1. Introduction

Geothermal energy is a reliable, weather-independent, and renewable source of energy with significant potential for contributing to a sustainable energy future. Several studies have shown that geothermal energy has the potential to provide a significant portion of the world's electricity demand [

1,

2]. In addition to heat and electricity production, geothermal energy can be utilised to extract critical raw materials essential for manufacturing various products. Recent studies have highlighted the potential of geothermal brine fluids to extract valuable minerals, including lithium and tungsten [

3,

4,

5].

The negative environmental impacts associated with traditional mining practices for valuable minerals are significant [

6,

7,

8]. The mining industry is responsible for more than 50% of greenhouse gas emissions and has contributed to biodiversity loss, water crises and climate change [

3]. As a result, there is a need for more sustainable and environmentally friendly options for mineral extraction. Geothermal brine fluids offer potential in this regard, as several studies have demonstrated their ability to extract valuable minerals while minimising negative environmental impacts [

9,

10]. Utilising geothermal brine fluids for mineral extraction could provide a more sustainable and environmentally friendly alternative to traditional mining practices [

11].

This review paper explores the potential of geothermal energy to extract critical metallic minerals and contribute to Europe's energy security and sustainability. Specifically, we investigate the development of "orebody-Enhanced Geothermal Systems" (EGS) that allow for the cogeneration of energy and metals from metal-containing geological formations. Previous studies have investigated the technical feasibility of this approach, highlighting its potential for reducing the environmental impact of geothermal mining practices [

12,

13].

The planned technology manipulates these formations to optimise energy and metal production in response to market needs. Several studies have explored the potential market demand for critical metallic minerals and highlighted the need for more sustainable and environmentally friendly extraction methods [

14,

15,

16].

The paper provides a detailed overview of the nature and classification of geothermal energy and its potential for energy storage, as well as its potential for mineral extraction. We also examine the role of metals in human history and their extraction technologies, highlighting the limitations and negative impacts of traditional mining practices. Numerous studies have investigated the environmental and social impacts of traditional mining practices and highlighted the need for more sustainable and socially responsible approaches [

17,

18].This study is primarily based on the results of the completed CHPM2030 project [

19] and the plans for the CRM-geothermal project that is now being launched [

20]. The core of the paper is focused on the possibilities of combined metal and heat production that have been explored so far rather than on a technological overview.

This review paper also discusses the economic aspects of the proposed technology and its potential applications for industries and governments. Specifically, we conduct a cost-benefit analysis to determine the financial feasibility of the technology, including the expected costs, revenues, and potential profits for different stakeholders. Several studies have investigated the economic feasibility of geothermal energy and mineral extraction, highlighting the potential for cost savings and revenue generation [

21,

22].

In addition, we explore the potential of geothermal energy to contribute to the energy transition and address climate change. We highlight the significance of fluid-rock interaction for mineral production and the potential advantages of extracting elements from geothermal brine fluid over traditional mining methods. A number of studies have highlighted the potential of geothermal energy to contribute to the transition to a low-carbon economy and address climate change [

23,

24].

Altogether, this review paper provides a comprehensive overview of the potential of geothermal energy to contribute to energy security and sustainability through mineral extraction and the cogeneration of energy and metals. By addressing existing research gaps and highlighting the potential of geothermal energy for sustainable mineral extraction and energy production, this paper contributes to ongoing discussions on the future of energy and natural resource management.

2. The Role of Metals in Human History and Their Extraction Technologies

2.1. Importance of Metals

The need for metals for humans is evident, starting far back in prehistoric times. Most metals originate from metal-bearing geologic materials, and the first step is their removal from positions on/in the Earth [

25]. This process is mining. Most mining takes place and is performed below the earth’s surface; the extraction and mining depth has increased in human history. This fascinating development is well described in [

26]. Nowadays, mining operations can be carried out in considerable depths;

Table 1 shows prominent examples. So far, the deepest one is the Mponeng gold mine in South Africa, with 4.0 km. Such deep mining is so far unique.

Mining operations are generally demanding, those of deep mining especially. Since humans are working down there in the drift, sufficient cooling and ventilation are indispensable. Fortunately, the gold-bearing districts of South Africa [

27] are characterised by low geothermal gradients, by which the in situ temperatures at great depth are correspondingly lower. Other measures, like the excavation and transport of metalliferous rock material from great depths, are also exigent with correspondingly high costs. However, today the depth of mineral exploration in the earth's crust is about 1 km. Little or no information is available from deeper regions to support reserve calculations.

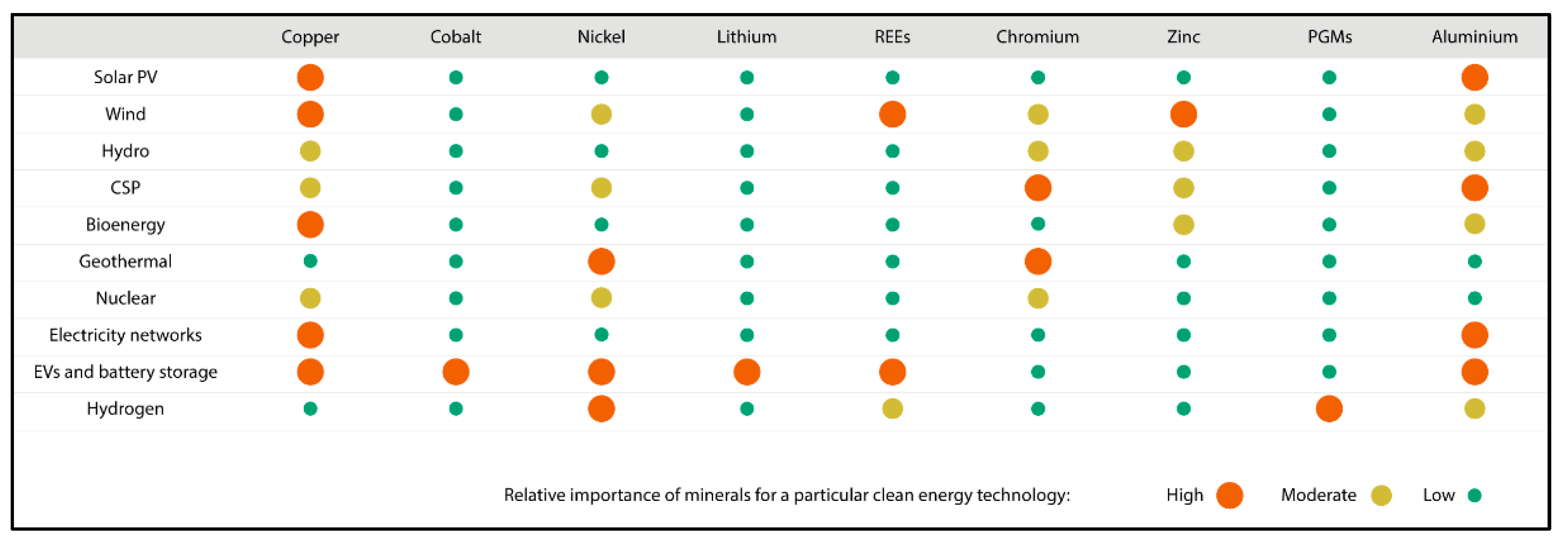

The energy transition will require a significant increase in the share of renewables compared to fossil energies. These energy production technologies, such as wind, solar, geothermal, biomass, etc. (including energy conversion and storage), require using a wide range of minerals and metals (

Figure 1). The type and quantity of minerals required varies depending on the form and kind of renewable energy production. Even within technology, there can be significant differences based on the stage of development of that technology readiness [

29].

The International Energy Agency (IEA) has elaborated two scenarios for the aggregate mineral resource requirements for clean energy production. The first assumes more moderate development - the IEA's Specific Policy Scenarios (STEPS), while the second is more ambitious - the IEA's Sustainable Development Scenarios (SDS), inclusive29 :

Low carbon energy generation: solar, wind, other renewables and nuclear;

Electricity grids;

Electric vehicles and battery storage;

Hydrogen (electrolysis and fuel cells).

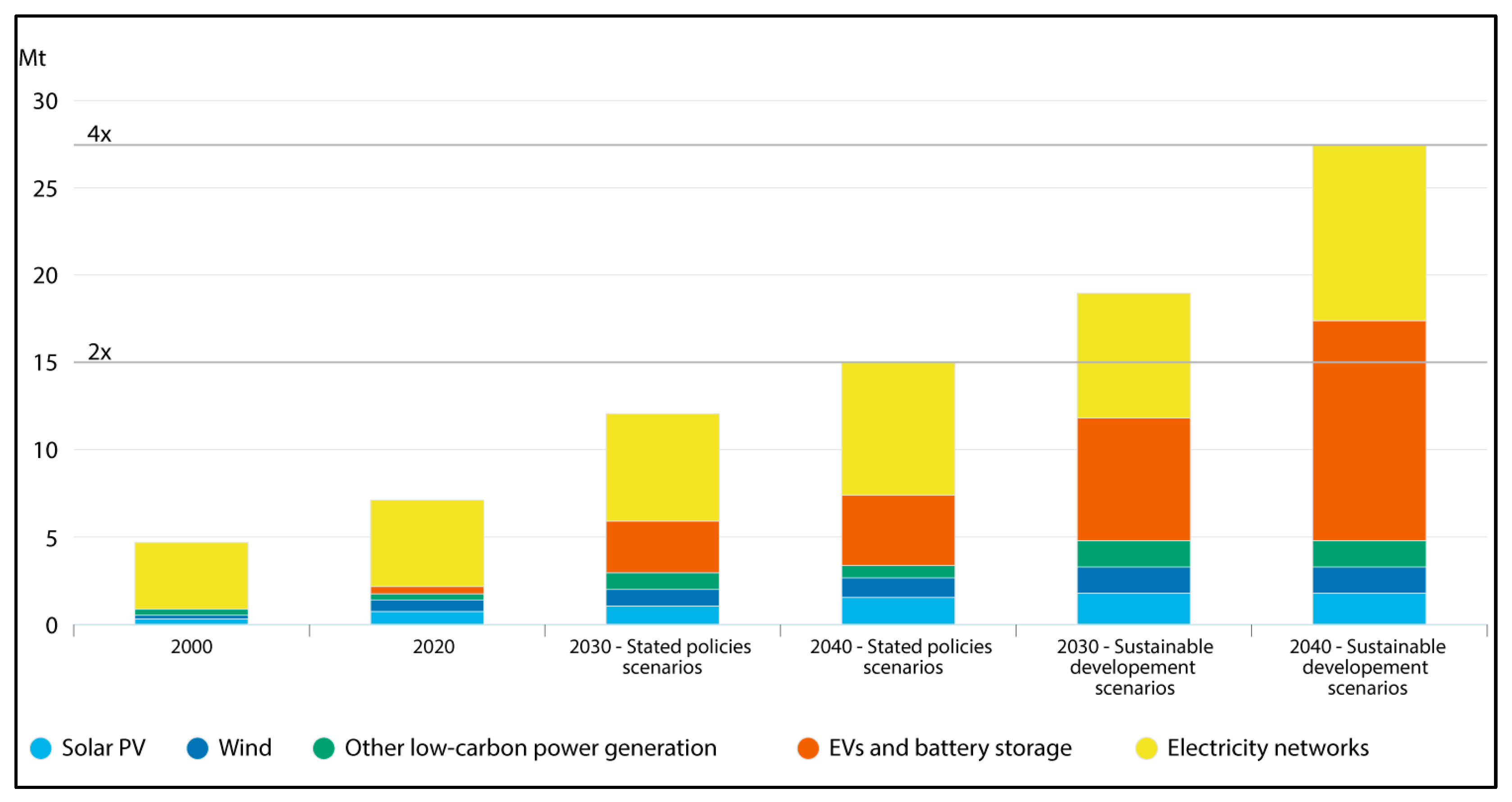

The global shift to clean energy is projected to have huge implications for mineral demand over the next 20 years. It will double by 2040, according to STEPS, and quadruple, according to SDS (

Figure 2). In both scenarios, about half of the growth in demand for minerals from clean energy technologies over the next two decades will come from electric vehicles and battery storage, driven by surging demand for battery materials. Mineral demand for EVs and battery storage will increase tenfold in STEPS and more than thirtyfold in SDS over the period to 2040. Lithium will produce the fastest growth rate, with demand increasing more than 40-fold in SDS [

29]. All this suggests that clean energy technologies will become a major driver of growth in demand for critical minerals.

In contrast to fossil fuels, which are produced and traded worldwide, they are mostly found on all continents; the production and processing of many minerals such as lithium, cobalt and some rare earths is highly concentrated in a few countries, with the three largest producers accounting for more than 75% of supply. Complex and sometimes opaque supply chains also increase the risk of physical disruption, trade restrictions or other developments in major producing countries. In addition, although there is no shortage of raw materials, the quality of available deposits declines as the most immediately accessible reserves are exploited, making production more costly [

30].

2.2. A New Method for Metal Extraction

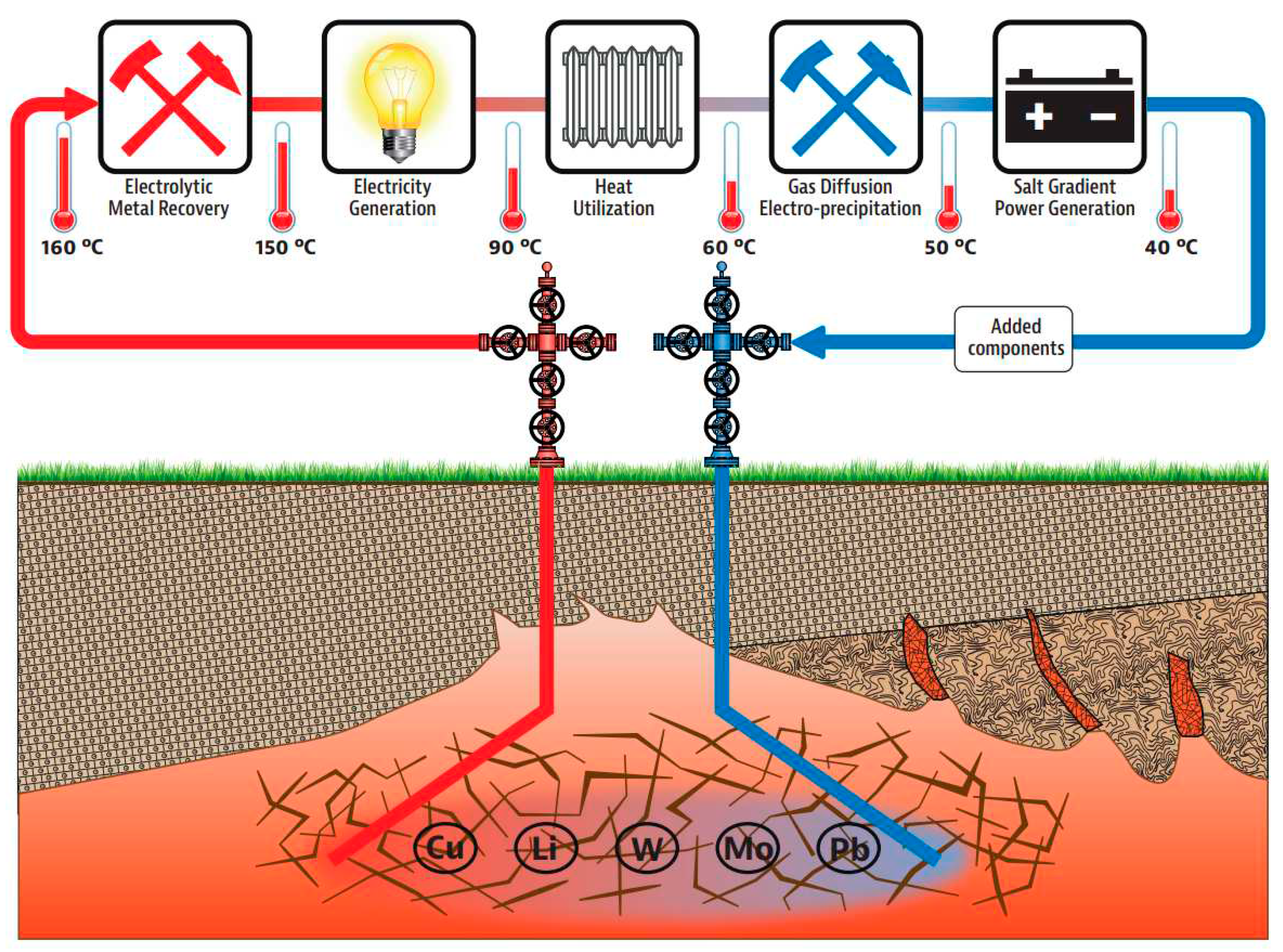

The CHPM2030 project aims to develop a novel technological solution for Combined Heat, Power and Metal (CHPM) extraction from ultra-deep ore bodies that will pave the way for pilot-scale systems to be operational by 2030 [

31]. Its primary goal is to facilitate the traditional deep metal mining by avoiding the host rock excavation, the transfer of the mined material to and the ore processing at the surface, while also harnessing geothermal fluid in a very complex way

Figure 3. This should be accomplished by leaching the metals in situ and sending them to the surface, both by a special “leaching” petrothermal EGS system, in ultra-deep settings of metal-bearing rocks.

Here the CHPM system could provide multiple remedies: no access is needed for a deep mine, excavation of metal-containing rock would be replaced by chemical processes to extract metal from the rocks in situ, whereas the metal transport to the surface by fluid flow would avoid massive transportation of solid rocks. By these means, securing workplace conditions –regulated by labour standards– would also become unnecessary. All these are in ultra-deep mining!

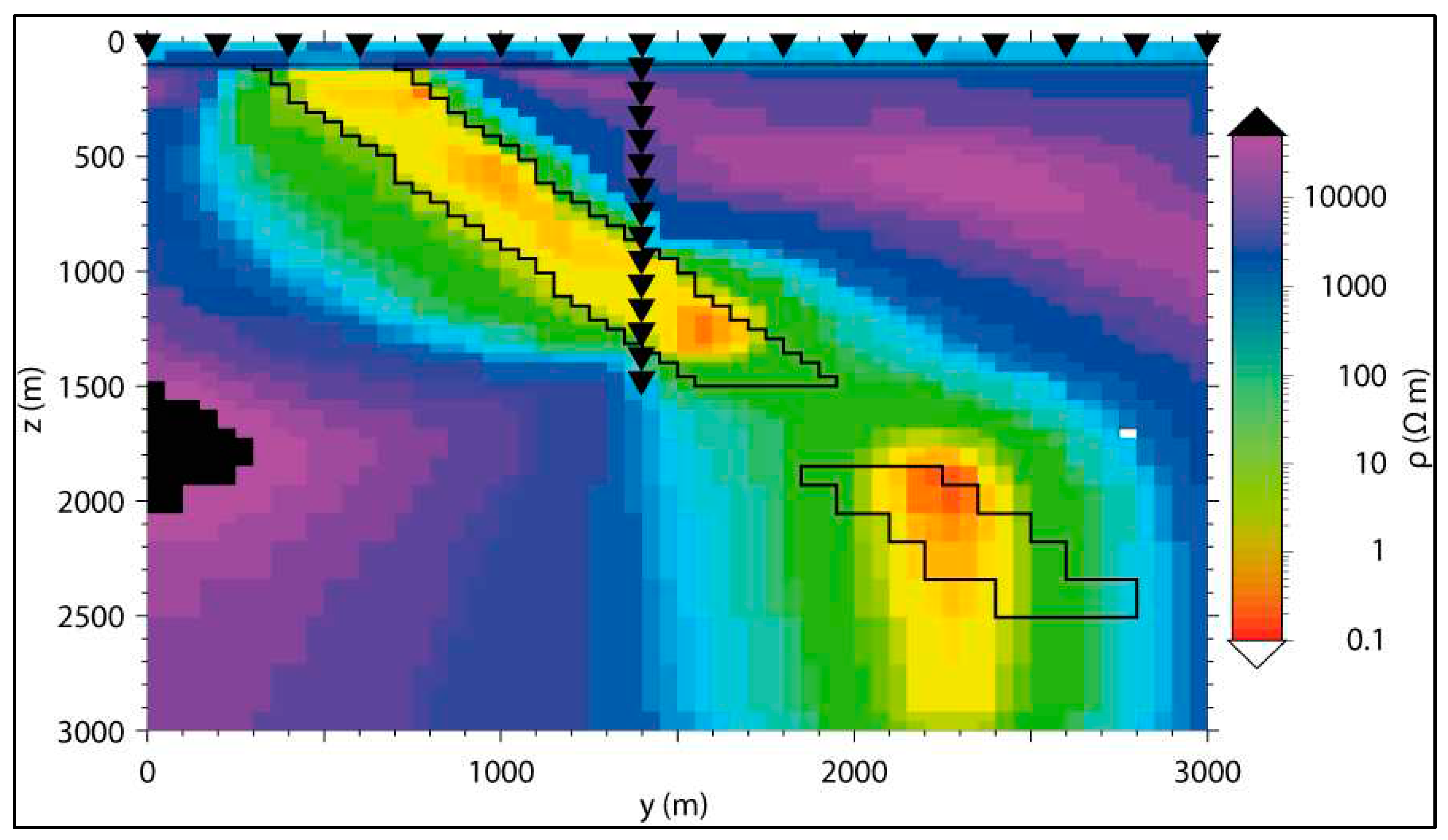

Before applying the CHPM system, the prospective metal ore bodies must be located first. For ultra-deep objects, this can be done only by geophysical surveys. In mining exploration, various geophysical techniques have been routinely used for many decades – albeit for moderate depths only. The most promising geophysical technique to unravel chances in locating ultra-deep ore bodies is undoubtedly the magnetotelluric (MT) technique. In magnetotelluric methods, naturally occurring electric and magnetic fields are used to sense the electrical conductivity structure of the subsurface. In combination, audiomagnetotelluric (AMT) and broadband magnetotelluric (BBMT) data explore a depth range from a few tens of meters down to a few tens of kilometres or more. This makes MT methods particularly suitable for investigating deep-seated (500–4000 m) mineral deposits [

32]. This is because metallic ore mineralisations have low electric resistivities: most metallic ore minerals are electronic semiconductors and have resistivities around or below 1 ∧m.

Although no deep ore bodies have been located by MT methods so far, numerous investigations find low-resistivity zones a posteriori in the subsurface at/around metalliferous formations. Numerical procedures to interpret magnetotelluric measurements are also widely available, e.g. [

33] presents such an example (

Figure 4). The figure clearly indicates a low-resistivity (0.1-1 ∧m) body in 2D, at around 2 km depth. Numerical, 3D inversion tools are also available [

34]. Together MT measurements and interpretations could pave the way to ultra-deep bodies and, subsequently, to the application of CHPM.

3. The Nature and Classification of Geothermal Energy

3.1. The Source of Geothermal Energy

The basis of geothermal energy is the immense heat content of the earth and the high temperatures in its interior. This is the basic resource. 99 % of the earth’s volume is at a temperature >1’000 °C; Planet Earth can afford to give away heat to the atmosphere with a thermal power of 42 million MW

th – without any measurable cooling. This thermal power is equivalent to the thermal capacity of 13’000 nuclear power plants of the 1 GW

e category. The total heat content of the earth is estimated to be around 10

31 J; it would take about 10

9 years to exhaust it by today’s global terrestrial heat flow. A more restrictive estimate considers the surface area of continents (some 2*10

14 m

2) and the continental crust to 1 km depth only. The heat content of this shell is still considerable, 3.9*10

8 EJ. Taking into account the world’s primary energy consumption, 540 EJ in 2021, this heat would be sufficient for about a million years. Would this heat have been extracted? It would need about 10

3 years to replenish the store by the terrestrial heat flow. Thus, the resource base is more than large enough and is basically ubiquitous. Among the renewables, geothermal has the highest potential (

Table 2) [

35].

3.2. Sustainability, Renewability

In the early days, geothermal power plants were designed to operate for 30 years (only) and to produce as much as possible to have a short return time on the investment. By this means, the resource is exhausted correspondingly fast. Nowadays, sustainable production is nearly mandatory; the production should remain constant over long times (on the order of 100 years).

Fortunately, nature has immanent power to counteract geothermal exhaustion. Geothermal is special: whereas in mining, the produced mineral resources (or coal, hydrocarbons, basic materials like gravel) will never come back to the place of extraction, whereas geothermal heat and/or fluid will come back, driven by natural forces. Geothermal heat/fluid production from the subsurface creates heat sinks/hydraulic minima there; these strong thermal/pressure gradients develop, which generate backflow and will fill up the deficits automatically. It only takes time—more details in [

36,

37].

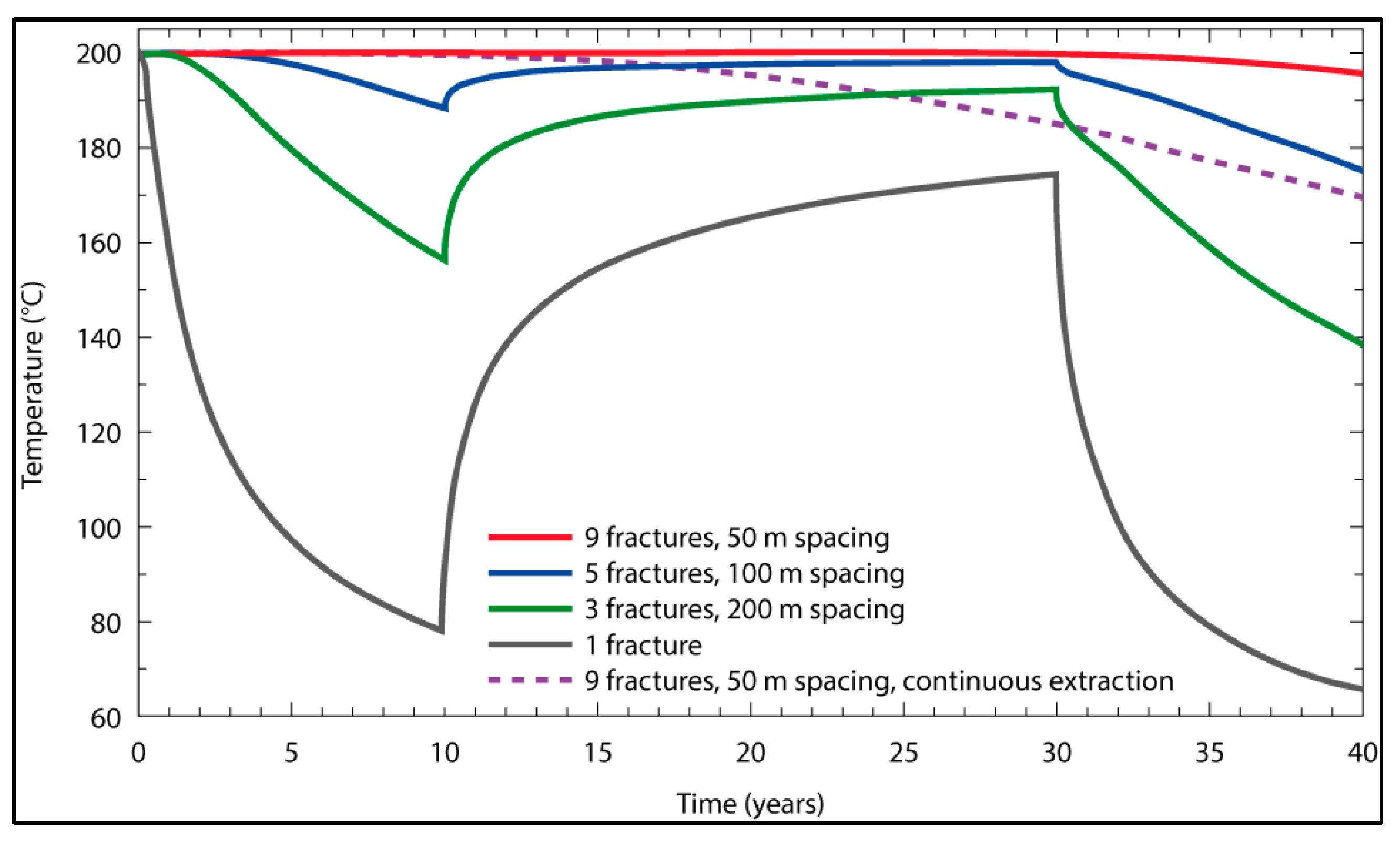

Two figures demonstrate below the principle: the geothermal resource’s temperature decreases during heat extraction, and the recovery increases the temperature again after production stop). The decrease and recovery are asymptotic in time: being strong initially and slowing down subsequently.

Figure 5 shows the production-caused temperature decrease and recovery for a geothermal heat-pump system, and

Figure 6 shows the same (but for variable heat exchange surfaces) for an EGS system. The form of the down- and up-going curves in the two figures is astonishingly similar. EGS will be described further below in more detail.

In summary: geothermal resources regrow, like biomass. Renewability can be achieved only by moderate extraction rates (“Sustainable Production Level”, for details, see [

38].

3.3. Types of Geothermal Energy

Geothermal resources can be grouped/categorised by their depth ranges (shallow, deep), heat characteristics (hydrothermal, petrothermal), temperature (low, medium, high) or energetic status (low- or high-enthalpy) resources. In the following, the most adequate categories are treated Shallow, Hydrothermal, Petrothermal), by their specific resources, utilisation technologies and achievements, and prospects.

3.3.1. Shallow Systems

The shallow geothermal resource is located in the top 400-500 meters of the subsurface (the lower limit is defined by regulation at 400 m in Germany and Switzerland). Geothermal Heat Pumps (or Ground-source heat pumps) is the key technology. The ground temperatures are generally below 30 °C; down to a depth of 100-150 m; the effects of global warming can be noticed nowadays by an increase of a few degrees °C; more details in [

41].

Geothermal Heat Pumps, GHP (or Ground-source heat pumps) represent the key utilisation technology of shallow resources. In these, closed-loop (vertical and horizontal), open-loop (groundwater) heat pump systems, energy plies, and geothermal baskets exist. The top 400 meters of the subsurface is warmer in winter and colder in summer than outside air; thus, it provides heating in winter and cooling in summer with GHP systems. These decentral, ground-coupled systems provide space heating, cooling, and domestic warm water production with the same installation. GHPs are nowadays applied in buildings of all kinds, types, sizes and numbers in many countries, for homes, schools, factories, and public and commercial buildings.

The ground is warmer in winter and cooler in summer than ambient air; thus, the same GHP system can heat in winter and cool in summer. More details about design, installation and operation are given in [

42,

43].

The GHP is one of the fastest-growing applications of renewable energy technologies worldwide and definitely the fastest-growing segment in geothermal technology.

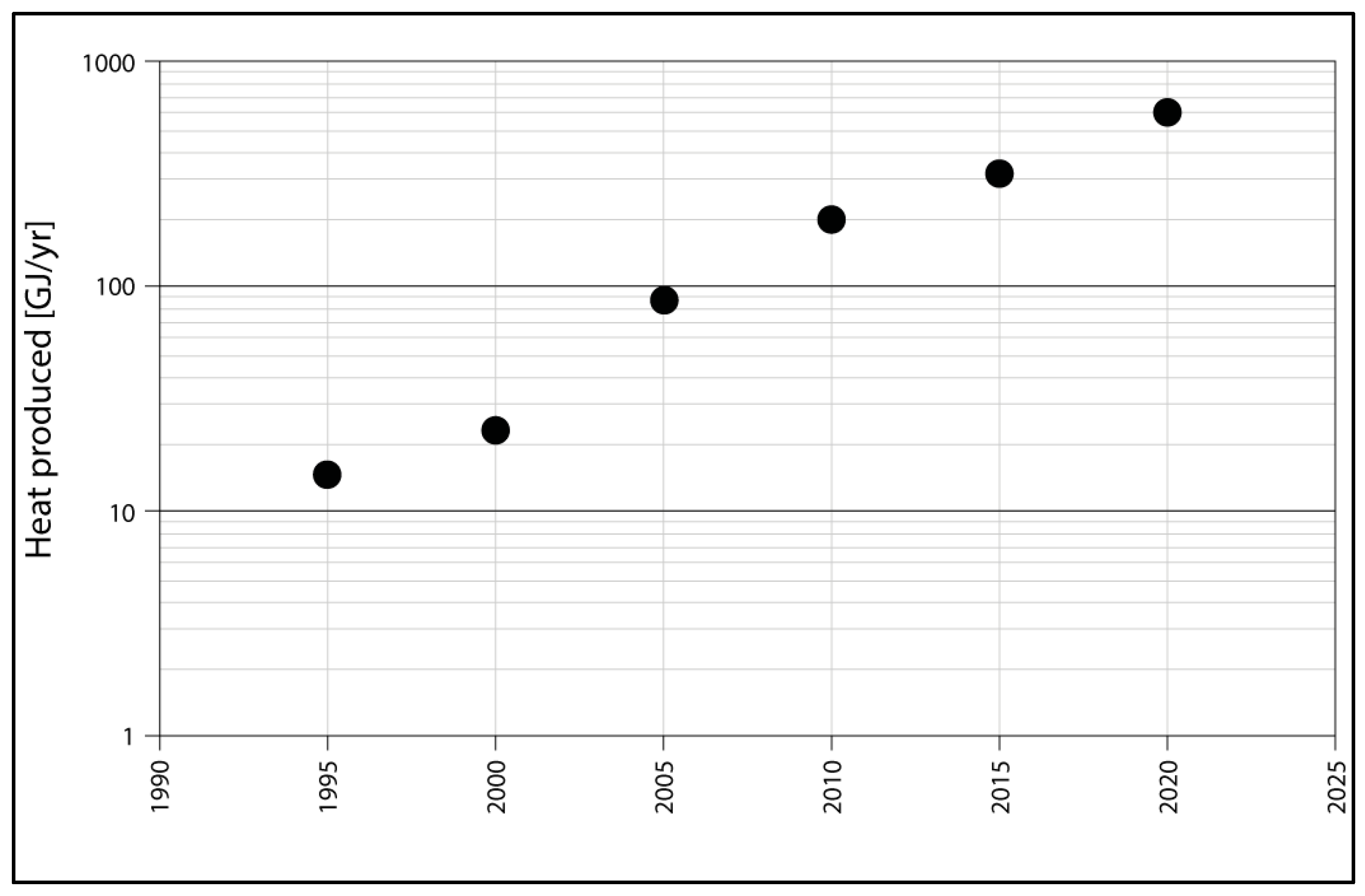

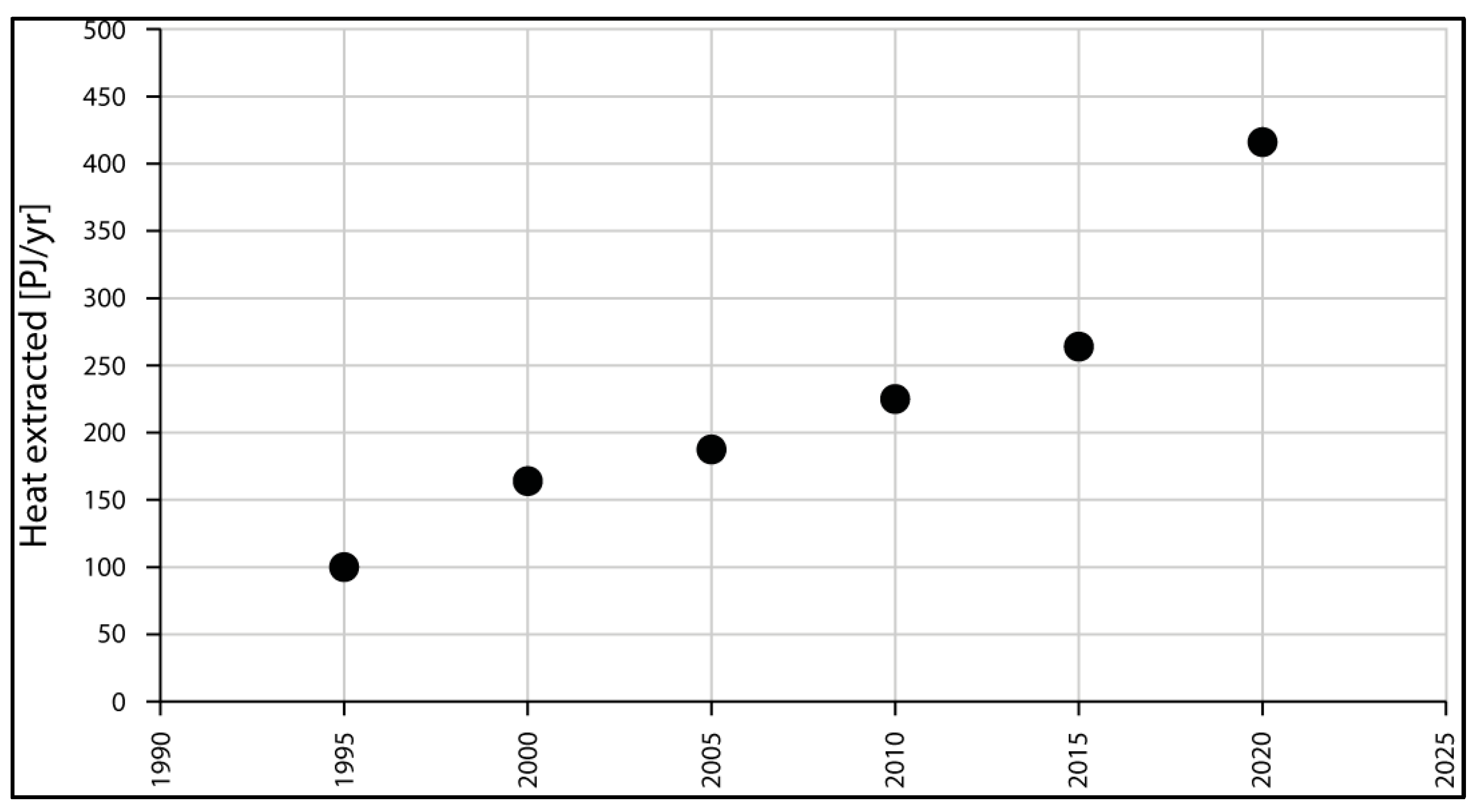

Figure 7 shows the growth of global heat supply by GHP systems over the years 1995 - 2020. The growth is impressive and exponential. Already, numerous countries have GHPs; their dissemination into more countries can be expected. In principle, GHPs belong to the Geothermal Direct Use category, but their rapid development justifies a separate treatment here - since their resource is also quite special (rather ubiquitous).

3.3.2. Hydrothermal Systems

Deeper, hotter geothermal resources than shallow ones have naturally occurring hot fluids at depth. The fluids can be used as heat carriers and taken out from the ground through boreholes. Such hydrothermal resources like deep aquifers exist only when specific geologic/hydrogeologic conditions prevail, which makes them rather rare. Their hot fluids (up to several 100 °C) can be used for two main applications: Geothermal Power Generation and Geothermal Direct Use. The boundary between the two is around 100 to 150 °C. All these applications can be treated only shortly here.

Geothermal Power Generation

This is an important and special technology of power generation, using specific machinery (mainly turbines) for heat to electric power conversion. High-temperature fields (>200 °C in less than 2 km depth) are mostly located in volcanic areas and are correspondingly rare. The average power plant size is about 50 MW

e. The largest hydrothermal plant to date, at Toanga (previously called Nga Awa Purua) in New Zealand, operates with a single 140 MW

e turbine unit and is fed by only six production wells. With advanced technology such as binary power plants, it is now possible to convert heat to power also with lower fluid temperatures (100–120 °C). But the conversion efficiency is correspondingly low (a few percentage points only, an average of 10 %), and the plant size is also limited (mostly only a few MW

e). There are very many publications about geothermal power generation and geothermal power plants. When here only two of them are mentioned [

45,

46], this does not mean that the others are less valuable.

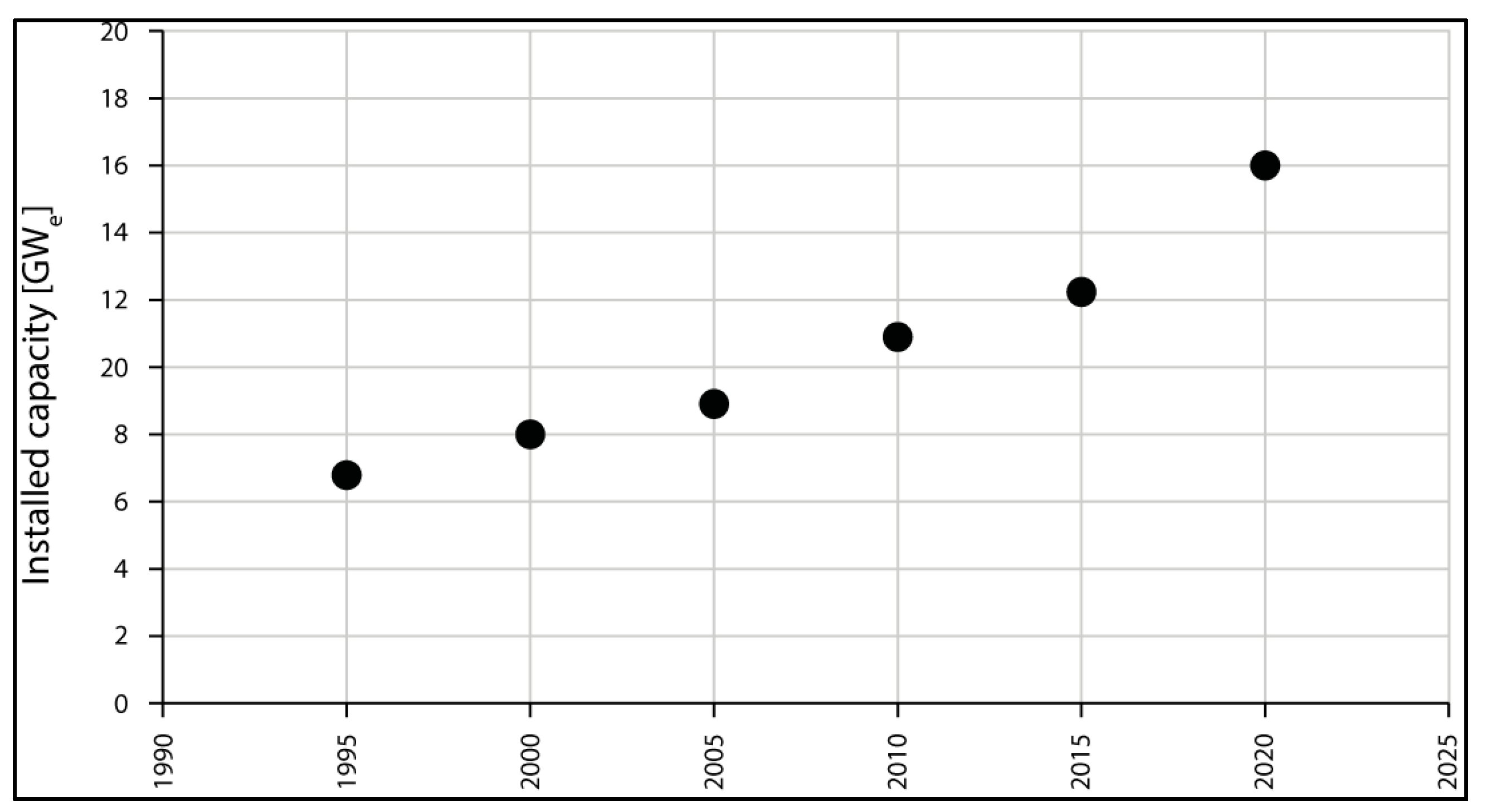

Geothermal power plants produce base-load electricity, thus significantly more than solar photovoltaic or wind power generation (their annual, global average availabilities are 70 %, 14 % and 21 %, respectively). The global geothermal electricity supply is growing annually (see

Figure 8), albeit with lower growth rates than solar PV and wind.

Geothermal Direct Use (Besides GHPs)

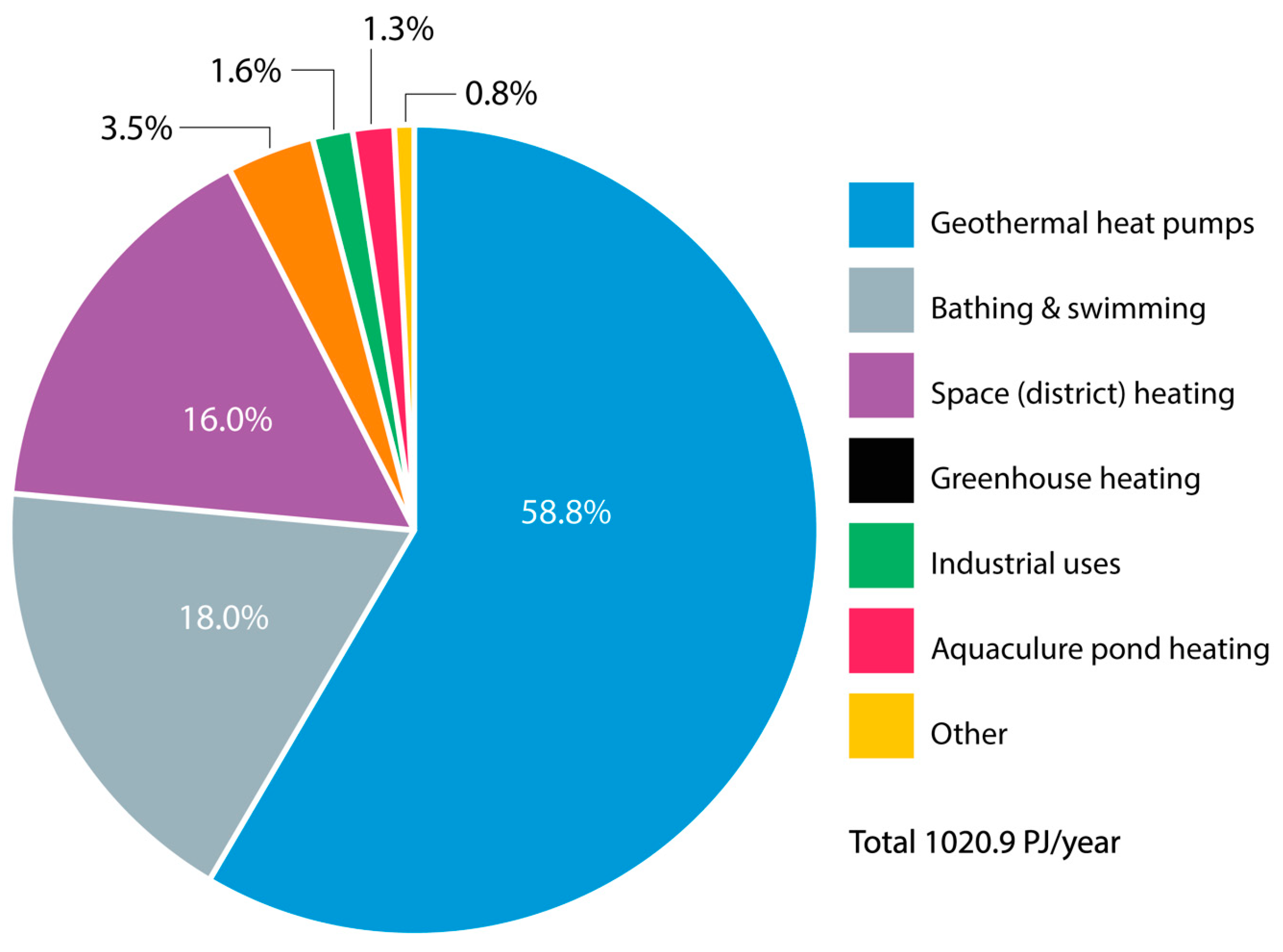

Hydrothermal resources with lower temperatures have permeable, layered formation-based aquifers and/or aquifers in fracture or karst systems, usable for geothermal direct-heat applications. The technologies provide space heating (especially with geothermal doublets, for district heating – nowadays also for cooling), bathing and swimming/wellness, industrial, agricultural (especially greenhouses) and aqua-cultural uses like fish-farming. Their current contributions (along with the shallow GHPs) are displayed in

Figure 9. More than half of direct-use heat production results from GHPs.

It must be mentioned here that in this hydrothermal category, in some places (in numerous countries), thermal springs deliver “automatically” hot water to the surface for centuries. In such hydrothermal systems, meteoric water infiltrates at the earth’s surface, finds its way to greater depths to gain heat, and then moves back to the surface, usually along permeable fractures. These occurrences are excellent examples of geothermal sustainability: the outflow and its temperature are sustainable over extended time periods.

The heat delivery of the above-mentioned direct systems (except for GHPs) is presented in

Figure 10 from 1995 – 2020. The growth is also impressive, albeit only more or less linear.

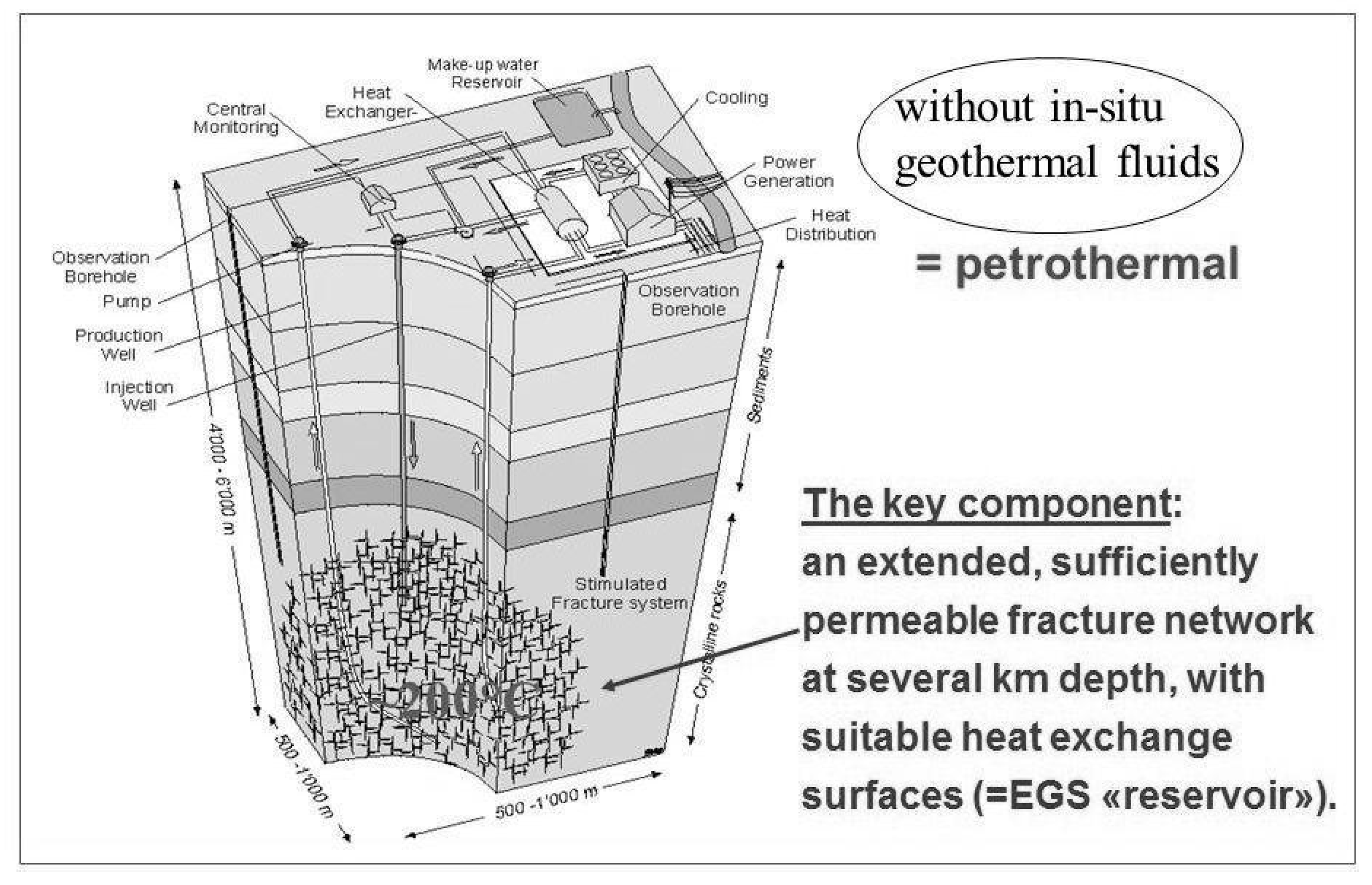

3.3.3. Petrothermal Systems

Deeper and deeper down, mostly basement-type, impermeable rocks (granites, gneisses, schists) on continents store enormous amounts of heat with correspondingly higher temperatures. This geothermal resource is enormous and, in principle, ubiquitous. On the other hand, formation (hot) fluids are usually absent.

The driving power of the CHPM system is envisaged to originate from an underground heat exchanger (

Figure 6). Of course, a heat exchanger (although a key element of the heat delivery) alone is not enough; the extracted heat must also be brought to the surface. In the following, the concept of this fundamental and decisive system is described in more detail.

Figure 11 shows the main constituents of an EGS system.

EGS stands here for Enhanced Geothermal System; although this general term can also comprise stimulated hydrothermal systems, it is mainly applied to petrothermal resources. Here, for clarity, the denomination Petrothermal EGS (PEGS) will be used. Here also, there are many publications about EGS; only two are mentioned again here [

40,

47].

The core piece of a PEGS, as shown in

Figure 11, is the above-mentioned heat exchanger in the subsurface, consisting of a network of permeable fractures. This can be established by hydraulic stimulation through the central injection borehole in the subsurface. Of course, this fracture setup should accrue at considerable depth, with correspondingly high rock temperatures. After completing the needed heat-exchanging fracture system, cold water through the central borehole is swept through the exchanger to extract heat from the rock matrix – and in a CHPM system to dissolve metals. The heated and metal-containing water is then circulated through the two extraction boreholes back to the surface. There, the fluid’s heat is converted to electricity and its metal content is recovered.

There is general agreement about the requirements of a standard, technically feasible and economically viable deep PEGS heat exchanger.

Table 3 shows the necessary numerical figures; the most relevant properties are heat exchanger volume, surface area and flow impedance for a standard 5 MW

e module.

One could expect that such an immense and ubiquitous geothermal resource as the Petrothermal would already be largely in development globally. This is, unfortunately, by no means the case. Although a recoverable PEGS potential of >2100,000 MW

e was indicated alone for the USA [

40], only one PEGS power plant operates commercially these days - in France. The Soultz power plant produces electricity with an installed capacity of 1.7 MW

e, whereas the Riffershofen PEGS plant provides industrial heat with a capacity of 24 MW

th [

48]. This is all for the moment.

Numerous field-scale investigations and tests have been carried out since the first efforts of this kind (in the USA at The Los Alamos Scientific Laboratory a half-century ago), in several countries (Australia, France, Germany, Japan, Sweden, Switzerland, UK). During this time, numerous obstacles and problems became evident. The most influential were man-made earthquakes in Basel, Switzerland (M

L=3.4, December 2006, [

50]) and at Pohang, South Korea (M

W=5.5, November 2017, [

51]. Especially the latter caused significant local damage (but no injuries or fatalities). The seismic risk of hydraulic stimulations for creating PEGS heat exchangers became evident; public opposition can currently influence or even stop PEGS development.

Besides, a number of further problems became evident (see, e.g. [

52,

53]. Accordingly, PEGS is currently still in the Proof of Concept phase. Very significant R & D will be needed to provide the proof.

In particular, a large number of problems need to be solved, too many to list them all. Here only five key goals are mentioned:

Establishing «tailor-made» PEGS heat exchangers, at any desired location, in suitable temperature/depth ranges, independent of the local subsurface conditions (lithology, temperature and stress field, natural seismicity, kind and degree of natural frustration), with limited induced seismicity;

Clarification of the long-term performance of PEGS heat exchangers in terms of productivity and environmental effects;

Determination of PEGS recovery factors (=extractable heat/heat in place), also on the long term. Today, some authors like [

53] postulate only 2 %, which would be far from economic;

Scaling problems both near-wellbore and in the casing and tubing

Upscaling the power plant size from a few MWe to several 10 – 100 MWe.

These and other research, development and demonstration efforts will have a long way and will need very substantial funding.

4. Combined Geothermal Energy and Mineral Extraction

4.1. Reservoir Stimulation

As discussed in the previous chapter, PEGS have a natural heat source, but the reservoirs and/or the fluids are artificial or engineered. Following this principle, thermal wells can also be considered an engineered/enhanced environment if different methods have been used to create artificial heat exchanger surfaces or to increase their yield.

The process of creating artificial pathways for fluid flow is called stimulation. There are three main concepts of such interventions, which are:

During hydraulic fracturing, high-pressure fluid is injected into the rock with the aim of generating new fractures within it or to expand already existing ones [

54]. Such hydraulic stimulations may use water as a fracturing agent or gel-proppant, or a combination of these two to make a hybrid agent. Geothermal applications use mainly water for this purpose. If the generation of the fracture system is based primarily on the existence of natural fractures, the process is called hydroshearing. In this case, lower pressures are sufficient, so there is less risk of induced seismicity [

55]. The most commonly used compounds are hydrochloric acid, hydrofluoric acid and various chelating reagents [

56].

Chemical stimulations are considered complementary or even as an alternative to hydraulic stimulation. Chemical treatment is most common in carbonate rocks or where fractures are filled with carbonates and other soluble minerals [

57].

Thermal treatment is usually used at high enthalpy geothermal fields. The injected cold water cools the rock in the vicinity of the wellbore, enabling the existing fracture system to expand slightly. The excitation of the pulling agent of the stress (thermo-elastic stress) is triggered by the cooling of the rock matrix around the wellbore. The value of this artificially generated thermal tension depends on several factors, such as the shape of the cooled rock volume, the thermal and elastic properties of the rock, the water temperature differences between the surface and downhole, and the direction of the injection.

When engineering a geothermal reservoir, the three main limiting factors are heat, rock type and stress regime. The most common rock types for this purpose are the granitoides of the crystalline basement. The reasoning behind it is that fluid losses in a circulating system can be minimised if the host rock has virtually no ‘in situ’ porosity and permeability. Another key factor is the stress field, which not only determines whether a reservoir can be created or not but also affects its future management and heat extraction too because the evolution of a reservoir is the function of the orientation of the fractures and the relation of these fractures to the direction of the main maximum stress. Experiments show that the evolution of a reservoir is mainly based on the existence of natural fractures. In addition to this, the so-called ‘in situ’ permeability (which is the natural permeability of the rock, prior to fracturing) is also very important. It is widely accepted that while stimulating a reservoir, the dominant key mechanism is the shearing/opening of the existing natural fractures rather than the generation of new hydraulic fractures.

The depths and bottom hole temperatures of abstraction and injection wells for PEGS are way beyond the depths and temperatures of regular thermal wells [

31]. Therefore, the main cost items of development usually account for drilling and downhole fracturing when it comes to PEGS. The petroleum industry has taken its fair share of developing technologies to drill very deep and high-temperature wells and to conduct successful fracturing under those conditions. At the same time, generating electricity from geothermal energy means larger well diameters and sometimes higher temperatures, which encourages the development of new equipment

58. Fracturing is a very complex procedure, which requires adequate qualification since the fracture system to be developed has to fulfil a number of criteria. In other words, the main risk associated with the developing of an EGS is the hydraulic fracturing itself and the quality of the generated fractures.

4.2. Metal Leaching Technologies

The idea of improving the economics of geothermal energy through the additional use of brines began to attract attention more than 50 years ago. Lithium was the first mineral to be extracted from geothermal fluids [

59]. The first lithium production operations were carried out in felsic magmatic environments in New Zealand [

60,

61] and in various magmatic sources, including granitoid environments, in the United States [

62,

63].

Leaching or element mobilisation studies use source and reservoir rocks from one or more systems and expose them to an aqueous medium (mild’ leaching agents) under conditions designed to mimic the reservoir environment (e.g. high temperature and pressure). Such studies focus on the interaction between water and rock to determine how much and what elements the injected fluid can mobilise or precipitate from the rock matrix. Under the technology outlined in the CHPM2030 project, metal-bearing geological formations will be manipulated so that the co-production of energy and metals will be possible and may be optimised according to the market demands at any given moment in the future [

31,

58]. Natural networks of hydraulically-conductive metallic mineral veins could readily function as “heat-exchanger surfaces” in a novel type of EGS system designed to tap into both the geothermal and ore potential of these structures at depths of 4 km and more [

31]. In addition to water, various environmentally friendly (EDTA, acetic acid, SDS) fluids are also being investigated to demonstrate that such utilisation of geothermal systems can make them more economically attractive, i.e. that metals can be leached from ore bodies in economical concentrations over a longer period of time and that this leaching increases the performance of the systems [

59]. There are also experiments to use CO

2 as a heat transfer medium in geothermal systems as it has a number of favourable properties both in terms of the amount of heat that can be extracted and the solubility of certain minerals [

64].

The tendency of certain metals for mobilisation under given conditions depends on their geochemical character. However, some metals, like iron, have manifold characteristics and can participate in several element associations with minerals of variable stability properties [

65].

Another major task is the recovery of chemical elements from the geothermal fluid in a usable form, using both bio- and chemical sorption processes [

66,

67].

4.3. New Technologies

The generation of the heat exchanger surface is an important part of the EGS design, so there is a strong emphasis on testing current technologies, and developing new stimulation techniques [

58,

68].

Among the new stimulation technologies, research on heat-shock fracture generation is of particular note. This can be done at a temperature higher than the rock temperature (e.g. plasma or laser) or at a significantly lower temperature. In the latter case, the Sabo Ltd. research shows that in extremely high-temperature reservoirs (T>500

oC), significant rock fragmentation can be induced by injecting water colder than 100

oC [

68].

Recent developments in the fields of laser technology enable us to use low energy loss high power laser devices (HPLD) even at large depths via the new standard high carrying capacity optical fibres [

69]. The system of ZERLUXHungary Ltd. is comprised of a high-power laser generator and a custom design directional laser drilling head. Ongoing development suggests that laser technology may be particularly suitable for cost-effectively drilling short lateral boreholes in rock. The thermal stress applied to the rock by the laser beam causes microcracks in the immediate vicinity of the laser-treated section. For the rock mechanics tests in the CHPM2030 project [

70], ZERLUX Ltd. used a laser with a laser beam power of 1.5 kW. Laboratory destructive rock mechanics tests have shown that laser-treated rock failure occurs at lower stress levels [

70,

71] . If this method proves successful, it will be possible to develop a laser device that boosts crack propagation during hydraulic fracturing without increasing the pressure.

4.4. Reservoir Operation

A reservoir can just conserve the resource in it or deliver from its content. For the latter case in PEGS, the deep heat exchanger is the central element. Besides producing the metals, such a heat exchanger in the CHPM system should also produce electricity for the metal extraction.

As mentioned in

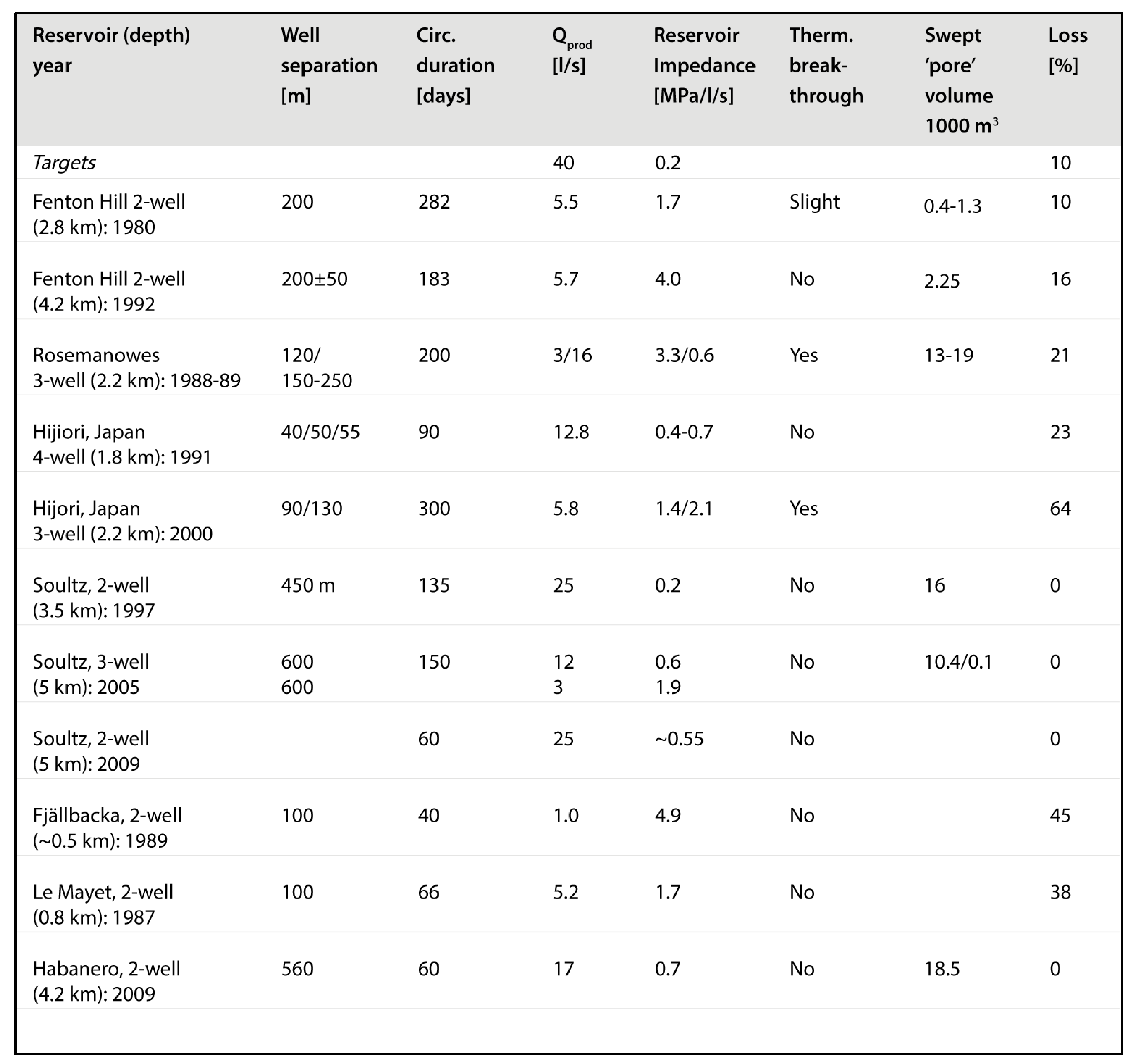

Section 3.3.3, numerous countries conducted extensive investigations into PEGS, especially about the heat exchangers. Primarily to see how such a deep heat exchanger can be created and operated how and how much it can produce. These field experiments were conducted (most of them decades ago) at full scale (depth, temperature). The numerous results of these efforts were analysed, interpreted and presented by Keith Evans (Chapters 4.2.1 and 4.2.2 in [

72]). The key results are assembled in

Table 4.

The main findings are as follows:

Already existing, well-permeable fracture zones and faults have been observed, but not regularly.

An increase in fluid injectivity and productivity in the respective boreholes has been generally achieved, although it is well documented only in the neighbourhood of the wells.

What the situation is farther away in the heat exchanger remains unclear.

3D mapping of microseismicity during hydraulic stimulation can reveal the growth and development of the heat exchanger to a kilometre from the injection well.

Specific features such as thermal breakdown or loss of circulated water are also reported.

The heat exchanger volumes were highly different, with the corresponding production flow rates between 1 and 25 l/sec.

None of the field-scale experiments led to detrimental environmental effects like groundwater contamination, unlike in shale-gas fracking.

The sustainability of the production from the heat exchanger would be highly desirable but it is still an open question. The shortages are summarised in [

49] and are as follows: “So far, no experience has been gained with respect to possible changes of a PEGS heat exchanger with time. Permeability enhancement (e.g. new fractures generated by cooling cracks, mineral dissolution) could increase the recovery factor, whereas permeability reduction (e.g. by mineral deposition) or short-circuiting could reduce recovery. Without having field-scale experience with long-term EGS production, the economic estimates about production and maintenance costs remain unsubstantiated.“

5. Economic and Climate Impacts, Future Opportunities

Lithium production from near-surface brine is almost four times greater than from minerals and extraction is relatively low cost. However, a thorough economic analysis is required to understand the financial feasibility of geothermal energy projects in terms of mineral extraction (e.g. lithium) and energy production. Assessing the economic and climate potential of sustainable mineral extraction from geothermal energy is key to ensuring environmental responsibility, sustainability and social benefits.

5.1. Geothermal Energy and Sustainable Mining for SDG 7

The potential of geothermal energy for sustainable mineral extraction and energy production aligns with Sustainable Development Goal (SDG) 7, which aims to ensure access to affordable, reliable, sustainable, and modern energy for all [

1]. By harnessing geothermal energy through "orebody-Enhanced Geothermal Systems", it enables simultaneous extraction of metals and power generation, contributing to clean and renewable energy sources [

12,

73]. This innovative approach reduces carbon emissions, minimizes dependence on non-renewable energy sources, and promotes resource efficiency [

5]. Key metallic minerals, such as lithium and tungsten, can be extracted sustainably, fostering a circular economy [

3]. According to [

74], if we consider the extraction of rare earth elements (REEs) from geothermal brines, with a similar approach to lithium and tungsten, we could expect to recover around 1071 kg of REEs per year, contributing to approximately 0.006% of REE domestic demand. The cost of geothermal energy production is estimated to be around 0.04-0.10

$/kWh, with capital costs of around 2500

$/kW installed. If REE extraction helps reduce operating costs and generates additional revenue, selling REOs could contribute to 0.11% or less of the operating budget. Additionally, geothermal energy's weather-independent nature ensures a stable and continuous supply of clean energy. In summary, integrating geothermal energy and sustainable mineral extraction supports SDG 7 by revolutionising the energy sector and paving the way for a sustainable future [

1].

5.2. Achieving a Low-Carbon Economy and Sustainable Mining Practices

Geothermal energy projects provide a weather-independent, reliable, and renewable energy source that significantly contributes to the transition to a low-carbon economy and addresses climate change. Geothermal energy is a clean energy alternative with low greenhouse gas emissions, resulting in a substantially lower carbon footprint compared to conventional energy sources [

75]. The continuous power generation capability of geothermal energy improves grid stability and enables the integration of other intermittent renewable energy sources [

76].

Compared to traditional mining practices, geothermal energy presents environmental benefits. The "Enhanced Geothermal Systems" (EGS) concept enables the extraction of valuable minerals such as lithium and tungsten in a more environmentally friendly manner 12. Mining from geothermal brines minimises the need for invasive mining operations, reducing land degradation, water pollution, and biodiversity loss. The cogeneration of energy and metals from geothermal resources optimises utilisation, promotes efficiency, and contributes to a circular economy4.

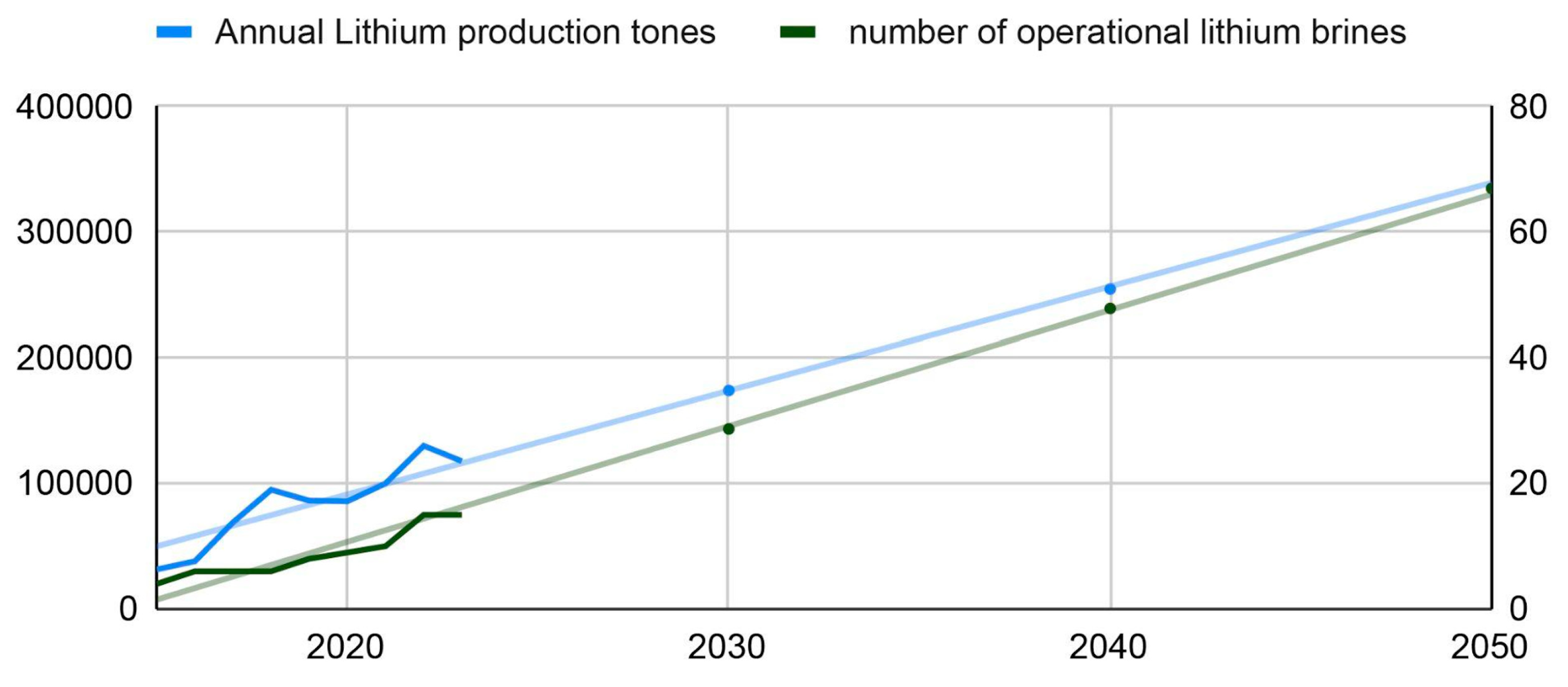

To investigate the increasing trend of worldwide operational lithium brines in recent years, data on the number of operational sites (For example, in the US, Argentina, Chile, China and other countries) producing lithium from brine were collected from the Mineral Commodity of the USGS [

77,

78,

79,

80,

81,

82,

83]. Additionally, the worldwide production of lithium was obtained from Statista.com to observe its increasing trend in the last few decades [

84]. Notably, in 2018, lithium production increased as demand for electric cars surged [

85]. A forecast formula based on linear regression analysis was used to predict the values for 2030, 2040, and 2050 based on historical data. The increasing demand for electric cars, which is becoming more common, is one of the contributing factors to the growing demand for lithium; for example, the consumption of Lithium in the consumption of Li in the production of heavy-duty batteries for powering electric vehicles is several orders of magnitude higher than the batteries used for portable electronics [

86].

Figure 12 provides valuable insights into the potential growth of lithium production in the coming years and the role of electric cars in driving this trend. It is important to note that the data presented in the graph includes both conventional and brine extraction methods for lithium production. However, the graph does not provide information on the percentage of lithium production that comes from brine extraction.

5.3. Stakeholder Collaboration for Effective Geothermal Energy Governance

Utilizing geothermal energy for mineral extraction and energy production presents challenges, but solutions exist to address them. Capital costs associated with drilling and infrastructure development can be offset by long-term operational cost savings and potential revenue from mineral extraction [

87,

88,

89]. Advanced exploration, drilling techniques, and Enhanced Geothermal Systems (EGS) can mitigate the limited availability of suitable geothermal resources. Scaling and corrosion of equipment can be overcome with advances in materials science and innovative extraction techniques [

90,

91]. Environmental impacts, including induced seismicity, water consumption, and greenhouse gas release from geothermal reservoirs, can be addressed by implementing rigorous monitoring systems, improving drilling techniques, and utilising advanced reservoir management practices [

92]. Geothermal energy projects can benefit industries by increasing resource efficiency and profitability, and governments can leverage them to meet climate goals, reduce dependence on fossil fuels, and stimulate local and national economies. Local communities can enjoy stable, clean energy, potentially lower energy costs, and improved quality of life. In conclusion, geothermal energy projects can yield significant benefits for stakeholders by driving resource efficiency, supporting sustainability goals, and stimulating economic growth while minimising environmental impacts [

4].

5.4. Future Challenges and Opportunities

Geothermal brine mining, while offering several environmental and economic advantages, also presents a number of challenges that need to be addressed to ensure its long-term viability and widespread adoption. One major challenge is the high upfront cost associated with the development of geothermal projects, including drilling, exploration, and the installation of surface equipment [

95,

96]. This substantial initial investment can create a barrier to entry, particularly for smaller companies or in regions with limited resources [

97]. Furthermore, the complexity and uncertainty surrounding subsurface geological formations can lead to increased risk and difficulty in predicting project success [

62].

In addition to the economic challenges, technical obstacles also exist. The extraction of minerals from geothermal brine can be a complex process, requiring specialised equipment and expertise [

98]. According to Kavanagh et al., 2018, pumping lithium from a 2 km depth could be difficult and expensive. The harsh chemical composition of some geothermal brines can pose difficulties for extraction technologies, leading to concerns over equipment corrosion, scaling, and operational issues [

95]. These factors can negatively impact the overall efficiency and lifespan of the equipment, resulting in increased maintenance costs and downtime.

Another challenge is the environmental impact associated with geothermal brine mining. Although the overall environmental footprint is generally lower compared to conventional mining practices9, there are still potential concerns, such as the release of greenhouse gases, water consumption, induced seismicity [

86,

99] and the management of waste products [

86,

95]. Developing effective strategies for mitigating these environmental impacts is crucial to ensuring the long-term sustainability and social acceptability of geothermal brine mining projects.

Addressing these challenges will require interdisciplinary collaboration between scientists, engineers, industry stakeholders, and policymakers. Advancements in exploration technologies, drilling techniques, and resource extraction methods can help to reduce costs and improve efficiency [

86], while regulatory frameworks can provide incentives and support for sustainable geothermal brine mining practices. By tackling these obstacles, geothermal brine mining can become a more viable and attractive option for sustainable mineral extraction and energy production.

6. Projects, Future Options

The most suitable rocks for the combined production of geothermal energy and critical elements are high-temperature metal-bearing geological formations. Apart from volcanic areas, these are usually located at depths of at least 4 km [

31]. In the CHPM project, European potential deposits were classified into metallogenic domains, as their distribution is strongly correlated with the tectonic environment [

31,

100]:

Precambrian Fennoscandian Shield province,

Early Paleozoic Caledonian province, Late

Paleozoic Variscan province,

Mesozoic-Cenozoic Alpine province

In particular, in the planned exploitation of PEGS, both the metal content of the ore body and the mineral phases should be taken into account to determine the metal mobilisation and the metal extraction methodology. Note that in the hydrothermal case, fluids with high dissolved metal content can also be found where the reservoir rock has low metal content due to transport processes.

Ongoing projects are focusing on deposits at the depths required for geothermal energy production, where metals have been shown to mobilise in hot water.

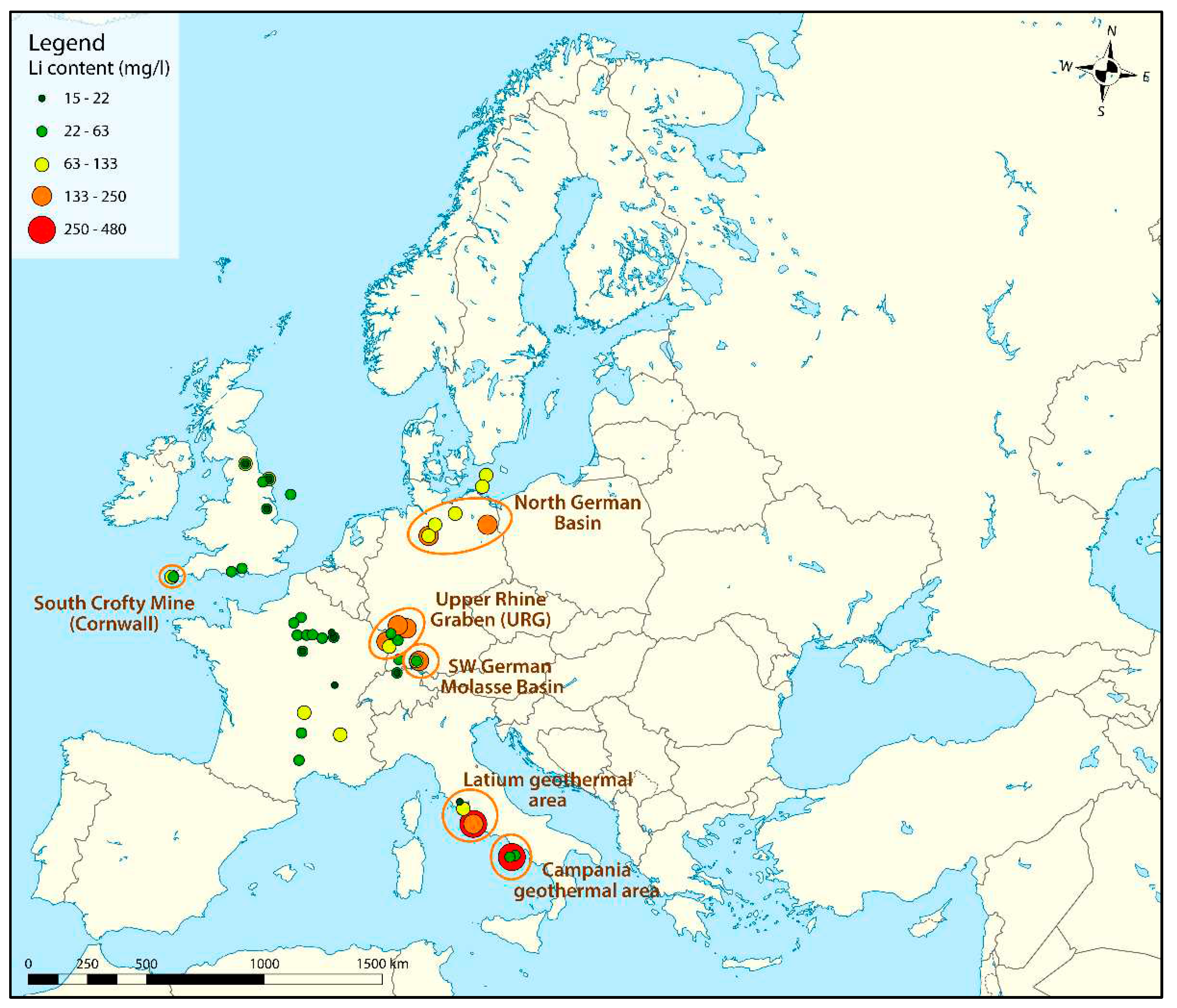

Sanjuan and co-authors reviewed among all known European geothermal and hydrocarbon fields in the literature so far; six main geothermal areas were detected whose deep fluids contain high Li concentrations, ranging from 125 to 480 mg/l, in Italy, Germany, France and the United Kingdom [

5] (

Figure 13). In this study, two of these areas are presented, the Upper Rhine Graben along the French-German border and Cornwall in south-east England. Of course, there are also studies outside Europe on the possibility of producing critical elements from thermal water, for example, in North America, in Nevada and Utah [

101] or in California for geothermal fields [

62], but also in Asia and Africa, notably in the case of Li [

102,

103].

6.1. Upper Rhine Graben

Among the high-temperature geothermal fluids in Europe, the Upper Rhine Graben (URG) was proved as one of the most promising areas to extract Lithium from geothermal brine. The European Geothermal Lithium Brine Project aim to extract lithium from existing geothermal wells in the URG. The main source of lithium at temperatures of around 225 °C, at the depth of the reservoir is probably the evaporite minerals of the Triassic Buntsandstein mica continental sandstone, up to 450 m thick. A minor contribution of granitic bedrock cannot be excluded. The Li concentrations can exceed 150 mg/L with high yields [

5]. The main objective of the project is to identify an active material, capable of selectively extracting lithium and chloride from geothermal brine at specific pressures and temperatures (20 bar, 80 °C). Sanjuan and co-authors estimate that the current short-term planned geothermal projects in URG could collectively produce 21,300-32,000 t/y of lithium carbonate equivalent, assuming that the currently known Li concentrations and production flow rates can be maintained for a long time [

5].

Even more ambitious is the Vulcan Zero Carbon Lithium™ project, which, according to the final feasibility study for its first phase, will produce 900 l/s of fluid from the URG area (2 project sites: Lionheart, Taro), assuming an average lithium content of 181 mg/l. This means an annual production of about 308,000 MWh of electricity sold and 252,000 MWh of heat, with 24,755 t of LiCl production in LHM (Lithium Hydroxide Monohydrate) equivalent [

105]. The production line is expected to produce two additional saleable by-products: hydrochloric acid (HCl) and sodium hypochlorite (NaOCl). In the economic model, an average realised price of 30,283 €/t LHM for the next 20 years was considered. The model takes into account the lithium dilution at each well site; lithium concentration in the project area decreases by ~1.6% per year. Vulcan's cost of capital expenditure (CAPEX) estimate, in-line with international and in-house cost guidelines: €1,496 million. The estimated annual operating expenditure (OPEX) is €112 million, 80% of which is directly or indirectly related to the production of lithium. The estimated annual revenue (20-year average) for the first phase is 704.4 M€/year (105). Vulcan targets to start its power, heat and lithium production by the end of 2025.

6.2. Cornwall

The Cornubian granit batholith of SW England is one of the UK's most promising geothermal energy-producing provinces. The estimated temperature at a depth of 5 km largely exceeds of 200 °C [

104]. Lithium was first identified when economic deposits of Sn, Cu, Pb, Zn and W were found in batholiths of the Variscan age. The Cornish Lithium company has conducted exploratory drilling beneath the old mine to test the Li potential of geothermal waters, which was generated by water-rock interaction. There is not much published information, but according to previous measurements, the lithium content can be as high as 125 mg/l [

5]. The current United Downs project is Cornish Lithium's flagship project because it is the first geothermal electricity project in the UK. The production well, drilled to 5,057 m, successfully reached the 180

oC permeable fractured zone with a high lithium concentration of 274 mg/, so it has ambitious plans for lithium production [

106].

7. Conclusions

The depth of ore exploration rarely exceeds 1 km due to current mining technologies, so we have only a guess at reserves up to 5-6 km deep. Combined heat and mineral production technology could tap a new, unexplored source, boosting the supply of previously untapped resources. This is also the aim of the CRM-geothermal project [

17], based on the CHMP2030 project [

31], to develop an economically viable technology for combined heat and critical raw materials co-production from geothermal reservoirs. This co-production avoids visible large-scale installations above ground, and it has minimal environmental footprint. It should be implemented under careful and transparent environmental control to ensure public acceptance, in which case positive social and economic impacts can be expected.

All in all, geothermal energy utilisation has evolved beyond its focus on the energy production to encompass a wider range of applications within mineral extraction, including the sustainable production of critical raw materials. These features make geothermal energy a cost-effective and weather-independent source of renewable energy and mineral resources at the same time. The geothermal sector, based on technological innovations, could be capable of producing critical minerals with a more equitable geographical distribution of resources.

Currently, in Europe, particularly in the Upper Rhine Graben and Cornwall, large-scale combined heat, power, and mineral extraction technology projects have been launched that could set the future direction of development.

However, there are still a number of challenges to be overcome, furthermore, it can be stated that there will not be one general solution, and there will be no single critical parameter for compatibility; everything needs to be evaluated on a case-by-case level, including the way thermal energy is utilised.

Acknowledgements

This article uses the results of the projects that received funding from the European Union's H2020 and Horizon Europe research and innovation programmes under grant agreements No. 654100 and No. 101058163.

References

- Edenhofer, O. , Pichs-Madruga, R., Sokona, Y., Seyboth, K., Kadner, S., Zwickel, T., Eickemeier, P., Hansen, G., Schlömer, S., von Stechow, C., Matschoss, P., Eds.: Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change, 1st ed.; Cambridge University Press, 2011. [CrossRef]

- Finster, M.; Clark, C.; Schroeder, J.; Martino, L. : Geothermal Produced Fluids: Characteristics, Treatment Technologies, and Management Options. Renew. Sustain. Energy Rev. 2015, 50, 952–966. [Google Scholar] [CrossRef]

- Agrawal, R.; Bhagia, S.; Satlewal, A.; Ragauskas, A. J. : Urban Mining from Biomass, Brine, Sewage Sludge, Phosphogypsum and e-Waste for Reducing the Environmental Pollution: Current Status of Availability, Potential, and Technologies with a Focus on LCA and TEA. Environ. Res. 2023, 224, 115523. [Google Scholar] [CrossRef] [PubMed]

- Balaram, V. : Potential Future Alternative Resources for Rare Earth Elements: Opportunities and Challenges. Minerals 2023, 13. [Google Scholar] [CrossRef]

- Sanjuan, B.; Gourcerol, B.; Millot, R.; Rettenmaier, D.; Jeandel, E.; Rombaut, A. : Lithium-Rich Geothermal Brines in Europe: An up-Date about Geochemical Characteristics and Implications for Potential Li Resources. Geothermics 2022, 101, 102385. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, C.; Su, P.; Tang, Y. : Huang, Z.; Ma, T. A Review of Acid Mine Drainage: Formation Mechanism, Treatment Technology, Typical Engineering Cases and Resource Utilization. Process Saf. Environ. Prot. 2023, 170, 1240–1260. [Google Scholar] [CrossRef]

- Pantelic, U.; Lilic, P.; Cvjetic, A.; Lilic, N. : Environmental Noise Impact Assessment for Large-Scale Surface Mining Operations in Serbia. Sustainability 2023, 15. [Google Scholar] [CrossRef]

- Fontaine, A.; Martyniuk, M. A. C.; Garnier, C.; Couture, P. : Assessing the Impacts of Mining Activities on Fish Health in Northern Québec. Can. J. Fish. Aquat. Sci. 2023. [Google Scholar] [CrossRef]

- Tabelin, C. B.; Dallas, J.; Casanova, S.; Pelech, T.; Bournival, G.; Saydam, S.; Canbulat, I. Towards a Low-Carbon Society: A Review of Lithium Resource Availability, Challenges and Innovations in Mining, Extraction and Recycling, and Future Perspectives. Miner. Eng. 2021, 163, 106743. [Google Scholar] [CrossRef]

- Tuschl, M.; Kurevija, T. : Defining Heat in Place for the Discovered Geothermal Brine Reservoirs in the Croatian Part of Pannonian Basin. Water 2023, 15. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, G.; Dong, G.; Zheng, H. : Research Progress of Working Electrode in Electrochemical Extraction of Lithium from Brine. Batteries 2022, 8. [Google Scholar] [CrossRef]

- Ali, S. H.; Giurco, D.; Arndt, N.; Nickless, E.; Brown, G.; Demetriades, A.; Durrheim, R.; Enriquez, M. A.; Kinnaird, J.; Littleboy, A.; Meinert, L. D.; Oberhänsli, R.; Salem, J.; Schodde, R.; Schneider, G.; Vidal, O.; Yakovleva, N. : Mineral Supply for Sustainable Development Requires Resource Governance. Nature 2017, 543, 367–372. [Google Scholar] [CrossRef] [PubMed]

- Ledésert, B. A.; Hébert, R. L.; Trullenque, G.; Genter, A.; Dalmais, E.; Herisson, J. : Editorial of Special Issue “Enhanced Geothermal Systems and Other Deep Geothermal Applications throughout Europe: The MEET Project. ” Geosciences 2022, 12. [Google Scholar] [CrossRef]

- Sharma, S. K.; Sharma, G. K. : Demand Forecasting Techniques Vis-à-Vis Demand Forecast for Lead. Procedia Earth Planet. Sci. 2015, 11, 418–424. [Google Scholar] [CrossRef]

- Savinova, E.; Evans, C.; Lèbre, É.; Stringer, M.; Azadi, M.; Valenta, R. K. : Will Global Cobalt Supply Meet Demand? The Geological, Mineral Processing, Production and Geographic Risk Profile of Cobalt. Resour. Conserv. Recycl. 2023, 190, 106855. [Google Scholar] [CrossRef]

- Yu, D.; Wenhui, X.; Anser, M. K.; Nassani, A. A.; Imran, M.; Zaman, K.; Haffar, M. : Navigating the Global Mineral Market: A Study of Resource Wealth and the Energy Transition. Resour. Policy 2023, 82, 103500. [Google Scholar] [CrossRef]

- 17. Home - CRM-geothermal, 2023.

- Bloomquist, R. G. : Economic Benefits of Mineral Extraction from Geothermal Brines. Transactions - Geothermal Resources Council 30:579-582, 2006. [Google Scholar]

- Mroczek, E.K. , Climo, M.D., Li, Y., Evans, D., Carey, B., & Gao, W.: From Waste to Wealth: Mineral Extraction from Geothermal Brines. Proceedings World Geothermal Congress 2015 Melbourne, Australia, 19-25 April, 25 April 2015. [Google Scholar]

- Bourcier, W. L.; Lin, M.; Nix, G. : Recovery of Minerals and Metals from Geothermal Fluids; 2005. United States. https://www.osti.gov/servlets/purl/883558.

- Di Somma, M.; Buonanno, A.; Caliano, M.; Graditi, G.; Piazza, G.; Bracco, S.; Delfino, F. Stochastic Operation Optimization of the Smart Savona Campus as an Integrated Local Energy Community Considering Energy Costs and Carbon Emissions. Energies 2022, 15. [Google Scholar] [CrossRef]

- Yin, H.; Hu, L.; Li, Y.; Gong, Y.; Du, Y.; Song, C.; Zhao, J. : Application of ORC in a Distributed Integrated Energy System Driven by Deep and Shallow Geothermal Energy. Energies 2021, 14. [Google Scholar] [CrossRef]

- Eras-Almeida, A. A.; Vásquez-Hernández, T.; Hurtado-Moncada, M. J.; Egido-Aguilera, M. A. A. : Comprehensive Evaluation of Off-Grid Photovoltaic Experiences in Non-Interconnected Zones of Colombia: Integrating a Sustainable Perspective. Energies 2023, 16. [Google Scholar] [CrossRef]

- Mehta, K.; Ehrenwirth, M.; Trinkl, C.; Zörner, W. : Mapping Potential for Improving Rural Energy Services in Kyrgyzstan: Factors for Achieving Sustainable Development Goals in the Community Context. World 2022, 3, 586–606. [Google Scholar] [CrossRef]

- Plass, W. T. : Madison, WI, USA, 2015; pp 1–20. https://doi.org/10.2134/agronmonogr41.c1.Legislation. In Agronomy Monographs; Barnhisel, R. I., Darmody, R. G., Lee Daniels, W., Eds.; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Madison, WI, USA, 2015. [Google Scholar] [CrossRef]

- Michael, C. : The History of Mining – The Events, Technology and People Involved in the Industry That Forged the Modern World; Harriman House Limited, 2012.

- van Schoor, M.; Nkosi, Z. : Magweregwede, F.; Kgarume, T.: Deep-Level Gold and Platinum Mining: The Application of Geophysics in South Africa, Ed.; Springer International Publishing: Cham, 2022. [Google Scholar] [CrossRef]

- Deepest-Global-Mines. https://www.statista.com/statistics/1343524/deepest-global-mines/ (accessed 2023-03-24).

- Mineral Requirements for Clean Energy Transitions. https://www.iea.org/reports/the-role-of-critical-minerals-in-clean-energy-transitions/mineral-requirements-for-clean-energy-transitions (accessed 2023-03-24).

- Clean-Energy-Demand-for-Critical-Minerals-Set-to-Soar-as-the-World-Pursues-Net-Zero-Goals. https://www.iea.org/news/clean-energy-demand-for-critical-minerals-set-to-soar-as-the-world-pursues-net-zero-goals (accessed 2023-03-24).

- Hartai, É.; Madarász, T.; Miklovicz, T. : Strasbourg, France, 2020; pp 1–5. https://doi.org/10.3997/2214-4609.202021076.Bodies. In 1st Geoscience & Engineering in Energy Transition Conference; European Association of Geoscientists & Engineers: Strasbourg, France, 2020. [Google Scholar] [CrossRef]

- Strangway, D. W.; Swift, C. M.; Holmer, R. C. : The Application of Audio-frequency Magnetotellurics (AMT) to Mineral Exploration. Geophisics, 1973, 38, 1159–1175. [Google Scholar] [CrossRef]

- Kalscheuer, T.; Juhojuntti, N.; Vaittinen, K. Two-Dimensional Magnetotelluric Modelling of Ore Deposits: Improvements in Model Constraints by Inclusion of Borehole Measurements. Surv. Geophys. 2018, 39, 467–507. [Google Scholar] [CrossRef]

- Moorkamp, M.; Heincke, B.; Jegen, M.; Roberts, A. W.; Hobbs, R. W. A Framework for 3-D Joint Inversion of MT, Gravity and Seismic Refraction Data: 3-D Joint Inversion. Geophys. J. Int. 2011, 184, 477–493. [Google Scholar] [CrossRef]

- 35. World Energy Council. Survey of Energy Resources, 2000.

- Rybach, L. Geothermal Sustainability or Heat Mining? Int. J. Terr. Heat Flow Appl. 2021, 4, 15–25. [Google Scholar] [CrossRef]

- Rybach, L. , Mégel, Th., Eugster, W.J.: At what timescale are geothermal resources renewable? In: Proc. World Geothermal Congress 2000, Kyushu-Tohoku, Japan, /: http, 2000. [Google Scholar]

- Axelsson, G. , Rybach, L., Júlíusson, G. (2020): Sustainable Management of Geothermal Production. Proceedings World Geothermal Congress 2020+1, Reykjavik, Iceland, April - 21. http://www.geothermal-energy.org/pdf/IGAstandard/WGC/2020/05055. 20 October.

- Rybach, L. Geothermal Heat Pump Production Sustainability—The Basis of the Swiss GHP Success Story. Energies 2022, 15. [Google Scholar] [CrossRef]

- Fox, D. B.; Sutter, D.; Beckers, K. F.; Lukawski, M. Z.; Koch, D. L.; Anderson, B. J.; Tester, J. W. Sustainable Heat Farming: Modeling Extraction and Recovery in Discretely Fractured Geothermal Reservoirs. Geothermics 2013, 46, 42–54. [Google Scholar] [CrossRef]

- Rybach, L. Shallow Systems—Geothermal Heat Pumps. In Comprehensive Renewable Energy; Elsevier, 2022; pp 197–219. [CrossRef]

- Rybach, L.; Bayer, P.; Rivera, J.A.; Blum, P. Influence Factors in the Depth Domain of Borehole Heat Exchangers – Global Warming and Urban Heating; Strasbourg, France, 2016.

- Lund, J.; Sanner, B.; Rybach, L.; Curtis, R.; Hellström, G. : Geothermal (Ground-source) Heat Pumps a World Overview. GHC Bull. /: 10p. http.

- Rybach, L. Global Status, Development and Prospects of Shallow and Deep Geothermal Energy. Int. J. Terr. Heat Flow Appl. 2022, 5, 20–25. [Google Scholar] [CrossRef]

- Dickson, M. H.; Faneli, M. What Is Geothermal Energy?; Pisa, Italy, 2006.

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies, and Environmental Impact, 3rd ed.; Butterworth-Heinemann: Amsterdam ; Boston, 2012.

- Olasolo, P.; Juárez, M. C.; Morales, M. P.; D´Amico, S.; Liarte, I. A. Enhanced Geothermal Systems (EGS): A Review. Renew. Sustain. Energy Rev. 2016, 56, 133–144. [Google Scholar] [CrossRef]

- Mouchot, J.; Genter, A.; Nicolas, C.; Scheiber, J.; Olivier, S.; Bosia, C.; Ravier, G. First Year of Operation from EGS Geothermal Plants in Alsace, France: Scaling Issues; Stanford University, Stanford, California, -14, 2018. 12 February.

- Rybach, L.; Kohl, T. : Geothermal Energy and a Future Earth. In Global Change and Future Earth; Beer, T., Li, J., Alverson, K., Eds.; Cambridge University Press, 2018; pp 364–376. [CrossRef]

- Häring, M. O.; Schanz, U.; Ladner, F.; Dyer, B. C. Characterisation of the Basel 1 Enhanced Geothermal System. Geothermics 2008, 37, 469–495. [Google Scholar] [CrossRef]

- Woo, J. -U.; Kim, M.; Sheen, D. -H.; Kang, T. -S.; Rhie, J.; Grigoli, F.; Ellsworth, W. L.; Giardini, D. An In-Depth Seismological Analysis Revealing a Causal Link Between the 2017 M W 5.5 Pohang Earthquake and EGS Project. J. Geophys. Res. Solid Earth 2019, 124, 13060–13078. [Google Scholar] [CrossRef]

- Grant, M. A.; Garg, S. K. Recovery Factor for EGS. In Proceedings; Stanford University: Stanford, California, 2012. [Google Scholar]

- Rybach, L. : “The Future of Geothermal Energy” and Its Challenges. In: Proceedings World Geothermal Congress 2010, Bali, Indonesia, 25-29 April, 29 April 2010. [Google Scholar]

- Haimson, B. C.; Cornet, F. H. ISRM Suggested Methods for Rock Stress Estimation—Part 3: Hydraulic Fracturing (HF) and/or Hydraulic Testing of Pre-Existing Fractures (HTPF). Int. J. Rock Mech. Min. Sci. 2003, 40, (7–8). [Google Scholar] [CrossRef]

- :Breede, K.; Dzebisashvili, K.; Liu, X.; Falcone, G.A. : Systematic Review of Enhanced (or Engineered) Geothermal Systems: Past, Present and Future. Geotherm. Energy 2013, 1. [Google Scholar] [CrossRef]

- Nami, P.; Schellschmidt, R.; Schindler, M.; Tischner, T. : Chemical Stimulation Operations for Reservoir Development of the Deep Crystalline HDR/EGS System at Soultz-Sous-Forets (France). In Proceedings; Stanford University, 2008.

- Portier, S.; André, L.; Vuataz, F.-D. : Review on Chemical Stimulation Techniques in Oil Industry and Applications to Geothermal Systems; ENhanced Geothermal Innovative Network for Europe; Technical; Deep Heat Mining Association – DHMA, Switzerland, 2007.

- Xing, P.; McLennan, J.; Moore, J. : In-Situ Stress Measurements at the Utah Frontier Observatory for Research in Geothermal Energy (FORGE) Site. Energies 2020, 13. [Google Scholar] [CrossRef]

- Osvald, M.; Kilpatrick, A. D.; Rochelle, C. A.; Szanyi, J.; Medgyes, T.; Kóbor, B. : Laboratory Leaching Tests to Investigate Mobilisation and Recovery of Metals from Geothermal Reservoirs. Geofluids 2018, 2018, 1–24. [Google Scholar] [CrossRef]

- Dang, V.-D.; Steinberg, M. : Preliminary Design and Analysis of Recovery of Lithium from Brine with the Use of a selective Extractant. In Lithium Needs and Resources; Elsevier, 1978; pp 325–336. [CrossRef]

- Duyvesteyn, W. P. C. : Recovery of Base Metals from Geothermal Brines. Geothermics 1992, 21, (5–6). [Google Scholar] [CrossRef]

- Kesler, S. E.; Gruber, P. W.; Medina, P. A.; Keoleian, G. A.; Everson, M. P.; Wallington, T. J. : Global Lithium Resources: Relative Importance of Pegmatite, Brine and Other Deposits. Ore Geol. Rev. 2012, 48, 55–69. [Google Scholar] [CrossRef]

- Neupane, G.; Wendt, D. S. : Stanford, California, 2017.US. In 42nd Workshop on Geothermal Reservoir Engineering; Stanford University: Stanford, California, 2017. [Google Scholar]

- Pruess, K. Enhanced Geothermal Systems (EGS) Using CO2 as Working Fluid—A Novel Approach for Generating Renewable Energy with Simultaneous Sequestration of Carbon. Geothermics 2006, 35, 351–367. [Google Scholar] [CrossRef]

- Dill, H. G. : The “Chessboard” Classification Scheme of Mineral Deposits: Mineralogy and Geology from Aluminum to Zirconium. Earth-Sci. Rev. 2010, 100, (1–4). [Google Scholar] [CrossRef]

- Brewer, A.; Chang, E.; Park, D. M.; Kou, T.; Li, Y.; Lammers, L. N.; Jiao, Y. : Recovery of Rare Earth Elements from Geothermal Fluids through Bacterial Cell Surface Adsorption. Environ. Sci. Technol. 2019, 53, 7714–7723. [Google Scholar] [CrossRef]

- Kohl, T.; Bremer, J.; Schill, E.; Kolditz, O.; Sass, I.; Zimmermann, G. : GeoLaB - Geothermal Laboratory in the Crystalline Basement. 2022. [CrossRef]

- Holtzman, B.; Groebner, N.; Mittal, T. : A Novel Drilling Head Designfor Routine Heat Mining Above the Brittle-Ductile Transition. In 48th Workshop on Geothermal Reservoir Engineering; Stanford University: Stanford University, 2023. [Google Scholar]

- Bajcsi, P ; Bozsó, T ; Bozsó, R ; Molnár, G ; Tábor, V ; Czinkota, I ; M, Tóth T ; Kovács, B ; Schubert, F ; Bozsó, G; Szanyi J.: New geothermal well-completion and rework technology by laser, Central European Geology. 2015; 58.

- Szanyi, J. , Osvald, M., Medgyes, T., Kóbor, B., M. Tóth, T., Madarász, T., Kolencsinké-Tóth, A., Debreczeni, Á., Kovács, B., Vásárhelyi, B., Rozgonyi-Boissinot, N.: Recommendations for Integrated reservoir Management. CHPM2030 Deliverable D2.

- Kovács, B.; Czinkota, I.; Szanyi, J.; Bozsó, T.; Tóth, M.; Simon, A.; Busuttil, L. : The permeability of laser drilled laterals in sand- 681 stone reservoirs. Geosciences and Engineering, 2014; 5. [Google Scholar]

- Hirschberg, S. , Wiemer, S., Burgherr, P. (eds).: Energy from the Earth – Deep Geothermal as a Resource of the Future? Forschungsverlag AG an der ETH Zürich. [CrossRef]

- Agusdinata, D. B.; Liu, W.; Eakin, H.; Romero, H. : Socio-Environmental Impacts of Lithium Mineral Extraction: Towards a Research Agenda. Environ. Res. Lett. 2018, 13. [Google Scholar] [CrossRef]

- Smith, Y.; Kumar, P.; McLennan, J. : On the Extraction of Rare Earth Elements from Geothermal Brines. Resources 2017, 6. [Google Scholar] [CrossRef]

- Man, S. S.; Lee, W. K. H.; Chan, A. H. S.; Tsang, S. N. H. : The Economic and Environmental Evaluations of Combined Heat and Power Systems in Buildings with Different Contexts: A Systematic Review. Appl. Sci. 2023, 13. [Google Scholar] [CrossRef]

- Fang, K.; Azizan, S. A.; Wu, Y. : Low-Carbon Community Regeneration in China: A Case Study in Dadong. Sustainability 2023, 15. [Google Scholar] [CrossRef]

- 77. Mineral Commodity Summaries 2017; U.S. Geological Survey: USA, 2017. [CrossRef]

- Mineral Commodity Summaries 2018; U.S. Geological Survey: USA, 2018. [CrossRef]

- Mineral Commodity Summaries 2019; U.S. Geological Survey: USA, 2019. [CrossRef]

- Mineral Commodity Summaries 2020; U.S. Geological Survey: USA, 2020. [CrossRef]

- 81. Mineral Commodity Summaries 2021. U.S. Geological Survey: USA, 2021. [CrossRef]

- 82. Mineral Commodity Summaries 2022. U.S. Geological Survey: USA, 2022. [CrossRef]

- 83. Mineral Commodity Summaries 2023. U.S. Geological Survey: USA, 2023. [CrossRef]

- 84. Global lithium production 2022. Statista, 6066.

- 85. Why Electric Cars Will Take over Sooner than You Think. BBC News, 31 May 5725.

- Khalil, A.; Mohammed, S.; Hashaikeh, R.; Hilal, N. : Lithium Recovery from Brine: Recent Developments and Challenges. Desalination 2022, 528, 115611. [Google Scholar] [CrossRef]

- Igogo, T.; Awuah-Offei, K.; Newman, A.; Lowder, T.; Engel-Cox, J. : Integrating Renewable Energy into Mining Operations: Opportunities, Challenges, and Enabling Approaches. Appl. Energy 2021, 300, 117375. [Google Scholar] [CrossRef]

- Preene, M.; Younger, P. L. : Can You Take the Heat? – Geothermal Energy in Mining. Min. Technol. 2014, 123, 107–118. [Google Scholar] [CrossRef]

- Wang, K.; Yuan, B.; Ji, G.; Wu, X. A. : Comprehensive Review of Geothermal Energy Extraction and Utilization in Oilfields. J. Pet. Sci. Eng. 2018, 168, 465–477. [Google Scholar] [CrossRef]

- Abid, K.; Sharma, A.; Ahmed, S.; Srivastava, S.; Toledo Velazco, A.; Teodoriu, C. : A Review on Geothermal Energy and HPHT Packers for Geothermal Applications. Energies 2022, 15. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Sobczak, A.; Soboń, D. : The Potential and Development of the Geothermal Energy Market in Poland and the Baltic States—Selected Aspects. Energies 2022, 15. [Google Scholar] [CrossRef]

- Moska, R.; Labus, K.; Kasza, P.; Moska, A. : Geothermal Potential of Hot Dry Rock in South-East Baltic Basin Countries—A Review. Energies 2023, 16. [Google Scholar] [CrossRef]

- Malau, H.; Fajri, H.; Yuanjaya, P.; Saputra, B.; Maani, K. D. : Knowledge of Local Communities Affected by the Development of Geothermal Energy. IOP Conf. Ser. Earth Environ. Sci. 2020, 448. [Google Scholar] [CrossRef]

- Soltani, M.; Moradi Kashkooli, F.; Souri, M.; Rafiei, B.; Jabarifar, M.; Gharali, K.; Nathwani, J. S. : Environmental, Economic, and Social Impacts of Geothermal Energy Systems. Renew. Sustain. Energy Rev. 2021, 140, 110750. [Google Scholar] [CrossRef]

- Backer, S. N.; Bouaziz, I.; Kallayi, N.; Thomas, R. T.; Preethikumar, G.; Takriff, M. S.; Laoui, T.; Atieh, M. A. : Review Brine Solution: Current Status, Future Management and Technology Development. Sustainability 2022, 14. [Google Scholar] [CrossRef]

- Ibarra-Gutiérrez, S.; Bouchard, J.; Laflamme, M.; Fytas, K. : Perspectives of Lithium Mining in Quebec, Potential and Advantages of Integration into a Local Battery Production Chain for Electric Vehicles. Mater. Proc. 2021, 5. [Google Scholar] [CrossRef]

- Do Thi, H. T.; Pasztor, T.; Fozer, D.; Manenti, F.; Toth, A. J. : Comparison of Desalination Technologies Using Renewable Energy Sources with Life Cycle, PESTLE, and Multi-Criteria Decision Analyses. Water 2021, 13. [Google Scholar] [CrossRef]

- Kavanagh, L.; Keohane, J.; Garcia Cabellos, G.; Lloyd, A.; Cleary, J. : Global Lithium Sources—Industrial Use and Future in the Electric Vehicle Industry: A Review. Resources 2018, 7. [Google Scholar] [CrossRef]

- Kelly, J. C.; Wang, M.; Dai, Q.; Winjobi, O. : Energy, Greenhouse Gas, and Water Life Cycle Analysis of Lithium Carbonate and Lithium Hydroxide Monohydrate from Brine and Ore Resources and Their Use in Lithium Ion Battery Cathodes and Lithium Ion Batteries. Resour. Conserv. Recycl. 2021, 174, 105762. [Google Scholar] [CrossRef]

- Hartai, E.; Németh, N.; Földessy, J. : CHPM2030 Team. Chpm2030 Deliverable D1.1: Egs-Relevant Review Of Metallogenesis. 2016. [CrossRef]

- Simmons, S. F.; Kirby, S.; Verplanck, P.; Kelley, K. : Stanford, California, 2018.Utah. In 43rd Workshop on Geothermal Reservoir Engineering; Stanford University: Stanford, California, 2018. [Google Scholar]

- Alekseeva, L. P.; Alekseev, S. V. : Industrial Groundwater of the Olenek Artesian Basin: Geochemistry and Development Prospects. Water Resour. 2018, 45, 79–88. [Google Scholar] [CrossRef]

- Li, R.; Liu, C.; Jiao, P.; Wang, J. : MNR Key Laboratory of Metallogeny and Mineral Assessment, Institute of Mineral Resources, Chinese Academy of Geological Sciences, Beijing 100037, China;,School of Earth and Space Sciences, Peking University, Beijing 100871, China. The Tempo-Spatial Characteristics and Forming Mechanism of Lithium-Rich Brines in China. China Geol. 2018, 1, 72–83. [Google Scholar] [CrossRef]

- Beamish, D.; Busby, J. : The Cornubian Geothermal Province: Heat Production and Flow in SW England: Estimates from Boreholes and Airborne Gamma-Ray Measurements. Geotherm. Energy 2016, 4. [Google Scholar] [CrossRef]

- Vulcan Energy, https://v-er.eu/wp-content/uploads/2023/03/Vulcan-Energy-DFS-presentation-2023-FINAL. 2023.

- Farndale, H.; Law, R. : The Effects of Soft Stimulation on Reservoir Growth and Injectivity at the United Downs Geothermal Project, Cornwall. In Proceedings; Stanford, California, 2023; Vol. 13p. SGP-TR-224.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).