Submitted:

27 August 2023

Posted:

29 August 2023

You are already at the latest version

Abstract

Keywords:

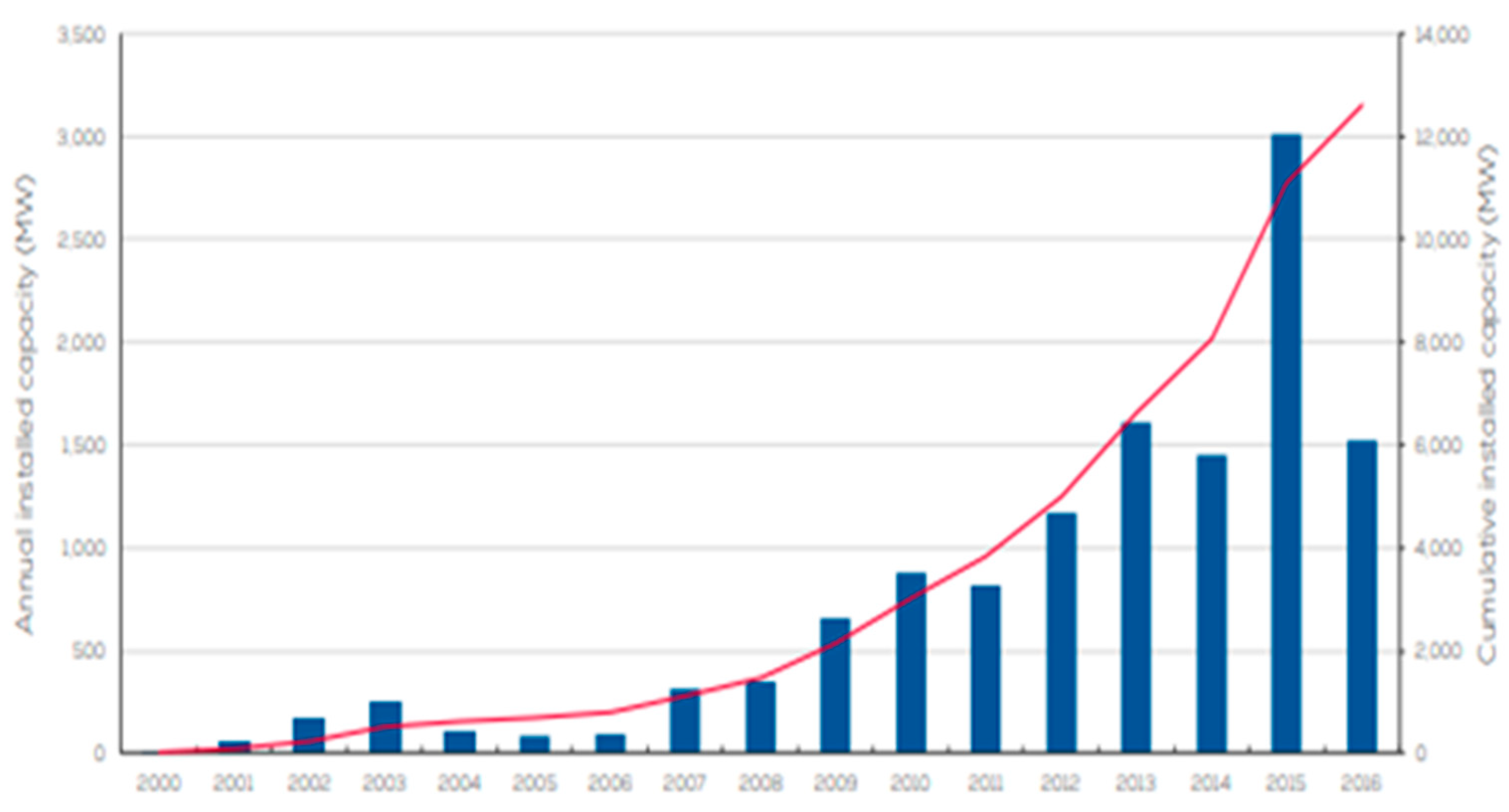

1. Introduction

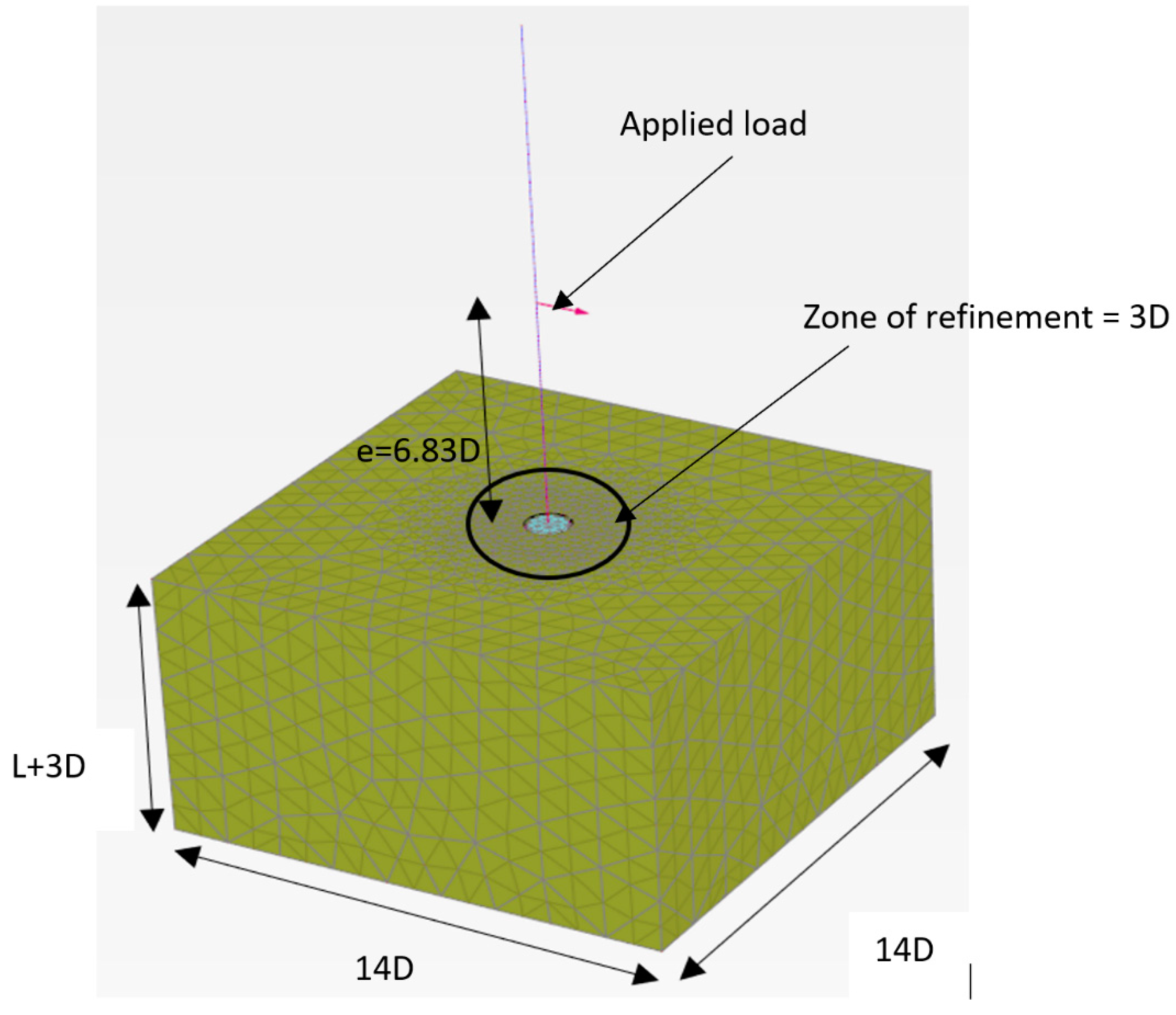

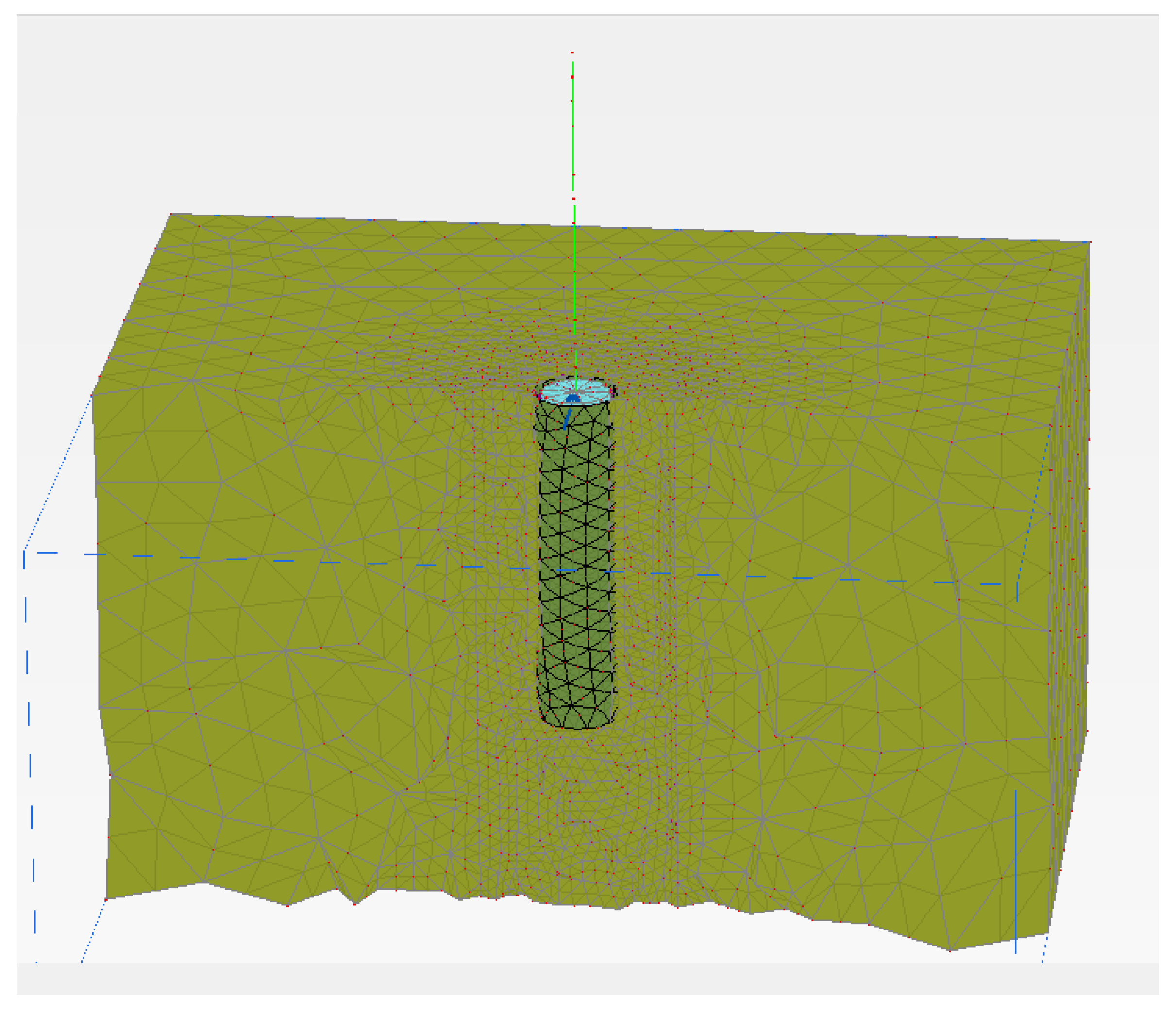

1.1. Methodology

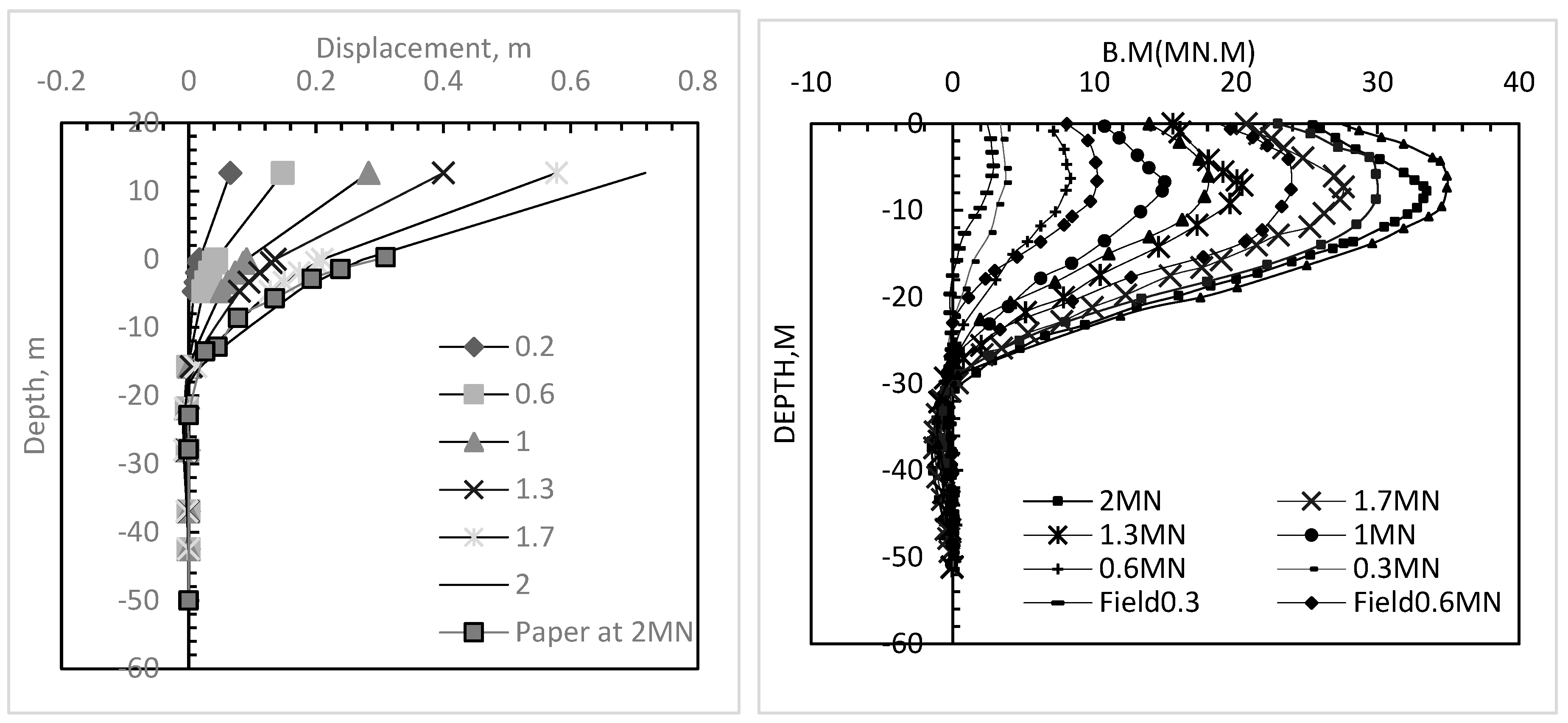

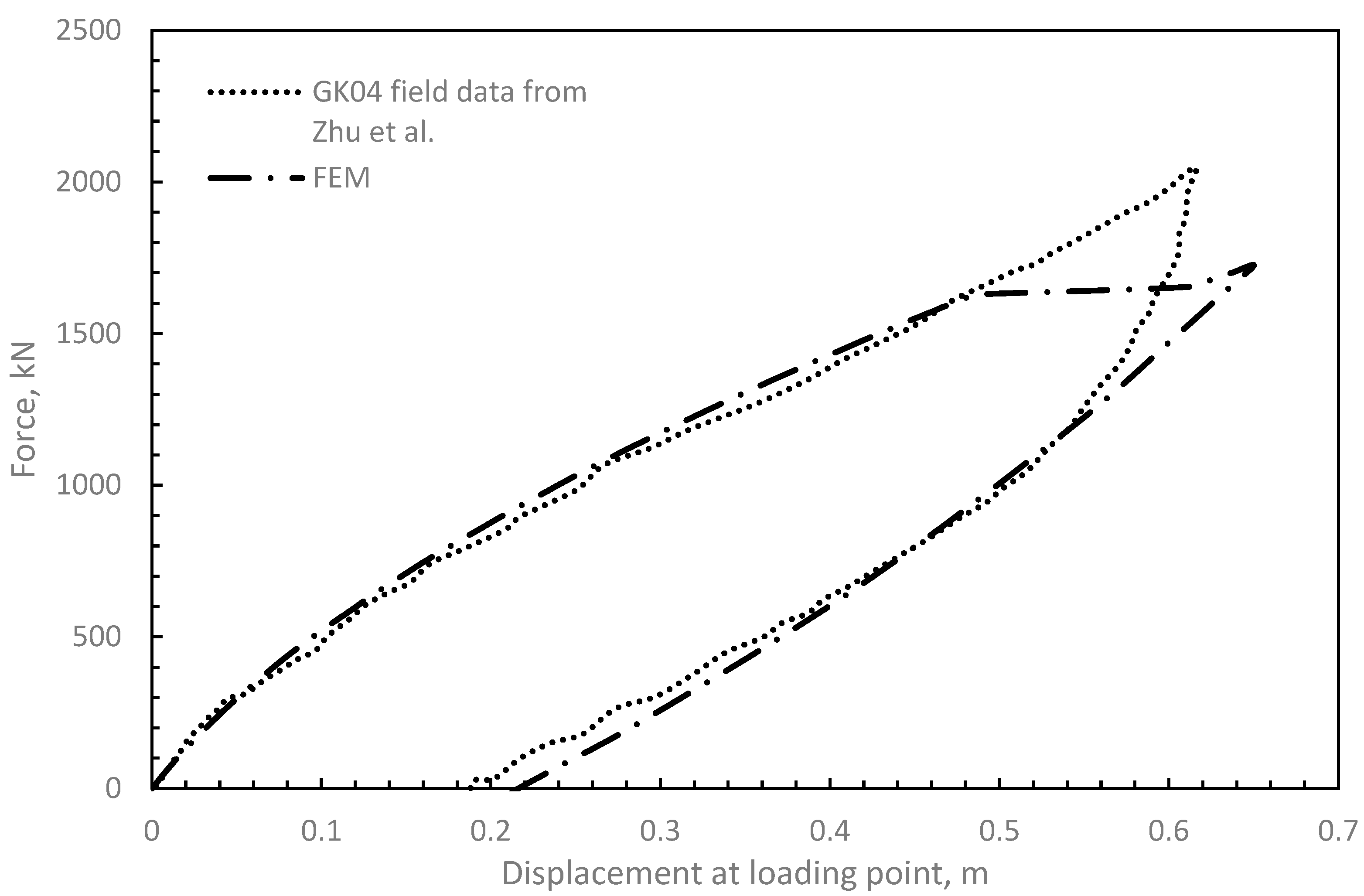

1.1.1. Validation

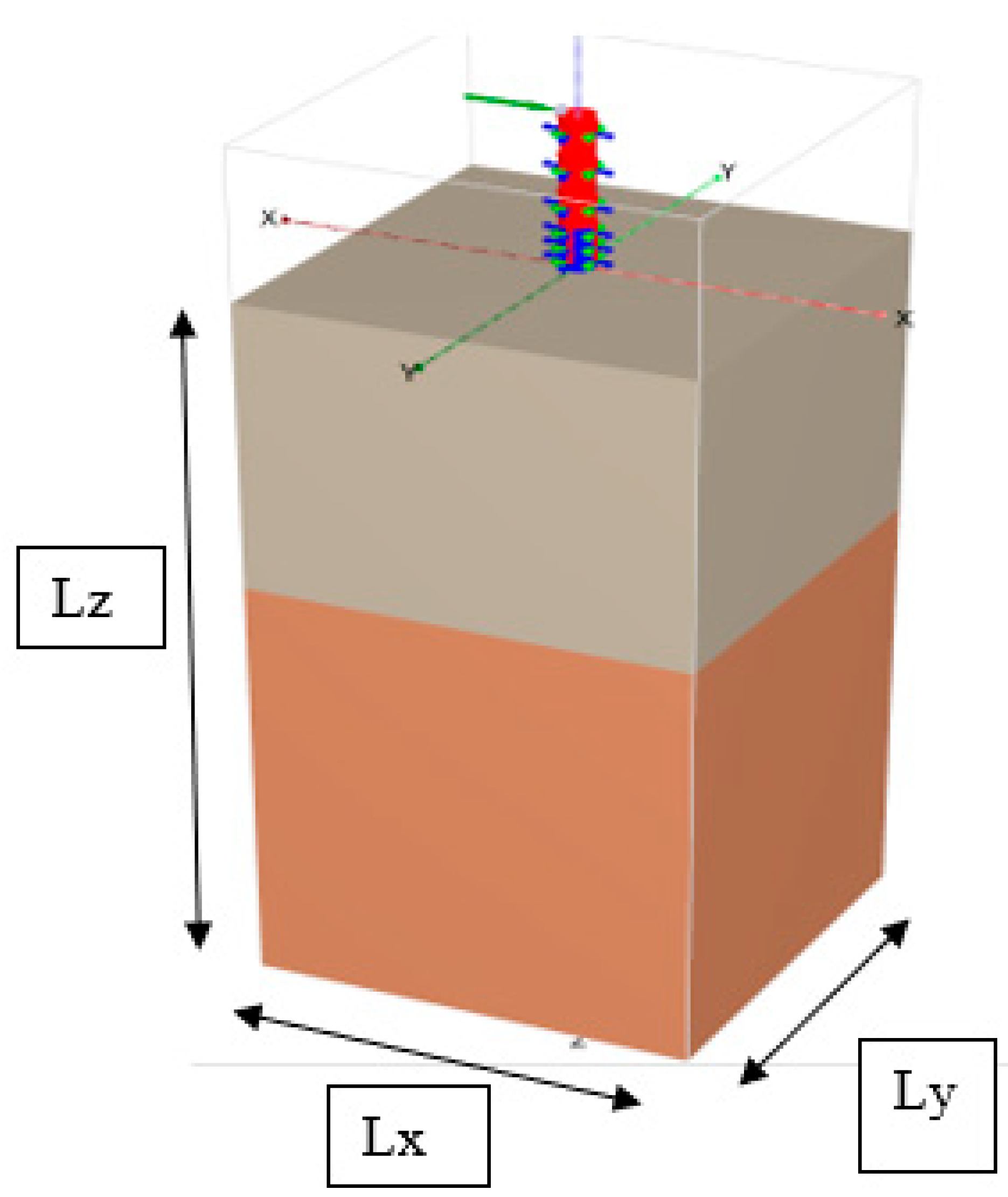

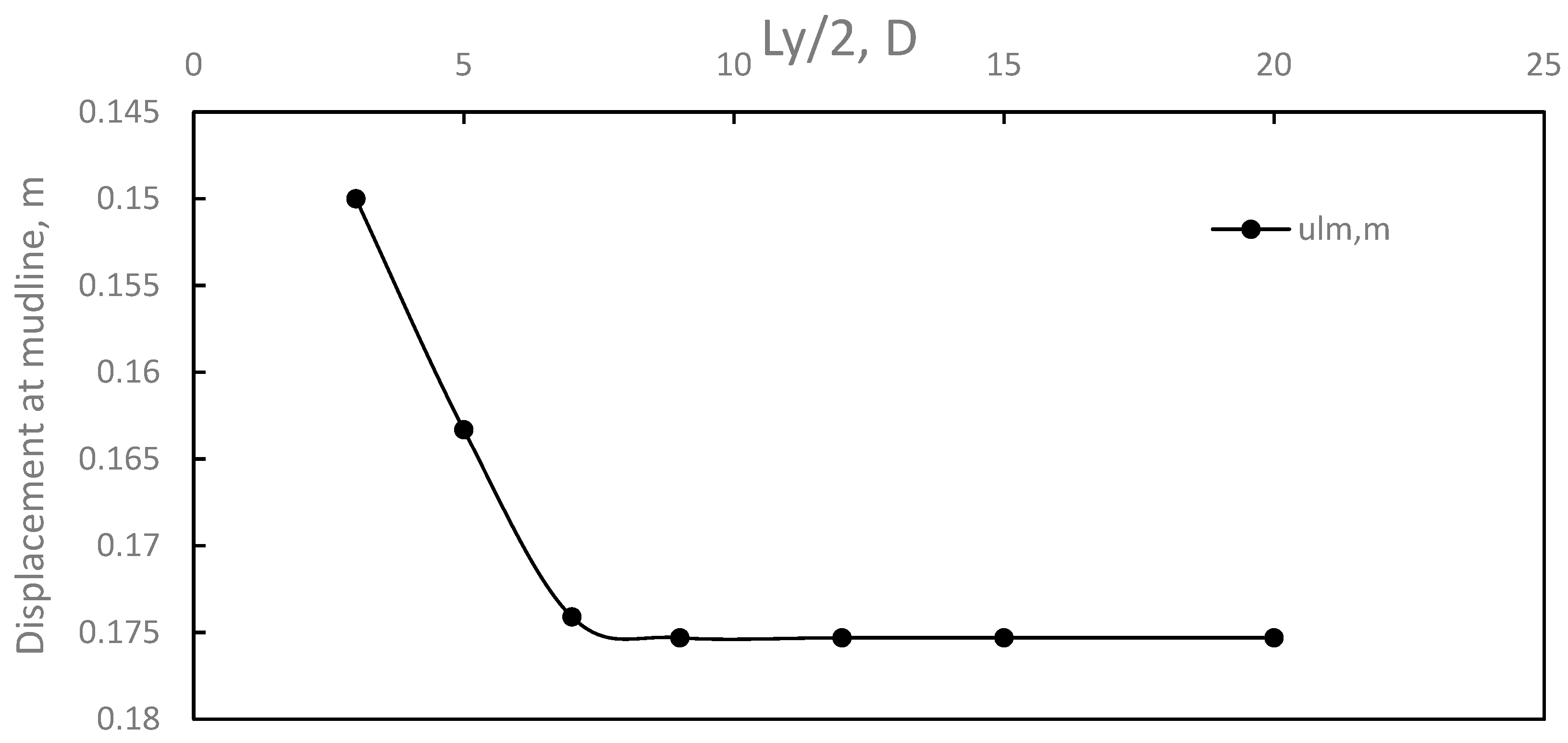

1.1.2. Convergence study

2. Parameter study

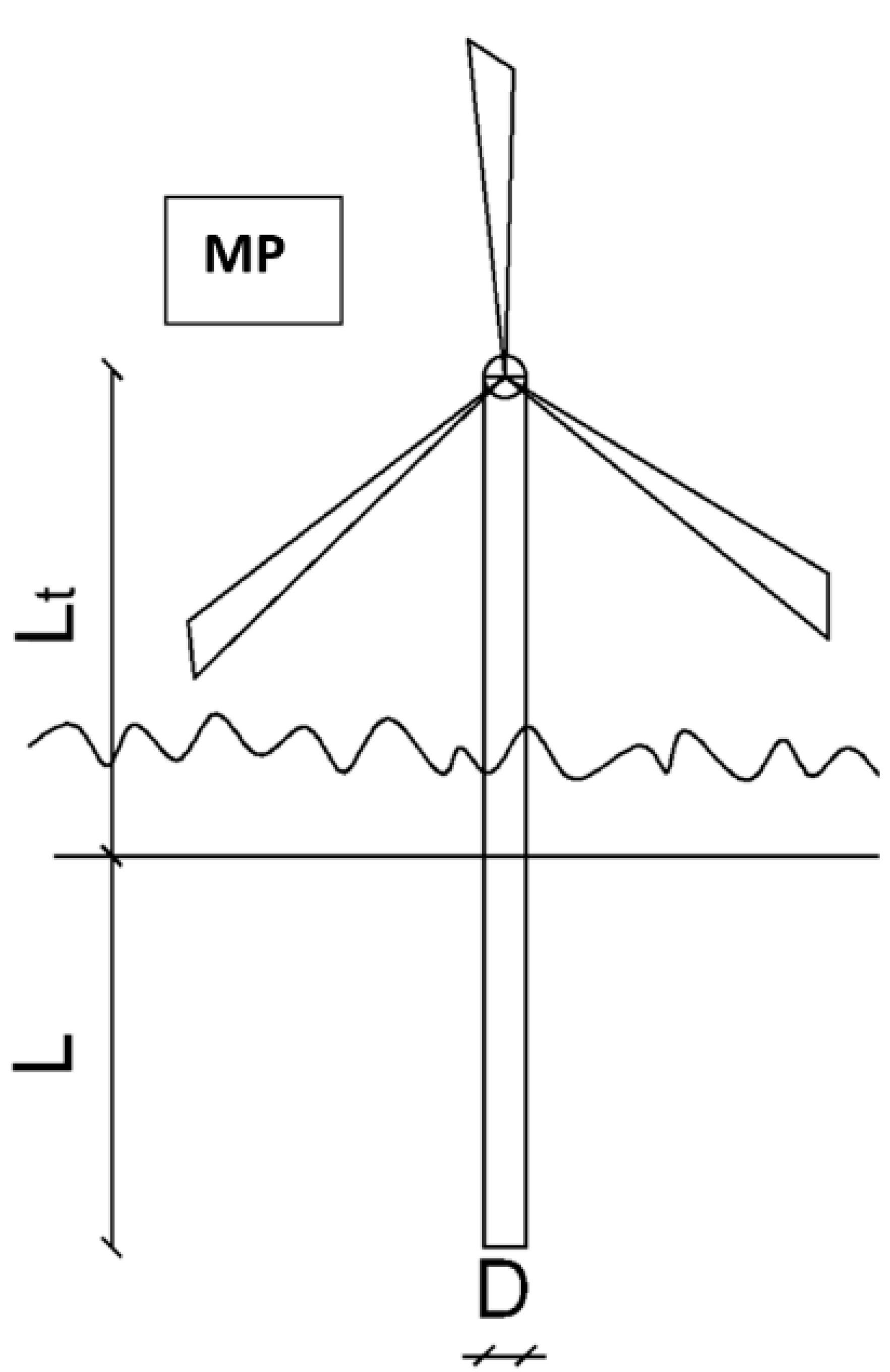

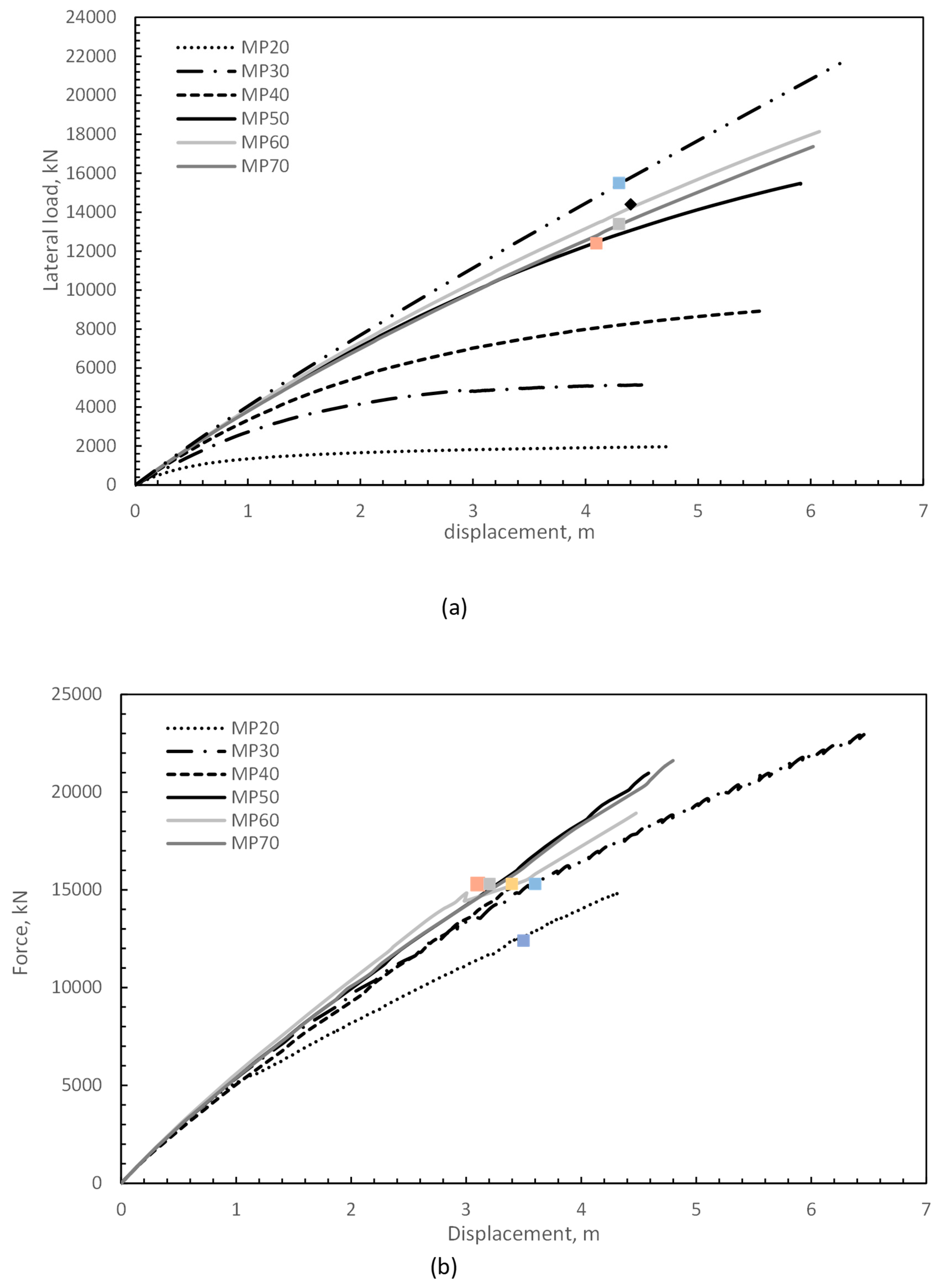

2.1.1. Monopile lateral ultimate capacity

3. Results

4. Discussion

4.1. Discussion of lateral ultimate capacity

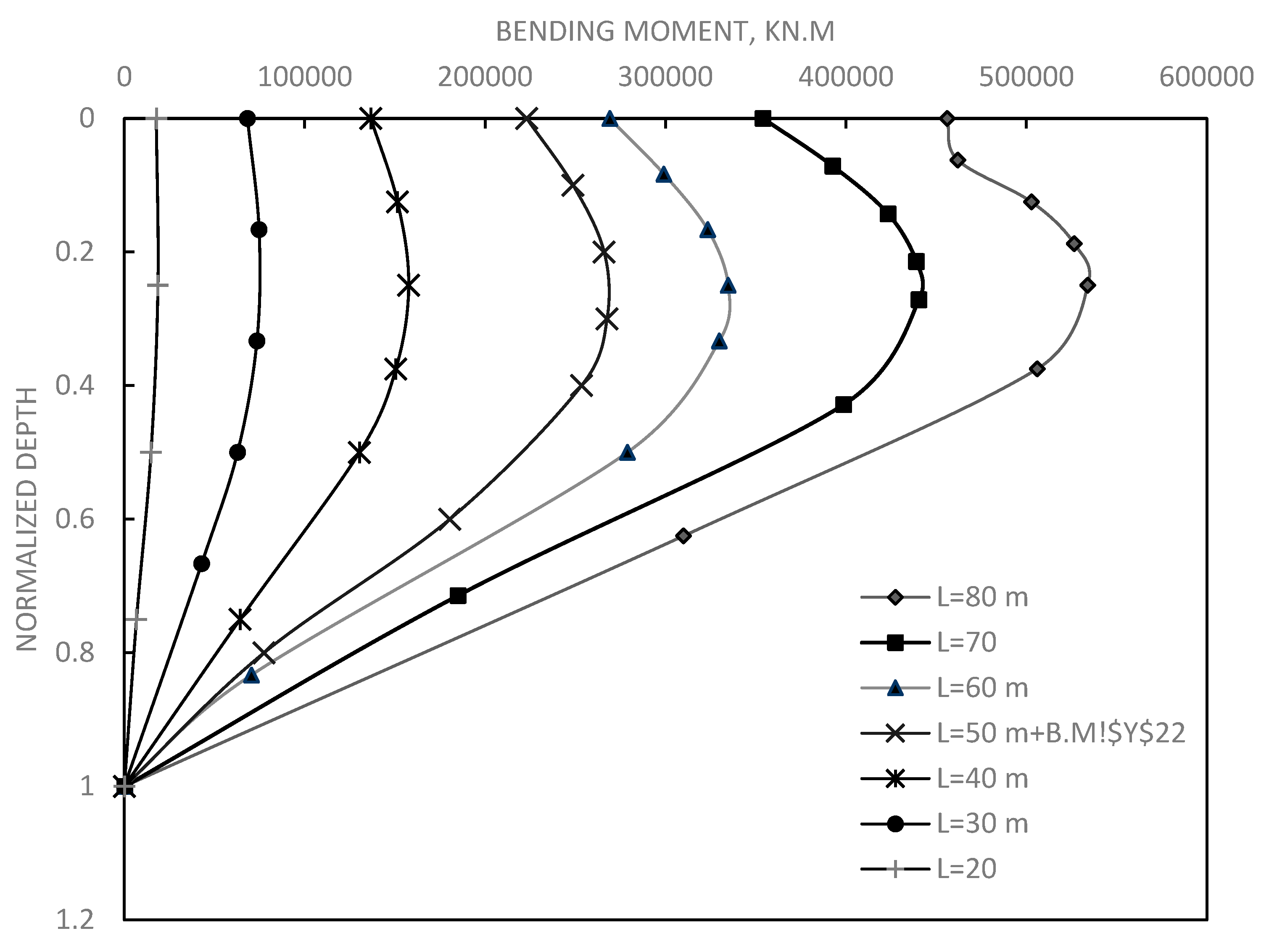

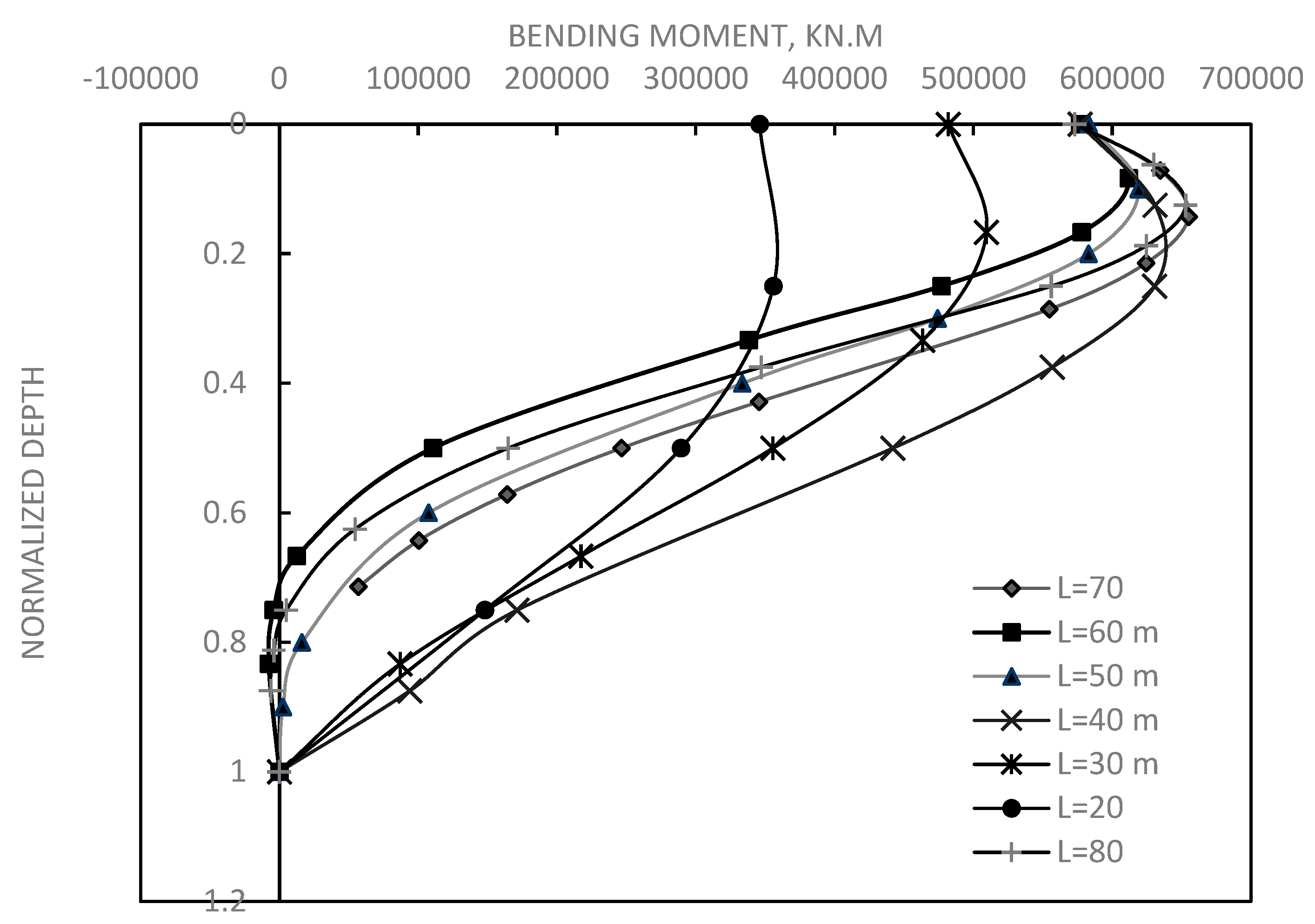

4.1.1. Monopile bending moment at lateral ultimate capacity

4.1.2. Predictive equations for determining lateral ultimate capacity for monopiles

5. Conclusion

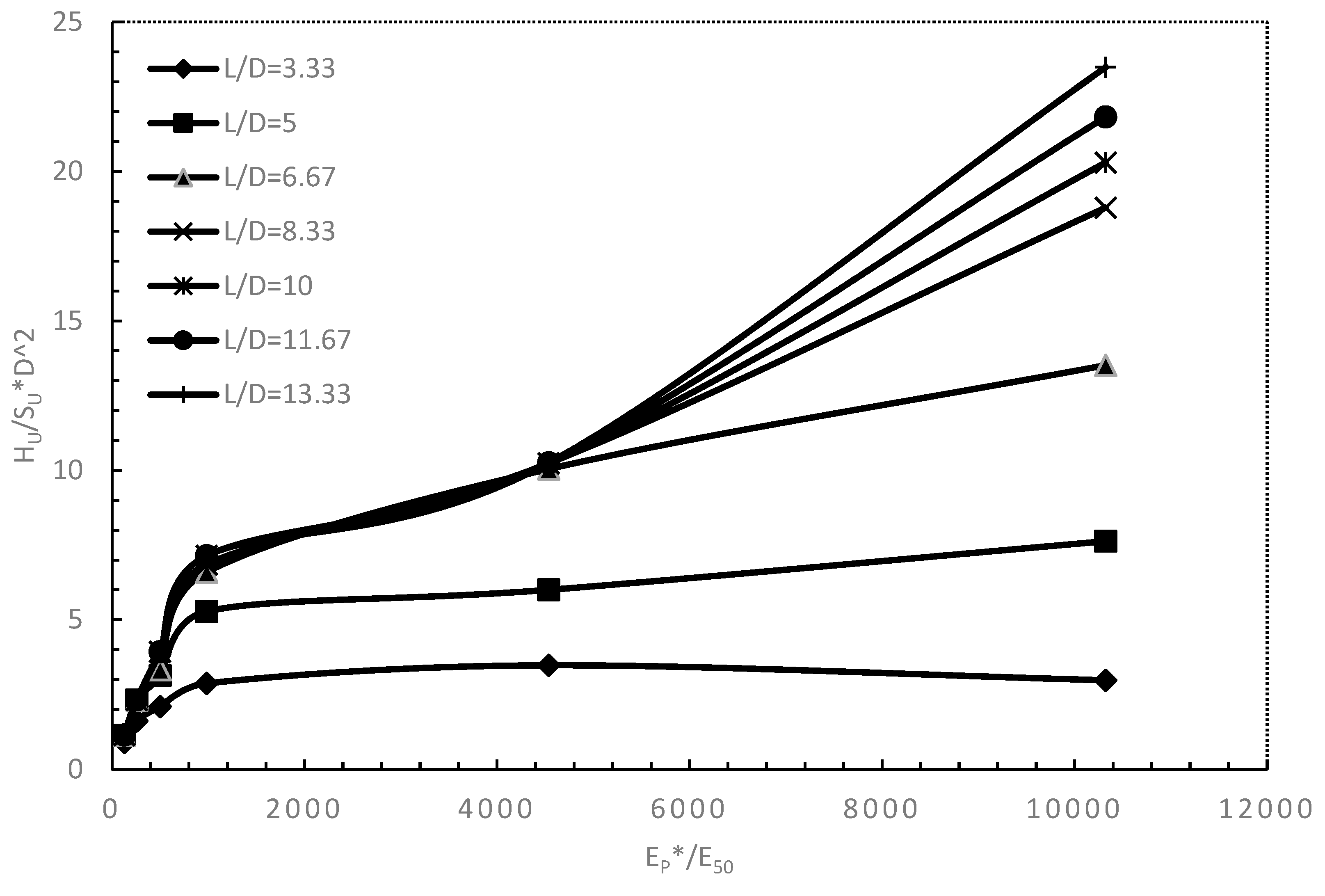

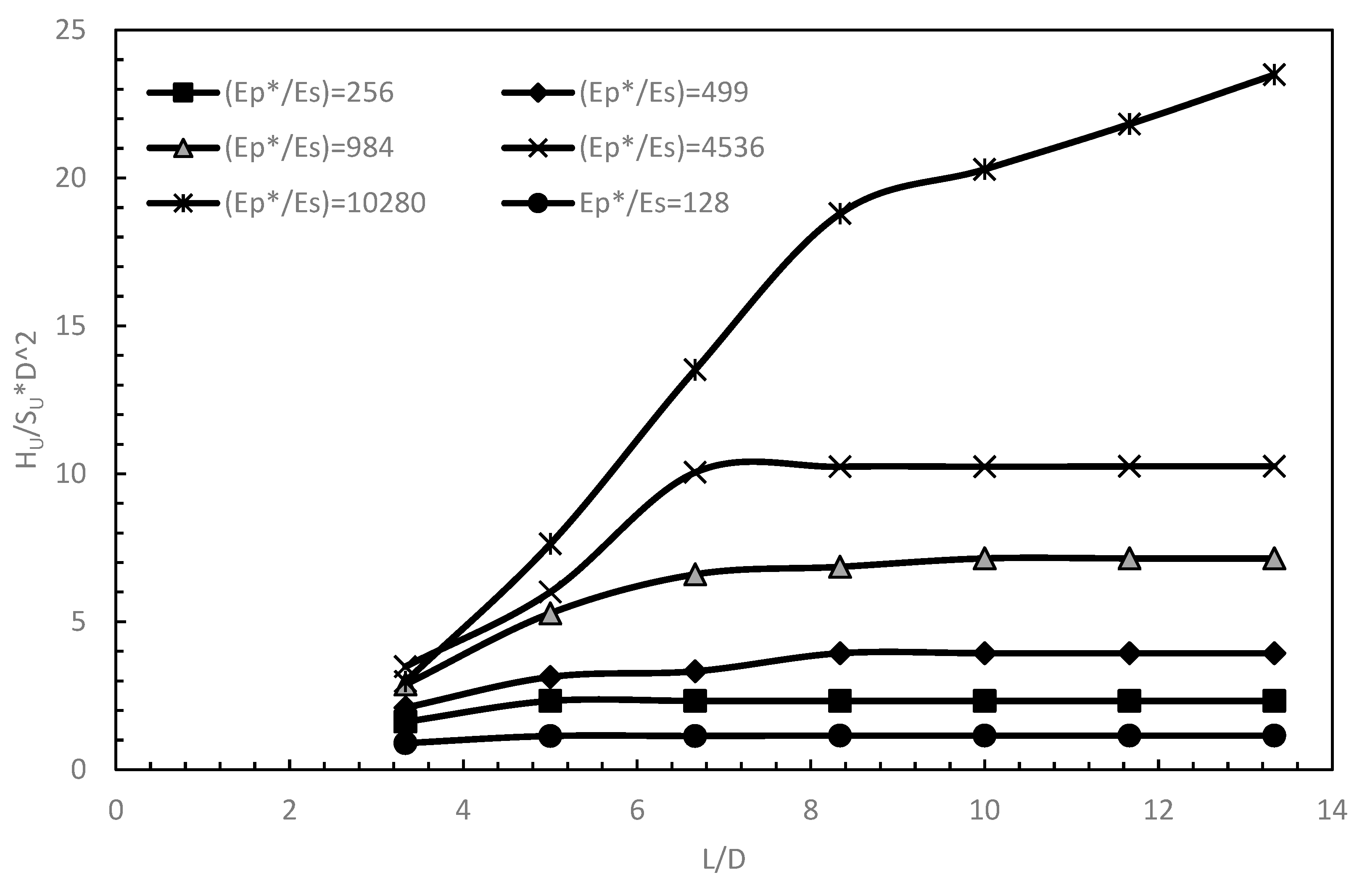

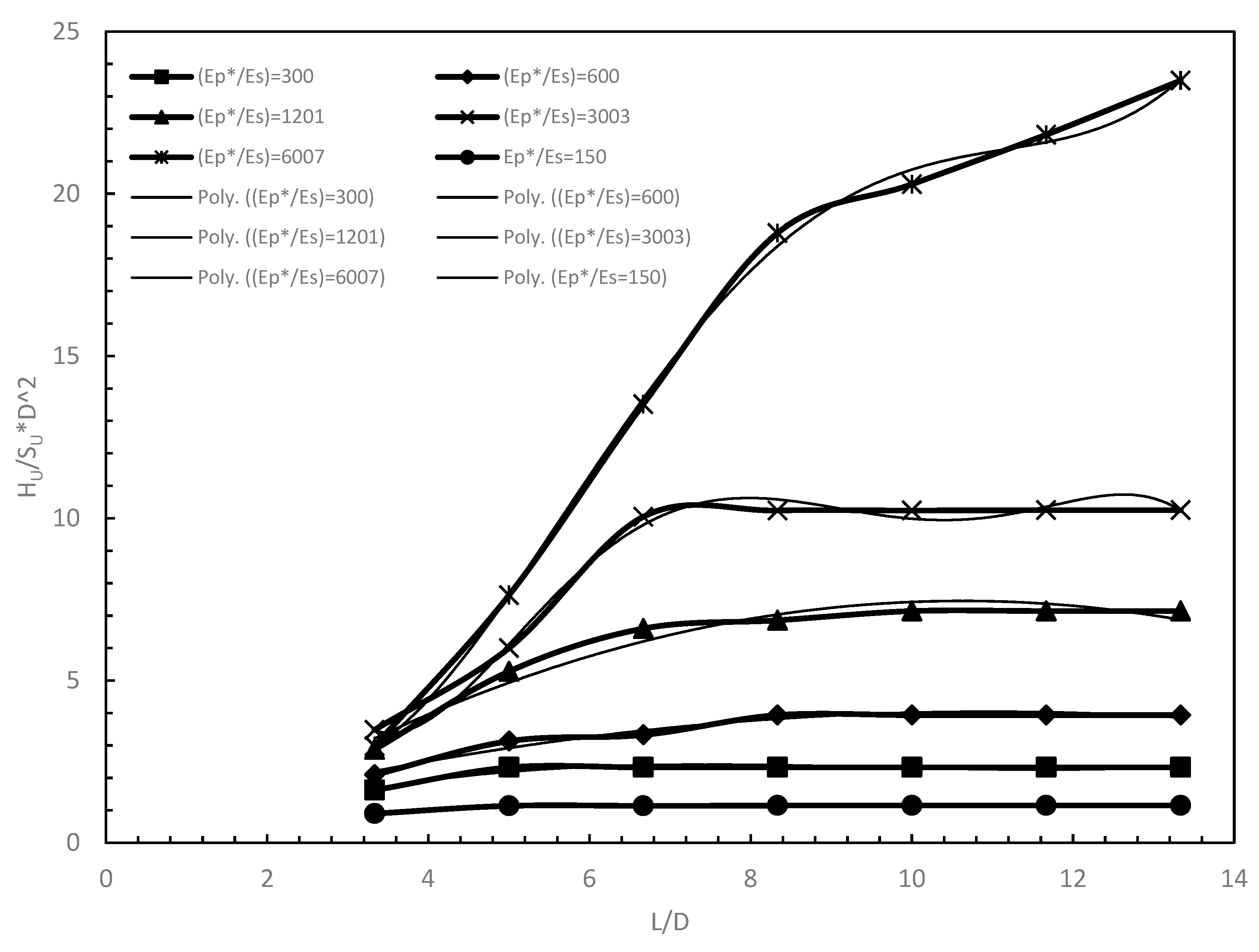

- The normalized ultimate capacity versus normalized stiffness of MP showed three distinct slopes, the normalized ultimate capacity was observed to increase significantly for Ep*/E50 values less than 984 for all L/D ratio. At normalized stiffness values of more than 2000, the effects of increasing the stiffness for a given L/D ratio was small for L/D ratios less than 6 and was considerable for higher L/D ratio.

- The normalized lateral ultimate capacity increase against L/D ratio was dependent on the normalized stiffness (Ep*/E50) values. At large Ep*/E50 values, the piles behaved as rigid piles and linear growth of normalized lateral ultimate capacity was observed for L/D ratios considered herein. As normalized stiffness (Ep*/E50) values decrease below 984, the effects of L/D ratio on lateral ultimate capacity diminish around L/D values of 5-8. These findings are better understood by inspection of bending moment profiles for clay 1 and 6.

- Higher L/D ratios had increased normalized lateral capacity for clay 1-5. In clay 6, no effects were observed of L/D on the normalized lateral capacity.

- For clay 1, increasing L/D ratio from 3.3 to 13.3 gave substantial increase in normalized lateral ultimate capacity of more than 700%. For clay 2, similar observation was made, however at lower magnitude.

- For clays 3-4, the effects of L/D ratio on the normalized lateral ultimate capacity was noticeable, amounting to 100%. However, the increase ceased after L/D value of 8.3.

- For clays 5-6, the effects of L/D ratio on the normalized lateral ultimate capacity were negligible due to flexibility of monopile.

- Predictive polynomials showed excellent match with FE data giving promising results and paving the way for more FE based charts for preliminary estimate of monopile lateral ultimate capacity.

Acknowledgments

References

- Abdelkader, Ahmed Mohamed Reda, Investigation of Hybrid Foundation System for Offshore Wind Turbine (Scholarship@Western). 2016.

- Alsharedah, Yazeed A., "Behavior of Hybrid and Monopile Foundation Systems for OWT: Centrifuge testing and Numerical Modelling" (2022). Electronic Thesis and Dissertation Repository. 8580. https://ir.lib.uwo.ca/etd/8580.

- Alsharedah, Y. Black, J.A, Newson, T and El Naggar M.H (2023). Centrifuge Testing of Improved Monopile Foundation for Offshore Wind Turbines. Ocean Engineering, V2, 285.

- Alsharedah, Y. Black, J.A, Newson, T and El Naggar M.H (2022). Monopile and Hybrid Foundation Comparisons under Lateral Loading. International Conference on Physical Modelling in Geotechnics, ICPMG 2022.

- API, 1993. Recommended practice for planning, designing, and Constructing fixed offshore platforms. API, RPT2A-WSD. American Petroleum Institute (API), Washington, D.C.

- Association EWE. The European Offshore Wind Industry–Key Trends and Statistics.

- 2016; January; 2017.

- Bayton, S., Black, J.., & Klinkvort, R.. (2018). Centrifuge modelling of long term cyclic lateral loading on monopiles. In Physical Modelling in Geotechnics (1st ed., pp. 689–694). Routledge. [CrossRef]

- Bisoi, S., and S. Haldar. 2014. “Dynamic analysis of offshore wind turbine in clay considering soil-monopile-tower interaction.” Soil Dyn. Earthquake Eng. 63: 19–35. [CrossRef]

- Broms, B. B. (1964b). Lateral Resistance of Piles in Cohesive Soils. Journal of the Soil.

- Mechanics and Foundations, 90(2): 27-64.

- Brown, D. A. (2007). Rapid lateral load testing of deep foundations. DFI Journal - the Journal of the Deep Foundations Institute, 1(1), 54-62. [CrossRef]

- Byrne, B.W. and Houlsby, G.T. (2003) “Foundations for Offshore Wind Turbines”, Philosophical Transactions of the Royal Society of London, Series A, Vol. 361, December, pp 2909-2930.

- Byrne B. W., McAdam R., Burd H. J., Houlsby G. T., Martin C. M., Zdravković L., Taborda D. M. G., Potts D. M., Jardine R. J., Sideri M., Schroeder F. C., Gavin K., Doherty P., Igoe D., Muir Wood A., Kellahave D., and Skov Gretlund J. 2015a. New design methods for large diameter piles under lateral loading for offshore wind applications. Proceedings of Third International Symposium on Frontiers in Offshore Geotechics 1, 705-710.

- Byrne B. W., McAdam R., Burd H. J., Houlsby G. T., Martin C. M., Gavin K., Doherty P., Igoe D., Zdravković L., Taborda D. M. G., Potts D. M., Jardine R. J., Sideri M., Schroeder F. C., Muir Wood A., Kellahave D. and Skov Gretlund J. 2015b. Field testing of large diameter piles under lateral loading for offshore wind applications. Proceedings of XVI European Conference on Soil Mechanics and Geotechnical Engineering, Edinburgh, 1255-1260.

- Cherchia, M. (2016). Centrifuge modeling of hybrid foundations for offshore wind turbines.

- El-Marassi M. Investigation of hybrid monopile-footing foundation systems subjected.

- to combined loading: The University of Western Ontario; 2011.

- Gerolymos, N., Giannakos, S., & Drosos, V. (2019). Generalised failure envelope for laterally loaded piles: Analytical formulation, numerical verification and experimental validation. Géotechnique,, 1-20. [CrossRef]

- TY - BOOKAU - Haigh, Stuart. PY- 2014/01/14SP - SN - 978-1-138-00152-7T1 - Fondations for offshore wind turbines. DO- 10.1201/b16200-13ER -.

- Heidari, M., Jahanandish, M., Naggar, H. E., & Ghahramani, A. (2014). Nonlinear cyclic behavior of laterally loaded pile in cohesive soil. Canadian Geotechnical Journal, 51(2), 129-143. [CrossRef]

- Heyer, Berry& Reese, L.C. Analysis of single piles under lateral loading. FHWA/TX-79/38+244-l. 1979.

- Lai, Y., Wang, L., Hong, Y., & He, B. (2020). Centrifuge modeling of the cyclic lateral behavior of large-diameter monopiles in soft clay: Effects of episodic cycling and reconsolidation. Ocean Engineering, 200, 107048–https://doi.org/10.1016/j.oceaneng.2020.107048.

- Lehane B, Powrie W, Doherty J. Centrifuge model tests on piled footings in clay for.

- offshore wind turbines. In: Proceedings of international conference in physical.

- modelling in geotechnics, ICPMG2010 Rotterdam: Balkema; 2010.

- L.J. Prendergast, D. Igoe. Examination of the reduction in natural frequency of laterally loaded piles due to strain-dependence of soil shear modulus, Ocean Engineering,Volume 258,2022,111614,ISSN00298018. [CrossRef]

- O'Neill, M. W., Reese, L. C., & Brown, D. A. (1987). Cyclic lateral loading of a large-scale pile group. Journal of Geotechnical Engineering, 113(11), 1326-1343. [CrossRef]

- Powrie, W., and Daly, M. P. (2007). “Centrifuge modeling of embedded retaining walls with stabilizing bases.” Geotechnique, 57(6), 485–497.

- T.P.T. Dao. Validation of PLAXIS Embedded Piles for Lateral Loading. Delft University of Technology. 2011.

- Wang, X., Zeng, X., Yang, X., & Li, J. (2018). Feasibility study of offshore wind turbines with hybrid monopile foundation based on centrifuge modeling. Applied Energy, 209, 127-139. [CrossRef]

- Wang, Z., Hong, Y., Ng, C. W. W., Wang, L. Z., Mašín, D., & He, B. (2017). Cyclic lateral response and failure mechanisms of semi-rigid pile in soft clay: Centrifuge tests and numerical modelling. Canadian Geotechnical Journal, 54(6), 806-824. [CrossRef]

- Zhang, G. (2017). A centrifuge study of the seismic response of pile–raft systems embedded in soft clay. Géotechnique, 67(6), 479–490. [CrossRef]

- Zhu, B., Zhu, Z., Li, T., Liu, J., & Liu, Y. (2017). Field Tests of Offshore Driven Piles Subjected to Lateral Monotonic and Cyclic Loads in Soft Clay. Journal of Waterway, Port, Coastal, and Ocean Engineering, 143(5), 5017003–. [CrossRef]

| Parameter | Clay1 |

|---|---|

| c' | 15 |

| Ψ | 0 |

| φ' | 8 |

| 15 | |

| 41 | |

| eini. | 4.23 |

| ɣ, kN/m3 | 17.9 |

| 1406 | |

| 1758 | |

| 5000 | |

| vur | 0.2 |

| M | 0.6 |

| PI, % | 30 |

| Ko,NC | 0.86 |

| Rf | 0.9 |

| Depth, m | 0-5 |

| Type of analysis | Undrained A |

| Parameter | Clay1 | Clay2 | Clay3 | Clay4 | Clay5 | Clay6 |

|---|---|---|---|---|---|---|

| c' | 4.23 | 24 | 44 | 87 | 170 | 354 |

| Ψ | 0 | 0 | 0 | 0 | 0 | 0 |

| θ' | 8 | 10 | 10 | 10 | 10 | 10 |

| 13 | 51 | 83 | 140 | 240 | 414 | |

| 41 | 100 | 100 | 100 | 100 | 100 | |

| e(ini). | 4.209 | 4.209 | 4.209 | 4.209 | 4.209 | 4.209 |

| ɣ, kN/m3 | 17.9 | 17.9 | 17.9 | 17.9 | 17.9 | 17.9 |

| 1406 | 3461 | 14747 | 29040 | 56628 | 113134 | |

| 1758 | 4000 | 18439 | 36310 | 70805 | 141457 | |

| 5000 | 10000 | 52444 | 103271 | 201380 | 402326 | |

| vur | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| M | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| PI | 30 | 30 | 30 | 30 | 30 | 30 |

| Ko, NC | 0.54 | 0.54 | 0.54 | 0.54 | 0.54 | 0.54 |

| Depth, m | 0-25 | 0-26 | 0-27 | 0-28 | 0-29 | 0-30 |

| Rf | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 |

| L, m | L/D/(Lp/W) | Foundation system | e/Dt | V, kN |

|---|---|---|---|---|

| 20 | 3.33 | Monopile | 6.83 | Own weight1 |

| 30 | 5 | 6.83 | ||

| 40 | 6.67 | 6.83 | ||

| 50 | 8.33 | 6.83 | ||

| 60 | 10 | 6.83 | ||

| 70 | 11.67 | 6.83 | ||

| 80 | 13.33 | 6.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).