Submitted:

21 August 2023

Posted:

22 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Plant materials and experimental design

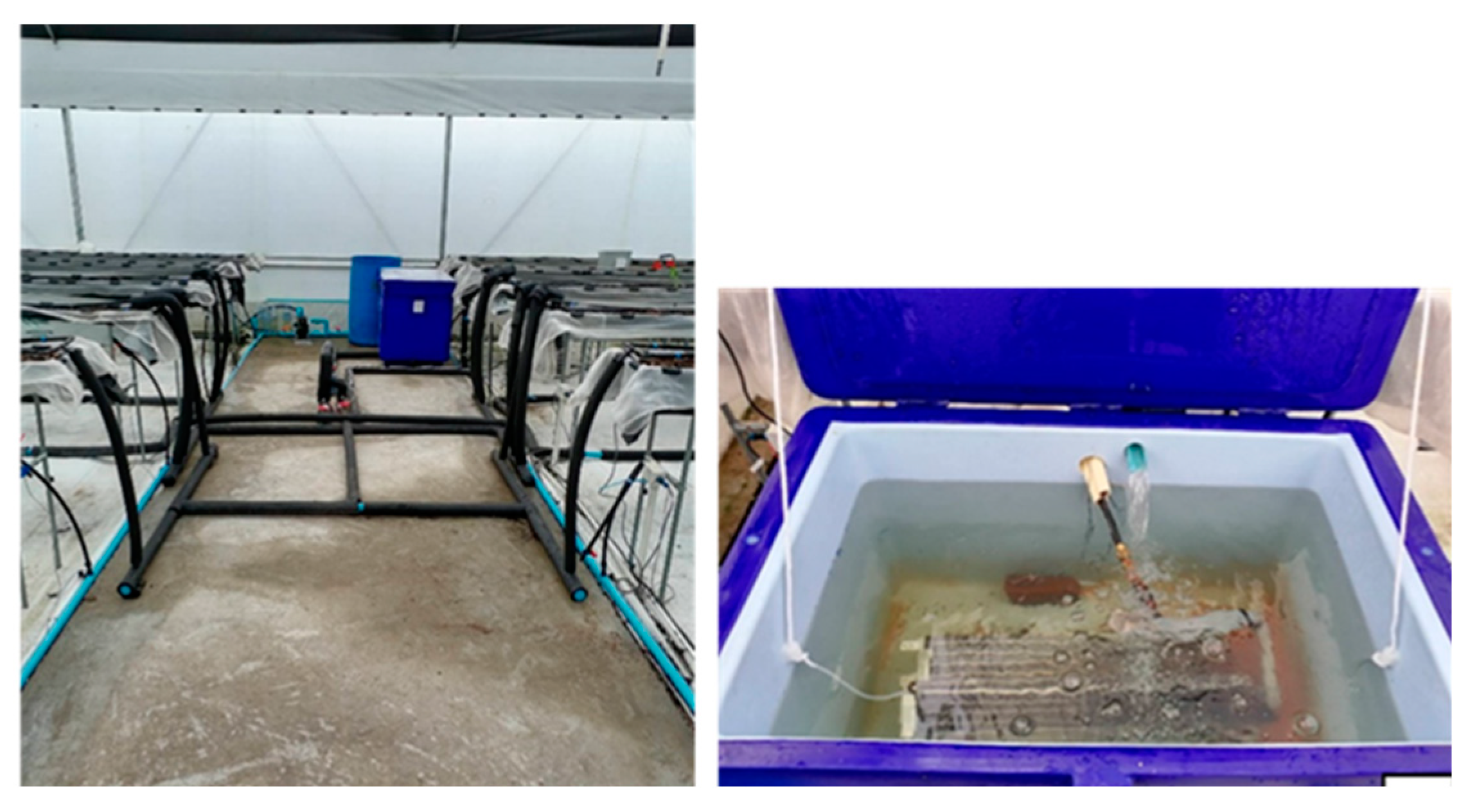

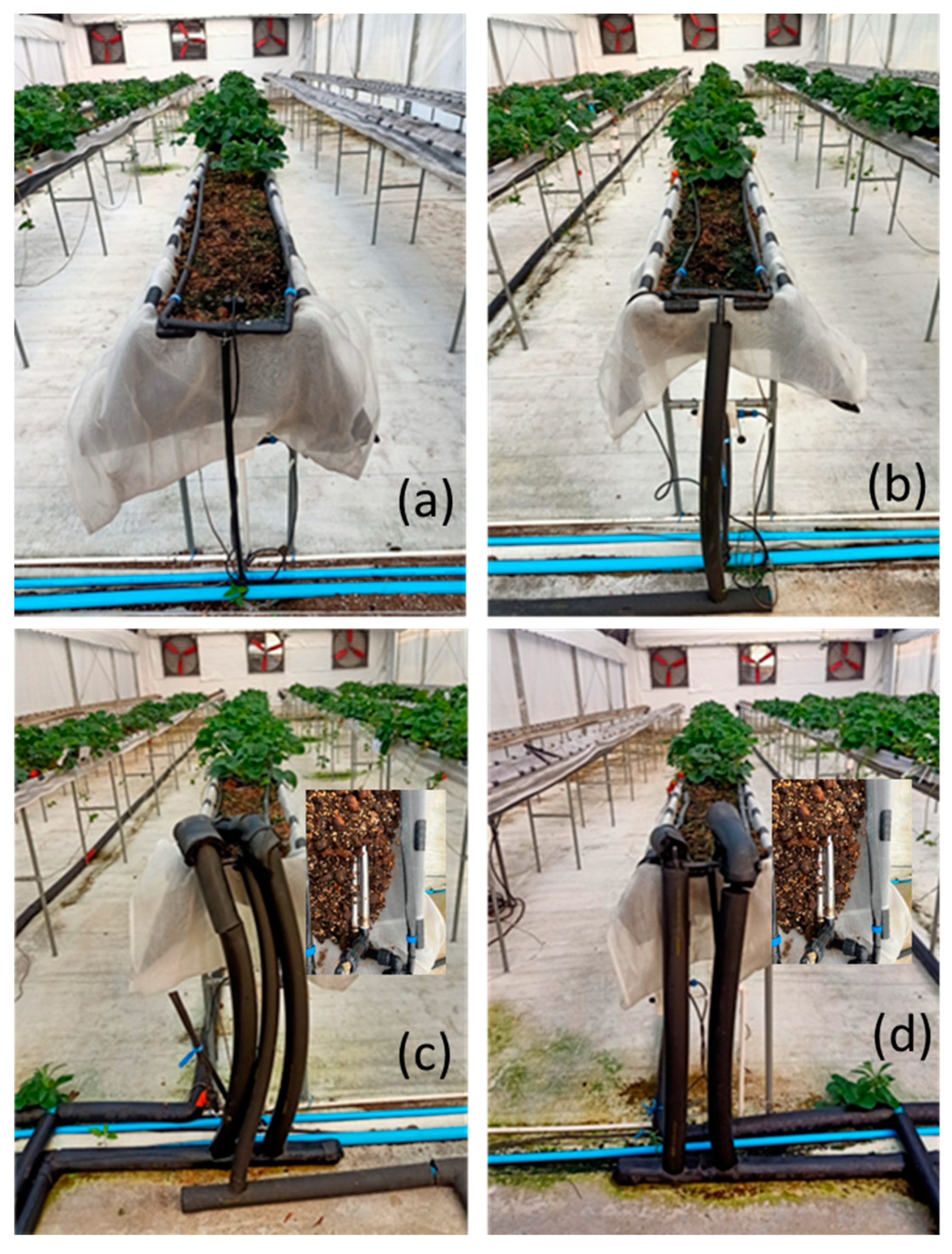

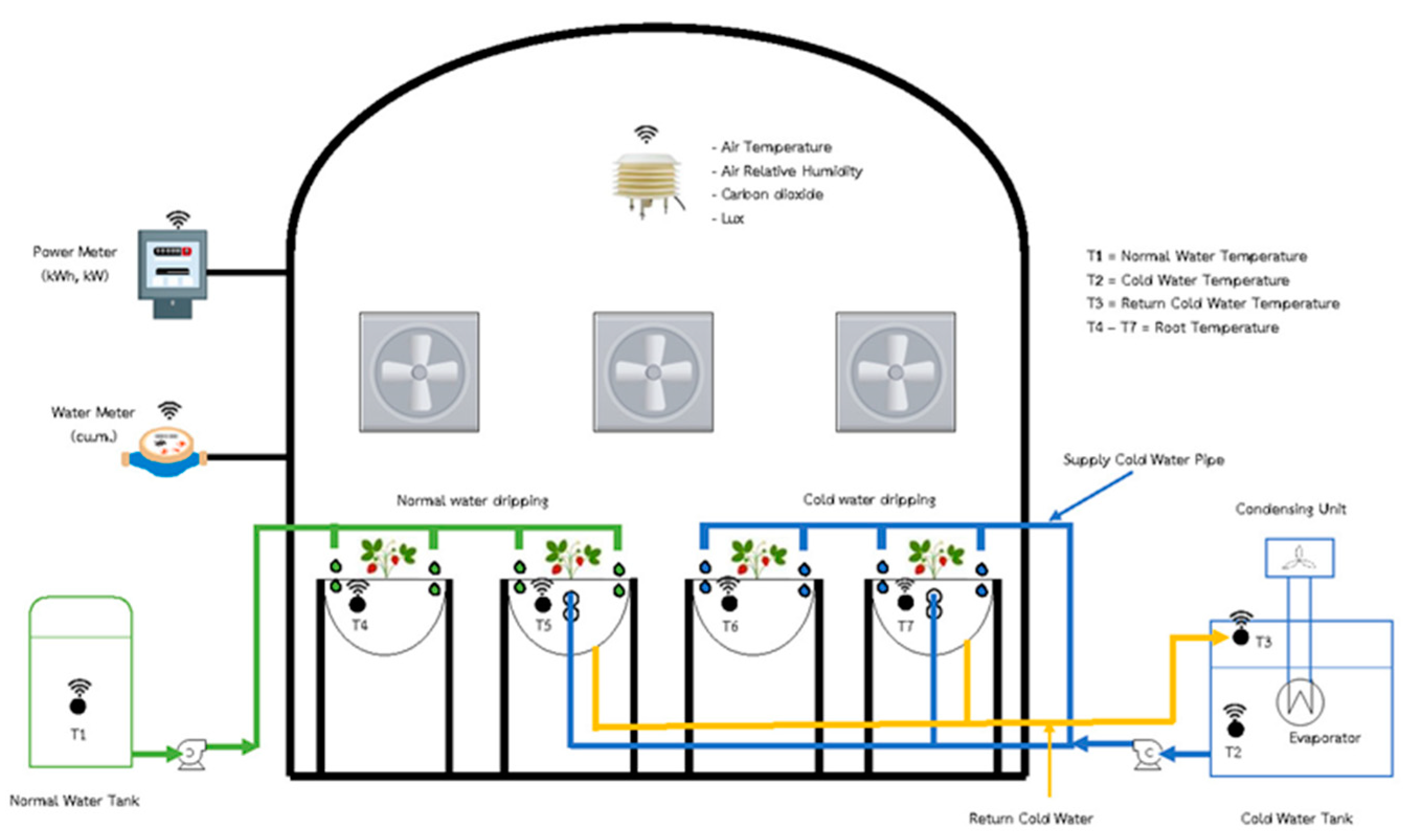

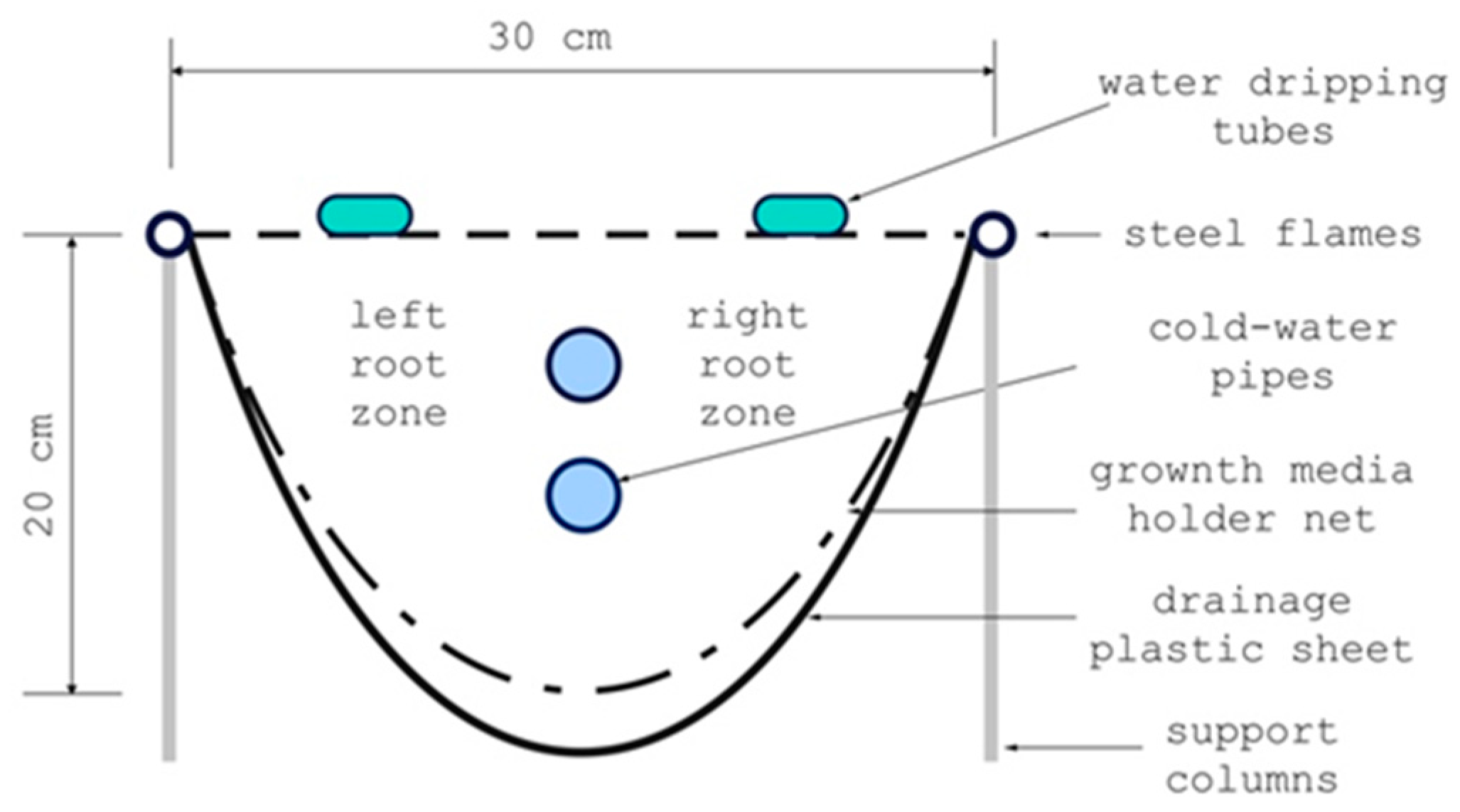

2.2. Greenhouse conditions, root-zone cooling system and strawberry planting

2.3. Greenhouse monitoring system

2.4. Physiology Measurement

2.5. Total soluble solid

2.6. Colorimetric evaluation (CIEL*a*b*)

2.7. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nelda, R. Hernández-Martínez, Caroline Blanchard, Daniel Wells, Melba R. Salazar-Gutiérrez, Current state and future perspectives of commercial strawberry production: A review, Scientia Horticulturae, 2023, 312, 111893.

- Strawberry production in 2021, Crops/Regions/World list/Production Quantity (pick lists)". UN.

- Food and Agriculture Organization, Corporate Statistical Database (FAOSTAT). 2023. (accessed on 2 August 2023).

- Konlanna. 2023. “Chiang Mai Agriculture Extension Office invites to visit the 20th strawberry and best products festival 2023 in Samoeng District”. Available online: https://konlanna.com/contents/read/2004 (accessed on 16 February 2023).

- Phiphatthanawong, N. Strawberry New Economic Crops; Kasetsart University: Bangkok, Thailand, 2007; p. 158. [Google Scholar]

- Phiphatthanawong, N. Strawberry production and the royal project foundation, Thailand. Journal of Developments in Sustainable Agriculture 2015, 10, 15–18. [Google Scholar]

- Wang, S.Y.; Camp, M.J. Temperatures after bloom affect plant growth and fruit quality of strawberry. Scientia Horticulturae 2000, 85, 183–199. [Google Scholar] [CrossRef]

- Palencia, P.; Martinez, F.; Medina, J. J.; Vázquez, E.; Flores, F.; López-Medina, J. Effects of climate change on strawberry production. Acta Hortic, 2009, 838, 51–54. [Google Scholar] [CrossRef]

- Khammayom, N.; Maruyama, N.; Chaichana, C. The effect of climatic parameters on strawberry production in a small walk-in greenhouse. AgriEngineering 2022, 4, 104–121. [Google Scholar] [CrossRef]

- Khoshnevisan, B.; Rafiee, S.; Mousazadeh, H. Environmental impact assessment of open field and greenhouse strawberry production. European journal of Agronomy 2013, 50, 29–37. [Google Scholar] [CrossRef]

- Bucklin, R. A.; Henley, R. W.; McConnell, D. B. Fan and pad greenhouse evaporative cooling systems. Circular Florida Cooperative Extension Service 1993.USA.

- Saha, T.; Jewel, M. K. H.; Mostakim, M. N.; Bhuiyan, N. H.; Ali, M. S.; Rahman, M. K.; Ghosh, H. K.; Hossain, M. K. Construction and development of an automated greenhouse system using Arduino Uno. International Journal of Information Engineering and Electronic Business 2017, 9, 1. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Hameed, I.A.; Thorp, K.R.; Balasundram, S.K.; Shafian, S.; Fatemieh, M.; Sultan, M.; Mahns, B.; Samiei, S. Greenhouse automation using wireless sensors and IoT instruments integrated with artificial intelligence. Next-generation greenhouses for food security 2021.

- Gutiérrez, E.; Gutiérrez, S.; Becerril, J.A.; Rodríguez, F. Low-cost prototype for monitoring and remote control in greenhouse for homes. In 2018 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC) 2018, pp 1-5.

- Hoque, M.J.; Ahmed, M.R.; Hannan, S. An automated greenhouse monitoring and controlling system using sensors and solar power. European Journal of Engineering and Technology Research 2020, 5, 510–515. [Google Scholar]

- Bhuvaneswari, T.; Yao, J.T.H. Automated greenhouse. In 2014 IEEE International Symposium on Robotics and Manufacturing Automation (ROMA) 2014 pp. 194-199.

- Sakamoto, M.; Uenishi, M.; Miyamoto, K.; Suzuki, T. Effect of root-zone temperature on the growth and fruit quality of hydroponically grown strawberry plants. Journal of Agricultural Science 2016, 8, 122–131. [Google Scholar]

- Greer, D.H.; Wünsche, J.N.; Norling, C.L.; Wiggins, H.N. Root-zone temperatures affect phenology of bud break, flower cluster development, shoot extension growth and gas exchange of ‘Braeburn’ (Malus domestica) apple trees. Tree Physiology 2006, 26, 105-111.

- Udagawa, Y.; Ito, T.; Gomi, K. Effects of root temperature on the absorption of water and mineral nutrients by strawberry plants ‘Reiko’ grown hydroponically. Journal of the Japanese Society for Horticultural Science 1991, 59, 711–717. [Google Scholar] [CrossRef]

- Mizuno, S.; Muramatsu, Y.; Tateishi, A.; Watanabe, K.; Shinmachi, F.; Koshioka, M.; Kubota, S. Effects of Root-zone Cooling with Short-day Treatment in Pot-grown Strawberry (Fragaria × ananassa Duch.) Nurseries on Flowering and Fruit Production. The Horticulture Journal 2022, 91, 1–7.

- Masaru, S.; Uenishi, M.; Miyamoto, K.; Suzuki, T. Effect of Root-Zone Temperature on the Growth and Fruit Quality of Hydroponically Grown Strawberry Plants. Journal of Agricultural Science 2016, 8, 122. [Google Scholar] [CrossRef]

- Deschamps, S.S.; Whitaker, V.M.; Agehara, S. White-striped plastic mulch reduces root-zone temperatures during establishment and increases early season yields of annual winter strawberry. Scientia horticulturae 2019, 243, 602–608. [Google Scholar] [CrossRef]

- Kumar, S.; Dey, P. Effects of different mulches and irrigation methods on root growth, nutrient uptake, water-use efficiency and yield of strawberry. Scientia Horticulturae 2011, 127, 318–324. [Google Scholar] [CrossRef]

- Moritani, S.; Nanjo, H.; Itou, A.; Imai, T. Root-zone cooling evaluation using heat pump for greenhouse strawberry production. HortTechnology 2018, 28, 570–577. [Google Scholar] [CrossRef]

- Thammasophon, T.; Pusadee, T.; Bundithya, W.; Naphrom, D. Effects of Vernalization on Off–Season Flowering and Gene Expression in Sub-Tropical Strawberry cv. Pharachatan 80. Horticulturae 2023, 9, 87. [Google Scholar] [CrossRef]

- Hidaka, K.; Dan, K.; Imamura, H.; Takayama, T. Crown-cooling treatment induces earlier flower bud differentiation of strawberry under high air temperatures. Environ. Control. Biol. 2017, 55, 21–27. [Google Scholar] [CrossRef]

- Cui, M.; Pham, M. D.; Hwang, H.; Chun, C. Flower development and fruit malformation in strawberries after short-term exposure to high or low temperature. Scientia Horticulturae 2021, 288, 110308. [Google Scholar] [CrossRef]

- Ariza, M.T.; Soria, C.; Medina-Mínguez, J.J.; Martínez-Ferri, E. Incidence of misshapen fruits in strawberry plants grown under tunnels is affected by cultivar, planting date, pollination, and low tempera-tures. Hortscience 2012, 47, 1569–1573. [Google Scholar] [CrossRef]

- Salamé-Donoso, T. P.; Santos, B. M.; Chandler, C. K.; Sargent, S. A. Effect of high tunnels on the growth, yields, and soluble solids of strawberry cultivars in Florida. International Journal of Fruit Science 2010, 10, 249–263. [Google Scholar] [CrossRef]

- Cruz, M.; Mafra, S.; Teixeira, E.; Figueiredo, F. Smart strawberry farming using edge computing and IoT. Sensors 2022, 22, 5866. [Google Scholar] [CrossRef]

- Elijah,O. ; Bakhit,A.A.; Rahman, T.A., Tien Han Chua, T.H., Ausordin, S.F., Rifhan Narrissa Razali, R.N., Eds.; Production of strawberry using internet of things: a review. Indonesian Journal of Electrical Engineering and Computer Science 2019, 15(3), pp. 1621-1628. [Google Scholar]

- Rivero, R.; Sønsteby, A.; Solhaug, K.A.; Heide, O.M; Remberg, S.F. Effects of temperature and photoperiod on photosynthesis in everbearing strawberry. Acta Hortic 2021, 1309, 379–386. [Google Scholar] [CrossRef]

- Gonzalez-Fuentes, J.A.; Shackel, K.; Lieth, J.H.; Albornoz, F.; Benavides-Mendoza, A.; Ev-ans, R.Y. Diurnal root zone temperature variations affect strawberry water relations, growth, and fruit quality. Scientia Horticulturae 2016, 203, 169–177. [Google Scholar] [CrossRef]

- Lee, G.B.; Lee, J.E.; Choe, Y.U.; Park, Y.H.; Choi, Y.W.; Kang, N.J.; Kang, J.S. Effects of Groundwater Cooling Treatment on Growth, Yield, and Quality of Strawberries under High Temperature Conditions. Journal of Environmental Science International 2018, 27, 631–639. [Google Scholar] [CrossRef]

- Jo, W.J.; Shin, J.H. Effect of root-zone heating using positive temperature coefficient film on growth and quality of strawberry (Fragaria x ananassa) in greenhouses. Horticulture, Environment, and Biotechnology 2022, 63, 89-100.

- Ruan, J.; Lee, Y.H.; Yeoung, Y.R.; Larson, K. Influence of short-day treatment on autumn fruit production of June-bearing strawberry cultivars. Horticulture, Environment and Biotechnology 2011, 52, 259-264.

- 37. Durner, Edward F. "Photoperiod and temperature conditioning of ‘Sweet Charlie’ strawberry (Fragaria× ananassa Duch.) plugs enhances off-season production. Scientia horticulturae 2016, 201, 184-189.

- MacKenzie, S.J.; Chandler, C.K. , The late season decline in strawberry fruit soluble solid content observed in Florida is caused by rising temperatures. Acta Hortic 2008, 842, 843–846. [Google Scholar] [CrossRef]

- Nakro, A.; Bamouh, A.; Bouslama, H.; San Bautista, A.; Ghaouti, L. The effect of potassium–nitrogen balance on the yield and quality of strawberries grown under soilless conditions. Horticulturae 2023, 9, 304. [Google Scholar] [CrossRef]

- He, F.; Thiele, B.; Watt, M.; Kraska, T.; Ulbrich, A.; Kuhn, A. J. , Effects of root cooling on plant growth and fruit quality of cocktail tomato during two consecutive seasons. Journal of Food Quality 2019, 3598172, 1–15. [Google Scholar] [CrossRef]

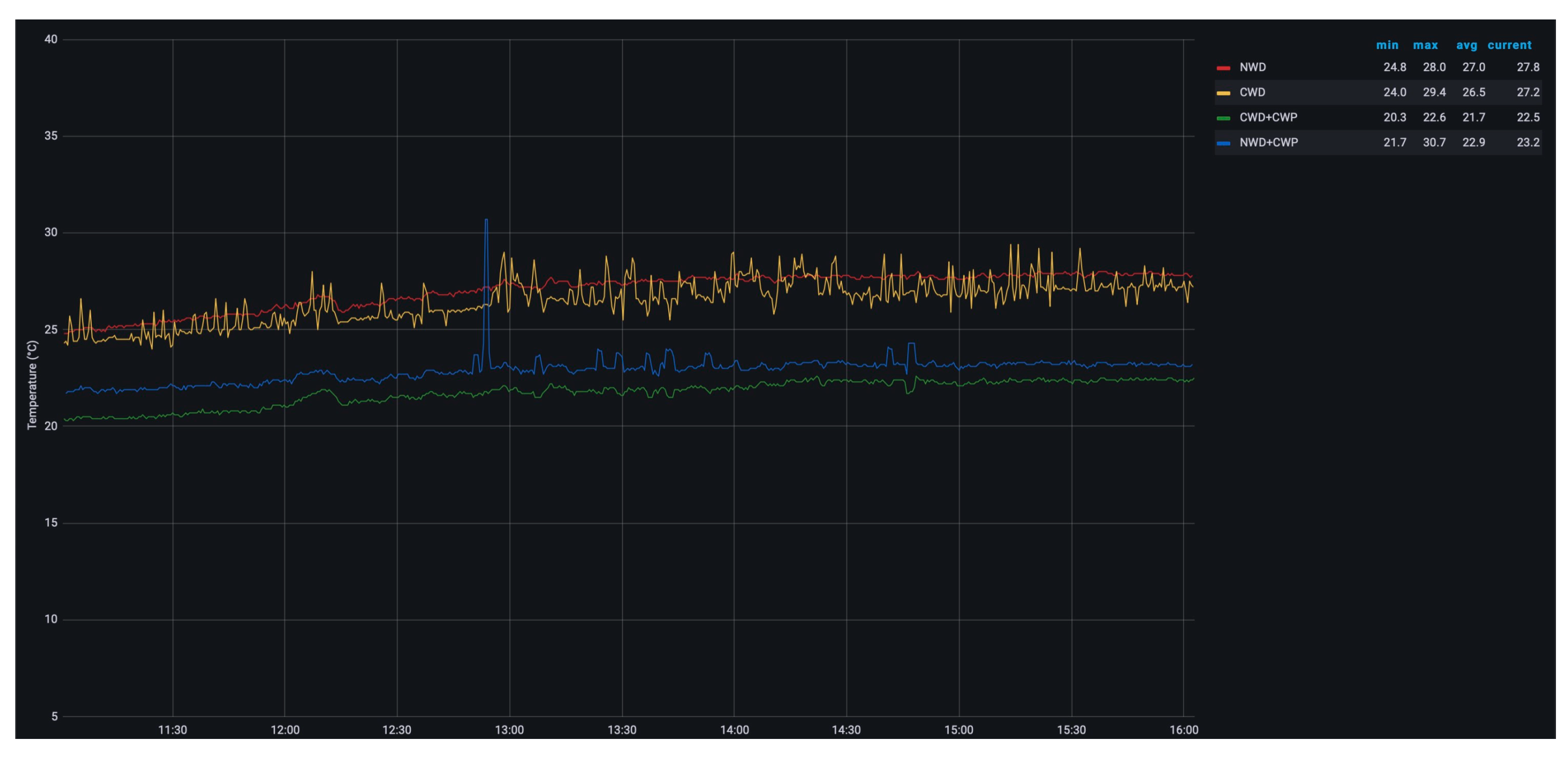

| No. | Sensors | Connection/Signal | Number |

| 1 | Light intensity, air temperature/humidity, and Carbon Dioxide content | RS485 | 2 sets |

| 2 | Water meter | RS485 | 1 piece |

| 3 | Soil temperature probe | Type-k thermocouple /WiFi | 16 sets |

| 4 | Cold-water temperature probe | Type-k thermocouple /WiFi | 3 sets |

| 5 | 1-phase power meter | RS485 | 1 set |

| 6 | 3-phase power meter | RS485 | 1 set |

| 7 | Air-condition control with thermostat | Thermocouple type-k | 1 set |

| 8 | Water dripping with scheduling timer and water-pumping control with 220V solenoid | Thermocouple type-k | 1 set |

| 9 | Internet router gateway and internet sim | 3G/4G/WiFi | 2 sets |

| 10 | Sensor interface board using ESP8266 with RS485, I2C, SPI, and serial interface | - | 1 set |

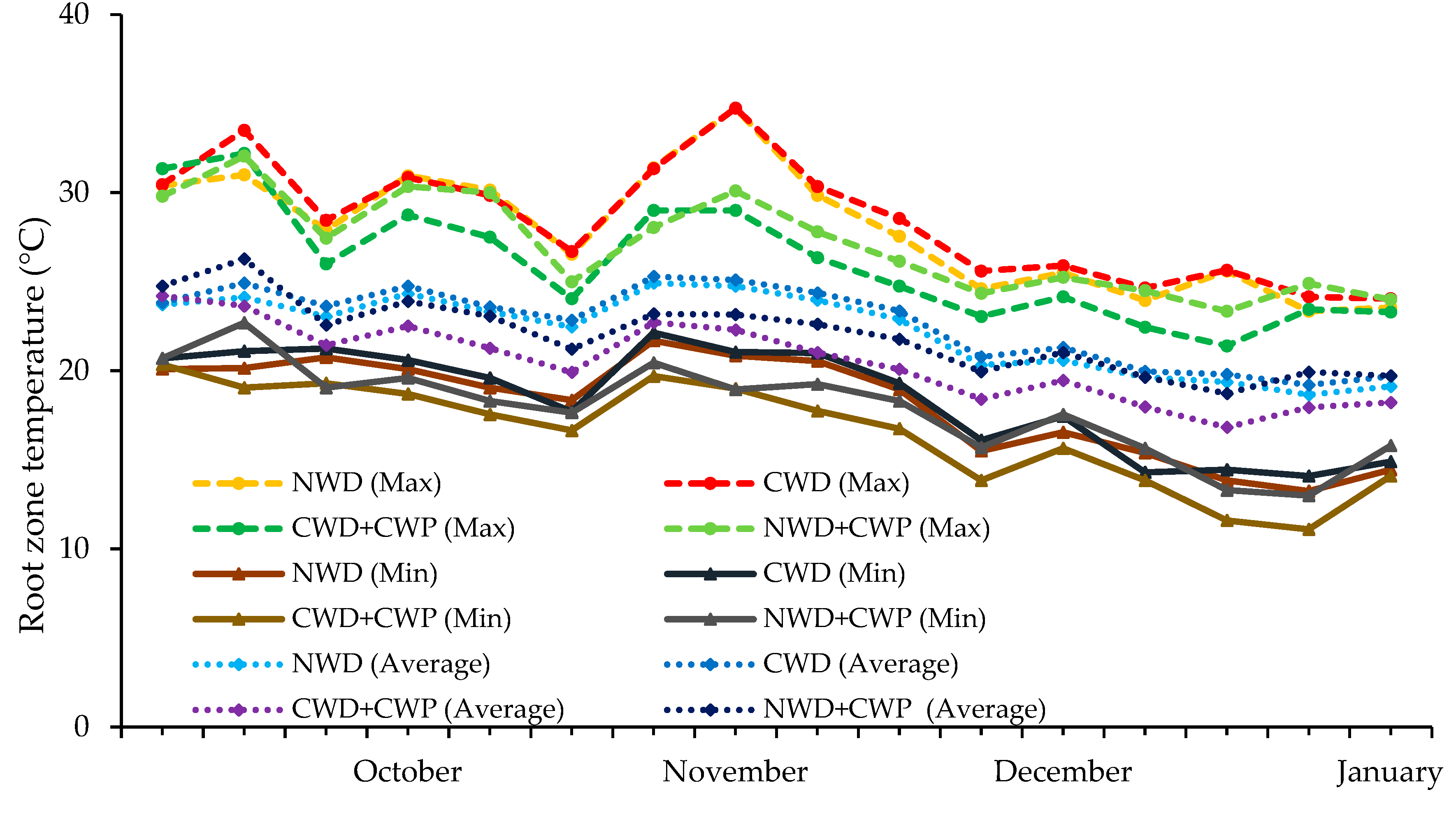

| Months | T (Max) (°C) | T (Min) (°C) | T (Aeverage) (°C) | RH (Max)(%) | RH (Min)(%) | RH (Aeverage) (%) |

|---|---|---|---|---|---|---|

| October | 31.4 | 17.6 | 23.2 | 90 | 62 | 83.9 |

| November | 34 | 18.1 | 21.6 | 91 | 42 | 83.8 |

| December | 29.3 | 14.9 | 21.1 | 89 | 53 | 84.2 |

| January | 23.7 | 13.1 | 18.6 | 90 | 68 | 83.5 |

| Average | 29.6 | 15.9 | 21.1 | 90 | 56 | 83.9 |

| Months | Co2 (Max) (ppm) | Co2 (Min) (ppm) | Co2 (Aeverage) (ppm) | Light intensity (Max) (Lux) | Light intensity (Min) (Lux) | Light intensity (Average) (Lux) |

|---|---|---|---|---|---|---|

| October | 659 | 408 | 509 | 51,498 | 538 | 12,040 |

| November | 745 | 407 | 519 | 53,087 | 382 | 15,287 |

| December | 740 | 407 | 489 | 46,769 | 48 | 12,565 |

| January | 549 | 409 | 461 | 24,338 | 65 | 11,899 |

| Average | 673 | 408 | 495 | 43,923 | 258 | 12,948 |

| Months | T (Max) (°C) | T (Min) (°C) | T (Aeverage) (°C) | RH (Max) (%) | RH (Min) (%) | RH (Aeverage) (%) |

|---|---|---|---|---|---|---|

| October | 34.6 | 16.3 | 25.6 | 98 | 40 | 84.3 |

| November | 35.2 | 17.1 | 24.9 | 98 | 41 | 82.1 |

| December | 33.5 | 12.9 | 23.0 | 99 | 43 | 82 |

| January | 31.9 | 10.7 | 20.8 | 98 | 35 | 75.8 |

| Average | 33.8 | 14.3 | 23.6 | 98 | 34 | 81 |

| Treatments | Canopy width (cm) |

Leaves width (cm) |

Crown diameter (mm) |

No. of flowers | |

|---|---|---|---|---|---|

| P88 | NWD CWD CWD+CWP NWD+CWP |

28.55 d 29.71 d 29.80 d 28.81 d |

7.31 c 6.71 c 7.12 c 7.17 c |

15.26 cde 18.24 bcd 19.65 ab 16.35 bcde |

8.62 ab 11.59 ab 10.11 ab 5.46 bc |

| P80 | NWD CWD CWD+CWP NWD+CWP |

38.86 abc 40.40 a 38.25 abc 34.19 bcd |

7.68 bc 9.23 ab 9.32 a 7.63 bc |

18.61 bcd 19.22 abc 18.92 bcd 18.51 bcd |

0.00 c 0.00 c 6.18 bc 9.18 ab |

| Akihime | NWD CWD CWD+CWP NWD+CWP |

38.15 abc 33.20 cd 43.03 a 39.51 ab |

6.81 c 6.52 c 8.00 abc 7.96 abc |

14.57 de 13.86 e 23.51 a 18.55 bcd |

11.20 ab 10.28 ab 15.37 a 15.30 a |

| A | ** | ** | ns | ** | |

| B | ns | Ns | ** | * | |

| A x B | * | * | * | ** | |

| Cultivars | Plant Height (cm) |

Leaves length (cm) |

SPAD | No. of inflorescences |

|---|---|---|---|---|

| P88 P80 Akihime |

21.08 b 22.99 b 24.94 a |

6.92 c 8.44 b 9.67 a |

41.46 a 33.51 b 40.03 a |

1.17 a 0.31 b 1.43 a |

| F-test | ** | ** | ** | ** |

| Treatments | Plant Height (cm) | leaves length (cm) | Chlorophyll content (SPAD unit) | No. of inflorescences |

|---|---|---|---|---|

| NWD CWD CWD+CWP NWD+CWP |

22.35 22.56 23.70 23.41 |

8.21 ab 8.70 a 8.67 a 7.79 b |

39.37 39.09 37.70 37.16 |

0.68 b 0.85 ab 1.25 a 1.10 ab |

| F-test | ns | * | ns | ** |

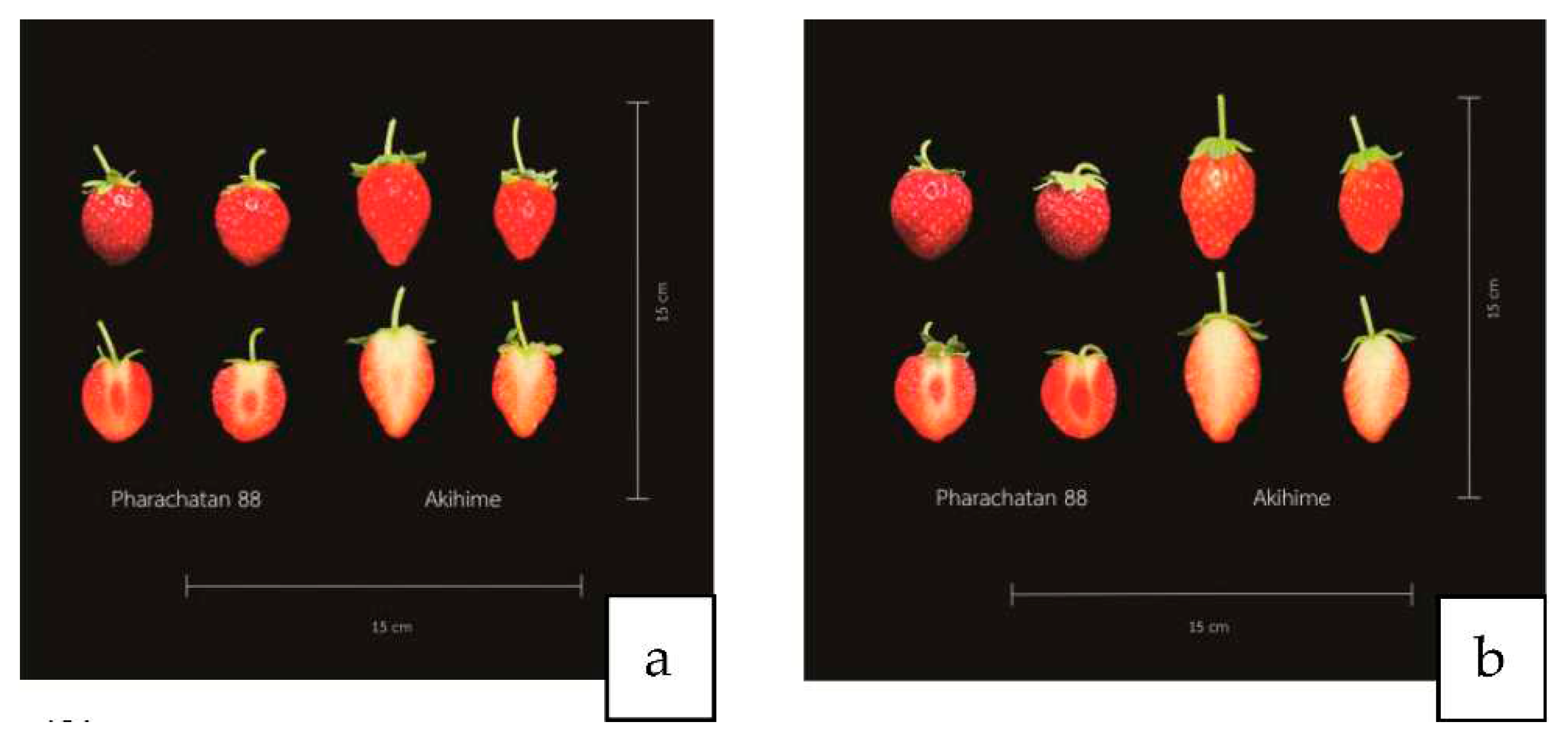

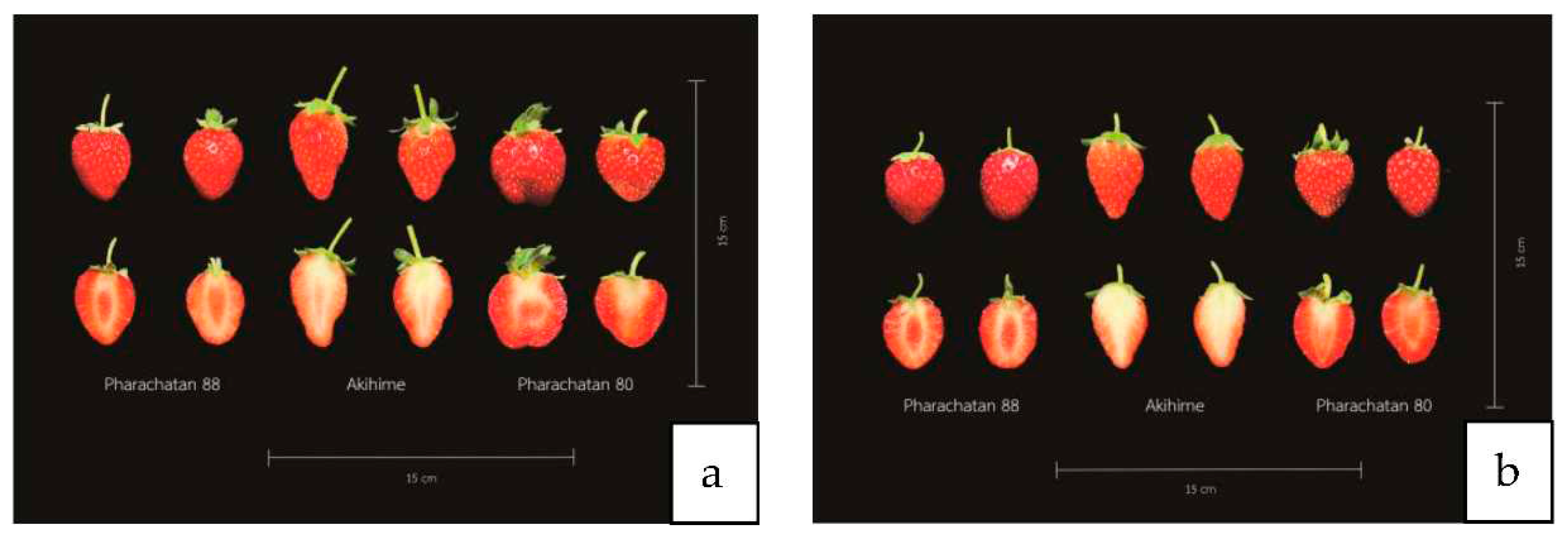

| Treatments | Fruit weight (gram) | Fruit width (mm) | Fruit length (mm) | Fruit firmness (kg) | TSS(%Brix) | Yield (gram/plant) | |

| P88 | NWD CWD CWD+CWP NWD+CWP |

7.60 b 11.66 a 7.24 b 9.33 ab |

22.84 ab 26.27 a 22.95 ab 24.34 ab |

27.44 d 32.38 bcd 27.59 d 31.01 cd |

0.27 de 0.30 cd 0.37 abc 0.24 def |

9.08 c 10.28 abc 9.97 abc 10.28 abc |

65.5 131.1 73.2 50.9 |

| P80 | NWD CWD CWD+CWP NWD+CWP |

- - 9.63 ab 12.04 a |

- - 24.46 ab 25.32 ab |

- - 30.06 cd 27.43 d |

- - 0.41 ab 0.41 a |

- - 10.85 ab 10.74 ab |

- - 59.5 110.5 |

| Akihime | NWD CWD CWD+CWP NWD+CWP |

7.50 b 9.32 ab 10.04 ab 9.51 ab |

22.11 b 23.71 ab 23.56 ab 22.77 b |

34.01 bc 31.89 bcd 40.41 a 36.39 ab |

0.15 f 0.19 ef 0.19 ef 0.33 bcd |

10.62 abc 9.39 bc 11.48 a 10.37 abc |

84.0 95.8 154.3 145.5 |

| A | * | * | * | * | * | - | |

| B | * | * | * | * | * | - | |

| A x B | * | * | * | * | * | - | |

| Treatments | L | a | B | |

| P88 | NWD CWD CWD+CWP NWD+CWP |

34.23 d 35.89 cd 36.38 bcd 38.53 abc |

31.60 b 25.30 d 26.28 d 26.17 d |

15.84 bcd 15.12 cd 16.71 bc 14.22 cd |

| P80 | NWD CWD CWD+CWP NWD+CWP |

0.00 e 0.00 e 34.26 d 36.01 bcd |

0.00 e 0.00 e 26.19 d 26.49 d |

0.00 e 0.00 e 11.63 d 13.27 cd |

| Akihime | NWD CWD CWD+CWP NWD+CWP |

38.65 abc 37.11 bcd 38.88 ab 40.34 a |

35.13 a 27.20 cd 31.86 ab 30.54 bc |

21.32 a 14.66 cd 16.20 bc 19.73 ab |

| A | ** | ** | ** | |

| B | ** | ** | ** | |

| A x B | ** | ** | ** | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).