Submitted:

26 August 2023

Posted:

29 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

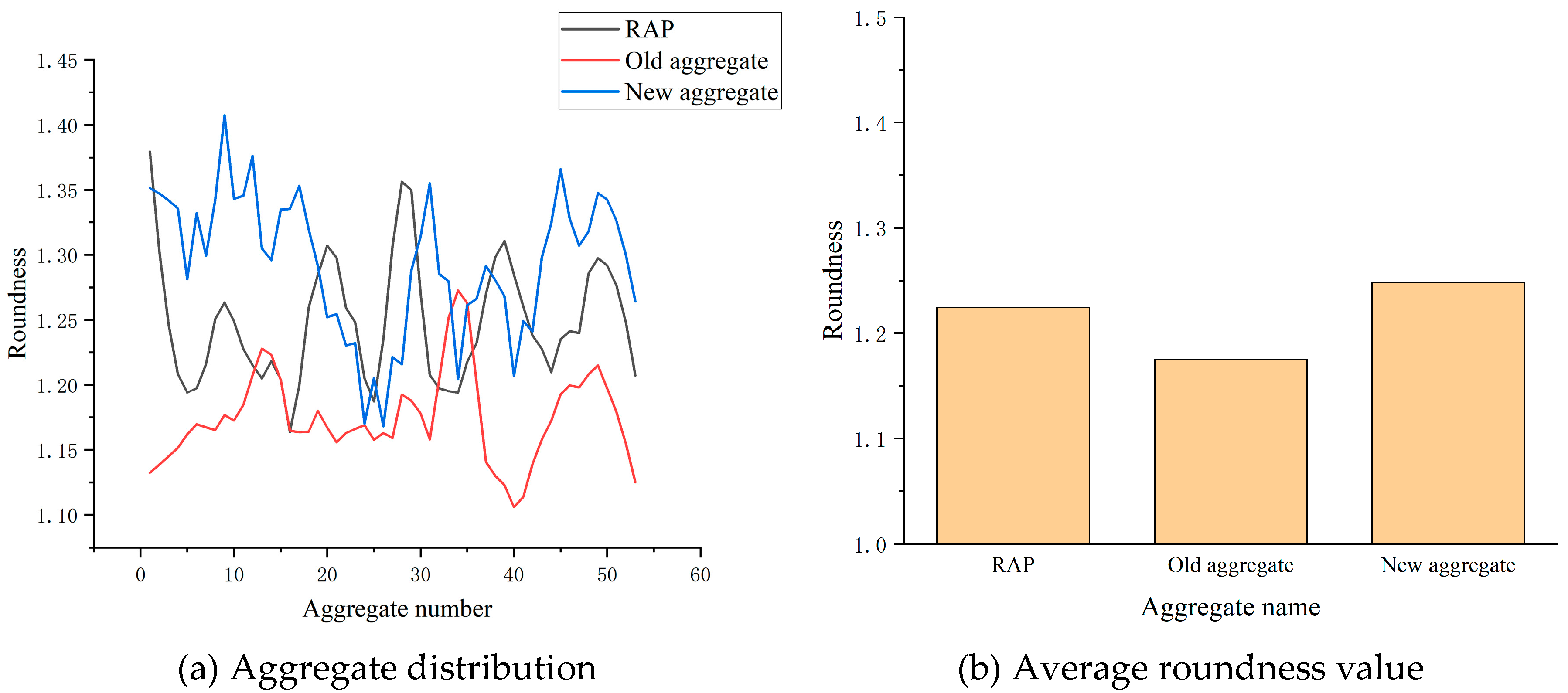

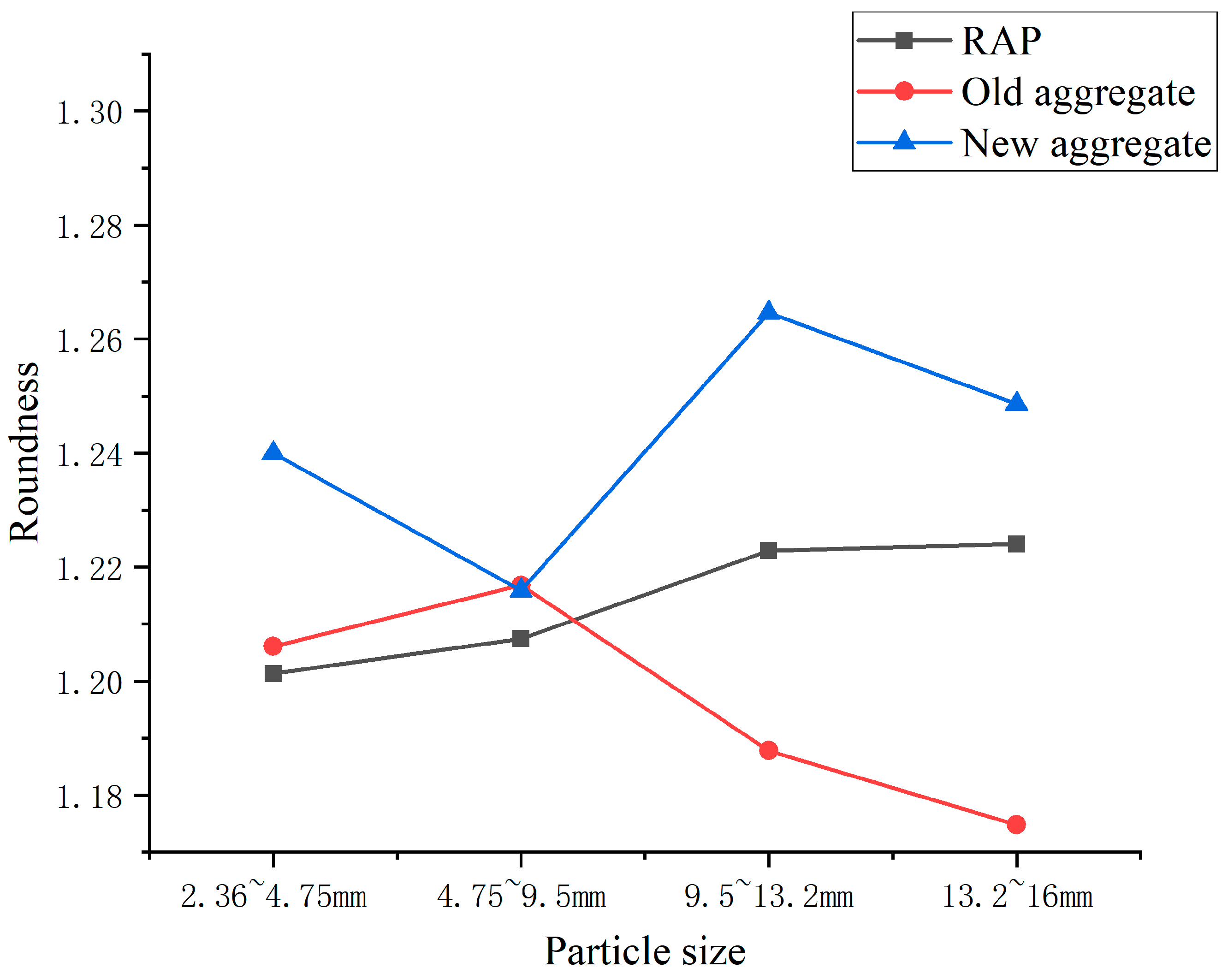

2. Study on the roundness characteristics of asphalt mixture recovery material

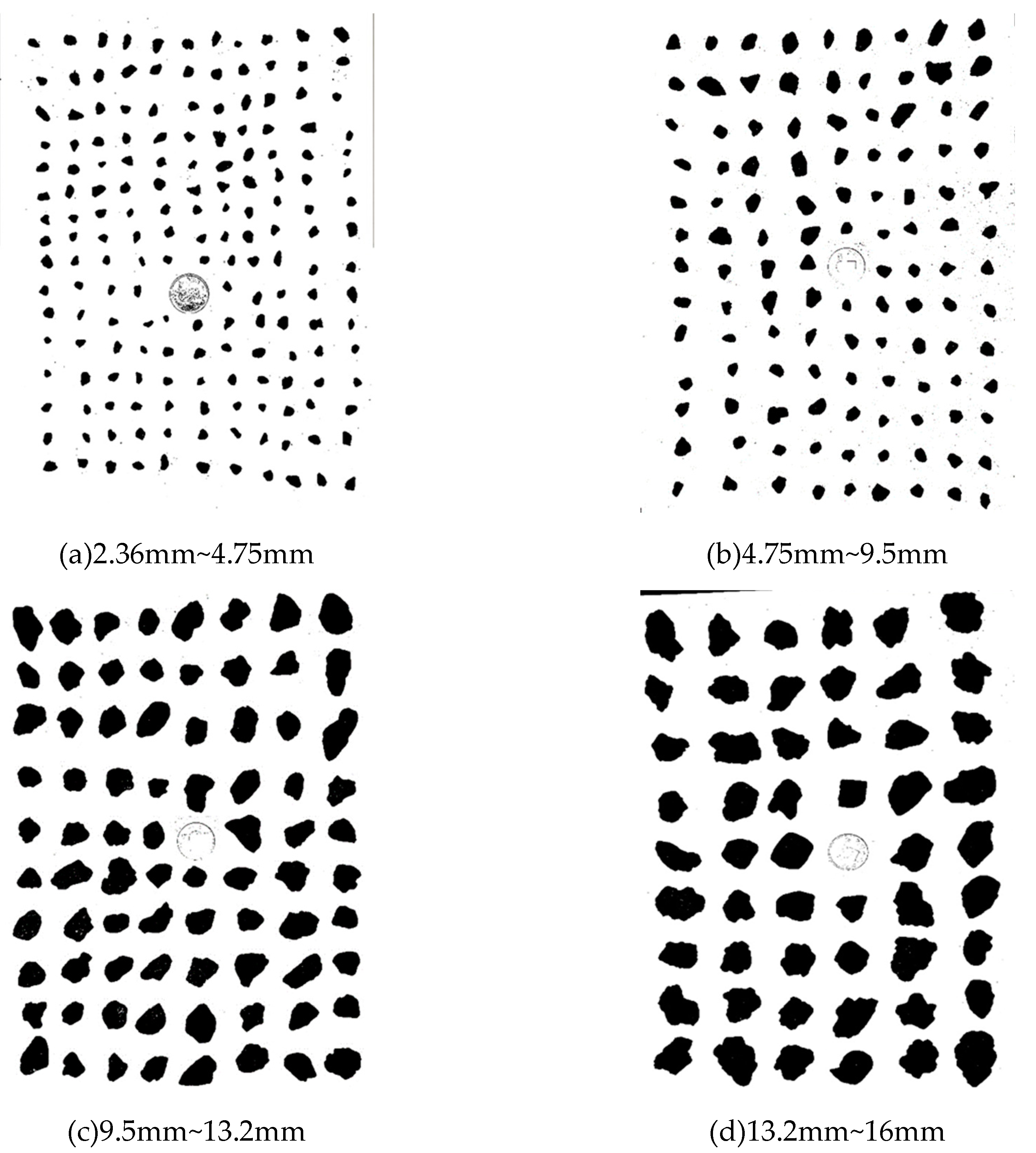

2.1. Acquisition and definition of aggregate rounarity characteristics

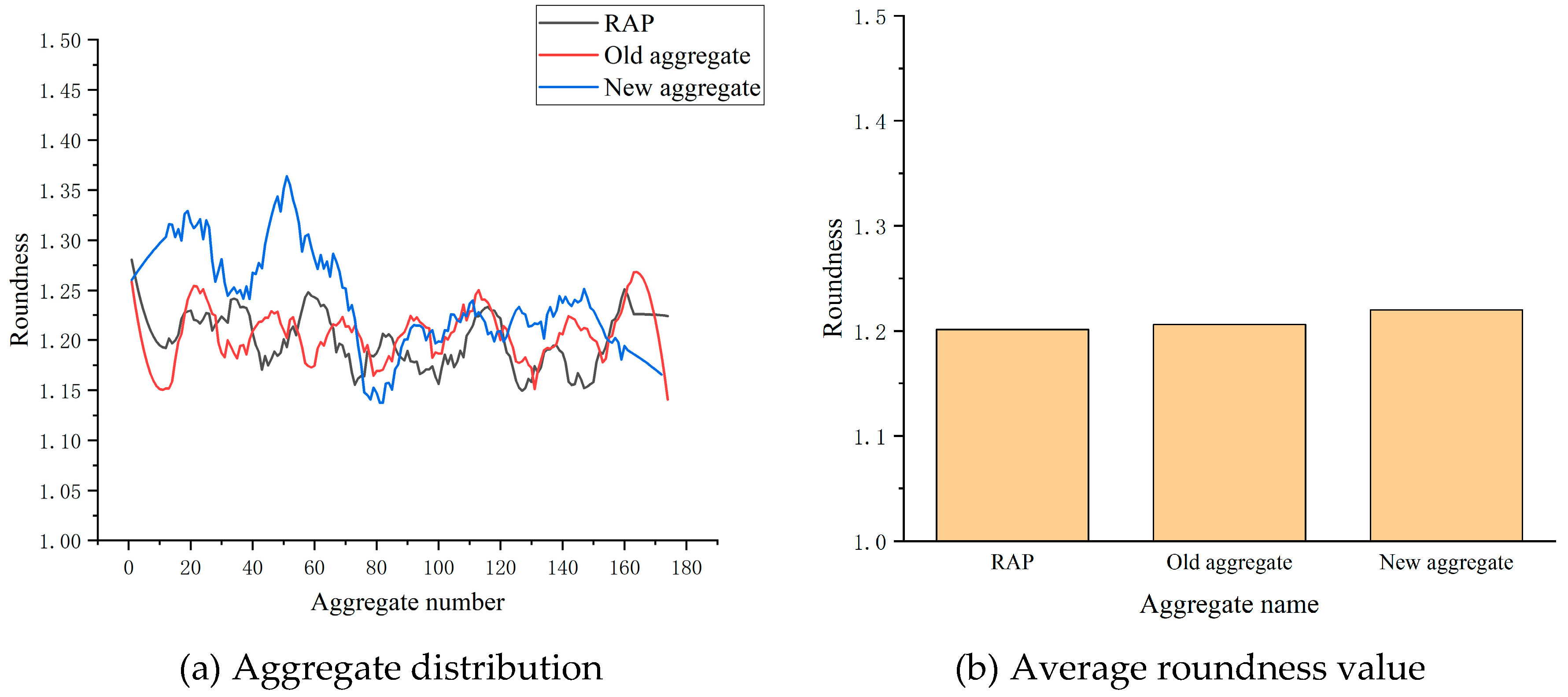

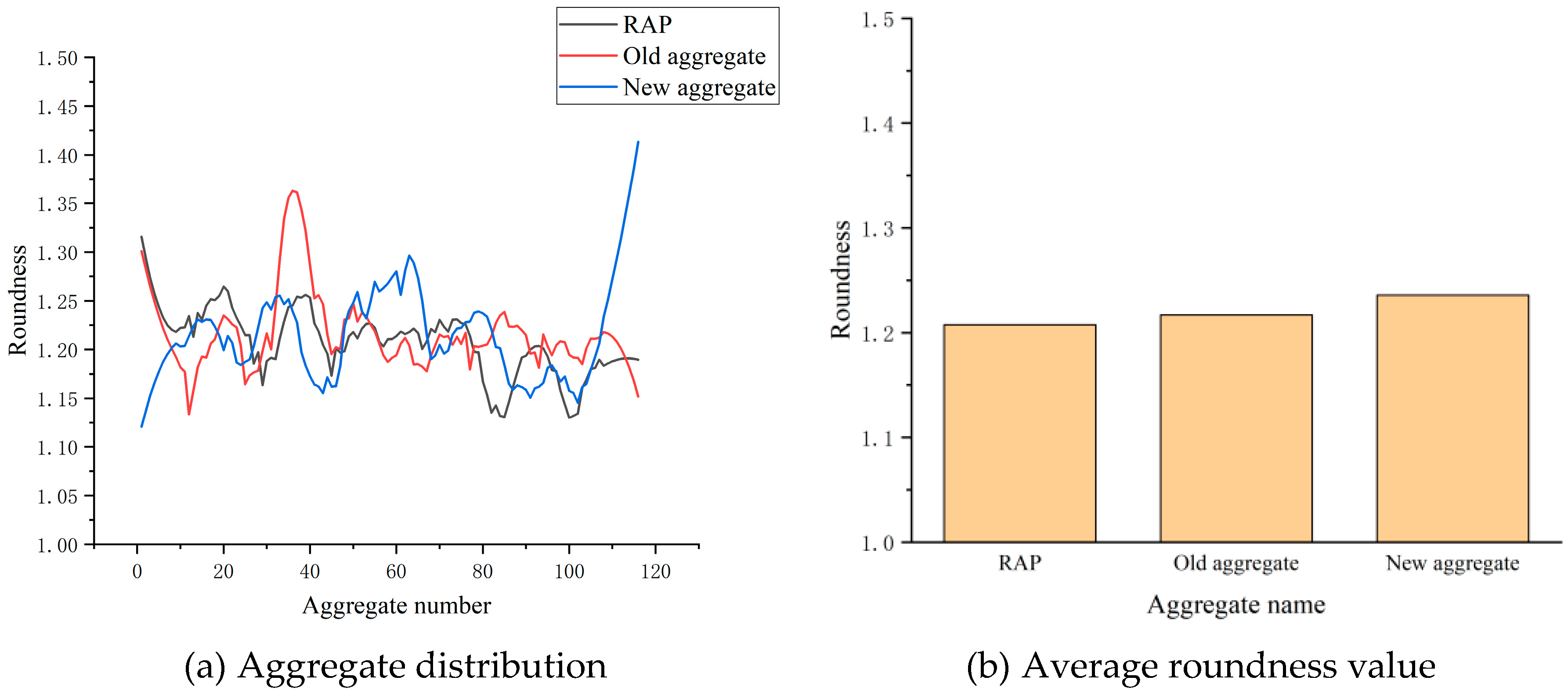

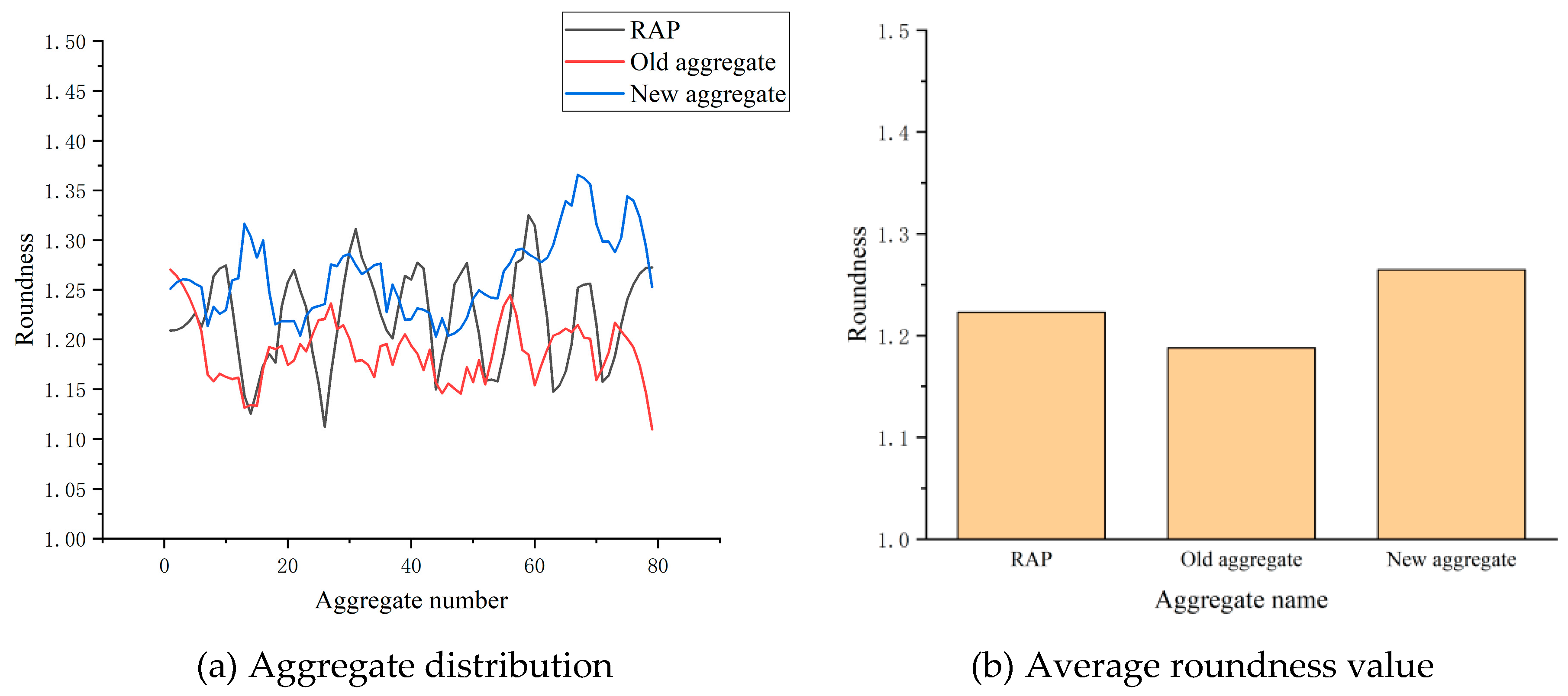

2.2. Analysis of roundness characteristics of aggregate of each size

3. The Influence of Roundness Characteristics on the Road Performance of Mixture

3.1. Grading design of reclaimed asphalt mixture

| Blending type | Grading One | Grading Two | Grading Three |

|---|---|---|---|

| Roundness | 1.2612 | 1.2291 | 1.1983 |

3.2. Effect of roundness on low-temperature performance

| Blending type | 9.5mm~16mm aggregate roundness | Flexural strength/MPa | Bending stiffness modulus/MPa | |

|---|---|---|---|---|

| Grading One | 1.2612 | 2901 | 8.76 | 5528 |

| Grading Two | 1.2291 | 2865 | 8.55 | 5281 |

| Grading Three | 1.1983 | 2832 | 8.41 | 5017 |

3.3. Effect of roundness on high temperature performance

3.4. Effect of roundness on water stability performance

4. Conclusion

References

- Tarsi G, Tataranni P , Sangiorgi C. The Challenges of Using Reclaimed Asphalt Pavement for New Asphalt Mixtures: A Review[J].Materials, 2020, 13(18): 4052. [CrossRef]

- Roja K L, Masad E, Mogawer W. Performance and blending evaluation of asphalt mixtures containing reclaimed asphalt pavement[J].Road Materials and Pavement Design, 2021,22(11): 2441-2457. [CrossRef]

- Zhou Z, Gu X, Jiang J, et al. Fatigue cracking performance evaluation of laboratory-produced polymer modified asphalt mixture containing reclaimed asphalt pavement material[J]. Construction and Building Materials, 2019, 216: 379-389. [CrossRef]

- Shatarat Nasim K,Katkhuda Hasan N,Hyari Khaled H,Asi Ibrahim.Effect of using recycled coarse aggregate and recycled asphalt pavement on the properties of pervious concrete[J]. Structural Engineering and Mechanics,2018, 67(3): 283-290. [CrossRef]

- Yang Jiangang, Tao Wenjie, Gao Jie, et al.Measurement of particle agglomeration and aggregate breakdown of reclaimed asphalt pavement[J].Construction and Building Materials, 2021, 296(Aug.16): 123681.1-123681.14. [CrossRef]

- Rout MKD, Sahdeo SK, Biswas S, Roy K. Feasibility Study of Reclaimed Asphalt Pavements (RAP) as Recycled Aggregates Used in Rigid Pavement Construction[J].Materials, 2023, 16(4):1504. [CrossRef]

- Liu S,Xu Y,Meng H . Laboratory evaluation of PE modified asphalt mixture containing reclaimed asphalt pavement[J]. Indian journal of engineering and materials sciences,2019(1):26.

- Paluri Y,Heeralal M,Kumar P R.A study on the use of reclaimed asphalt pavement aggregates in pavement quality concrete[J].CEMENT WAPNO BETON,2019,24(6):421. [CrossRef]

- Poursoltani M, Hesami S. Performance evaluation of microsurfacing mixture containing reclaimed asphalt pavement[J]. International Journal of Pavement Engineering, 2020,21(12): 1491-1504. [CrossRef]

- Guo Peng, Wei Wanfeng, Tang Boming, Yang Fan. Evaluation of High-temperature Performance of Asphalt Mixture based on Angularity of Recycled Coarse Aggregate[J].Highway, 2017, 62 (9): 220-225. [CrossRef]

- Gang Zengjun. Impact of Morphological Characteristics of Aggregate Particles on High Temperature Performance of Asphalt Mixture[J].Road Machinery & Construction Mechanization, 2017, 34(1): 47-51.

- Wang Chaofan. Study on image analysis of aggregate morphological features and mixture grading[D].Xi 'an: Chang' an University, 2011.

- Diao Zhijun. Analysis of mechanical properties of asphalt mixture based on morphological characteristic parameters of coarse aggregate[D].Liaoning province: Jilin University, 2020.

- Liu Y,Huang Y,Sun W, et al.Effect of coarse aggregate morphology on the mechanical properties of stone matrix asphalt[J]. Construction and Building Materials, 2017, 152: 48-56. [CrossRef]

- Aragão F T S, Pazos A R G, da Motta L M G, et al.Effects of morphological characteristics of aggregate particles on the mechanical behavior of bituminous paving mixtures[J].Construction and Building Materials, 2016, 123: 444-453. [CrossRef]

- Bao Yingning, Bao Sheng.Experimental study on the influence of coarse aggregate characteristics on the skid resistance of asphalt pavement[M].Yunnan Provincial Transportation Planning and Design and Research Institute,2016.

| Inspection items | Needle-like(%) | Aggregate crushing value(%) | Abrasion loss(%) | Water absorption rate(%) | Apparent relative density(~) | Adhesiveness (degree) |

|---|---|---|---|---|---|---|

| measured value | 11.2 | 21.3 | 24.1 | 1.32 | 2.53 | 4 |

| standard value | >20 | >30 | >35 | >3.0 | >2.45 | >3.0 |

| Blending type | Aggregate type | ||||

|---|---|---|---|---|---|

| RAP fineness mixing content(%) | 4.75~9.5mm RAP content(%) | 9.5~16mm RAP content(%) | New aggregate content(%) | Mineral powder dosage(%) | |

| Grading One | 10 | 20 | 0 | 67 | 3 |

| Grading Two | 10 | 10 | 10 | 67 | |

| Grading Three | 10 | 0 | 20 | 67 | |

| Blending type | 9.5mm~16mm aggregate roundness | Dynamic stability (times/mm) | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | average value | ||

| Grading One | 1.2612 | 2347 | 2394 | 2315 | 2352 |

| Grading Two | 1.2291 | 2235 | 2301 | 2259 | 2265 |

| Grading Three | 1.1983 | 2145 | 2103 | 2178 | 2142 |

| Blending type | 9.5mm~16mm aggregate roundness | Residual stability(%) | Freeze-thaw splitting strength ratio(%) |

|---|---|---|---|

| Grading One | 1.2612 | 95.51 | 92.57 |

| Grading Two | 1.2291 | 93.43 | 91.33 |

| Grading Three | 1.1983 | 90.54 | 90.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).