, if the tracks are located in a marine environment, the presence of chlorides reduces rail-to-ground resistance. Tracks built on street sections are also exposed to salts, which are used in the winter months to prevent the pavement from freezing. Since closed tracks dry very slowly, the track is wet most of the year, resulting in lower electrical resistance values, which also applies to tracks located in tunnels, subways, etc. These are the main reasons why there is no uniform value of rail-to-ground resistance that must be fulfilled to prevent stray currents. Furthermore, due to many influences, rail-to-ground resistance will vary greatly during service life of the track.

3.1. Types of the Track and Electrical Resistance of Fastening Systems

When choosing the type of track, rail-to-ground resistance should be one of the parameters that the track must meet. Different methods can be used for the different types of tracks to prevent stray currents and achieve a high rail-to-ground resistance. Tracks can be divided into two groups:

The main difference between these two groups is that in tracks with continuously fastened rails, rails are placed in paved slabs and supported continuously by an elastic compound. In contrast, in tracks with discretely fastened rails, rails are fastened at regular intervals using different types of fastening systems [

44].

In tracks with continuously fastened rails, rail is laid in a longitudinal recess created in the base structure and poured out with elastic embedding material. Rail fastening is realized by the contact of the embedding material with the rail and the recessed surface, which ensures complete insulation of the rail and a high value of rail-to-ground resistance [

45]. In tracks with discretely laid and fastened rails, more attention should be paid to rail-to-ground resistance, especially when the tracks are built on street sections. In this type of track, the rails are not completely isolated, and many parameters affect rail-to-ground resistance. The most important ones are the type of fastening systems, whether the track is open or closed, the maintenance of the track, the distance between the rail and the adjacent metallic structure, etc.

During the service life of the track, the most important is keeping the track dry and well-drained to prevent contact between the rails and the electrolyte, i.e. the water that remains in the track. During track construction, anchor bolts cannot cut the reinforcement bar or be in contact with the reinforcement bar in the concrete base slab [

46]. When effective drainage is provided in tracks with discretely fastened rails and the rails are not in contact with the electrolyte, each fastening system provides a spot resistance to ground [

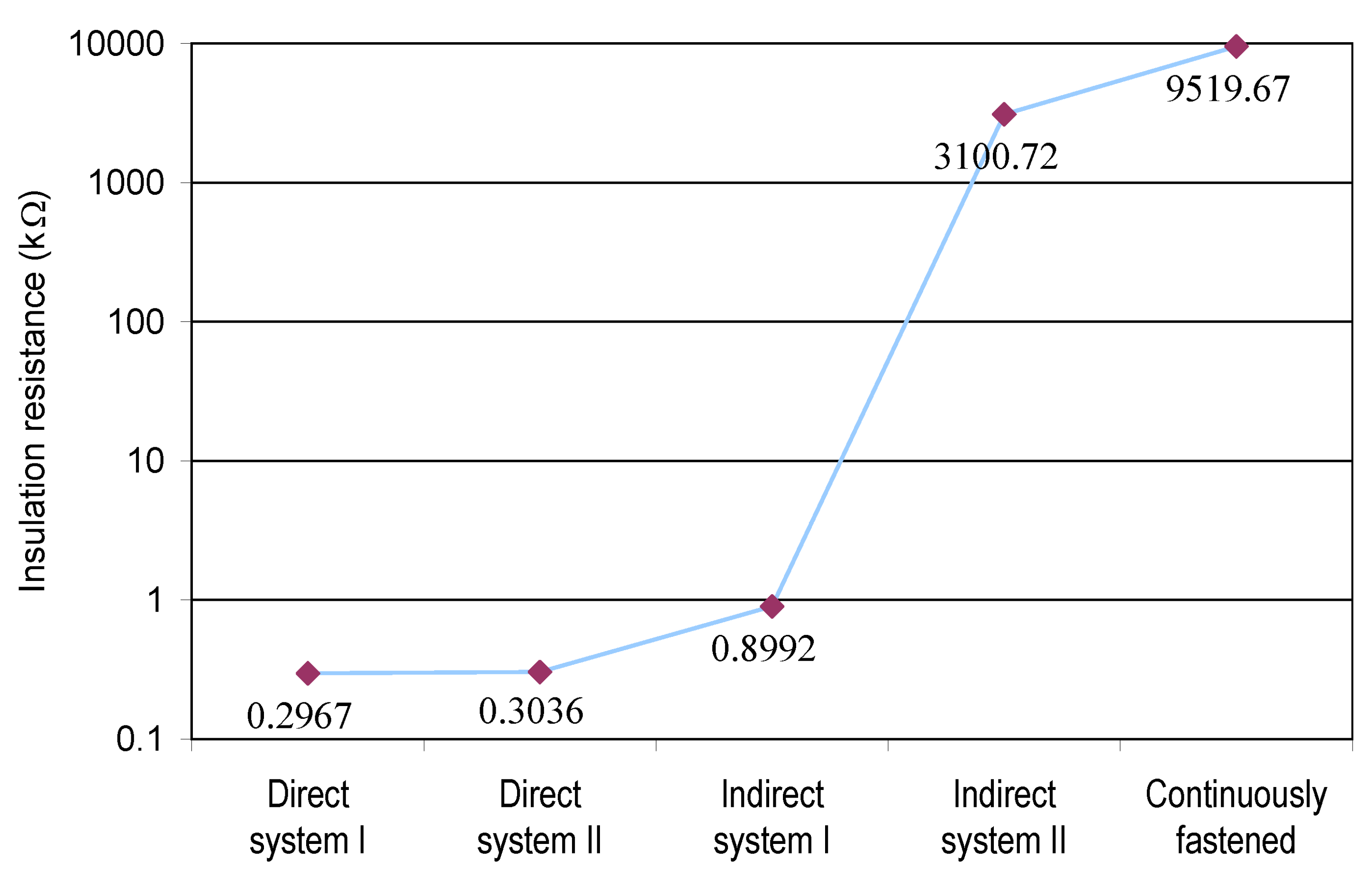

47] so by using appropriate type of the fastening system rail-to-ground resistance can be increased. The electrical resistance of five different types of fastening systems on concrete base is analyzed in paper [

48]. The results show that the electrical resistance of indirect fastening systems is significantly higher than resistance of direct systems, with an incomparably higher electrical resistance value found in the sample of continuously fastened rail (

Figure 4).

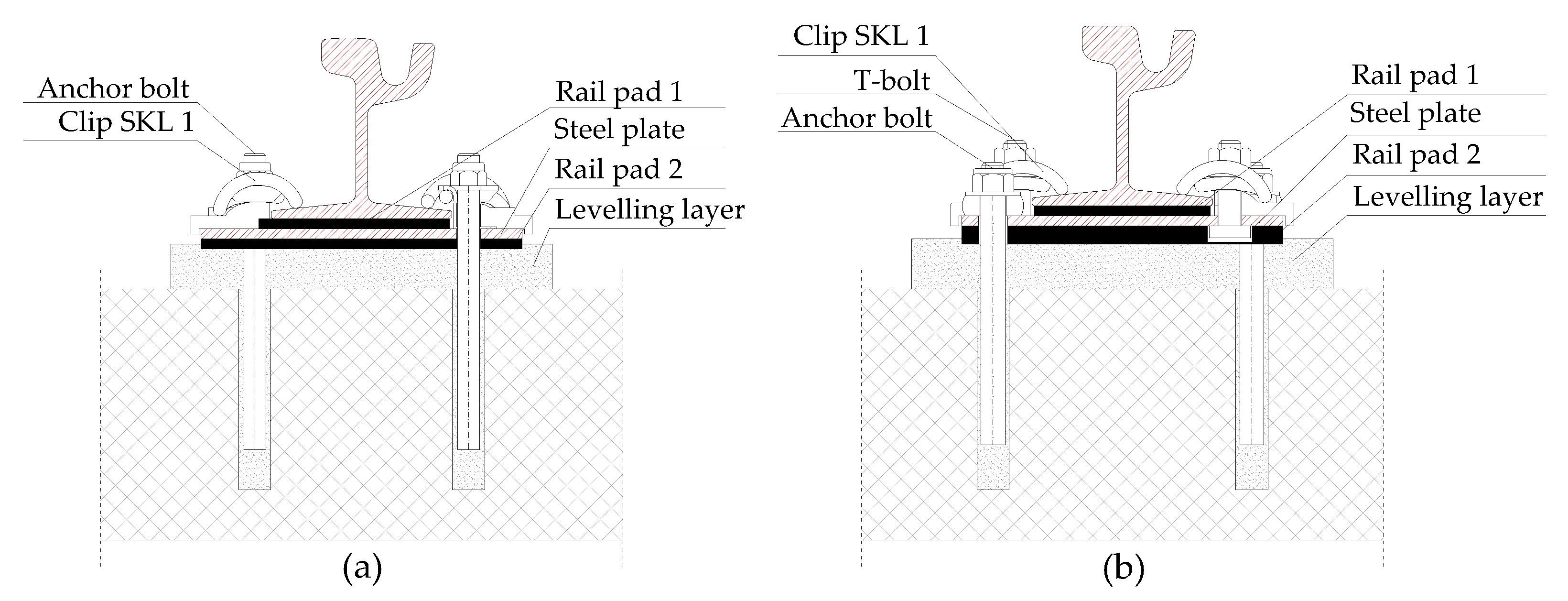

These direct and indirect fastening systems are characteristic of tracks with discretely supported and fastened rails, in which the rail is supported by an elastomer pad on a steel base plate laid on a concrete base. In direct systems, the rail is fastened with clips and anchor bolts. The anchor bolts provide anchorage of the fastening system in the concrete base (

Figure 5). In the indirect systems, the rail is fastened to the steel plate by means of clips and T-bolts, and the anchor bolts are separate and serve only to anchor the steel plates in the concrete base (

Figure 5). In the direct fastening system, all elements are in direct contact and the clip is in contact with the rail, which is why the current flows from the rail into the concrete base. In indirect fastening systems, higher electrical resistance is achieved by insulating the anchor bolts from the steel base plate.

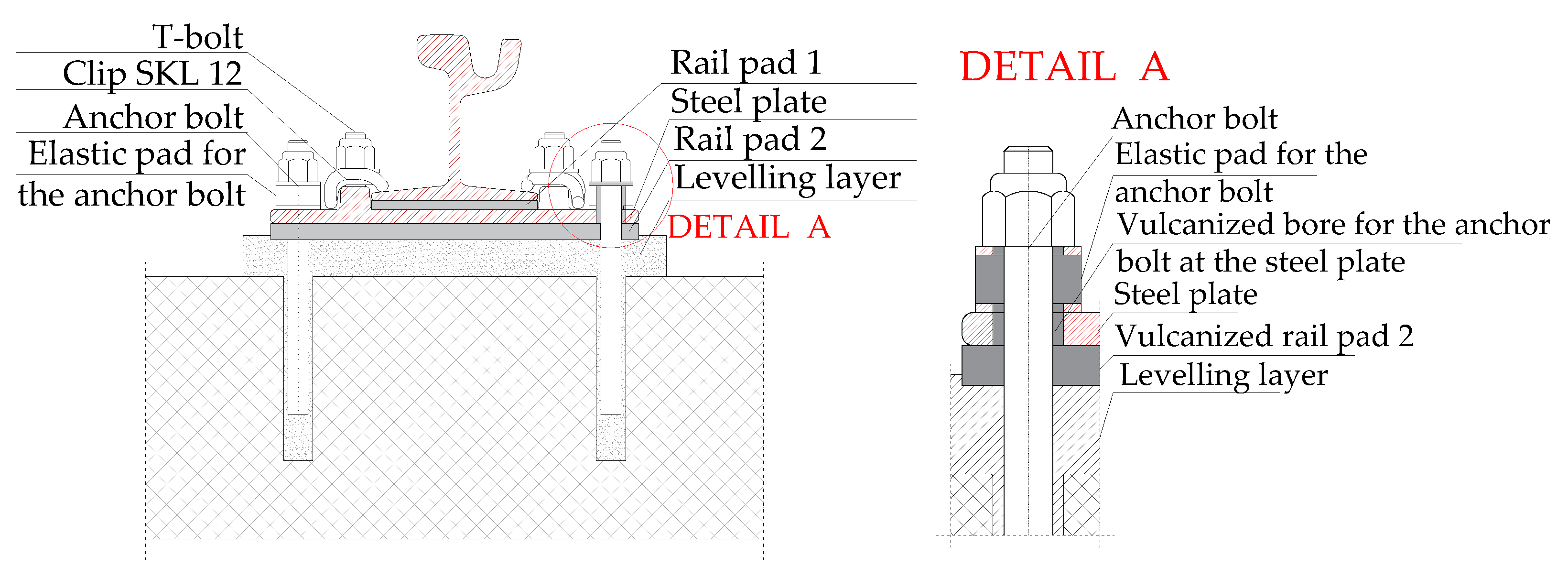

A good practice example of an isolated fastening system is the Zagreb 21-CTT indirect fastening system, which was developed for the tram infrastructure in the city of Zagreb (

Figure 6). In this system, special care was taken to prevent contact between the steel base plate and the anchor bolt, which was ensured by vulcanizing the steel base plate and designing a special elastomer pad for the anchor bolt, whereby the elastic material used for vulcanizing the plate and manufacturing the pad had to meet high values of electrical resistance. In the laboratory measurements of the electrical resistance of the fastening system on a concrete base, the electrical resistance was more than

k

[

49].

Based on the results presented in [

48] it can be concluded that in order to prevent stray currents, it is necessary that the metallic components of the fastening systems are not in direct contact with the rail, so to prevent current leakage through the fasteners into the track base. This can be achieved by the use of insulating pads between the rail and the clip or by preventing contact between the fastening system components and the track base, i.e., by insulating the anchor bolts in indirect fastening systems like in Zagreb 21 CTT fastening system. The value of the electrical resistance of the elastomer elements must also be specified, as it may vary greatly depending on the additives added to the raw rubber during the vulcanization process. Two types of elastomers are generally used for slab track systems, rubber compounds and chloroprene [

46].

Speaking of volume resistivity specification for the elastomer elements, with a requirement of

in (

m) fastener stiffness would be compromised. The upper electrical resistance limit of compounds containing carbon black is

in (

m). Compounds containing carbon black must be avoided if very high resistance is required and, in this case, silicone elastomers would have the required electrical insulation performance but poor stiffness properties [

46]. If the fastening system selected for the new or reconstructed track does not have a specified electrical resistance value, it is recommended to carry out some laboratory measurements. A laboratory test method for determining electrical resistance under wet conditions between running rails provided with a fastening system fastened to a concrete sleeper is described in the standard EN 13146-5 [

50]. The paper [

48] describes the possibility of applying such laboratory test to measure the electrical resistance of fastening systems used in urban railway tracks and to evaluate its impact on the stray current.

According to [

46] the minimum resistance of one fastener at 500 Vdc shall be 10 M

when dry and 1 M

when wet. According to [

48] a minimum value of electrical resistance of the fastening system can be calculated using Ohm’s law, where I is the maximum value of stray current that will cause no degradation on the track in the period of 25 years (defined for example in standard EN 50122-2 [

34]) and U is the average value of rail-to-ground potential.

3.2. Track Bed Design

As seen, the running rails and the fastening system are the first and most important elements of the train supporting structure that ensure stray current control if the insulation level is adequate. If rails are not properly insulated (e.g. when structural robustness exigencies prevail or for a matter of reasoned cost containment), the electrical resistance of the track bed has a greater influence on stray current. In [

51] it is stated that the resistivity of the material the rail is laid on does not have an effect on the stray current leakage density until the rail coating resistivity drops significantly lower than 100 k

m. The determination of a threshold value is not reasonably accurate in view of the variability of the various parameters and environmental conditions: a great influence comes from the expected resistance of the track bed that in turn depends on the construction technique, and in particular on the use of structural reinforcement and waterproofing membranes.

Designing the track bed with proper insulation layers can isolate the track from the ground. This prevents the flow of stray currents into the ground, minimizing their impact on nearby structures or underground utilities.

In slab tracks rail-to-ground resistance can be increased by using concrete with a higher electrical resistivity. The electrical resistivity of concrete can vary greatly and depends on the moisture content, temperature, and concentration of salts dissolved in the water that remains trapped in the cement pores [

52]. In [

53], an analysis of various parameters of slab track concrete was studied, and it was found that reducing the water-binder ratio, adding mineral admixtures, and limiting the air content are important engineering approaches to provide concrete with higher electrical resistivity. The research came with advisable reference values: the water-binder ratio of slab track concrete should be less than 0.31, the air content should be less than 4 % and the mineral admixtures used in the concrete should have low electrical conductivity.

Care should be taken to ensure that the track bed has an effective drainage system to prevent the accumulation of water and moisture. Water can increase the conductivity of the track bed, increasing the likelihood of stray current of relevant intensity. Proper drainage helps minimizing the risk of stray current corrosion: suitable cant, compatible with train stability, ensures that water drains away from the fastener.

Insulating elements, such as rubber mats or other synthetic materials, can be used to create a barrier that restricts stray currents from leaking through the track bed. Such elements are usually used for other reasons than simply electrical insulation: water tightness and vibration control, the latter quite common to reduce the impact of the transportation system in a densely urbanized context. More in detail, insulating mats under the concrete base in the slab track can reduce the stray current on the rest of the system and third parties, as well as waterproofing membranes surrounding an entire excavated or bored tunnel. Under sleeper pads and under ballast pads can also increase rail-to-ground resistance and reduce stray current in ballasted tracks.

3.3. Traction Power Station (TPS) Separation

A shorter TPS separation reduces the length of the positive and negative circuits connected to the running trains, reducing the voltage drop in the rails and the amount of stray current [

54]. Substations are usually located near a passenger station, which provides an additional advantage in reducing stray current because the current demand of trains is highest during acceleration, while keeping the voltage drop in the return circuit low due to the short track length [

51,

54]. Distributing the TPSs more closely along the line increases the number of TPSs for which the cost is not determined by the deployed power (a larger number of smaller TPSs), but by a range of electrical and non-electrical factors: a TPS requires circuit breakers, switches, monitoring and control whatever its size, so that, simply speaking, a 1 or 2 MW rectifier group has almost the same impact on the overall cost; in addition the construction of a TPS requires road access, appropriation costs, availability of a Medium Voltage feeding point [

10]. In urban areas, available space is often limited, making it challenging to position and build TPSs [

55]. Thus TPS separation is subject to trade-offs bringing the optimized span at about 2km–4km for urban and metro systems.

Construction and maintenance of TPSs can cause disruptions to the urban transportation network. The TPS location should be carefully planned to minimize impacts on road traffic flow and to provide convenient access for maintenance and emergency personnel. This consideration is particularly important in areas with high commuter volumes and complex transportation networks [

56]. Junctions with branched lines, as well as multiple tracks, typically require a larger installed power compared to straight sections and have a more complex power distribution diagram, including additional circuit breakers and disconnectors. The coordination of protections as well is more complex in terms of selectivity and switch on/off and isolation maneuvers. In general in such cases longer feeding lines are necessary, increasing voltage drops, both for the catenary/third rail system (lower available voltage) and for the return circuit (higher track potential and lower available voltage).

3.4. Traction Return Grounding Scheme

When selecting and designing the grounding schemes for a DC transit system a number of factors must be taken into consideration [

57], mainly electrical safety for touch voltage and minimization of stray current. Although an ungrounded solution minimizes stray current, grounding should be provided to keep track voltage under control and prevent high voltage potential that might threaten personnel and equipment safety [

58,

59].

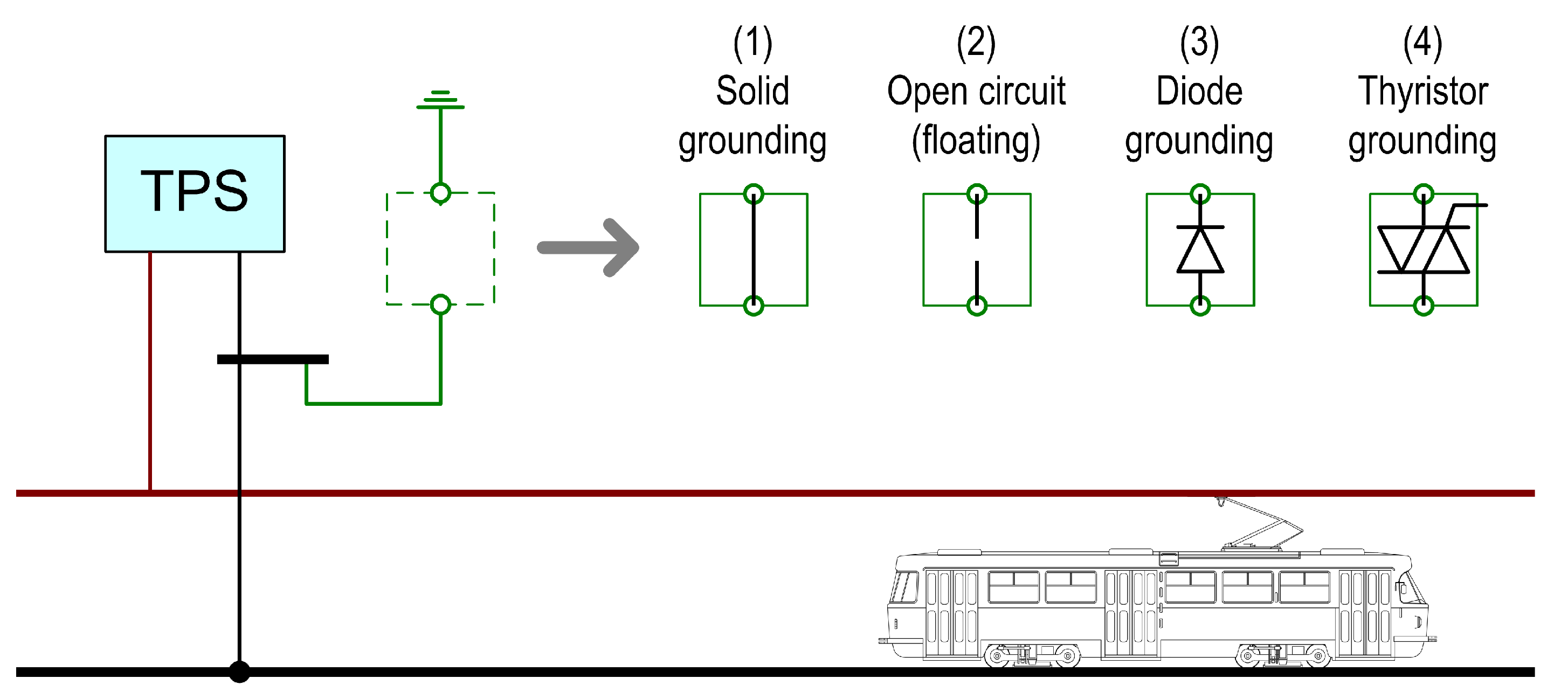

The grounding schemes for DC transit systems mainly include the solidly grounded scheme, floating scheme, diode grounded scheme, contactor/switch grounding or thyristor grounding [

10,

59,

60,

61]. Such grounding schemes are schematically shown in

Figure 7.

More in detail the four introduced schemes can be described as follows:

In the solidly grounded scheme, the TPS negatives are grounded without interposed impedance to ensure zero potential of the TPS and to meet safety requirements. This scheme permits stray currents to flow unregulated between the negative bus of the TPS and any underground metallic path in the vicinity [

51,

62]. In addition, large currents may flow through the rails between different TPSs due to the unavoidable ground potential differences, as caused for example by using different utility Medium Voltage feeding points.

In the floating scheme, the TPS negatives are not connected to ground, reducing stray current, but increasing the rail potential at the TPS and elsewhere. As known, at the trains locations the track potential will be maximum [

63]. Such potentials may result in a hazard for passengers, so that for safety reasons a protection mechanism must be adopted by all means. The permissible touch voltage levels are indicated first of all in the EN 50122-1 [

39], that allows a variable threshold depending on duration, but may be subject to additional local regulations (such as a constant 60 V or 50 V independent of the time factor), as discussed in [

40]. A compromise is usually achieved by setting active voltage limiting devices (VLDs), as described below.

In diode and thyristor grounding schemes, the connections between the negative terminal of the TPS and ground are made by diodes (or thyristors). When the diodes or thyristors are on, the diode and thyristor grounding schemes are the same as the solidly grounded scheme, otherwise they are the floating grounded scheme. The diode and thyristor grounding schemes can therefore be considered a combination of the grounded and floating schemes [

59,

62], or in other words a selective grounding scheme only for positive track potential. Stray current collection mats located at regular intervals under the tracks are also connected with a diode through the longitudinal stray current collection cable [

10].

The risk of dangerous electrical potentials in ideally ungrounded schemes can be reduced by using VLDs, also named overvoltage protecting devices (OVPDs), and stray current drainage devices (DD) [

6,

13,

51,

64]. VLDs are usually installed at the TPS and at passenger stations, distinguishing between type F and type O devices, the former being able to withstand short-circuit fault situations [

54]. A VLD is an active device with different construction principles depending on the normal and fault current intensity it must withstand and if a lighting surge protection function is associated to it (from which the term OVPD is more suitable to describe it). They can be built on a semiconductor device of the thyristor type or still based on electro-mechanical units for heavy use.

If the rail potential exceeds a prescribed limit, the VLD goes in short-circuit state and connects the protected conductive part (e.g. the running rails themselves) to the ground reducing the potential. In this situation, the DD is activated to drain the current in the stray current collection mats back to the TPS [

6,

13]. VLDs have high-impedance state in normal conditions, providing as a matter of fact an ungrounded system, thus minimizing stray current, and preventing long-term corrosion on third party infrastructure as well [

13].

Since the objective of VLDs is to control (and reduce) the track potential to ground and that potential is caused by the traction return current flow, another solution is to drain the return current on an auxiliary conductor. The most obvious and straightforward solution is to run large insulated conductors in parallel to the running rails, possibly interconnecting intermediate points between TPSs directly to the negative terminals of the TPSs themselves, as it is done for the positive feeding points (see

Figure 8). The necessary cross section is evidently large as it should be comparable to that of the running rails themselves, roughly equivalent to more than 1000 mm2 for each track.

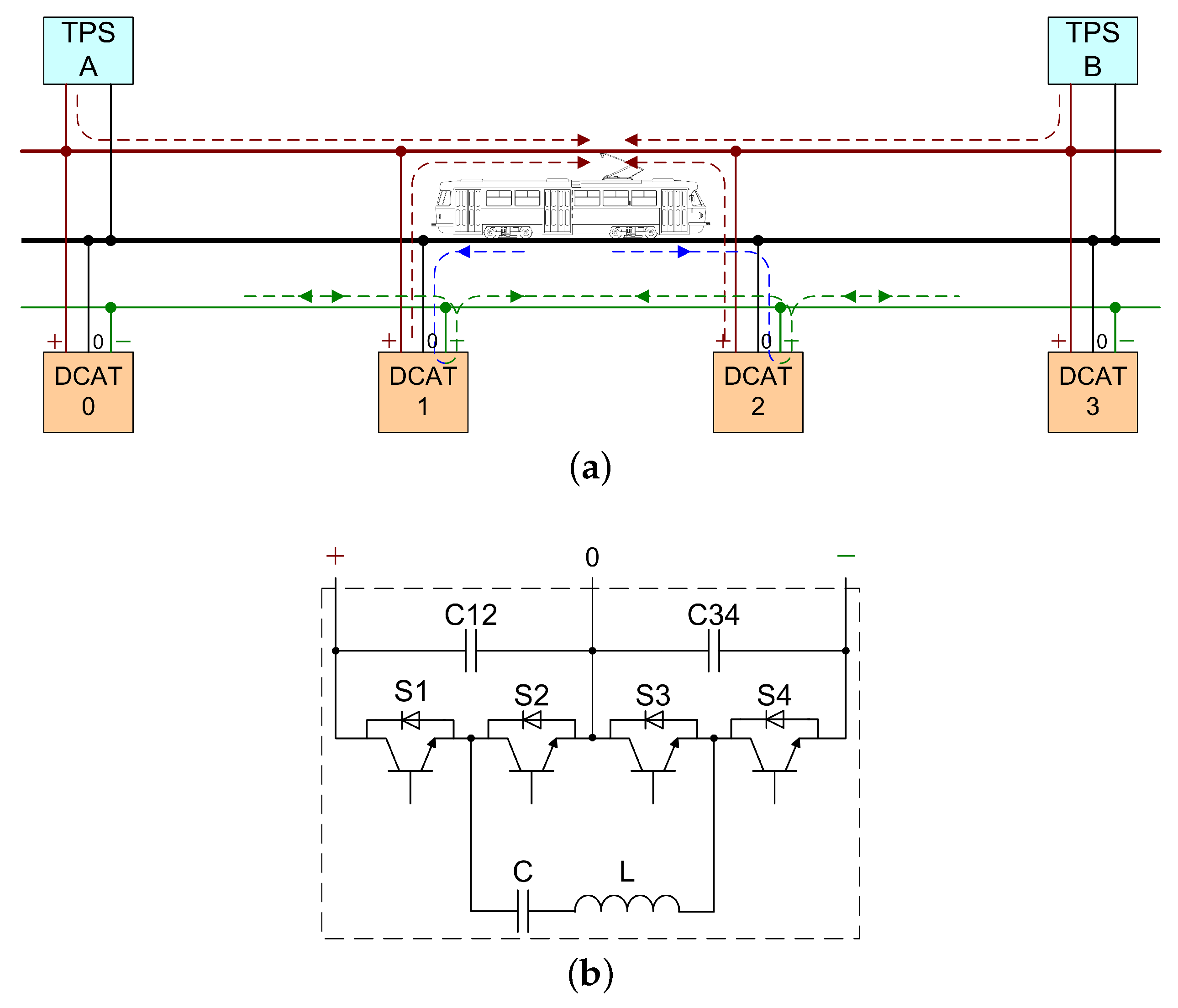

The DCAT (DC AutoTransformer) system proposed in [

59] is effective in driving away from the running rails the current returned by the train (that is always and only in contact with the running rails through its wheels), as soon as that return current reaches one of the DCAT devices distributed along the line. Since the only relevant voltage drop becomes the one for the section between two DCATs where a train is located, the overall longitudinal voltage drop along the whole length between two TPSs is reduced: the larger the number of DCATs the lower the resulting voltage drop. The connection scheme is shown in

Figure 9(a).

The DCAT operation is based on a three-terminal device connecting the catenary (plus terminal), the negative external return conductor (minus terminal), keeping the track at a nearly zero potential (zero terminal). The balancing is achieved by an active semiconductor-based balancing bridge with a resonant circuit (shown in

Figure 9(b)), as used for DC link balancing in multi-level converters [

65], achieving soft switching operation.

3.5. Rail/Track Cross Bonding

In transit system with large return current intensity it is common practice for the rails of each track to be bonded together and for the tracks to be cross bonded to balance traction return current, to reduce the resistance of the return path, as well as to decrease track potential and reduce the generation of stray current [

66]. As an additional positive effect, the reduction of the return path resistance and the possibility of recirculate current between different tracks at intermediate points between TPSs and not only at TPSs contribute positively to energy efficiency, improving the exchange of regenerative braking energy (improving system receptivity) [

67].

Cross bonding is achieved by deploying short circuiting cable connections between the rails of the same track or of adjacent tracks at regular intervals (using standardized terminals, such as those manufactured by Cembre): connection sizing is such to withstand the normal current flowing under the most unfavorable unbalance conditions, as well as short circuit current scenarios, creating thus a low-resistance path for electrical current [

19,

42]. Experience has shown that a bond separation of around 200 m is appropriate for rails in a track and that approximately 400 m are appropriate for track-to-track bonds. However, such distance values depend on many factors such as headway, TPS separation, traction load, and others [

54], so that for other systems larger separation may be effective as well. The goal is in fact to keep track voltage to safe voltage values [

39], in particular for the interface to standing passengers in front of PSDs [

40], besides a general concern of touch voltage. This is normally demonstrated by electromechanical simulations, focusing in particular on areas where access is not restricted during service life, such as platforms and the PSD area in particular. Stray current reduction comes as added value, although —we must underline —it is rarely specified as a contractual requirement specifically with respect to rail bonding, although it is known to prevent the formation of potential differences and reduces the risk of stray currents [

68].

So far practical issues and non-stray-current-related constraints have not been considered. The short-circuit bond of running rails and adjacent tracks has a significant impact on signaling circuits of the track circuit type, for which their operation could be compromised, not to mention the existence of parallel electrical paths shunting the incoming train axles and compromising also the detection of track integrity. In general, cross bonds and track circuits are not compatible and cannot be used in the same system. Another practical issue is theft which not only has the obvious impact of economic loss, but also puts the infrastructure integrity in troubles, requiring more frequent track walks for verification and maintenance. For this reason, many countries use aluminum, steel, or copper-steel mixtures instead of pure copper.

3.6. Drainage Bond

A drainage bond is a conductive bond through an insulated cable between the rail and buried pipeline that provides an alternative path for the current to return to the rail (

Figure 10). The aim of drainage bonds is to shift down the potential of anodic areas and thus prevent harmful stray current corrosion on pipelines [

69].

Drainage bond connection should be made at the points where the rail and the pipeline cross or are parallel but very close to each other. The place where the drainage bond is installed should also be suitable for the control of the equipment and located so that it does not interfere with traffic [

69].

Direct, polarized and forced drainage bond methods can be used to mitigate the stray current corrosion on pipelines [

70]. The principle is to connect the pipeline to the rail by an electrical connection and discharge the stray current either by an applied voltage or by the voltage difference between the pipeline and the rail. A direct drainage bond between the threatened structure and a reference point that is electronegative enough aims to shift the potential of the anodic region downward, but this solution transfers the corrosion risk to the second structure, which may require further mitigation [

71]. When using a polarized drainage system stray currents cannot leave the protected structure through the electrolyte. The negative pole of the TPS is usually electronegative enough to effectively lower the potential of the protected structure, except for short periods of time (e.g., the moment a train passes the substation) [

71]. During these short periods, the diode ensures that no stray current can flow toward the protected structure. In a forced drainage system, the driving voltage for discharging the stray current from the pipeline is controlled by thyristors, while in polarized drainage system it is controlled by diodes [

70].

However, some European track operators do not recommend drainage-bond mitigation techniques because it is noticed that drainage bonds can increase the overall leakage of the stray current and also increase the corrosion rate of the running rails [

19,

72]. According to [

1] the installation of drainage bonds was recognized only as a supplemental or temporary measure because drainage bonds increase the overall amount and magnitude of stray current due to the lower resistance in the parallel resistance paths of the utility and the return rail.

3.7. Stray Current Collection System (SCCS)

During track construction, SCCS can be constructed under the rails to “capture” the stray current that leaks from the running rails and avoid damage to the segments [

9,

73]. Such collection systems usually take the form of added conductors (such as rebars themselves or welded meshes) in the concrete track bed of a traction system [

14,

54,

74]. If rail insulation and power-system design cannot keep stray current levels below “damage-causing” levels, a SCCS should be provided when building new track or rebuilding existing track [

33]. If a SCCS does not exist, stray current would leak directly into the ground and the rest of infrastructure. A stray current collection system is also useful in the extreme case of local insulation deterioration by failure of some of the track elements, providing temporary protection whilst the failure is located and repaired.

This system ensures a low resistance path for the stray current, thus avoiding possible interference with third-party infrastructure [

9]. An important point is that these elements must be insulated from the remaining reinforcement of the track bed and, at the same time, have a good electrical interface with the leaking elements of the track, maximizing the conductive coupling with them [

12]. To simplify a bit, the introduction of a stray current capturing element beneath the rails increases slightly the overall rail leakage current as the thickness of insulating concrete is reduced and conductive parts are added.

According to [

32], different solutions can be used for stay current capturing system, such as steel bars placed under the running rails and connected every 50 m, a copper plate placed under each rail and along the entire track or a mesh of welded smaller steel with a suitable mesh width in the order of 10cm–15cm.

Current designs use an amount of capturing steel between 600mm2–1000mm2 total cross-section for one rail, in the order of 1/8 to 1/10 of the rail cross-section (for a UIC 60 the cross-sectional area is 7660 mm2 and for gauges 54 and 49 it is slightly, but not proportionally, less). Construction steel usually has an electrical resistivity that is 13–14 times higher than copper. As the mechanical properties of these capturing rebars are of secondary importance, selecting steel with lower electrical resistivity like low-grade carbon steel may be an option. However, resistance to corrosion is poor and tests with various chloride concentrations in concrete have shown that the expected life is in the order of 10 years, even for moderate chloride concentrations [

12].

3.8. Monitoring and Maintenance During Track Lifetime

Perhaps in the initial stage, the insulating protecting measures are good and ensure high values, the welds between the tracks are not affected by mechanical vibration, corrosion and dirt, and the longitudinal resistance of the track is low as per design. Therefore, the track potential and stray current are low and do not cause serious corrosion.

However, as the operating time of the track increases, with the influence of moisture and vibration over a long period of time, and with the wear and aging of the insulating materials, the degree of track insulation gradually deteriorates, resulting in an increase of stray current [

75]. Such reduced insulation does not correspondingly reduce the track potential, as one may guess by observing that

shunts in principle the longitudinal track resistance: an estimate was provided in [

12,

40] simply observing that the order of magnitude is quite different and that the effect of

is negligible if values remain in the range of acceptability of the EN 50122-2 (values of some

) compared to the track longitudinal resistance (in the order of 20m

km–25m

km).

Since the rails serve as current return conductors, any rail breakage that causes an increase in the electrical resistance of the rail must be detected and repaired in a timely manner. Wear of the rail head due to traffic loading also increases the electrical resistance of the rail, resulting in higher stray current values. According to [

47], the electrical resistance of the rail can increase by up to 19 % due to the wear of the rail head caused by traffic during the service life.

It is important to observe that rails are characterized by an intrinsic variability between samples of the same type, as well as large increase of electrical resistivity for hardened rails, such as those used at turnouts and at curves [

76]. It is thus evident that the overall longitudinal resistance of the track is made of different contributing terms, and depending on the specific location (junction with many turnouts) and on the used rail lot it may vary by 5 %–10 %. To such figure another 1 %–5 % should be considered for the effect of rail welding points [

34].

The relationship between the distribution of track potential and the resulting stray current is an important indicator of track insulation. The track potential is affected by the operating conditions of the running vehicles and should always be weighted against the flowing absorbed and regenerated current intensity; in addition the values should be considered with respect to the local ground potential [

12].This is the approach preferentially proposed for Stray Current Monitoring Systems (SCMS). Stray current is not only a dynamic quantity depending on vehicle traffic and type, and driving mode (accelerating, decelerating, driving with the same speed), but also on track conditions and soil moisture [

25,

68]. Some of these parameters affect the rail potential

and others affect the rail-to-ground resistance

[

68]. Theoretically, it was assumed that the rail potential is negative at the substation and positive at the point where the current leaks from the rail. In [

77] the authors analyzed the rail potential in front of seven substations in urban and suburban areas and concluded that the rail potential can be positive in urban areas and negative in suburban areas. This means that stray current can flow from the rail to the ground in urban areas and flow back to the rail in suburban areas.

There are instead more direct methods to evaluate track insulation, as described in the EN 50122-2 [

34], which have been discussed in [

7,

78,

79] and critically reviewed recently in [

35]. There are in synthesis three methods for track insulation determination: voltamperometric measurement on electrically sectioned track sections, similar measurement on electrically continuous tracks estimating and correcting for the rail current leaving the measured section, and lateral electric field measurement (as an estimate of stray current flowing in the soil). The third method is suitable for measurements in traffic conditions, so with negligible disruption of system operation, whereas the first two require the use of engineering hours at night time. Such methods provide a direct indication of the track insulation level and provide the SCMS with reference information on the health status of the track. Stray current as track leakage current can then be determined by the measured track potential. Alternatively, when a Stray Current Collection System (SCCS) was also provided during system construction, the SCCS collects the Stray Current Collector (SCC) current intensity, as an indirect quantification of the track leakage occurring in the collected sections [

12].

According to the standard [

34], the average measurement period should be 24 hours to cover all changes in rail potential during the day: stray current is in fact the highest during rush hours when traffic is intense and track potential at maximum [

14]. SCMS experience shows that meaningful trends and behaviors are detected only by comparing suitably processed measured data are compared on much longer time intervals, at least to bracket weekly changes (working days and weekends) and to reach statistical consistency.

However, the lack of standardized requirements and technical references results in unclear contractual specifications for the SCMS, without identification of benchmarks or formulation of acceptance criteria. Desired performance levels for acquisition and analysis of electrical quantities are discussed in [

12]. In SCMS track voltage is usually measured and the measurement is implemented at VLDs (as said, located at TPSs and in some cases at all stations) [

12,

80]. If only TPSs are equipped with track voltage measurement points, not only are they quite sparse (e.g. 2km–4km apart), but the readings are also collected in front of TPSs, where the track voltage change is lowest, and the representativeness and completeness of such monitoring is questionable. If VLDs are placed at all stations, the density of measurement points is increased and track voltage will be monitored approximately every 0.6km–1.2km [

12].

If high values of stray currents are found from the measured values, a specific inspection and maintenance should be initiated, culminating in more extensive repairs, parts replacement or even track reconstruction. However, if high rail-to-ground resistance is ensured during the construction of the track, timely maintenance of the track must ensure that stray current values do not increase during operation. Preventive maintenance and track cleaning are the cheapest and most effective measures for monitoring and prevention of insulation worsening. More extensive maintenance activities that also can effectively reduce stray currents should include rail replacement due to wear of the rail head, detecting broken rails, maintaining ballast on ballasted tracks to ensure effective drainage, and keeping effective drainage on the tracks built on street sections.

4. Discussion of the Various Approaches

The measures that should be anticipated at the design stage to prevent stray currents in track construction depend primarily on the type of track. For example, in the case of tracks with continuously fastened rails, a high value of rail-to-ground resistance is ensured so it is not necessary to take care of the electrical resistance of the concrete base. When anticipating the measure to reduce stray current, care must also be taken to ensure that the measure applied does not interfere with the other characteristics that the track must meet. For example, the application of a floating grounding system will reduce the values of stray currents but may cause the formation of high potential values in the rails, which may endanger human safety. Therefore, in these cases, devices such as voltage limiting devices must be used to prevent high potential values. In addition, for fastening systems used on tracks with discretely supported and fastened rails, it is important that the elastomer elements have a high electrical resistivity to prevent current from flowing from the rail through the fasteners into the track base and the ground. However, changing the composition of the material used in the vulcanization process to achieve high electrical resistance should not result in a loss of other properties that the elastomer elements must have. These are primarily stiffness and damping. To effectively prevent stray currents, several measures described in this paper must be combined during track construction. Track maintenance is also important to ensure high rail-to-ground resistance during the service life. Since designing and building track construction is an interdisciplinary project to define the best solution that will meet the required track characteristics collaboration between engineers from different fields is necessary.

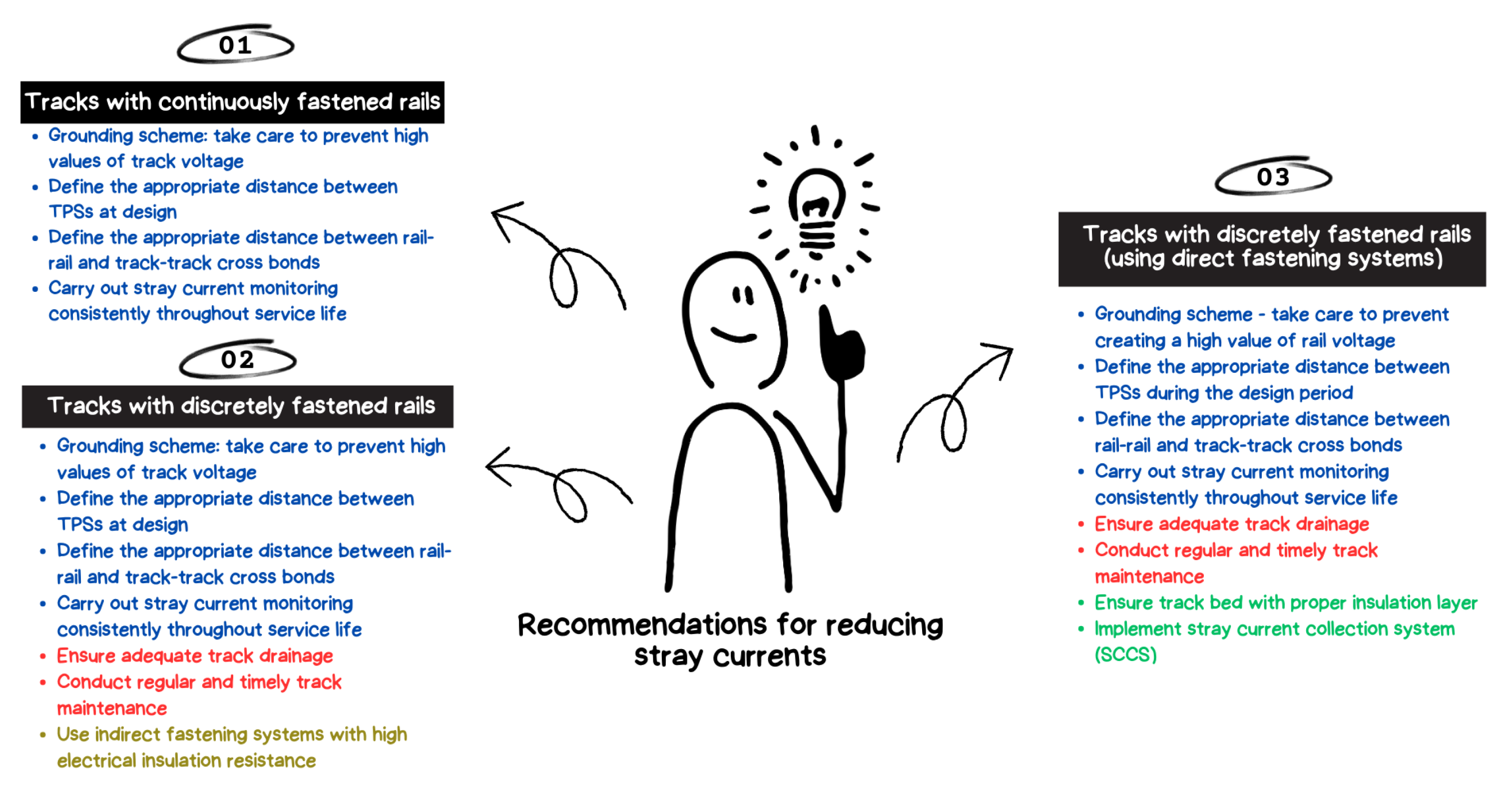

Figure 11 contains recommendations for reducing stray currents depending on the type of track construction - in tracks with continuously fastened rails, where a high rail-to-ground resistance is ensured, and in tracks with discretely fastened rails, where rail-to-ground resistance depends on the type of fastening system.

In tracks with continuously fastened rails, the rails are laid in the grooves of the precast concrete slab, and the free space between the rail and the slab is filled with an elastic material that provides continuous support for the rails (see

Figure 2). Since the electrical resistivity of elastic material is very high, it also serves as rail insulation, so in this type of track high rail-to-ground resistance is achieved, and stray currents are prevented. In discretely fastened rails stray current can also be reduced, but it is extremely important to pay more attention to regular and timely track maintenance to maintain a well-designed drainage system throughout the service life of the track, especially for tracks built on a road section (where road vehicles and rail vehicles share the same driving surface). Maintenance does not need to be performed cyclically at specific intervals, but as needed depending on the condition of the track. In the case of tracks with discretely fastened rails located in a separate corridor and closed with different materials, such as crusted stone, this material should be replaced when a high level of dirt and small particles is detected, since the presence of dirt and small particles, which is very common near passenger stations, leads to water retention and prolonged drying of the tracks. Since recommendation No. 3 allows stray current to leak from the rail through the fastening system into the track substructure due to poor insulation of the rail and fastening system, SCCS should be used to “capture“ the current flowing off the rails. It can be concluded that a combination of different measures, regardless of the type of track, can achieve satisfactory results in preventing stray currents. However, for recommendations No. 2 and No. 3, it is extremely important to pay more attention to track maintenance to preserve track characteristics, especially to maintain the high efficiency of the drainage system.

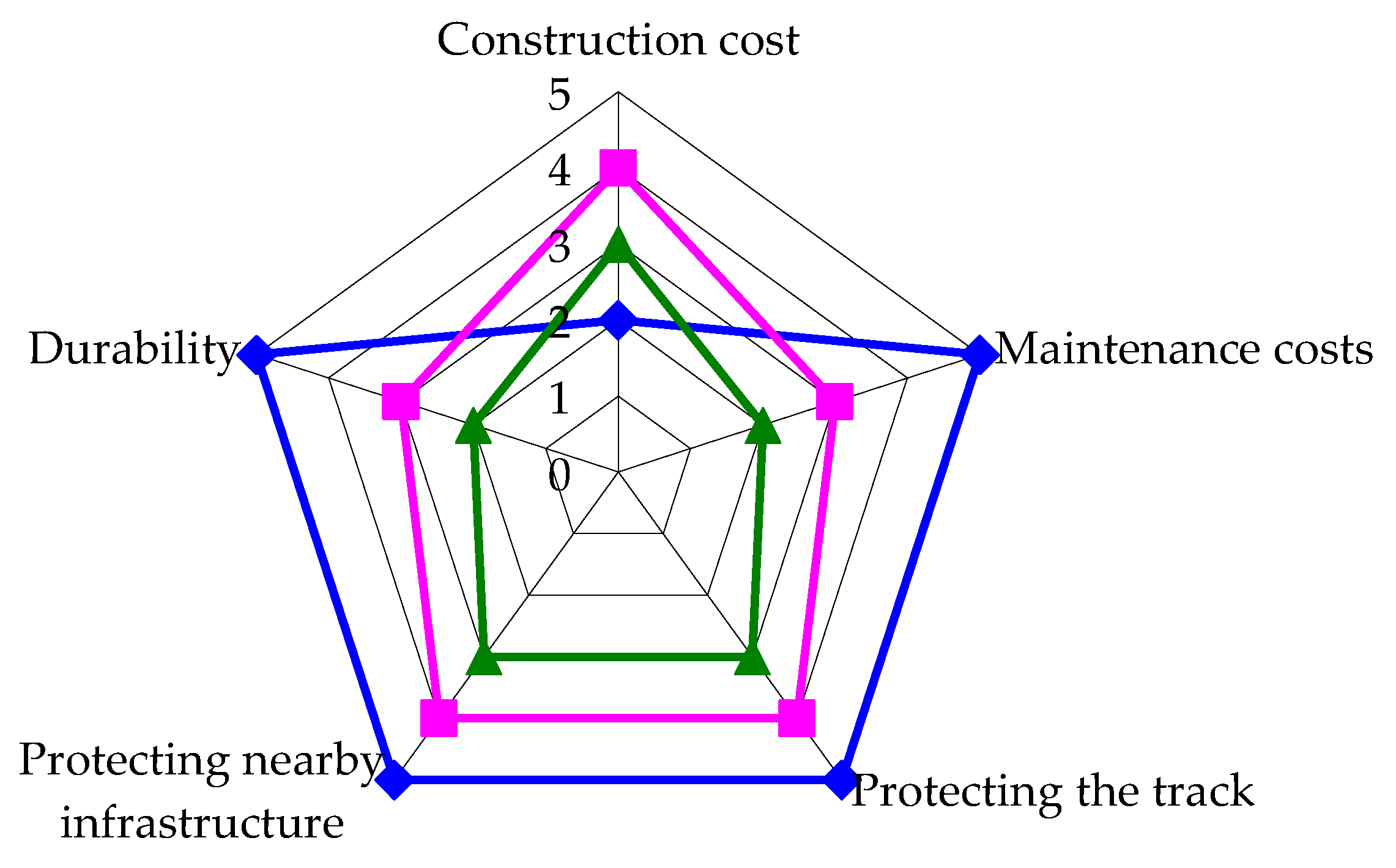

A comparison of discussed and suggested measures in terms of their construction cost, maintenance, effectiveness in protecting against stray current corrosion on rails and adjacent metallic infrastructure, and durability is provided in

Table 2 and

Figure 12. Proposed measures are rated from 1 to 5 plus symbols +, from worst to best performance for a given measure - i.e., lower construction and maintenance costs, better properties in terms of protection of tracks and nearby structures, and greater durability. The best result to prevent stray currents is achieved by using a track with continuously fastened rails (suitable for tramways, much less for heavier transit systems). However, when considering the cost sheets of some past realizations, it is found that the price per meter for a track with continuously fastened rails is twice as high as the price for a track with discretely supported and fastened rails. In addition, the application of this type of track on an existing track with discretely supported and fastened rails requires a complete reconstruction due to the difference in track heights, leading to long-lasting works with very high costs. Another disadvantage of the continuously fastened track is the fact that with this type of track, it is not possible to carry out visual inspections nor to replace a single element, as is the case with tracks with discretely fastened rails - for example, it is not possible to replace only the rails after the wear of the rail head caused by traffic load.

Application of suggested measures No. 1 not only prevents stray currents but also improves other properties of the track, especially with regard to the dynamic effects of vehicles on the track, resulting in a longer life of the track structure and thus lower maintenance costs.

In track construction or reconstruction, recommendations No. 2 and No. 3 result in lower construction costs, but maintenance of the designed track properties require higher maintenance costs. In these tracks, the dynamic loads from passing vehicles are much more pronounced than in tracks with continuously fastened rails, so the degradation of the track is much faster, which reduces the life of the track and, consequently, the properties of the track in terms of preventing stray currents.

Indirect fastening systems, which should be used in recommendation No. 2, in most cases have a greater ability to effectively damp rail vibrations induced by passing streetcar vehicles (explained in detail in paper [

81]). This results in a longer service life than when a direct fastening system is used.

Good performance in preventing stray currents can be ensured by using tracks with discretely fastened rails in combination with other methods described in this paper that result in high rail-to-ground resistance. The methods to be used depend on the type of fastening system and its insulation. Track maintenance is extremely important to ensure effective drainage of the track during the operating period, especially for closed track formations built on street sections where drainage is shared between the track and the road network. If the track is not adequately drained, the water remaining in the track will lead to a reduction in rail-to-ground resistance and an increase in stray current levels. Regardless of the type of track construction, the low longitudinal electrical resistance of the rail must be ensured by rail and track cross bonding and by defining appropriate distances between TPSs. These measures also serve to reduce high values of electrical potential in the rail, which can be particularly pronounced in tracks with continuously fastened rails. The value of the potential in the rail is also influenced by the grounding system used.

5. Conclusion

Stray current related to DC rail traffic causes aggressive corrosion processes on the tracks themselves and on nearby conductive structures. Today, third-party metallic infrastructure located near DC tracks is usually protected at some extent from stray current corrosion, such as the extensive use of cathodic protection for pipelines. A better solution is to reduce stray currents at the source, i.e. at the track and operating on the traction power supply system.

Some rail infrastructure operators and associations recognized the harmful effect of stray currents and have specified in their guidelines advised measures and provisions to ensure that stray current impact is within acceptable limits. However, given the different types of track structures, it is not possible to define unique measures that ensure low values of stray current. For this purpose, it is necessary to ensure first of all a high insulation resistance between the track and the ground (or the supporting structure) and a low value of the longitudinal electrical resistance of the running rails. This can be achieved by appropriate provisions during the design phase, but it must be ensured that limits are met for the entire operating life of the transit system and that some prescriptions do not cause the deterioration of other track characteristics. For this reason, the cooperation of engineers from different disciplines is required to find an optimal solution for the track and its interaction with other structures in the vicinity. In the U.S., most cities that have DC transit systems also have a Corrosion Coordinating Committee (sometimes called Electrolysis Committee). These committees hold regular meetings to discuss general stray current conditions. In many cases, utility owners notice a change or increase in stray current activity before the transit agencies notice it. Therefore, the transit system and utility owners must work together to find solutions to unacceptable stray current levels.

The work has reviewed quantitative prescriptions from various guidelines and standards, as well as approaches suggested in the literature and based on experience.

Regardless of the measures taken during the operation, regular maintenance and monitoring of the track is also essential to detect any changes in time. As rail systems become the primary means of transportation in many cities around the world, the demands on rails and vehicles to achieve higher transportation capacities and speeds are increasing. To meet these demands, infrastructure and vehicles must be modernized, requiring the addition of many guidelines that rail operators use today. In these additions, stray currents must be among the fundamental parameters to be considered in track design and maintenance.