1. Introduction

1.1. Overview of Shale Gas and Hydraulic Fracturing

Shale gas, an unconventional natural gas type, is trapped within formations made of fine particles that are densely packed over time. Predominantly comprising methane, shale gas is derived from various sources like heat-decomposed crude oil or microorganisms breaking down organic matter in oil. This organic carbon exists either as free gas interspersed among pores and fractures or attached to the surface of organic matter. As part of the unconventional gas category, which also includes coalbed methane (CBM), tight gas, and gas hydrates, shale gas presents unique extraction challenges due to its depth and wide dispersion within rock fractures. It is produced in a shale layer made of fine-grained particles, serving simultaneously as a source rock, reservoir, and trap. Shale gas remains deep within shale formations, unlike natural gas, which migrates closer to the surface. This depth, along with the gas’s dispersion throughout rock fractures, poses a significant challenge to extraction. Despite these complexities, the composition of shale gas closely mirrors that of natural gas. However, for many years, shale gas was thought to be not productive since it is thinly dispersed in wide rock layers [

1].

The discovery of shale gas traces back to the 1800s, and it is evenly spread across the globe. There are an estimated 7,257 trillion cubic feet (Tcf) of total world proved reserves of natural gas, which is nearly on par with the 7,299 trillion cubic feet of world shale gas resources [

2,

3]. —roughly on par with the global natural gas reserve (approximately 6.9 quadrillion cubic feet). These quantities could potentially cater to the world’s energy demands for over 60 years. Until the 1990s, the lack of developed extraction techniques made shale gas production unfeasible. However, with the advent of improved techniques in the 2000s, mainly in the United States, production has surged. This surge enabled the U.S. to outstrip Russia, becoming the largest producer of natural gas post-2009. The increased attention to shale gas worldwide can be attributed to a few key factors: it’s more cost-effective than other fossil fuels, produces only half the carbon dioxide of coal when burned, and has vast reserves that can address escalating energy demands. While shale gas presents significant potential as a future energy source, its low cost and high availability could divert investments or focus away from renewable energy industries such as solar power.

Unlike conventional gas sources like petroleum and natural gas, which leverage their high permeability for extraction via a single borehole, unconventional gases like shale gas necessitate unique techniques due to their extremely low permeability. Hydraulic fracturing, also known as fracking, was developed to overcome this challenge. The method involves injecting a fracturing fluid—a mixture of water and chemical additives—under high pressure to create fractures in the rock, enhancing its permeability. This approach has made it possible to tap into vast reserves of petroleum and natural gas accumulated in shale formations. As a result, hydraulic fracturing emerged as a breakthrough technology that revolutionized the extraction process, enabling a rapid increase in petroleum and shale gas production. This rapid increase in energy production, attributable to hydraulic fracturing, has fortified the energy security of the United States, fueled economic growth, and mitigated consumer energy costs [

4].

To extract shale gas trapped within petroleum source rocks, it’s crucial to have a technology that can both reach extensive gas reservoirs and enable fluid flow within these low-permeability layers. The advent and commercialization of horizontal drilling and hydraulic fracturing in the 2000s transformed shale gas into a viable energy source, starting in the United States. Unlike conventional drilling methods that relies on the natural pressure of the reservoir to release gas, unconventional techniques, hydraulic fracturing, utilize high-pressure fluid injection to liberate and extract the gas. Leveraging hydraulic fracturing alongside horizontal drilling has significantly reduced surface disruption and enabled access to previously inaccessible gas reserves due to environmental and groundwater concerns. However, despite its significant contribution to energy production, hydraulic fracturing raises environmental and health concerns. Potential drawbacks include water pollution from fracking chemicals, induced seismic activity due to ground instability, and impacts on water resources and wildlife [

1,

5]. Such issues necessitate a careful consideration of the technology’s environmental footprint alongside its economic benefits.

The workflow of shale gas reservoir development unfolds in distinct steps. Starting with exploration, experts utilize seismic surveys to pinpoint potential reservoir locations [

6,

7]. Once a suitable site is identified, drilling operations commence, first vertically and then transitioning to horizontal drilling to tap into the shale formation [

8,

9]. Upon successful drilling, hydraulic fracturing or ‘fracking’ is applied, a technique that involves injecting fluid under high pressure to create fractures in the rock, enhancing its permeability. As the gas is released from the fractured rock, it’s collected and processed for use. After the productive life of the well, decommissioning procedures are carried out to safely close operations and mitigate environmental impact.[

8].

1.2. Shale gas in the U.S.: Successes, Challenges, and Mitigations

The U.S. has experienced a surge in shale gas production, notably in regions like Barnett, Marcellus, and Eagle Ford with an impressive potential of 26.2 trillion cubic feet [

10]. Factors that determine the productivity of shale formation include the organic matter content, maturity, and limestone barriers. Historically, the U.S. has drilled over 4 million oil and gas wells, and recently, hydraulic fracturing has been employed in over 95% of them to an estimated total of 2 million wells. This technique has bolstered economic growth, creating millions of jobs [

11] and significantly contributing to petroleum and natural gas output.

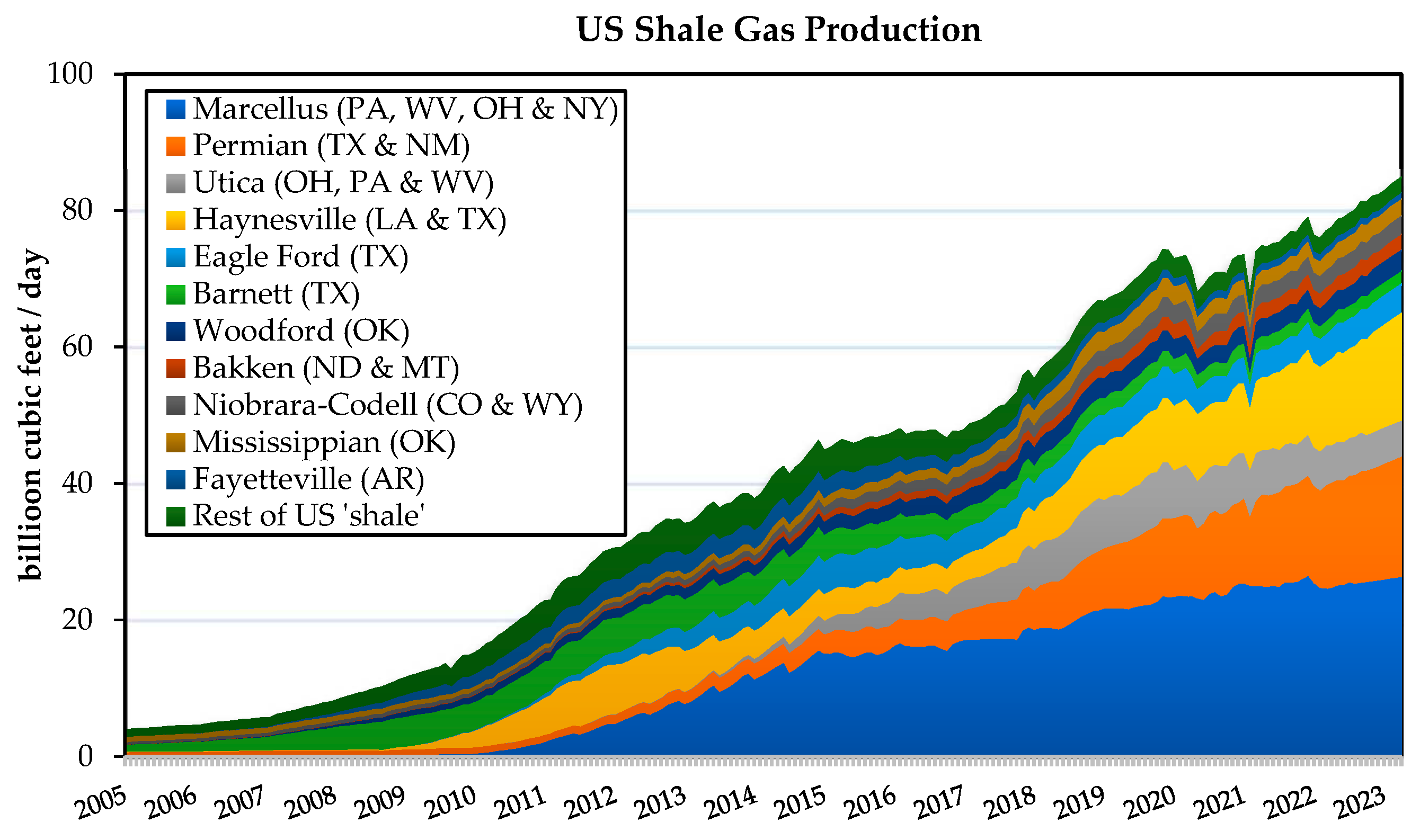

A comparison of the contributions of different shale plays to the overall shale gas production in the U.S. is depicted in

Figure 1. The figure represents the average monthly gas production in billion cubic feet per day (bcf/d), obtained by averaging daily production values for each month. This highlights the overall increase in shale gas production over time in each play, underscoring the impact of hydraulic fracturing and horizontal drilling. The source for this data is the U.S. Energy Information Administration (EIA).

While the benefits of hydraulic fracturing are evident, it simultaneously presents notable environmental challenges throughout its lifecycle especially potential contamination of water and soil resources as well as induced seismicity. Starting with seismic surveys that can disturb local ecosystems, the process then delves into deep drilling phase, which can extend more than a mile underground, is not only an intense process but is also accompanied by methane emissions—a potent greenhouse gas [

12,

13,

14]. As extraction commences, fracturing process itself consumes millions of gallons of water per site, introducing chemicals deep underground [

9,

14,

15,

16,

17]. This brings considerable risk, with contaminants such as heavy metals and specific hydraulic fracturing chemicals such as halides appearing in nearby groundwater and surface water [

14,

15,

18,

19,

20]. Vengosh et al. (2014) also highlighted the potential for shallow aquifer contamination and water depletion from these massive operations. Small but statistically significant regional correlations between groundwater chloride concentrations and proximity and density of fracturing sites was reported [

21].

An additional concern is the potential for induced seismicity, especially during the wastewater injection phase. The injection of large volumes of fluid and waste increases pore pressure, which can lead to the movement of existing faults and trigger earthquakes. Studies have reported an increase in seismic activity near hydraulic fracturing sites, particularly in areas with pre-existing faults [

22,

23]. The need for consistent recognition of cases, proposed triggering mechanisms, geologically susceptible conditions, identification of operational controls, effective mitigation efforts, and science-informed regulatory management are required to better understand and manage earthquake rupture processes induced by hydraulic fracturing [

24]. Concluding the process, the gas collection phase presents its own challenges, primarily through methane leaks which bolster greenhouse gas concentrations. The journey wraps up with decommissioning, a phase aiming to restore the extraction site safely. Its magnitude varies depending on the operation’s scale, but the objective remains constant: achieving a pollutant-free restoration.

To mitigate these environmental concerns, stricter regulations on chemical usage and wastewater disposal are necessary. New materials like hydrogel additives that optimize production performance without using environmentally hazardous chemicals are being developed [

25]. Davoodi et al. (2023) also highlights beneficial applications of viscoelastic surfactants in wellbore hydraulic fracturing fluid which are considered as clean and do not leave deposits in reservoirs, making them suitable for use in tight reservoirs. Sun et al. (2019) focuses on the characterization of hydraulic fracturing wastewater and establishes strategies to mitigate environmental impacts. The paper identifies a number of potentially harmful organic compounds in hydraulic fracturing wastewaters and predicts their associated toxicity to freshwater organisms and suggests that partial treatment and reuse remain the preferred method for managing hydraulic fracturing wastewater where feasible. However, advanced technologies such as membrane separation, mechanical vapor compression, and advanced oxidation will be required to meet sustainable reuse or surface discharge. Additionally, emerging technologies like adsorption chillers offer the potential to utilize waste heat from the hydraulic fracturing process, producing both cool and desalinated water, showcasing another avenue for waste repurposing [

27,

28]. Ongoing research and monitoring of the environmental impact of hydraulic fracturing are also essential for ensuring the responsible development of shale gas resources.

2. Environmental Problems Caused by Hydraulic Fracturing

Despite the abundant economic and resource benefits of shale gas, its exploitation has sparked heated discussions due to concerns about environmental pollution. In this review, we investigate the environmental impact of shale gas exploitation, with a focus on the potential effects of hydraulic fracturing on groundwater quality, seismic activity, and soil health.

2.1. Surface and Groundwater Contaminations

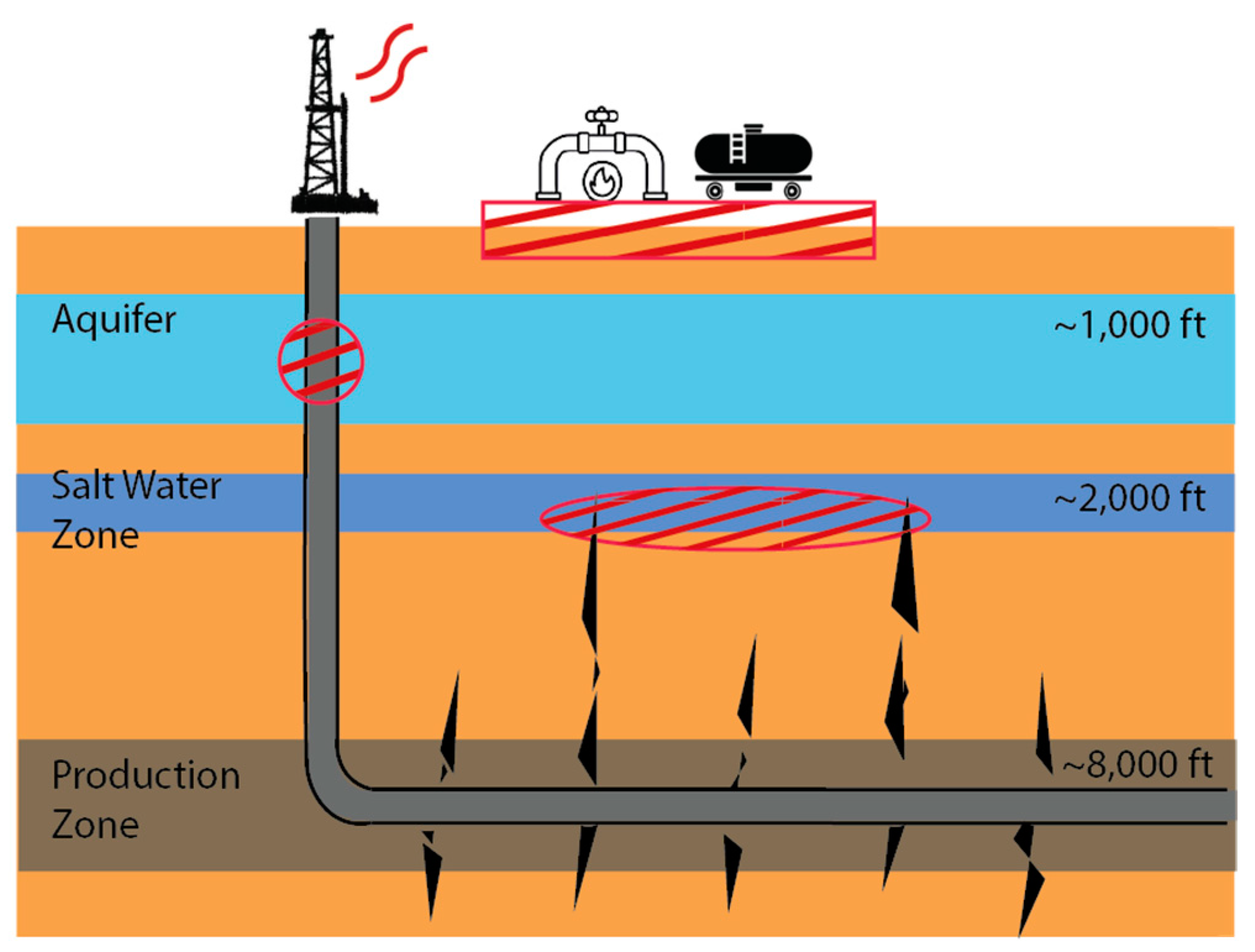

Hydraulic fracturing, a process used to extract natural gas and oil from shale rock formations, poses substantial threats to surface water and groundwater quality. As depicted in

Figure 2, contamination may occur through various channels such as well leakage, cracks in rocks, spillage of flowback water, or faulty cementing work. Notably, numerous incidents of water contamination linked to poor well construction, leaks, and inadequate wastewater treatment and disposal have been reported across various regions in the United States [

15].

Despite the absence of comprehensive evidence indicating shallow potable aquifer contamination due to deep hydraulic fracturing [

29], contaminants such as stray natural gas and drilling-related fluid spillage have been documented [

30,

31,

32]. Instances of contamination include the detection of various harmful compounds in the groundwater of the Pavillion gas field area, Wyoming [

33]. In areas overlying the Marcellus and Utica shale formations of northeastern Pennsylvania and upstate New York, studies have observed methane contamination in drinking water originating from bedrock aquifers, rather than atmospheric sources [

13]. Importantly, these methane concentrations in drinking-water wells were found to increase with proximity to the nearest gas well. Building on this, numerical simulations have investigated the possible contamination pathways between tight-gas reservoirs and overlying freshwater aquifers. These simulations underscore the role of factors such as the permeability of the connecting pathway and the volume of the connecting feature in determining the risk of contamination. However, while such models provide insight, real-world evidence remains pivotal in confirming these risks [

34]. For a more comprehensive overview of real-world instances, refer to

Table 1, which summarizes key studies on soil and water contamination related to hydraulic fracturing.

The depth of shale gas formations and aquifers is a crucial consideration in preventing water pollution from gas exploitation. As depicted in

Figure 2, aquifers typically exist around 1,000 feet below the surface, while shale gas production zones lie between 7,000 and 10,000 feet.

Table 2 indicates the depth of extraction well used for hydraulic fracturing in the United States. The depth of well where hydraulic fracturing was used is approximately 8,300 feet in average. In Texas, the average depth was approximately 8.7 thousand feet, 10.4 thousand feet in North Dakota, and 7 thousand feet in Pennsylvania. These depth variations, further detailed in

Table 2, are dependent on several factors including shale gas exposure, formation characteristics, and regional characteristics [

38]. Adequate consideration of these factors can help prevent water pollution during hydraulic fracturing operations.

Hydraulic fracturing for shale gas exploitation requires a substantial amount of water. On average, a well drilled for shale gas extraction uses around 2.4 million gallons of water, as of 2013 (

Table 2), for horizontal drilling and hydraulic fracturing. However, the actual amount of water used in shale gas exploitation may vary depending on the formation characteristics, regional environment, and the well depth. For instance, approximately 0.7 million gallons of water are used in New Mexico, and 2.5 million gallons of water are used in Texas. The vast amount of water used for each well has the potential to become severely contaminated when retrieved after passing through the formation. Moreover, complicating the situation, typically only 15-35% of the water used for extraction is retrieved, posing risks of groundwater pollution and local water shortages. Recent studies underscore how hydraulic fracturing fluids interact with geologic formations, affecting the chemistry of produced fluids and potential environmental impacts [

39]. Understanding these chemical reactions and their implications on fluid composition is vital for developing strategies to mitigate potential environmental impacts.

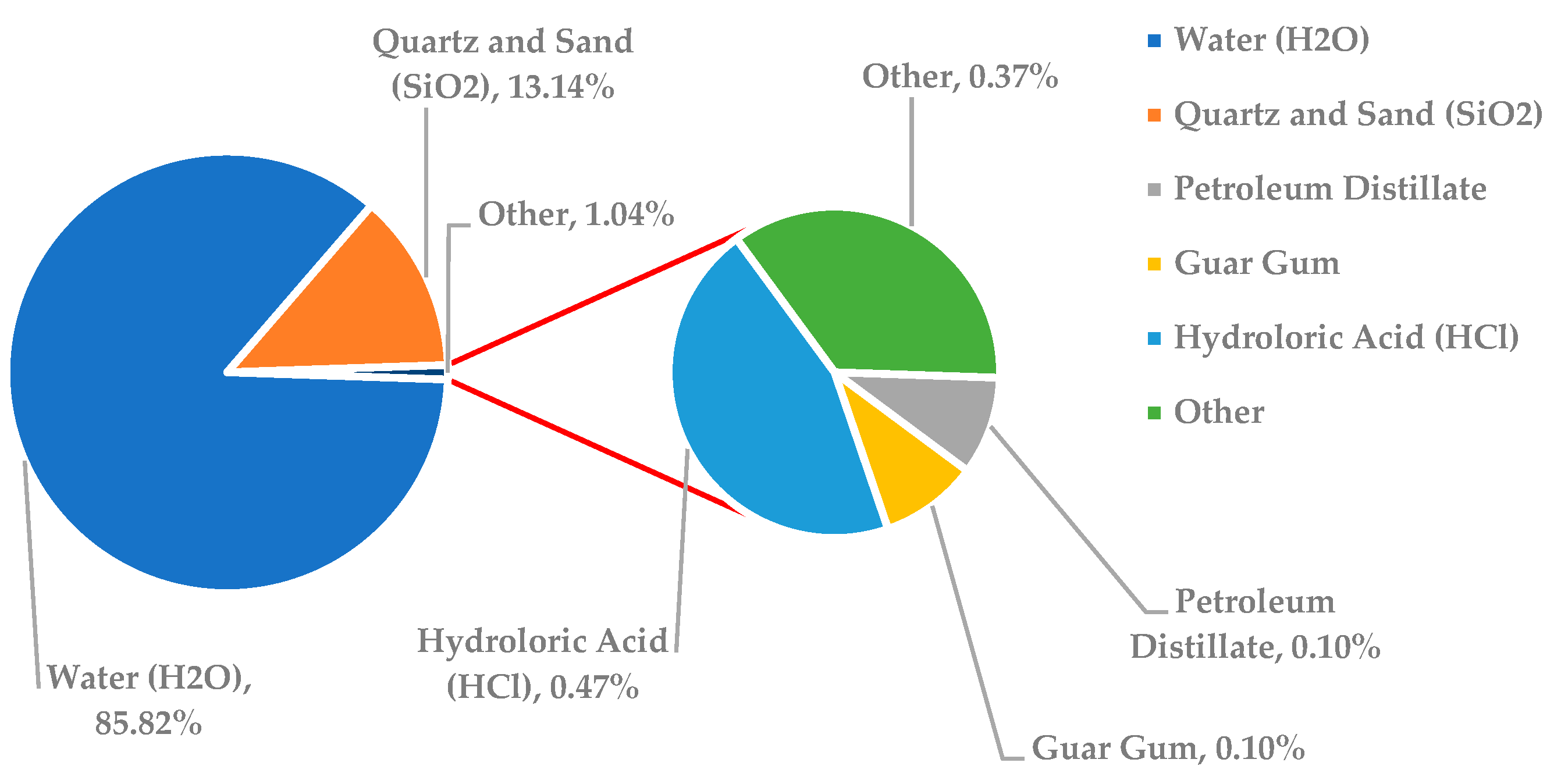

Fracturing fluids require additional chemicals to facilitate the fracturing of underground formations [

41]. These chemicals, as outlined in

Table 3 and

Figure 3, can pose a risk to groundwater quality. They can migrate into groundwater sources through cracks in the well casing or via surface spills. The flowback water from hydraulic fracturing may contain harmful substances, including heavy metals, salts, and radioactive materials, potentially contaminating nearby water sources if improperly managed. The composition of the input fluid for hydraulic fracturing significantly influences the chemistry of the flowback water, which has considerable implications for managing produced water and its potential environmental impacts [

42]. These findings emphasize the importance of careful selection, monitoring, and management of input fluid composition.

Despite these risks, several mitigation measures can help protect groundwater quality. These include the use of high-intensity and multiple casings, cementing, and underground water monitoring. Public disclosure of chemicals used in fracturing fluids facilitates better regulatory oversight by allowing agencies to monitor and evaluate the substances being used. Industrial activities are governed by federal and state laws including the Safe Drinking Water Act, Clean Water Act, Clean Air Act, and National Environment Policy Act [

40]. Technological advancements could aid in water recycling and mitigate deep-well injection, thereby reducing the risks associated with water contamination from hydraulic fracturing operations [

43]. Further insights into the transport of pollutants in subsurface water resources can significantly enhance the design of more effective remediation strategies [

40,

44]. These include innovative approaches for accurately estimating gas-in-place (GIP) in shale reservoirs, which could improve our understanding of potential gas losses through well leakage [

45]. This knowledge could then inform the design of better well construction and maintenance strategies, further minimizing the risk of groundwater contamination. These measures emphasize the potential for responsible development of shale gas resources through ongoing research and advancements.

2.2. Soil and Environmental Contaminations

Soil contamination is a significant concern associated with shale-gas hydraulic fracturing operations. During the development and production of shale gas, various pollutants are generated, posing potential risks to soil quality [

37,

46]. The impact of shale gas exploitation on soil pollution (

Table 1) is supported by evidence from the Barnett Shale in Texas. Fontenot et al. (2013) conducted a study that provides explicit evidence of the relationship between shale gas exploitation and soil pollution. The study revealed a clear correlation between proximity to the hydraulic fracturing site and higher concentrations of total dissolved solids (TDS) in the soil, indicating increased contamination nearer to the well. This correlation between shale gas activities and surface water and soil pollution is primarily attributed to the leakage of highly compressed fluids during storage, transportation, and disposal processes associated with hydraulic fracturing. Notably, in 2009, a leak of the liquid gel used for hydraulic fracturing, along with its waste, resulted in the pollution of wetlands and rivers, leading to the death of fish in nearby rivers.

Soil pollution associated with hydraulic fracturing can result from the accumulation of various contaminants, including metals, salts, organic compounds, and naturally occurring radionuclides (NORM). The presence of NORM, such as radium isotopes, in wastewater fluids from hydraulic fracturing operations can pose significant risks to the environment and human health. When these fluids are disposed of in freshwater streams or ponds, radium can adsorb onto sediments in disposal and spill sites. Studies have observed the accumulation of radium in stream sediments downstream of these sites, with levels sometimes exceeding regulatory limits [

48]. Elevated levels of NORM have also been detected in soils near roads used for spreading conventional oil and gas brines for deicing and in pond bottom sediments associated with hydraulic fracturing spills [

49,

50].

The accumulation of NORM-rich flowback and produced waters during hydraulic fracturing operations can lead to the buildup of radium and radiation, posing substantial risks to the environment and human health. Radium-bearing barite, a common component of scale and sludge deposits in oil and gas exploration, can contribute to elevated radium levels in soil and pipe-scale near production sites [

51]. These reactive residuals in brines, including metals and radioactive elements, have the potential to accumulate in river and lake sediments, as well as in soil near shale gas drilling sites and brine treatment facilities. Over time, these accumulations can release toxic elements and radiation, posing long-term environmental and health effects in the affected areas [

15].

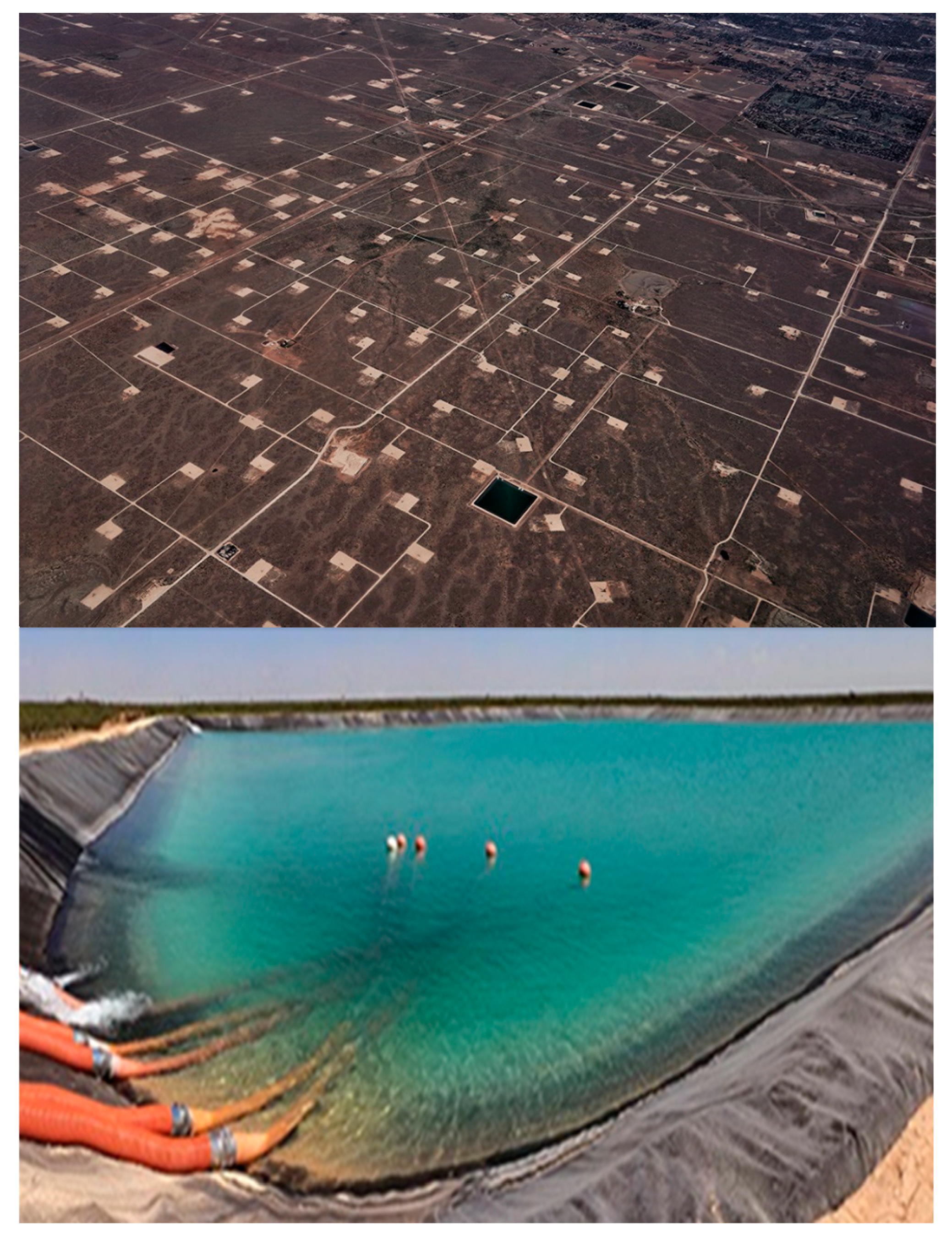

To mitigate the risk of soil pollution associated with hydraulic fracturing, it is crucial to implement effective measures. One approach is to ensure the secure storage of flowback water in heavy-duty storage tanks to prevent leakage of fracturing fluid and pollutants into the soil. This method has been implemented in some horizontal wells, effectively preventing soil contamination. However, it is important to address potential sources of surface-level pollution during the storage, transportation, and disposal of flowback water. Measures such as using double-lined pits for storage and maximizing the reuse of flowback water can help minimize the risks of soil pollution (

Figure 4). Additionally, strict leak prevention protocols should be followed at all stages, including storage tanks, transportation trucks, and pipelines, to ensure minimal environmental impact and protect soil quality. By adopting these measures, the risks of soil pollution associated with shale gas hydraulic fracturing operations can be reduced.

Beyond soil contamination risks, hydraulic fracturing activities also have wider ecological implications, particularly concerning biogeochemical changes and the impacts on hydrologic system [

52]. Hydraulic fracturing can alter the deep subsurface’s biogeochemical landscape, encouraging the growth of halotolerant microbial communities. This shift can potentially affect reservoir sustainability and infrastructure integrity [

53]. Furthermore, the development of unconventional oil and gas infrastructure such as well pads, roads, and pipelines can lead to ‘catchment disturbance’ impacting the health of local ecosystems. For instance, a study conducted in the Upper Susquehanna River Basin in Pennsylvania found that only a small percentage of catchments in the headwater streams exhibited medium to high levels of unconventional oil and gas disturbance [

54]. This suggests that with responsible development and careful management, the environmental impact of hydraulic fracturing on catchments can be minimized. Moreover, studies have underscored the potential role of climate change in exacerbating water contamination issues, especially from nonpoint source (NPS) pollution, which can be impacted by activities such as hydraulic fracturing [

55]. The implications of changing rainfall patterns on the dispersion and concentration of contaminants in catchment areas should be a factor in the design of sustainable management strategies for hydraulic fracturing operations.

2.3. Earthquakes

The process of hydraulic fracturing, while indispensable for enhanced oil and gas production, has been a topic of scientific and public debate due to its potential for inducing seismic activity. The injection of high-pressure fluids into shale formations, a crucial step in this method, creates cracks through which artificially generated seismic energy is released. This seismic energy is transmitted underground, similar to naturally occurring seismic waves. In some instances, these waves can cause ground shaking noticeable at the surface. Although the general consensus indicates a low risk of harm from such seismic events, the topic remains an active area of research and discussion [

56].

Concerns also arise regarding potential earthquakes induced by the disposal of water after hydraulic fracturing. On average, approximately 10 barrels of brine water are formed per one barrel of petroleum [

59]. The brine water is generally processed through disposal wells, following the guidelines provided by the Underground Injection Control (UIC) Manual issued by the EPA (EPA Class III). In the United States, there are approximately 35,000 disposal wells in use to process the fluid generated from petroleum and natural gas production. The equipment involved in this process, which include over 800,000 processing units throughout the United States, is strictly monitored by the EPA and other subsidiary agencies. Despite the vast majority of these disposal wells not being associated with induced seismicity, a comprehensive record of anthropogenic activity leading to earthquakes particularly in the context of extraction industries, underlines the importance of such considerations when analyzing the occurrence and severity of earthquakes [

60].

While the hydraulic fracturing process itself does not typically pose a significant concern for induced seismicity, specific geological conditions combined with large-scale hydraulic fracturing and a concentrated number of injection wells can lead to earthquakes perceptible at the surface. This phenomenon, although rare, is evidenced in a select list of incidents provided in

Table 4. The selection is based on incidents of induced earthquakes of relatively higher magnitudes associated with hydraulic fracturing and wastewater disposal wells. It aims to highlight notable occurrences, though it does not include all earthquakes associated with hydraulic fracturing. For example, in the Barnett Shale regions of Texas, which had seen no seismic activities for over a century, several earthquakes were detected during 2008 and 2009, leading to claims from residents that these earthquakes were caused by increased hydraulic fracturing in the area [

61]. Moreover, increased detection of seismic activities in Oklahoma is also thought to be caused by increased shale gas exploitation. While researchers from the USGS (United States Geological Survey) claim that there is no direct relationship between hydraulic fracturing and earthquakes, they also report that induced earthquake could occur in the process of applying water into the disposal wells to process contaminated water [

33,

62].

Though seismic waves are produced during hydraulic fracturing, the magnitude of such seismic activity was small in most of the cases, measured in Richter scale [

63,

64]. Since small-magnitude earthquake occurring during shale gas exploitation is rare and is a very low risk, continuous monitoring would be necessary [

63,

64,

65]. Induced earthquakes are extremely complicated to study, and the knowledge base related to the phenomenon is quickly changing. Due to its complexity, an umbrella-approach that could cover mostly anywhere would not be appropriate as induced earthquakes vary greatly by the population, building, infrastructure, and the region’s geological condition.

Understanding the underlying science is essential when evaluating requirements for mitigating and managing potential earthquake risks. Historical records since 1920 indicate that induced seismicity primarily results from human activities and man-made structures including large-scale water reservoir behind dams, geothermal plant project, mining, construction, underground nuclear weapons testing [

37,

52,

55]. Given this context, a scientific approach is imperative for discussing earthquake risk management and mitigation. Notably, seismic energy can be generated in areas with geological defects or stress. For example, increased pressure from fluid influx can expand a fault or even cause it to slip, leading to surface tremors.

To effectively manage and mitigate such potential risks, engineers are developing a variety of strategies, including designating and overseeing the location of hydraulic fracturing and disposal well. The effectiveness of these strategies depends on the accurately detecting high-risk earthquake locations. Comprehensive databases of human-induced earthquakes can play a vital role in this regard [

60]. The U.S. Geological Survey (USGS), possibly in collaboration with agencies like the Environmental Protection Agency (EPA), could be considered to help formulate suggestions on addressing both the occurrence and impact of these earthquake. To ensure safer energy production, the creation of a safe and eco-friendly disposal method for the water generated from hydraulic fracturing and shale gas production, as well as the study of induced seismicity and its complex scientific and physical mechanism must be done through the collaboration of the industry, academia, and government.

2.4. Air Pollution

Air pollution is a significant environmental concern associated with shale-gas hydraulic fracturing. Despite advancements in technology and emission reduction within the petroleum and natural gas industry, the production of shale gas still contributes to air pollution, primarily through the release of methane gas. Methane can escape from various points in the production process, including wellheads, pipelines, and storage tanks. A summary of key studies exploring various air pollutants associated with shale-gas hydraulic fracturing is provided in

Table 5.

Notable progress has been made in minimizing methane emissions. The implementation of emission reduction strategies by the industry has resulted in a more than 28% decrease in methane emissions from all fossil fuel systems since 1990, with petroleum production specifically experiencing an 8% decrease by 2014. Despite a substantial increase in natural gas production, methane emissions from the natural gas system have remained relatively stable, with only a slight increase of 1.7%. It is worth noting that methane emissions from the petroleum and natural gas industry account for only 4% of the total greenhouse gas emissions in the United States.

In addition to methane, other air pollutants are associated with shale gas extraction and processing. Volatile organic compounds (VOCs) are emitted, which contribute to air pollution and the formation of ground-level ozone. Vinciguerra et al. (2015) observed a significant increase in daytime ethane concentrations in the Baltimore, MD and Washington, DC areas since 2010, which coincided with the rapid expansion of natural gas production in neighboring states, particularly Pennsylvania and West Virginia. Additionally, diesel-powered machinery and vehicles used in drilling and hydraulic fracturing activities release air pollutants, including nitrogen oxides (NOx) and particulate matter (PM). A comprehensive study by Zhang et al. (2023) conducted in Pennsylvania utilized a quasi-experimental approach and satellite-based measurements to estimate the impact of shale gas development on particulate matter (PM) pollution. The study findings reveal a causal increase in PM2.5 concentration in the vicinity of over 20,000 wells, highlighting the significant environmental implications of shale gas extraction. Furthermore, fracking operations also release toxic air pollutants, such as benzene, toluene, ethylbenzene, and xylene (BTEX), which pose risks to respiratory and neurological health. Furthermore, the inhalation of silica, a component of fracking sand, can cause lung-related diseases, particularly among workers exposed to silica dust and diesel fumes in the fracking industry [

71].

To mitigate air pollution from shale-gas hydraulic fracturing, strict regulations and best practices are crucial, involving the adoption of technologies that minimize methane leaks and improve equipment, detection systems, and vapor recovery. Additionally, transitioning from diesel-powered machinery to cleaner energy sources and implementing emission control technologies can help reduce the impacts of air pollution. Raheja et al. (2022) and similar studies demonstrate the significant air pollution effects of shale-gas development, particularly in heavily affected regions like Belmont County, Ohio. The study revealed shortcomings in the current regulatory air pollution monitoring network, highlighting the importance of enhanced monitoring practices and collaboration among residents, environmental advocates, and regulatory agencies to establish more effective air quality standards for protection of public health.

Overall, air pollution is significant environmental concerns associated with shale-gas hydraulic fracturing operations. It is crucial to implement comprehensive measures that minimize pollution and adopt cleaner technologies and practices to mitigate these environmental impacts. By doing so, the sustainable development of shale gas resources can be ensured.

3. Conclusion

The United States is the leading producer of shale gas globally, with active shale gas exploitation in regions such as Barnett, Eagle Ford, and Permian Basin of Texas, Marcellus in Pennsylvania, and Bakken shale formation in North Dakota. Hydraulic fracturing has spurred this rapid increase in shale gas production, effectively catalyzing the economic development of modern society and signaling a renaissance of energy production. This advancement has not come without significant environmental implications. Groundwater contamination may be a result of fracturing fluid leakage due to geological faults or inadequate cement and casing work within the drilling hole. The average of depth of hydraulic fracturing is approximately 8,000 feet, and the average water use for shale gas extraction is around 2.4 million gallons per well. Soil and environmental contaminations may occur due to flowback water leakage from defective storage tanks or pits. The practice of hydraulic fracturing could also lead to induced earthquakes because of the use of high-pressure injection wells and wastewater processing. Several earthquakes between M 3.0 and 5.8 were detected in Texas and Oklahoma during the 2010s, caused by the process of injecting water into the disposal wells for treating contaminated water. An increase in methane gas emissions, Volatile Organic Compounds (VOCs) and Total Dissolved Solids (TDS), as well as the potential for blowouts, may lead to air pollution. The industry has reduced methane emissions from all fossil fuel systems by around 30% since 1990, and the hydraulic fracturing industry is experiencing an 8% decrease by 2014. These provide significant information for developing better well construction and maintenance strategies, furth contributing to the decrease in environmental contamination.

Among the environmental concerns associated with shale gas exploitation are groundwater and soil pollution, induced earthquakes, and fires. Such environmental problem could negatively impact the health of the locals, harm the ecosystem, and could even cost precious lives of the people living nearby the extraction site. Therefore, a continuous environmental monitoring for pollution as well as caution on the developers and site managers would be necessary, and a preventive measure against such damages must be implemented. In particular, the contaminants of concern, as highlighted by previous studies, include methane and TDS. To effectively manage the impacts of hydraulic fracturing, regulations must be customized to address local geological and regional needs, which would require state government intervention. If properly implemented, these regulations, alongside the contributions of private resource companies, can strike a balance between increased energy production and minimized environmental impact. The industry should work cooperatively with the government to decrease pollution caused by shale gas production, and also take proactive measures to protect local communities and the environment. Furthermore, our review suggests more studies are needed to understand the intersection of hydraulic fracturing, water contamination, and climate change. Through combined efforts of industry, government, and continued research, we can strive to minimize the environmental pollution caused by shale gas extraction and mitigate disruptions to ecosystems.

Author Contributions

B.H. calculated the surface and groundwater contaminations, collected detailed information on the earthquakes and developed the arguments. J.H. designed the structure, developed the arguments, and contributed to the overall paper. J.P. calculated soil and environmental pollutions, and developed the arguments. C.L. analyzed air pollutions, and contributed to the overall paper. All authors have read and agreed to the published version of the manuscript.

References

- Arthur, M.A.; Cole, D.R. Unconventional Hydrocarbon Resources: Prospects and Problems. Elements 2014, 10, 257–264. [Google Scholar] [CrossRef]

- EIA International Energy Statistics; Energy Information Administration, EIA., 2023.

- EIA Shale Oil and Shale Gas Resources Are Globally Abundant; Energy Information Administration, EIA., 2013.

- API Hydraulic Fracturing: Unlocking America’s Natural Gas Resources; American Petroleum Institute, API., 2017.

- Zhang, D.; Yang, T. Environmental Impacts of Hydraulic Fracturing in Shale Gas Development in the United States. Pet. Explor. Dev. 2015, 42, 876–883. [Google Scholar] [CrossRef]

- Wilson, T.H.; Smith, V.; Brown, A. Developing a Model Discrete Fracture Network, Drilling, and Enhanced Oil Recovery Strategy in an Unconventional Naturally Fractured Reservoir Using Integrated Field, Image Log, and Three-Dimensional Seismic Data. AAPG Bull. 2015, 99, 735–762. [Google Scholar] [CrossRef]

- EIA Oil and Gas Supply Module - NEMS Documentation; Energy Information Administration, 2020.

- Holditch, S. Tight Gas Sands. J. Pet. Technol. 2006, 58. [Google Scholar] [CrossRef]

- King, G.E. Hydraulic Fracturing 101: What Every Representative, Environmentalist, Regulator, Reporter, Investor, University Researcher, Neighbor and Engineer Should Know About Estimating Frac Risk and Improving Frac Performance in Unconventional Gas and Oil Wells. In Proceedings of the All Days; SPE: The Woodlands, Texas, USA, February 6 2012; p. SPE-152596-MS. [Google Scholar]

- Montgomery, S.L.; Jarvie, D.M.; Bowker, K.A.; Pollastro, R.M. Mississippian Barnett Shale, Fort Worth Basin, North-Central Texas: Gas-Shale Play with Multi–Trillion Cubic Foot Potential. AAPG Bull. 2005, 89, 155–175. [Google Scholar] [CrossRef]

- EIA Technically Recoverable Shale Oil and Shale Gas Resources: An Assessment of 137 Shale Formations in 41 Countries Outside the United States; Energy Information Administration, EIA., 2013.

- Allen, D.T.; Torres, V.M.; Thomas, J.; Sullivan, D.W.; Harrison, M.; Hendler, A.; Herndon, S.C.; Kolb, C.E.; Fraser, M.P.; Hill, A.D.; et al. Measurements of Methane Emissions at Natural Gas Production Sites in the United States. Proc. Natl. Acad. Sci. 2013, 110, 17768–17773. [Google Scholar] [CrossRef] [PubMed]

- Osborn, S.G.; Vengosh, A.; Warner, N.R.; Jackson, R.B. Methane Contamination of Drinking Water Accompanying Gas-Well Drilling and Hydraulic Fracturing. Proc. Natl. Acad. Sci. 2011, 108, 8172–8176. [Google Scholar] [CrossRef] [PubMed]

- Vidic, R.D.; Brantley, S.L.; Vandenbossche, J.M.; Yoxtheimer, D.; Abad, J.D. Impact of Shale Gas Development on Regional Water Quality. Science 2013, 340, 1235009. [Google Scholar] [CrossRef]

- Vengosh, A.; Jackson, R.B.; Warner, N.; Darrah, T.H.; Kondash, A. A Critical Review of the Risks to Water Resources from Unconventional Shale Gas Development and Hydraulic Fracturing in the United States. Environ. Sci. Technol. 2014, 48, 8334–8348. [Google Scholar] [CrossRef] [PubMed]

- Cooper, J.; Stamford, L.; Azapagic, A. Economic Viability of UK Shale Gas and Potential Impacts on the Energy Market up to 2030. Appl. Energy 2018, 215, 577–590. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, D.; Tsang, D.C.W.; Wang, L.; Ok, Y.S.; Feng, Y. A Critical Review of Risks, Characteristics, and Treatment Strategies for Potentially Toxic Elements in Wastewater from Shale Gas Extraction. Environ. Int. 2019, 125, 452–469. [Google Scholar] [CrossRef] [PubMed]

- Stringfellow, W.T.; Domen, J.K.; Camarillo, M.K.; Sandelin, W.L.; Borglin, S. Physical, Chemical, and Biological Characteristics of Compounds Used in Hydraulic Fracturing. J. Hazard. Mater. 2014, 275, 37–54. [Google Scholar] [CrossRef]

- Wollin, K.-M.; Damm, G.; Foth, H.; Freyberger, A.; Gebel, T.; Mangerich, A.; Gundert-Remy, U.; Partosch, F.; Röhl, C.; Schupp, T.; et al. Critical Evaluation of Human Health Risks Due to Hydraulic Fracturing in Natural Gas and Petroleum Production. Arch. Toxicol. 2020, 94, 967–1016. [Google Scholar] [CrossRef]

- Abraham, D.G.; Liberatore, H.K.; Aziz, Md.T.; Burnett, D.B.; Cizmas, L.H.; Richardson, S.D. Impacts of Hydraulic Fracturing Wastewater from Oil and Gas Industries on Drinking Water: Quantification of 69 Disinfection by-Products and Calculated Toxicity. Sci. Total Environ. 2023, 882, 163344. [Google Scholar] [CrossRef]

- Shaheen, S.W.; Wen, T.; Herman, A.; Brantley, S.L. Geochemical Evidence of Potential Groundwater Contamination with Human Health Risks Where Hydraulic Fracturing Overlaps with Extensive Legacy Hydrocarbon Extraction. Environ. Sci. Technol. 2022, 56, 10010–10019. [Google Scholar] [CrossRef]

- Ellsworth, W.L. Injection-Induced Earthquakes. Science 2013, 341, 1225942. [Google Scholar] [CrossRef] [PubMed]

- Weingarten, M.; Ge, S.; Godt, J.W.; Bekins, B.A.; Rubinstein, J.L. High-Rate Injection Is Associated with the Increase in U.S. Mid-Continent Seismicity. Science 2015, 348, 1336–1340. [Google Scholar] [CrossRef]

- Schultz, R.; Skoumal, R.J.; Brudzinski, M.R.; Eaton, D.; Baptie, B.; Ellsworth, W. Hydraulic Fracturing-Induced Seismicity. Rev. Geophys. 2020, 58. [Google Scholar] [CrossRef]

- Kreipl, M.P.; Kreipl, A.T. Hydraulic Fracturing Fluids and Their Environmental Impact: Then, Today, and Tomorrow. Environ. Earth Sci. 2017, 76, 160. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S. A Comprehensive Review of Beneficial Applications of Viscoelastic Surfactants in Wellbore Hydraulic Fracturing Fluids. Fuel 2023, 338, 127228. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Nowak, W.; Mika, Ł.; Krzywański, J.; Grabowska, K.; Sosnowski, M.; Alharbi, A.A. Performance Evaluation of a Single-Stage Two-Bed Adsorption Chiller With Desalination Function. J. Energy Resour. Technol. 2021, 143, 082101. [Google Scholar] [CrossRef]

- Koushaeian, M.; Duong, X.Q.; Park, M.Y.; Lee, W.S.; Kwon, O.K.; Shah, N.A.; Chung, J.D. Investigation of the Cascade Type of Hybrid Adsorption-Vapor Compression Chiller. Case Stud. Therm. Eng. 2023, 47, 103037. [Google Scholar] [CrossRef]

- Llewellyn, G.T.; Dorman, F.; Westland, J.L.; Yoxtheimer, D.; Grieve, P.; Sowers, T.; Humston-Fulmer, E.; Brantley, S.L. Evaluating a Groundwater Supply Contamination Incident Attributed to Marcellus Shale Gas Development. Proc. Natl. Acad. Sci. 2015, 112, 6325–6330. [Google Scholar] [CrossRef]

- Rodriguez, J.; Heo, J.; Park, J.; Lee, S.-S.; Miranda, K. Inorganic Pollutants in the Water of Midland and Odessa, Permian Basin, West Texas. Air Soil Water Res. 2019, 12, 117862211986108. [Google Scholar] [CrossRef]

- Lozano, J.; Heo, J.; Seo, M. Historical Assessments of Inorganic Pollutants in the Sinkhole Region of Winkler County, Texas, USA. Sustainability 2021, 13, 7513. [Google Scholar] [CrossRef]

- Haskell, D.; Heo, J.; Park, J.; Dong, C. Hydrogeochemical Evaluation of Groundwater Quality Parameters for Ogallala Aquifer in the Southern High Plains Region, USA. Int. J. Environ. Res. Public. Health 2022, 19, 8453. [Google Scholar] [CrossRef]

- Folger, P.; Tiemann, M. The EPA Draft Report of Groundwater Contamination Near Pavillion, Wyoming: Main Findings and Stakeholder Responses. 2016.

- Reagan, M.T.; Moridis, G.J.; Keen, N.D.; Johnson, J.N. Numerical Simulation of the Environmental Impact of Hydraulic Fracturing of Tight/Shale Gas Reservoirs on Near-surface Groundwater: Background, Base Cases, Shallow Reservoirs, Short-term Gas, and Water Transport. Water Resour. Res. 2015, 51, 2543–2573. [Google Scholar] [CrossRef] [PubMed]

-

Investigation of Ground Water Contamination near Pavillion, Wyoming; US Environmental Protection Agency, Office of Research and Development, National Risk Management Research Laboratory., 2011.

- Olmstead, S.M.; Muehlenbachs, L.A.; Shih, J.-S.; Chu, Z.; Krupnick, A.J. Shale Gas Development Impacts on Surface Water Quality in Pennsylvania. Proc. Natl. Acad. Sci. 2013, 110, 4962–4967. [Google Scholar] [CrossRef] [PubMed]

- Nelson, R.; Heo, J. Monitoring Environmental Parameters with Oil and Gas Developments in the Permian Basin, USA. Int. J. Environ. Res. Public. Health 2020, 17, 4026. [Google Scholar] [CrossRef] [PubMed]

- Jackson, R.B.; Lowry, E.R.; Pickle, A.; Kang, M.; DiGiulio, D.; Zhao, K. The Depths of Hydraulic Fracturing and Accompanying Water Use Across the United States. Environ. Sci. Technol. 2015, 49, 8969–8976. [Google Scholar] [CrossRef] [PubMed]

- Welch, S.A.; Sheets, J.M.; Daly, R.A.; Hanson, A.; Sharma, S.; Darrah, T.; Olesik, J.; Lutton, A.; Mouser, P.J.; Wrighton, K.C.; et al. Comparative Geochemistry of Flowback Chemistry from the Utica/Point Pleasant and Marcellus Formations. Chem. Geol. 2021, 564, 120041. [Google Scholar] [CrossRef]

- Rodriguez, J.; Heo, J.; Kim, K.H. The Impact of Hydraulic Fracturing on Groundwater Quality in the Permian Basin, West Texas, USA. Water 2020, 12, 796. [Google Scholar] [CrossRef]

- Heo, J.-H.; Lee, D.-H.; Koh, D.-C.; Chang, H.-W. The Effect of Ionic Strength and Hardness of Trichloroethylene-Contaminated Synthetic Groundwater on Remediation Using Granular Activated Carbon. Geosci. J. 2007, 11, 229–239. [Google Scholar] [CrossRef]

- Welch, S.A.; Sheets, J.M.; Saelans, E.; Saltzman, M.R.; Newby, S.M.; Darrah, T.H.; Lutton, A.; Olesik, J.W.; DeFranco, K.C.; Heraty, L.J.; et al. Chemical and Isotopic Evolution of Flowback Fluids from the Utica Gas Shale Play, Eastern Ohio USA. Chem. Geol. 2022, 614, 121186. [Google Scholar] [CrossRef]

- Cole, D.R.; Allen, G.R. Utica Shale Energy and Environment Laboratory Final Scientific/Technical Report; 2017; p. DOE-OSU--0024357, 1416539.

- Hwang, B.; Srivastava, D.J.; Deng, H.; Grandinetti, P.J.; Cole, D.R. Sodium Diffusion in Heterogeneous Porous Media: Connecting Laboratory Experiments and Simulations. Geochim. Cosmochim. Acta 2022, 338, 93–104. [Google Scholar] [CrossRef]

- Xiong, F.; Hwang, B.; Jiang, Z.; James, D.; Lu, H.; Moortgat, J. Kinetic Emission of Shale Gas in Saline Water: Insights from Experimental Observation of Gas Shale in Canister Desorption Testing. Fuel 2021, 300, 121006. [Google Scholar] [CrossRef]

- Swigart, J.; Heo, J.; Wolf, D. Soil Contamination Assessments from Drilling Fluids and Produced Water Using Combined Field and Laboratory Investigations: A Case Study of Arkansas, USA. Int. J. Environ. Res. Public. Health 2021, 18, 2421. [Google Scholar] [CrossRef]

- Fontenot, B.E.; Hunt, L.R.; Hildenbrand, Z.L.; Carlton Jr., D. D.; Oka, H.; Walton, J.L.; Hopkins, D.; Osorio, A.; Bjorndal, B.; Hu, Q.H.; et al. An Evaluation of Water Quality in Private Drinking Water Wells Near Natural Gas Extraction Sites in the Barnett Shale Formation. Environ. Sci. Technol. 2013, 47, 10032–10040. [Google Scholar] [CrossRef]

- Warner, N.R.; Christie, C.A.; Jackson, R.B.; Vengosh, A. Impacts of Shale Gas Wastewater Disposal on Water Quality in Western Pennsylvania. Environ. Sci. Technol. 2013, 47, 11849–11857. [Google Scholar] [CrossRef]

- Skalak, K.J.; Engle, M.A.; Rowan, E.L.; Jolly, G.D.; Conko, K.M.; Benthem, A.J.; Kraemer, T.F. Surface Disposal of Produced Waters in Western and Southwestern Pennsylvania: Potential for Accumulation of Alkali-Earth Elements in Sediments. Int. J. Coal Geol. 2014, 126, 162–170. [Google Scholar] [CrossRef]

- Warner, N.R.; Jackson, R.B.; Vengosh, A. Tracing the Legacy of Accidental Spills and Releases of Marcellus Wastewater in Pennsylvania; Geological Society of America: Denver, CO, 2013. [Google Scholar]

- Zielinski, R.A.; Otton, J.K.; Budahn, J.R. Use of Radium Isotopes to Determine the Age and Origin of Radioactive Barite at Oil-®eld Production Sites. Environ. Pollut. 2001. [Google Scholar] [CrossRef]

- English, S.; Heo, J.; Won, J. Investigation of Sinkhole Formation with Human Influence: A Case Study from Wink Sink in Winkler County, Texas. Sustainability 2020, 12, 3537. [Google Scholar] [CrossRef]

- Daly, R.A.; Borton, M.A.; Wilkins, M.J.; Hoyt, D.W.; Kountz, D.J.; Wolfe, R.A.; Welch, S.A.; Marcus, D.N.; Trexler, R.V.; MacRae, J.D.; et al. Microbial Metabolisms in a 2.5-Km-Deep Ecosystem Created by Hydraulic Fracturing in Shales. Nat. Microbiol. 2016, 1, 16146. [Google Scholar] [CrossRef] [PubMed]

- Maloney, K.O.; Young, J.A.; Faulkner, S.P.; Hailegiorgis, A.; Slonecker, E.T.; Milheim, L.E. A Detailed Risk Assessment of Shale Gas Development on Headwater Streams in the Pennsylvania Portion of the Upper Susquehanna River Basin, U.S.A. Sci. Total Environ. 2018, 610–611, 154–166. [Google Scholar] [CrossRef] [PubMed]

- Seo, M.; Heo, J.; Kim, Y. Present and Potential Future Critical Source Areas of Nonpoint Source Pollution: A Case of the Nakdong River Watershed, South Korea. Environ. Sci. Pollut. Res. 2021, 28, 45676–45692. [Google Scholar] [CrossRef] [PubMed]

- Hildenbrand, Z.L.; Mach, P.M.; McBride, E.M.; Dorreyatim, M.N.; Taylor, J.T.; Carlton, D.D.; Meik, J.M.; Fontenot, B.E.; Wright, K.C.; Schug, K.A.; et al. Point Source Attribution of Ambient Contamination Events near Unconventional Oil and Gas Development. Sci. Total Environ. 2016, 573, 382–388. [Google Scholar] [CrossRef]

-

U.S. Geological Survey USGS Earthquake Catalog 2023.

- Railroad Commission of Texas (RRC) Seismicity Response; 2023.

- Burnett, D.B. Potential for Beneficial Use of Oil and Gas Produced Water; Global Petroleum Institute: Texas Water Resources Institute, 2004. [Google Scholar]

- Foulger, G.R.; Wilson, M.P.; Gluyas, J.G.; Julian, B.R.; Davies, R.J. Global Review of Human-Induced Earthquakes. Earth-Sci. Rev. 2018, 178, 438–514. [Google Scholar] [CrossRef]

- Frohlich, C.; Ellsworth, W.; Brown, W.A.; Brunt, M.; Luetgert, J.; MacDonald, T.; Walter, S. The 17 May 2012 M 4.8 Earthquake near Timpson, East Texas: An Event Possibly Triggered by Fluid Injection: 2012 May 17 East Texas Earthquake. J. Geophys. Res. Solid Earth 2014, 119, 581–593. [Google Scholar] [CrossRef]

- Hough, S.E.; Page, M. A Century of Induced Earthquakes in Oklahoma? Bull. Seismol. Soc. Am. 2015, 105, 2863–2870. [Google Scholar] [CrossRef]

- Frohlich, C. Two-Year Survey Comparing Earthquake Activity and Injection-Well Locations in the Barnett Shale, Texas. Proc. Natl. Acad. Sci. 2012, 109, 13934–13938. [Google Scholar] [CrossRef]

- Magnani, M.B.; Blanpied, M.L.; DeShon, H.R.; Hornbach, M.J. Discriminating between Natural versus Induced Seismicity from Long-Term Deformation History of Intraplate Faults. Sci. Adv. 2017, 3, e1701593. [Google Scholar] [CrossRef]

- Kim, J.-W.; Lu, Z. Association between Localized Geohazards in West Texas and Human Activities, Recognized by Sentinel-1A/B Satellite Radar Imagery. Sci. Rep. 2018, 8, 4727. [Google Scholar] [CrossRef] [PubMed]

- Colborn, T.; Schultz, K.; Herrick, L.; Kwiatkowski, C. An Exploratory Study of Air Quality Near Natural Gas Operations. Hum. Ecol. Risk Assess. Int. J. 2014, 20, 86–105. [Google Scholar] [CrossRef]

- Field, R.A.; Soltis, J.; Murphy, S. Air Quality Concerns of Unconventional Oil and Natural Gas Production. Environ. Sci. Process. Impacts 2014, 16, 954–969. [Google Scholar] [CrossRef] [PubMed]

- Helmig, D. Air Quality Impacts from Oil and Natural Gas Development in Colorado. Elem. Sci. Anthr. 2020, 8, 4. [Google Scholar] [CrossRef]

- Vinciguerra, T.; Yao, S.; Dadzie, J.; Chittams, A.; Deskins, T.; Ehrman, S.; Dickerson, R.R. Regional Air Quality Impacts of Hydraulic Fracturing and Shale Natural Gas Activity: Evidence from Ambient VOC Observations. Atmos. Environ. 2015, 110, 144–150. [Google Scholar] [CrossRef]

- Zhang, R.; Li, H.; Khanna, N.; Krupnick, A.J.; Hill, E.L.; Sullivan, D.M. Air Quality Impacts of Shale Gas Development in Pennsylvania. J. Assoc. Environ. Resour. Econ. 2023, 10, 447–486. [Google Scholar] [CrossRef]

- Srebotnjak, T.; Rotkin-Ellman, M. Fracking Fumes: Air Pollution from Hydraulic Fracturing Threatens Public Health and Communities. 2014.

- Raheja, G.; Harper, L.; Hoffman, A.; Gorby, Y.; Freese, L.; O’Leary, B.; Deron, N.; Smith, S.; Auch, T.; Goodwin, M.; et al. Community-Based Participatory Research for Low-Cost Air Pollution Monitoring in the Wake of Unconventional Oil and Gas Development in the Ohio River Valley: Empowering Impacted Residents through Community Science. Environ. Res. Lett. 2022, 17, 065006. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).