1. Introduction

In a longer period from now, coal resources must keep accounting for majority of energy consumption in China and continue to be widely used in all over the world[

1].Underground electric trackless rubber-tired vehicle(ETRV) is an efficient and green auxiliary transportation vehicle in the underground coal mine production, which takes task of transporting persons or materials between surface and underground and can transfer mining machinery and materials from one working area to another new area obviously faster than other existing transportation tools.The existing braking system of mine ETRV generally uses disk braking structure,which is consists of braking pedal,hydraulic pressure pines,piston,braking caliper and braking pads[

2],where braking torque is generated by friction force between braking pads and disk,which further derived from pressure of highly compressed hydraulic oil. Although traditional hydraulic disc brakes are applied currently, there are some obvious disadvantages such as more complex structure,slower response under low environmental temperature,larger components account, potential pollution risk of oil leak ,lower automation level[

3].And this traditional one is impossible to be integrated into intelligent chassis control system of automated mine vehicle. Therefore,it’s significantly valuable to consider adopting a novel brake-by-wire system with pure mechanical transmission structure controlled by high-performance micro controller unit(MCU).Aiming to ensure safety of drivers,materials,vehicle-self and concerning traffic participants and achieve reliable braking performance of autonomous driving for intelligent mine,it is very necessary to research accurate and reliable EMB actuator and its control method for UTRVs in coal mine.

However,related scholars also still stay on stage of theoretical research or experimental prototype test,meanwhile there is no any mature braking system product sold on market so far.Especially,there is no practical engineering application of EMB device in both ETRV and other type of transportation vehicles in coal mine,which restrict development of underground unmanned transportation system.

Fortunately,there are some research achievements of EMB system in passenger cars published in journals and other documents in most recent years.Jin and Feng et al.[

4] built a EMB bench and test both the open-loop control method and single force close-loop control method on it.Dealing with improving tracking control ability of the braking force, He Cheng et al.[

5]designed the braking torque closed-loop control based on switch-reluctance-motor,in which estimated value of braking torque only lags behind the actually measured value of torque sensor by just one electrical period and it can achieve fast close-loop regulator.Xiao and Gong et al.[

6] have used a linear motor to design a novel brake-by-wire actuator,which can omit motion conversion mechanism and provides a new design idea for BBW actuator. For solving nonlinear and disturbance problems of EMB system,Soohyeon Kwon et al.[

7] consider EMB to be affected by both linear part and nonlinear one, and further design a force status estimator based on Kalman filter.Zhao et al.[

8] proposed a slide-mode reaching law to deal with load torque variation.Focusing on friction and gap distance detection,Chihoon Jo et al.[

9] established a friction model which involves friction effect of the motor and mechanical motion parts, and then utilized motor torque gradient change to achieve initial gap distance control.In field of mine auxiliary transportation,Jin et al.[

10] combine PI and Linear quadratic regulator(LQR) to control positive pressure of EMB system in coal mine hoist,and achieve a approximately linear relationship between motor and positive pressure.

Currently,Electro-hydraulic-braking(EHB)system (one structure type of BBW systems) has become more and more popular and mature in automotive field, while EMB still stay on theoretical and experimental stage without reaching safety regulations.In view of this, some research achievements of mature EHB applications also can guide our research ideas for our reference.For dealing with the uncertainties and disturbances of EHB system,Shi and Huang et al. [

11]proposed a dual-loop braking pressure control method with speed and current tracking controllers.In [

12],an adaptive sliding mode controller combining desired-state and integral-antiwindup compensation facilitate the improvement of the system steady tracking performance.To consider the significantly nonlinear behaviors of Integrated-braking-control(IBC) system which is an electro-mechanical-hydraulic coupling system and critical impact of vehicle dynamics on cylinder pressure estimation precision,[

13] adopted EKF method to estimate cylinder pressure error based on hybrid of hydraulic model and single-wheel one whose error is always less than 2MPa in typical road.Also for dealing with actual friction problem,In [

14],linearizing the nonlinear Tustin friction model improve pressure-tracking accuracy,a sliding mode controller is utilized to suppress friction disturbances, and subsequently Lyapunov method verified its stability.

The existing literature also indicates that response speed of EHB system may be slower than EMB because of pressure transfer delay in hydraulic pipelines.Especially when tackling with nonlinear problems of electro-mechanical-hydraulic couple and hydraulic pressure hysteresis characters as well as hydraulic parameters uncertainty disturbance caused by hydraulic leak and working temperature variation,braking force tracking performance seems to be obviously weaker than EMB.In fact, current braking system of UTRV is traditional hydraulic system manipulated by driver without close-loop and decoupled control performance,whose pressure response time is significantly longer than EMB.Therefore,it is benefit for improvement of braking safety and active control performance of underground auxiliary transportation system to research and develop an practical EMB system of UTRV with force close-loop feedback to track clamping force.

In generally,The main contributions of this paper are listed as follows:

We develop a practical clamping force controller with cascade three-close-loop control architecture,which can also achieve adaptive tracking of clamping force & automation adjustment of gap distance.The clamping force response rate is obviously faster than traditional hydraulic braking method.

we propose a contact point detection method to achieve control mode switch between gap distance control and clamping force control.

Simulation and experiment verified above two contents.

The rest parts of this paper are described as follows. The next section introduces modeling and analysis of EMB. Section III presents the overall control system, involving of cascaded three-closed-loop control method with contact point detection technology utilized for force/position control mode switch.The results and analysis of simulations based on software model and experiments of prototype in real mine vehicle are shown in Section IV. Finally,Section V describes some conclusion.

2. Mathematical Modeling of EMB

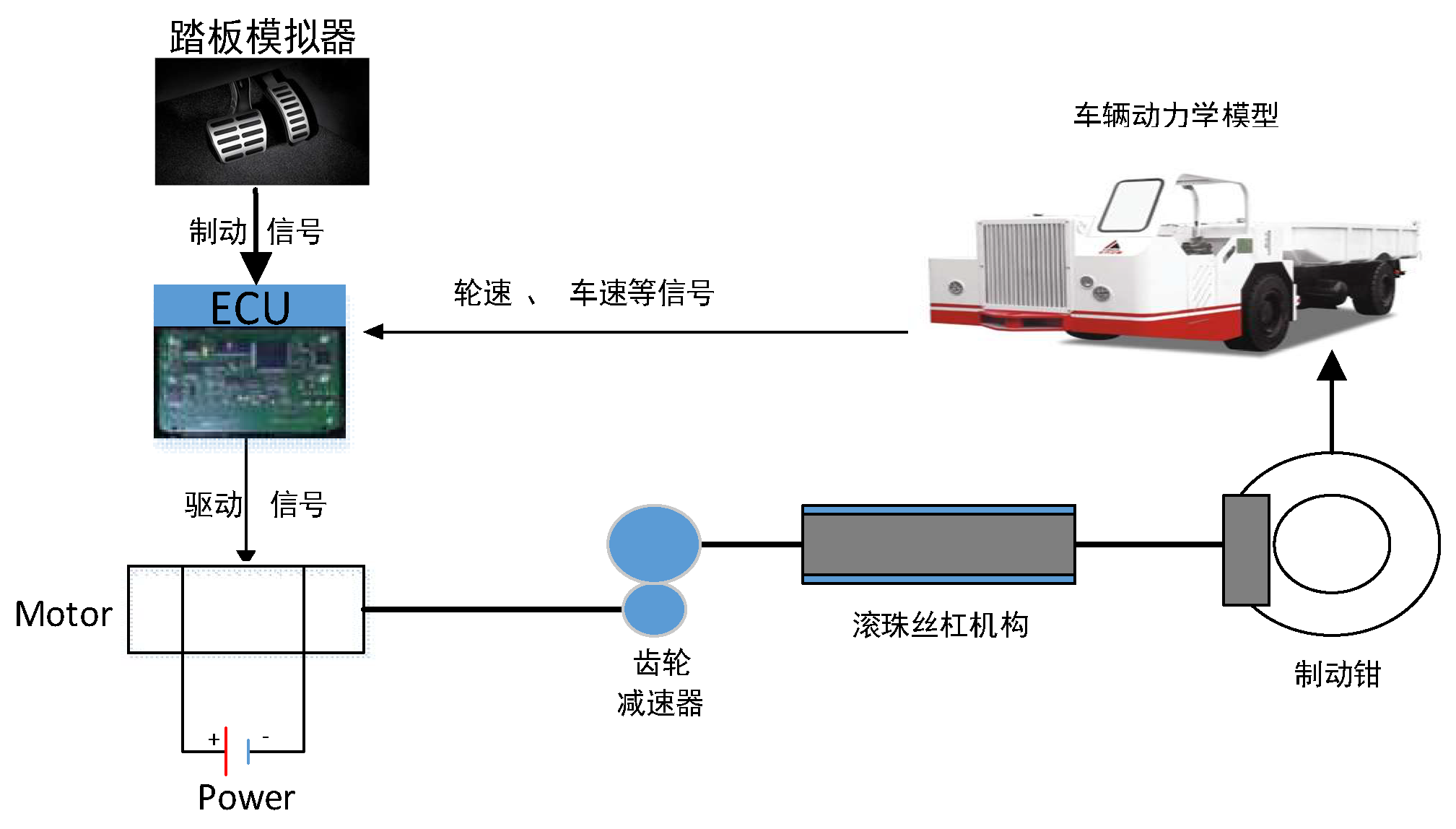

The Electro-mechanical brake generates initial force by a surface-mounted permanent magnet synchronous motor (SPMSM) whose advantage involves high power density and small size.The reminder parts in this EMB also include a planetary reduction gear, a ball screw ,a pair of frictional pads and a braking disk.It is seen in

Figure 1 that driver pushes the pedal to provide a braking intensity signal for the ECU of this EMB.The ECU calculates braking force command according to target braking intensity. EMB controller will send Pulse Width Modulation(PWM) signal corresponding to reference braking force into three-phase power inverter.And than the inverter provide 3-phase sine wave input for EMB motor to rotate. Further,the reduction gear and ball screw achieve function of motion conversion and force enlarging where the head part in screw directly compress frictional pads onto disk to make vehicle to decelerate and stop.In this work, the electro and mechanical subsystem model is discussed,respectively.

2.1. Modeling of motor

2.1.1. PMSM model

Considering higher requirement torwards speed and precision of braking force response,the surface permanent magnetic synchronous motor(SPMSM) is selected as torque motor in this EMB actuator [

15]. We transformed current or voltage vectors in three-phase coordinates to stator orthogonal coordinates in two-phase

coordinates. And than, these vectors under

axis are transformed into the synchronous rotation d-q coordination.Coordinate transformation of above two steps is expressed as follows [

16,

17]respectively,namely “Clarke transportation” and “Park transportation”.

where

is the electrical rotor angle. Therefore,d-q voltage formula of PMSM are rewritten as follows:

where

,

is the d- and q-axis voltage;

,

is stator current in d-q axis;

,

are inductance in d-q coordinates;

,

is flux linkage in d-q coordinates and it can be expressed by

where

presents back electromotive force constant and

presents pole pairs number; Relationship between electrical angle speed

and mechanical angular speed

can be expressed as

.

;

is flux linkage of rotor magnetic field;R presents stator resistance; The SPMSM torque equation can be show as equation (5)

According to SPMSM principle,if

is fixed at zero,the torque will go up to maximum value[

16,

17].Hence, Equation (5) can further become a simple form similar to DC motor torque formula in which current can have a linear expression with torque:

where a torque constant

further replace

.Therefore,the Eq. (6) can be simply again expressed as follows:

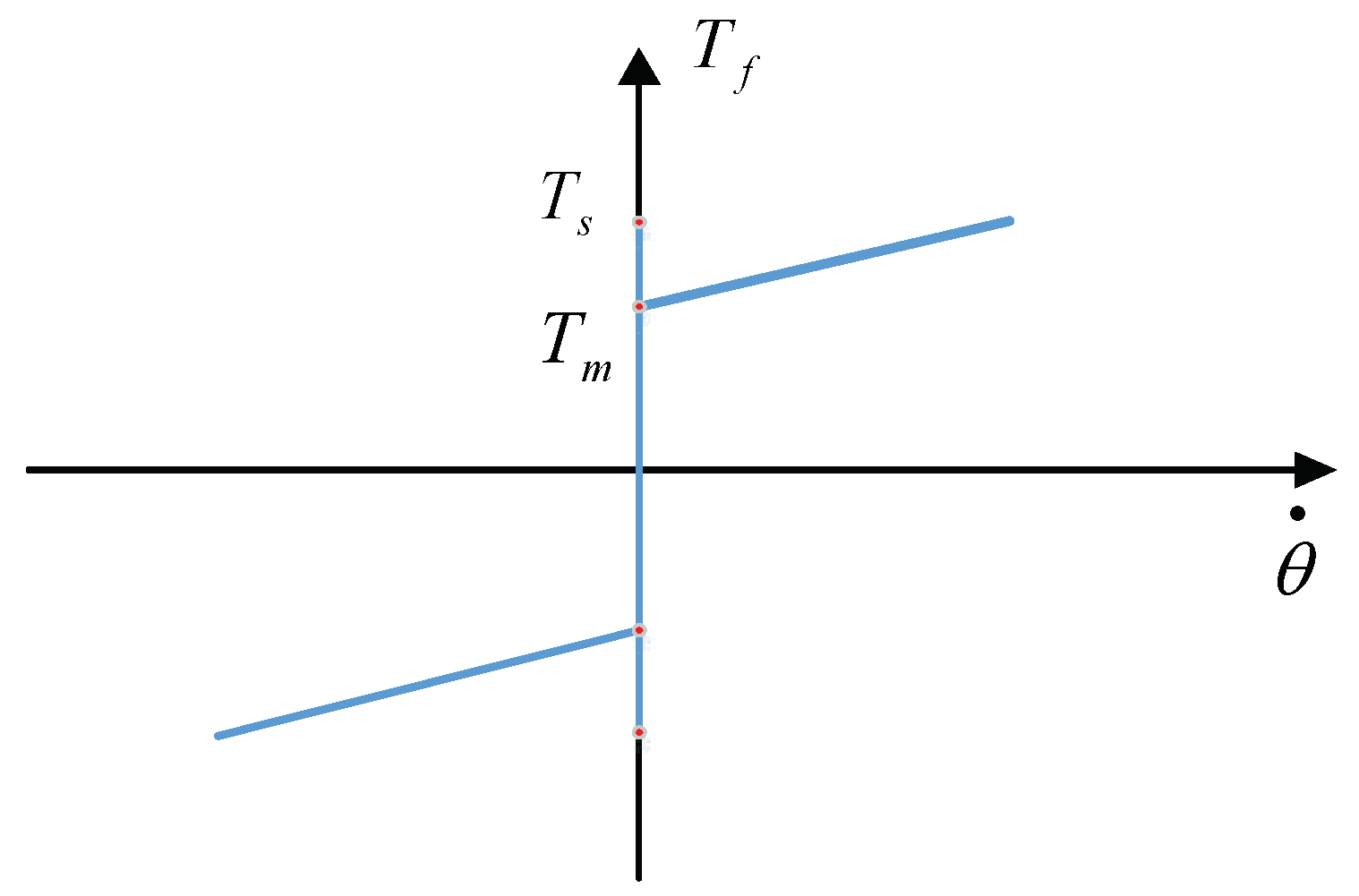

2.1.2. Motor friction model

The motor of EMB is required to have a relatively high precision control performance, and the friction in the motor will directly affect the clamping force generated by the EMB system. Therefore, it is very important to establish an accurate motor friction model for improving the overall braking performance of the EMB system. In this paper, static friction characteristic models of static friction, Coulomb friction and viscous friction are selected. The static friction characteristic curve of the motor is shown in

Figure 2, and the friction torque is given:

where

is the relative sliding speed;

is the external torque, N·m;

is static friction moment, N·m;

is the coulomb friction torque, N·m.

2.2. Model of mechanical components

2.2.1. Mechanical transmission model

Reduction gear is utilized to enlarge force generated from motor. Subsequently, ball screw can generate linear motion of ball-screw nut which directly generates positive pressure on pad. Generally speaking,we can control position of screw nut via adjusting motor rotor angle displacement because they have a relatively linear mapping relationship between them[

18]. The load torque

is generated from clamping force between pads and disk and can be calculated as follows:

where

presents efficiency coefficient of the gear box and

presents the one of ball screw;

is the reduction ratio of gear,

is lead of ball screw. Eq. (9) is usually expressed as

in which

is total gearing transfer gain.

should be specifically expressed as Eq.(10)

where

is rotor inertia constant and

is damping coefficient of the rotor .

where g is a actual nonlinear mapping principle of the .

2.2.2. Load model

The load torque of the motor comes from the thrust generated by the ball screw mechanism, and the brake liner generates a clamping force on the brake disc under the action of the thrust. There is a certain mathematical relationship between the clamping force of the EMB system and the shape variable of the friction disc [

22], which indicates that the clamping force on the brake disc is given:

where

,

,

is the coefficient of the clamping force cubic polynomial;

is the shape variable of the friction plate, mm.

2.2.3. Brake Disc Model

The brake liner is installed in the caliper end, and the ball screw mechanism is used to push the brake disc to clamp, so that the left and right sides of the brake disc produce the same friction torque, which is given:

where

is the clamping force, N;

is the friction coefficient of the friction plate;

is the effective radius of the brake disc, m.

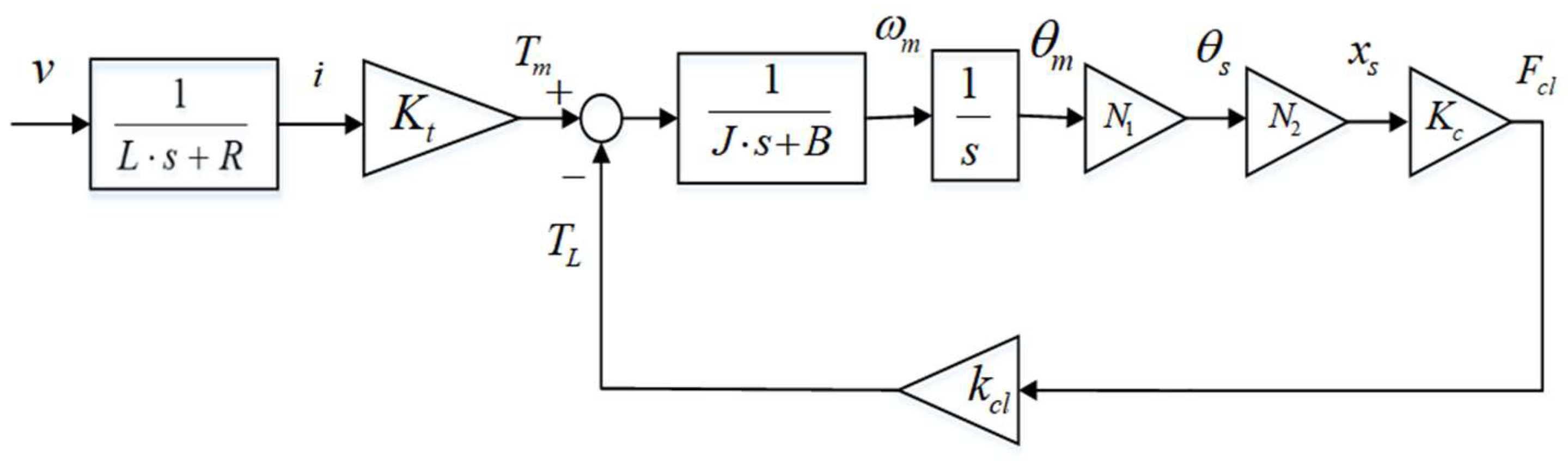

Figure 3 presents our proposed EMB model in UTRVs. The voltage generated from three-phase inverter for motor operation is delivered to input ports of torque motor.The ball-screw

and its displacement

have a proportional relationship expressed as

.

,

is lead of ball screw.In this model,we also consider mapping relationship curve between

and

as a cubic polynomial[

19]described as Eq.(11).

3. Design of Controllers

3.1. Cascaded three close-loop Force/Position control strategies

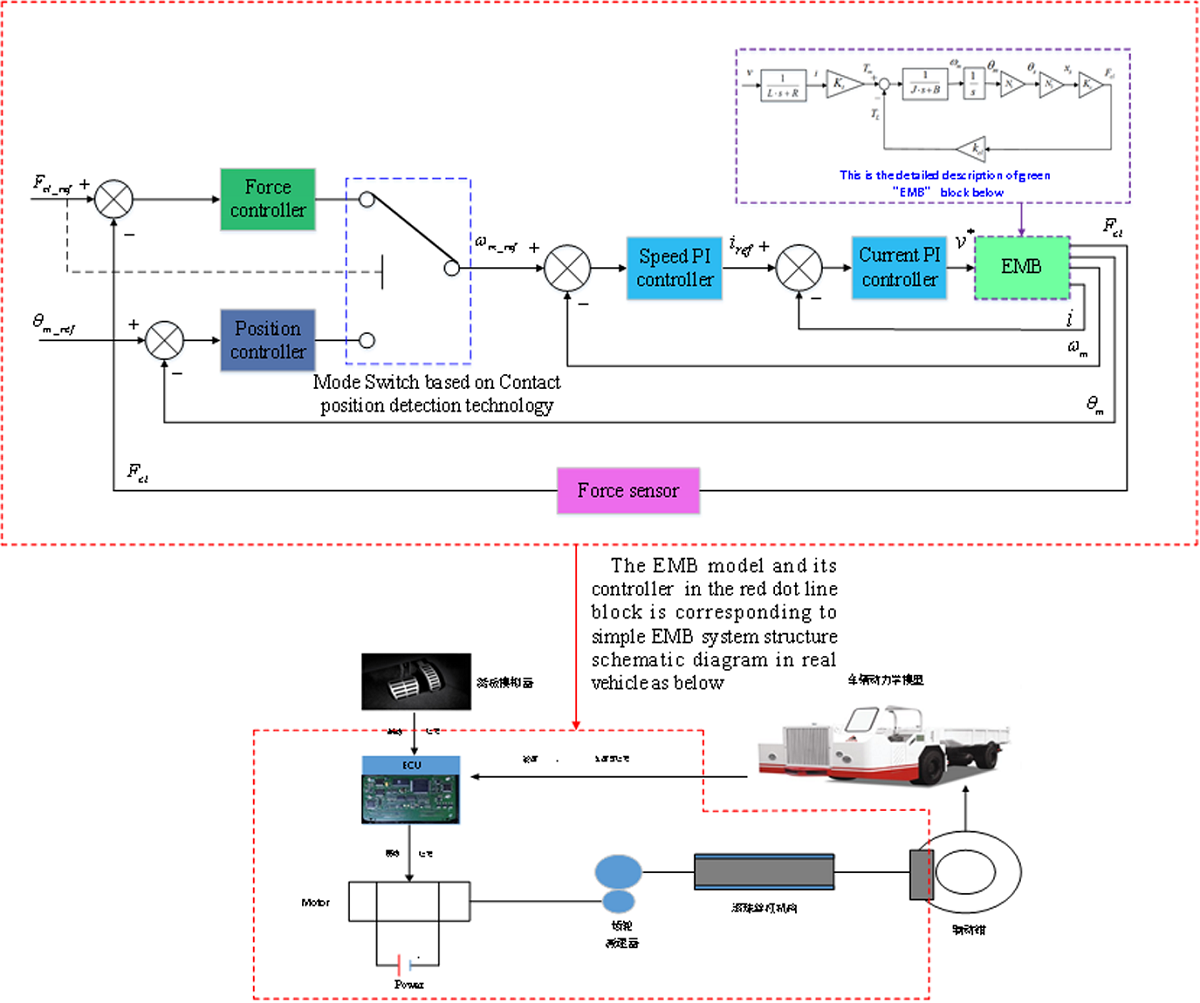

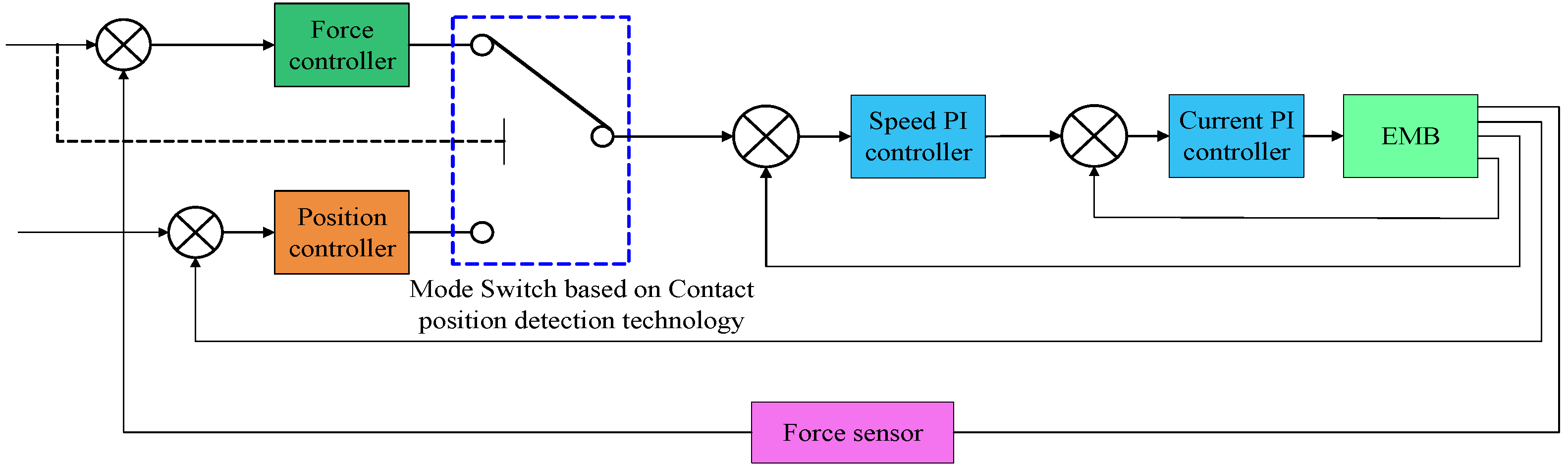

Based on modeling of this EMB along with key contact point position detection technology introduced in Section II,a three-close-loop PI/PID control system for EMB in underground UTRVs is proposed because it’s needed to be considered that very accurate EMB dynamic model in actual braking work condition is hard to be established,but tracking stability in steady-state of PID control method don’t rely on detailed and precised mathematical model.The whose overall control architecture is shown in

Figure 4.

It’s can be seen in above model block diagram that the overall control system is cascaded architecture with three close-loop control units. Two Proportional-Integral (PI) feedback controllers with each different gain parameters is utilized for current and speed controllers of this EMB,respectively.However, both clamping force controller and contact point angle position controller adopt PID method and provide target velocity of motor into subsequent speed control loop.The position controller aims to eliminate or reset the braking gap distance by utilizing relationship between the motor angular position and stoke displacement of screw nut . After EMB local controller receive non zero measured value from load force sensor, The force controller start to work.

The comprehensive control of current, speed, and force close-loop units aims to make balance between transient response speed and steady-state tracking performance where data refresh rate of controlled variables in ECU is set around 20-50Hz.

3.1.1. Current loop

The current close loop PI controller is shown in

Figure 6, Eq. (13) is its open loop transfer function.

Figure 5.

Current control loop.

Figure 5.

Current control loop.

zero point of PI controller is designed to compensate for the pole of plant, such as in (14), the closed-loop transfer function can be written as (15). Proportional gain

and integral gain

are set to satisfy the given time-domain requirements on the current response.

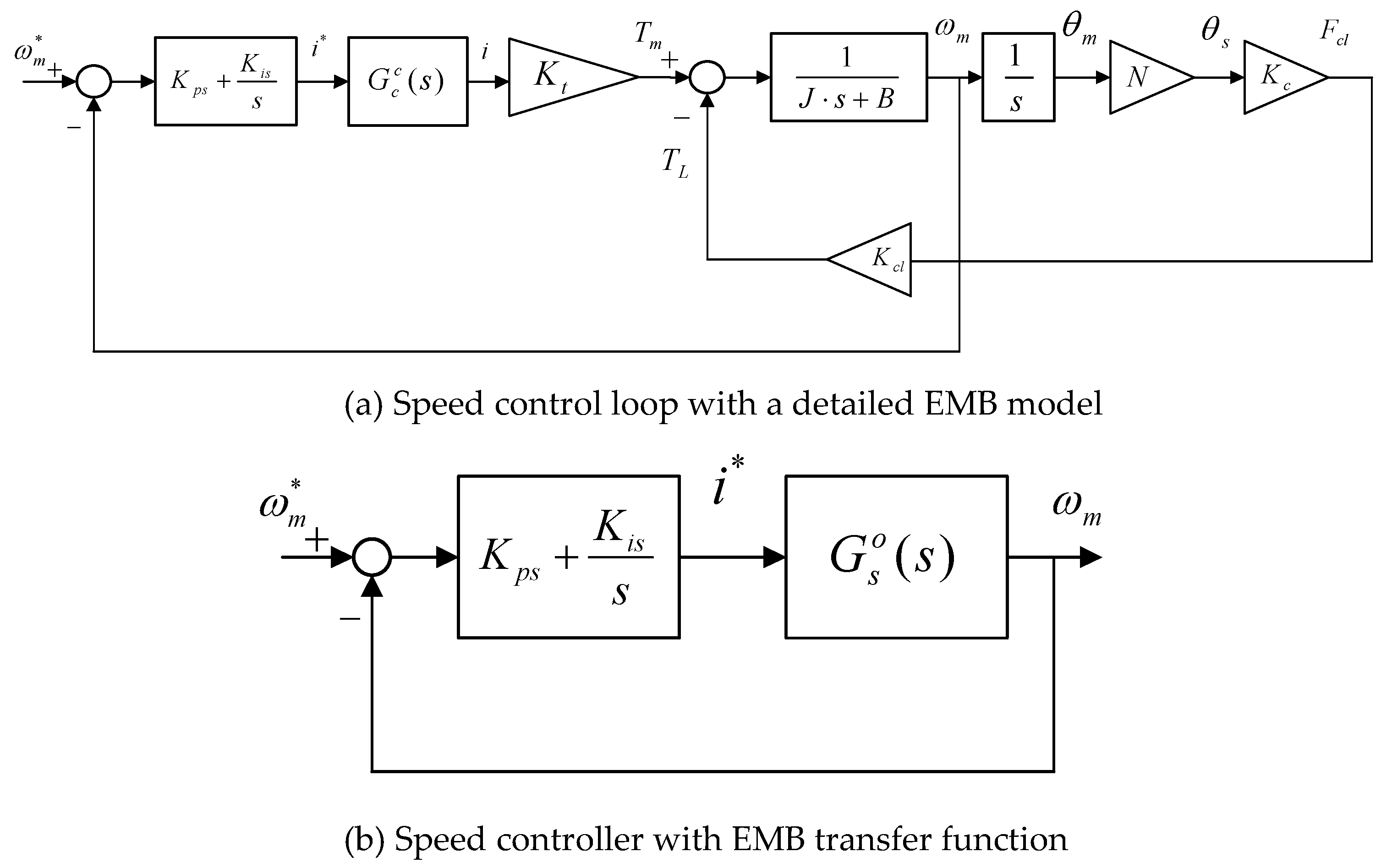

3.1.2. Speed loop

The motor speed controller is also a PI controller which is in front of current control loop in

Figure 4. Detailed speed control loop model is in

Figure 6(a).

The

and

of speed controller are obtained via pole placement method based on root locus and we have find the damping ratio and natural frequency meeting time- domain requirements of speed controller.In

Figure 6(b), EMB transfer function

is calculated out and placed after the speed PI controller.

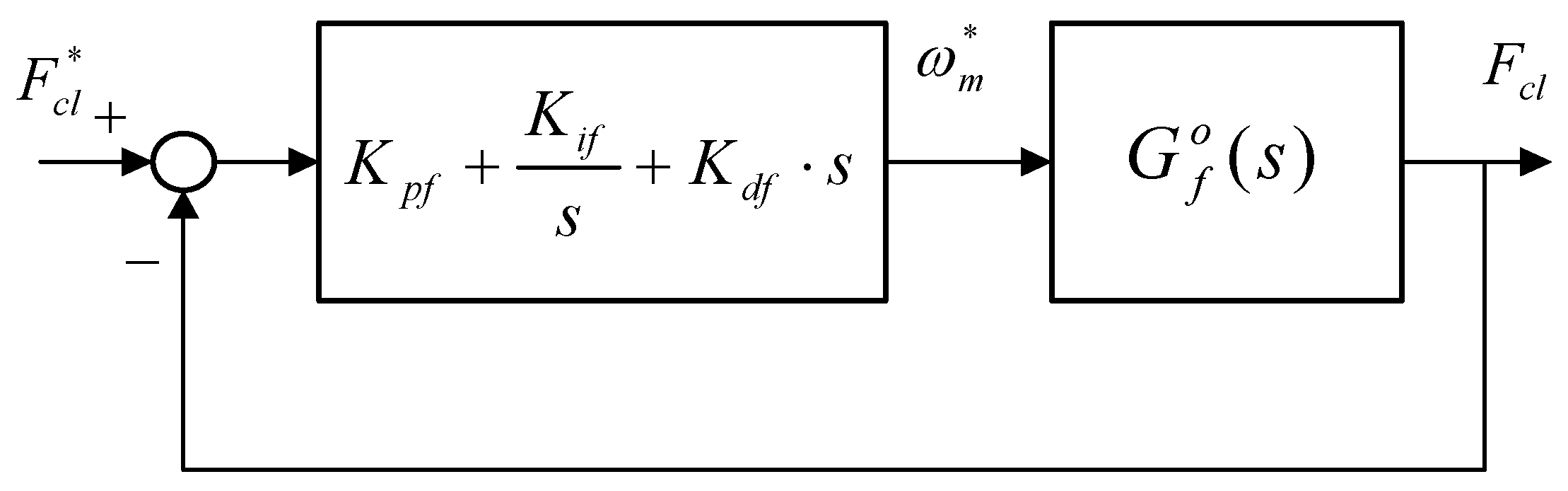

3.1.3 Force Controller

The actuator clamping force control is a PID controller which output reference speed. The clamping force control loop is shown in

Figure 7 where the transfer function

is obtained as shown in Eq.(16). We also need to find the damping ratio and natural frequency corresponding to the desired pole locations based on requirements of force response in time-domain.The PID gains are obtained at dominant pole locations

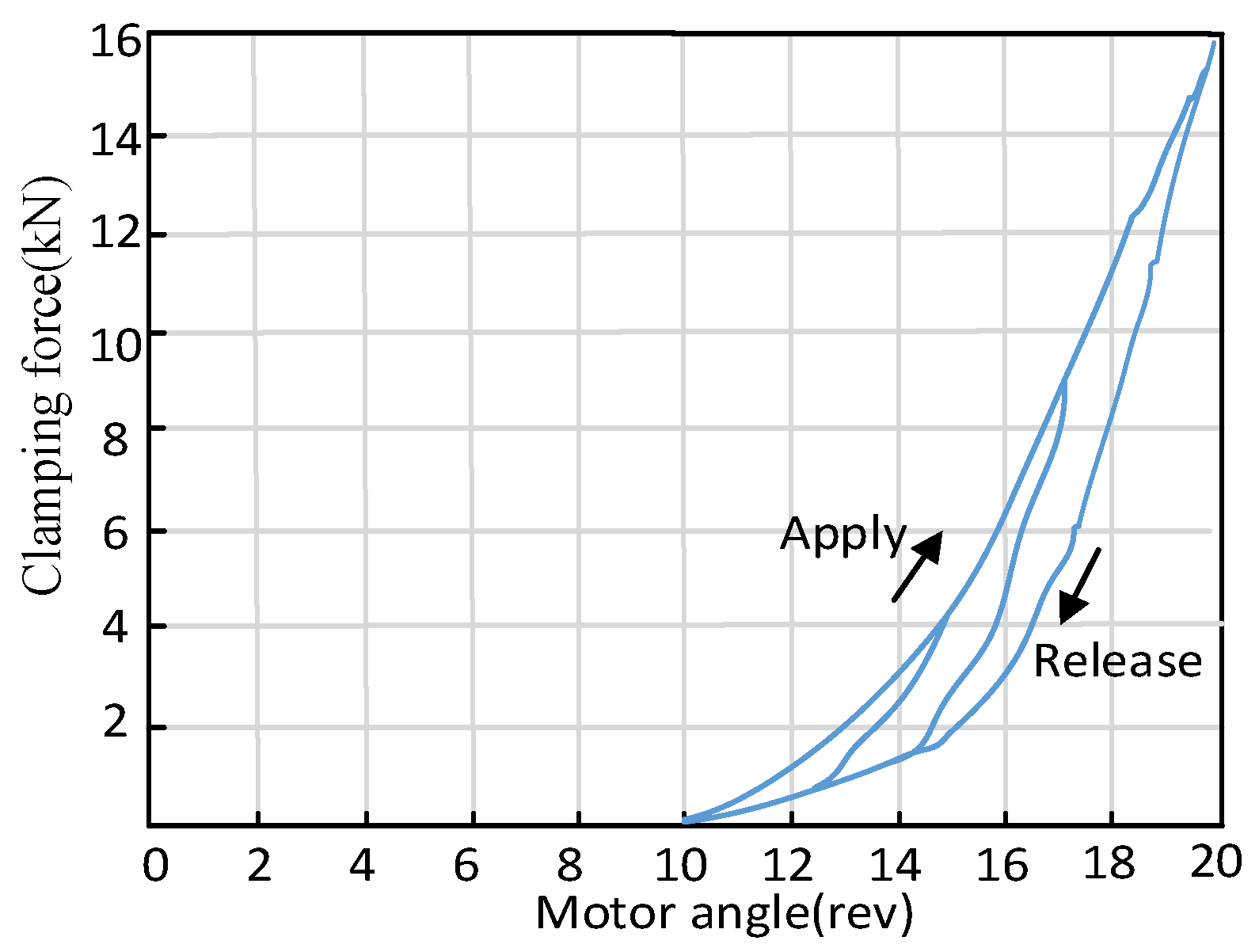

3.2. Estimation method of Contact Point utilized for Force/Position switch

It is necessary to estimate the critical contact position of pad and disk for transient switch process between force control mode and position control mode.Because motor of EMB always rotate related fixed revolutions after pads really contact the braking disk ,we utilize rotor revolutions of torque motor to substitute angle position and control clamping force by tracking motor revolutions.we consider the relationship curve between the positive compressing force and motor rotor angle position as below form so that it is possible to control clamping force by motor angular position.

In this paper,motor revolutions corresponding to the contact point is achieved via experimental method. In

Figure 8, the contact revolutions is 10.

Aim at getting motor revolutions value which presents initial contact position of this EMB,we use a force sensor to provide feedback signal for motor angle position control of EMB.As actual force reaches command demand,the motor revolutions ranges from zero to 60.The measured signals for feedback include clamping force signal from pressure sensor ranging from 0-30kN,motor revolutions from encoder with precision of 360 count per turn and motor current signal from current sensor ranging from 0 to 30A.

4. Simulation results and discussion

The specific parameters of EMB apparatus used for both model simulation and development of prototype are listed in

Table 1.

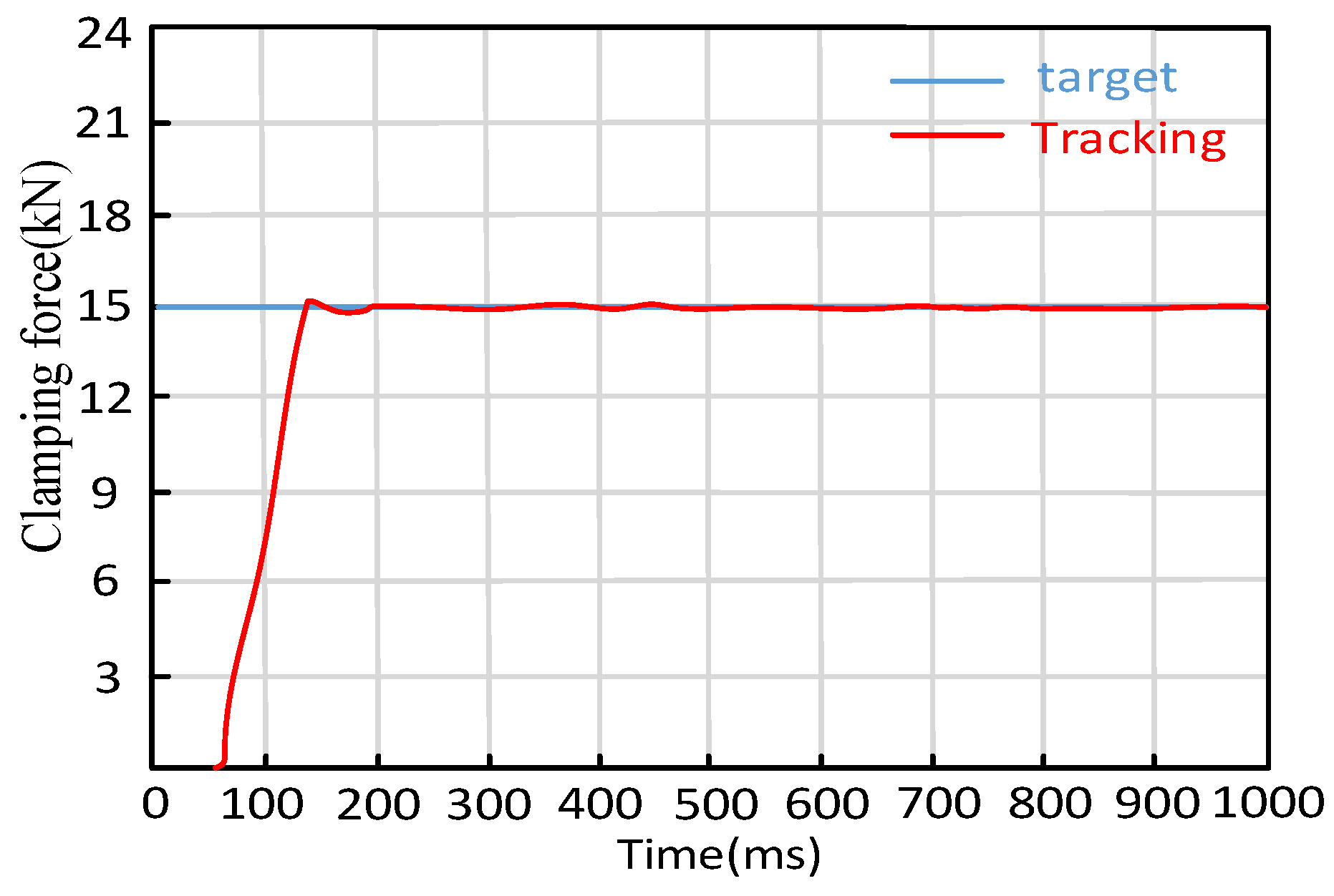

The clamping force step response simulation in MATLAB/Simulink is shown in

Figure 9.Dead-zone time is 45 ms.The raise time is 75 ms.The steady-state error is 118N(0.79%).After 190ms,system established stable clamping force at value of 15kN which is faster than traditional hydraulic braking.

5. Experimental Results and analysis

5.1. Experimental platform

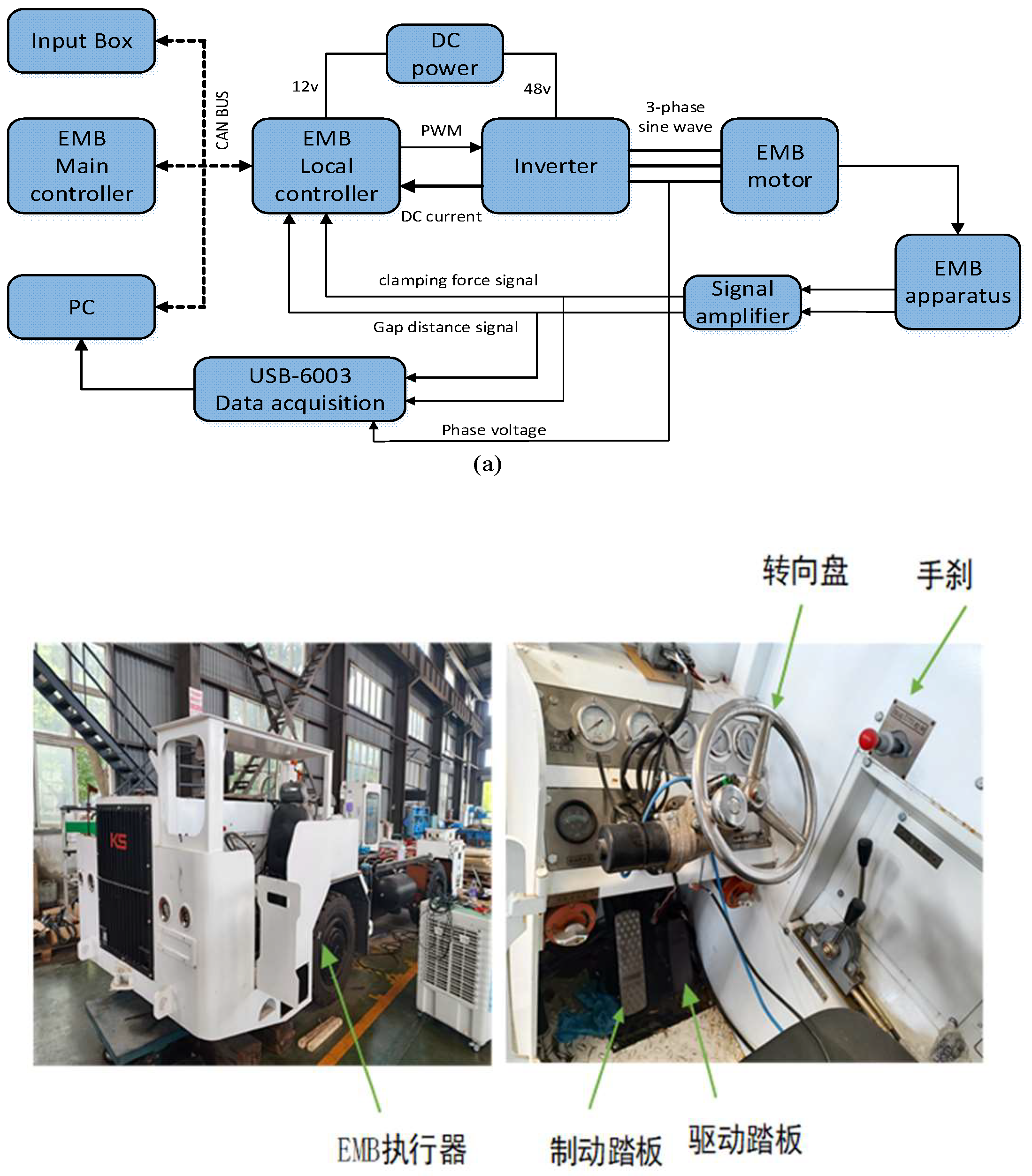

In this work,it is seen in

Figure 10 that we established a experimental EMB prototype controlled by our developed ECU with explosion-proof processing according to safety standard of explosive atmospheres in underground coal mine.The metal terminals are the only electric signal transmission interface with inner electric parts in this white explosion-proof shell.The core of this ECU was a Infineon high performance micro-processor(32bits) with many integrated interface circuits and meets highest commercial vehicle safety level of D.

System architecture of this prototype test in real rubber-tired vehicle is presented in

Figure 11(a).We select a 400W(2.5

) surfaced PMSM supplied by a three-phase inverter power with DC input of 48V voltage as initial braking force source in this EMB system.Motor current measurement sensor ranges from 0-30A.The clamping force sensor ranges form 0-30kN.All of these signals simultaneously can feedback into the EMB local controller to achieve close-loop tracking control and also be collected into PC monitor software via high-speed data collector. The master controller of EMB managing the whole distributed braking system sends target braking force to the local controller(only one of four shown in

Figure 11(a) as a example). The whole communication mode between every parts in this prototype is Controller Area Network(CAN).The computer send control signal to EMB controller which also can monitor experimental detailed operation process.The real vehicle test is conducted and implement in test field of Keshi Group in Changzhou,China as shown in

Figure 11(b).

Table 2 show the specific parameters used for simulation and experiment.

5.2. Experimental Results

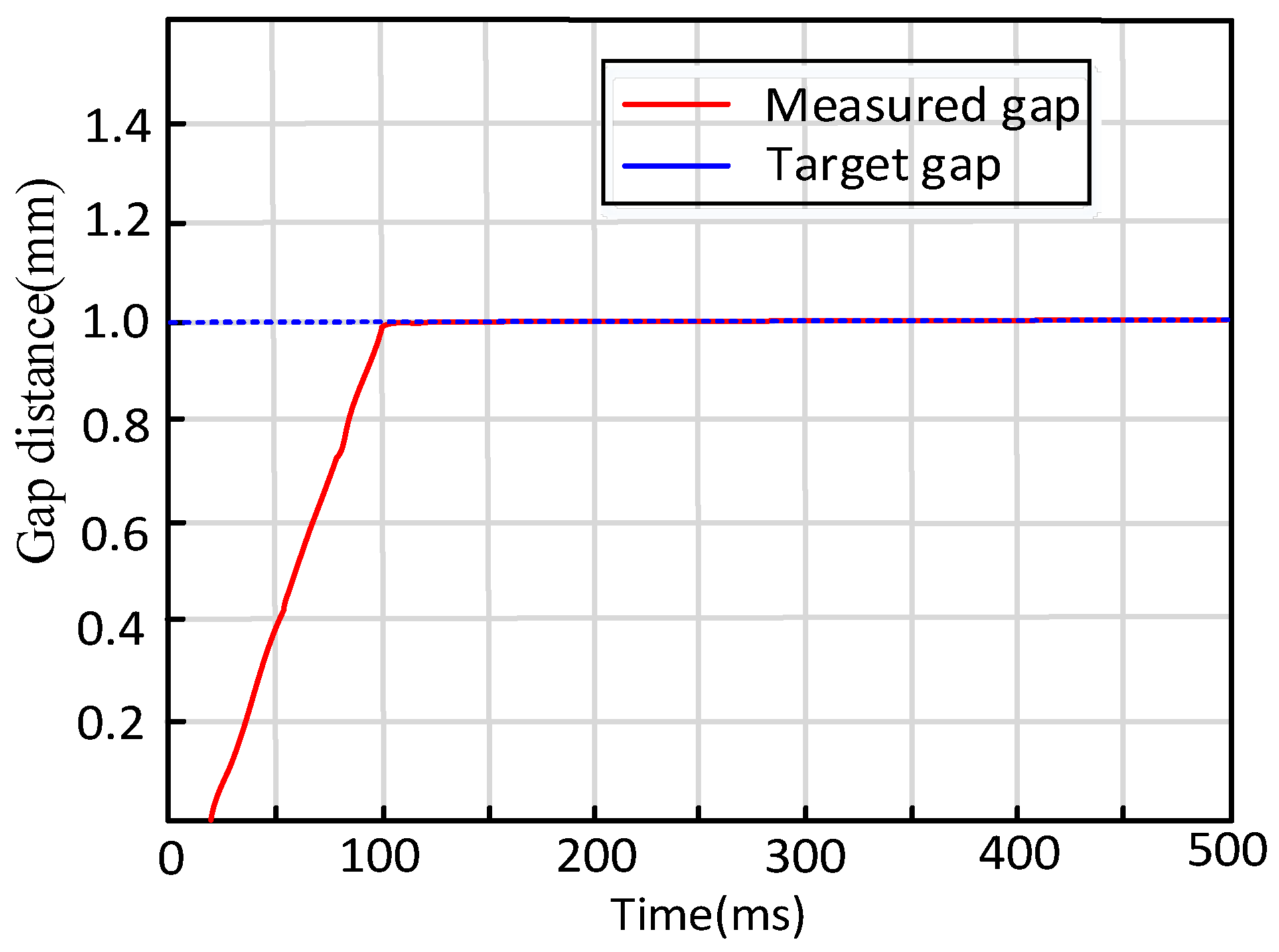

Experimental initial state is that distance between friction pad and disk is zero mm.The target clearance is set to 1.5±0.1mm.When test is started,the braking command value is sent into local controller where the three-close-loop controller with proper gain parameter can fast tracking the input reference clearance value.within 500ms and keep stable.

It is shown in above

Figure 12 that the initial 30ms is dead-zone of EMB and data receiver don’t get any effective sensor data.After this time,braking motor began rotating.Rising time of braking clearance is 65ms.After 0.11s,Stead error range is 0.02mm.These indexes is obviously better than ones of traditional mechanical-hydraulic and electro-hydraulic braking method

- 2.

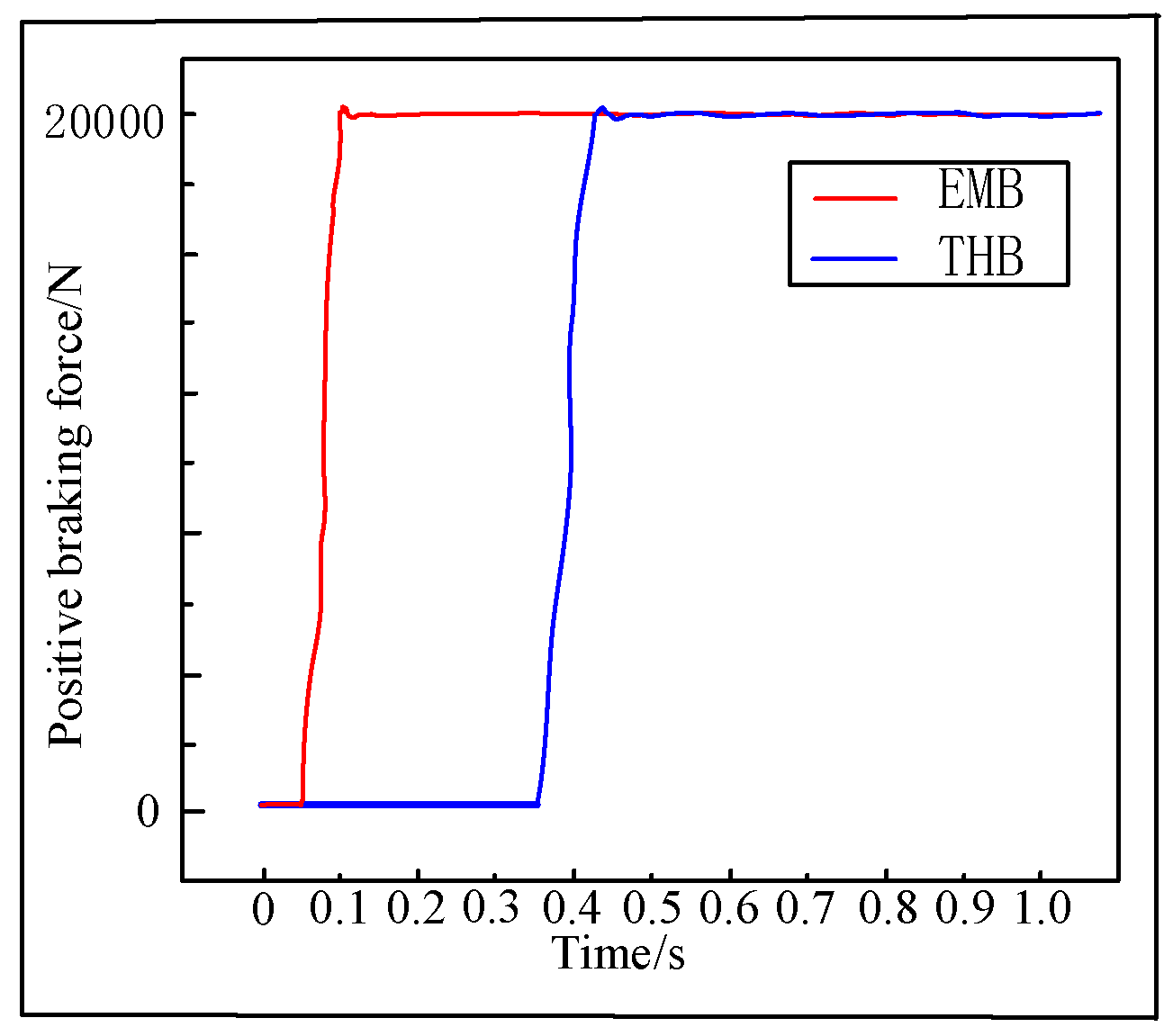

Brake positive pressure test

It is interesting to compare the braking clamping force step response curves between EMB system and traditional hydraulic pressure braking system as shown in

Figure 14.According to total vehicle parameters calculation of underground UTRVs,the

related to EMB actuator performance is 60000N. Considering that the usual braking intensity of this vehicle is approximately

,it’s proper to set the step response test value of clamping force command at 20000N.

The force response of EMB display that after dead-zone time(0.45s) caused by spending some time to eliminate gap and mechanical inertia,the control priority of the controller is received by force controller and the motor start to generate braking force . The system rise time is 0.125s which is sufficient to meet braking safety requirement based on National Coal Mine Safety Regulations.After 0.15s,the steady-state mean value of 19786N is reached at, the error is 186N(0.93%).The sum of dead-zone time and raise time of THB is .43s.It’s obviously seen that proposed EMB system has more shorter braking acting time and shorter braking distance compared with THB,which means better vehicle safety.

6. Conclusions

In this paper, a novel EMB apparatus is proposed to replace the existing open-loop hydraulic brake which has intrinsic shortage such as slower response speed,lower automation level,hard maintenance and hydraulic oil leakage risk,.Simulation and experimental curves present that this cascaded control strategy with three close-loop units can track target clamping force more rapidly and automatically adjust braking gap,which also can autonomously switch mode between force control mode and clearance distance control mode. This proposed EMB of mine electric trackless rubber-tired can eliminate hydraulic climbing problem and shorten braking distance,which could have a significant enhancement on emergency braking safety of ETRV in coal intelligent transportation system.

Author Contributions

Conceptualization,J.L.; methodology, J.L.; software, J.L.; validation, J.L., Z.L; formal analysis, J.L.; investigation,C.M.; resources, C.M.; data curation, J.L.; writing—original draft preparation, J.L.; writing—review and editing, Z.L.; visualization, J.L.; supervision, C.M.; project administration, C.M.; funding acquisition,X.X.;All authors have read and agreed to the published version of the manuscript.

Funding

This work was also supported by National Natural Science Foundation of China [grant numbers: 51975569,51675520].

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The author(s) would like to express appreciations to Meilin Wang, Fahui Shi and other colleagues in Changzhou Keshi Group for their valuable support in the tests of real mine vehicle.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Song,Y; Wang N. Exploring temporal and spatial evolution of global coal supply-demand and flow structure. Energy. 2019, 168, 1073–1080. [CrossRef]

- Li, J.; Meng, G.; Xie, G.; Wang, A.; Ding, J.; Zhang, W.; Wan, X. Study on Health Assessment Method of a Braking System of a Mine Hoist. Sensors 2019, 19, 769. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Xu, G.; Zhang, X.; Sha, S. Design and research of the disc brake of mine hoists for monitoring the disc spring force and positive brake pressure. Meas. Sci. Technol. 2019, 30, 125903. [Google Scholar] [CrossRef]

- Jing Houhua,Feng Ruixue,Lin Qinggan.Design and Test of Electro-Mechanical Brake Experiment System.Proceedings of the 2022 6th CAA International Conference on Vehicular Control and Intelligence 2022.

- He Cheng *, Hao Chen †, Zhou Yang *, and Weilong Huang * Braking Torque Closed-Loop Control of Switched Reluctance Machines for Electric Vehicles. Journal of Power Electronics 2015, 15, 469–478. [CrossRef]

- Xiao, F.; Gong, X.; Lu, Z.; Qian, L.; Zhang, Y.; Wang, L. Design and Control of New Brake-by-Wire Actuator for Vehicle Based on Linear Motor and Lever Mechanism. IEEE Access 2021, 9, 95832–95842. [Google Scholar] [CrossRef]

- Soohyeon Kwon1,Seonghun Lee1, Jaeseong Lee1 Daehyun Kum1.Accurate State Estimation for Electro Mechanical Brake Systems. Journal of Electrical Engineering & Technology 2019, 14, 889–896.

- Zhao, Y.; Lin, H.; Li, B. Sliding-Mode Clamping Force Control of Electromechanical Brake System Based on Enhanced Reaching Law. IEEE Access 2021, 9, 19506–19515. [Google Scholar] [CrossRef]

- Jo, C.; Hwang, S.; Kim, H. Clamping-Force Control for Electromechanical Brake. IEEE Trans. Veh. Technol. 2010, 59, 3205–3212. [Google Scholar] [CrossRef]

- Huawei Jin;Huwei Xu;Shun Wang Design and test of electromechanical disc brake controller for mine hoist. Measurement and Control 2022, 55, 146–148. [CrossRef]

- Jialei Shi,Chao Huang,Xiangyu Wang,Liang Li.Adaptive Dual-Loop Hydraulic Pressure Controller for Electric Booster Brake System.IEEE 28th International symposium on Industrial Electronics 2019, 1481-1486.

- Xiong, L.; Han, W.; Yu, Z. Adaptive sliding mode pressure control for an electro-hydraulic brake system via desired-state and integral-antiwindup compensation. Mechatronics 2020, 68, 102359. [Google Scholar] [CrossRef]

- Liu, H.; Wei, L.; Liu, H.; Wu, J.; Li, L. Brake Pressure Estimation of the Integrated Braking System Considering Vehicle Dynamics. Actuators 2022, 11, 329. [Google Scholar] [CrossRef]

- Jiawang,Yong, Feng,Gao, Nenggen,Ding,Yuping,He Pressure-tracking control of a novel electro-hydraulic braking system considering friction compensation. Journal of Center South University 2017, 24, 1909–1921. [CrossRef]

- C -Y.Lin and Y.-C.Liu.Precision tracking control and constraint handling of mechatronic servo systems using model predictive control. IEEE/ASME Trans. Mechatronics. 2012, 17, 593–605. [CrossRef]

- Beak SK, Oh HK, Kwak MH, et al A design method of three phase IPMSM and clamping force control of EMB for high-speed train. J Korea Academia-Industrial Cooperation Soc. 2018, 19, 578–585.

- Weng, J.; Tian, C.; Wu, M.; Chen, M. Coupled rigid-flexible modelling and dynamic characteristic analysis of electromechanical brake (EMB) units on trains. Proc. Inst. Mech. Eng. Part F: J. Rail Rapid Transit 2020, 235, 700–712. [Google Scholar] [CrossRef]

- Jo, C.; Hwang, S.; Kim, H. Clamping-Force Control for Electromechanical Brake. IEEE Trans. Veh. Technol. 2010, 59, 3205–3212. [Google Scholar] [CrossRef]

- Chen, Q.; Lv, Z.; Tong, H.; Xiong, Z. Clamping Force Control Strategy of Electro-Mechanical Brake System Using VUF-PID Controller. Actuators 2023, 12, 272. [Google Scholar] [CrossRef]

- Park Giseo, Choi Seibum, Hyun Dongyoon Clamping force estimation based on hysteresis modeling for electro-mechanical brakes. Int J Automot Technol. 2017, 18, 883–890. [CrossRef]

- Li, Y.; Shim, T.; Shin, D.-H.; Lee, S.; Jin, S. Control System Design for Electromechanical Brake System Using Novel Clamping Force Model and Estimator. IEEE Trans. Veh. Technol. 2021, 70, 8653–8668. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Y.; Chen, L. A Gap Control Method for Electromechanical Brakes. Acta Armamentarii 2022, 43, 1478–1487. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).