Submitted:

21 September 2023

Posted:

26 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

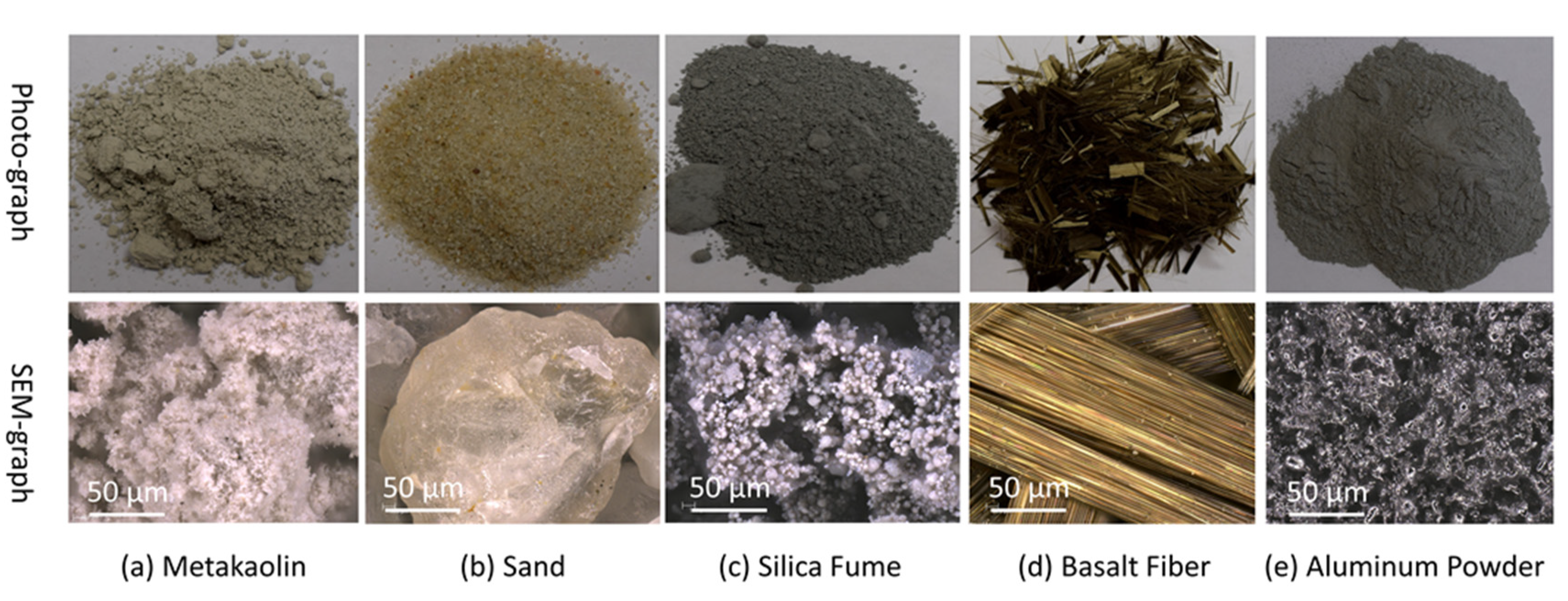

2.1. Materials

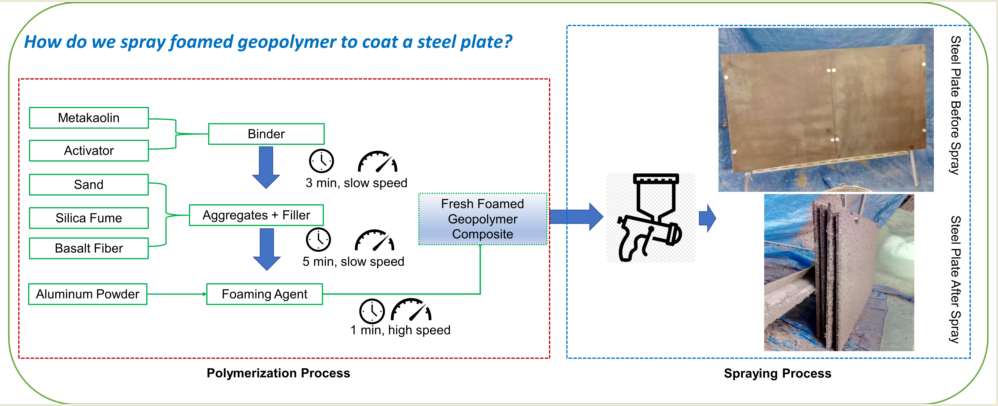

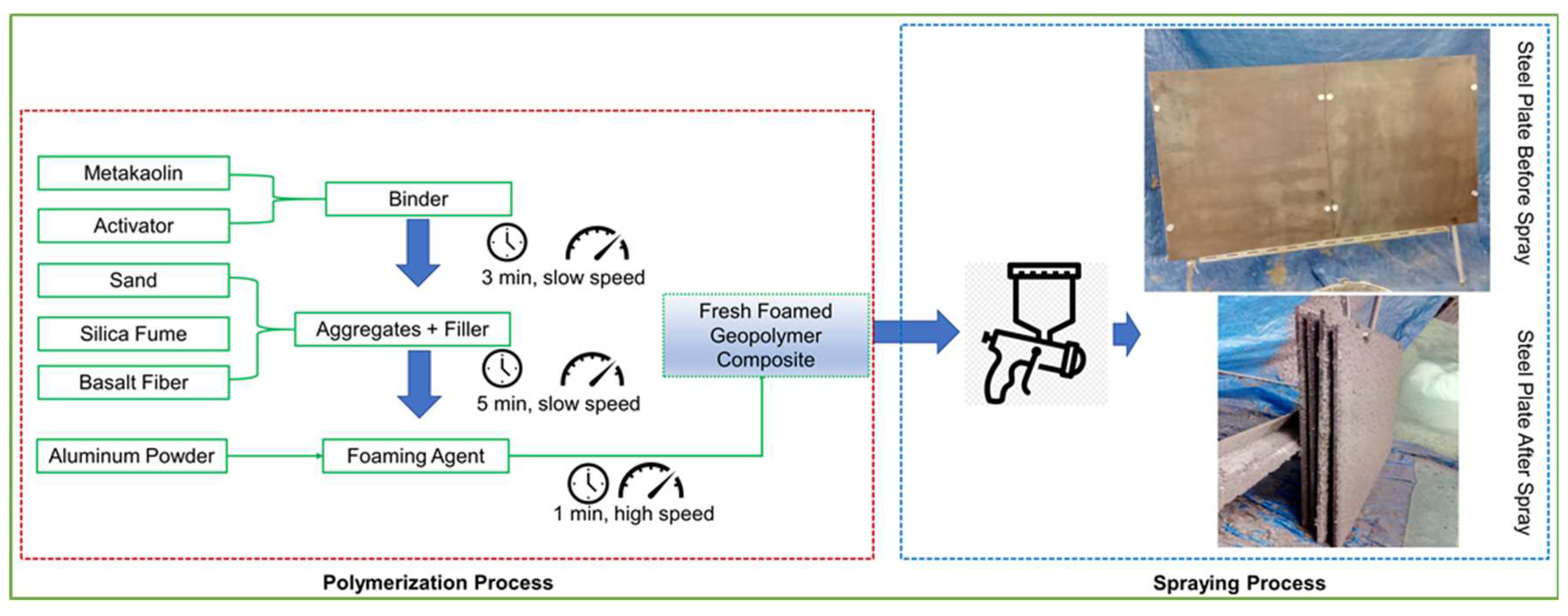

2.2. Samples preparation

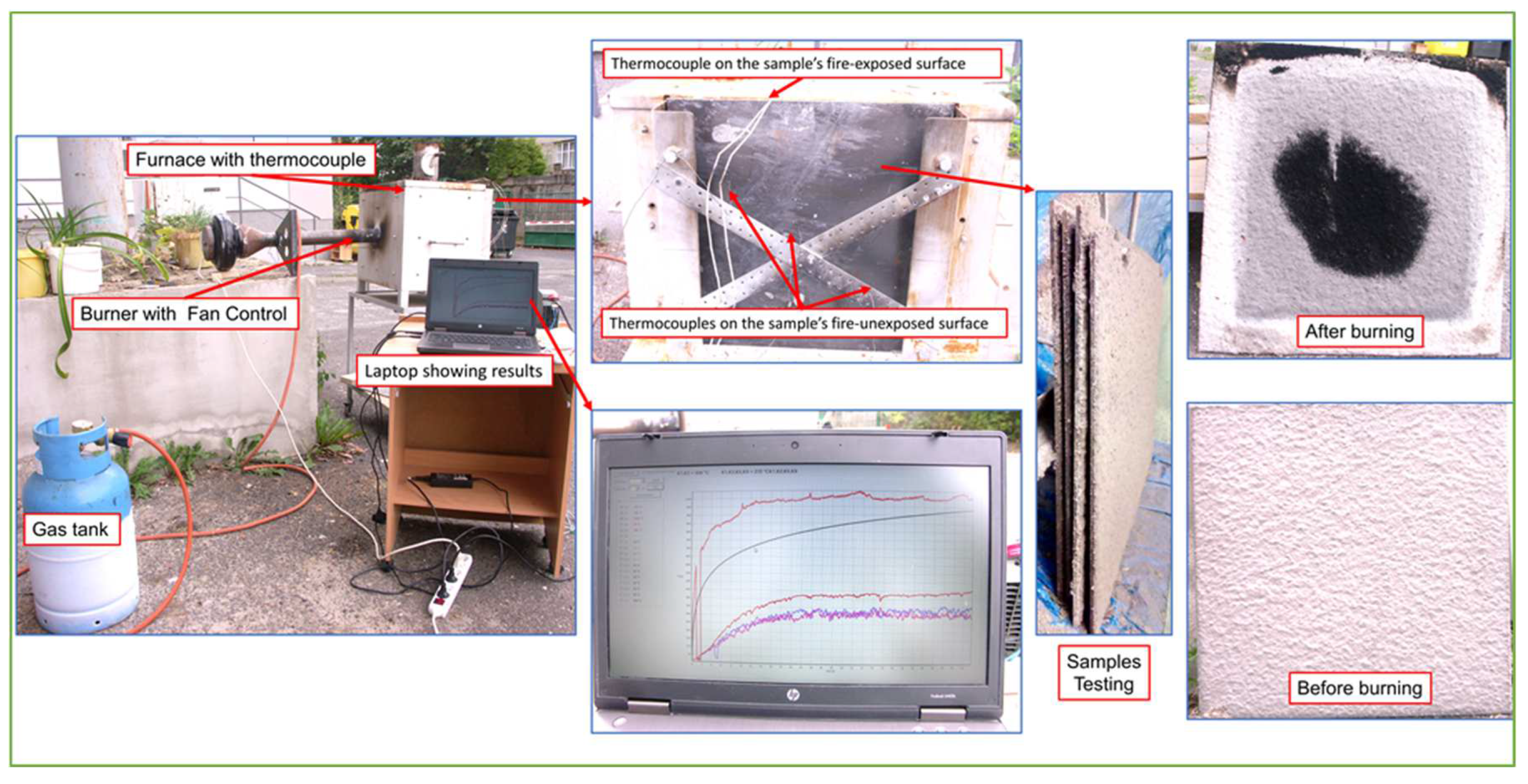

2.3. Methods

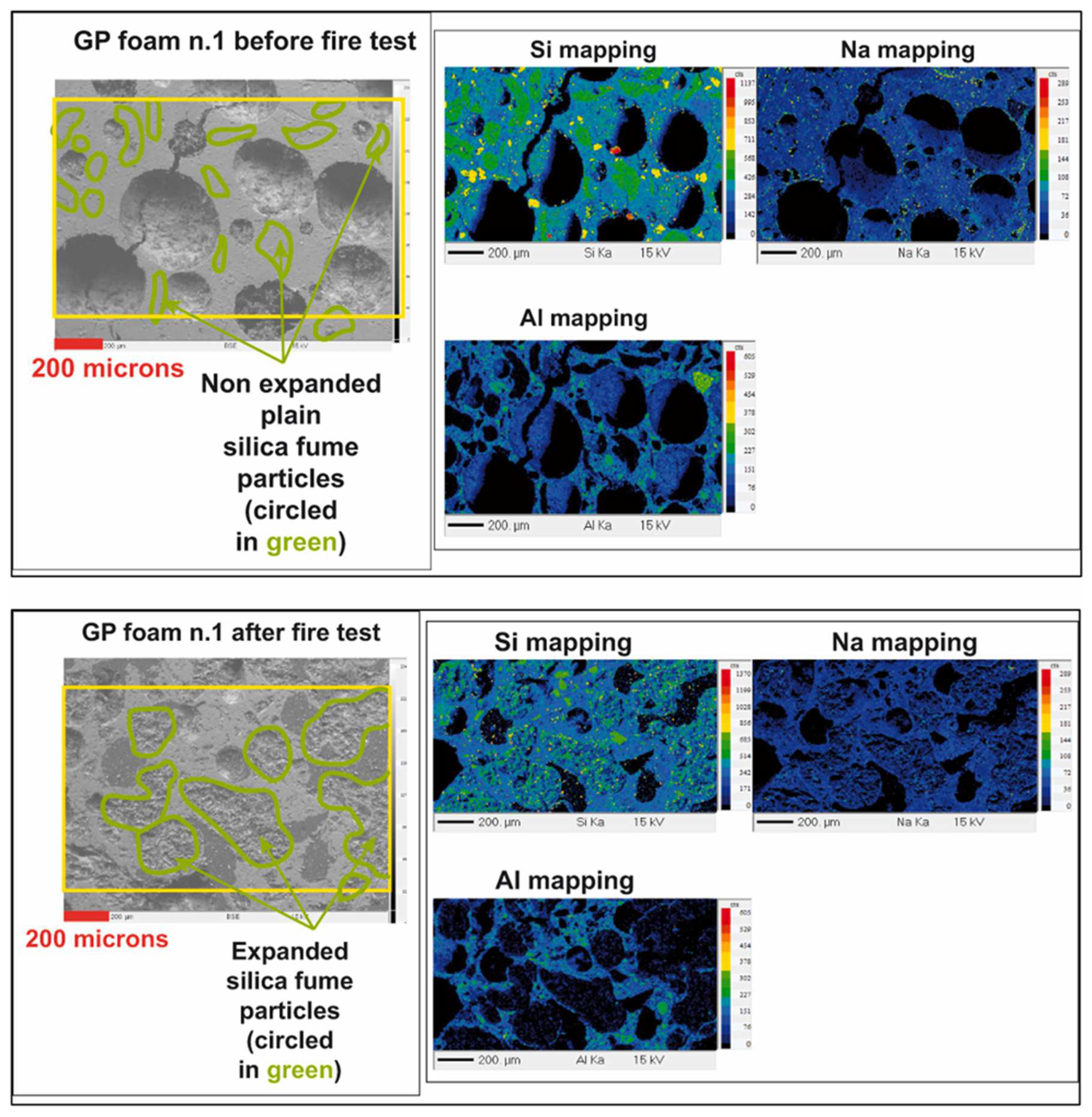

3. Results and discussion

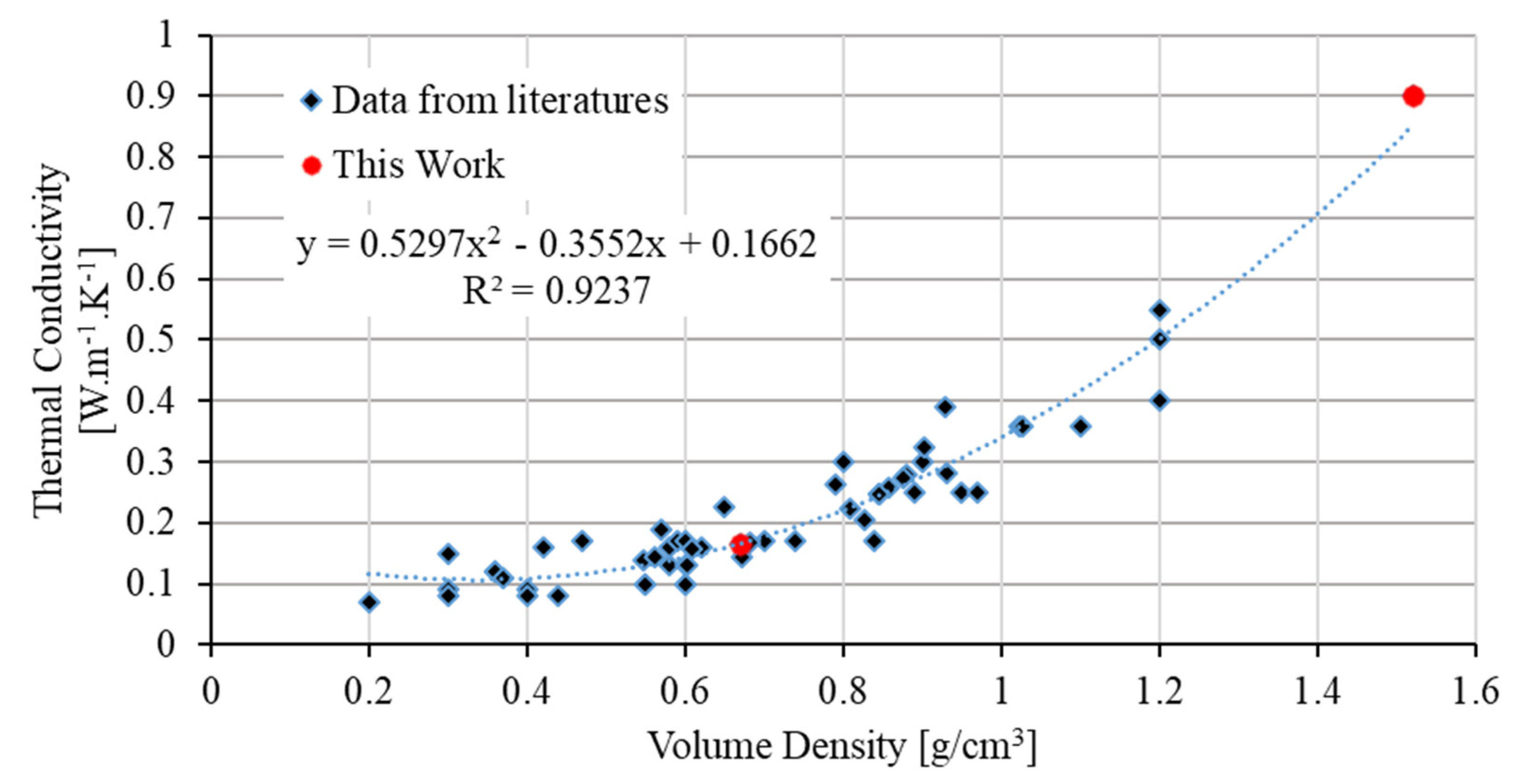

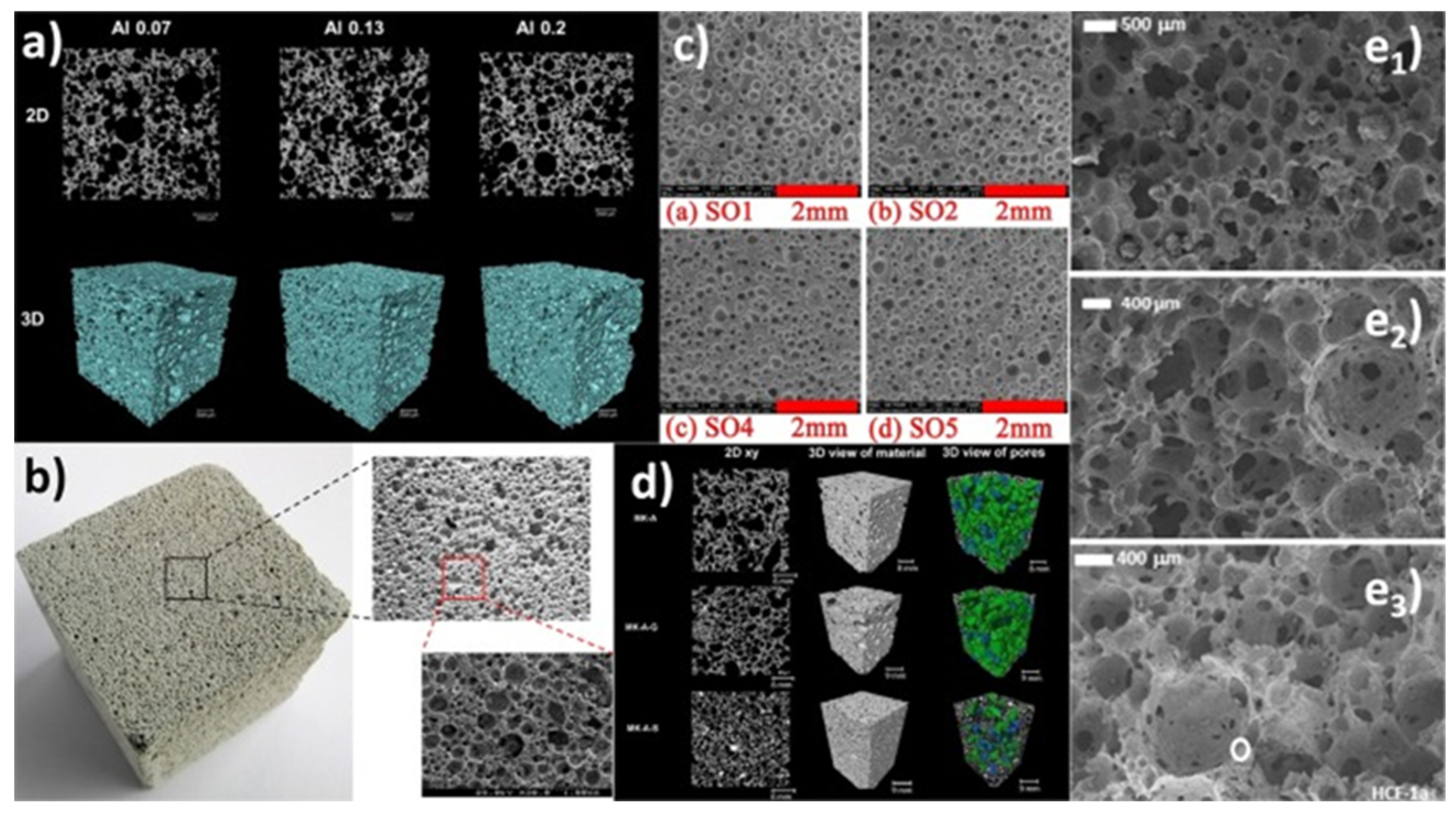

3.1. Physical, mechanical, and thermal properties

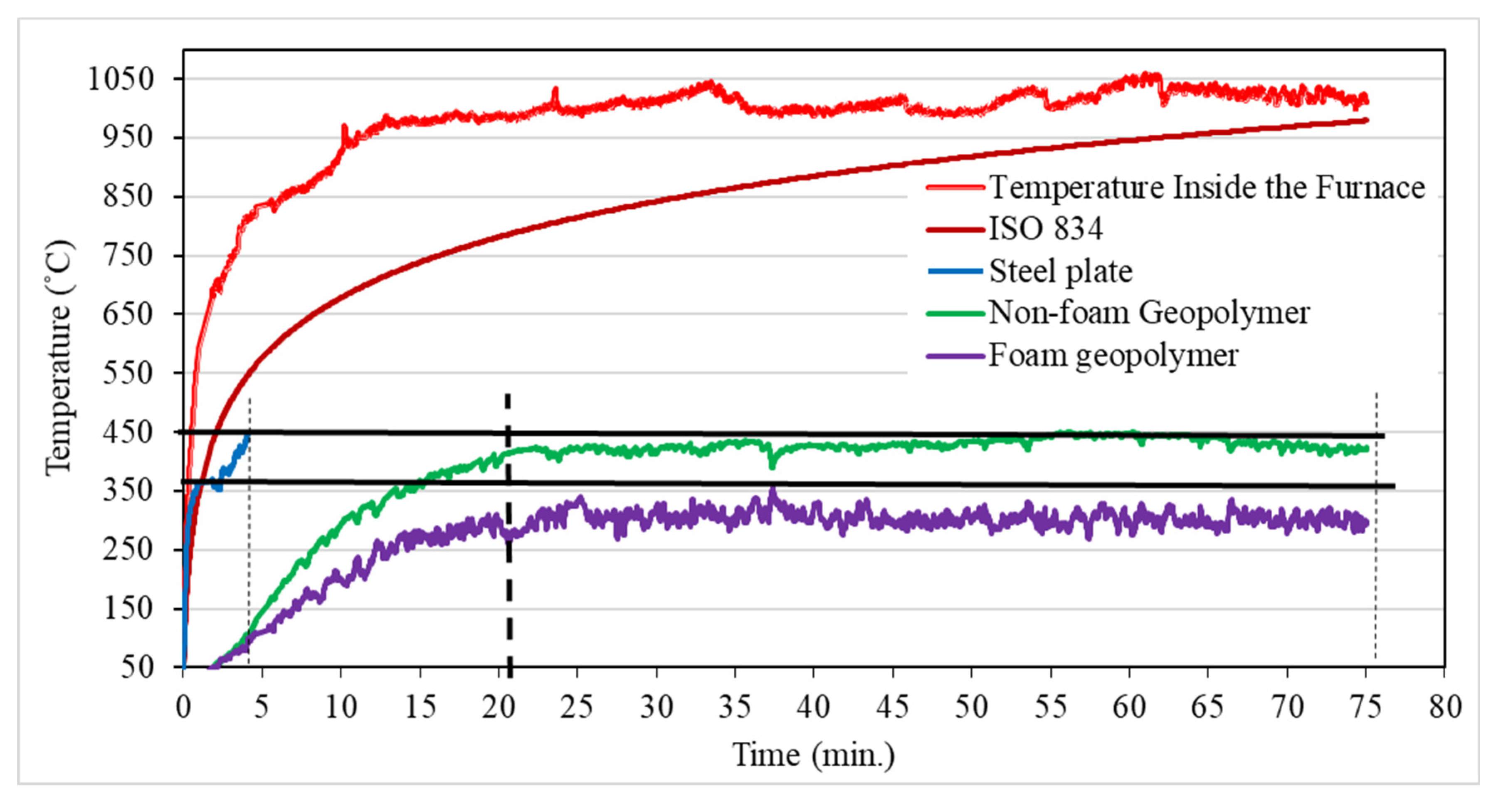

3.2. Fire resistance properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer Concrete: A Review of Some Recent Developments. Constr Build Mater 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Nguyen, V.V.; Le, V.S.; Louda, P.; Szczypiński, M.M.; Ercoli, R.; Růek, V.; Łoś, P.; Prałat, K.; Plaskota, P.; Pacyniak, T.; et al. Low-Density Geopolymer Composites for the Construction Industry. Polymers (Basel) 2022, 14. [Google Scholar] [CrossRef]

- Sarazin, J.; Davy, C.A.; Bourbigot, S.; Tricot, G.; Hosdez, J.; Lambertin, D.; Fontaine, G. Flame Resistance of Geopolymer Foam Coatings for the Fire Protection of Steel. Composites Part B-engineering 2021, 222, 109045. [Google Scholar] [CrossRef]

- Hanun, Y.; Alisjahbana, S.W.; Ma’Soem, D.M.; Setiawan, M.I.; Ahmar, A.S. Designing Cost Production of Concrete. J Phys Conf Ser 2018, 1028. [Google Scholar] [CrossRef]

- Degefu, D.M.; Liao, Z.; Berardi, U.; Labbé, G. The Dependence of Thermophysical and Hygroscopic Properties of Macro-Porous Geopolymers on Si/Al. J Non Cryst Solids 2022. [Google Scholar] [CrossRef]

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13. [Google Scholar] [CrossRef]

- Carabba, L. Cement-Free Building Materials: Mix Design and Properties in View of Their Application in Civil Engineering.; 2018.

- Le, V.S.; Louda, P. Research of Curing Time and Temperature-Dependent Strengths and Fire Resistance of Geopolymer Foam Coated on an Aluminum Plate. Coatings 2021. [Google Scholar] [CrossRef]

- dos Santos, M.N.G.; dos Santos, C.M.; de Souza, M.T.G.; de Vasconcelos, E.A.; Nobrega, A.C.V.; Marinho, É.P. Use of Sodium Metasilicate as Silica Source and Stabilizing Agent in Two–Part Metakaolin–H2o2 Geopolymer Foams. SSRN Electronic Journal 2023. [Google Scholar] [CrossRef]

- Clements, D.H. ‘Concrete’ Manipulatives, Concrete Ideas. Contemporary Issues in Early Childhood 2000, 1, 45–60. [Google Scholar] [CrossRef]

- Wu, H.; Liang, C.; Yang, D.; Ma, Z. Development of sustainable geopolymer materials made with ground geopolymer waste powder as renewable binder up to 100%. Construction and Building Materials 2023, 400, 132746. [Google Scholar] [CrossRef]

- Liu, M.; Wu, H.; Yao, P.; Wang, C.; Ma, Z. Microstructure and macro properties of sustainable alkali-activated fly ash mortar with various construction waste fines as binder replacement up to 100%. Cement and Concrete Composites 2022, 134, 104733. [Google Scholar] [CrossRef]

- Prałat, K.; Ciemnicka, J.; Koper, A.; Szczypiński, M.M.; Łoś, P.; Nguyen, V.V.; Le, V.S.; Rapiejko, C.; Ercoli, R.; Buczkowska, K.E. Determination of the Thermal Parameters of Geopolymers Modified with Iron Powder. Polymers (Basel) 2022, 14. [Google Scholar] [CrossRef]

- Le, V.S.; Louda, P.; Tran, H.N.; Nguyen, P.D.; Bakalova, T.; Buczkowska, K.E.; Dufková, I. Study on Temperature-Dependent Properties and Fire Resistance of Metakaolin-Based Geopolymer Foams. Polymers (Basel) 2020, 12. [Google Scholar] [CrossRef]

- Peng, X.; Li, H.; Shuai, Q.; Wang, L. Fire Resistance of Alkali Activated Geopolymer Foams Produced from Metakaolin and Na2O2. Materials 2020, 13. [Google Scholar] [CrossRef]

- Ye, J.; Zhang, W.; Shi, D. Effect of Elevated Temperature on the Properties of Geopolymer Synthesized from Calcined Ore-Dressing Tailing of Bauxite and Ground-Granulated Blast Furnace Slag. Constr Build Mater 2014, 69, 41–48. [Google Scholar] [CrossRef]

- Chithambaram, S.; Kumar, S.; Prasad, M.M. Thermo-Mechanical Characteristics of Geopolymer Mortar. Constr Build Mater 2019. [Google Scholar] [CrossRef]

- Yang, Z.; Mocadlo, R.; Zhao, M.; Sisson, R.D.; Tao, M.; Liang, J. Preparation of a Geopolymer from Red Mud Slurry and Class F Fly Ash and Its Behavior at Elevated Temperatures. Constr Build Mater 2019. [Google Scholar] [CrossRef]

- Kürklü, G. The Effect of High Temperature on the Design of Blast Furnace Slag and Coarse Fly Ash-Based Geopolymer Mortar. Composites Part B-engineering 2016, 92, 9–18. [Google Scholar] [CrossRef]

- František, Š.; Rostislav, Š.; Zdeněk, T.; Petr, S.; Vít, Š.; Zuzana, Z.C. Preparation and Properties of Fly Ashbased Geopolymer Foams. Ceramics-Silikáty 2014, 58, 188–197. [Google Scholar]

- Hlaváek, P.; milauer, V.; kvára, F.; Kopecký, L.; ulc, R. Inorganic Foams Made from Alkali-Activated Fly Ash: Mechanical, Chemical and Physical Properties. J Eur Ceram Soc 2015, 35, 703–709. [Google Scholar] [CrossRef]

- Cilla, M.S.; de Mello Innocentini, M.D.; Morelli, M.R.; Colombo, P. Geopolymer Foams Obtained by the Saponification/Peroxide/Gelcasting Combined Route Using Different Soap Foam Precursors. Journal of the American Ceramic Society 2017, 100, 3440–3450. [Google Scholar] [CrossRef]

- Liu, L.; Cui, X.; He, Y.; Liu, S.; Gong, S. The Phase Evolution of Phosphoric Acid-Based Geopolymers at Elevated Temperatures. Mater Lett 2012, 66, 10–12. [Google Scholar] [CrossRef]

- Sprayed Concrete Multipurpose Nozzle (2020) | Tong Youdan. Available online: https://typeset.io/papers/sprayed-concrete-multipurpose-nozzle-2zn9lf93qi (accessed on 15 August 2023).

- Concrete Spraying Construction Method (2019) | Wang. Available online: https://typeset.io/papers/concrete-spraying-construction-method-4ix4w13ma1 (accessed on 15 August 2023).

- Concrete Spraying Construction Technology (2019) | Xiao Fulei. Available online: https://typeset.io/papers/concrete-spraying-construction-technology-4x1lmjzcsq (accessed on 15 August 2023).

- Alekseev, V.; Bazhenova, S. Optimization of Concrete Compositions for Sprayed Concrete in the Consruction of Underground Structures. Bulletin of Belgorod State Technological University named after. V. G. Shukhov 2020, 8–17. [Google Scholar] [CrossRef]

- Melbye, T.A.; Dimmock, R.H. Modern Advances and Applications of Sprayed Concrete. Shotcrete: Engineering Developments 2020, 7–29. [CrossRef]

- Le, V.S.; Louda, P.; Tran, H.N.; Nguyen, P.D.; Bakalova, T.; Buczkowska, K.E.; Dufková, I. Study on Temperature-Dependent Properties and Fire Resistance of Metakaolin-Based Geopolymer Foams. Polymers (Basel) 2020, 12. [Google Scholar] [CrossRef]

- Sharma, A.S. Influence of Foam Densities in Cellular Lightweight Concrete. Int J Res Appl Sci Eng Technol 2017, 1078–1089. [Google Scholar] [CrossRef]

- Le, V.S. Thermal Conductivity Of Reinforced Geopolymer Foams. Ceramics - Silikaty 2019. [Google Scholar] [CrossRef]

- Bai, C.; Franchin, G.; Elsayed, H.; Zaggia, A.; Conte, L.; Li, H. , et al., “High-porosity geopolymer foams with tailored porosity for thermal insulation and wastewater treatment,” Journal of Materials Research, vol. 32, pp. 3251-3259, 2017. [CrossRef]

- Novais, R.M.; Buruberri, L.; Ascensão, G.; Seabra, M.; Labrincha, J. , “Porous biomass fly ash-based geopolymers with tailored thermal conductivity,” Journal of cleaner production, vol. 119, pp. 99-107, 2016. [CrossRef]

- Hlaváček, P.; Šmilauer, V.; Škvára, F.; Kopecký, L.; Šulc, R. , “Inorganic foams made from alkali-activated fly ash: Mechanical, chemical and physical properties,” Journal of the European Ceramic Society, vol. 35, pp. 703-709, 2015. [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. , “Mechanical, thermal insulation, thermal resistance and acoustic absorption properties of geopolymer foam concrete,” Cement and Concrete Composites, vol. 62, pp. 97-105, 2015. [CrossRef]

- Papa, E.; Medri, V.; Kpogbemabou, D.; Morinière, V.; Laumonier, J.; Vaccari, A. , et al., “Porosity and insulating properties of silica-fume based foams,” Energy and Buildings, vol. 131, pp. 223-232, 2016. [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P.; Sanjayan, J. , “Regulating the chemical foaming reaction to control the porosity of geopolymer foams,” Materials & Design, vol. 120, pp. 255-265, 2017. [CrossRef]

- Bai, C.; Ni, T.; Wang, Q.; Li, H.; Colombo, P. , “Porosity, mechanical and insulating properties of geopolymer foams using vegetable oil as the stabilizing agent,” Journal of the European Ceramic Society, vol. 38, pp. 799-805, 2018. [CrossRef]

- Kamseu, E.; Ngouloure, Z.N.; Ali, B.N.; Zekeng, S.; Melo, U.; Rossignol, S. , et al., “Cumulative pore volume, pore size distribution and phases percolation in porous inorganic polymer composites: Relation microstructure and effective thermal conductivity,” Energy and buildings, vol. 88, pp. 45-56, 2015. [CrossRef]

- Prud’homme, E.; Joussein, E.; Rossignol, S. , “Use of silicon carbide sludge to form porous alkali-activated materials for insulating application,” The European Physical Journal Special Topics, vol. 224, pp. 1725-1735, 2015. [CrossRef]

- Rickard, W.D.; Vickers, L.; Van Riessen, A. , “Performance of fibre reinforced, low density metakaolin geopolymers under simulated fire conditions,” Applied Clay Science, vol. 73, pp. 71-77, 2013. [CrossRef]

- Novais, R.M.; Ascensão, G.; Buruberri, L.; Senff, L.; Labrincha, J. , “Influence of blowing agent on the fresh-and hardened-state properties of lightweight geopolymers,” Materials & Design, vol. 108, pp. 551-559, 2016. [CrossRef]

- Rickard, W.D.; Van Riessen, A. , “Performance of solid and cellular structured fly ash geopolymers exposed to a simulated fire,” Cement and Concrete Composites, vol. 48, pp. 75-82, 2014. [CrossRef]

- Feng, J.; Zhang, R.; Gong, L.; Li, Y.; Cao, W.; Cheng, X. , “Development of porous fly ash-based geopolymer with low thermal conductivity,” Materials & Design (1980-2015), vol. 65, pp. 529-533, 2015. [CrossRef]

- Han, F.; Seiffert, G.; Zhao, Y.; Gibbs, B. , “Acoustic absorption behaviour of an open-celled aluminium foam,” Journal of Physics D: Applied Physics, vol. 36, p. 294, 2003. [CrossRef]

- Ravindrarajah, R.S.; Jones, W. Properties of adjusted density high-performance concrete. Futures in Mechanics of Structures and Materials 2008, 351. [Google Scholar]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. , “Geopolymer foam concrete: An emerging material for sustainable construction,” Construction and Building Materials, vol. 56, pp. 113-127, 2014. [CrossRef]

- Jaya, N.A.; Yun-Ming, L.; Cheng-Yong, H.; Abdullah, M.M.A.B.; Hussin, K. , Correlation between pore structure, compressive strength and thermal conductivity of porous metakaolin geopolymer, Constr. Build. Mater. 2020; 12. [Google Scholar] [CrossRef]

- Palmero, P.; Formia, A.; Antonaci, P.; Brini, S.; Tulliani, J.M. , Geopolymer technology for application-oriented dense and lightened materials. Elaboration and characterization, Ceram. Int. 41 (10) (2015) 12967–12979. [CrossRef]

- Bai, C.; Ni, T.; Wang, Q.; Li, H.; Colombo, P. , Porosity, mechanical and insulating properties of geopolymer foams using vegetable oil as the stabilizing agent, J. Eur. Ceram. Soc. 38 (2) (2018) 799–805. [CrossRef]

- Murri, A.N.; Medri, V.; Papa, E.; Laghi, L.; Mingazzini, C.; Landi, E. , Porous geopolymer insulating core from a metakaolin/biomass ash composite, Environ. 2017; 13. [Google Scholar] [CrossRef]

- Bai, C. , et al., High-porosity geopolymer foams with tailored porosity for thermal insulation and wastewater treatment, J. Mater. Res. 2017. [Google Scholar] [CrossRef]

- Qiao, Y.; et al. , Effects of surfactants/stabilizing agents on the microstructure and properties of porous geopolymers by direct foaming, J. Asian Ceram. Soc. 2021. [Google Scholar] [CrossRef]

- Bai, C.; Franchin, G.; Elsayed, H.; Conte, A.; Colombo, P. , High strength metakaolinbased geopolymer foams with variable macroporous structure, J. Eur. Ceram. Soc. 2016. [Google Scholar] [CrossRef]

- Degefu, D.M.; Liao, Z.; Berardi, U.; Labb’e, G. The effect of activator ratio on the thermal and hygric properties of aerated geopolymers. J. Build. Eng. 2022, 45, 103414. [Google Scholar] [CrossRef]

- Novais, R.M.; Buruberri, L.H.; Ascensão, G.; Seabra, M.P.; Labrincha, J.A. Porous biomass fly ash-based geopolymers with tailored thermal conductivity. J Clean Prod 2016;119:99–107. [CrossRef]

- Bai C, Ni T, Wang Q, Li H, Colombo P. Porosity, mechanical and insulating properties of geopolymer foams using vegetable oil as the stabilizing agent. J Eur Ceram Soc 2018;38:799–805. [CrossRef]

- Bai C, Li H, Bernardo E, Colombo P. Waste-to-resource preparation of glass-containing foams from geopolymers. Ceram Int 2019;45:7196–202. [CrossRef]

- Dembovska L, Bajare D, Ducman V, Korat L, Bumanis G. The use of different by-products in the production of lightweight alkali activated building materials. Constr Build Mater 2017;135:315–22. [CrossRef]

- Xu F, Gu G, Zhang W, Wang H, Huang X, Zhu J. Pore structure analysis and properties evaluations of fly ash-based geopolymer foams by chemical foaming method. Ceram Int 2018;44:19989–97. [CrossRef]

- De Rossi A, Carvalheiras J, Novais RM, Ribeiro MJ, Labrincha JA, Hotza D, et al. Waste-based geopolymeric mortars with very high moisture buffering capacity. Constr Build Mater 2018;191:39–46. [CrossRef]

- Zaidi SFA, Ul Haq E, Nur K, Ejaz N, Anis-ur-Rehman M, Zubair M, et al. Synthesis & characterization of natural soil based inorganic polymer foam for thermal insulations. Constr Build Mater 2017;157:994–1000. [CrossRef]

- Font A, Borrachero MV, Soriano L, Monzó J, Payá J. Geopolymer eco-cellular concrete (GECC) based on fluid catalytic cracking catalyst residue (FCC) with addition of recycled aluminium foil powder. J Clean Prod 2017;168:1120–31. [CrossRef]

- Verdolotti, L.; Liguori, B.; Capasso, I.; Errico, A.; Caputo, D.; Lavorgna, M.; Iannace, S. Synergistic Effect of Vegetable Protein and Silicon Addition on Geopolymeric Foams Properties. J Mater Sci 2015, 50, 2459–2466. [Google Scholar] [CrossRef]

- Novais, R.M.; Pullar, R.C.; Labrincha, J.A. Geopolymer Foams: An Overview of Recent Advancements. Prog Mater Sci 2020, 109, 100621. [Google Scholar] [CrossRef]

| Binder |

Silica fume/ Baucis lk |

Sand/ Baucis lk |

Basalt Fiber/ Baucis lk |

Al Powder/ Baucis lk |

Note. | |

| Baucis lk |

Activator/ Baucis lk |

|||||

| 1 | 0.9 | 0.05 | 1 | 0.083 | 0.006 | Foamed geo. |

| 1 | 0.9 | 0.05 | 1 | 0.083 | - | Non-foam geo. |

| Scheme 3. |

Compressive strength, σc, MPa |

Bending strength, σf, MPa |

Density, ρ, kg/m3 |

Thermal conductivity λ [W/(m·K)] |

Thermal resistance [m2·K/W] |

Porosity, % |

Production cost, $/м3 |

| Foam | 3.05 ± 0.27 | 0.8 ± 0.07 | 670 ± 0.047 | 0.164 ± 0.002 | 0.084 ± 0.001 | 68*/58** | 250 |

| Non-foam | 33.1 ± 0.11 | 10.8 ± 0.93 | 1520 ± 0.086 | 0.901 ± 0.127 | 0.018 ± 0.003 | - | 450 |

| Density (g/cm3) | Thermal conductivity (W/M·K) | Porosity (%) | References |

| 0.471-1.212 | 0.11-0.30 | 36-86 | [48] |

| 0.33-1.66 | 0.12-0.78 | - | [49] |

| 0.37-0.74 | 0.11-0.17 | 66-83 | [50] |

| 0.31 | 0.73 | - | [51] |

| 0.3-0.75 | 0.289-0.091 | 67.6-86.5 | [52] |

| 0.546-1.028 | 0.13-0.359 | 41.8-62.5 | [53] |

| 0.35-1.2 | - | 50-86 | [54] |

| 0.26-0.51 | - | 62-89.2 | [55] |

| 0.46-0.5 | 0.085-0.1 | 56.48-64.03 | [56] |

| 0.46-0.53 | 0.08-0.1 | 52.82-55.71 | [5] |

| 0.56-1.20 | 0.107-0.432 | 42-73 | [57] |

| 0.37-0.74 | 0.11-0.17 | 66-83 | [58] |

| 0.27-0.48 | 0.11-0.15 | 77-88 | [59] |

| 0.38-0.47 | 0.14-0.15 | 83-86 | [60] |

| 0.14-1.02 | 0.183-0.646 | 32-63 | [61] |

| 1.0-1.7 | 0.19-0.44 | 44-56 | [62] |

| 0.92 | 0.21 | 54.5 | [63] |

| 0.86-1.09 | 0.267-0.334 | 54.8-63.1 | [64] |

| 0.63-0.79 | 0.581-0.7 | 60-75 | [65] |

| 0.67 | 0.164 | 68 | This work |

| 1.52 | 0.901 | - | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).