1. Introduction

Stimuli-responsive soft materials [

1,

2,

3,

4,

5] change their physical properties in response to stimuli such as light, temperature, and pH. Magnetic gels are one of the stimuli-responsive soft materials, and their physical properties change in response to magnetic fields. Magnetic soft materials have attracted a great attention as next-generation actuators because their physical properties change instantaneously and dramatically when a magnetic field is applied [

6,

7,

8,

9,

10,

11,

12,

13]. When a magnetic field is applied to magnetic gels, the elastic modulus is higher compared to that without the magnetic field. This is called the magnetorheological effect. The underlying mechanism is that magnetic particles come into contact with each other and form a chain-like structure.

Because magnetic particles strongly interact with the polymer network, they are subjected to compressive and tensile resistance forces from the polymer network when they are displaced in the gel. In other words, as this resistance force increases, it becomes more difficult for the magnetic particles to move within the gel, and a chain structure of magnetic particles is not formed. As a result, the amplitude of the magnetorheological effect is reduced. Actually, the magnetorheological effect decreases as the elastic modulus of the matrix increases in magnetic gels [

13,

14]. Magnetic gels with a matrix of natural polymers, such as carrageenan and agar gels, show a significant change in elastic modulus with magnetic field compared to those with a matrix of synthetic polymers [

11,

12,

15]. This suggests that the network structure of natural polymers allows magnetic particles to move more easily than that of synthetic polymers. This feature is considered to be due to the cross-linking points of natural polymers formed by hydrogen (physical) bonds. Since the force that magnetic particles receive from the magnetic field is much stronger than the binding force, the cross-linking points are broken when the magnetic particles move.

In our previous investigations measured at a low magnetic field and low concentration of magnetic particles, it was shown that the change in storage modulus for carrageenan magnetic hydrogels took a maximum at around 2.0 wt.% [

16]. This is anomalous behavior because it is normal that the change in modulus increases with decreasing the polymer concentration. The decrease in the change in storage modulus is caused by increasing the strength of carrageenan network which was proved by increasing the critical strain. Conversely, we can find the strength of carrageenan network from the critical strain.

Beside this, there are some literatures describing that the physical property for polysaccharide gels are strongly affected by the gelation speed, i.e. cooling rate. A stiff and heterogeneous gel structure with high storage modulus is formed at low cooling rate, meanwhile, a weak and homogeneous gel structure with low storage modulus at high cooling rate [

17]. It was also reported that the size of junction zone (cross-linking point) decreased when a carrageenan solution cooled rapidly [

18,

19,

20]. The changes in the structure of cross-linking points or the strength of cross-links might affect the magnetic response for magnetic gels. In this study, we investigate the effect of cooling rate on the viscoelastic properties of carrageenan magnetic gels and their magnetic response to clear the influence of cross-linking structure on the mobility of magnetic particles within the gel.

2. Results and Discussion

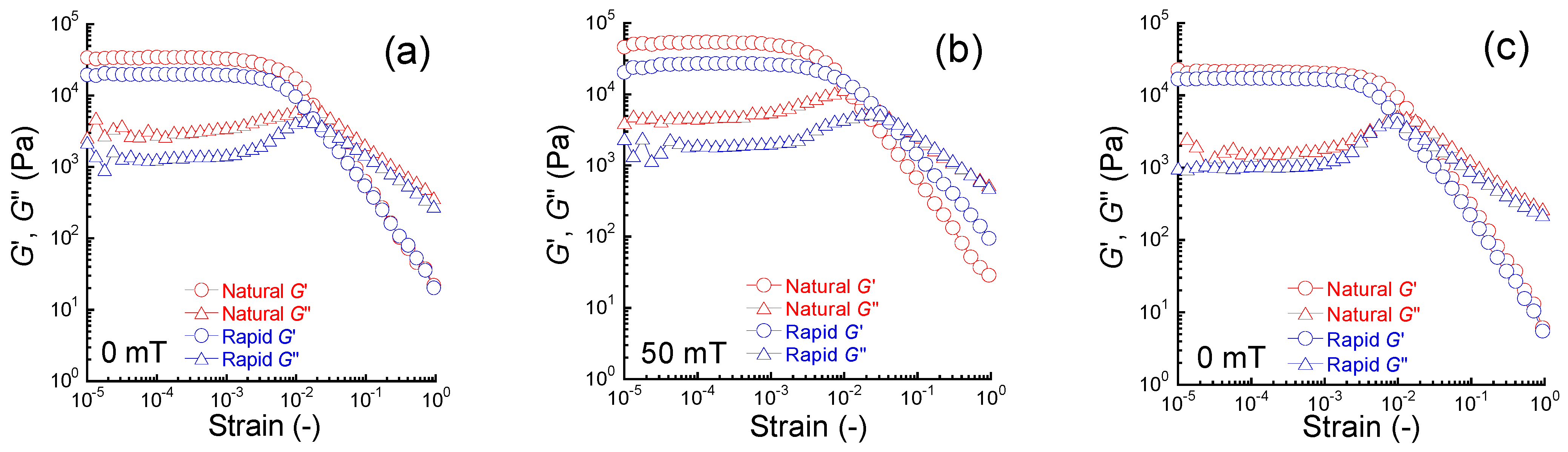

Figures 1(a,b) show the strain

γ dependence of the storage modulus

G' and loss modulus

G" at 0 and 50 mT for magnetic gels of natural cooling and rapid cooling, respectively. At 0 mT, regions of the linear viscoelasticity were seen at strains below 1.7×10

-3 and 2.4×10

-3 in magnetic gels of natural cooling and rapid cooling, respectively. The strains at where the

G' was intersected

G" were at 0.023 and 0.034 for magnetic gels of natural cooling and rapid cooling, respectively. At

γ=1, the storage moduli for these magnetic gels showed the same value. At 50 mT, the

G' showed the linear viscoelastic region at strains below 1.3×10

-3 and 2.4×10

-3 for magnetic gels of natural cooling and rapid cooling, respectively. The

G' crossed

G” at a strain of 0.016 for the magnetic gel of natural cooling and 0.052 for the magnetic gel of rapid cooling. An interesting behavior was observed at

γ=1, the storage modulus for the magnetic gel of rapid cooling was higher than that of natural cooling, which is opposite to the result at low strains. This might be due to a structural change by large strains enabling the movement of magnetic particles.

Figure 1(c) shows the strain dependence of

G' and

G" at 0 mT for carrageenan gels without magnetic particles (abbreviated as “carrageenan gel” hereafter) of natural cooling and rapid cooling. Linear viscoelastic regions were observed at strains below 2.4×10

-3 and 1.7×10

-3 for carrageenan gels of natural cooling and rapid cooling, respectively. The strains of

G' crossed

G” were 0.014 and 0.013 for carrageenan gels of natural cooling and rapid cooling, respectively. The parameters

G'(

γ=1)/

G'(

γ=10

-4), representing the amplitude of the Payne effect [

21] were 2.9×10

-4 and 3.2×10

-4 for carrageenan gels of natural cooling and rapid cooling, respectively, and were almost the same.

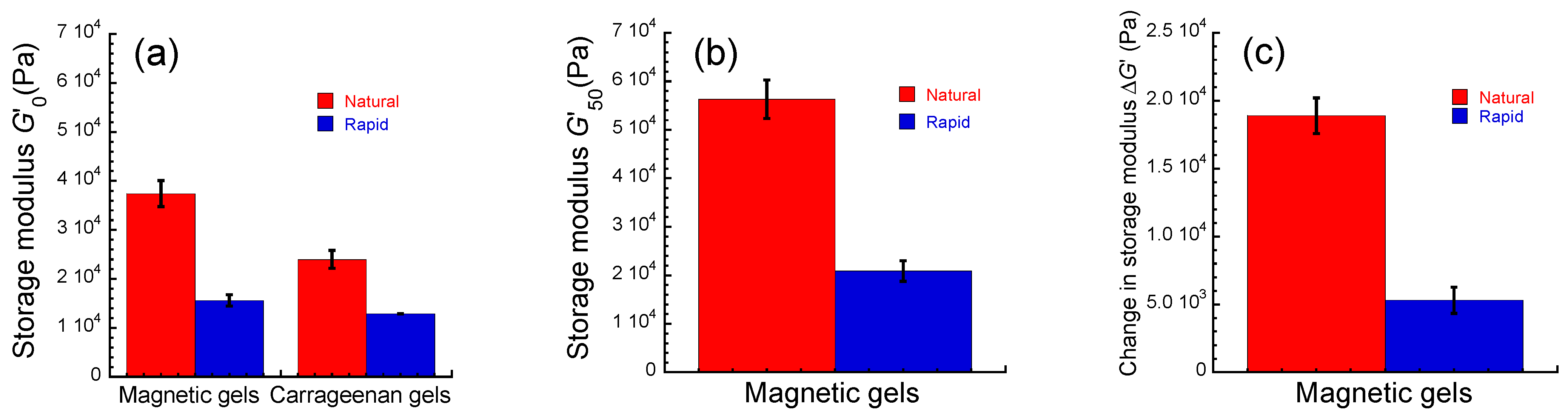

Figure 2(a) exhibits the storage modulus at 0 mT in the linear viscoelastic regime (

γ=10

-4) for magnetic gels and carrageenan gels of natural cooling and rapid cooling. The storage modulus for the magnetic gel of natural cooling was 3.7×10

4 Pa, which is 2.3 times higher than that of rapid cooling (=1.6×10

4 Pa). The storage modulus for the carrageenan gel of natural cooling was 2.4×10

4 Pa, which is 1.8 times higher than that of rapid cooling (=1.3×10

4 Pa). Accordingly, this indicates that a secondary structure of carrageenan network with low elasticity was formed by rapid cooling. Similar phenomenon has been observed for gellan gum [

17]. The storage modulus for the magnetic gel of natural cooling was 1.5 times higher than that for the carrageenan gel of natural cooling. The storage modulus for the magnetic gel of rapid cooling was almost the same as that of rapid cooling. The storage moduli at 0 mT for magnetic gels

G’ can be written by the following Einstein’s equation [

25];

G’=

G’

matrix(1 + 2.5

ϕ), where

G’

matrix is the storage modulus of the matrix at 0 mT and

ϕ is the volume fraction of magnetic particles. Since the

ϕ was constant at 0.12 in this experiment, the storage modulus for the magnetic gel should be 1.3 times higher than that of the matrix irrespective to the cooling rate. The storage moduli for magnetic gels of natural cooling and rapid cooling were 1.6 and 1.2 times higher than those for carrageenan gels, respectively. This suggests that the aggregations of magnetic particles were made in the magnetic gel of natural cooling and less aggregations were made in the magnetic gel of rapid cooling.

Figure 2(b) shows the storage modulus at 50 mT in the linear viscoelastic regime (

γ=10

-4) for magnetic gels of natural cooling and rapid cooling. The storage modulus for the magnetic gel of natural cooling was 5.6×10

4 Pa, which is 2.7 times higher than that of rapid cooling (=2.1×10

4 Pa).

Figure 2(c) shows the change in the storage modulus for magnetic gels of natural cooling and rapid cooling. The change in the storage modulus is the difference between the storage moduli at 0 mT

G'

0 and at 50 mT

G'

50 (Δ

G'=

G'

50-

G'

0). The change in the storage modulus was 1.9×10

4 Pa for the magnetic gel of natural cooling and 5.3×10

3 Pa for that of rapid cooling. Thus, an interesting result was obtained here that the cooling rate affects the change in the storage modulus by the magnetic field; the modulus change for the magnetic gel of natural cooling was 3.6 times higher than that of rapid cooling. The change in the storage modulus for the magnetic gel of natural cooling was consistent with the value we previously reported [

16].

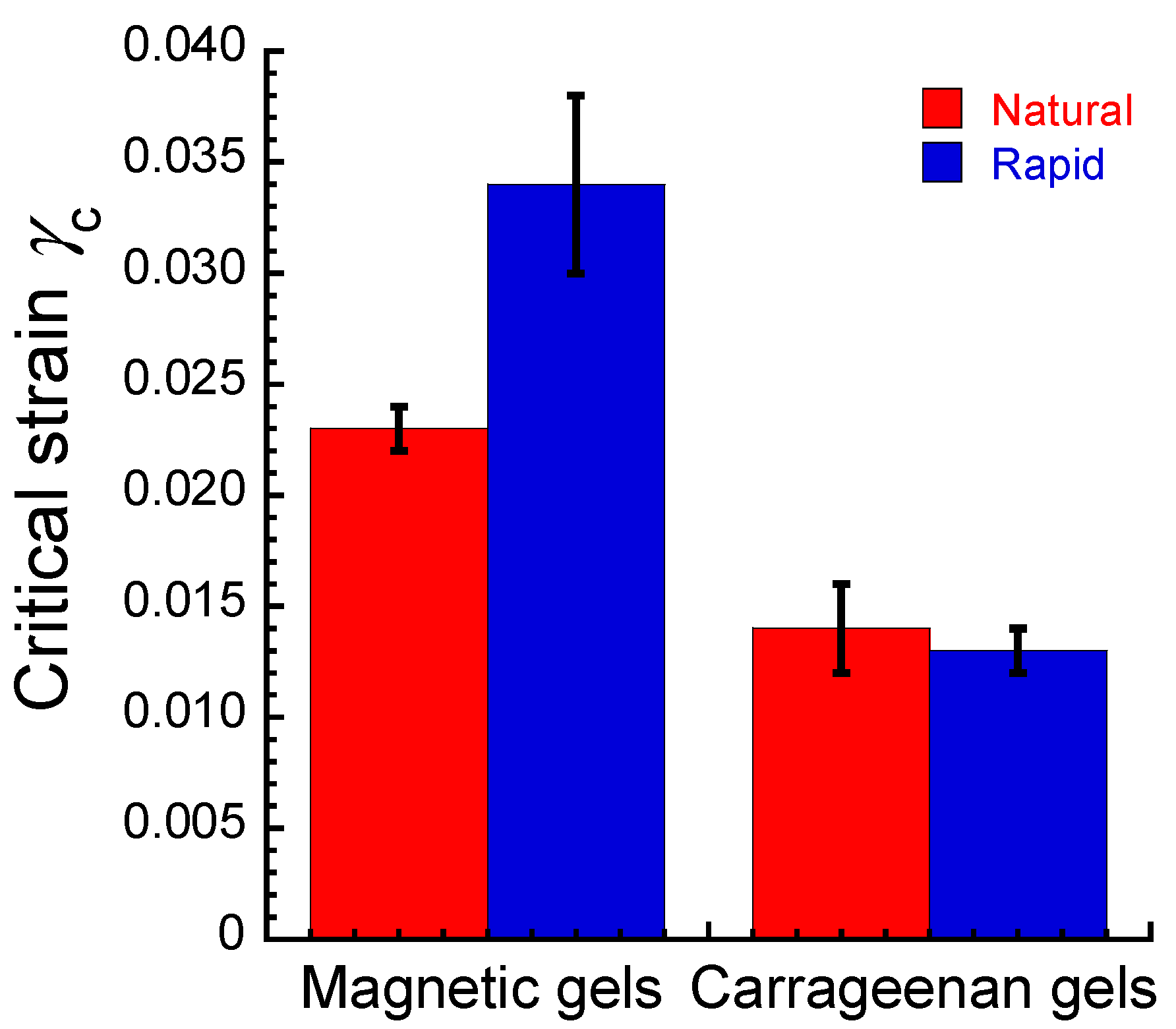

Figure 3 shows the critical strain at 0 mT

γc for magnetic gels and carrageenan gels of natural cooling and rapid cooling. The critical strain is a yield point intersecting the

G’ and

G” in

Figure 1, which is the onset of a fluidlike response and has been related to the failure of the network structure [

22,

23,

24]. Accordingly, it can be understood that the critical strain indicates the mechanical strength of the gel network. The critical strains were 0.023 and 0.034 for magnetic gels of natural cooling and rapid cooling, respectively. This indicates that the network structure for the magnetic gel of rapid cooling is stronger than that of natural cooling. The critical strain for carrageenan gel of natural cooling was almost the same as that of rapid cooling (~0.012). This strongly indicates that magnetic particles strongly interacted with the matrix of carrageenan for the magnetic gel of rapid cooling; it should be noted that rapid cooling does not make the carrageenan network reinforce itself. It can be considered for the magnetic gel of rapid cooling that the strong interaction between magnetic particles and the matrix of carrageenan reduced the change in the storage modulus by the magnetic field.

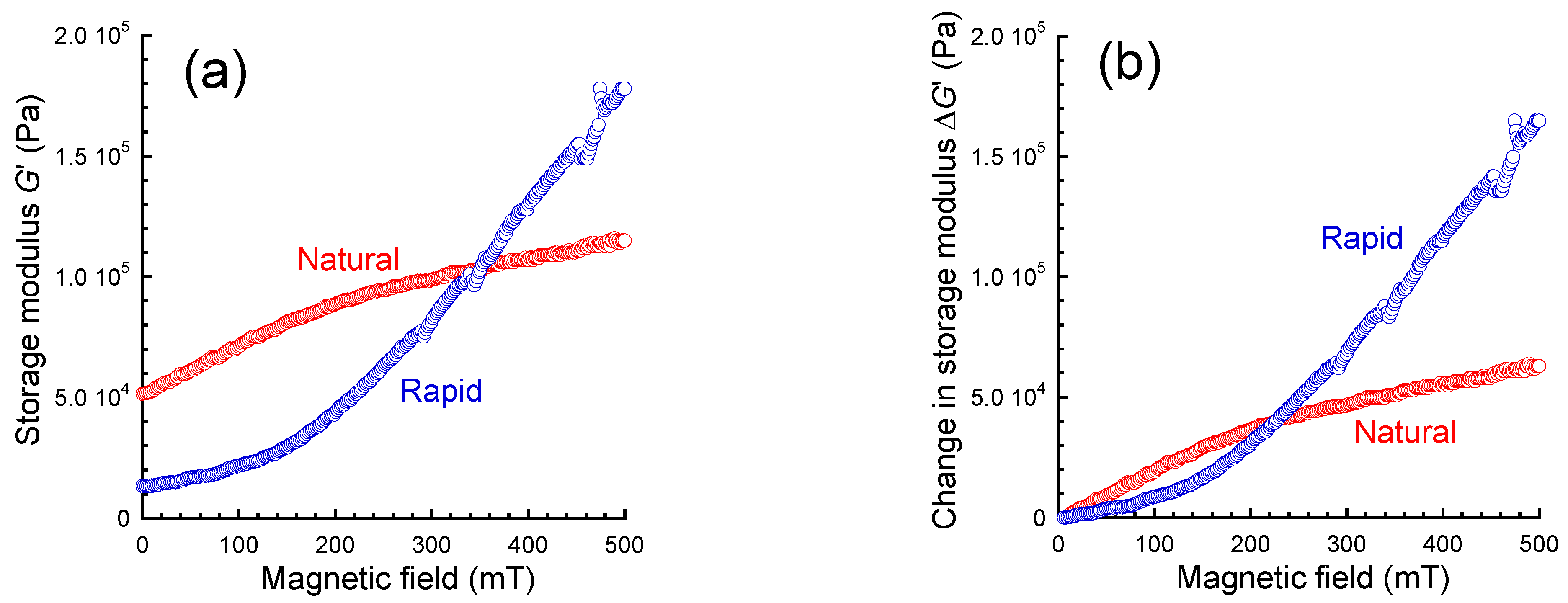

Figure 4(a) exhibits the magnetic field dependence of the storage modulus at a strain of 10

-4 for magnetic gels of natural cooling and rapid cooling. The storage modulus for the magnetic gel of natural cooling at 0 mT was 5.2×10

4 Pa and increased with the magnetic field to 1.1×10

5 Pa at 500 mT. On the other hand, the storage modulus for the magnetic gel of rapid cooling at 0 mT was 1.3×10

4 Pa and increased with the magnetic field to 1.8×10

5 Pa at 500 mT. An interesting behavior is that the differential coefficient d

G’/d

B for the magnetic gel of natural cooling was high at low magnetic fields and it decreased with the magnetic field, which is opposite to the behavior of typical magnetic soft materials as seen in the magnetic gel of rapid cooling.

Figure 4(b) shows the magnetic field dependence of the change in the storage modulus at a strain of 10

-4 for magnetic gels of natural cooling and rapid cooling. The change in the storage modulus of natural cooling demonstrated a curve with upward convex, as explained in

Figure 4(a), and reached 6.3×10

4 Pa at 500 mT. The change in the storage modulus for the magnetic gel of rapid cooling demonstrated a curve with downward convex, and reached 1.6×10

5 Pa at 500 mT. In other words, the change in the storage modulus at 500 mT for the magnetic gel of rapid cooling was 2.5 times larger than that of natural cooling. It is very interesting that such a clear difference was observed for these magnetic gels even though the magnetic particle concentration and magnetic field strength were exactly the same.

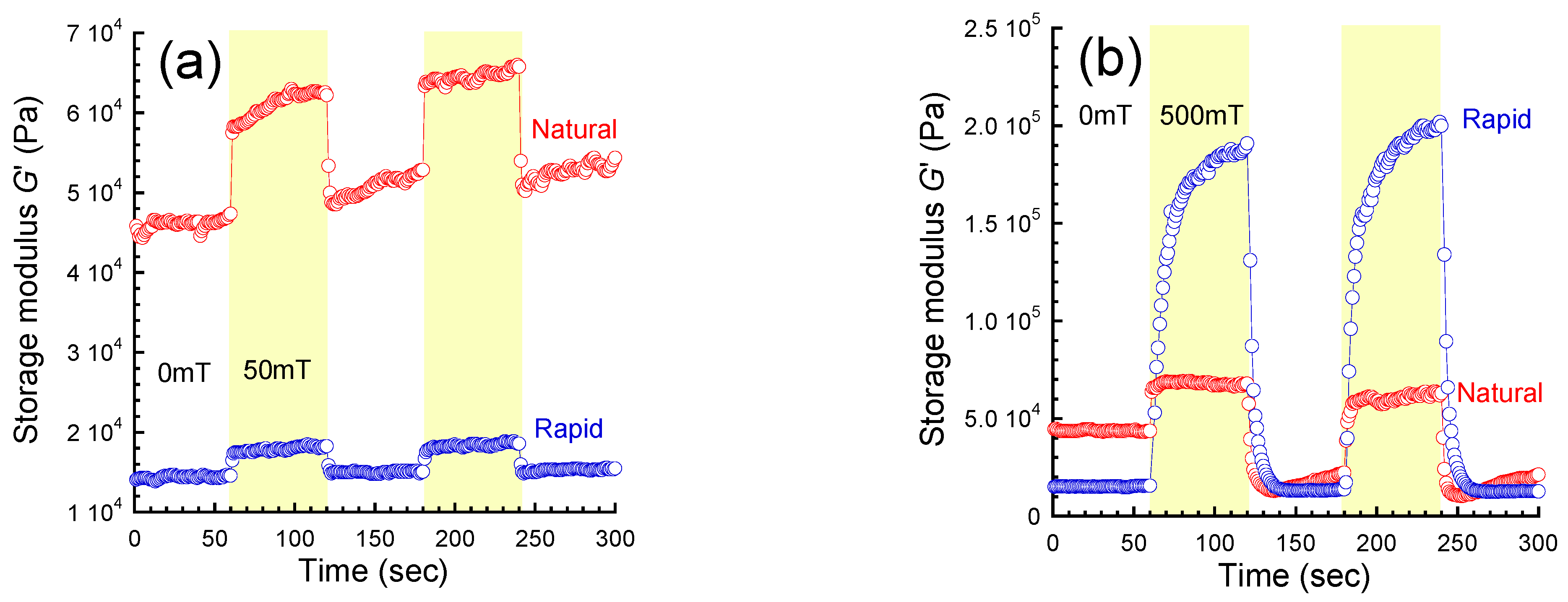

Figure 5 (a) demonstrates the magnetic field response of the storage modulus at 50 mT and

γ=10

-4 for magnetic gels of natural cooling and rapid cooling. For both magnetic gels, the storage modulus changed synchronized with the on-off switching of the magnetic field. The storage modulus for the magnetic gel of natural cooling at 0 mT was 4.6×10

4 Pa and increased to 5.8×10

4 Pa at 50 mT. On the other hand, the storage modulus for the magnetic gel of rapid cooling at 0 mT was 1.4×10

4 Pa and increased to 1.7×10

4 Pa at 50 mT. By applying the magnetic field repeatedly, the storage modulus at 0 mT for both magnetic gels showed a trend to increase gradually. This indicates that a certain structure was formed by the application of the magnetic field and remained after switching-off the field.

Figure 5(b) shows the magnetic field response of the storage modulus at 50 mT and

γ=10

-4 for magnetic gels of natural cooling and rapid cooling. Similar to the response at 50 mT, the storage moduli for both magnetic gels changed synchronized with the on-off switching of a magnetic field of 500 mT. The storage modulus at 0 mT for the magnetic gel of natural cooling was 4.5×10

4 Pa and increased to 6.8×10

4 Pa at 500 mT. On the other hand, the storage modulus at 0 mT for the magnetic gel of rapid cooling was 1.5×10

4 Pa and gradually increased to 2.0×10

5 Pa at 500 mT. The storage modulus for the magnetic gel of natural cooling decreased apparently by the first application of the magnetic field. This suggests that the original structure was destructed upon the first application of the magnetic field and the broken structure was not further destructed by the subsequent applications of the field. The values of the storage modulus for magnetic gels measured in the switching experiments were consistent with those measured in the strain dependence as shown in

Figure 2.

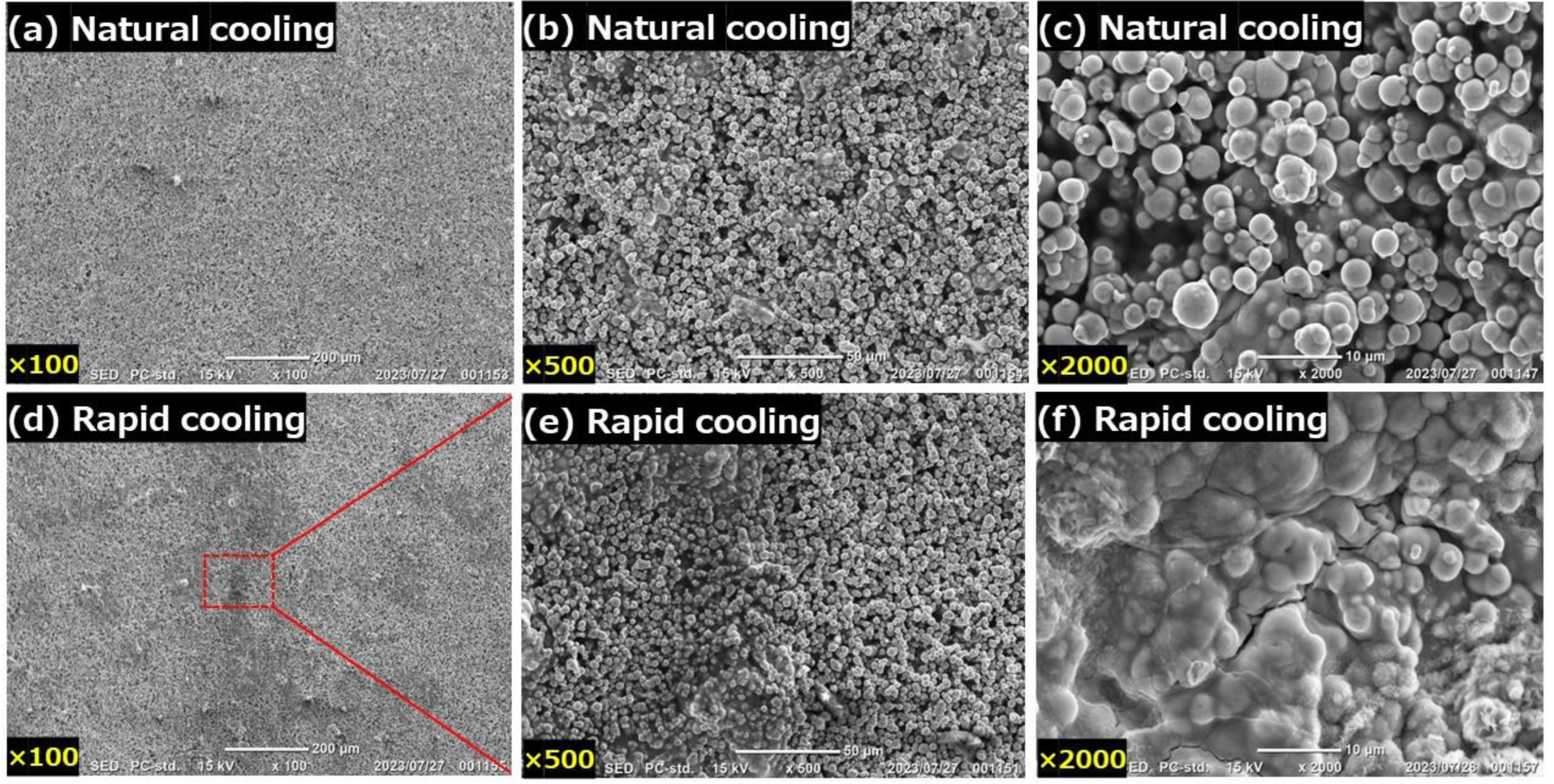

Figure 6 displays the SEM photographs for magnetic gels of natural cooling and rapid cooling in the absence of magnetic fields. A clear difference in the morphology between magnetic gels of natural cooling and rapid cooling can be seen in photos at low magnification. The morphology for the magnetic gel of natural cooling was heterogeneous showing many dark parts, meanwhile, it for the magnetic gel of rapid cooling was homogeneous without any dark parts. This feature can be clearly seen in

Figure 6(b,e).

Figure 6(e) is an enlarged photo of the square indicated by broken line of

Figure 6(d). The left half of

Figure 6(e) is a dark part of

Figure 6(b). That is, the dark part is due to not the heterogeneity of magnetic particles but the inhomogeneity of carrageenan network.

Figure 6(f) clearly showed that the dark part is a continuous phase of carrageenan in which magnetic particles are embedded, like a chocolate bar with nuts. The continuous phase of carrageenan was also seen in

Figure 6(c), however, it was very small just connecting only few particles. Thus, the area of the continuous phase of carrageenan for the magnetic gel of rapid cooling was far larger than that of natural cooling. It is considered that the movement of magnetic particles in the magnetic gel of rapid cooling is prevented by the continuous phase of carrageen, which may have resulted in small MR effects, as observed at 50 mT. Oppositely, the MR effect at 500 mT for the magnetic gel of rapid cooling was larger than that of natural cooling. It is also considered that the continuous phase of carrageenan was broken by the movement of magnetic particles on which strong magnetic force acts.

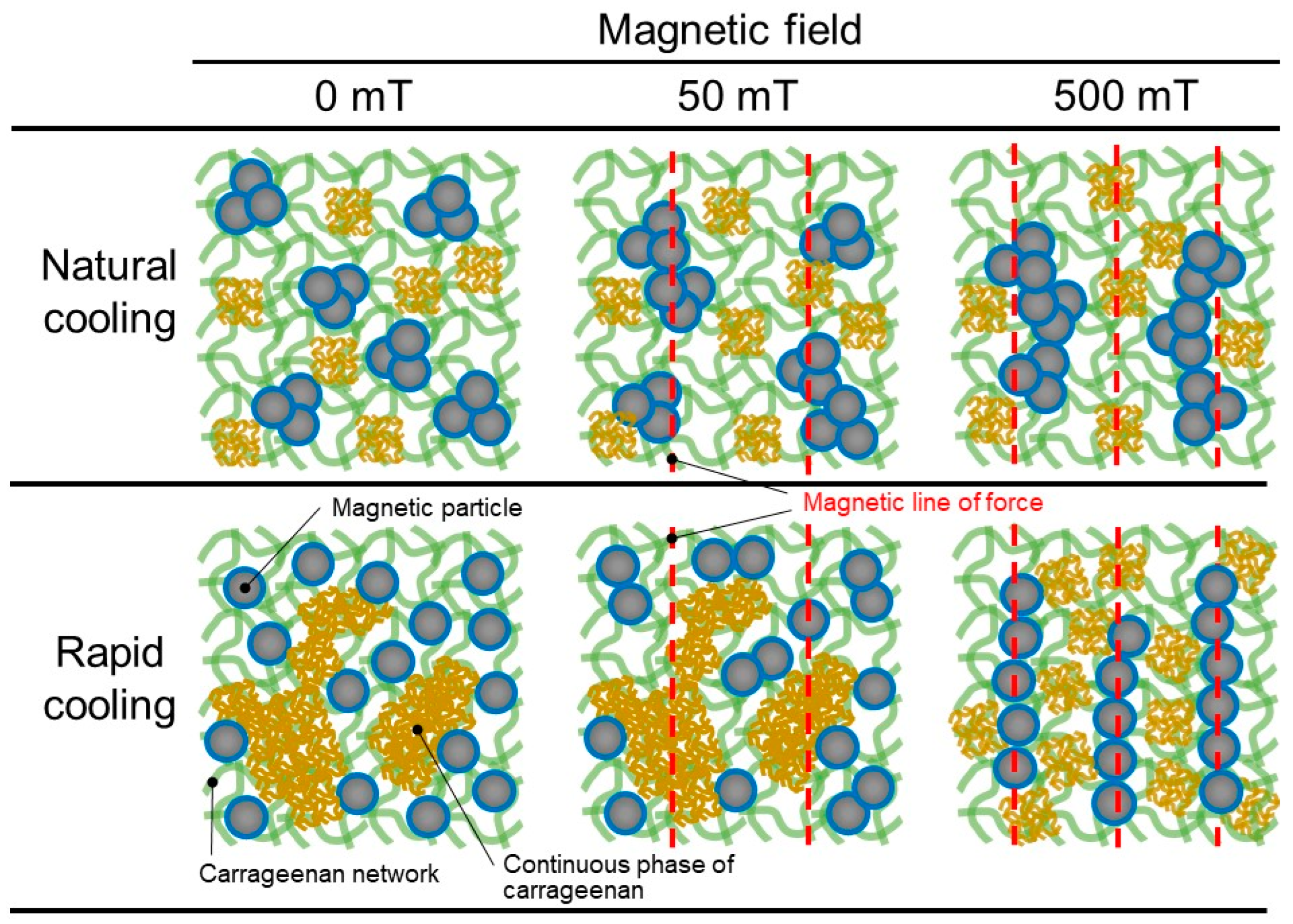

Figure 7 exhibits the schematic illustrations representing the surface morphologies of magnetic particles and carrageenan network, and the magnetorheological effect for magnetic gels prepared by natural cooling and rapid cooling. The storage moduli at 0 mT for magnetic gels of natural cooling and rapid cooling were higher and lower than those calculated from the Einstein’s equation, respectively. Therefore, magnetic particles form aggregations in the magnetic gel of natural cooling and they are dispersed randomly in the magnetic gel of rapid cooling. Large continuous phases of carrageenan were observed in SEM photographs for the magnetic gel of rapid cooling; some small aggregations of carrageenan were randomly distributed in the magnetic gel of natural cooling. The parameters representing the amplitude of the Payne effect for carrageenan gels of natural cooling and rapid cooling were almost the same, suggesting that the brittleness of the carrageenan network is not affected by the cooling rate. It can be considered under low magnetic fields that magnetic particles in the magnetic gel of rapid cooling are difficult to move due to the obstruction from the continuous phase of carrageenan. This may result in that the MR effect at 50 mT for the magnetic gel of natural cooling was higher than that of rapid cooling. At high magnetic fields (~500 mT), magnetic particles in the magnetic gel of rapid cooling can move and form a chain structure by breaking the restriction from the continuous phase of carrageenan. The number density of the chains should be high for the magnetic gel of rapid cooling since magnetic particles are well dispersed as primary particles, which may contribute to a large change in the storage modulus.