Submitted:

10 August 2023

Posted:

11 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. SCAPS 1D-Software and Mathematical Modeling

- Poisson Equation:

- Transport Equation

- Continuity Equation

- Diffusion Length

- Diffusivity

- Open Circuit Voltage

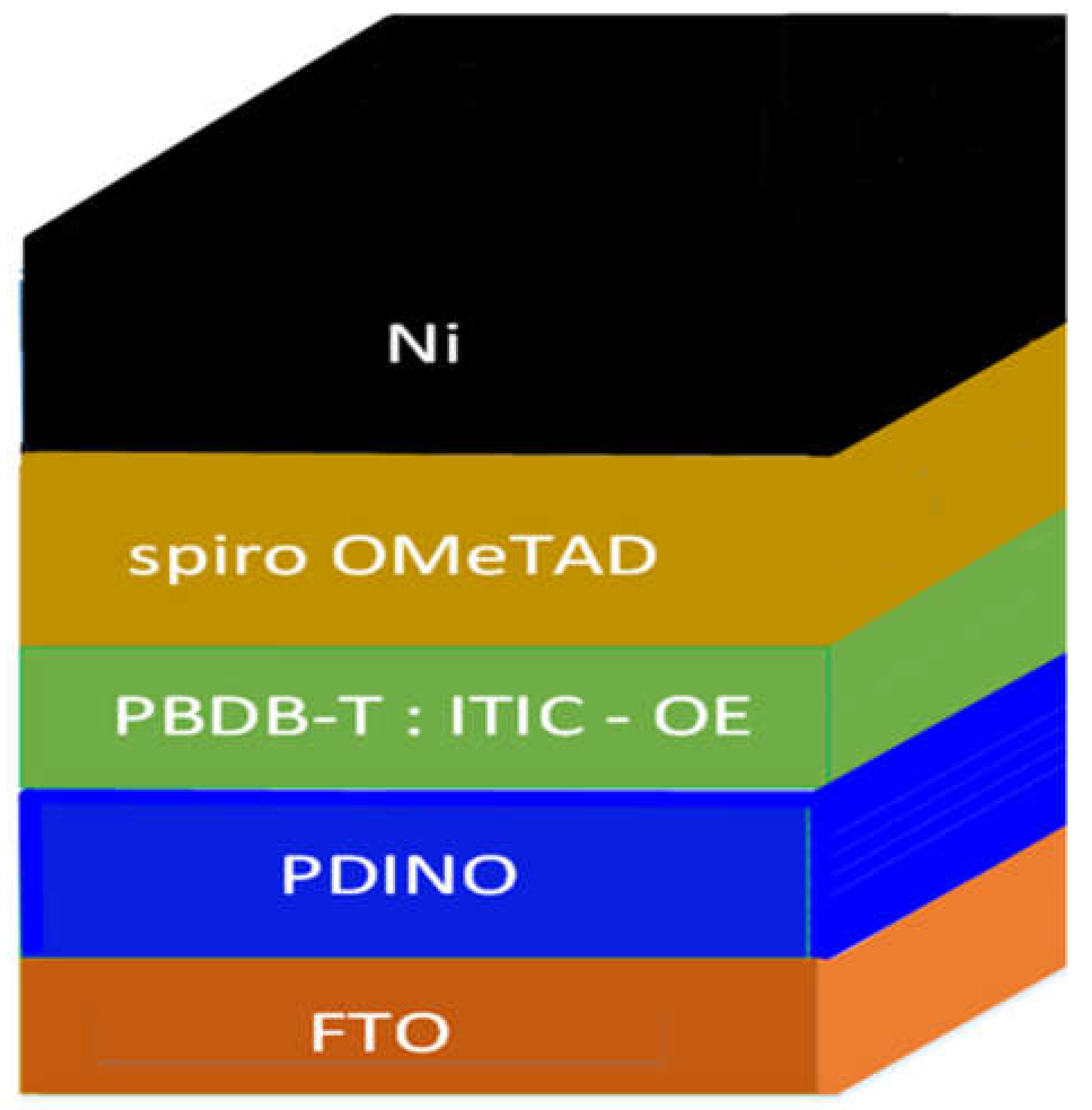

2.2. Device Architecture

2.3. Parameters used in the simulation

3. Results and Discussions

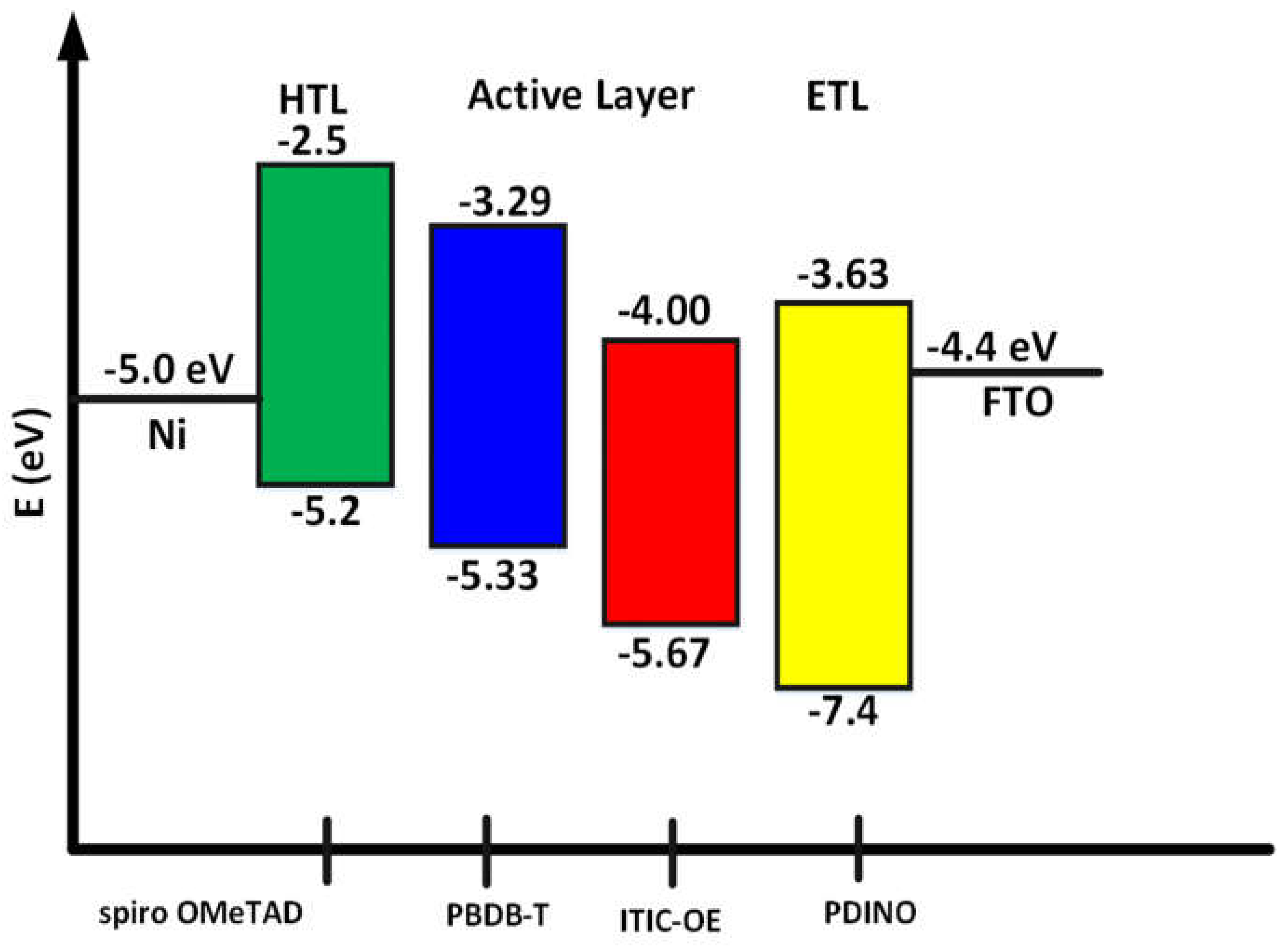

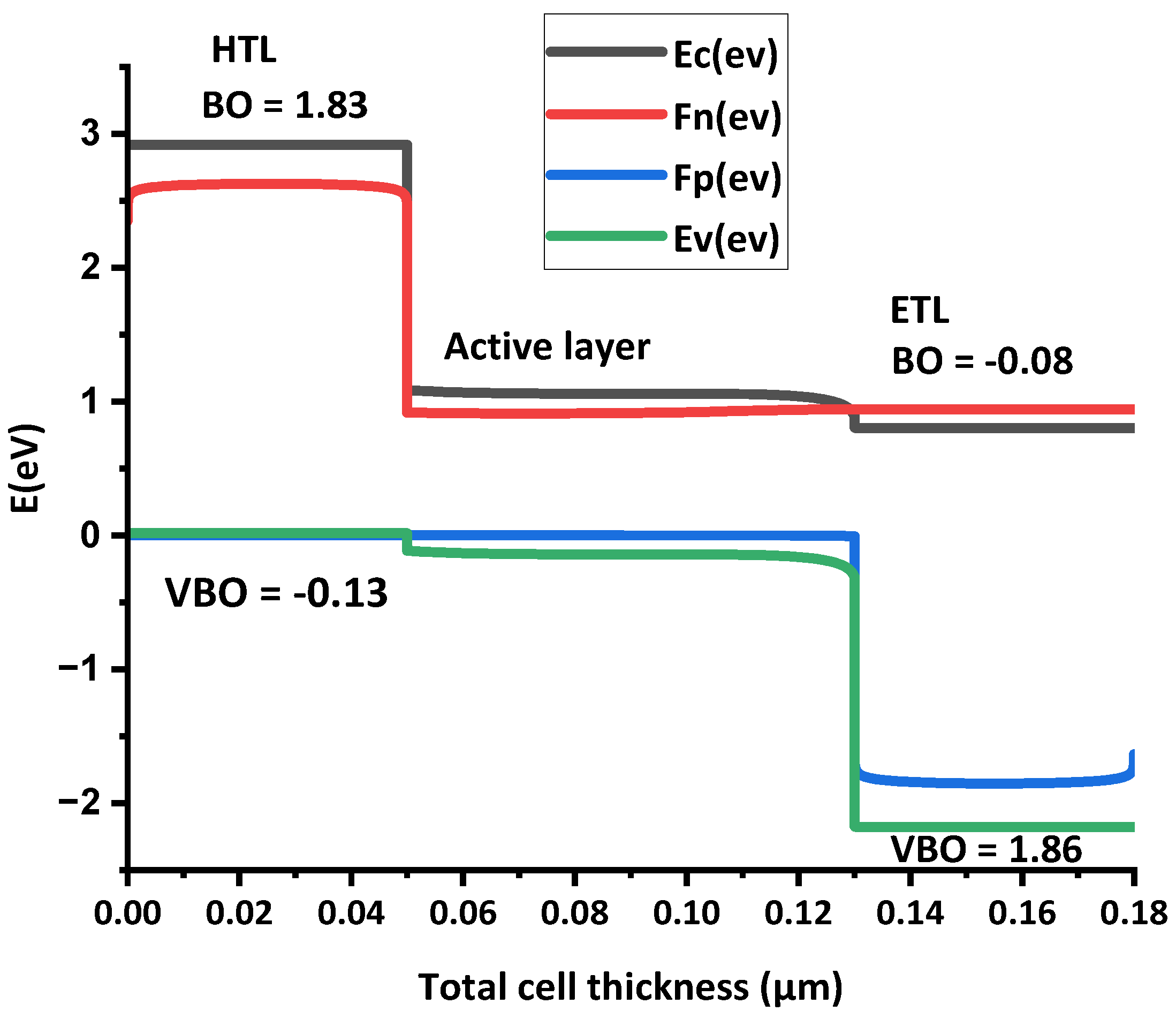

3.1. J-V characteristics relation with energy band alignment

- Ec- In a semiconductor, the conduction band comprise of lowest occupied molecular orbital (LOMO). It is the highest energy level where the electrons can move freely within the solid [32].

- Fn- represents the n-type material Fermi level, where the probability of electron is 0.5. Fermi level is act as a boundary, it distinguishes the energy levels where electrons high likelihood of existence and from those where their presence is relatively unlikely. In an ETL or in n-type semiconductor, the Fn is close to conduction band due to surplus of electrons [32].

- Fp- represents the holes Fermi level, which is located near the valence band due to surplus of holes [32].

- Ev- In a solid ,the valence band represents the lowest energy level, where the electrons are tightly bound to the atoms and lack freedom of movement. In solar cells, this VB is comprised of the semiconductors materials highest occupied molecular orbital (HOMO) [32].

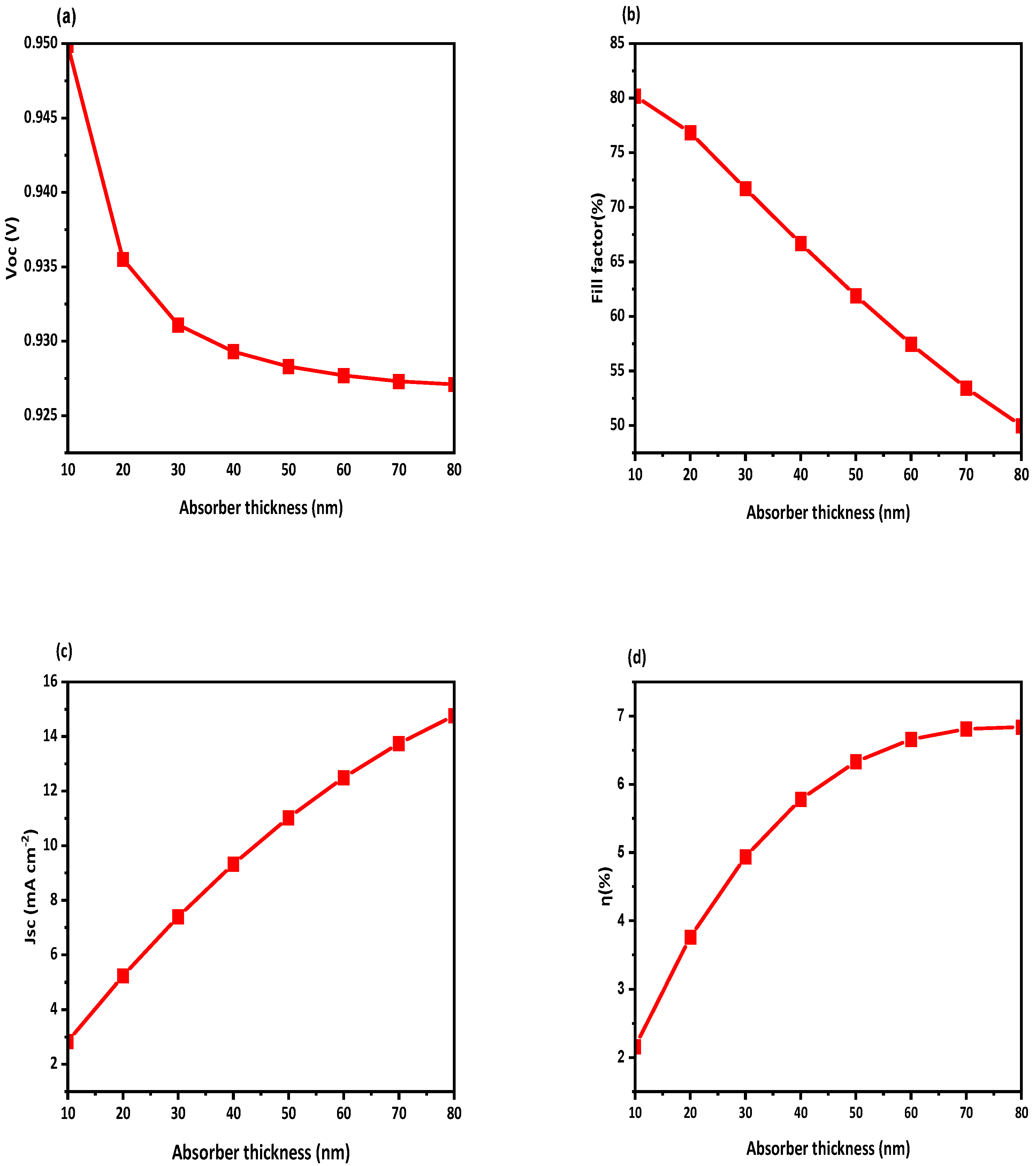

3.2. Impact of active layer thickness on OSC

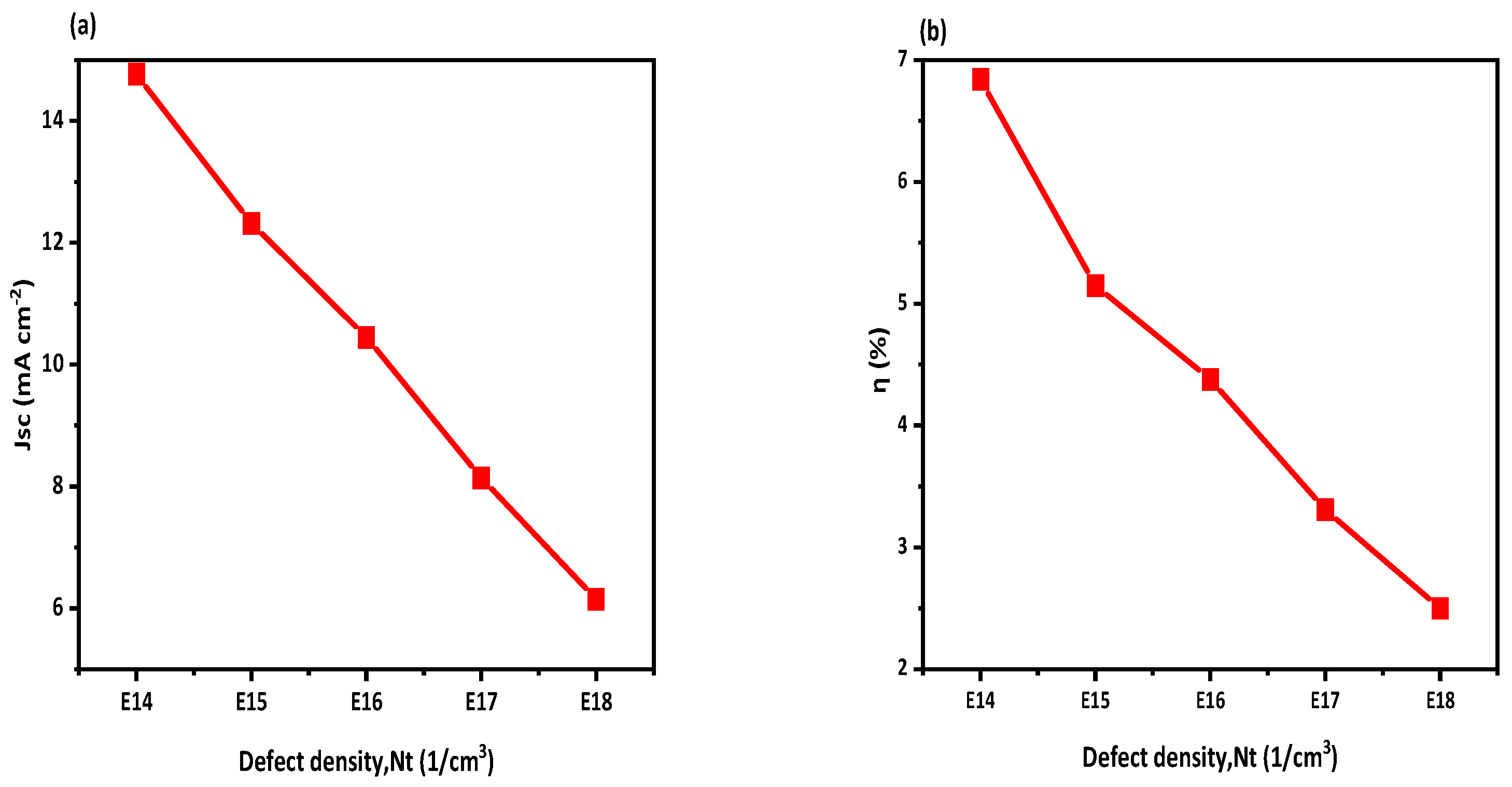

3.3. Active layer defect density effect on the performance of solar cell

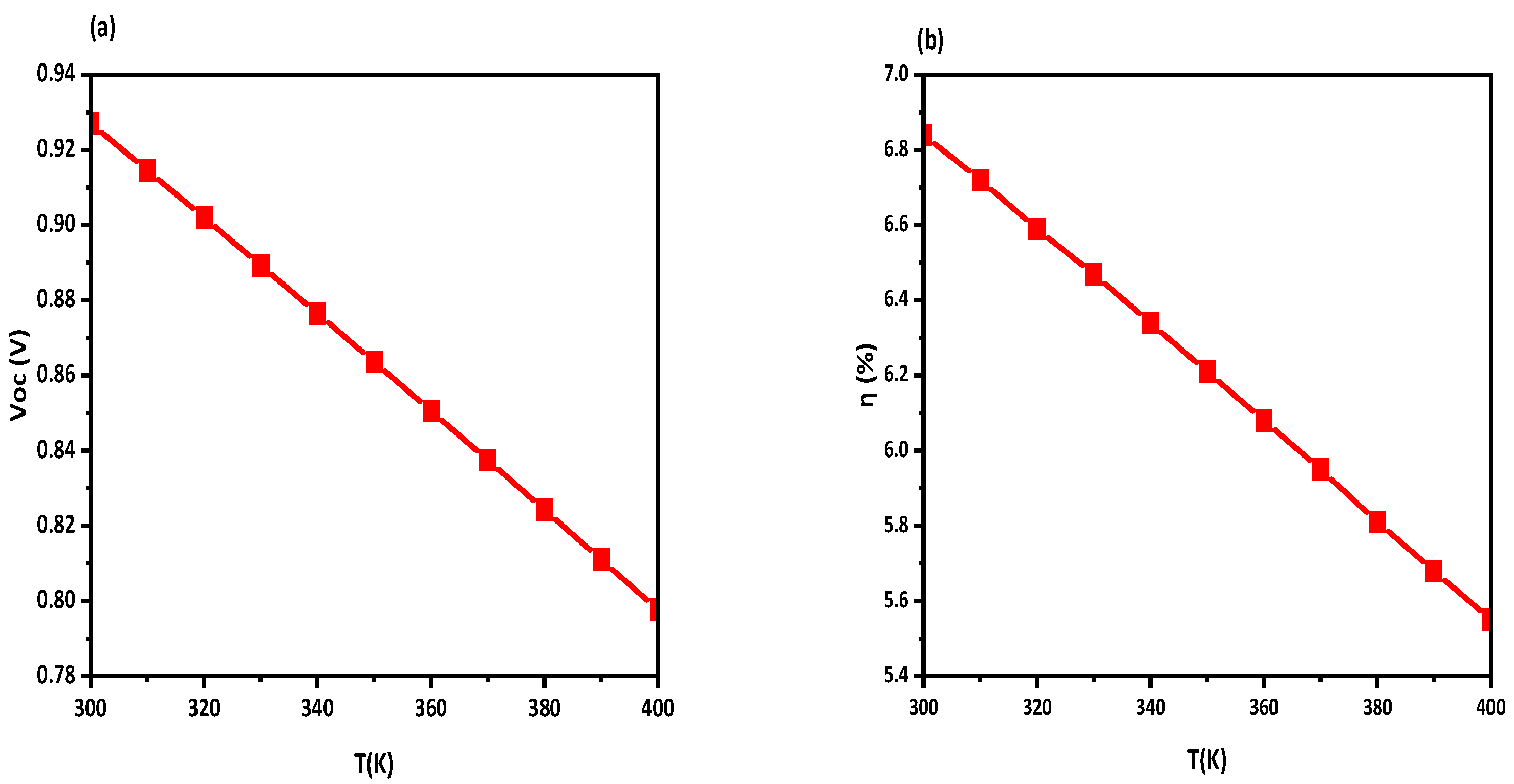

3.4. Effect of Temperature

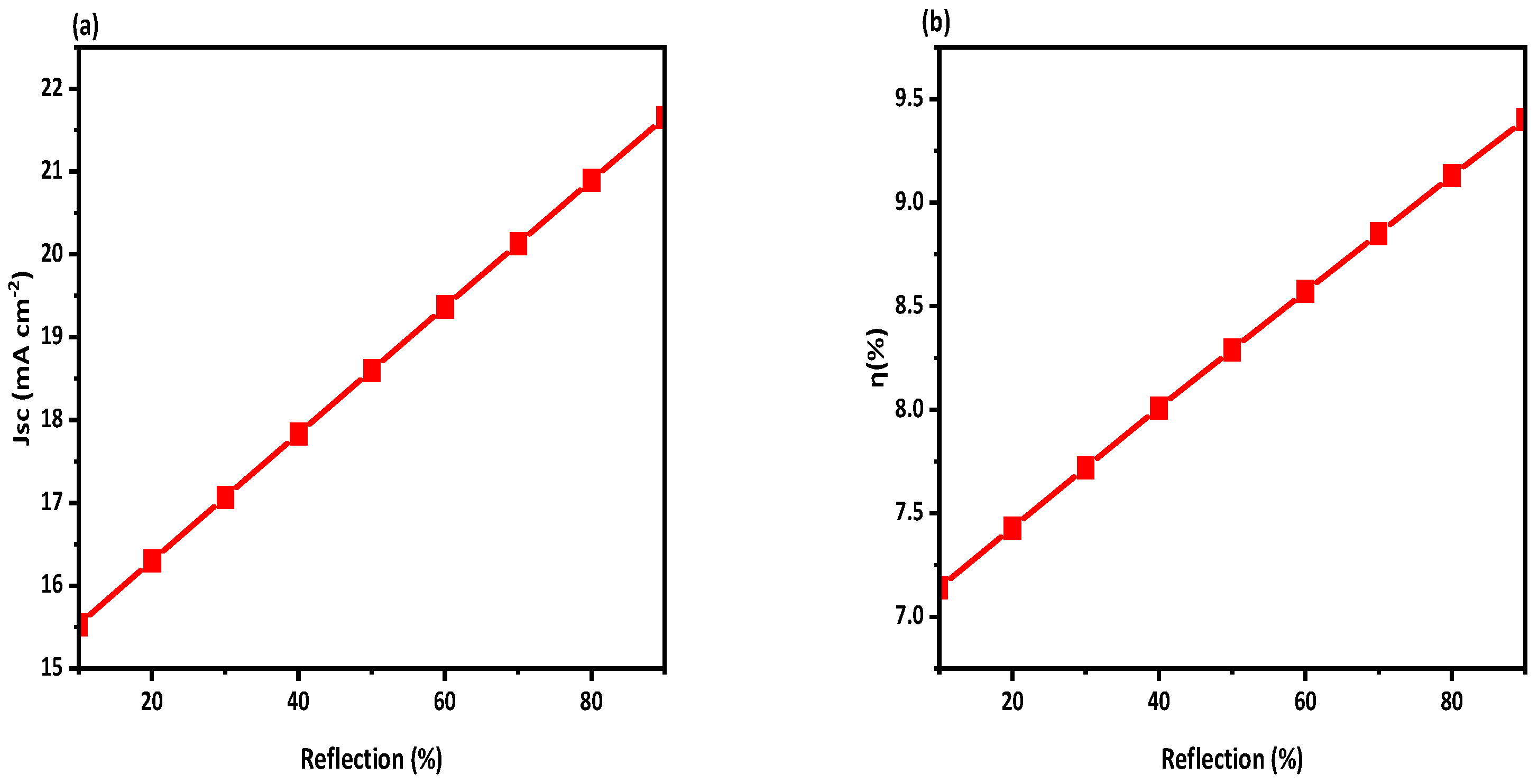

3.5. Effect of Reflection Coating

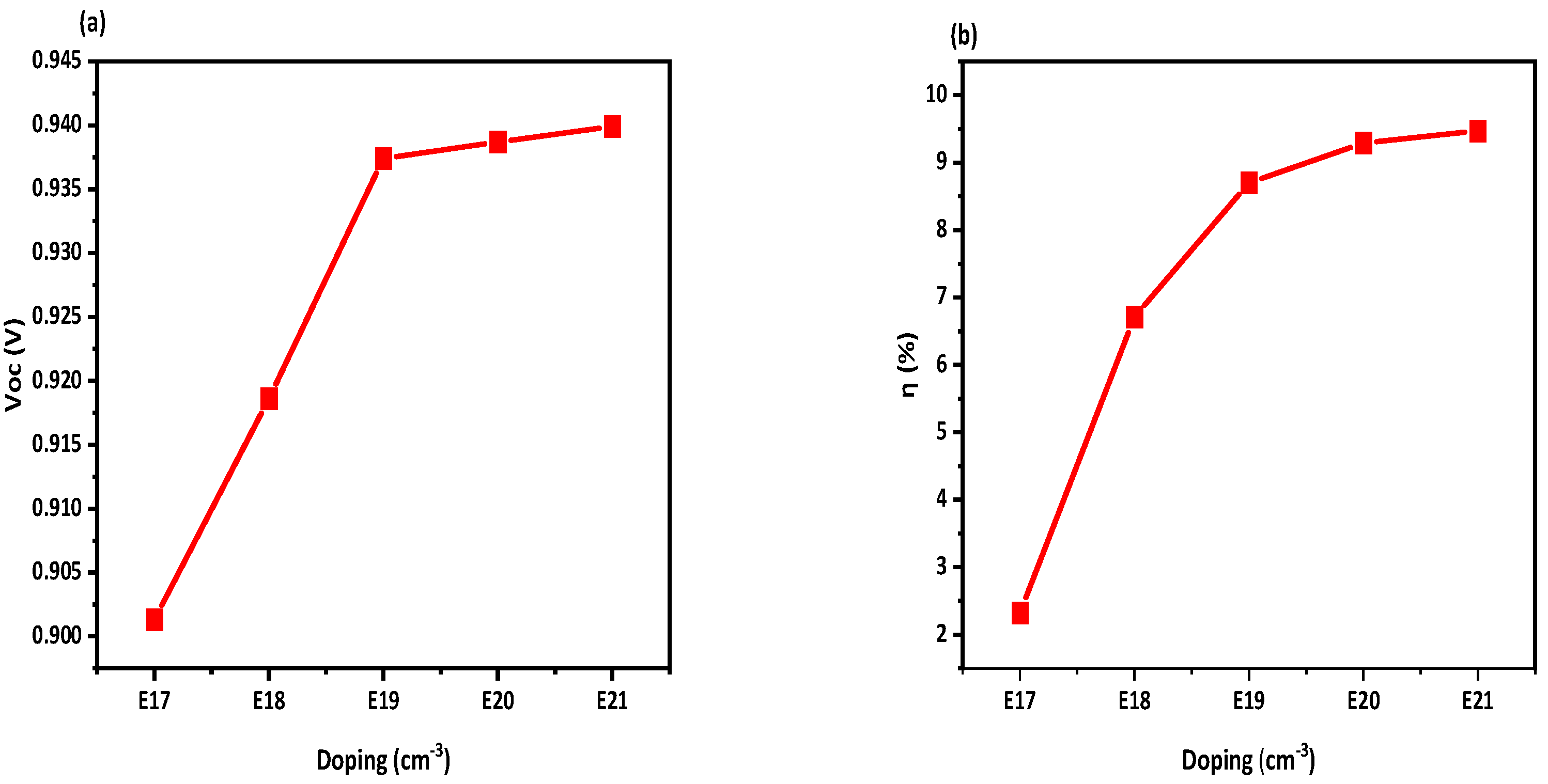

3.6. Hole transport layer doping density

3.7. Electron transport layer doping effect

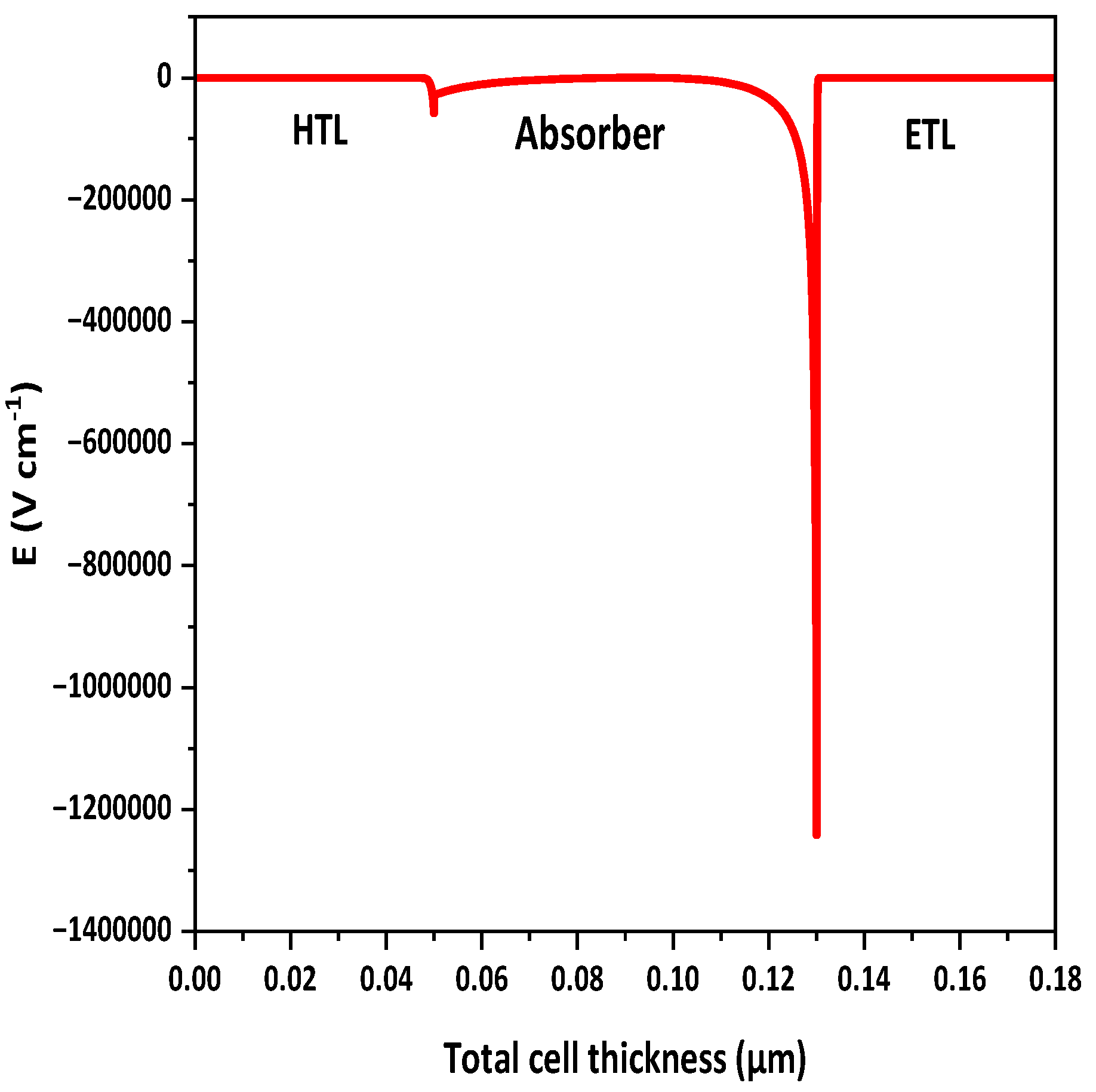

3.8. Electric Field at interface

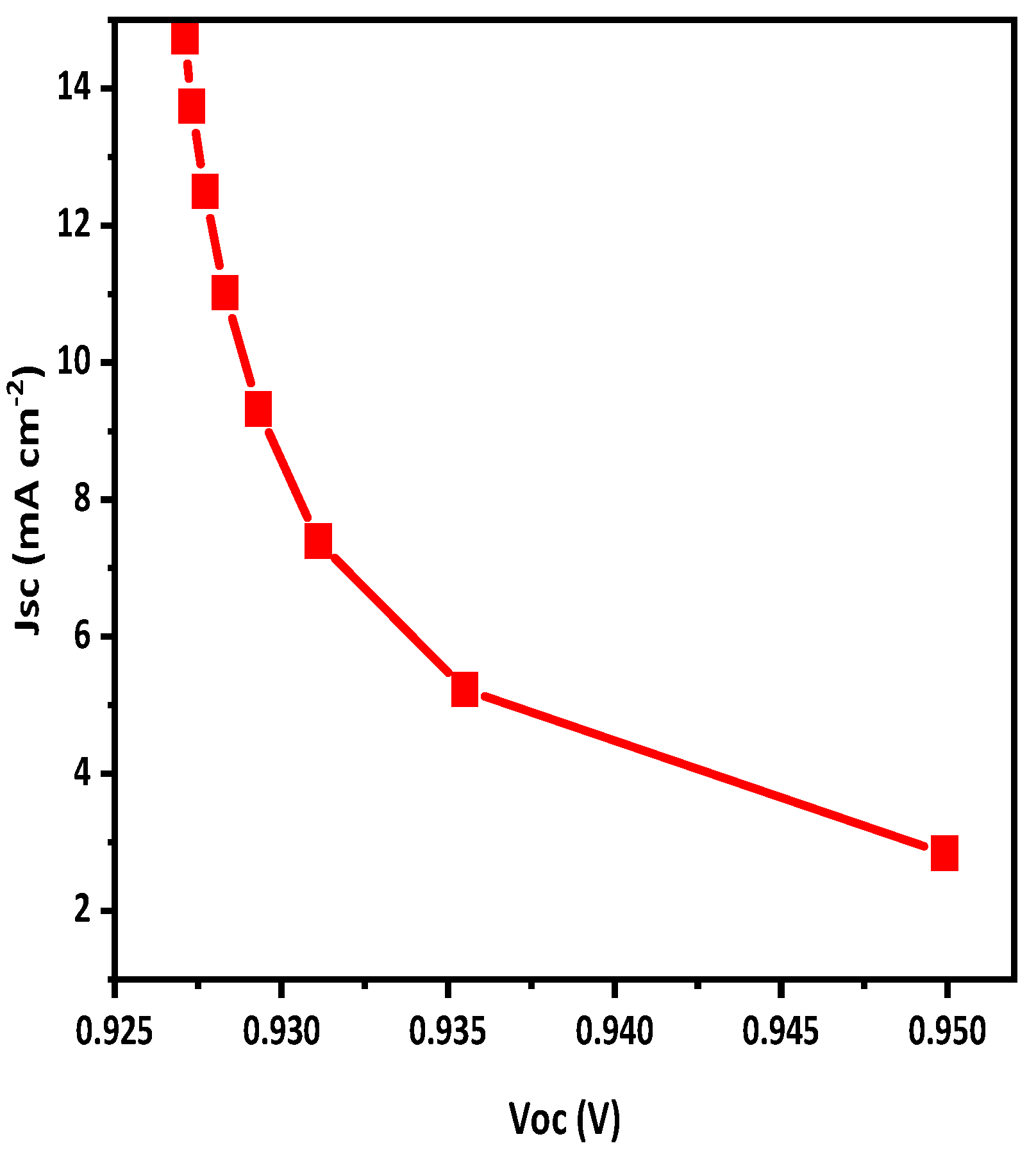

3.9. Comparison of simulation results with experimental studies

| Parameters | Experimental [20] | Simulated |

| Voc | 0.85 | 0.939 |

| Jsc | 14.8 | 21.654 |

| FF | 67.0 | 46.2 |

| PCE | 8.5 | 9.40 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Alahmadi, A. N. (2022). Design of an efficient PTB7: PC70BM-based polymer solar cell for 8% efficiency. Polymers, 14(5), 889. [CrossRef]

- Seri, M., Mercuri, F., Ruani, G., Feng, Y., Li, M., Xu, Z. X., & Muccini, M. (2021). Toward real setting applications of organic and perovskite solar cells: A comparative review. Energy Technology, 9(5), 2000901. [CrossRef]

- Peng, W., Lin, Y., Jeong, S. Y., Genene, Z., Magomedov, A., Woo, H. Y., ... & Wang, E. (2022). Over 18% ternary polymer solar cells enabled by a terpolymer as the third component. Nano Energy, 92, 106681. [CrossRef]

- Ghosekar, I. C., & Patil, G. C. (2021). Review on performance analysis of P3HT: PCBM-based bulk heterojunction organic solar cells. Semiconductor Science and Technology, 36(4), 045005. [CrossRef]

- Moiz, S. A., Alahmadi, A. N. M., & Karimov, K. S. (2020). Improved organic solar cell by incorporating silver nanoparticles embedded polyaniline as buffer layer. Solid-State Electronics, 163, 107658. [CrossRef]

- Li, W., Ye, L., Li, S., Yao, H., Ade, H., & Hou, J. (2018). A high-efficiency organic solar cell enabled by the strong intramolecular electron push–pull effect of the nonfullerene acceptor. Advanced Materials, 30(16), 1707170. [CrossRef]

- Fan, X., Zhang, M., Wang, X., Yang, F., & Meng, X. (2013). Recent progress in organic–inorganic hybrid solar cells. Journal of Materials Chemistry A, 1(31), 8694-8709. [CrossRef]

- Chen, C. C., Chang, W. H., Yoshimura, K., Ohya, K., You, J., Gao, J., … & Yang, Y. (2014). An efficient triple-junction polymer solar cell having a power conversion efficiency exceeding 11%. Advanced materials, 26(32), 5670-5677. [CrossRef]

- Malik, A., Hameed, S., Siddiqui, M. J., Haque, M. M., Umar, K., Khan, A., & Muneer, M. (2014). Electrical and optical properties of nickel-and molybdenum-doped titanium dioxide nanoparticle: improved performance in dye-sensitized solar cells. Journal of materials engineering and performance, 23, 3184-3192. [CrossRef]

- R. Murad, A., Iraqi, A., Aziz, S. B., N. Abdullah, S., & Brza, M. A. (2020). Conducting polymers for optoelectronic devices and organic solar cells: A review. Polymers, 12(11), 2627.

- Sharma, N., Gupta, S. K., & Negi, C. M. S. (2019). Influence of active layer thickness on photovoltaic performance of PTB7: PC70BM bulk heterojunction solar cell. Superlattices and Microstructures, 135, 106278. [CrossRef]

- Ramírez-Como, M., Balderrama, V. S., Sacramento, A., Marsal, L. F., Lastra, G., & Estrada, M. (2019). Fabrication and characterization of inverted organic PTB7: PC70BM solar cells using Hf-In-ZnO as electron transport layer. Solar Energy, 181, 386-395.

- Dridi, C., Touafek, N., & Mahamdi, R. (2022). Inverted PTB7: PC70BM bulk heterojunction solar cell device simulations for various inorganic hole transport materials. Optik, 252, 168447. [CrossRef]

- Chen, J., Chen, Y., Feng, L. W., Gu, C., Li, G., Su, N., ... & Marks, T. J. (2020). Hole (donor) and electron (acceptor) transporting organic semiconductors for bulk-heterojunction solar cells. EnergyChem, 2(5), 100042. [CrossRef]

- Su, G. M., Pho, T. V., Eisenmenger, N. D., Wang, C., Wudl, F., Kramer, E. J., & Chabinyc, M. L. (2014). Linking morphology and performance of organic solar cells based on decacyclene triimide acceptors. Journal of Materials Chemistry A, 2(6), 1781-1789. [CrossRef]

- Cui, Y., Yao, H., Zhang, J., Xian, K., Zhang, T., Hong, L., … & Hou, J. (2020). Single-junction organic photovoltaic cells with approaching 18% efficiency. Advanced Materials, 32(19), 1908205. [CrossRef]

- Yan, C., Barlow, S., Wang, Z., Yan, H., Jen, A. K. Y., Marder, S. R., & Zhan, X. (2018). Non-fullerene acceptors for organic solar cells. Nature Reviews Materials, 3(3), 1-19.

- Ma, L., Zhang, S., Wang, J., Xu, Y., & Hou, J. (2020). Recent advances in non-fullerene organic solar cells: From lab to fab. Chemical Communications, 56(92), 14337-14352. [CrossRef]

- Liu, X., Xie, B., Duan, C., Wang, Z., Fan, B., Zhang, K., ... & Cao, Y. (2018). A high dielectric constant non-fullerene acceptor for efficient bulk-heterojunction organic solar cells. Journal of Materials Chemistry A, 6(2), 395-403. [CrossRef]

- Torabi, S., Jahani, F., Van Severen, I., Kanimozhi, C., Patil, S., Havenith, R. W., ... & Koster, L. J. A. (2015). Strategy for enhancing the dielectric constant of organic semiconductors without sacrificing charge carrier mobility and solubility. Advanced Functional Materials, 25(1), 150-157. [CrossRef]

- Alam, S., Akhtar, M. S., Shin, H. S., & Ameen, S. (2020). New energetic indandione based planar donor for stable and efficient organic solar cells. Solar Energy, 201, 649-657. [CrossRef]

- Akhtar, M. S., Kim, E. B., Fijahi, L., Shin, H. S., & Ameen, S. (2020). A symmetric benzoselenadiazole based D–A–D small molecule for solution processed bulk-heterojunction organic solar cells. Journal of Industrial and Engineering Chemistry, 81, 309-316. [CrossRef]

- Abdelaziz, W., Zekry, A., Shaker, A., & Abouelatta, M. (2020). Numerical study of organic graded bulk heterojunction solar cell using SCAPS simulation. Solar Energy, 211, 375-382. [CrossRef]

- Nowsherwan, G. A., Samad, A., Iqbal, M. A., Mushtaq, T., Hussain, A., Malik, M., ... & Choi, J. R. (2022). Performance analysis and optimization of a PBDB-T: ITIC based organic solar cell using graphene oxide as the hole transport layer. Nanomaterials, 12(10), 1767. [CrossRef]

- Bendenia, C., Merad-Dib, H., Bendenia, S., Bessaha, G., & Hadri, B. (2021). Theoretical study of the impact of the D/A system polymer and anodic interfacial layer on inverted organic solar cells (BHJ) performance. Optical Materials, 121, 111588. [CrossRef]

- Nithya, K. S., & Sudheer, K. S. (2020). Device modelling of non-fullerene organic solar cell with inorganic CuI hole transport layer using SCAPS 1-D. Optik, 217, 164790. [CrossRef]

- Jan, S. T., & Noman, M. (2022). Influence of absorption, energy band alignment, electric field, recombination, layer thickness, doping concentration, temperature, reflection and defect densities on MAGeI3 perovskite solar cells with Kesterite HTLs. Physica Scripta, 97(12), 125007. [CrossRef]

- Ahmad, W., Noman, M., Tariq Jan, S., & Khan, A. D. (2023). Performance analysis and optimization of inverted inorganic CsGeI3 perovskite cells with carbon/copper charge transport materials using SCAPS-1D. Royal Society Open Science, 10(3), 221127. [CrossRef]

- Nithya, K. S., & Sudheer, K. S. (2022). Device modelling and optimization studies on novel ITIC-OE based non-fullerene organic solar cell with diverse hole and electron transport layers. Optical Materials, 123, 111912. [CrossRef]

- Salem, M. S., Shaker, A., & Salah, M. M. (2023). Device Modeling of Efficient PBDB-T: PZT-Based All-Polymer Solar Cell: Role of Band Alignment. Polymers, 15(4), 869. [CrossRef]

- Abdelaziz, W., Zekry, A., Shaker, A., & Abouelatta, M. (2020). Numerical study of organic graded bulk heterojunction solar cell using SCAPS simulation. Solar Energy, 211, 375-382. [CrossRef]

- Ismail, M., Noman, M., Tariq Jan, S., & Imran, M. (2023). Boosting efficiency of eco-friendly perovskite solar cell through optimization of novel charge transport layers. Royal Society Open Science, 10(6), 230331. [CrossRef]

- Gan, Y., Qiu, G., Qin, B., Bi, X., Liu, Y., Nie, G., ... & Yang, R. (2023). Numerical Analysis of Stable (FAPbI3) 0.85 (MAPbBr3) 0.15-Based Perovskite Solar Cell with TiO2/ZnO Double Electron Layer. Nanomaterials, 13(8), 1313.

- Sherkar, T. S., Momblona, C., Gil-Escrig, L., Avila, J., Sessolo, M., Bolink, H. J., & Koster, L. J. A. (2017). Recombination in perovskite solar cells: significance of grain boundaries, interface traps, and defect ions. ACS energy letters, 2(5), 1214-1222. [CrossRef]

- Haider, S. Z., Anwar, H., & Wang, M. (2018). A comprehensive device modelling of perovskite solar cell with inorganic copper iodide as hole transport material. Semiconductor Science and Technology, 33(3), 035001. [CrossRef]

- Khan, A. D., Subhan, F. E., Khan, A. D., Khan, S. D., Ahmad, M. S., Rehan, M. S., & Noman, M. (2020). Optimization of efficient monolithic perovskite/silicon tandem solar cell. Optik, 208, 164573. [CrossRef]

- Jan, S. T., & Noman, M. (2022). Influence of layer thickness, defect density, doping concentration, interface defects, work function, working temperature and reflecting coating on lead-free perovskite solar cell. Solar Energy, 237, 29-43. [CrossRef]

| Parameters | Active layer [19,29] |

HTL [30] |

ETL [31] |

| Thickness, d (nm) | 80 | 50 | 50 |

| Electron affinity, X (eV) | 4.03 | 2.2 | 4.110 |

| Energy band gap, Eg (eV) | 1.2 | 2.9 | 2.98 |

| Dielectric permittivity, ε | 6.1 | 3 | 5 |

| Valence band effective density of states, Nv (cm-3) | 1E+19 | 1E+19 | 1E+19 |

| Conduction band effective density of states, Nc (cm-3) | 1E+19 | 1E+19 | 1E+19 |

| Electron thermal velocity, Vthe (cm/s), | 1E+7 | 1E+7 | 1E+7 |

| Hole thermal velocity, Vthp (cm/s), | 1E+7 | 1E+7 | 1E+7 |

| Electron mobility, μn (cm2/Vs) | 1.2E-5 | 1E-4 | 2E-6 |

| Hole mobility, μp (cm2/Vs) | 3.5E-4 | 2E-4 | 1E-3 |

| Donor density, Nd (1/cm3) | - | - | 2E+21 |

| Acceptor density, Na (1/cm3) | - | 2.8E+19 | - |

| Defect density, Nt (1/cm3) | 1E+14 | 1E+14 | 1E+14 |

| Parameters | Values [24] |

| Thermionic emission velocity for electron | 1E+5 cm / sec |

| Thermionic emission velocity for hole | 1E+7 cm / sec |

| Back electrode work function, Ni | 5.01 eV |

| Parameters | Values [24,27] |

| Thermionic emission velocity for electron | 1E+7 cm / sec |

| Thermionic emission velocity for hole | 1E+5 cm / sec |

| Front electrode work function, (FTO) | 4.4 eV |

| Structure | Voc, (V) | Jsc (ma cm -2) | FF (%) | η (%) |

|---|---|---|---|---|

| Before | 0.927 | 14.763 | 49.98 | 6.84 |

| After | 0.939 | 21.654 | 46.2 | 9.40 |

| CTL | CBO | VBO |

|---|---|---|

| Spiro Ometad (HTL) | 1.83 | -0.13 |

| PDINO (ETL) | -0.08 | 1.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).