1. Introduction

With the development of building materials, construction technology and computational theory, large-scale structures spring up in the past decades. For example, concrete filled steel tube (CFST) structures have attracted more and more attention in super high-rise buildings, long-span bridges, harbor engineering, subway stations and other large-scale structures due to their excellent mechanical properties and convenient constructions when compared with reinforced concrete (RC) or steel structures [

1,

2,

3]. Although CFST structural systems have the potential to provide cost-effective alternatives to traditional steel or RC structures, they are prone to yield defects such as interface debonding and concrete core voids under various factors, e.g. concrete shrinkage and creep, complex loads, temperature variation and etc. Existing studies show that the ultimate load-carrying capacity and stiffness of CFST members are dramatically weakened due to the loss of confinement effect of steel tube on concrete core and the existence of voids in concrete core, even structural failure and catastrophic accidents probably happen [

4,

5,

6,

7,

8,

9]. Therefore, it is vital and urgent to explore a non-destructive inspection and health assessment technique for CFST members.

As a classic non-destructive testing technology, stress wave analysis for large CFST structures has become one of hot spots in the area of damage detection in recent years [

10]. For example, Xu et al., Chen et al. and Wang et al. [

11,

12,

13,

14,

15,

16] carried out theoretical and experimental studies to investigate the feasibility and the principle of defect detection approaches for CFST members using stress wave measurements with Piezoelectric lead zirconate titanate (PZT) actuators and sensors embedded in concrete or mounted on the outer surface of steel tube of CFST members. The proposed detection approaches work for both interface debonding and concrete core void defects in CFST members. In addition to the PZT based methods, scanning analysis approaches, e.g. time or frequency analysis [

17,

18], wavelet analysis [

19], travel time analysis [

20,

21] and etc., are also capable of determining whether there are defects in concrete. Moreover, they enable the estimation of the approximate area where the defects appear through feature extractions of stress wave signals and previous engineering experiences. However, scanning analysis methods still struggle to quantitatively identify the sizes and positions of the internal defects of CFST members. Therefore, it is desired to develop defect imaging technologies to detect the defects of CFST members quantitatively and in a visualization way.

Tomography techniques, including attenuation tomography (AT) [

22] and travel time tomography (TTT) [

23,

24], are able to detect defects in concrete structures composed of a sole material. However, strong scattering attenuation may be trigged by the concrete inhomogeneity at the scale of ultrasonic wavelength, which will hinder the application of AT in large-scale engineering structures such as CFST members in high-rise buildings or long-span bridges. By contrast, TTT gets rid of such restrictions and has been widely applied to subsurface medium detection. For instance, a crosshole tomography method is proposed based on the straight ray tracing algorithm [

25]. Although it is quite suitable when the medium of the cross-section changes slightly, a big imaging error may be yielded if it is treated as a homogeneous material for the case that the medium of the measured cross-section changes greatly. To overcome this shortcoming, Clement et al. [

26] proposed a crosshole radar TTT algorithm based on curved ray tracing method. This method is essentially an iterative inversion scheme based on two-dimensional ray tracing technique and it successfully provides a 2-D image of the subsurface along a transect through a wellfield designed to support hydrologic and geophysical research. Compared with the straight ray tracing approach, the accuracy of the calculated ray path via curved ray tracing way is greatly promoted. Therefore, the curved ray tracing based TTT method has been widely accepted and it gradually extends from geophysical exploration to non-destructive inspection of civil engineering structures [

27,

28,

29,

30,

31,

32]. However, current TTT case studies mostly focus on concrete structures [

33,

34] and few attention has been paid on CFST members composed of two different kinds of materials with different structural properties [

35]. Actually, the travel velocity of stress waves depends on the elastic modulus and density of propagation mediums. Due to this, the propagation process of stress waves through CFST members is more complicated when compared with traditional concrete structures with sole concrete material. In addition, the thickness of the surrounding steel tube only shares a few parts of the whole ray path, resulting in that the imaging of the steel tube remains not well resolved. Therefore, how to accurately track the travel paths inside steel tube and concrete core and acquire the travel velocity distributions becomes a critical issue for the quantification of internal defects inside CFST members.

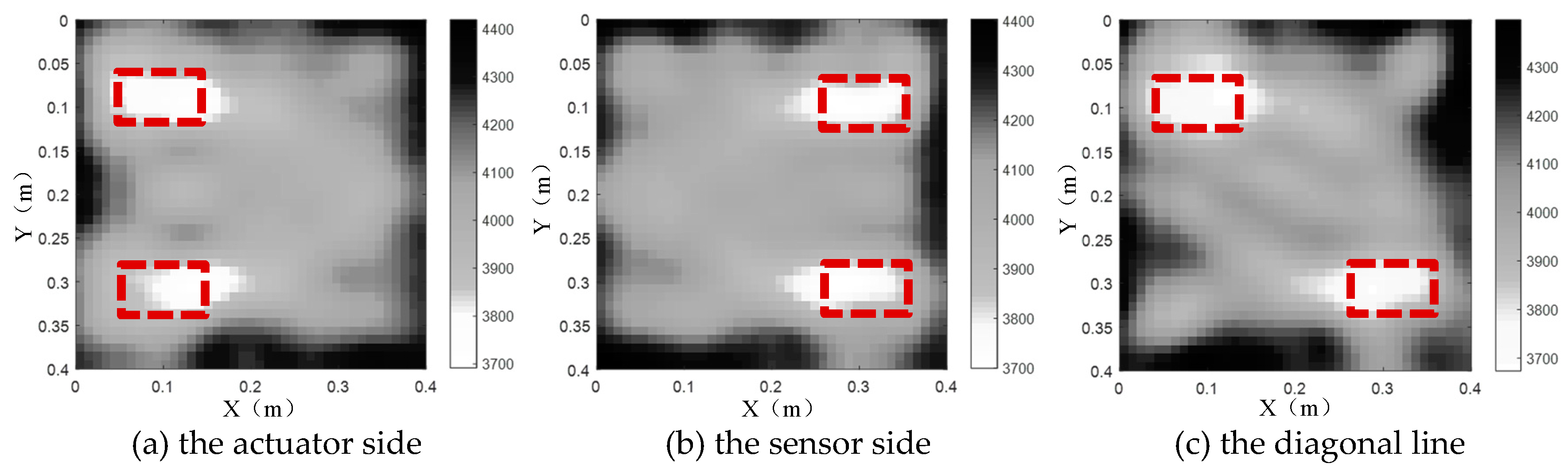

To address these issues mentioned above, TTT is introduced in this paper to carry out concrete core void defect imaging for CSFT members. The results demonstrate that the curved ray theory based TTT algorithm is capable of identifying the position and size of the void defects in concrete core effectively. Moreover, a parameter analysis is performed to investigate the relationship between TTT imaging qualities and inversion parameters, defect size and position. Due to this, several optimum parameters are recommended to benefit the future study of this promising TTT approach for inner concrete core voids imagination of CFST members.

The outline of this paper is as follows. The TTT algorithm is detailed in

Section 2 while the multi-physics coupling finite element model of PZT-CFST is established in

Section 3. The analysis of inversion imaging parameters and generality of the proposed imaging approach for CFST members considering concrete core void size, position and number are investigated in

Section 4 and

Section 5, respectively. Concluding remarks are drawn in

Section 6.

2. Travel Time Tomography for Concrete Core Voids Imagination of CFST Members

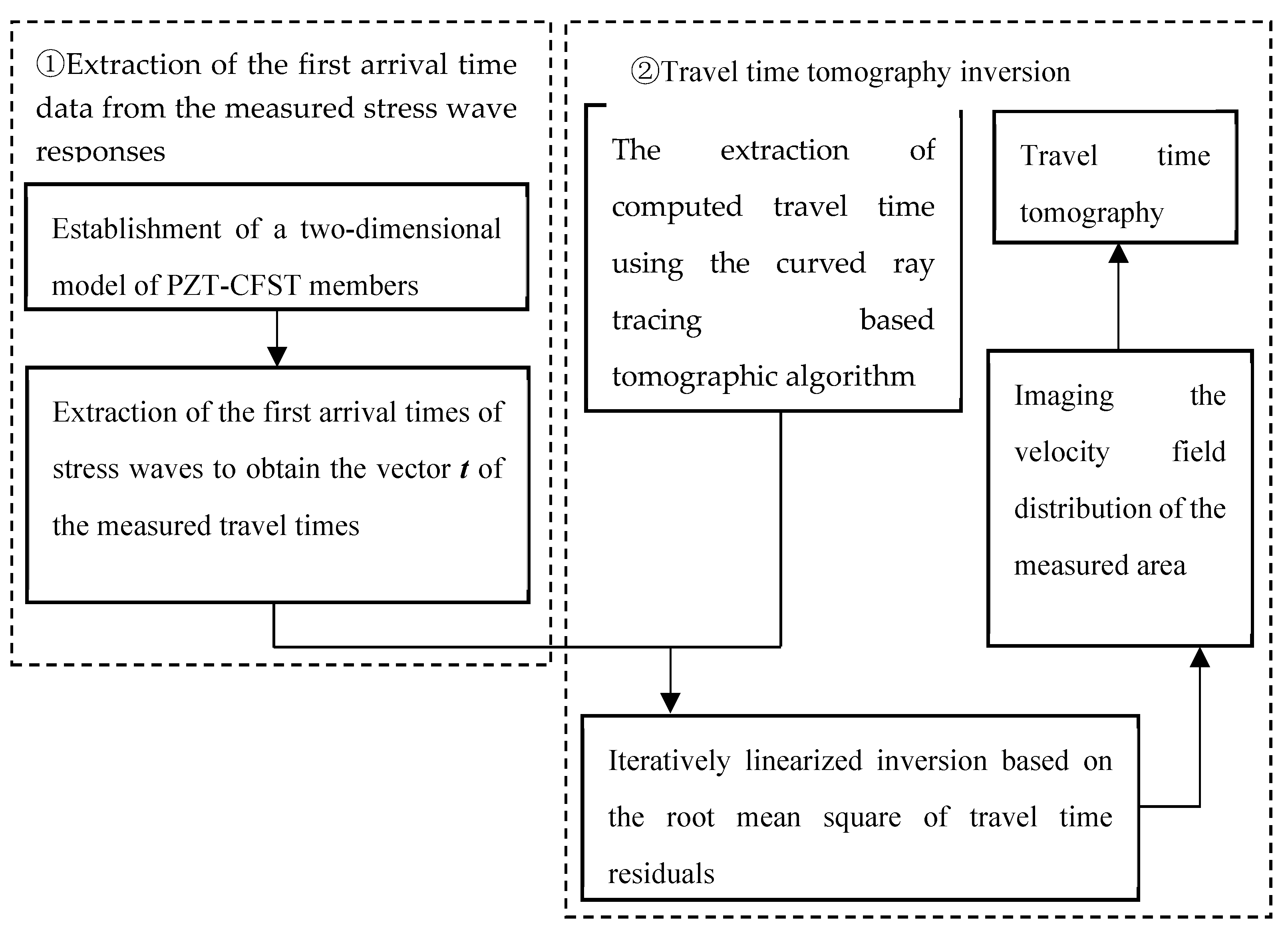

Travel time tomography (TTT) is a method that applies first arrival time of stress waves to inverse velocity/slowness distributions between the actuators and sensors mounted on the outer surface of CFST members. The flowchart of TTT is plotted in

Figure 1. As shown in

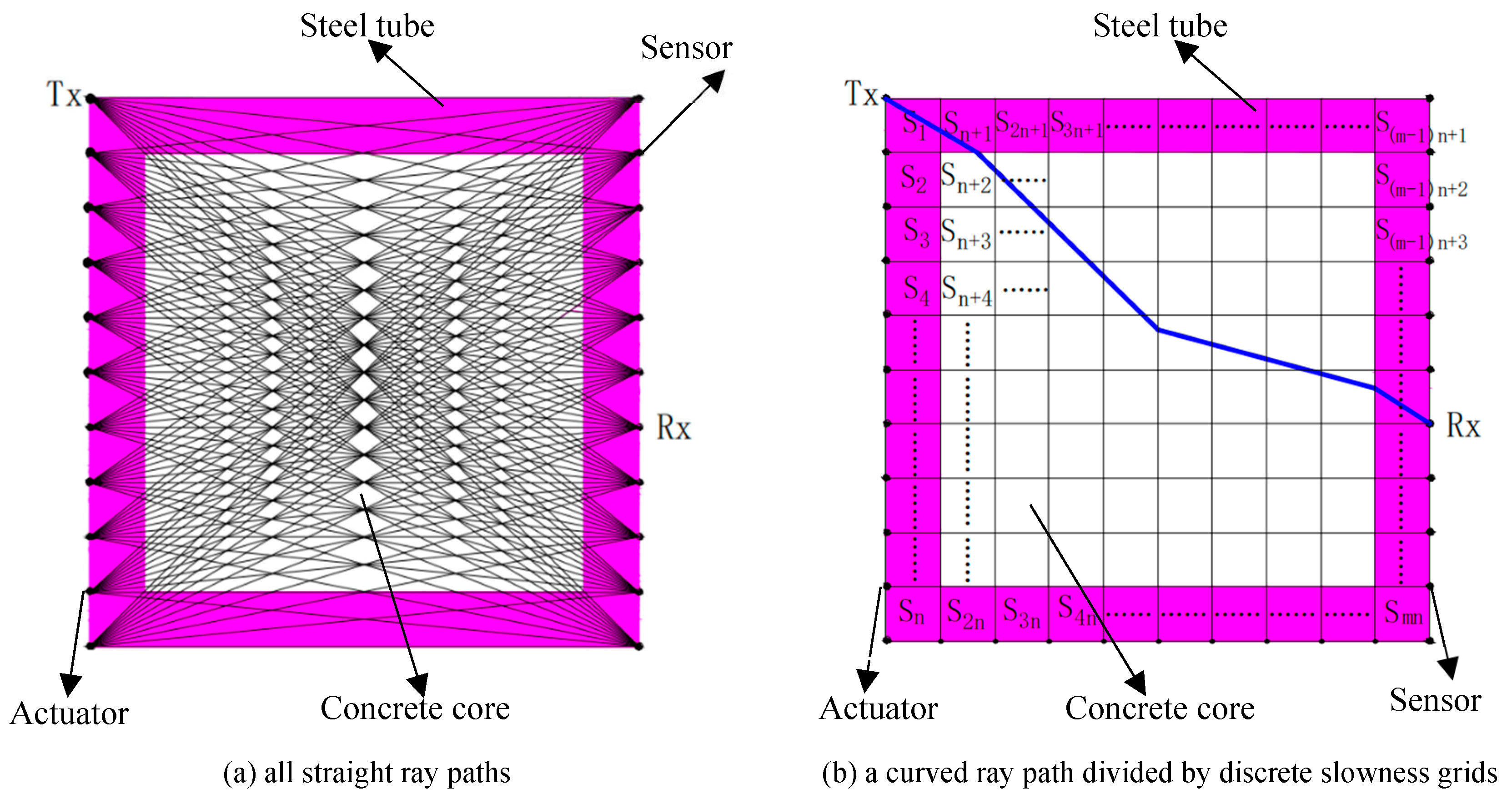

Figure 1, a ray tracing technique is required in TTT. Typically, the propagation medium of the stress wave is assumed to be homogeneous. Therefore, we can approximately assume that the ray path between an arbitrary actuator and sensor is a straight ray. It is shown in

Figure 2(a) that

n actuators and sensors are mounted on the two sides of cross section of a CFST member. Tx and Rx represent actuators and sensors, respectively. If an excitation signal is generated from an arbitrary actuator, all

n sensors on the opposite side will receive a stress wave that travels through the CFST member and as a result

n straight rays are yielded. Similarly,

n×

n straight rays will be received if all

n excitation signals are generated. Nevertheless, traditional straight ray theorem is no longer suitable for simulating the transmission of stress waves inside CFST members with concrete core void defects due to the different structural properties of steel and concrete. Moreover, void defects in concrete core also create challenge for the straight ray tracing method. To be specific, stress waves are likely to bypass the internal concrete core void defects/abnormal low-velocity areas and turn to travel along the path with least time. By contrast, the curved ray tracing theory provides a more real ray tracing path than the typical straight ray method for CFST members and yields a more accurate velocity distribution as well.

According to the principle of TTT, an arbitrary curved ray path can be regarded as a sum of several straight rays when the path is divided by discrete slowness grids of a cross section of a CFST member as illustrated in

Figure 2(b). Actually, the discrete slowness grids are square areas that are yielded by meshing the cross section of CFST members with an equivalent interval and surface-mounted actuators and sensors are located at the nodes. Here, slowness indicates the reciprocal of velocity. That is to say, the size of a slowness grid, e.g. S

1, equals the distance between adjacent actuators/sensors. As a result, the travel time of stress wave along the curved ray path can be obtained by summing up the counterparts of all straight rays that constitutes it. For example, the time travelling along the

i-th curved ray, expressed as

, is calculated according to Equation (1).

where

i and

j denote the

i-th curved ray and the

j-th grid, respectively.

m represents the total number of grids that the

i-th ray passes through. Here,

is the slowness inside the

j-th grid, while

represents the length of the

i-th curved ray within in the

j-th grid.

If

n actuators and

n sensors are both arranged on the two opposite sides (left and right sides in

Figure 2) of CFST members, the total number of rays will equal

n×

n. Then, the measured travel time matrix as expressed in Equation (2) can be established on a basis of Equation (1).

where

, and

represent matrices of travel time and slowness, respectively. Here,

is a coefficient matrix containing the lengths of the curved ray paths that passing through the slowness grids. Each element in

denotes the length of the ray path inside a slowness grid.

After that, Equation (2) can be rewritten as Equation (3) by pre-multiplying

.

where

represents the inverse matrix of the matrix

.

Due to

L is usually a sparse matrix, it has the possibility to be a singular matrix, which implies the inverse matrix of

does not exist. In order to address this issue, Tikhonov regularization function [

36] is introduced to define the objective function in Equation (4).

where

is weighting factor. and represent data and model weighting matrices, respectively. and separately represent the slowness vector to be solved and the initial slowness vector defined in advance. As symmetric matrices, the priori information contained in and can effectively guarantee the uniqueness of the solution to the nonlinear equation as shown in Equation (4).

It can be seen from Equation (4) that the coefficient matrix

L is actually a function of the slowness matrix

on condition that

t is solved by employing the first arrival time of the stress wave as mentioned before. Therefore,

can be expressed as

and then is defined as the theoretical travel time vector as well. After that, it can be solved by the finite difference method. To minimize Equation (4), the partial derivative of

with respect to time is calculated and hence Equation (4) can be expressed as

where

denotes the Jacobian matrix, while the subscript of

T indicates transposed matrix.

With a consideration of the nonlinear properties of

,

J cannot be obtained directly and the initial Jacobian matrix

can only be solved by knowing the initial slowness vector

in advance. Hence, an iterative algorithm is required to solve Equation (5). Typically, a linear iteration method is used to take a Taylor series expansion on

and the first order term is retained alone, leading to

as illustrated in Equation (6).

As such, Equation (5) becomes

It should be noted here that is replaced by in Equation (7) due to it only denotes the initial iteration step.

After that, Equation (7) can be rewritten in the iterative form and shown as Equation (8).

where

k represents the number of iterations.

The updated slowness vector can be solved according to Equation (8). Normally, it will be iterated repeatedly until the error between the theoretical travel time vector and the observed travel time vector t reaches a determined threshold or the number of iterations that exceeds the number defined beforehand. Thus, the final updated slowness vector can be regarded as the actual slowness field inside the CFST member.

To enhance the efficiency of solving Equation (8), the least square algorithm is used instead of applying the above mentioned iterative approach alone. Due to this, Equation (8) is equivalent to Equation (9) and the process of solving Equation (9) by the least square method is called least square iterative linear inversion algorithm.

where

,

, and

λ represent data weighting matrix, model weighting matrix and weighting factor, respectively.

As seen in Equation (10), the Jacobian matrix J equals the coefficient matrix L according to the curved ray theory based TTT method. Therefore, the Jacobian matrix J can be established by calculating the ray length of the i-th ray within j-th grid, that is, .

3. Multi-Physics Finite Element Model for Stress Wave Travelling Time Determination of PZT-CFST Coupling System

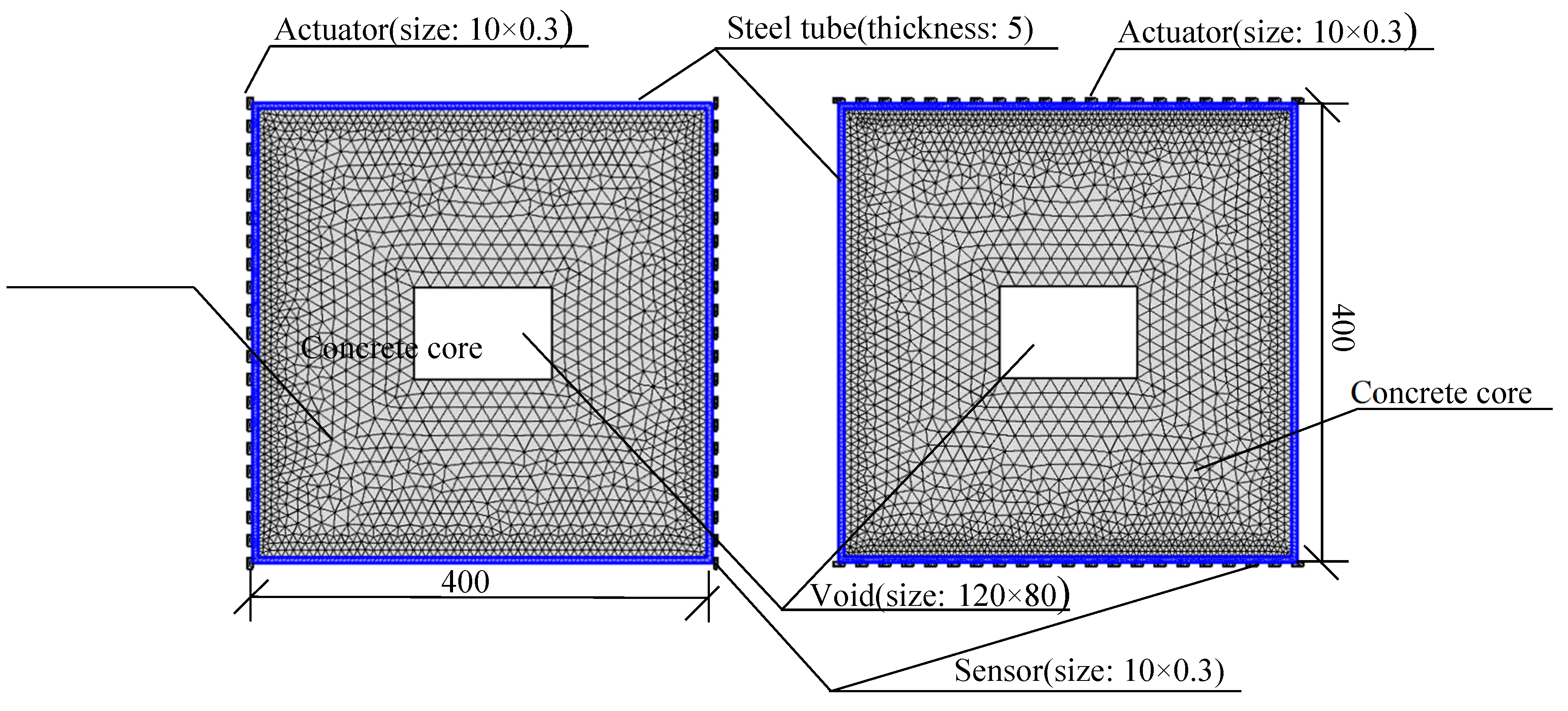

A multi-physics coupling finite element model of PZT-CFST is established in

Figure 3 with the assumption of homogeneous material. As shown in

Figure 3, the sizes of the square CFST model and the concrete core void defects are separately 400mm×400mm and 120mm×80mm, while the thickness of the surrounding steel tube is 5mm. 21 PZT patches with a definition of actuators are arranged with an equal interval of 20mm (0.02m) on the left/upper side of the outer wall of the steel tube, while other 21 PZT patches, used as sensors, are laid out on the opposite side. The plane size of each PZT patch is 10mm×10mm and the thickness is 0.3mm. Here, the employed PZT patches is compressive type and its polarization direction is along the thickness direction. The material properties of the PZT-CFST coupling model are illustrated in

Table 1.

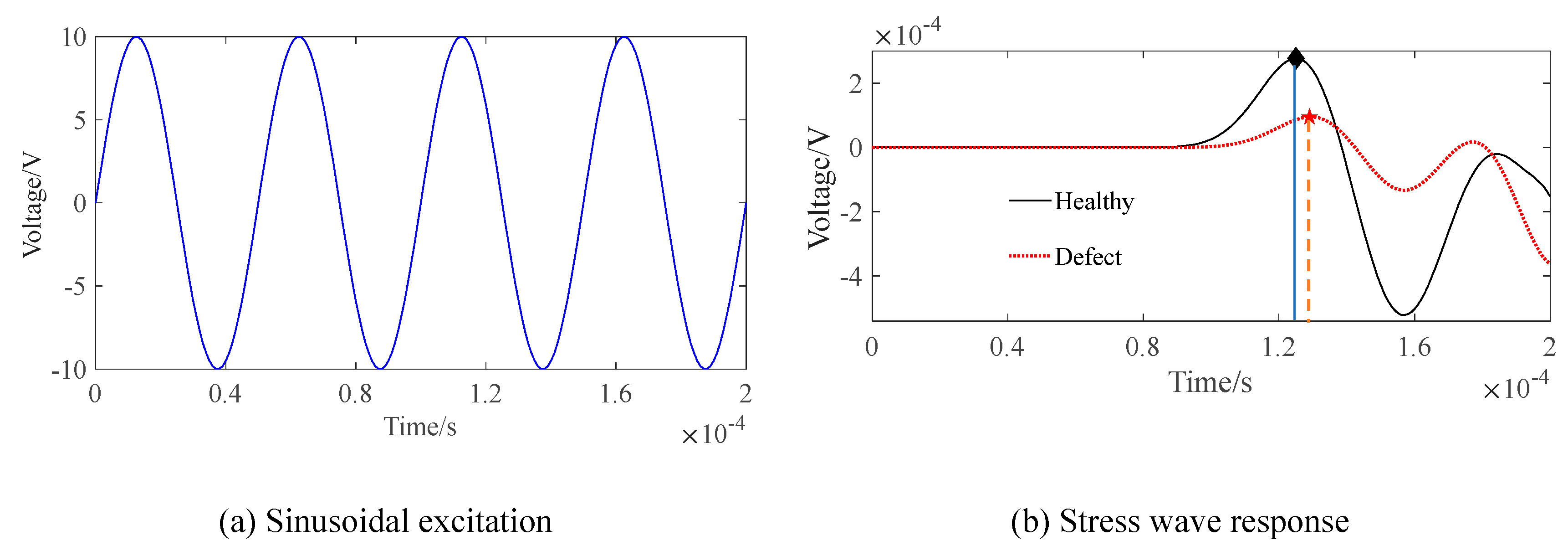

At first, a sinusoidal signal with a frequency of 20 kHz and an amplitude of 10 V is set as the excitation and its waveform is plotted in

Figure 4(a). Here, four cycles of the excitation signal are selected for signal processing, that is to say, the excitation signal at least has a time duration of 4×1/20=0.2ms. After that, the stress wave is going to propagate in the CFST section with a concrete core void defect under the excitation and the resultant response signal as shown in

Figure 4(b) is received by a sensor. In order to extract the first wave peak time from the measured response signal more effectively, the peak picking method is used. As seen in

Figure 4(b), the red dashed line indicates the received response signal after the stress wave travels through the cross section of the CFST model with a concrete core void defect, and the red pentagram represents the first wave peak time of the received stress wave response signal. Compared with the first wave peak time under the healthy condition (black diamond), the counterpart under defect case (red pentagram) is slightly delayed and the amplitude decreases to an extent as well. The reason for this phenomenon is that the travel path will be changed when the stress wave encounters the concrete core void defect. In other words, the stress wave is likely to propagate along the edge of the concrete core void instead of traveling through the concrete core void itself. As a result, the travel path becomes relatively longer, leading to a delayed travel time and an energy attenuation as well.

Following the extraction of the first wave peak time, the time interval between the first wave peak time of the response signal and that of the excitation signal is defined as the first wave arriving time. Since 21 actuators and sensors are separately arranged on the left and right sides of the cross section, 441 travel paths (21×21=441) will be yielded and hence the same number of first wave arriving times needs to be extracted accordingly. After that, the 441 extracted first wave arriving time data constitutes a measured travel time matrix () as shown in Equation (11) and then the TTT algorithm is introduced to yield a defect imaging result. Similarly, another defect imaging result will be yielded when 21 actuators and sensors are mounted on the upper and lower sides of the cross section, respectively. To reduce the errors caused by the sparsity of the rays located at the four edges of CFST cross section, the two obtained defect imaging results are comprehensively considered and hence an algorithm of average is used for getting a better cross section imaging result.

where

represents the first wave arriving time between the

n-th actuator and the

n-th sensor.

4. Analysis of Inversion Imaging Parameters

In TTT, the default inversion algorithm is the least square QR (LSQR). According to Equation (9), the inversion parameters of , and λ are artificially defined and hence the selection of the , and λ is likely to pose a great impact on the results of TTT. In addition, the inversion grid size (d) not only affects the computational efficiency of TTT, but also applies influence on the accuracy of the imaging results to an extent. Unfortunately, few attention has been paid on the influence caused by the four parameters mentioned above and hence it deserves an extensive study.

4.1. Selection of Inversion Parameters

As mentioned before, , and λare the three inversion parameters that pose impacts on the imaging results. Normally, the unit matrix operator is used for , which indicates the data is uniformly weighted. Due to this, does not affect the imaging results too much and hence its effect is no longer considered here. By contrast, the influence of other inversion parameters including the model weighting matrix () and weighting factor (λ) are investigated in addition to the inversion grid size (d).

In order to better understand the influence of

,

λ and

d on the TTT results of the concrete core void defects inside the CFST section, the PZT-CFST coupling model as illustrated in

Figure 3 is investigated and seven cases are preset as shown in

Table 2.

4.2. Model Weighting Matrix

Since the model weighting matrix contains prior information to reduce the multiple solutions of inversion problems, its selection is vital for concrete core void defects imaging by TTT. Three types of model weighting matrices, including unit matrix operator, first-order difference operator and second-order difference operator, are selected in this section to perform TTT.

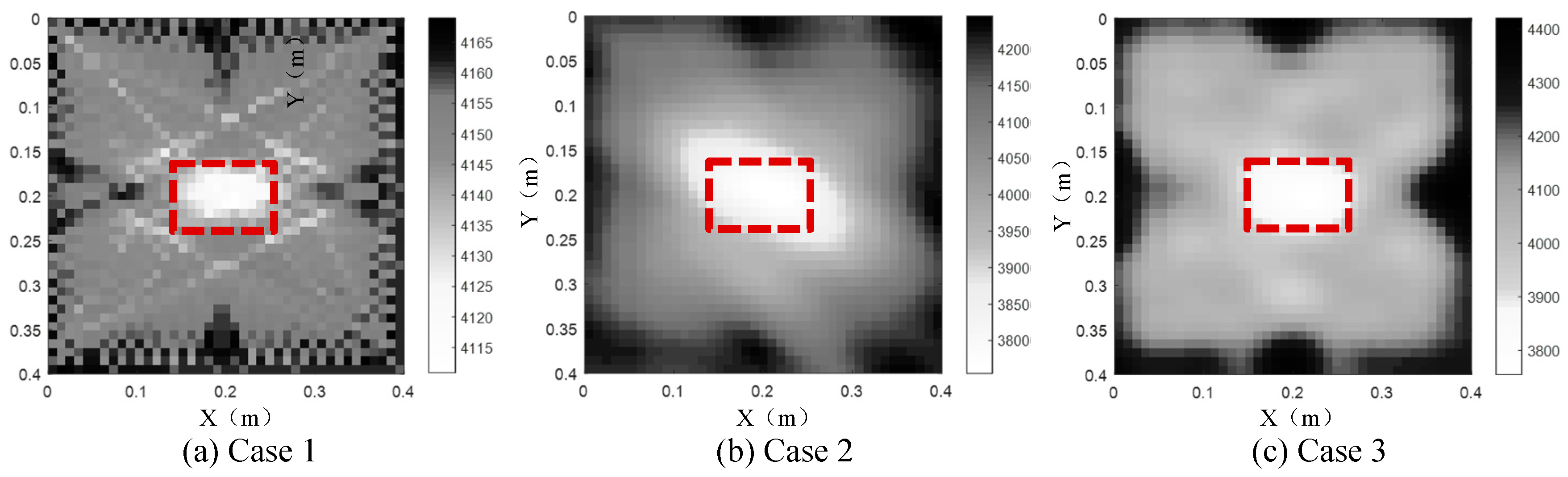

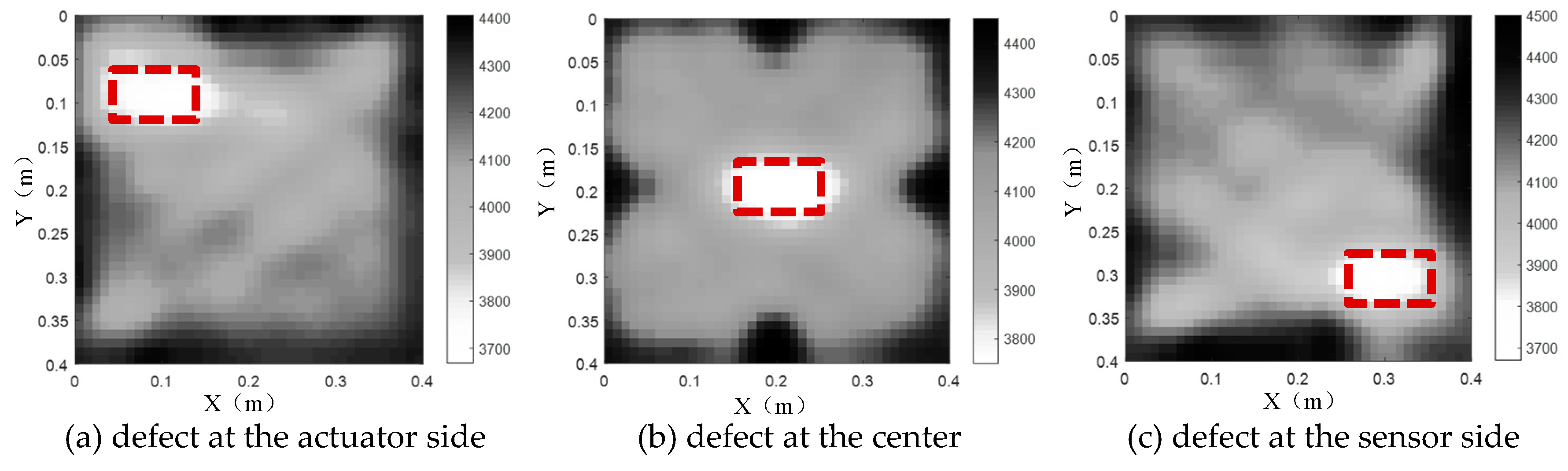

By using TTT, the concrete core void defect of the CFST model is inverted and illustrated in

Figure 5. It is noted here that all void defect imaging results in the rest sections of this paper are plotted in the style of grey-scale map. That is to say, the white color in the grey-scale maps represents the concrete core void defects, while the grey and black colors denote concrete cores and steel tubes, respectively. X and Y in the grey-scale map separately represent the horizontal and vertical coordinates of the cross section. In addition, the number on the color bar denotes the inverted velocity (Unit: m/s).

As shown in

Figure 5(a), the position of the concrete core void defect basically agrees with the theoretical result when the unit matrix operator is selected, however, the steel tube, concrete core and the size of the concrete core void defect are not accurately imaged in Case 1. When the first-order difference operator is employed (Case 2), the size of the inverted concrete core void defect is larger than that of the actual model. In addition to this, the imaged shape of the concrete core void defect is also distorted in Case 2. It can be seen from

Figure 5(c) that the position and size of the concrete core void defect agree with the theoretical result best in Case 3 when compared with

Figure 5(a) and (b). Moreover, the surrounding steel tube can also be effectively imaged even though it is slightly thicker than the counterpart of the actual model when the second-order difference operator is selected in Case 3. The reason for this phenomenon is that the curved rays in TTT cannot ensure a good coverage for the four sides of the cross section. In contrast, the concrete core region is covered very well by the curved rays and hence can be imaged effectively. In a word, the TTT has the potential to accurately image CFST members on condition that the second-order difference operator is selected and both actuators and sensors are mounted on the four sides of CFST cross sections.

4.3. Weighting Factor

In addition to model weighting matrix, the weighting factor (

λ) also plays an important role on TTT. As the name implies,

λ controls the weight between data space and model space. If

λ is too small, it cannot smooth the model very well. Otherwise, excessive smoothness will be caused for a big

λ. Therefore, an optimum

λ needs to be determined during the TTT inversion process. As suggested in [

30], the

L-curve method is recommended to decide the optimum value range of

λ (usually 2~20). For simplicity,

=2 (Case 4),

=5 (Case 3) and

=10 (Case 5) are investigated in this study.

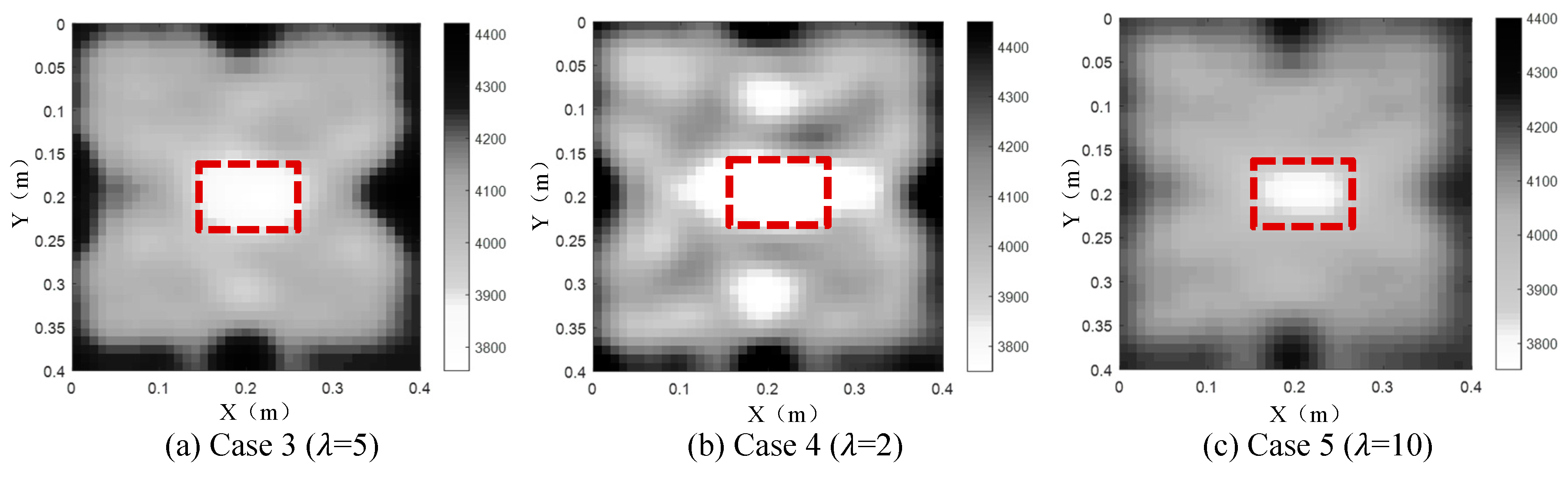

The imaging results under Cases 3, 4 and 5 are plotted in

Figure 6. It can be seen from

Figure 6 that the concrete core void defect imaging result inside the CFST section does not agree with the real concrete core void defect well in Case 4 (

=2). Moreover, two fake concrete core void images appear on the upper and lower sides of the central concrete core void defect inside the CFST section. By contrast, the imaging results of the concrete core void defect is consistent with the real size and position of the concrete core void defect if

=5 (Case 3). Compared with Case 3, the images effect in Case 5 (

=10) is worse due to the size of the imaged concrete core void defect is smaller than the actual size. The reason for this phenomenon is that the model is smoothed excessively for a big weighting matrix (e.g.

=10), which probably leads to an obvious reduction of fake images. However, the inverting error of the whole velocity field inside the CFST section is likely to increase accordingly due to a big

. By contrast, fake images will be yielded if a small

is selected. In a word, the TTT inversion result in Case 3 agrees with the true velocity field distribution best, and hence

=5 can be thought as the optimum value for this numerical example.

4.4. Inversion Grid Size

During the process of TTT, the selection of inversion grid size (d) depends on what kind of accuracy you require. Usually, the inversion grid size is determined according to the distance of actuators/sensors. In other words, d is often set to be equal to or smaller than the distance of actuators/sensors to reach a relatively accurate inverted image. If the inversion grid size is large, the number of discrete grids in the inverted region will decrease greatly, and the accuracy of the theoretical/calculated travel time and curved ray tracing is going to be reduced. Moreover, the inversion accuracy of the slowness/velocity field inside the CFST section is affected. On the contrary, the number of discrete grids divided in the inversion region will increase dramatically while the inversion grid size is small.

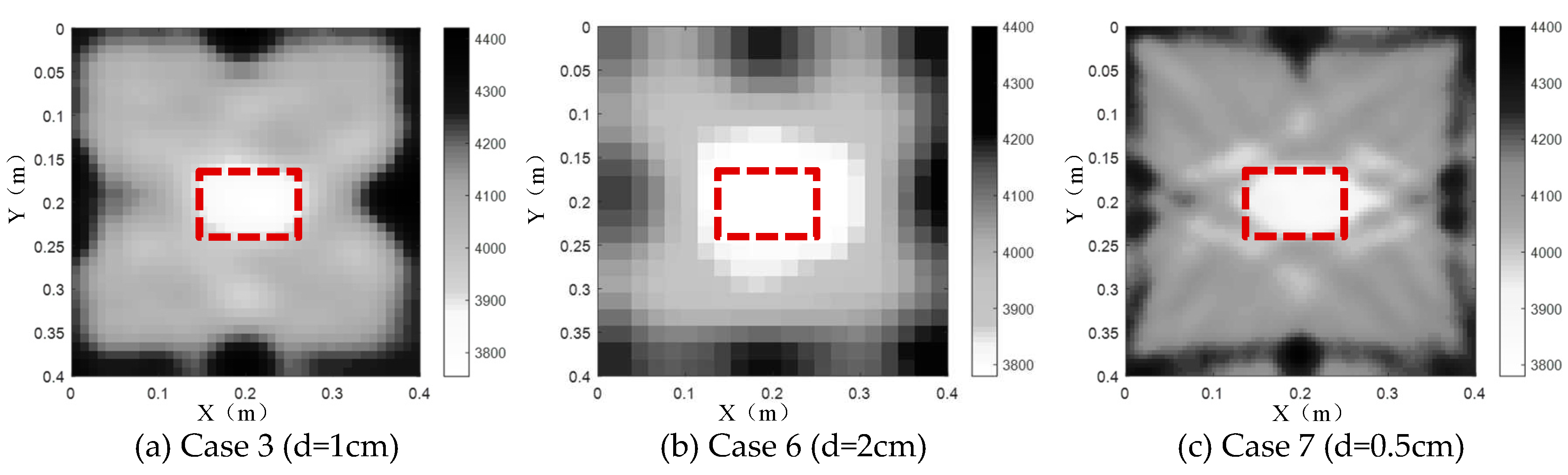

In order to investigate the impact of the inversion grid size on the imaging results of TTT, three kinds of inversion grid size (

d) are considered, that is, 2cm (Case 6), 1cm (Case 3) and 0.5cm (Case 7). As shown in

Figure 7(b), the position of the concrete core void defect inside the CFST section is effectively imaged when

d equals 2cm (Case 6), however, the inversion quality of the size of the concrete core void defect, the concrete core and the steel tube can be thought as the worst in Case 6. The reason accounting for this phenomenon is that a large

d will cause the reduction of the inversion accuracy. Hence, false abnormal velocity distribution areas are prone to be generated. When the inversion grid size is 1cm (Case 3), the imaging quality of the CFST section is going to be better. That is to say, the inverted position and size of the concrete core void defect agrees with the real model well in Case 3. Nevertheless, the defect imaging effect is not promoted for Case 7 (

d=0.5cm).

Figure 7 (c) also illustrates that a few fake images appear due to the interferences from more large angle rays, which implies the imaging effect of the concrete core void defects are decreased to an extent. In addition to a worse concrete core void imaging result than the counterpart in

Figure 7 (a), the computing efficiency is also reduced in Case 7. Therefore, too large or small inversion grid size probably leads to a bad inversion imaging effect and hence an appropriate inversion grid size is required. Here,

d=1cm is recommended in this numerical example according to the imaging results illustrated in

Figure 7.