1. Introduction

Marine lysozyme (ML) has the characteristics of a low action temperature, a wide pH range, vigorous activity at room temperature, and a moderate reduction in activity as temperature decreases [

1,

2]. It gives new energy and chances to cleaning, medicine, environmental protection, and food processing sectors [

3,

4]. To take full advantage of the unique enzymatic properties of marine lysozyme and maximize production efficiency and product quality, it is necessary to have dynamic regulation and real-time optimization of the marine lysozyme fermentation process. However, the fermentation of marine lysozyme is a multivariate, time-varying, and complex nonlinear process. Key biochemical parameters that directly reflect the quality of the fermentation process, such as cell concentration, substrate concentration, and relative enzyme activity, can only be roughly estimated through offline sampling and analysis due to practical process technology and cost considerations. This procedure not only delays the collection of information, affecting the operator’s ability to make accurate decisions about the real-time response status, but it also limits the implementation of the best control methods. Therefore, it is urgently to find a method to achieve real-time and accurate prediction of key biochemical parameters in marine lysozyme fermentation process.

Soft sensor technology is an effective way to solve the above problems [

5,

9]. However, most of the soft sensor models currently used for online prediction are single global soft sensor models. Hua et al [

10] proposed a new hybrid soft sensor model based on RF-IHHO-LSTM for penicillin fermentation process in order to determine the key biological parameters in the process. The simulation results show that the established soft sensor model has high measurement accuracy and good effect, which can meet the practical requirements of the project. Wang et al [

11] introduced a hybrid ICS-MLSSVM soft sensor model to achieve online detection of key biochemical variables in the l-lysine fermentation process, and the simulation results showed that the proposed regression model could accurately predict the key biochemical variables. Tokuyama et al [

12] developed a novel soft sensor model for estimating the concentration of target products, substrates and bacterial cells in commercial fermenters. The results suggest that the machine learning-based soft sensor model could represent a novel monitoring system for digital transformation in the biotechnology process field. Wang et al [

13] used an artificial neural network model to develop soft sensors to monitor the microbial lipid fermentation process in lipolytic yeast, and the results showed that this model offers the possibility of monitoring stem cell weight, glucose concentration, and lipids online with high accuracy. Sun et al [

14] developed a SOM-LSSVM global modeling method for predicting the fermentation potency of CTC. Field experiments showed that the method could obtain more accurate potency prediction values.

Although the above models can fulfill the basic requirements of online prediction of key biochemical parameters, they do not take into account the nonlinear, multivariate, time-varying, and multi-stage characteristics of the biological fermentation process, making the global soft sensor model challenging to describe the multi-stage characteristics of the fermentation process and cannot guarantee prediction accuracy in the global scope. Some academics advise applying ensemble learning to this issue. Ensemble learning is a type of advanced machine learning method that combines underlying models along different lines to achieve accurate predictions. The underlying idea is that even if one weak base model gets an incorrect prediction, other weak base models can correct the mistake. Typically, ensemble learning has a stronger generalization capability than the base model. Shen et al [

15] proposed a new approach based on stochastic programming to realize a quality-related monitoring scheme for batch processing of multiple output modes through integrated learning. Wang et al [

16] established a prediction model for rumen fermentation parameters in dairy cows using stacked integrated learning method and in vitro technique, and the comparison results showed that the stacking ensemble learning method had better prediction results. Shen et al [

17] proposed a multivariate trajectory based integrated punctual learning strategy to realize a batch quality prediction scheme to solve the batch diversity problem. This demonstrates that the method based on ensemble learning theory framework, as a new soft sensor modeling method, has the characteristic of improving the accuracy of traditional single learning algorithms and significantly improving the generalization ability of learning systems. Due to its flexible adaptability, ensemble learning methods have been successfully applied in various fields. However, the marine lysozyme fermentation process is characterized by strong phase characteristics, the prediction curves of different phases differ greatly, and the sample data are small, if we continue to use the traditional average weighted ensemble learning method to form the model, we may not be possible to take advantage of the ensemble learning.

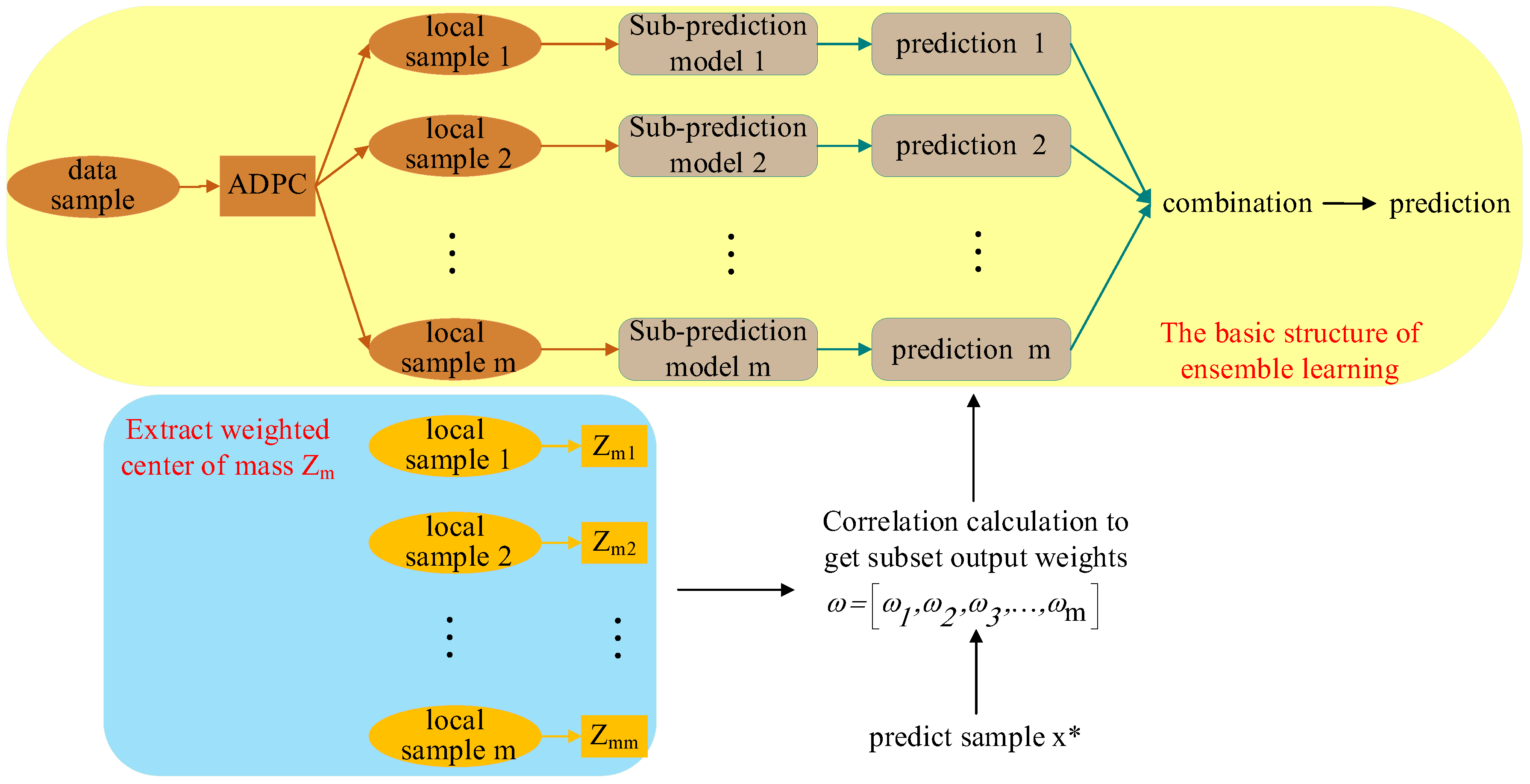

Based on the excellent characteristics of ensemble learning method in soft sensor model, and considering the non-linear, multivariate, and multi-stage characteristics of the marine lysozyme fermentation process, within the scope of ensemble learning theory, a soft sensor model based on improved seagull optimization algorithm coupled with Gaussian Process Regression (ISOA-GPR) weighted ensemble learning is proposed, as shown in

Figure 1. First, a subset of local samples is divided and trained using an improved density peak clustering algorithm (ADPC) to generate the ISOA-GPR local prediction sub-model. Then, this paper extract the center of mass of each local sample subset using the enhanced grey correlation algorithm and weight the information entropy to derive a weighted "center of mass" that more accurately represents the subset’s characteristics. Ultimately, the integration strategy for enhancing the weighting of the grey correlation algorithm is proposed by selecting the local sub-models with a higher degree of association with the test samples. The simulation results show that the proposed method has less prediction error and reduced volatility compared to the single global soft sensor model based on ISOA-GPR.

Figure 1.

The structure of ISOA-GPR weighted ensemble learning for marine lysozyme fermentation process.

Figure 1.

The structure of ISOA-GPR weighted ensemble learning for marine lysozyme fermentation process.

2. Theoretical analysis

2.1. Data subsets construction strategy

Using the distribution of marine lysozyme fermentation process data, this paper propose an improved density peak clustering algorithm (ADPC) that evaluates the similarity between data in terms of the proximity between data samples. Density peak clustering (DPC) is a typical methodology founded on density clustering [

22]. The algorithm requires that each data point relied on for classification has two feature values, local density

and relative distance

.The cluster center is assumed to have a more significant local density and a greater relative distance from other cluster centers than other data points.

For the sample set

, the local density

of data

is

where

and

represent the

i th and

j th data points, respectively.

is the distance between data

and

, and

is the truncation distance.

This research employs a declining trend inscription adaptive cluster center acquisition approach to increase cluster center selection accuracy. Because the DPC algorithm’s clustering center has a higher local density and relative distance than other data points, the logarithmic function was picked to accentuate the disparity between the clustering center and other data points. After arranging the acquired choice parameters in descending order, the declining trend of values is determined as .

Define a decision parameter

that combines local density and relative distance:

where

represents the current

value and

represent the

values at the preceding and subsequent times, respectively. The flowchart of the ADPC algorithm is shown in

Figure 2.

Figure 2.

Flowchart of the ADPC algorithm.

Figure 2.

Flowchart of the ADPC algorithm.

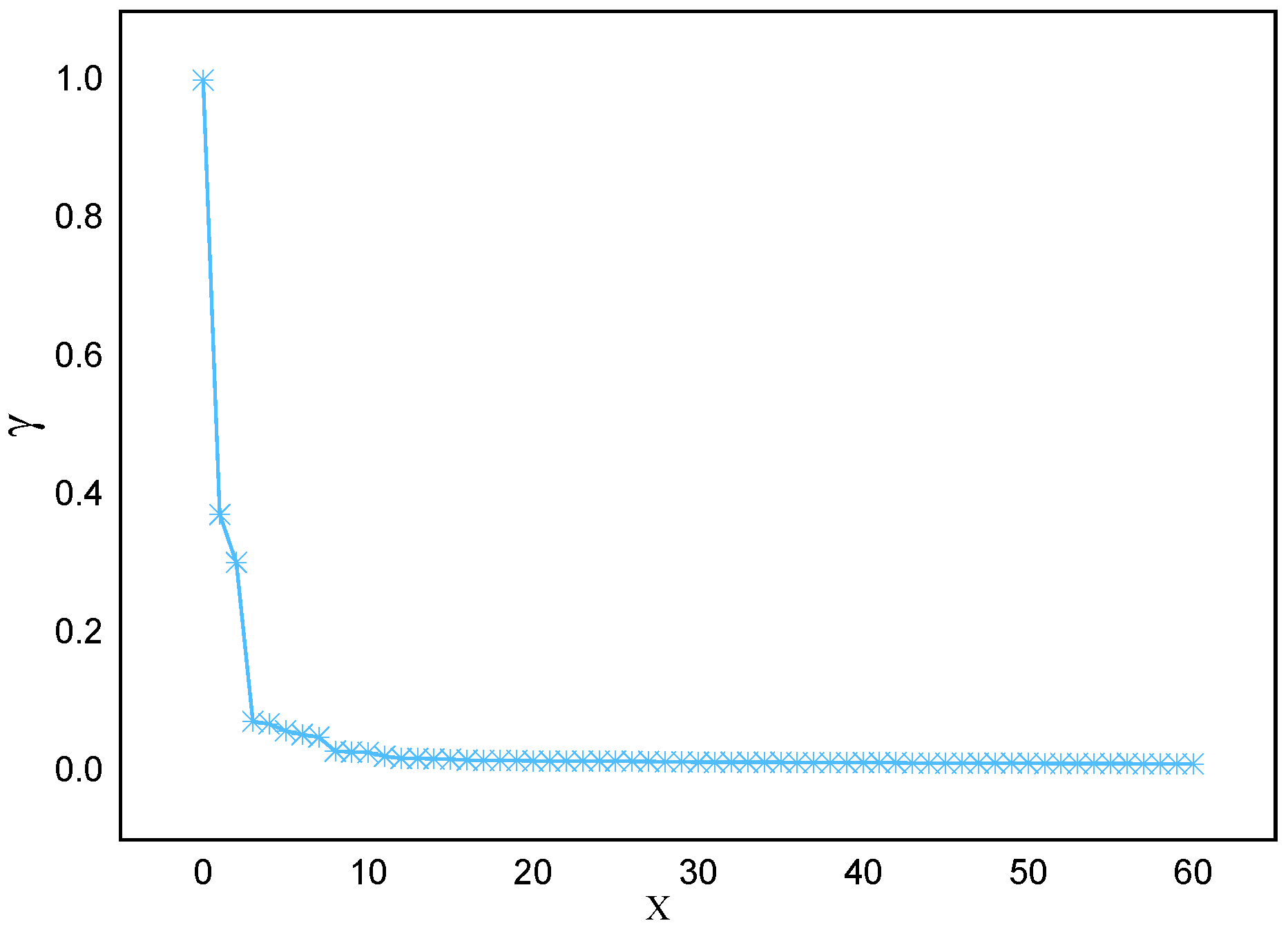

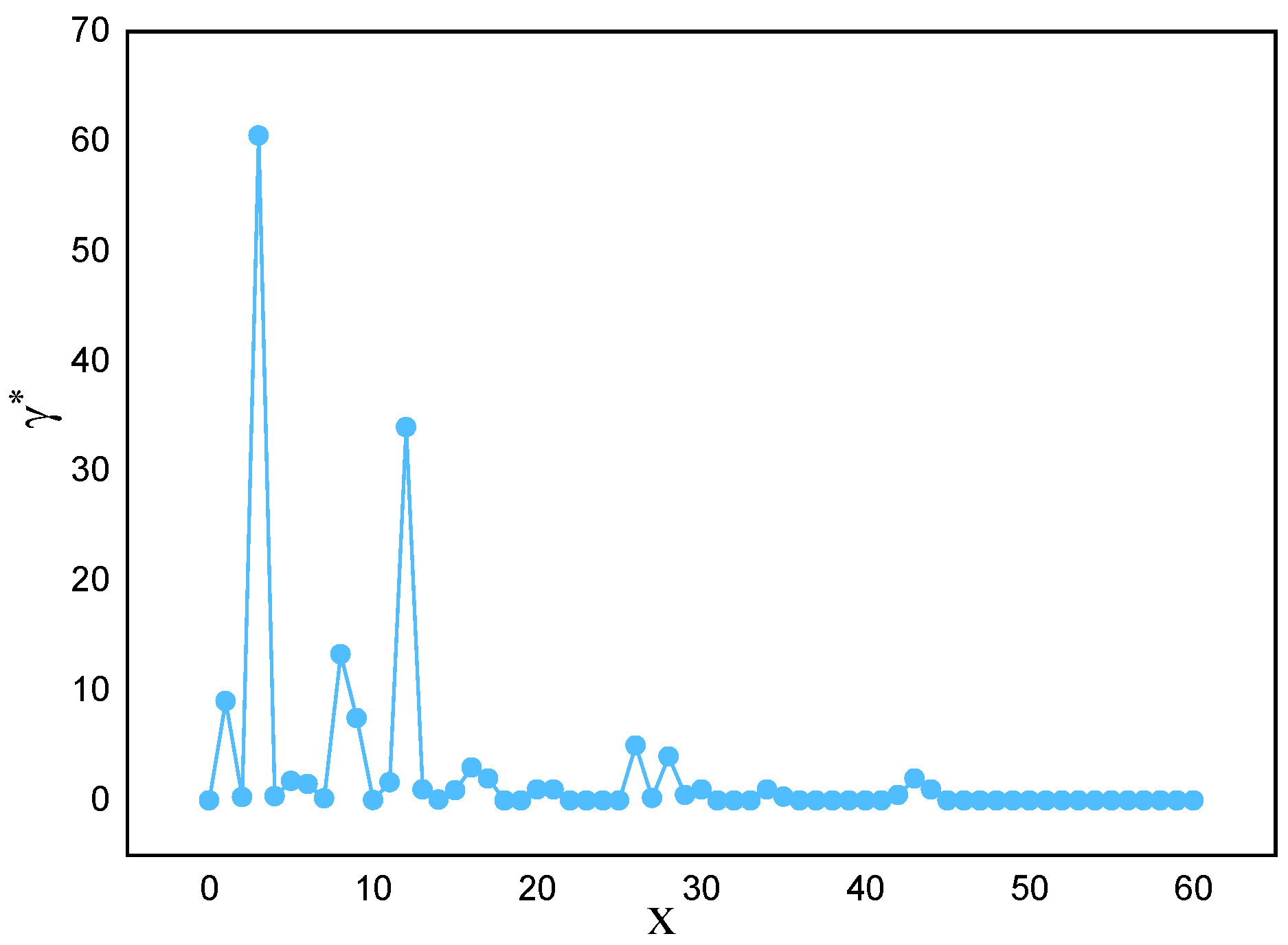

The method was applied to the marine lysozyme data samples, and distribution of the decision parameters and the tendency for the decision parameters to decrease were obtained, as shown in

Figure 3 and

Figure 4, respectively. As can be seen from the analysis in

Figure 3, except for the first few data points, the decision coefficients of the rest of the data points do not fluctuate much and are not suitable to be selected as clustering centers.

Figure 3.

Decision parameter distribution in descending order.

Figure 3.

Decision parameter distribution in descending order.

Figure 4.

The tendency for decision parameters to decrease.

Figure 4.

The tendency for decision parameters to decrease.

2.2. Sub-model construction

The real marine lysozyme fermentation process exhibits apparent non-linear properties, a tiny data sample size, and challenging offline extraction. The Gaussian process regression method was chosen to establish a sub-prediction model for marine lysozyme fermentation in this paper [

23]. For Gaussian process regression models, the choice of hyperparameters substantially affects the prediction model’s precision. Traditional parameter selection methods rely heavily on experience and trial and error; regression accuracy and calculation speed are not guaranteed. In order to generate a sub-model with a better prediction effect, this paper uses the Improved Seagull Optimization Algorithm (ISOA) for online optimization and adjustment of hyperparameters.

2.3. Improved seagull optimization algorithm

The seagull optimization algorithm (SOA) is an intelligent algorithm that simulates individual seagull flocks in nature and seeks to perform iterative optimization search in the solution space by employing the long-distance migration and spiral attack behavior of individual seagulls with the change of seasons [

24]. When compared to other optimization algorithms, the SOA method has a simpler structure, more adaptability and stability, and only one modifiable parameter A in practice .

In the conventional seagull optimization algorithm, the inertia weight decreases linearly as the number of iterations increases. Even though the repetition speed is faster, it is easy to cause the population variety to fall with each iteration. There is also a problem with weak global search ability in the early stage and poor local mining ability in the later stage. So this paper proposes a non-linear change in the inertia weight updating strategy. The specific expression is as follows:

where

is the current number of iterations,

is the maximum number of iterations, and

is a constant whose initial value is set to 2.

In the early iterations of the improved seagull optimization algorithm, the inertia weight

decreases abruptly to maintain population diversity while enhancing its global search capability; in the later stages of execution, the inertia weight

decreases gradually to increase the local search capability while ensuring that the algorithm is not easily trapped in a local optimum. Therefore, the optimal adjustment for the hyperparameters with the improved seagull optimization algorithm will undoubtedly result in a more accurate soft sensor model. The pseudocode of ISOA algorithm is given in

Appendix.

2.4. Sub-model selection and fusion strategy

This paper finds the weighted "center of mass"

that best represents the whole data subset and describes the relationship between the sub-model and the test sample by the degree of association between

and the test sample so that the right sub-model can be selected for integration weighting. The correlation coefficient between the test sequences and the weighted "center of mass" of the local subset was analyzed using an improved gray correlation algorithm that more accurately reflects the fluctuation between the marine lysozyme fermentation data sequences to determine their degree of correlation. Given a sample subset of marine lysozyme fermentation process data

, where

is the number of samples in each subgroup and

is the feature variable’s dimensionality. Let the reference sequence be

and calculate the gray correlation coefficient:

where

,

indicates the resolution coefficient, which is taken as 0.5.

The correlation between the reference and comparison sequences is calculated as follows:

So that each sample of the local sample subset is used as a reference sequence and the remaining samples are comparison sequences, the correlation matrix of the generated samples is calculated as follows:

The sample with the strongest correlation with all subsets data is picked as the data set’s initial center of mass, and its correlation coefficients with other samples in that subset are reported to generate the correlation coefficient matrix:

In this paper, this paper present information entropy weighting to characterize the degree of variation for each feature variable under the correlation coefficient matrix, assign objective weights to the feature variables, and derive an objective subset of the "center of mass." In general, the lower a feature variable’s information entropy, the larger its degree of variation and the higher its given weight. Conversely, when information entropy increases, the relevance of feature variables decreases, and weights decrease. The characteristic weight of the

nd characteristic variable of the

th sample is calculated as:

Entropy value of the

characteristic variable:

Then, the weights of each characteristic variable are in the correlation system matrix.

The previous computation produces the weighted center of mass

of the

m sample subsets of the fermentation process, assuming that the enhanced density peak clustering approach correctly collects

m local sample subsets. This paper obtained the

correlation set

using the fermentation test sample as the reference sequence and the

m subsets of "center of mass"

as the comparison sequence. This paper kept the ISOA-GPR sub-model corresponding to a correlation degree greater than or equal

. Its corresponding fermentation process sub-model prediction result is

, so the final prediction result of gray correlation weighted integration is:

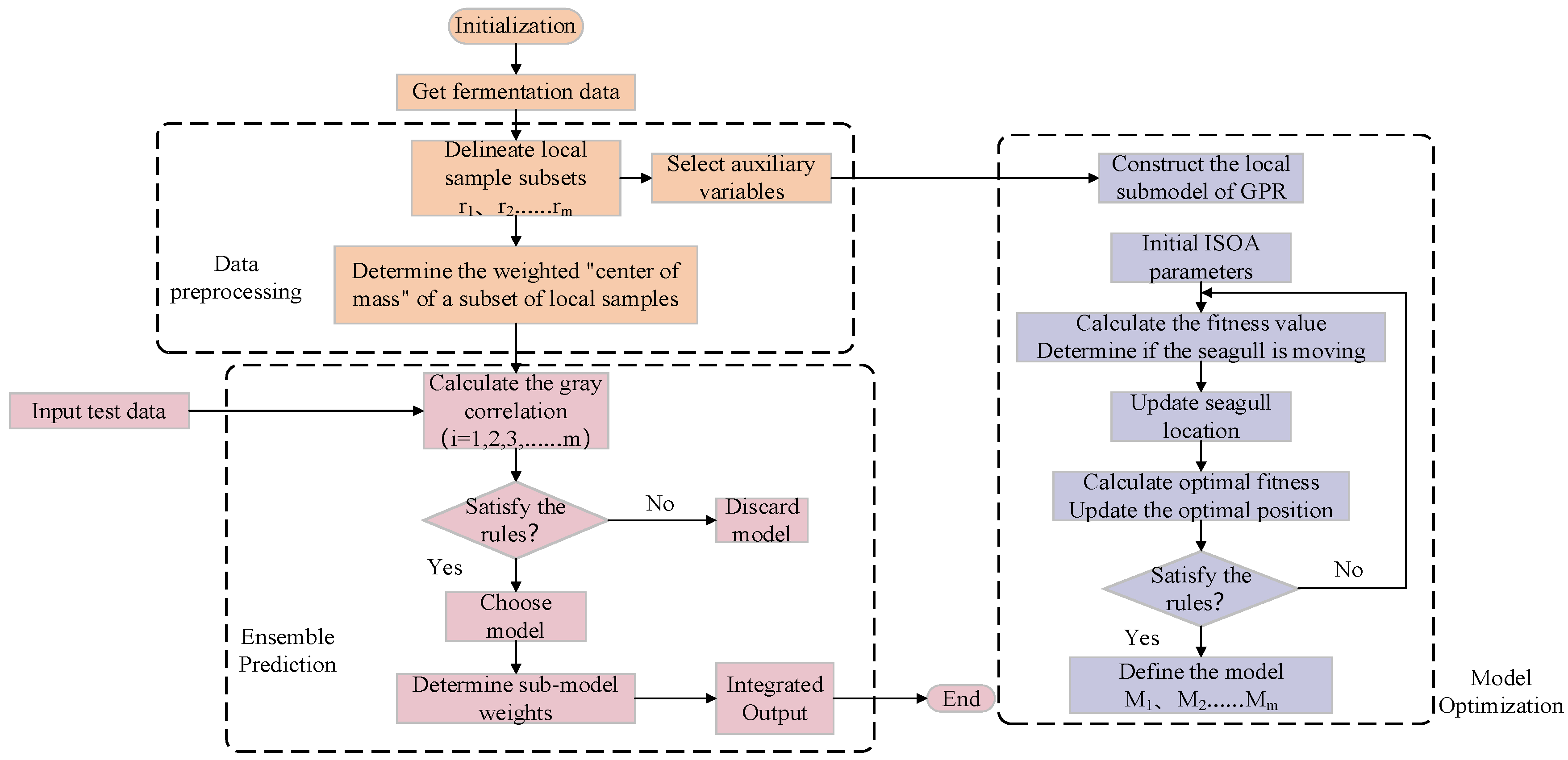

3. Modeling process

Figure 5 depicts the specific flow of soft sensor model for marine lysozyme fermentation process. The procedure of modeling is described as follows:

Step 1: Obtain data on marine lysozyme fermentation process through experiments, including major environmental parameters and key biochemical parameters (bacteriophage concentration, substrate concentration, relative enzyme activity). The upgraded density peak clustering technique is utilized to define local sample subsets ()as well as to calculate the weighted center of mass () for each local sample subset.

Step 2: Calculate the consistent correlations degree between various environmental parameters and key biochemical parameters, and select environmental parameters with correlations greater than 0.7 as auxiliary variables. Building a GPR sub-model for ISOA optimization.

Step 3: Send the measured data () to be bested, calculate its gray correlation () with each weighted "center of mass", and select the ISOA-GPR model () as a sub-model. Determine the output weights of each sub-model and output predictions according to equation (12).

Figure 5.

Soft sensor model specific flow chart.

Figure 5.

Soft sensor model specific flow chart.

4. Example Simulation

In this study, simulations are done utilizing marine lysozyme fermentation process data to demonstrate the efficiency of the proposed online soft sensor model. The culture strain was S-12-86, and the fermenter model was A103-500L. The Yellow Sea Fisheries Research Institute of the Chinese Academy of Fisheries Sciences gave the marine lysozyme fermentation method, and the Jiangsu University fermentation control system platform provided the navigational lysozyme fermentation data.

With bacterium concentration (

X), substrate concentration (

S), and relative enzyme activity (

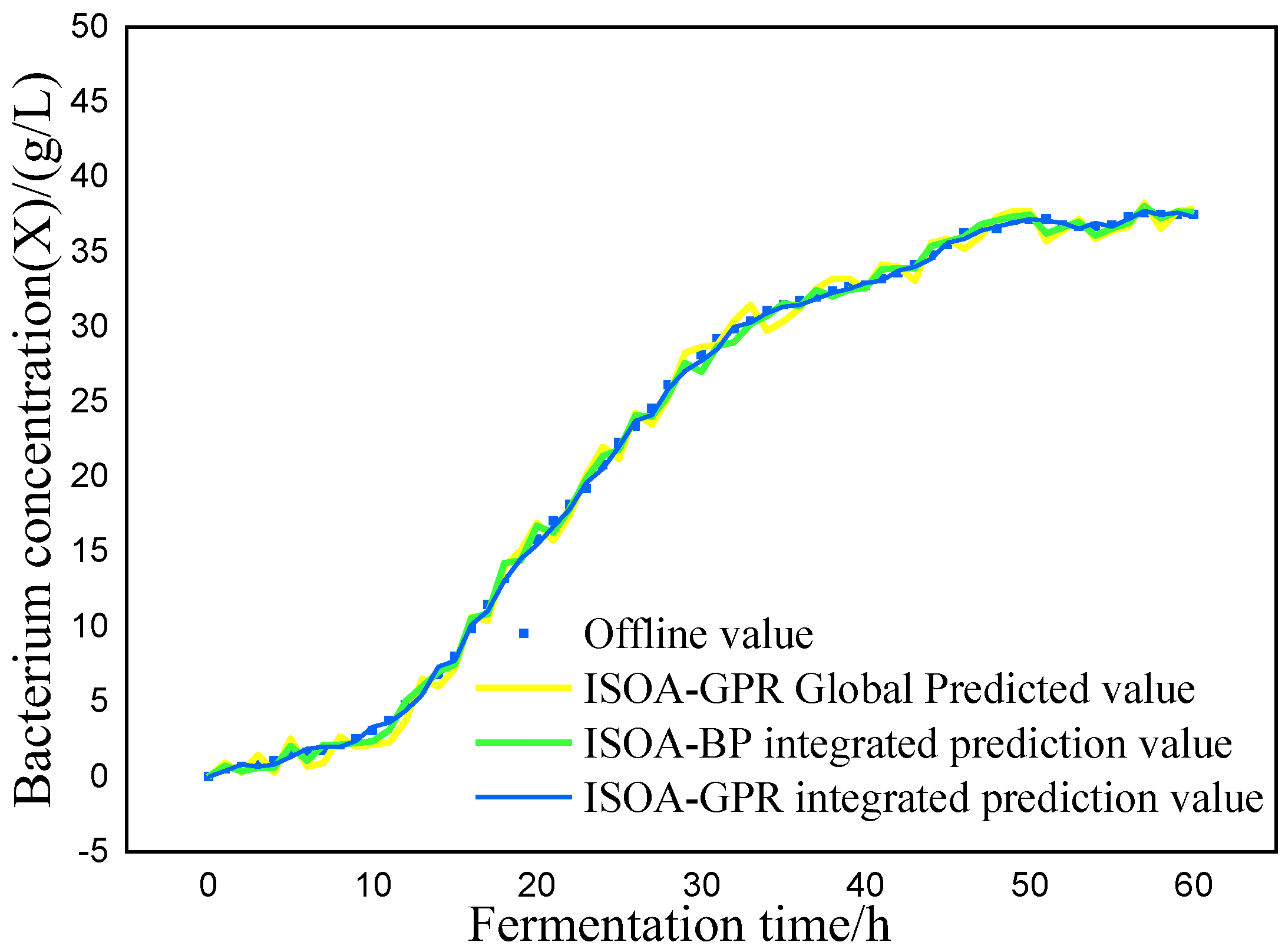

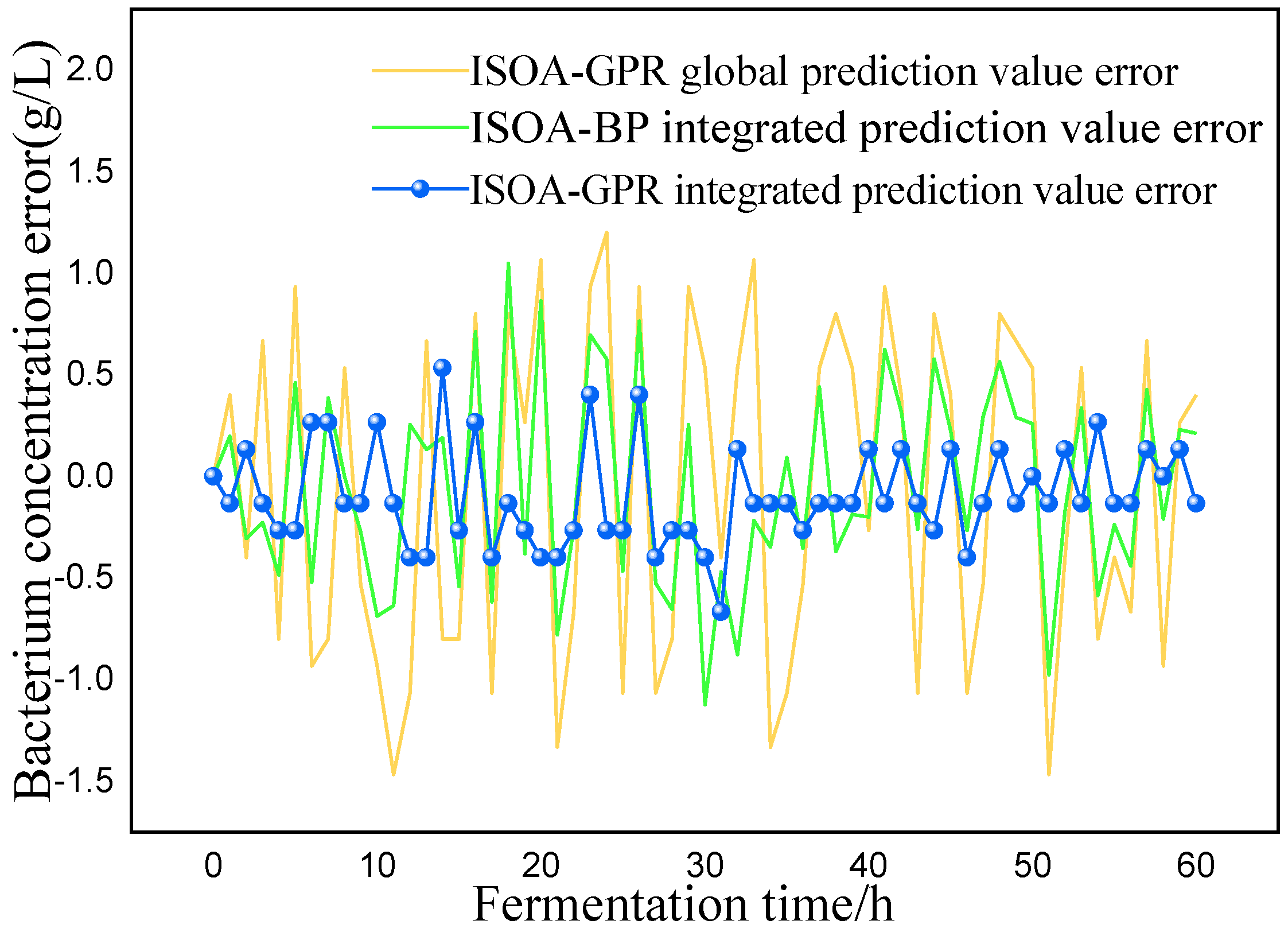

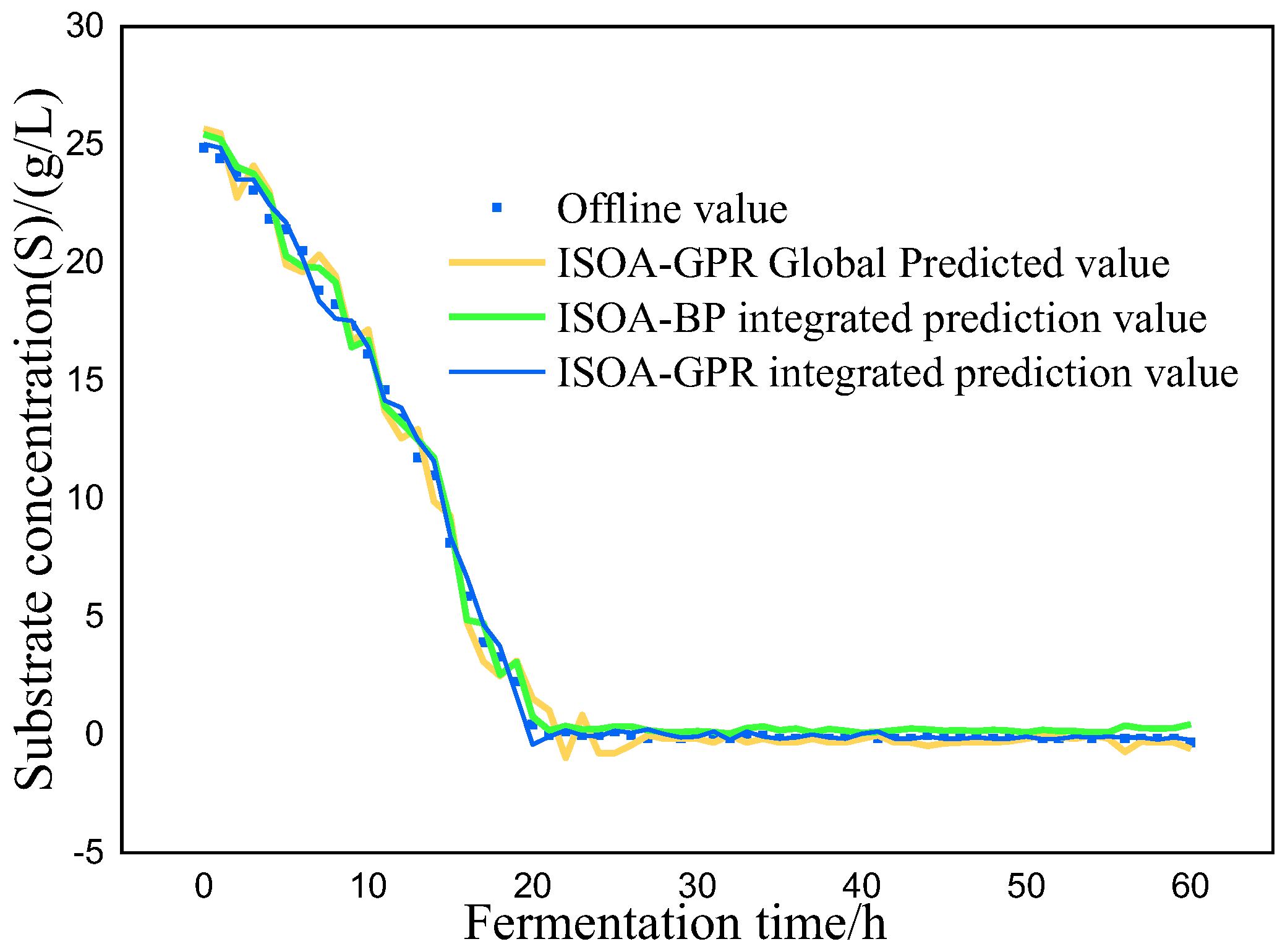

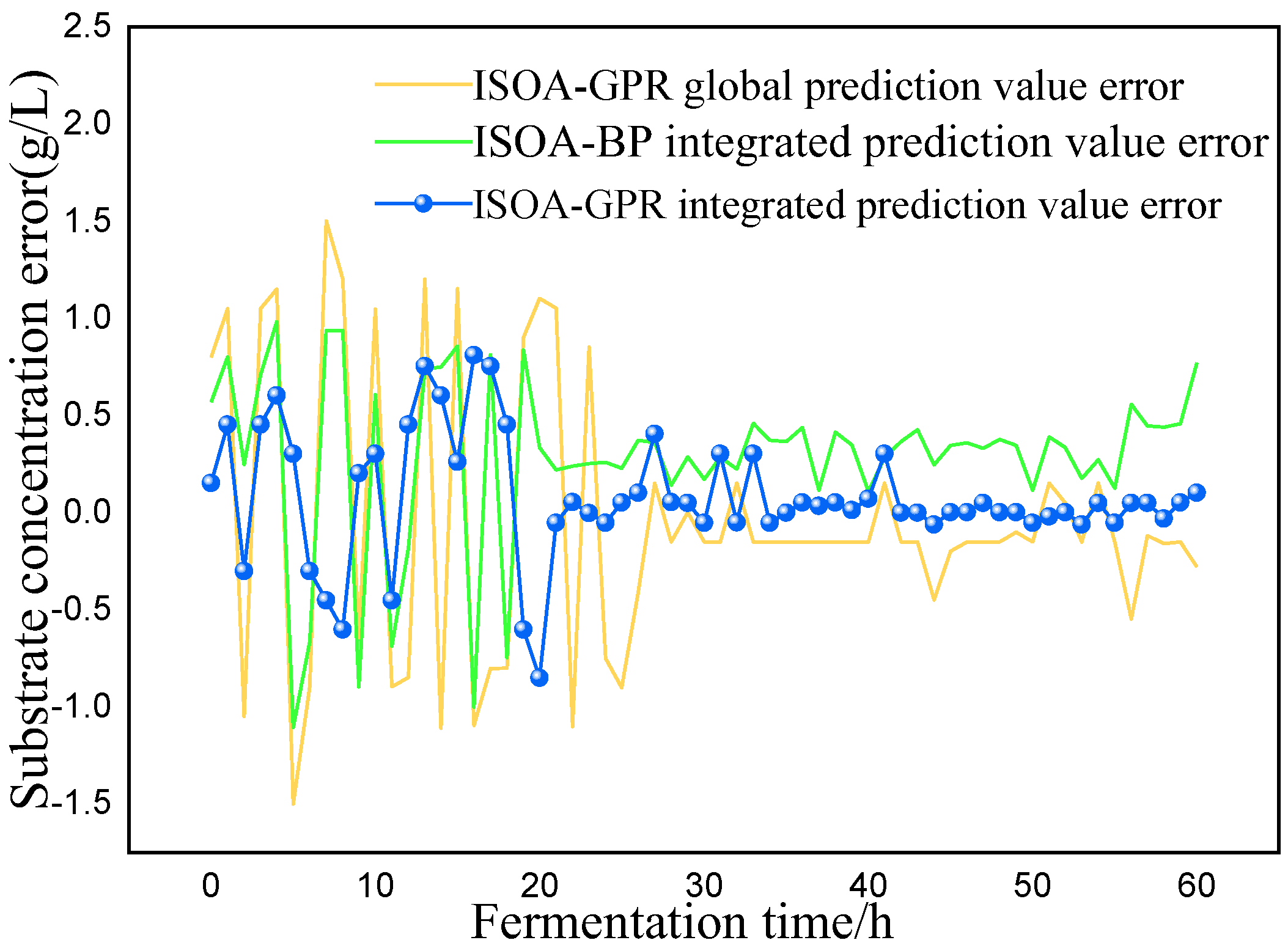

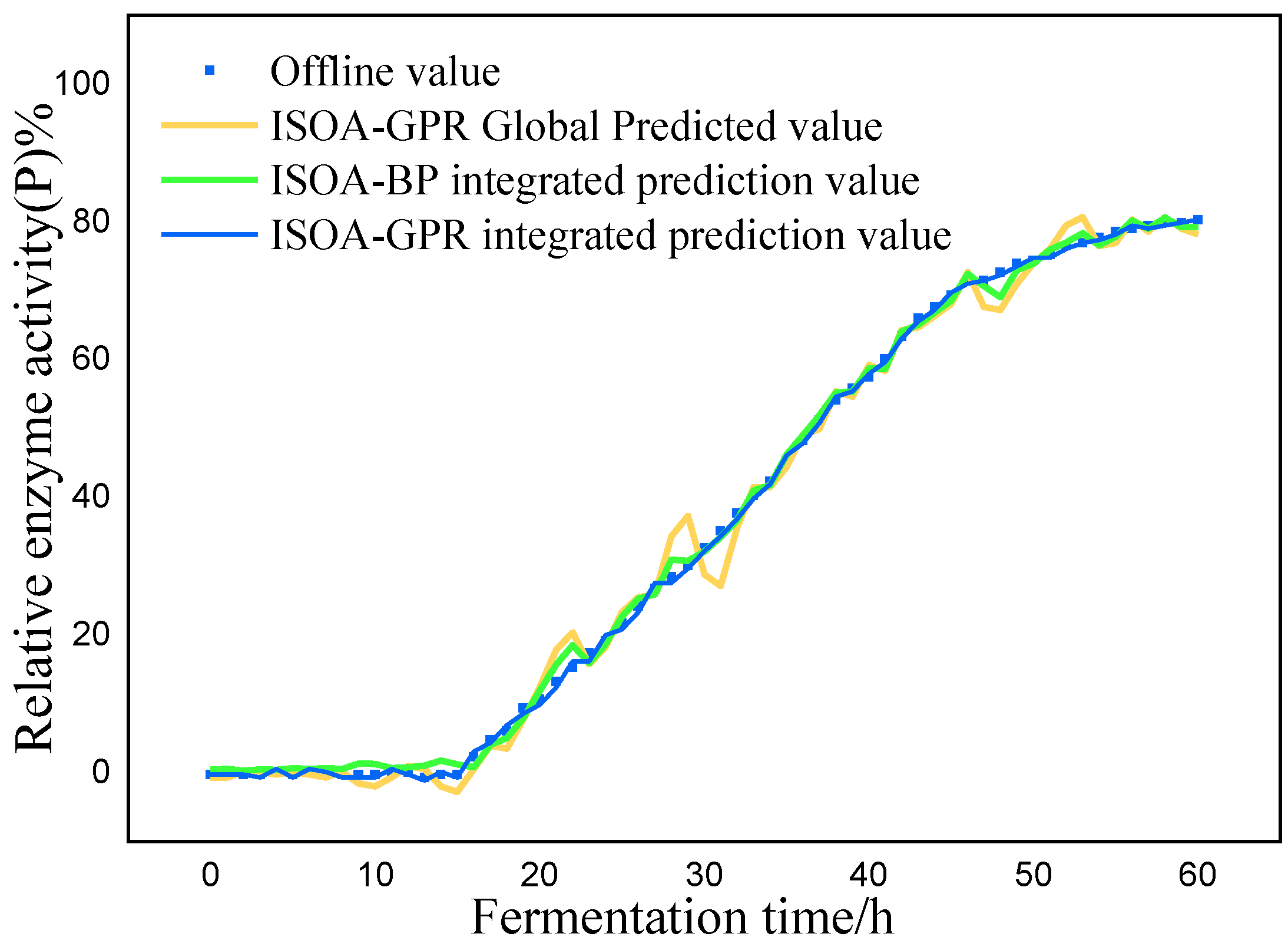

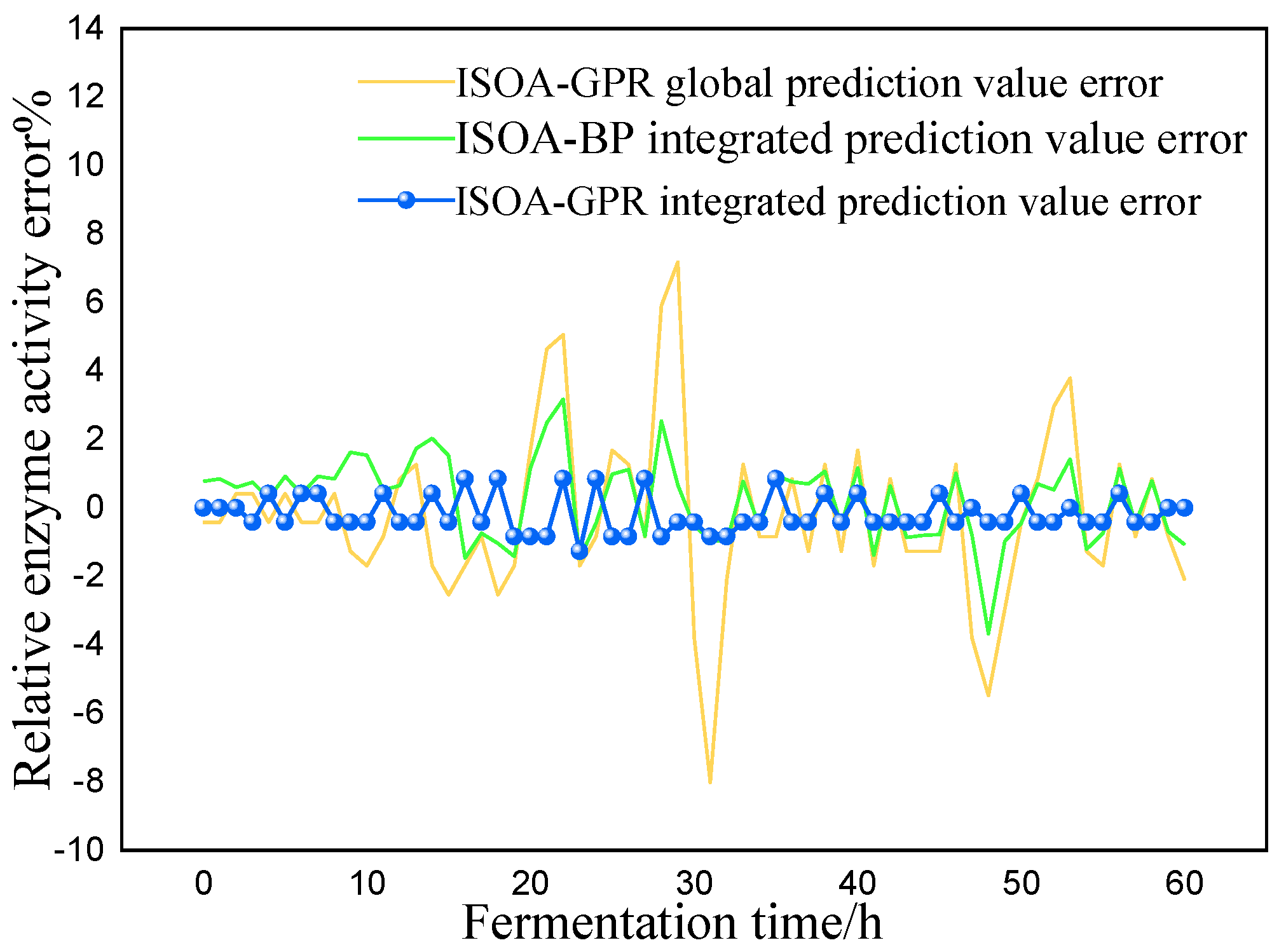

P) as the most critical variables for marine lysozyme fermentation, this paper used the consistent correlation method to filter the auxiliary variables and took data from a total of 15 fermentation batches. The first 12 batches, which included 720 total data points, served as training samples, while the final three batches, which had 180 total data points, served as test samples. These measurements were utilized for training simulations based on a single global ISOA-GPR model, an ISOA-BP-weighted ensemble soft sensor model and an ISOA-GPR-weighted ensemble soft sensor model. The simulation results are depicted in

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10 and

Figure 11. To show that the ISOA-GPR weighted ensemble soft sensor model performs better, root mean square and maximum absolute errors compare how well the three models can predict.

Table 1 displays the results.

where

represents the values of all actual key biological parameters (bacterial concentration, substrate concentration, and relative enzyme activity) for the tested samples and

represents the values of all predicted key biological parameters (bacterial concentration, substrate concentration, and relative enzyme activity) for the tested samples.

Figure 6.

Predicted curve of bacterium concentration.

Figure 6.

Predicted curve of bacterium concentration.

Figure 7.

Error variation curve of bacterium concentration.

Figure 7.

Error variation curve of bacterium concentration.

Figure 8.

Predicted curve of substrate concentration.

Figure 8.

Predicted curve of substrate concentration.

Figure 9.

Error variation curve of substrate concentration.

Figure 9.

Error variation curve of substrate concentration.

Figure 10.

Predicted curve of relative enzyme activity.

Figure 10.

Predicted curve of relative enzyme activity.

Figure 11.

Error variation curve of relative enzyme activity.

Figure 11.

Error variation curve of relative enzyme activity.

Table 1.

Comparison of the errors of the two modeling methods.

Table 1.

Comparison of the errors of the two modeling methods.

| Modeling Method |

eMAE |

eRMSE |

| X |

S |

P |

X |

S |

P |

| Single global ISOA-GPR model |

1.2 |

1.5017 |

7.1730 |

0.8153 |

0.6946 |

2.4651 |

| Weighted ensemble ISOA-BP model |

1.05 |

0.9820 |

3.1801 |

0.4943 |

0.5381 |

1.2316 |

| Weighted ensemble ISOA-GPR model |

0.5333 |

0.8103 |

0.8439 |

0.2561 |

0.3281 |

0.5509 |

From the above figures and table analysis:

1) Comparing the prediction results of the single global ISOA-GPR model and the weighted ensemble ISOA-GPR model for bacterial concentration, substrate concentration and relative enzyme activity, it is intuitively found that the prediction results based on the weighted ensemble ISOA-GPR model are significantly less volatile than those based on the single global ISOA-GPR model, and the root-mean-square prediction errors are 68.6%, 52.8% and 77.7% lower, respectively. allowing better monitoring of the actual values of key biochemical parameters.

2) Comparing the prediction results of the single global ISOA-GPR model and the weighted ensemble ISOA-BP model for the three biochemical parameters, it was found that the weighted ensemble ISOA-BP model increased the prediction accuracy to a certain extent, but not as much as the weighted ensemble ISOA-GPR model did. In the late stage of substrate concentration prediction, the prediction error of the weighted ensemble ISOA-BP model increased significantly, so the weighted ensemble ISOA-GPR model has some advantages in the prediction process of the three biochemical parameters.

4. Conclusion

The fundamental biological characteristics of marine lysozyme fermentation process are challenging to assess online and in real-time. To handle the problem that a single global model method is less reliable and does not guarantee global forecast accuracy. This paper present an ISOA-GPR-weighted ensemble soft sensor model in this research. First, the fermentation process data are adaptively partitioned on the improved density peak clustering algorithm. Then, a soft sensor sub-model of the fermentation process was created swith an enhanced seagull optimization algorithm and the Gaussian process regression (ISOA-GPR) methodology. Finally, an improved grey correlation algorithm is employed to extract the subset’s entropy-weighted "centre of mass" and filter the sub-model integration output. This paper use the developed soft sensor model to predict key parameters of marine lysozyme. The simulation data show that the root means square errors of the proposed method in marine lysozyme fermentation process are 0.5333, 0.8103, and 0.8439, respectively, which can achieve the prediction of bacteriophage concentration based on less training data, and the prediction errors are small enough to meet the demand for online measurement of key parameters of marine lysozyme.

Compared with the traditional single global soft sensor model, the method proposed in this paper is more in line with the actual situation of marine lysozyme fermentation at the theoretical level, which not only realizes the on-line prediction of the key biological parameters of the marine lysozyme fermentation process, but also effectively improves its on-line prediction and tracking ability, and solves the problem of poor prediction accuracy of the traditional single global soft sensor model. At the same time, it provides new solution ideas for other complex nonlinear online prediction industries. The conclusions of the article are obtained under ideal experimental conditions, but in the actual industrial fermentation process, the fermentation conditions are prone to sudden changes, and subtle differences in the fermentation conditions will have an impact on the prediction results, so the next stage of the study is to solve the problem of how to apply this method to the actual complex fermentation process.

Appendix

|

Algorithm 1: Improved Seagull Optimization Algorithm (ISOA). |

| Input: seagull population Pos |

| Output: optimal search agent bestPos |

1: Initialize the parameters maxIter, population and func

/*here func represents the fitness function*/ |

| 2: procedure ISOA |

| 3: set fc ← 2 |

| 4: set u ← 1 |

| 5: set v ← 1 |

| /*Initialize Pos*/ |

6: Pos ← Init(population,dim,lb,ub)

/*Initialize the Pos of each seagull agent using Init function*/

/*here dim represents the dimension of the given problem*/

/*here ub, lb represent the upper and lower bounds*/ |

| 7: fitness ← func(Pos) |

| 8: [sortfitness, index] ← sort(fitness) |

| 9: bestfitness ← sortfitness(1) |

| 10: bestPos ← Pos(index(1), :) |

| 11: for t ← 1 to maxIter do

|

| /*Migration behavior*/ |

| 12: A ← -fc*tan(t/maxIter*pi/4-pi/4) |

| 13: Cs ← A.*Pos |

| 14: B ← 2.*A^2.*rand(population,1) |

| 15: Ms ← B.*(bestPos-Pos) |

| 16: Ds ← abdz(Cs+Ms) |

| /*Attacking behavior*/ |

| 17: theta ← rand(population,1).*2.*pi |

| 18: r ← u.*exp(theta.*v) |

| 19: x ← r.*cos(theta) |

| 20: y ← r.*sin(theta) |

| 21: z ← r.* theta |

| 22: Pos ← Ds.*x.*y.*z+Pos |

| /*Update optimal search agent*/ |

| 23: for i ← 1 to population do

|

| 24: fitness(i) ← func(Pos(i), :) |

| 25: if (fitness(i) < bestfitness) then |

| 26: bestfitness ← fitness(i) |

| 27: bestPos ← Pos(i, :) |

| 28: end for

|

| 29: end for

|

| 30: return bestPos |

| 30: end procedure

|

References

- Lesnierowski G, Yang TY. Lysozyme and its modified forms: A critical appraisal of selected properties and potential. Trends in Food Science & Technology. 2021;107:333-342. 10.1016/j.tifs.2020.11.004. [CrossRef]

- Li LS, Cardoso JCR, Felix RC, Mateus AP, Canario AVM, Power DM. Fish lysozyme gene family evolution and divergent function in early development. Developmental and Comparative Immunology. 2021;114:69-75. 10.1016/j.dci.2020.103772. [CrossRef]

- Wu TT, Jiang QQ, Wu D, Hu YQ, Chen SG, Ding T, Ye XQ, Liu DH, Chen JC. What is new in lysozyme research and its application in food industry? A review. Food Chemistry. 2019;274:698-709. 10.1016/j.foodchem.2018.09.017. [CrossRef]

- Xiao WH, Gu N, Zhang B, Liu Y, Zhang YH, Zhang ZX, Qin G, Liu Q. Characterization and expression patterns of lysozymes reveal potential immune functions during male pregnancy of seahorse. Developmental and Comparative Immunology. 2023;142,104654. 10.1016/j.dci.2023.104654. [CrossRef]

- Sheng XC, Xiong WL. Soft sensor design based on phase partition ensemble of LSSVR models for nonlinear batch processes. Mathematical Biosciences and Engineering. 2020;17(2):1901-1921. 10.3934/mbe.2020100. [CrossRef]

- Wang B, Yu MF, Zhu XL, Zhu L. Soft - sensing modeling based on ABC - MLSSVM inversion for marine low - temperature alkaline protease MP fermentation process. BMC Biotechnology 2020;20(1):1-13. 10.1186/s12896-020-0603-x. [CrossRef]

- Wang P, Sun QY, Qiao YX, Liu LL, Han X, Chen XG. Online prediction of total sugar content and optimal control of glucose feed rate during chlortetracycline fermentation based on soft sensor modeling. Mathematical Biosciences and Engineering. 2022;19(10):10687-10709. 10.3934/mbe.2022500. [CrossRef]

- Wang JL, Qiu KP, Guo YQ, Wang RT, Zhou XJ. Soft sensor development based on improved just-in-time learning and relevant vector machine for batch processes. Canadian Journal of Chemical Engineering. 2021;99(1):334-344. 10.1002/cjce.23848. [CrossRef]

- Medl M, Rajamanickam V, Striedner G, Newton J. Development and Validation of an Artificial Neural-Network-Based Optical Density Soft Sensor for a High-Throughput Fermentation System. Processes. 2023;11(1). 10.3390/pr11010297. [CrossRef]

- Hua L, Zhang C, Sun W, Li YM, Xiong JL, Nazir MS. An evolutionary deep learning soft sensor model based on random forest feature selection technique for penicillin fermentation process. Isa transactions. 2023;136:139-151. 10.1016/j.isatra.2022.10.044. [CrossRef]

- Wang B, Shahzad M, Zhu XL, Rehman KU, Ashfaq M, Abubakar M. Soft-sensor modeling for l-lysine fermentation process based on hybrid ICS-MLSSVM. Scientific reports. 2020;10(1). 10.1038/s41598-020-68081-4. [CrossRef]

- Tokuyama K, Shimodaira Y, Kodama Y, Matsui R, Kusunose Y, Fukushima S, Nakai H, Tsuji Y, Toya Y, Matsuda F, Shimizu H. Soft-sensor development for monitoring the lysine fermentation process. Journal of Bioscience and Bioengineering. 2021;132(2):183-189. 10.1016/j.jbiosc.2021.04.002. [CrossRef]

- Wang KF, Zhao WY, Lin L, Wang TJ, Wei P, Ledesma-Amaro R, Zhang AH, Ji XJ. A robust soft sensor based on artificial neural network for monitoring microbial lipid fermentation processes using Yarrowia lipolytica. Biotechnology and Bioengineering. 2023;120(4):1015-1025. [CrossRef]

- Sun YM, Du N, Sun QY, Chen XG, Yang JW. Research and application of biological potency soft sensor modeling method in the industrial fed-batch chlortetracycline fermentation process. Cluster Computing-the Journal of Networks Software Tools and Applications. 2019;22:S6019- S6030. [CrossRef]

- Shen FF, Zheng JQ, Ye LJ, Gu D. Quality-Relevant Monitoring of Batch Processes Based on Stochastic Programming with Multiple Output Modes. Processes. 2020;8(2). 10.3390/pr8020164. [CrossRef]

- Wang YX, Zhou JZ, Wang XJ, Yu QY, Sun YK, Li Y, Zhang YG, Shen WZ, Wei XL. Rumen Fermentation Parameters Prediction Model for Dairy Cows Using a Stacking Ensemble Learning Method. Animals. 2023;13(4). 10.3390/ani13040678. [CrossRef]

- Shen FF, Zheng JQ, Ye LJ, Ma XS. LSTM Soft Sensor Development of Batch Processes With Multivariate Trajectory-Based Ensemble Just-in-Time Learning. IEEE Access. 2020;8:73855-73864. [CrossRef]

- Pearce R, Ireland P, Romero E. Thermal matching using Gaussian process regression. Proceedings of the Institution of Mechanical Engineers Part G-Journal of Aerospace Engineering. 2020;234(6):1172-1180. 10.1177/0954410020901961. [CrossRef]

- Mahmoodzadeh A, Mohammadi M, Abdulhamid SN, Ali HFH, Ibrahim HH, Rashidi S. Forecasting tunnel path geology using Gaussian process regression. Genmechanics and Engineering. 2022;28(4):359-374. 10.12989/gae.2022.28.4.359. [CrossRef]

- Shi XD, Kang Q, Zhou MC, Abusorrah A, An J. Soft Sensing of Nonlinear and Multimode Processes Based on Semi-Supervised Weighted Gaussian Regression. IEEE Sensors Journal. 2020;20(21):12950-12960. 10.1109/JSEN.2020.3003826. [CrossRef]

- Zadkarami M, Ghanavati AK, Safavi AA. Soft Sensor Design for Distillation Columns Using Wavelets and Gaussian Process Regression. In: 6th International Conference on Control, Instrumentation and Automation (ICCIA). Univ Kurdistan, Sanandaj, IRAN. 2019.p.254-259. 10.1109/iccia49288.2019.9030850. [CrossRef]

- Zhao J, Wang G, Pan JS, Fan TH, Lee IV. Density peaks clustering algorithm based on fuzzy and weighted shared neighbor for uneven density datasets. Pattern Recognition. 2023;139. 10.1016/j.patcog.2023.109406. [CrossRef]

- Sun N, Zhang N, Zhang S, Peng T, Zhou JZ, Zhang HR. Monthly Runoff Prediction Model and Its Application Based on GPR with Physically Composite Kernel. Water Resources and Power. 2023;41(4):39-43. 10.20040/j.cnki.1000-7709.2023.20221932. [CrossRef]

- Yang S, Ye P, Liu LL, Wang H, Sun F. Research on Opimal Planning of Integrated Energy System Based on Seagull Algorithm. Journal of Shenyang Institute of Engineering (Natural Science). 2022;18(4):62-69.10.13888/j.cnki.jsie(ns).2022.04.012. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).