Submitted:

29 August 2023

Posted:

30 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Role and Characterization of Sizing Agent Used for the Modification of Carbon Fibers:

2.1. Role of Sizing Agent in Enhancing the Interfacial Strength of CFRP’s:

2.2. Physical and Chemical Methods of Surface Modification of Carbon Fibers:

2.3. Surface Modification of Carbon Fibers with Nanoparticles:

2.4. Discussion and Summary:

Conclusion:

Acknowledgements

References

- He M, Qi P, Xu P, Cai Q, Li P, Jia X, Yang X (2019) Establishing a phthalocyanine based cross linking interphase enhances the interfacial performance of carbon fiber/epoxy composites at elevated temperatures. 2: Composites science and technology 173.

- Yao SS, Jin FL, Rhee KY, Hui D, Park SJ (2018) Recent advances in carbon fiber-reinforced thermoplastic composites: A review. 2: Composites Part B 142.

- Wang J, Zhen T, Liu W, Jiao W, Wang R (2019) Molecular dynamics simulations of the effect of sizing agent on the interface property in carbon fiber reinforced vinyl ester resin composite. 1: Applied Surface Science 479, 1192.

- Viswanathan B, Indra Neel P, Varadarajan TK (2009) Development of carbon materials for energy and environmental applications. 1: Catalysis Surveys from Asia 13.

- Liu P, Zhang S, Lu Ch, Yuan H (2016) Increased interfacial adhesion between carbon fiber and poly (vinylidene fluoride) by an aqueous sizing agent. 1: Surf Interface Annal 48, 1410.

- Inoue H (2019) Epoxy-amine adduct used in, e.g. sizing agent, comprises epoxy compound containing compound having alicyclic epoxy groups in each molecule, and amine compound containing having two or more amino groups in each molecule at both ends. 2018. [Google Scholar]

- Inoue H (2019) Water-dispersible-type resin composition used as processing agent and sizing agent for carbon fiber, comprises compound which is addition product of epoxy compound and amine compound, higher fatty acid ester, and surfactant. JP201905 6043–A.

- Xiao L, Xiao J (2019) Hybrid resin comprises e.g. monomers and intermediates, the monomer includes bisphenol A type epoxy E44, bisphenol A type epoxy E51, styrene, 2-Hydroxyethyl methacrylate, methacrylate, methacrylic acid, acrylonitrile and acrylamide. 1096.

- Hao R, Jiao X, Zhang X, Tian Y (2019) Fe3O4/graphene modified waterborne polyimide sizing agent for high modulus carbon fiber. 3: Applied Surface Science 485.

- Jiao W, Liu W, Yang F, Jiang L, Jiao W, Wang, R. (2017) Improving the interfacial property of carbon fiber/vinyl ester resin composite by grafting modification of sizing agent on carbon fiber surface. 1: J Mater Sci 52, 1381.

- Jiao W, Zheng T, Liu W, Jiao W, Wang R (2019) Molecular dynamics simulations of the effect of sizing agent on the interface property in carbon fiber reinforced vinyl ester resin composite. Applied Surface Science, 479:1192-1199.

- Li L, Yan C, Xu H, Liu D, Shi P, Zhu Y, Chen G, Wu X, Liu W (2019) Improving the interfacial properties of carbon fiber-epoxy resin composites with a graphene-modified sizing agent. 4: Applied polymer science 36, 4712.

- Schaefer A, Simat TJ (2004) Migration from can coatings: Part 3: Synthesis, identification and quantification of migrating epoxy-based substances below 1000 Da. Food additives and contaminants. 3: 21.

- Yu Z, Bai Y, Li Y, Wang X, Wang W, Liu J (2018) Fiber length distribution and thermal, mechanical and morphological properties of thermally conductive polycarbonate/chopped carbon fiber composites. 1: Polymer International 67, 1137.

- Peng X, Huang Y, Sun X, Han X, Fan R (2019) Effect of chromium coated carbon fiber on the thermal and mechanical properties of Cr@Gf/Cr@CF/Al composites. 7: Journal of materials science: Materials in electronics 30, 7226.

- Jeffries R (1971) Prospects for carbon fibers.

- Zhao X, Qi S, Liu J, Han X, Zhang F (2019) Preparation and mechanical performances of carbon fiber reinforced epoxy composites by Mxene nanosheets coating. 1: Journal of materials science: Materials in Electronics, 30, 1051.

- Zhang W, Deng X. Sui G, Yang X (2019) Improving interfacial and mechanical properties of carbon nanotube-sized carbon fiber/epoxy composites. 6: Carbon 145.

- Chand S (2000) Review: Carbon fibers for composites. 1: J Mat Sci 35, 1303.

- Shi LL, Ma L, Li P, Wang M, Guo S, Han P, Song G (2019) The effect of self-synthesized hydroxyl-terminated hyperbranched polymer interface layer on the properties of carbon fiber reinforced epoxy composites. Applied Surface Science. 3: 479.

- Fu J, Zhang M, Jin L, Liu L, Li N, Shang L, Li M, Xiao L, Ao Y (2019) Enhancing interfacial properties of carbon fibers reinforced epoxy composites via layer-by-layer self-assembly GO/SiO2 multilayer films on carbon fibers surface. 5: Applied Surface Science 470.

- Ge HY, Ma XL, Liu HS (2015) Preparation of emulsion-type thermotolerant sizing agent for carbon fiber and the interfacial properties of carbon fiber/epoxy resin composite. 4: J Appl Poly Sci 132, 4188.

- Ma XL, Ge HY, Liu HS (2016) Enhanced interfacial adhesion in carbon fiber/poly (acrylonitrile-butadiene-styrene) composite through fiber surface treatment by an emulsion sizing. 2: Polymer Composites 37, 2940.

- Yuan XM, Zhu B, Cai X, Liu JJ, Qiao K, Yu JW (2017) Optimization of interfacial properties of carbon fiber/epoxy composites via a modified polyacrylate emulsion sizing. 4: Appl Surf Sci 401.

- Yang Y, Lu CX, Su XL, Wu GP, Wang XK (2007) Effect of nano-SiO2 modified emulsion sizing on the interfacial adhesion of carbon fibers reinforced composites. 3: Mater Lett 61, 3601.

- Wang, Y. H. , Zhang, S. C., Liu, P. P. Jing, D. Q., Zhang, X. H., Preparation and characterization of polyimide-modified carbon fiber reinforced polyphenylene sulfide composites. New carbon materials, 34 (1), 2019, 68-74.

- Chen, Ch. , Zhou, J. P., Hong, Z, Huang, J. T., Qi, W. Z., Study of modified carbon fiber with carbon nanotubes sizing agent and its composites, China Plastics Industry, 47 (5), 2019, 121-124.

- Zhang, T. , Song, Y. X., Zhao, Y. Q., Effect of hybrid sizing with nano SiO2 on the interfacial adhesion of carbon fiber/nylon 6 composites. Colloids and surface Zhang, B. M., A-Physicochemical and Engineering Aspects, 553, 2018, 125-133.

- Wu, Z. J. , Cui, H. Y., Chen, L., Jiang, D. W., Weng, L., Ma, Y. Y., Li, X. J., Zhang, X. H., Liu, H., Wang, N., Zhang, J. X., Ma, Y., Zhang, M. Y., Huang, Y. D., Guo, Z. H., Interfacially reinforced unsaturated polyester carbon fiber composites with a vinyl ester-carbon nanotubes sizing agent. Composites Science and Technology, 164, 2018, 195-203.

- Jiao, W. W. , Cai, Y. M., Liu, W. B., Yang, F., Jiang, L., Jiao, W. C., Wang, R. G., Preparation of carbon fiber unsaturated sizing agent for enhancing interfacial strength of carbon fiber/vinyl ester resin composite. Applied Surface Science, 439, 2018, 88-95.

- Jiao, W. W. , Liu, W. B., Yang, F., Jiang, L., Jiao, W. C., Wang, R. G., Improving the interfacial property of carbon fiber/vinyl ester resin composite by grafting modification of sizing agent on carbon fiber surface. Journal of materials science, 52 (24), 2017, 13812-13828.

- Andideh, M. , Esfandeh, M., Effect of surface modification of electrochemically oxidized carbon fibers by grafting hydroxyl and amine functionalized hyper branched polyurethanes on inter laminar shear strength of epoxy composites. Carbon, 123, 2017, 233-242.

- He, H. W. , Li, K. X., Gao, F., Improvement of the bonding between carbon fibers and an epoxy matrix using a simple sizing process with a novolac resin. Construction and building materials, 116, 2016. 87-92.

- Cao, L. J. , Yang, Y., Lu, C. X., A sizing agent modified with carbon nanotubes used for the production of carbon fiber/bisphenol A epoxy composites. New Carbon Materials, 31 (2), 2016, 151-158.

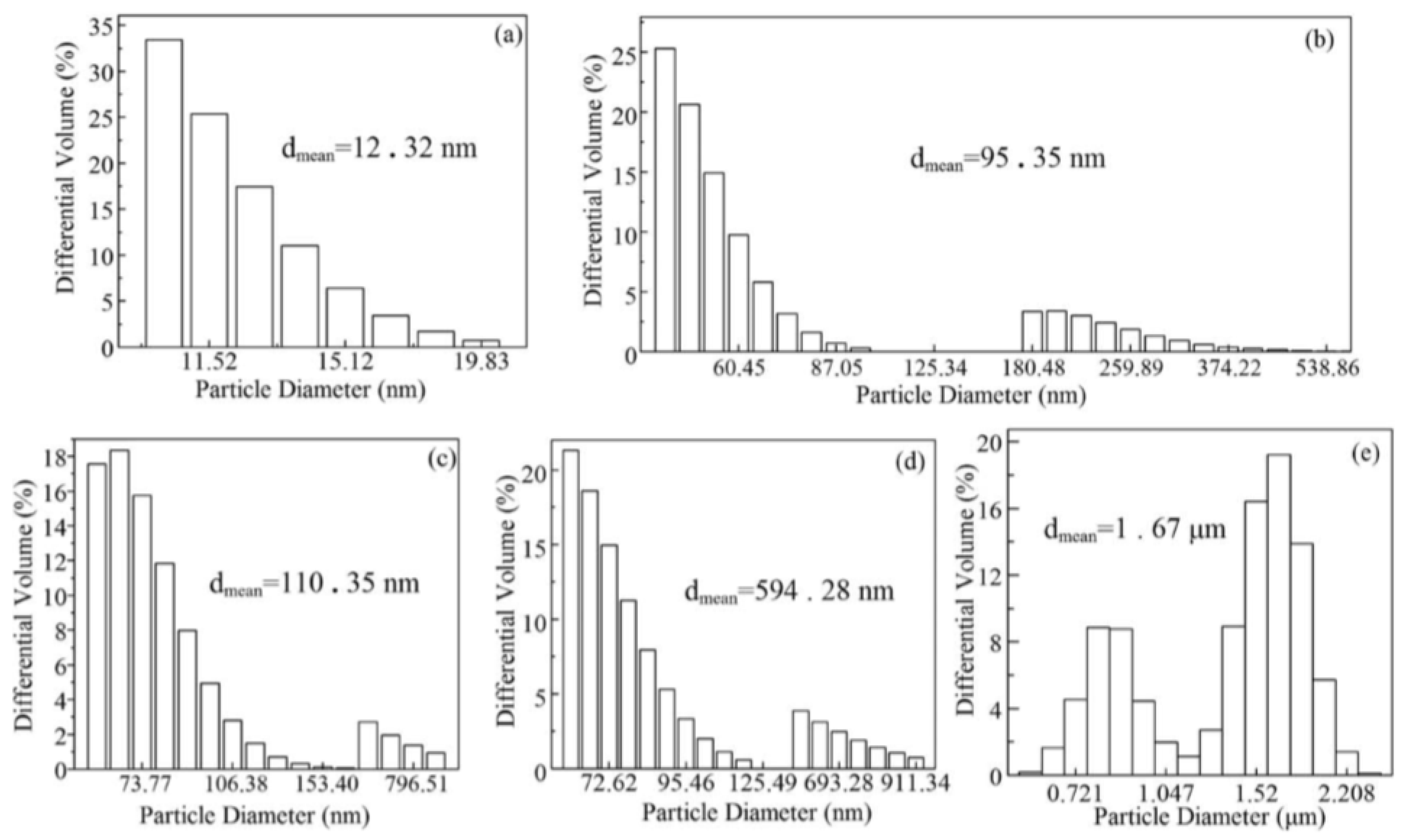

- Yuan X, Zhu B, Cai X, Zhao S, Qiao K, Zhang M (2018) Effects of particle size and distribution of the sizing agent on carbon fiber/epoxy composites interfacial adhesion. Polymer composites E 2036–E2045.

- Zhang RL, Huang YD, Li N, Liu L, Su D (2012) Effect of the concentration of the sizing agent on the carbon fibers surface and interface properties of its composites. 4: Journal of Applied Polymer Science 125.

- Zhang RL, Liu Y, Huang YD, Liu L (2013) Effect of particle size and distribution of the sizing agent on the carbon fibers surface and interfacial shear strength (IFSS) of its composites. Applied Surface Science, 287:423-427.

- Vedrtnam, A. , Sharma, S. P., Study on the performance of different nano-species used for surface modification of carbon fiber for interface strengthening. Composites Part A-Applied Science and Manufacturing, 125, 2019, 1-11.

- Zhang, Y. , Zhao, Q., Li, L., Liu, Y., Gong, Y. J., He, M., Research progress of carbon fiber surface modification. Engineering plastics application, 47 (10), 2019, 135-139.

- Zhang, D. D. , Zhang, F., Yang, J. X., Li, X. F., Li, Y. X., Zeng, J., Research progress on surface modification of carbon fiber and its application in polyamide. Engineering plastics application, 47 (7), 2019, 141-146.

- Raphael, N. , Namratha, K., Chandrashekar, B. N., Sadasivuni, K. K., Ponnamma, D., Smitha, A. S., Krishnaveni, S., Cheng, C., Byrappa, K., Surface modification and grafting of carbon fibers: A route to better interface. Progress in crystal growth and characterization of materials, 64 (3), 2018, 75-101.

- Hung, P. Y. , Lan, K. T., Fox, B., Hameed, N., Lee, J. H, Hui, D.,, Surface modification of carbon fiber using graphene-related materials for multifunctional composites. Composites Part B-Engineering, 133, 2018, 240-257.

- Corujeira-Gallo, S. , Dong, H. S., Effect of microstructure on the plasma surface treatment of carbon fibers. Journal of composite materials, 51 (23), 2017, 3239-3256.

- Naito, K. , Effect of hybrid surface modifications on tensile properties of polyacrylonitrile- and pitch based carbon fibers. Journal of materials engineering and performance, 25 (5), 2016, 2074-2083.

- Liu, J. X. , Liu, H. L., Wu, G. S., Chemical grafting of salicylaldehyde onto carbon fiber for enhancing interfacial strength of silicone resin composites, Polymer composites, 41 (3), 2020, 911-919.

- Mao, L. , Pan, C. 14 Feb 2020, China, CN110794012–A. [Google Scholar]

- Ao, Y. , Zhang, M. 14 Feb 2020, China, CN110791963–A. [Google Scholar]

- Shi, X. H. , Chen, L., Zhao, Q., Long, J. W., Li, Y. M., Wang, Y. Z., Epoxy resin composites reinforced and fire-retarded by surficially-treated carbon fibers via a tunable and facile process. Composites Science and Technology, 187, 2020, 1-7.

- Zhao, D. , He, J. M., Zheng, N., Huang, Y. D., Improved atomic oxygen erosion resistance of the carbon fiber-epoxy interface with polyhedral oligomeric silsesquioxane. 2020. [Google Scholar] [CrossRef]

- Zheng, Y. , Chen, L., Wang, X. Y., Wu, G. S., Modification of renewable cardanol onto carbon fiber for the improved interfacial properties of advanced polymer composites. Polymers, 12 (1), 2020.

- Cai, F. , Modifying carbon fiber in carbon fiber polyamide 66 thermoplastic composite material by placing carbon fiber in organic solution for soaking, drying to form organic layer, subjecting to low-temperature treatment and oxidation treatment. 24 Dec 2019, CN110607693–A. [Google Scholar]

- Ashrafi, F. , Firouzzare, M., Ahmad, S. J., Sohrabi, M. R., Khosravi, M., Preparation and modification of force spin polypropylene nanofibers adsorption of uranium (VI) from simulated seawater. Ecotoxicology and environmental safety, 186, 2019, Article No. UNSP 109746, 1-9.

- Sun, X. L. , Song, J. Y., Zhang., Liu, J. Y., Ke, H. Z., Wei, Q. F., Cai, Y. B., Effects of chemical pretreatment on structure and property of polyacrylonitrile based pre-oxidized fibers. Journal of Engineered fibers and fabrics, 15, 2020, 1-8.

- Turan, K. , Kaur, P., Manhas, D., Sharma, J., Verma, G., Novel insights into the dispersed and acid-medidated surface modification of the carbon nanofibers. Materials Chemistry and Physics, 239, 2020, 1-9.

- Diblikova, L. , Masek, Z., Kral, M., The effect of carbon fiber plasma treatment on the wettability and interlaminar shear strength of geopolymer composite. Journal of the Australian ceramic society, 55 (4), 2019, 1139-1145.

- Chukov, D. , Nematulloev, S., Torokhov, V., Stepashkin, A., Sherif, G., Tcherdyntsev, V., Effect of carbon fiber surface modification on their interfacial interaction with polysulfone. Results in Physics, 15, 2019, 1-7.

- Cheng, Y. M. , Liu, P. F., Xiao, P., Li, Z., Jiang, T. H., Huang, Y. Q., Li, Y., Effect of surface chemical modification on the bioactivity of carbon fibers reinforced epoxy. Surface and coatings technology, 377, 2019, 1-10.

- Wang, F. , Wang, X. L., Jiang, Y. J., Niu, Z. W., Wu, W. S., Zhang, H. X., Study of adsorption performance and adsorption mechanism for U (VI) ion on modified polyacrylonitrile fibers. Journal of radio analytical and nuclear chemistry, 323, (1), 2020, 365-377.

- Liu, H. S. , Zhao, Y., Li, N., Zhao, X. R., Han, X., Li, S., Lu, W. K., Wang, K., Du, S. Y., Enhanced interfacial strength of carbon fiber/PEEK composites using a facile approach via PEI and ZiF-67 synergistic modification,, Journal of materials research and technology-JMR&T, 8 (6), 2019, 6289-6300.

- Liu, H. L. , Liu, J. X., Wu, G. S., Facile preparation of hyperbranched polysilaxone-grafted carbon fibers with improved interfacial strength of silicone resin composite. Polymer composites, 41 (11), 2019, 4257-4265.

- Ran, J. C. , Lai, X. J., Li, H. Q., Zeng, X. R., Remarkable enhancement of mechanical and tribological properties of polyamide 46/polyphenylene oxide alloy by polyurethane-coated carbon fiber. High performance polymers, 31, 2019, 1122-1131.

- Fang, C. , Hu, P., Dong, S., Song, J. T., Zhang, X. H., An efficient hydrothermal transformation approach for construction of controllable carbon coating on carbon fiber from renewable carbohydrate. Applied Surface Science, 491, 2019, 478-487.

- Zhan, W. , Cao, Y. Z., Yang, P, Chen, M. Z., Zhou, X. Y., Manufacturing and interfacial bonding behavior of plasma-treated carbon fiber reinforced veneer based composites. Composite structures, 226, 2019.

- Regner, S. , Drechsler, K., Sentpali, S., Modification of the fiber/matrix bonding by a plasma treatment to reduce the structure-borne sound transmission. Applied Acoustics, 153, 2019, 78-86.

- Li, W. W. , Liu, X. J., Feng, M., Yang, J., Bamboo-like ultra-high molecular weight polyethylene fibers and their epoxy composites. Composites science and technology, 182, 2019, 1-6.

- Feng, S. Z. , Luo, W. X., Wang, L. X., Zhang, S., Guo, N. N., Xu, M. J., Zhao, Z. B., Jia, D. Z., Wang, X. C., Jia, L. X., Preparation and property of extremely stable superhydrophobic carbon fibers with core-shell structure. Carbon, 150, 2019, 284-291.

- Zhou, J. T. , Liu, F. F., Dai, X. M., Jiao, L., Yao, H. B., Du, Z. J., Wang, H. F., Qiu, X. P., Surface modification optimization of high-performance polyimide fibers. Materials Research Express, 6(9), 2019, 1-12.

- Liu, A. , Fu, Y. B., Zai, J. Z., Duan, Z. W., Zai, X. R., Electrochemical and electric field response properties of highly sensitive electrodes based on carbon fiber with oxygen and nitrogen surface groups. IEEE Sensors Journal, 19 (11), 2019, 3966-3974.

- Jiang, Z. D. , Effects of plasma treatment of carbon fibers on interfacial properties of BMI resin composites. Surface and interface analysis, 51 (4), 2019, 458-464.

- Pan, Y. S. , Mao, J. H., Ding, J., Effect of carbon fiber surface modification on the mechanical properties of carbon fiber-reinforced ultrahigh-molecular weight polyethylene composite. Journal of materials engineering and performance, 28 (4), 2019, 1995-2005.

- Raju, D. , Mendoza, A., Wonnenberg, P., Mohanaraj, S., Sarbanes, M., Truong, C., Zestos, A. G., Polymer modified carbon fiber microelectrodes and wave form modifications enhance neutrotransmitter metabolite detection. Analytical methods, 11 (12), 2019, 1620-1630.

- Gao, B. , Du, W. T., Hao, Z. N., Zhou, H. F., Zou, D. C., Zhang, R. L., Bioinspired modification via green synthesis of Mussel-inspired nanoparticles on carbon fiber surface for advanced composite materials. ACS sustainable Chemistry and Engineering, 7 (6), 2019, 5638-5648.

- Fu, J. S. , Zhang, M. J., Jin, L., Liu, L., Li, N., Shang, L., Li, M., Xiao, L. H., Ao, Y. H., Enhancing interfacial properties of carbon fibers reinforced epoxy composites via layer-by-layer selfassembly GO/SiO2 multipayer films on carbon fibers surface. Applied Surface Science, 470, 2019, 543-554.

- Ma, L. C. , Wang, G., Li, X. R., Yang, C., Zheng, H., Yu, C. Y., Li, Q. J., Xin, J. P., Lv, B. K., Shen, Y. H., Song, G. J., Grafting hyper branched polymer with terminal hydroxyl groups onto carbon fiber surface in two-step polycondensation for improving the interfacial properties of carbon fiber/epoxy resin composite. Polymer composites, 40, 2019, E1378-E1387.

- Wang, K. ,, Li, M., Liang, Y. Q., Wang, J., He, L., Du, S. Y., Huang, Z. R., Huang, Q., Interface modification of carbon fibers with TiC/Ti2AlC coating and its effect on the tensile strength. Ceramics international, 45 (4), 2019, 4661-4666.

- Hassan, E. A. M. , Elagib, T. H. H., Memon, H., Yu, M. H., Zhu, S., Surface modification of carbon fibers by grafting PEEK-NH2 for improving interfacial adhesion with polyether ether ketone. Material, 12 (5), 2019, 1-11.

- Kruppke, I. , Scheffler, C., Simon, F., Hund, R. D., Cherif, C., Surface treatment of carbon fibers by oxy-fluorination, Materials, 12 (4), 2019, 1-18.

- Szabo, L. , Imanishi, S., Tetsuo, F., Hirose, D., Ueda, H., Tsukegi, T., Ninomiya, K., Takahashi, K., Lignin as a funcational green coating on carbon fiber surface to improve interfacial adhesion in carbon fiber reinforced polymers. Materials, 12 (1), 2019, 1-15.

- Randall, J. D. , Eyckens, D. J., Stojeevski, F., Francis, P. S., Doeven, E. H., Barlow, A. J., Barrow, A. S., Arnol, C. L., Moses, J. E., Henderson, L. C.,, Modification of carbon fiber surface by sulfur-fluoride exchange click chemistry. ChemPhysChem, 19 (23), 2018, 3176-3181.

- Ma, L. C. , Wu, G. S., Zhu, Y. Y., Li, X. R., Han, P., Wang, G., Song, G. J., An effective non-covalent grafting approach to functionalized carbon fiber with polyethylene imine in supercritical fluid to enhance the interfacial strength of carbon fiber/epoxy composites. Polymer Composites, 39, 2018, E2381-E2389.

- Ma, L. C. , Wu, G. S., Zhao, M., Li, X. R., Han, P., Song, G. J., Modification of carbon fiber surfaces with polyether amines: The role of interphase microstructure on adhesion properties of CF/epoxy composites. Polymer composites, 39, 2018, E2346-E2355.

- Song, B. , Wang, T. T., Sun, H. G.,, Liu, H., Mai, X. M., Wang, X. J., Wang, L., Wang, N., Huang, Y. D., Guo, Z. H., Graphitic carbon nitride (g-C3N4) inter facially strengthened carbon fiber epoxy composites. Composites Science and Technology, 167, 2018, 515-521.

- Zhu, P. , Ruan, F. T., Bao, L. M., Preparation of polyetherimide nanoparticles on carbon fiber surface via evaporation induced surface modification method and I ts effect on tensile strength and interfacial shear strength. Applied Surface Science, 454, 2018, 54-60.

- Moosburger-Will, J. , Lachner, E., Loffler, M., Kunzmann, C., Greisel, M., Ruhland, K., Horn, S., Adhesion of carbon fibers to a amine hardened epoxy resin: Influence of ammonia plasma functionalization of carbon fibers. Applied Surface Science, 453, 2018, 141-152.

- Deng, H. M. , Xu, J. Y., Li, X. Y., Ye, Y. L., Chen, H. Q., The synergistic action between anhydride grafted carbon fiber and intumescent flame retardant enhances flame retardency and mechanical properties of polypropylene composites. Science and technology of advanced materials, 19 (1), 2018, 718-731.

- Yuan, J. M. , Fan, Z. F., Yang, Q. C., Li, W., Wu, Z. J., Surface modification of carbon fibers by microwave etching for epoxy resin composite. Composites Science and Technology, 164, 2018, 222-228.

- Peng, C. Z. , Improving the interfacial property of carbon fiber/PI resin composite by grafting modification of carbon fiber surface. Surface and interface analysis, 50 (6), 2018, 628-633.

- Zang, C. X. , Wu, G. S., Jaing, H., Tuning interfacial strength of silicone resin composites by varying the grafting density of octamaleamic acid-POSS modified onto carbon fiber. Composites Part A-Applied Science and manufacturing, 109, 2018, 555-563.

- Fei, J. , Duan, X., Luo, L., Zhang, C., Qi, Y., Li, H., Feng, Y. Q., Huang, J. F., Grafting methyl acrylic onto carbon fiber via Diels-Alder reaction for excellent mechanical and tribological properties of phenolic composites. Applied Surface Science, 433, 2018, 349-357.

- Boehm, A. V. , Meininger, S., Tesch, A., Gbureck, U., Muller, F. A., The mechanical properties of biocompatible apatite bone cement reinforced with chemically activated carbon fibers. Materials, 11 (2), 2018, 1-12.

- Wang, L. , Gao, S. B., Wang, J. J., Wang, W. C., Zhang, L. Q., Tian, M., Surface modification of UHMWPE fibers by treatment and UV grafting for adhesion improvement. Journal of Adhesion, 94 (1), 2018, 30-45.

- Fang, Y. , Liu, Y., Liu, X. L., Xu,, S., Yang, B., Effect of carbon fiber surface dopamine modification on the properties of PVDF/CF composites. Journal of Functional polymer, 31 (4), 2018, 366-373.

- Xi, X. F. , Chen, Y. S., Wang, J., Li, Y. Y., Shao, X. D., He, L., Huang, Q., Pie, X. L., A multiscale hydrothermal carbon layer modified carbon fiber for composite fabrication. RSC Advances, 8 (41), 2018, 23339-23347.

- Giebel, E. , Herrmann, T., Simon, F., Fery, A., Buchmeiser, M. R., Surface modification of carbon fibers by free radical graft-polymerization of 2-hydroxyethyl methacrylate for high polymerization of 2-hydroxymethyl methacrylate for high mechanical strength fiber-matrix composites. Macromolecular materials as engineering, 302 (12), 2017, 1-5.

- Liu, Y. , Fang, Y. C., Liu, X. L., Wang, X. L., Yang, B., Mussel-inspired modification of carbon fiber via polyethylene imine/poly dopamine co-deposition for the improved interfacial adhesion. Composites Science and Technology, 151, 2017, 164-173.

- Motozuka, S. , Tagaya, M., Hayashi, K., Kameyama, T., Oguri, H., Xu, Z., Mechanochemical surface modification on carbon fibers using a simple rubbing method. Journal of composite materials, 51 (25), 2017, 3577-3584.

- Gao, B. , Zhang, J., Hao, Z. N., Huo, L. J., Zhang, R. L., Shao, L., In-situ modification of carbon fibers with hyperbranched polyglycerol via anionc ring-opening polymerization for use in high-performance composites. Carbon 123, 2017, 548-557.

- Szczurek, A. , Barcikowski, M., Leluk, K., Babiarczuk, B., Kaleta, j., Krzak, J., Improvement of interaction in a composite structure by using a sol-gel functional coating on carbon fibers. Materials, 10 (9), 2017.

- Wang, C. F. , Chen, L., Li, J., Sun, S. F., Ma, L. C., Wu, G. S., Zhao, F., Jiang, B., Huang, Y. D., Enhancing the interfacial strength of carbon fiber reinforced epoxy composites by green grafting of poly(oxopropylene) diamines. Composites Part A – Applied Science and manufacturing, 99, 2017, 58-64.

- Chang, Q. X. , Zhao, H. J., He, R. Q., Improvement of interfacial adhesion in PP/PS blends enhanced with supersonic atmosphere plasma spraying-treated carbon fiber. Surface and interface analysis, 49 (8), 2017, 750-754.

- Sun, J. F. , Zhao, F., Yao, Y., Jin, Z., Liu, X., Huang, Y. D., High efficient and continuous surface modification of carbon fibers with improved tensile strength and interfacial adhesion. Applied surface science, 412, 2017, 424-435.

- Lee, E. S. , Lee, C. H., Chun, Y. S., Han, C. J., Lim, D. S., Effect of hydrogen plasma-mediated surface modification of carbon fibers on the mechanical properties of carbon-fiber reinforced polyetherimide composites. Composites Part B-Engineering, 116, 2017, 451-458.

- Friedrich, J. , Altmann, K., Wettmarshausen, S., Hidde, G.,, Coating of carbon fibers with adhesion-promoting thin polymer layers using plasma polymerization or electrospray ionization technique – A comparison. Plasma processes and polymers, 14 (3), 2017, 1-14.

- Wu, J. , Chen, H., Wu, Q., Liu,, H. B., Luo, Z. J., Surface modification of carbon fibers and the selective laser sintering of modified carbon fiber/nylon 12 composite powder. Materials and Design, 116, 2017, 253-260.

- Yang, X. W. , Jiang, X., Huang, Y. D., Guo, Z. H., Shao, L., Building nanoporous metal organic frameworks “armor” on fibers for high-performance composite materials. ACS Applied Materials and Interfaces, 9 (6), 2017, 5590-5599.

- Zhao, M. , Meng, L. H., Ma, L. C., Wu, G. S., Xie, F., Ma, L., Wang, W., Jiang, B., Huang, Y. D., Stepwise growth of melamine-based dendrimers onto carbon fibers and the effects on interfacial properties of epoxy composites. Composites science and technology, 138, 2017, 144-150.

- Liu, R. L. , Wang, Y., Ge, X. L., Yu, P., Liu, H. Q., Wang, M. C., Lu, W.,, Fu,, Q., Polydopamine/polyethyleneimine complex adhered to micrometer sized magnetic carbon fibers for high-efficiency hemoperfusion. Journal of biomaterials science, polymer edition, 28 (14), 2017, 1444-1468.

- Lan, D. S. , Xiong, L., Wanyan, H. T., Yuan, Y. M., Fan, Q., Zeng, X. K., Chen, Y. L., Cao, X. Y., Poly (glycidylmethacrylate) grafted to carbon fiber surface by RAFT polymerization for enhancing interface adhesion and mechanical properties of carbon fiber/epoxy composites. Polymers and polymer composites, 25 (1), 2017, 113-118.

- Moseenkov, S. I. , Krasnikov, D. V., Kazakova, M. A., Kuznetsov, V. L., Serkova, A. N., Modification of the surface of carbon fibers with multi-walled carbon nanotubes and its effect on mechanical characteristics of composites with epoxy resin. Russian Journal of Applied Chemistry, 89 (12), 2016, 1969-1977.

- Gao, B. , Zhang, R. L., Wang, C. G., Enhanced mechanical properties of carbon fiber composites by grafting different structural poly(amidoamine) onto fiber surface. Polymer testing, 56, 2016,192-199.

- Gao, B. , Zhang, R. L., He, M. S., Wang, C. G., Liu, L., Zhao, L. F., Wen, Z. J., Ding, Z. P., Interfacial microstructure and mechanical properties of carbon fiber composites by fiber surface modification with poly(amidoamine)/polyhedral oligomeric silsesquioxiane. Composites Part A-Applied Science and manufacturing, 90, 2016, 653-661.

- Shi, Y. N. , Li, M., Wang, N., Xing, M., Wu, X. L., Para-amino benzoic acid doped micro-grooved carbon fibers to improve strength and biocompatibility of PLA-PEG. Science China-Materials, 59 (11), 2016, 911-920.

- Yi, T. W. , Lee, W., Seong, D. G., Won, H. J., Kim, S. W., Um, M. K., Byun, J. H., Effect of phenoxy-based coating resin for reinforcing pitch carbon fibers on the interlaminar shear strength of PA6 composites. Composites Part A-Applied science and manufacturing, 87, 2016, 212-219.

- Wang, L. , Huang, R. H., Zhou, B. Q., Zhang, Y., Dong, Y. W., Carbon fibers modified with silicone peroxide containing vinyl groups for silicone rubber reinforcement. Materials Letters, 176, 2016, 38-41.

- Chen, H. F. , Wang, K. Y., Zhang, Y. J., Tang, P. S., Xu, M. H., Cao, F., Effect of acidification-oxidation on life of ribbon consisted of carbon fibers. Rare metal material and engineering, 45, 2016, 47-50.

- Rahmani, H. , Ashori, A., Varnaseri, N., Surface modification of carbon fiber for improving the interfacial adhesion between carbon fiber and polymer matrix. Polymers for advanced technologies, 27 (6), 2016, 805-811.

- Hu, H. B. , Zhang, X. Q., Liu, D., Yan, C., Chen, X., Hui, D., Zhu, Y. D., Cyclomatrix-type polyphosphazene coating: Improving interfacial property of carbon fiber/epoxy composites and preserving fiber tensile strength. Composites Part B-Engineering, 93, 2016, 244-251.

- Xu, D. X. , Liu, B. Y., Zhang, G., Long, S. R., Wang, X. J., Yang, J., Effect of air plasma treatment on interfacial shear strength of carbon fiber-reinforced polyphenylene sulfide. High performance polymers, 28 (4), 2016, 411-424.

- Wu, G. S. , Ma, L. C., Wang, Y. W, Lin, L., Huang, Y. D., Interfacial properties and impact toughness of methyl phenyl silicone resin composites by chemically grafting POSS and tetraethylene pentamine onto carbon fibers. Composites Part A-Applied Science and Manufacturing. 84, 2011, 1-8.

- Wang, L. , Liu, N., Guo, Z., Wu, D. P., Chen, W. W., Chang, Z., Yuan, Q. P., Hui, M.,, Wang, J. S., Nitric acid treated carbon fibers with enhanced hydrophilicity for Candida tropicalis immobilization in xylitol fermentation. Materials, 9 (31), 2016.

- Mordkovich, V. Z. , Karaeva, A. R., Urvanov, S. A., Kazennov, N. V., Zhukova, E. A., Novel flexible composites reinforced with CNT-grafted carbon fibers. MRS Advances, 1 (20), 2016, 1453-1458.

- Feng, M. J. , Wang, S. B., Yu, Y. L., Feng, Q. H., Yang, J. P., Zhang, B. M., The H3PO4/H2SO4/HNO3 chemical functionalization optimized performances of functionalized carbon fibers via preventing fibers from over-oxidation. Journal of the electrochemical Society, 163 (10), 2016.

- Borooj, M. B. , Shoushtari, A. M., Sabet, E. N., Haji, A., Influence of oxygen plasma treatment parameters on the properties of carbon fiber. Journal of adhesion Science and Technology, 30 (21), 2016, 2372-2382.

- Beggs, K. M. , Perus, M. D., Servinis, L., O’Dell, L. A., Fox, B. L., Gengenbach, T. R., Henderson, L. C., Rapid surface functionalization of carbon fibers using microwave irradiation in anionic liquid. RSC Advances, 6 (39), 2016, 32480-32488.

- Zhang, X. P. , Liu, L., Li, M., Chang, Y. J., Shang, L., Dong, J. L., Xiao, L. H., Ao, Y. H., Improving the interfacial properties of carbon fibers/vinyl ester composites by vinyl functionalization on the carbon fiber surface. RSC Advances, 6 (35), 2016, 29428-29236.

- Zai, X. R. , Liu, A., Tian, Y. H., Chai, F. G., Fu, Y. B., Oxidation modification of polyacrylonitrile based carbon fiber and its electro-chemical performance as marine electrode for electric field test. Journal of Ocean University of China, 19 (2), 2020, 361-368.

- Fu, Y. P. , Li, H. X., Cao, W. Y., Enhancing the interfacial properties of high modulus carbon fiber reinforced polymer matrix composites via electrochemical surface oxidation and grafting, Composites Part A-Applied Science and Manufacturing, 130, 2020, 1-11.

- Casimero, C. , Hegarty, C., Mc Glynn, R. J., Davis, J., Ultrasonic exfoliation of carbon fiber: electroanalytical perspectives. Journal of Applied Electrochemistry, 50, 2020, 383-394.

- Liang, Y. , Li, X., Semitekolos, D., Charitidis, C. A., Dong, H., Enhanced properties of PAN-derived carbon fibers and resulting composites by active screen plasma surface functionalization. Plasma Process Polym. 2020, 1-11.

- Sun, Y. , Yang, C., Lu, Y., Weak layer exfoliation and an attempt for modification in anodic oxidation of PAN-based carbon fiber. J Mater Sci., 55, 2020, 2372-2379.

- Sun, T. , Li, M. X., Zhou, S. T., Liang, M., Chen, Y., Zou, H. W., Multi-scale structure construction of carbon fiber surface by electrophoretic deposition and elctropolymerisation to enhance the interfacial strength of epoxy resin composites. Applied Surface Science, 499, 2020, Article no. 143929, 1-12.

- Cao, Y. H. , Farha, F. I., Ge, D. S., Liu, X. H., Liu, W., Li, G., Zhang, T., Xu, F. J., Highly effective E-heating performance of nickel coated carbon fiber and its composites for de-icing application. Composites, 229, 2019, 1-7.

- Eyckens, D. J. , Arnold, C. L., Randall, J. D., Stojcevski, F., Hendlmeier, A., Stanfield, M. K., Pinson, J., Gengenbach, T. R., Alexander, R., Soulsby, L. C., Francis, P. S., Henderson, L. C., Fiber with butterfly wings: Creating colored carbon fibers increased strength, adhesion, and reversible malleability. ACS Applied Materials and Interfaces, 11 (44), 2019, 41617-41625.

- Li, H. Y. , Liebscher, M., Ranjbarian, M., Hempel, S., Tzounis, L., Schrofl, C., Mechtcherine, V., Electrochemical modification of carbon fiber yarns in cementitious pore solution for an enhanced interaction towards concrete matrices. Applied Surface Science, 487, 2019, 52-58.

- Wen, Z. P. , Xu, C., Qian, X., Zhang, Y. G., Wang, X. F., Song, S. L., Dai, M. Z., Zhang, C., A two step carbon fiber surface treatment and its effect on the interfacial properties of CFIEP composites: The electro chemical oxidation followed by grafting of silane coupling agent. Applied surface science, 486, 2019, 546-554.

- Fu, Y. P. , Lu, Y. K., You,, T., Wu, J. L., Cao, W. Y., Study on multistage anodization for high-modulus carbon fiber. Surface and interface analysis, 51 (8), 2019, 798-808.

- Arnold, C. L. , Eyckens, D. J., Servinis, L., Nave, M. D.,, Yin, H. Y., Marceau, R. K. W., Pinson, J., Demir, B., Walsh, T. R., Henserson, L. C., Simultaneously increasing the hydrophobicity and interfacial adhesion of carbon fibers: a simple pathway to install passive functionality into composites. Journal of Material Chemistry A, 7 (22), 2019, 13483-13494.

- Schenck, T. K. , Bruck, B., Schulz, M., Sporl, J. M., Hermanutz, F., Cl auss, B., Mueller, W. M., Heidenreich, B., Koch, D., Horn, S., Buchmeiser, M. R., Carbon fiber surface modification for tailored fiber-matrix adhesion in the manufacture of C/C-SiC composites. Composites Part A – Applied Science and manufacturing, 120, 2019, 64-72.

- Zhang, S. B. , Dai, Q. L., The surface modification of carbon fiber for thermoplastic HDPE composites surface and interface analysis. 51 92), 2019, 184-189.

- Bu, A. M. , Zhang, Y. F., Zhang, Y. P., Chen, W. W., Cheng, H. W., Wang, L., Wang, Y. X., A novel electrolytic plasma spraying preparation of SiO2/SiC coating on carbon fiber fabric. Coatings, 8, 2018, 1-8.

- Barlow, S. T. , Lonie, M., Hao, R., Defnet, P. A., Zhang, B., Electrodeposited gold on carbon-fiber microelectrodes for enhancing amperometric detection of dopamine release from pheochromocytoma cells. Analytical Chemistry, 90 (16), 2018, 10049-10055.

- Arnold, C. L. , Beggs, K. M., Eyckens, D. J., Stojcevski, F., Servinis, L., Henderson, L. C., Enhancing interfacial shear strength via surface grafting of carbon fibers using the Kolbe decarboxylation reaction. Composites Science and technology, 159, 2018, 135-141.

- Mikolajcsyk, T. , Pierozynski, B., Influence of surface oxidation of nickel-coated carbon fiber on oxygen evolution reaction in alkaline solution. International Journal of electrochemical science, 12 (12), 2017, 11455-11464.

- Servinis, L. , Beggs, K. M., Scheffler, C., Wolfel, E., Randall, J. D., Gengenbach, T. R., Demir, B., Walsh, T. R., Doeven, E. H., Francis, P. S., Hederson, L. C., Carbon, 118, 2017, 393-403.

- Zhang, A. L. , Zhang, Y. H., Wang, S., Li, S. X., Guo, T. T., Electrochemical copolymerization of acrylic acid and acrylamide on the carbon fiber surface. High performance polymers, 29 (41), 2017, 386-395.

- Gallo, S. C. , Charitidis, C., Dong, H. S., Surface functionalization of carbon fibers with active screen plasma. Journal of vacuum science and technology, 35 (7), 2017, 1-11.

- Zhang, Y. Y. , Zhang, Y. Z., Liu, Y.,, Wang, X. L., Yang, B., A novel surface modification of carbon fiber for high-performance thermoplastic polyurethane composites. Applied Surface Science, 382, 2016, 144-154.

- Zhang, A. L. , Guo, T. T., Wang, S., Electro polymerization modification on surface of carbon fiber with acrylic acid. Journal of Shenyang University of Technology, 38 (5), 2016, 491-496.

- Yamamoto, T. , Uematsu, K., Irisawa, T., Tanabe, Y., Controlling of the interfacial shear strength between thermoplastic resin and carbon fiber by adsorbing polymer particles as carbon fiber using electrophoresis. Composites part A – Applied surface and manufacturing. 88, 2016, 75-78.

- Kim, D. K. , An, K. H.,, Bang, Y. H., Kwac, L. K., Oh, S. Y., Kim, B. J., Effects of electrochemical oxidation of carbon fibers on interfacial shear strength using a micro-bond method. Carbon letters, 19 (1), 2016, 32-39.

- Wu, B. , Zheng, G., Sun, Y., Cui, Y., Bu, B. Y., Surface properties of PAN-based carbon fibers modified by electrochemical oxidation in organic electrolyte systems. Journal of Materials Engineering, 44 (9), 2016, 52-57.

- Ke, F. Y. , Tang, J., Guang, S. Y., Xu, H. Y., Controlling the morphology and property of carbon fiber/polyaniline composites for supercapacitor electrode materials by surface functionalization. RSC Advances, 6 (18), 2016, 14712-14719.

- Beggs, K. M. , Randall, J. D., Servinis, L., Krajewsi, A., Denning, R., Henderson, L. C., Increasing the reactivity and IFSS of unsized carbon fiber by covalent surface modification. Reactive and functional polymers, 129, 2008, 123-128.

- Yamashita, A. , Sasaki, T., Tanaka, S., Electrochemical synthesis and immobilization of a bead work-like prussion blue on carbon fiber and the removal of cesium. Journal of Environmental Chemical Engineering, 5 (3), 2017, 2913-2920.

- Kakhki, R. M. , A review to recent developments in identification of carbon fiber electrodes. Arabian Journal of Chemistry 12 (7), 2019, 1783-1794.

- Zhang, M. Ding, L., Zheng, J., Liu, L. B., Alsulami, H., Kutbi, M. A., Xu, J. L., Surface modification of carbon fibers with hydrophilic Fe3O4 nanoparticles for nickel based multifunctional composites. Applied Surface Science, 509, 2020, 1-11.

- Zhu, P. , Shi, J., Bao, L. M., Effect of polyetherimide nanoparticle coating on the interfacial sheer strength between carbon fiber and thermoplastic resins. Applied Surface Science, 509, 2020, 1-8.

- Wu, G. , Liu, Y. 10 Jan 2020, China, CN110670352–A. [Google Scholar]

- Yandrapu, S. , Gagineni, P. K., Ramamoorthy, S. K., Ray, B. C., Prusty, R. K., Effects of electrophoretic deposition process parameters on the mechanical properties of graphene carboxyl-grafted carbon fiber reinforced polymer composite. Journal of Applied Polymer Science, 2020, article no. 48925, 1-11.

- Kareem, A. A. , Rasheed, H. K., Electrical and thermal characteristics of MWCNT’s modified carbon fiber epoxy composite films. Materials Sciene-Poland, 37 (4), 2019, 622-627.

- Zhou, L. , Fu, Y. W., Yin, T., Tian, X. F., Qi, L. H., Building the silicon carbide nanowire network on the surface of carbon fibers: Enhanced interfacial adhesion and high performance wear resistance. Ceramics International, 45 (17), 2019, 22571-22577.

- Zheng, Y. W. , Wang, X. Y., Wu, G. S., Chemical modification of carbon fiber with diethylene triamine penta acetic acid/holloysite nanotube as a multifunctional interfacial reinforcement for silicon resin composites. Polymers for advanced technologies, 31 (31), 2020, 527-535.

- Nandi, A. , Das, S., Halder, S., Chakraborty, A., Imam, M. A,, Ultrasonically assisted electrophoretic deposition of oxidized graphite nanoparticle onto carbon fiber, amending interfacial property of CFRP, Journal of composite materials, 2019.

- Zheng, Y. W. , Wang, X. Y., Wu, G. S., Facile strategy of improving interfacial strength of silicone resin composites through self-polymerized poly dopamine followed via the sol-gel growing of silica nanoparticles onto carbon fiber. Polymers 11 (10), 2019, 1-11.

- Zhao, W. , Yi, X., Wei, D., Surface modification method of carbon fiber involves embedding carbon fiber in mixed powder containing nanotitania powder and phenolic resin, carbonizing, washing, vacuum-drying, immersing in mixture containing of lithium fluoride. CN110219168-A, 10 Sep 2019.

- Kusiak-Nejman, E. , Czyzewski, A., Wanag, A., Dubicki, M., Sadlowski, M., Wrobel, R. J., Morawski, A. W., Photocatalytic oxidation of nitric oxide over AgNPs/TiO2 loaded carbon fiber cloths. Journal of environmental management. 262, 2020, 1-10.

- Fakhrhoseini, S. M. , Li, Q. X., Unnikrishnan, V., Naebe, M., Nano-magnetite decorated carbon fiber for enhanced interface shear strength, Carbon, 148, 2019, 361-369.

- Gangineni, P. K. , Yandrapu, S., Ghosh, S. K., Anand, A., Prusty, R. K., Ray, B. C., Mechanical behavior of graphene decorated carbon fiber reinforced polymer composites: An assessment of the influence of functional groups. Composites Part A-Applied Science and manufacturing, 122, 2019, 36-44.

- Huang, H. , Xu, N., Sun, G. R., Yang, X., Hu, J., Improvement of oxidation resistances of carbon fibers by coating SiC. Materials Research Express, 6 (6), 2019, 1-7.

- Cui, X. , Ma, L. , Wu, G. S., Mussel-inspired co-deposition of polydopamine/silica nanoparticles onto carbon fiber for improved interfacial strength and hydrothermal aging resistance of composites. Polymers, 2020, 12, 1–7. [Google Scholar]

- Yang, X. , Tu, Q. Z., Shen, X. M., Pan, M., Jiang, C. M., Zhu, P. X., Li, Y., Li, P., Hu, C. B., Surface modification of poly (p-phenylene terephalamide) fibers by polydopamine-polyethylene imine (graphene oxide) multilayer films to enhance interfacial adhesion with rubber matrix. Polymer testing, 78, 2019, 1-10.

- Puthongkham, P. , Venton, B. J., Nanodiamond coating improves the sensitivity and antifouling properties of carbon fiber microelectrodes. ACS Sensors, 4 (9), 2019, 2403-2411.

- Zhang, C. X. , Zhang, X. D., Wu, G. S., Enhancing interfacial strength and hydrothermal aging resistance of silicone resin composites by different modification of carbon fibers with silica nanoparticles. Polymer composites, 40, 2019, E975-E982.

- Levin, D. D. , Romashkin, A. V., Polikarpov Yu, A., Struchkov, N. S., Kireynov, A. V., Komarov, I. A., Increase of composite structures strength by carbon fiber surface modification with spray deposited carbon nanotubes. IOP conference series: Materials science and engineering, 683, 2019, 1-5.

- Zhang, X. D. , Wu, G. S., Grafting halloysite nanotubes with amino carboxyl groups onto carbon fiber surface for excellent interfacial properties of silicon resin composites. Polymer, 10 (10), 2018.

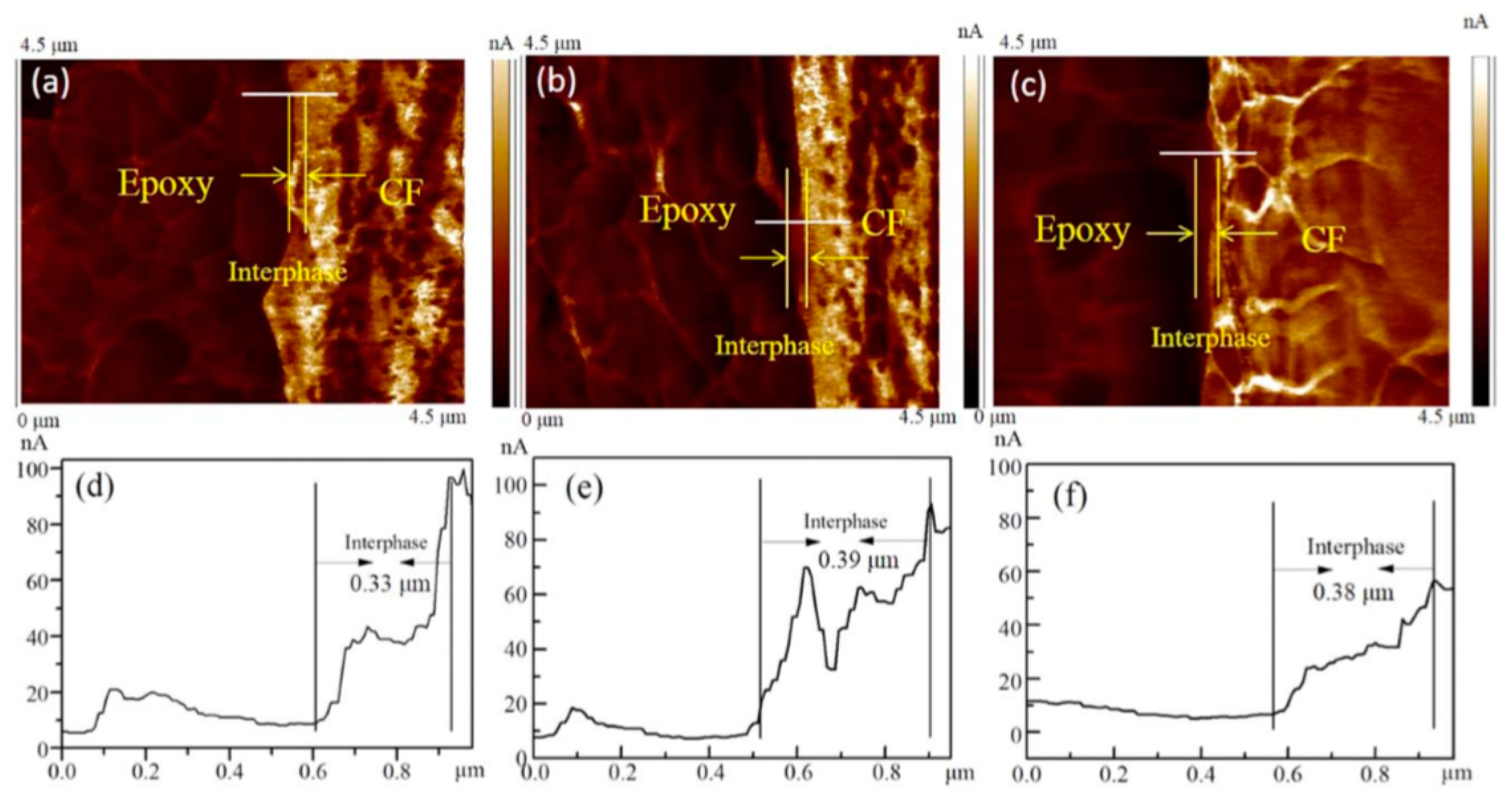

- Ma, Y. Y. , Yan, C., Xu, H. B., Liu, D., Shi, P. C., Zhu, Y. D., Liu, J. L., Enhanced interfacial properties of carbon fiber reinforced polyamide 6 composites by grafting graphene oxide onto fiber surface. Applied Surface Science, 452, 2018, 286-298.

- Zhao, N. , Ma, Z. K., Song, H. H., Wang, D. L., Xie, Y. G., Polyaniline/reduced graphene oxide-modified carbon fiber brush anode for high-performance microbial fuel cells. Interfacial Journal of Hydrogen Energy, 43 (37), 2018, 17867-17872.

- Xu, S. Q. , Jiang, Q., Surface modification of carbon fiber support by ferrous oxalate for biofilm wastewater treatment system. Journal of cleaner production, 194, 2018, 416-424.

- Liu, X. G. , Cui, X. J., Zhang, C. X., Zhang, X. D., Wu, G. S., Effects of different silanization followed via the sol-gel growing of silica nanoparticles onto carbon fiber on interfacial strength of silicone resin composites. Chemical physics letters, 707, 2018, 1-7.

- Cui, H. Z. , Jin, Z. Y., Zheng, D. P., Tang, W. C., Li, Y. B., Yan, Y. C., Lo, T. Y., Xing, F., Effect of carbon fibers grafted with carbon nanotubes on mechanical properties of cement-based composites. Construction and building materials, 181, 2018, 713-720.

- Qiu, J. W. , Li, J. S., Yuan, Z. S.,, Zeng, H. X., Chen, X. G., Surface modification of carbon fibers for interface improvement in textile composites. Applied composite materials, 25 (4), 2018, 853-860.

- Yadav, A. K. , Benerjee, S., Kumar, R., Kar, K. K., Ramkumar, J., Dasgupta, K., Mechanical analysis of nickel particle-coated carbon fiber – reinforced epoxy composites for advanced structural applications. ACS applied nano materials, 1 (8), 2018, 4332-4339.

- Luo, Z. J. , Chen, H., Wu, J., Xia, X. H., Liu, H. B., Yang, L., Surface modification of short carbon fibers with carbon nanotubes to reinforce epoxy matrix composites. Journal of nanoscience and nanotechnology, 18 (7), 2018, 4940-4952.

- Chen, B. B. , Li, X. F., Li, X., Jia, Y. H., Yang, J., Li, C. S., Hierarchial carbon fiber-SiO2 hybrid/polyimide composites with enhanced thermal, mechanical and tribological properties. Polymer composites, 39, 2018, E1626-E1634.

- Xie, F. , Hu, W. J., Ning, D. D., Zhuo, L. H., Deng, J. B., Lu, Z. Q., ZnO nanowires decoration on carbon fiber via hydrothermal synthesis for paper based friction materials with improved friction and wear properties. Ceramics International, 44 (4), 2018, 4204-4210.

- Senthilkumar, N. , Kumar, G. G., Manthiram, A., 3D hierarchical core-shell nanostructured arrays on carbon fibers as catalysts for direct urea fuel cells. Adv Energy Mater, 8, 2018, 1-11.

- Yu, P, Ma, J. C, Zhang, R., Zhang, J. Z., Botte, G. G., Novel Pd-Co electrocatalyst supported on carbon fibers with enhanced electrocatalytic activity for coal electrolysis to produce hydrogen. ACS Applied Energy Materials, 1 (2), 2018, 267-272.

- Xie, J. G. , Song, M. M., Fu, H. Q., Synthesis and properties of electrical conductive and antibacterial siloxane-modified carbon fiber-silver-acrylate nanocomposites. International Journal of Polymeric materials and polymeric biomaterials. 67 (16), 2018, 951-960.

- Awan, F. S. , Fakhar, M. A., Khan, L. A., Zaheer, U., Khan, A. P., Subhani, T., Interfacial mechanical properties of carbon nanotube-deposited carbon fiber epoxy matrix hierarchical composites. Composite Interfaces, 25 (8), 2018, 681-699.

- Zabihi, O. , Ahmadi, M., Li, Q.,, Shafei, S.,, Huson, M. G., Naebe, M., Carbon fiber surface modification using functionalized nanoclay: A hierarchical interphase for fiber-reinforced polymer composites. Composites Science and Technology, 148, 2017, 49-58.

- Fang, J. , Xie, Z. G., Wallace, G., Wang, X. G., Co-deposition of carbon dots and reduced graphene oxide nanosheets on carbon –fiber micro electrode surface for selective detection of dopamine. Applied surface science, 412, 2017, 131-137.

- Zhou, W. , Long, L., Xiao, P., Li, Y., Luo, H., Hu, W. D., Yin, R. M., Silicon carbide nano-fibers in-situ grown on carbon fibers for enhanced microwave absorption properties. Ceramics International, 43 (7), 2017, 5628-5634.

- Gao, B. , Zhang, R. L., He, M. S., Sun, L. C., Wang, C. G., Liu, L., Zhao, L. F., Cui, H. Z., Cao, A. P., Effect of a multiscale reinforcement by carbon fiber surface treatment with graphene oxide/carbon nanotubes on the mechanical properties of reinforced carbon/carbon composites. Composites Part A – Applied Science and manufacturing, 90, 2016, 433-440.

- Mei, H. , Zhang, S. M., Chen, H., Zhou, H. S., Zhai, X. Y., Chen, L. F., Interfacial modification and enhancement of toughening mechanisms in epoxy composites with CNT’s grafted as carbon fibers. Composites Science and Technology, 134, 2016, 89-95.

- Zhang, R. L. , Gao, B.,, Ma, Q. H., Zhang, J., Cui, H. Z., Liu, L., Directly grafting graphene oxide onto carbon fiber and the effect on the mechanical properties of carbon fiber composites. Materials and Design, 93, 2016, 364-369.

- Hoshi, K. , Maramatsu, K., Sumi, H., Nishioka, Graphene coated carbon fiber cloth for electrodes of glucose fuel cells. Japanese Journal of Applied Physics, 55 (2), 2016.

- Jiang, J. J. , Yao, X. M., Xu, C. M., Su, Y., Deng, C., Liu, F., Wu, J. J., Preparation of graphene oxide coatings onto carbon fibers by electrophoretic deposition for enhancing interfacial strength in carbon fiber composites. Journal of Electrochemical Society, 163 (5), 2016, D133-D139.

- Wu, G. S. , Ma, L. C., Wang, Y. W., Lie, L., Huang, Y. D., Interfacial properties and thermos-oxidative stability of carbon fiber reinforced methyl phenyl silicone resin composites modified with polyhedral oligomeric silsesquioxanes in the interphase. RSC Advances, 6 (6), 2016, 5032-5039.

- Wang, C. F. , Li, J., Sun, S. F., Li, X. Y., Wu, G. S., Wang, Y. W., Xie, F., Huang, Y., Controlled growth of silver nanoparticles on carbon fibers for reinforcement of both tensile and interfacial strength. RSC Advances, 6 (17), 2016, 14016-14026.

- Potschke, L. , Huber, P., Schriever, S., Rizzotto, V., Gries, T., Blank, L. M., Rosenbaum, M. A., Rational selection of carbon fiber properties for high-performance textile electrodes in bioelectrochemical systems. Frontiers in energy research, 7, 2019, 1-15.

- Ding, Y. , Gou, L., Li, Y., Modifying nano carbon fiber surface comprises e.g. subjecting nano carbon fiber to low temperature plasma treatment, coating the nano carbon fiber with polydopamine, coupling modification on the nano carbon fiber with coupling agent. CN110130102, 16 Aug 2019.

- Lv, X. , Wang, F., Mixed solution formulation for surface modification of conductive fibers, comprises nitric acid, lead nitrate, binder, and rest is pure water, adhesive is sodium silicate or starch with high purity, placing formulated mixed solution. CN110085825-A, 2 Aug 2019.

- Du, B. , Qian, J., He, C., Wang, X., Shui, A., Preparing carbon fiber having multi-scale silicon carbide-silicon oxide carbides ceramic coating on surface involves adding transition metal compound to water and mixing uniformly to obtain mixed solution and soaking carbon fiber. CN110042653, 23 Jul 2019.

- Qin, W. , He, J., Zhu, F., Meng, J., Method for surface modification of carbon fiber surface functionalization, involves soaking carbon fiber raw material with acetone, and preparing dopamine hydrochloride solution, and placing washed carbon fiber in dry box. CN1100168007-A, 16 Jul 2019.

- Ikeda, T. , Nishina, Y., Kano, S., Aoyagi, Y., Fujiwara, T., Mori, M., Surface modification method for carbon fiber of carbon nanostructure e.g. carbon nanotube involves cutting the C-C coupling of the carbon fiber by the ultraviolet rays which generate on the light emission process of gas. JP2019099989-A, 24 Jun 2019.

- Tao, F. , Preparing high thermal conductive polymer involves carrying out surface modification on carbon nanofibers and composite structure aluminum particles, and then mixing with filler and PVDF resin. CN109593305-A, 9 Apr 2019.

- Li, G. , Xu, P., Lin, J., Xiang, Z., Yu, Y., Yang, X., Modifying carbon fiber surface by aromatic condensed ring molecular assembly comprises carrying out imidization reaction, immersing carbon fiber and combining. CN109338730-A, 15 Feb 2019.

- Guo, P. , Preparing high-strength carbon fiber involves pretreating carbon fiber surface by first immersing carbon fiber in sulphuric acid solution, continuously stirring, filtering fiber out, and then using deionized water, until it is neutral. CN109371662-A, 22 Feb 2019.

- Guan, M. , Surface modification method of polymer fiber by soaking untreated carbon fiber in sulphuric acid solution, cleaning residual sulfuric acid in carbon fiber surface, oven drying and fixing carbon fiber filament ribbon on PTFE oriented frame. CN109265921-A, 25 Jan 2019.

- Ma, S. , Zhang, S., Jiao, Z., Sun, Z., Preparing modified carbon fiber comprises mixing carbon fiber in nitric acid solution and carrying out oxidation process, adding carbon oxide fiber into ethanol solution of the silane coupling agent and carryingout surface modification. CN108997719-A, 14 Dec 2018.

- Xu, H. , Chen, X., Yan, C., Liu, D., Zhu, Y., Thermoplastic sizing agent useful for surface modification of carbon fiber comprises cyclic phenyl sulfide mixture composed of cyclic phenyl sulfide. CM108951173-A, 7 Dec 2018.

- Park, S. W. , Jung, H. K., Shin, Y. J., Song, S. H., Surface modifying carbon fiber useful for reinforced plastic comprises dissizing the carbon fibers, surface modifying the surface of the desized carbon fiber, and sizing the plasma treated carbon fibers. KR2018128578-A; KR1968646-B1, 4 Dec 2018.

- Jin, Y. , Zheng, X., Fang, Y., Chen, J., He, G., Huang, C., Shi, B., Modifying of spiral nano carbon fibers involves mixing graphitized spiral nano carbon fiber with ethanol and ball milling to obtain spiral nano carbon fiber, and acidifying ball-milled spiral nanocarbon fiber. CN108864773-A, 23 Nov 2018.

- Li, M. , Improved power generation efficiency of a wind power generator and reducing noise, comprises choosing carbon fiber blade of wind power generator, subjecting the activation treatment, surface modification, and applying a performance coating. CN108864457-A, 23 Nov 2018.

- Park, Y. B. , Kim, B. J., Cha, S. H., Method for forming zinc oxide nanostructure of carbon fiber using plasma process, involves reforming surface of woven carbon fiber (WCF) using atmospheric pressure plasma and growing nanostructure on surface-modified surface. KR1919496-B1, 16 Nov 2018.

- Lv, Y. , Yao, L., Zhang, W., Zhang, J., Guo, Y., Method for surface modification of carbon fibers involves subjecting carbon fiber coated with thermostetting resin sizing agent to low-temperature heat treatment. CN108642882-A, CN108642882-B, 12 Oct 2018.

- He, Y. , Li, S., Zhang, Z., Xue, L., Miao, S., Wang, C., Carbon nanotube modified carbon fiber surface large-scale production equipment include anode insulating bracket, clamping hopper, anode discharge wire, electric push rod, oven, and electronic portion including pulse high-voltage generator. CN108442101-A, 24 Aug 2018.

- Wang, J. , Jiang, Y., Preparing high strength carbon fiber sizing agent comprises e.g. reacting acetic anhydride ammonium persulfate, sulfuric acid solution, polycarbonate, tetrahydrofuran, emulsifier, heating, agitating and ultrasonically dispersing. CN108360252-A, 3 Aug 2018.

- Wang, Z. Y. , Replacement method of oil agent of surface of carbon fiber, involves performing pasting step that covers second type oil agent to carbon fiber, after plasma surface treatment to provide plasma gas flow and making it act on carbon fiber. JP2018115396-A, 26 Jul 2018; JP6393348-B2, 19 Sep 2018.

- Joo, S. W. , Dillip, G. R., Kim, C. S., Carbon fiber/metal oxide complex composite used in electrode for ultrahigh capacity capacitor, comprises carbon fiber, and at least one metal oxide bonded to the carbon fiber. KR2018082799-A, ; KR1960154-B1, 4 Jul 2019. 19 July.

- Zhu, B. , Yuan, X., Qiao, K., Yu, J., Zhao, S., Preparing oxidized graphene modified carbon fiber by silane coupling agent assisted electrophoretic deposition comprise e.g. placing carbon fiber after desulfurization in aqueous solution containing amino propyl triethoxy-silane and ethanol. CN108286187-A, 17 Jul 2018.

- Jin, Y. , Chen, J., Wang, L., Jiang, C., Zhou, X., Li, B., Modification of nanosilica particles on spiral nano carbon fiber, condensing and refluxing liquids, suction filtering obtained mixture and drying filter residue. CN108219194-A, 29 Jun 2018; CN108219194-B, 17 Dec 2019.

- Tian, Y. , Zhang, X., Yang, Y., Surface-modification of carbon fiber involves carrying out electrochemical treatment using composite electrolyte containing mixture of water, glycol, oxalic acid and acetonitrile as solvent, and nitrogen containing compound. CN108193482-A, 22 Jun 2018.

- Song, G. , Ma, L., Tang, L., Li, J., Zhao, T., Grafting branched molecular tannic acid on carbon fiber surface by adding tannic acid into ethyl acetate, adding p-toluene sulfonic acid, stirring, obtaining reaction liquid, and adding dried acryl chloride carbon fiber into reaction liquid. CN107761375-A, 6 Mar 2018.

- Xue, Z. , Wenqi, C., Xiaoming, C., Hebin, H., Preparation of carbon fiber reinforced epoxy resin matrix composite by modified double-sizing agent involves dissolving silane coupling agent into ethanol solution, stirring, and introducing modified carbon. CN107629224-A, 26 Jan 2018.

- Chen, F. , Anti-static high-rigidity linear low density polyethylene composition for film comprises linear low-density polyethylene having certain density and certain value of melt flow rate, and surface modified carbon nanofibers modified surface. CN107365443-A, 21 Nov 2017.

- Lee, Y. S. , Jung, M. J., Park, M. S., Lee, S., Jo, H., Surface modification of carbon fiber by irradiation with acid involves supporting carbon fiber in acid solution, irradiating carbon fiber supported on acid solution, and then washing and drying carbon fiber, where radiation is electron rays. IR1789205-B1, 24 Oct 2017.

- Yang, H. , Feng, J., Yan, W., Modification of carbon fiber surface by in-situ polymerization of pyrrole comprises soaking carbon fiber in poly pyrrole aqueous dispersion, and reacting mixture with oxidizing agent to polymerize in situ on carbon fiber surface. CN107083680-A, 22 Aug 2017.

- Wang, L. , Chang, Z., Wei, Q., Hu, Y., Chen, W., Wang, J., Modifying immobilized enzyme vector by using microwave assisted method comprises e.g. pretreatment of enzyme vector, using organic reagents for carbon fiber surface treatment and drying, stirring and washing. CN107058280-A, 18 Aug 2017.

- Gao, S. , Chen, K., Xu, Z., Li, H., Hu, C.,, Luo, Y., Yang, H., Surface modification of carbon fiber used in e.g. biomedical material involves degelling carbon fiber, oxidising carbon fiber, reducing oxidized carbon fiber, cleaning, and drying. CN107034662-A, Aug 2017.

- He, Y. , Bai, Y., Li, S., Jing, C.,, Zhu, Y., Device for surface modification of carbon fibers by rapid attachment of double-phase carbon nanotubes, has power source which is comprised with high voltage module, positive connection line and negative connection line. CN106906642-A, 30 Jun 2017.

- Wang, R. , Lin, W., Jiao, W., Preparation of acylamide-based graft-modified carbon fiber involves dissolving modified in volatile organic solvent, heating, carrying out surface modification of carbon fiber with modifier solution and drying. CN106835695-A, 13 Jun 2017; CN106835695-B, 14 May.

- Ren, L. , Sang, L., Ding, F., Liu, X., Zhao, Q., Li, Y., Preparation of cathode used for oxygen dissolved seawater battery, involves forming surface active layer by subjecting poly acrylonitrile carbon fiber material surface matrix core to surface modification treatment and heat-treating surface. CN106654163, 10 May.

- Qian, X. , Ren, Q., She, Z., Song, Y., Yuan, H., Zhang, L., Zhao, C., Preparation method of bioactive carbon fiber used in sewage treatment, involves pre-oxidizing poly acrylonitrile fibers, carbonizing fibers, and performing activation treatment for modification of carbon fiber surface. CN106567158-A, 19 Apr 2017.

- Yin, R. , Zhou, W.,, Preparing carbon fiber sialon ceramics composite material comprises subjecting carbon fiber to surface treatment to obtain modified carbon fiber having silicon carbide coating on its surface, chopping, ball milling, drying and molding. CN106518124-A, 24 Mar 2017; CN106518124-B, 27 Aug 2019.

- Chu, Y. , Liu, S., Song, W., Wang, H., Wang, J., Producing surface modified layer of carbon fiber-titanium carbide – titanium diboride for ship involves utilizing friction agitation processing and forming S-shaped groove on upper surface of substrate and small holes in periphery of groove. CN106480451-A, 8 Mar 2017; CN106480451-B, 21 Aug 2018.

- Li, Y. , Method for surface modification of carbon fiber material involves putting carbon fiber material into extraction device, extracting in acetone solution, removing surface coating of carbon fiber material, and wetting with deionized water. CN106436273-A, 22 Feb 2017.

- Jiang, J. , Guo, Q., Zhou, L., Su, Y., Xu, C., Deng, G., Surface modification of carbon fiber involves graphene solution on carbon fiber surface, placing dried carbon fiber in plasma device and spraying plasma on surface of carbon fiber coated with nano graphene of graphene solution. CN106283601-A, 4 Jan 2017.

- Jiang, J. , Guo, Q., Zhou, L., Su, Y., Xu, C., Chen, X., Surface modification of carbon fiber by extracting carbon fiber material with acetone by boiling, cleaning in deionized water, putting into vacuum drying box, with mixed acid, magnetically stirring, washing and vacuum drying. CN106245319-A, 21 Dec 2016.

- Li, Y. , Carbon fiber coating modification process comprises e.g. adding tetra butyl titanate to ethanol solution, then adding alcohol solution of hydrochloric acid, stirring to obtain titanium dioxide sol, and post-processing. CN106245318-A, 21 Dc 2016.

- Li, Y. , Surface modification of carbon fiber involves dispersing material (CF-3) formed by processing carbon fiber in diethyl ether and lithium borohydride, to silane coupling agent hydrolysate, ultrasonically processing filters and drying. CN106192407-A, 7 Dec 2016.

- Gao, X. , Guo, S., Ding, C., Surface modification of carbon fiber comprising using titanic acid ester as coupling agent for carrying out surface treatment to the carbon fiber, then carrying out high-temperature air oxidation to the processed carbo n fiber. CN106032410-A, 19 Oct 2016.

- Gao, Z. , Tan, Y., Yang, H., Zhang, B., Wang, M., Preparation of atomic layer deposition modified confinement catalyst used for preparation of heterogeneous solid catalyst, involves dispersing dried carbon nanofibers in alcohol, depositing platinum nanoparticles and aluminum oxide. CN105771972-A, 20 Jul 2016; CN105771972-B, 20 Jul 2018.

- Liu, D. , Lv, F., Li, G., Li, S., Yi, W., Zhang, F., Zhou, Y., Li, C., Zhang, X., Li, N., Chen, Y., Preparing filter screen filler involves heating the carbon fiber, treating carbon fiber with concentrated nitric acid for surface modification and then dissolving fluorinated organosilane solution in dimethyl sulfoxide solutions. CN105350287-A, 24 Feb 2016; CN105350287-B, 18 Jul 2017.

- Ma, J. , Zhai, C., Zhang, Q., Preparing carbon fiber enhanced polyimide coated complex and short carbon fiber and subjecting to surface modification and increasing carbon fiber. CN105295373-A, 03 Feb 2016.

- Han, W. , Hong, C., Hu, P., Zhao, C., Zhang, X., Cheng, Y., An, J., Du, H., Zhou, S., Chemically grafting graphene oxide on carbon fiber surface comprises using modified Hummer’s method for preparing graphene oxide, oxidizing carbon fiber, carrying out carbon fiber surface modification and amination process and grafting. CN105239357-A, 13 Jan 2016.

- Zeininger, H. , Eder, F., Maleika, M., Modified carbon fiber used for preparing composite plastic, comprises silicone-containing coating laser having thickness less than preset value. WO2015197299-A1, 30 Dec 2015; DE102014212241-A1, 31 Dec 2015; EP3129543-A1, 15 Feb 2017; US2017130393-A1, ; JP2017524835-W, 31 Aug 2017. 11 May.

- Feng, R. , Sun, M., Sun, H., Yang, H., Nickel-graphite-poly (methyl meth acrylate) nano-composite wave-absorbing material useful e.g. in preparation of high temperature plastic, comprises e.g. modified sub-miron nickel plated carbon fiber and modified nano-nickel graphite. CN104592461-A, 6 May.

- Liu, J. , Production of polypyrrole/carbon fiber composite electromagnetic wave absorbing material, involves dispersing surface-modified carbon fiber in valine, adding pyrrole monomer and ammonium persulfate solution, reacting, washing and drying. CN104592514-A, ; CN104592514-B, 31 Aug 2016. 6 May.

- Qin, H. , Anodized carbon fiber surface treatment method involves carrying out anode oxidation treatment of carbon fiber beam, washing with distilled water, carrying out acetone extraction, rinsing with distilled water, and drying. CN104562631-A, 29 Apr 2015.

- Han, W. , Xue, Z., Wang, P., Zhao, G., Zhang, X., Cheng, Y., Surface modification of carbon fiber comprises e.g. carrying out surface halogenation and azidation of nano silicon dioxide, carrying out alkynylation of carbon fiber, and grafting nano silicon dioxide on surface of carbon fiber. CN104499270-A, 8 Apr 2015; CN104499270-B, 6 Jul 2016.

- Polycarbonate modified rubber, e.g. used in vehicle and electric industries comprises polycarbonate surface modified, organic montmorillonite, compatibilizer, light stabilizer, composite antioxidant and lubricant. (Inventor name not available in the Web of Science), CN104419181-A, 18 Mar 2015.

- He, J. , Li, J., Liu, C., Wei, F., Wang, Z., Carbon fiber surface modification method comprise extracting carbon fiber with acetone in a soxhlet extractor, drying, carrying out oxidation and acylation, then grafting with bis (3-aminophenyl) phenyl phosphine oxide. CN104195824-A, 10 Dec 2014; CN104195824-B, 27 Apr 2016.

- Guo, Z. , Huang, H., Pan, M., Surface modification method for carbon fiber powder used in e.g. aviation involves air preprocessing powder, heating in muffle furnace and immersing into oxidizing liquid for surface modification using strong oxidizing agent/sulfuric acid. CN104088132-A, 8 Oct 2014; CN10404088132-B, 16 Nov 2016.

- Sun, H. , Yao, C., Method for modifying carbon fiber that is utilized in anode material of vanadium redox flow battery, involves preprocessing carbon fiber fabric, depositing beta-lead oxide particles, and scanning fiber fabric for multiple times. CN104064781-A, 24 Sep 2014; CN104064781-B, 4 Jan 2017.

- Wang, B. , Duan, Y., Wang, H., Li, J., Chemically modifying microwave ultrasonic handled carbon fiber surface involves immersing carbon fiber in solvent among sonication carbon fibers, adding acid solution while ultrasonic dispersion and microwave radiation, adding initiator. CN104032565-A, 10 Sep 2014; CN104032565-B, 17 Aug 2016.

- Wang, C. , Pan, H., Zhang, X., Zheng, X., Jiao, S., Continuous surface modification of carbon fibers involves purifying by immersing carbon fiber in acetone solution while continuously stirring, cleaning using ultra-pure water to surface of carbon fibers, oxidizing, dispersing and drying. CN104018340-A, 3 Sep 2014; CN104018340-B, 9 Dec 2015.

- Xu, H. , Lu, Y., Oxygen and nitrogen co-doped poly acrylonitrile-based carbon fiber is prepared by electro chemical modification of raw material of poly acrylonitrile-based carbon fiber. WO2014127501-A1, 28 Aug 2014; CN104838051-A, 12 Aug, 2015; JP2016510367-W, 07 Apr 2016; CN104838051-B; JP6106766-B2, 05 Apr 2017; US9683314-B2, 20 Jun 2017; EP2960361-B1, 30 May.

- Cai, T. , Chen, D., Huang, X., Lie, Z., Song, W., Yi, M., Xie, H., Emulsion used for preparing modified carbon fiber for polyamide composite material, comprises specified amount of surface modifier containing hydroxyl group-containing compound, polyamide, emulsifier, organic solvent and water. CN103993484-A, 20 Aug 2014; CN103993484-B, 23 Dec 2015.

- Huang, Y. , Mengi, L., Ma, L., Pan, L., Wang,, Y., Qi, M., Yu, J., Modification of carbon fiber surface involves performing primary soxhlet-extraction in carbon fiber beam with acrylic ketone, removing impurity, leaching in supercritical acetone-water system, and removing carbon fiber epoxy coating. CN103966843-A, 6 Aug 2014; CN103966843-B, 2 Dec 2015.

- Xu, Z. , Wang, J., Huang, H., Hao, Y., Surface modification of carbon fiber comprises layering an industrial crbon fiber felt and an active metal in an inert material lining container, reacting under inert gas atmosphere, cooling, washing with water and the air-drying. CN103966837-A, 6 Aug 2014.

- Fan, X. , Liu, D., Xu, H., Yan, C., Zhang, X., Surface modification of carbon fiber used for interface modification composite material, involves preparing surface grafted polyphophazene carbon fiber, reacting with graphite, and obtaining surface grafted graphene carbon fiber. CN103850123-A, 11 Jun 2014; CN103850123-B, 3 Feb 2016.

- Xu, F. , Liu, B., Qiu, Y., Hu, Q., Zhang, Y., Carbon fiber interface modification comprises carrying out cryogenic treatment of carbon fiber with liquid nitrogen in cryogenic medium, and heating. CN103590233-A, 19 Feb 2014; CN103590233-B, 28 Oct 2015.

- Chen, S. , Feng, J., Surface modification of carbon fibers comprises a material containing catechol structure as surface modifying agent on a carbon fiber surface under polymerization condition. CN103572591-A, 12 Feb 2014.

- Cai, T. , Huang, X., Ma, L., Song, W., Xin, W., Zeng, X., Yi, M., Chen, D., Modifying carbon fiber surface, useful e.g. in aerospace, comprises e.g. performing electrolytic oxidation with strong alkaline electrolyte to electrochemically modify and performing electrolytic oxidation with week alkaline electrolyte. CN103541212-A, 20 Jan 2014; CN103541212-B, 18 May, 2016.

- Zhang, C. , Ma, L., Zhou, H., Meng, L., Qi, M., Yu, J., Modification method of surface-modified carbon fibers involves extracting carbon fiber into soxhlet extractor, cleaning acetone as extraction agent, removing surface impurities from carbon fibers, purifying soaking and washing. CN103450501-A, 18 Dec 2013; CN103450501-B, 26 Nov 2014.

- Xu, S. , Modification of poly acrylo nitrile-based carbon fiber surface involves plasma treating poly acrylonitrile based carbon fiber plasma under inert gas atmosphere and atomizing with grafting liquid. CN103361768-A, 23 Oct 2013.

- Huang, S. , Lv, C., Wu, G., Method for modifying carbon fiber surface, involves dissolving graphene oxide in water followed by obtaining graphene oxide water solution, and carrying out thermal treatment with coated carbon fiber on furnace to obtain finished product. CN103243544-A, 14 Aug 2013; CN103243844-B, 2 Sep 2015.

- Li, J. , Huang, Y., Song, Y., Hu, Z., Liu, L., Preparation of carbon fiber surface modification coating used for, e.g. aviation, by reacting monomer phenolic and aldehyde compounds with catalyst, diffusing in slurry to obtain phenolic resin pre polymer, drying and carbonizing. CN103061111-A, 24 Apr 2013.

- Tu, L. , Meng, J., yang, M., Li, L., Environment friendly carbon fiber surface modification for, e.g. lake water, by soaking carbon fiber precursor in acetone solution, drying, soaking in nitric acid, drying to obtain modified carbon fiber wire, and placing in gas atmosphere. CN103058356-A, 24 Apr 2013; CN103058365-B, 18 Jun 2014.

- Li, J. , Song, Y., Huang, Y., Hu, Z., Liu, L., Etching surface of controllable fiber e.g. carbon fiber, comprises passing continuous fibers to irradiation furnace, controlling twisting degree of fibers, reducing fibers from furnace, and washing fiber tow layers away by solvent. CN103046308-A, 17 Apr 2013; CN103046308-B, 27 Aug 2014.

- Meng, L. , Qi, M., Lin, Y., Zhang, C., Yu, J., Fan, D., Surface modification method of carbon fiber used in chemical industry, involves pre-processing carbon fiber bundle surface, carrying out surface oxidation treatment of obtained surface-treated carbon fiber bundle, washing and drying. CN102888750-A, 23 Jan 2013; CN102888750-B, 12 Mar 2014.

- Fang, L. , Deng, C., Jiang, J., Shi, J., Method of ultrasonic enhanced carbon fiber surface comprises surface preprocessing, washing and drying. CN102851940-A, 2 Jan 2013.

- Shi, J. , Deng, C., Jiang, J., Fang, L., Surface modification of carbon fiber used for composite material, involves coating sol solution of nano graphene and water on carbon fiber surface, drying and spraying plasma to surface of coated carbon fiber under specified conditions. CN102839534-A, 26 Dec 2012; CN102839534-B, 11 Jun 2014.

- Liu, J. , Liang, J., Wang, C., Electrochemical surface modification of carbon fiber involves preparing electrolyte solution, processing composite electrolyte system, providing carbon fiber, pouring into electrolyte cell, washing and drying. CN102660866-A, 12 Sep 2012.

- An, F. , Guo, J., Li, D., Lv, C., Wu, G., Electrochemical surface – modification of carbon fiber, involves carrying out electrochemical reaction using electrolyte containing modified carbon nanotubes, carbon fibers as anode, and conductive metal or graphite material as cathode. CN102505449-A, 20 Jun 2012.

- Fan, X. , Li, X., Ruan, C., Yu, L., Zhang, X., Yan, C.,, Zhu, Y., Modification of carbon fiber surface used for carbon fiber/polycaprolactam composite material, by reacting carbon fiber with hexa chloro cyclo triphosphazene, and reacting modified carbon fiber surface with caprolactam monomer. CN102493184-A, 13 Jun 2012; CN102493184, 26 Mar 2014.

- Li, J. , Luo, R., Xu, N., Modification of poly acrylonitrile-base carbon fiber by carbon nanotube, involves loading prefabricating component of carbon fiber pricking felt in catalyst precursor, calcining, deoxidizing, cooling, and thermally treating. CN101671951-A, 17 Mar 2010; CN10167951-B, 15 Feb 2012.

- Wu, G. S. , Ma, L. C., Liu, L., Wang, Y. W., Xie, F., Zhong, Z. X., Zhao, M., Jiang, B., Huang, Y. D., Interfacially reinforced methyl phenyl silicone resin composites by chemically grafting multiwall carbon nanotubes onto carbon fibers. 82, 2015, 50-58.

- Friedrich, J. F. , Wattmarshausen, S., Altmann, K., Hidde, G., Adehsion promotion by ESI deposition of thin polymer layers onto carbon fibers. Surface innovations, 3 (4), 2015, 215-227.

- Fang, C. Q. , Wu, J. X., Wang, J. L., Zhang, T., Modification of carbon fiber surfaces via grafting with Meldrum’s acid. Applied surface science, 356, 2015, 9-17.

- Wu, G. S. , Ma, L. C., Liu, L., Wang, Y. W., Huang, Y. D., Interfacial improvement of carbon fiber-reinforced with sizing agent containing functionalized carbon nanotubes journal of adhesion science and technology, 29 (21), 2015, 2291-2310.

- Kim, H. H. , Han, W., Lee, H. S., Min, B. G., Kim, B. J., Preparation and characterization of silicon nitride (Si-N) coated carbon fibers and their effects on thermal properties in composites. Materials science and engineering B-Advanced functional solid state materials, 200, 2015, 132-138.

- Pan, Y. S. , Chen, Y., Shen, Q. Q., Pan, C. L., Effect of carbon fibers surface modification on the flexural mechanical properties of carbon fiber reinforced polyether ether ketone biocomposites. Journal of Polymer Engineering, 35 (7), 2015, 657-663.

- Deng, C. , Jiang, J. J., Liu, F., Fang, L. C., Wang, J. B., Li, D. J., Wu, J. J., Effects of electrophoretically deposited graphene oxide coatings on interfacial properties of carbon fiber composite. Journal of materials science, 50 (17), 2015, 5886-5892.

- Wettmarshausen, S. , Friedrich, J. F.,, Meyer-Plath, A., Kalinka, G., Hidde, G., Weidner, S., Coating of carbon fibers with adhesion-promoting thin poly(acrylic acid) and poly(hydroxyehtylmethacrylate) layers using electrospray ionization. Journal of Adhesion Science and Technology, 29 (15), 2015, 1628-1650.

- Song, J. B. , Yuan, Q. P., Liu, X. S., Wang, D., Fu, F., Yang, W. B., Combination of nitrogen plasma modification and water borne polyurethane treatment of carbon fiber used for electric heating of wood floors. Bioresources, 10 (3), 2015, 5820-829.

- Grigoryan, N. S. , Gubanov, A. A., Vogramyan, J. A., Korshak, Y. V., Electrochemical modification of the carbon fiber surface. Russian Journal of Applied Chemistry, 88 (7), 2015, 1150-1156.

- Ma, L. C. , Meng, L. H., Wu, G. S., Wang, Y. W., Zhao, M., Zhang, C. H., Huang, Y. D., Improving the interfacial properties of carbon fiber-reinforced epoxy composites by grafting of branched polyethylene imine on carbon fiber surface in supercritical methanol. Composites Science and Technology, 114, 2015, 64-71.

- Montero, J. , de la Casa-Lillo, M. A., Sanchez-Montero, M. J., Martin-Sanchez, N., Izquierdo, C., Salvador, F., Effect of supercritical activation on the diameter of carbon fibers, Journal of supercritical fluids, 101, 2015, 131-139.

- Liu, L. S. , Wu, F., Yao, H. W., Shi, J., Chen, L., Xu, Z. W., Deng, H., Investigation of surface carbon fibers: Effects of fiber instinct structure and radiation medium. Applied Surface Science, 337, 2015, 241-248.

- Shelestova, V. A. , Zhandarov, S. F., Danchenko, S. G., Grakovich, P. N., Surface modification of carbon fiber by fluoropolymer in a low temperature plasma. Inorganic Materials: Applied Research, 6 (3), 2015, 219-224.

- Jiang, S. , Li, Q. F., Zhao, Y. H., Wang, J. W., Kang, M. Q., Effect of surface silanization of carbon fiber reinforced polyurethane composites. Composites Science and Technology, 110, 2015, 87-94.

- Yuan, H. J. , Lu, C. X., Zhang, S. C., Wu, G. P., Preparation and characterization of a polyimide coating on the surface of carbon fibers. New Carbon Materials, 30 (2), 2015, 115-121.

- Ivanov, K. G. , Grebennikov, S. F., Saklakava, E. V., Astashkina, O. V., Electrophysical properties of carbon fibers decorated with bismuth and indium. Free Chemistry, 46 (6), 2015, 373-377.

- Li, W. W. , Li, R. P., Li, C. Y., Zhang, L., Surface characterization and electrical property of carbon fibers modified by air oxidation. Surface and Interface analysis, 47 (3), 2015, 325-330.

- Pierozynski, B. , Mikolajczyk, T., Turemko, M., Czerwosz, E., Kozlowski, M., Hydrogen evolution reaction at Pd-modified carbon fibers in 0.1 M NaOH. International Journal of Hydrogen Energy, 40 (4), 2015, 1795-1799.

- Liu, Y. , Fang, Y. C., Qian, J. H., Liu, Z. Z., Yang, B., Wang, X. L., Bio-inspired polydopamine functionalization of carbon fiber for improving the interfacial adhesion of polypropylene composites. RSC Advances, 5 (130), 2015, 107652-107661.

- Ghaemi, F. , Yuanus, R., Ahmadian, A., Ismail, F., Salleh, M. A. M., Rashid, S. A., Few and multilayer graphene on carbon fibers: Synthesis and application. RSC Advances, 5 (991), 2015, 81266-81274.

- Yang, Y. Y. , Ibrahim, A. A., Stockdill, J. L., Hashemi, P., A density-controlled scaffolding strategy for covalent functionalization of carbon fiber microelectrodes. Analytical methods, 7 (17), 2015, 7352-7357.

- Li, J. , Improvement of interfacial adhesion in PP/PS blends enhanced with polyethylene-polyamine surface treated carbon fiber. Advanced materials research, 1061- 1062, 2015, 170–174. [Google Scholar] [CrossRef]

- Pierozynski, B. ,Mikolajczyk, T., Hydrogen evolution reaction at Ru-modified nickel-coated carbon fiber in 0.1 M NaOH. Polish Journal of Chemical Technology, 17, 2015, 18-22.

- Fei, J. , Luo, W., Huang, J. F., Ouyang, H. B., Wang, H. K., Cao, L. Y., Effect of hydrothermal modified carbon fiber through Diels-Alder reaction and its reinforced phenolic composites. RSC Adv., 5 (79), 2015, 64450-64455.

- Sumin, L. , Yutao, Z., Zhao, Z., Hua, T., Haojie, S., Yaping, W., Electrochemical and mechanical effects of acid and thermal treatments of carbon fiber. Advances Engineering Materials, 17 (1), 2015, 52-67.

- Ghaemi, F. , Yunus, R.,, Salleh, M. A. M., Rashid, S. A., Ahmadian, A., Lim, H. N., Effects of the surface modification of carbon fiber by growing different types of carbon nanomaterials on the mechanical and thermal properties of polypropylene. RSC Advances, 5 (36), 2015, 28822-28831.

- Servins, L. , Gengenbach, T. R., Huson, M. G., Henderson, L. C., Fox, B. L., A novel approach to the functionalization of pristine carbon fiber using azomethine 1, 3 dipolar cycloaddition. Australian Journal of Chemistry, 68 (2), 2015, 335-344.

- Servins, L. , Henderson, L. C., Andrighetto, L. M., Huson, M. G., Gengenbach, T. R., Fox, B. L., A novel approach to functionalized pristine unsized carbon fiber using in situ generated diazonium species to enhance interfacial shear strength. J. Mater. Chem. A., 3 (7), 2015, 3360-3371.