Submitted:

29 August 2023

Posted:

07 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

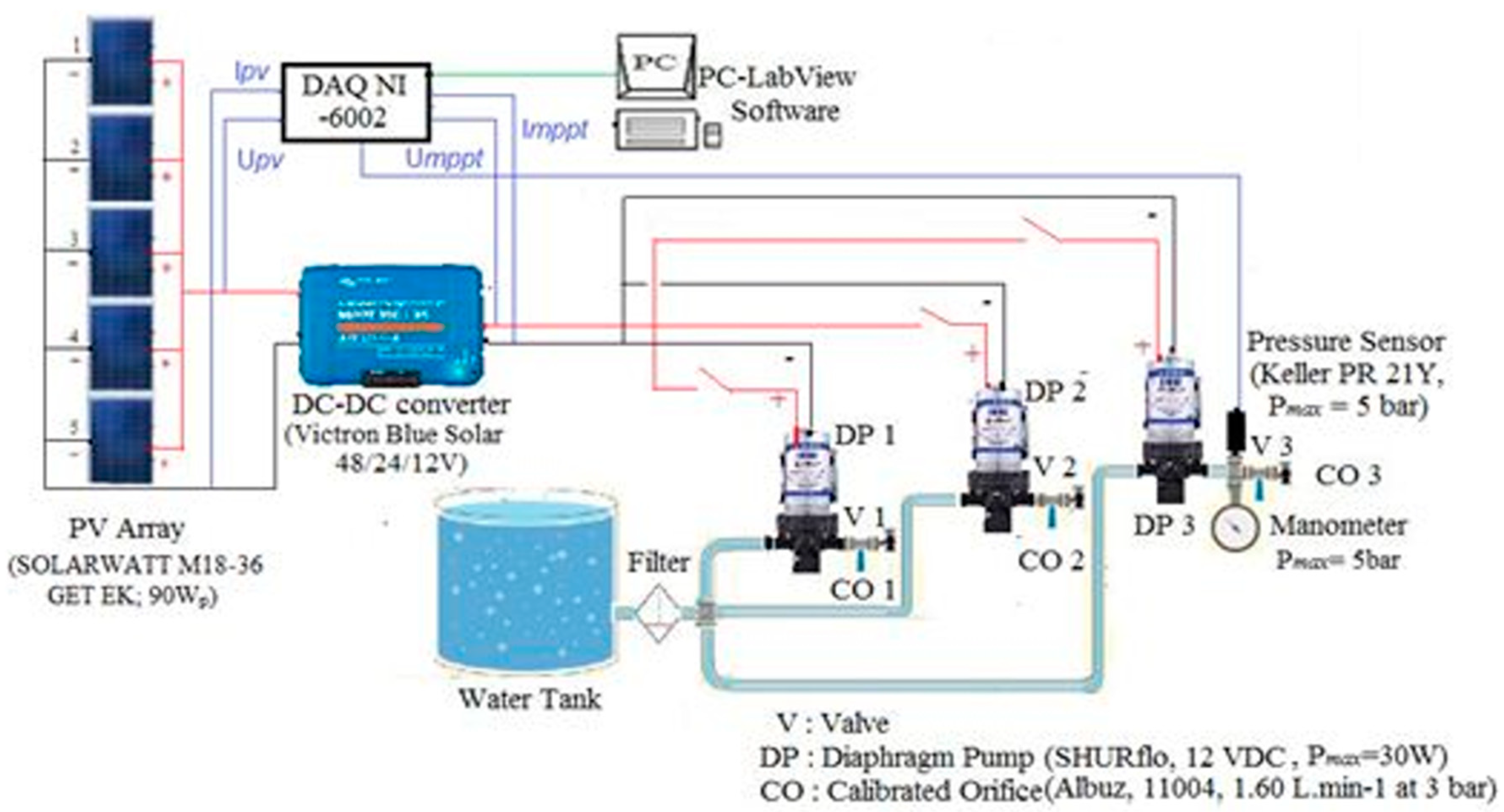

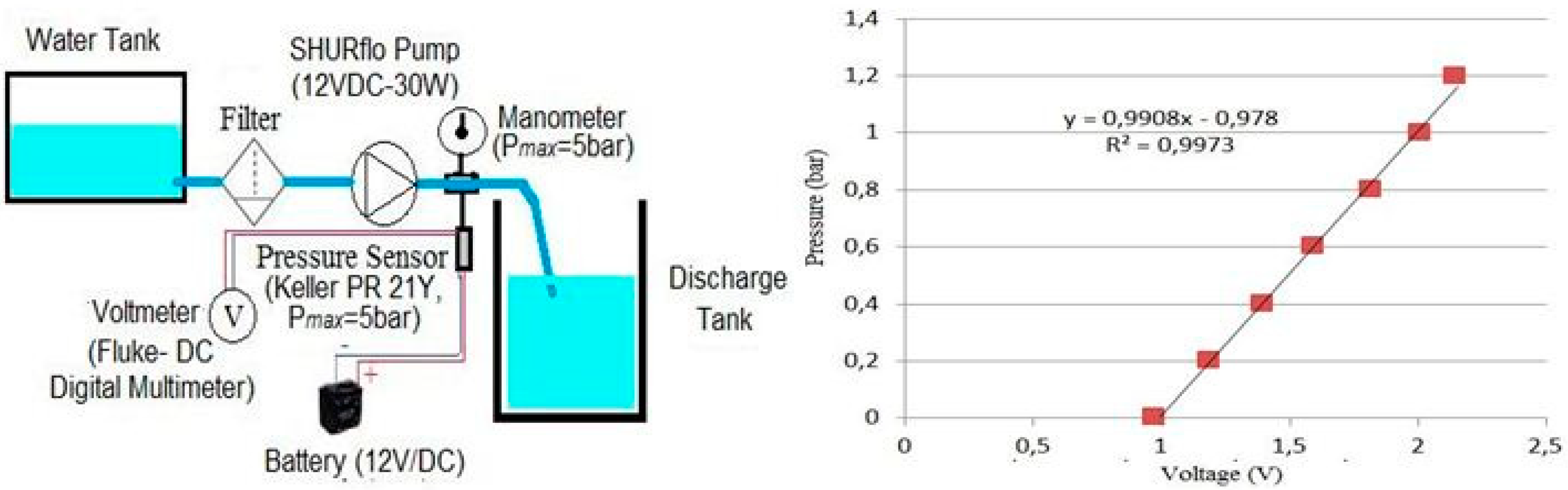

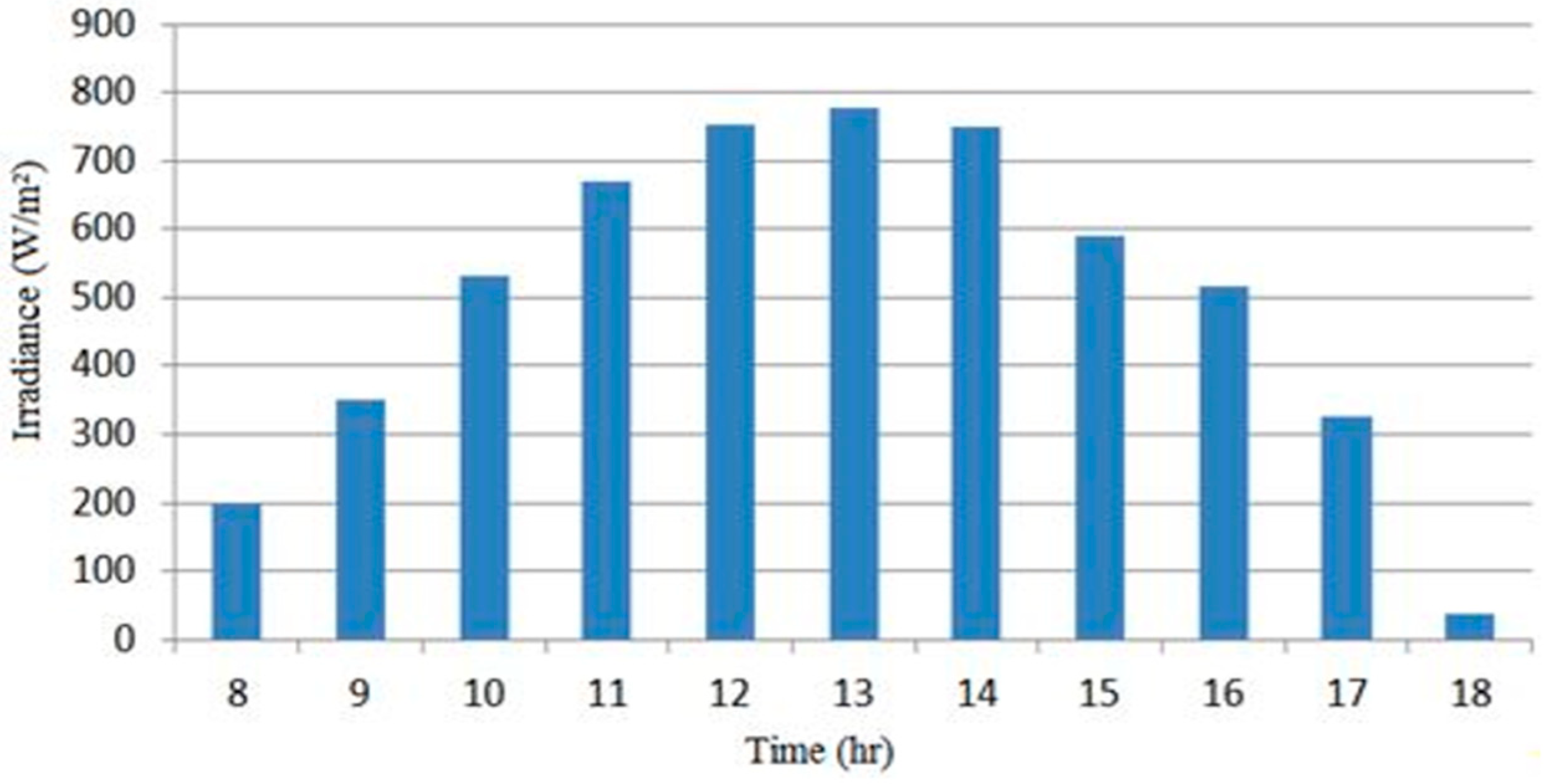

2. Experimental study of PVWPS

PVWPS design

3. Modeling of PVWPS

4. Results and Discussions

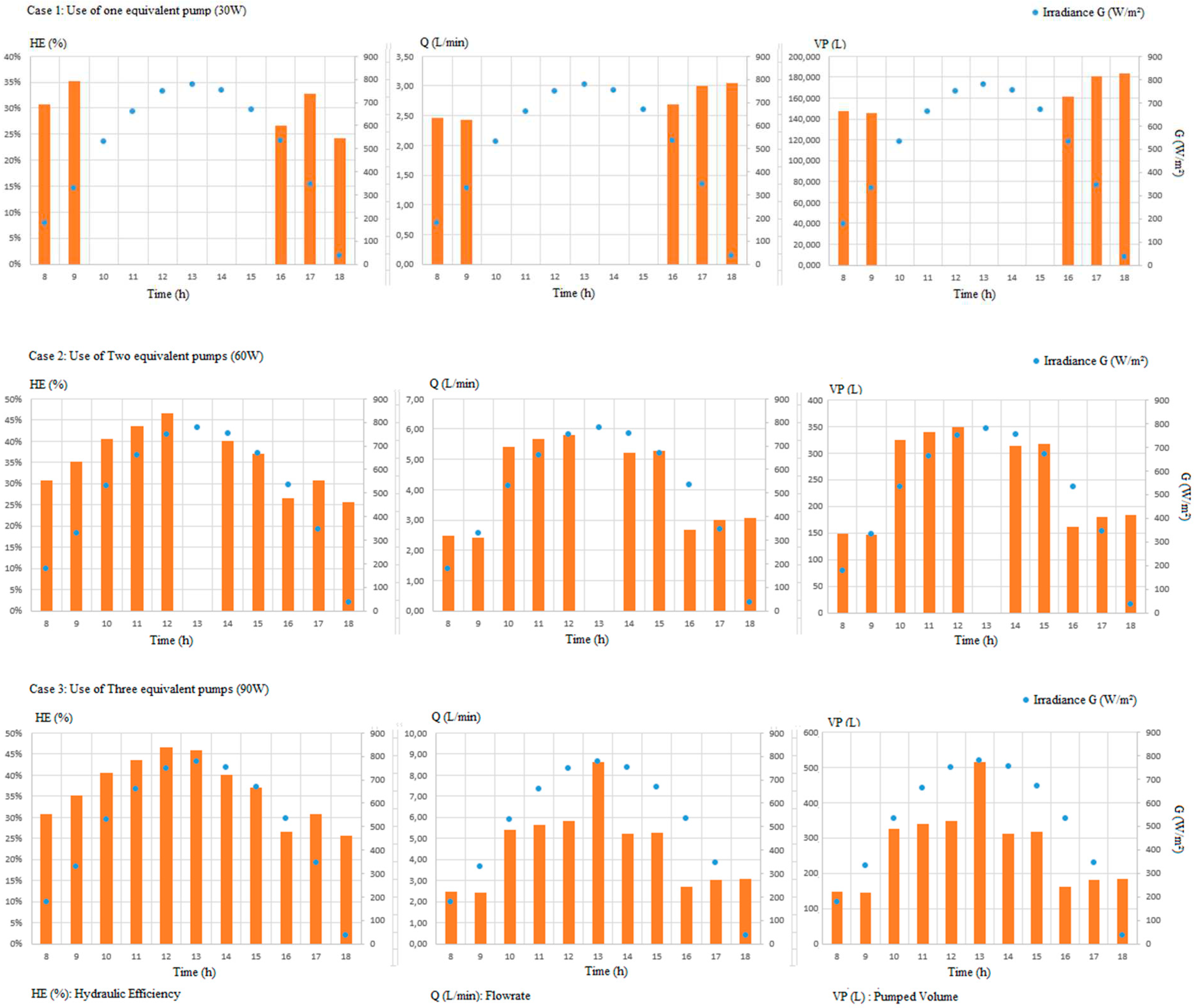

4.1. Results of Experimental Study

| Time | Irradiance (W/m²) | Number of operating Pumps | Mean Pressure (bar) (CV%) | Mean Flowrate (L/min) (CV%) |

Mean Hydraulic Power (CV%) |

Mean Hydraulic Yield% (CV%) |

|---|---|---|---|---|---|---|

| 08. am | 178 | 1 | 01.18 (16) | 02.46 (08) | 04.65 (24) | 30 (19) |

| 197 | 2 | 00.45 (20) | 03.28 (11) | 02.41 (28) | 13 (31) | |

| 213 | 3 | 00.26 (19) | 03.61 (10) | 01.51 (27) | 07 (26) | |

| 09. am | 331 | 1 | 01.24 (17) | 02.43 (09) | 04.74 (24) | 33 (18) |

| 350 | 2 | 00.71 (20) | 02.91 (10) | 03.44 (28) | 14 (23) | |

| 368 | 3 | 00.45 (22) | 03.29 (12) | 02.39 (32) | 07 (32) | |

| 10. am | 515 | 1 | 02.63 (27) | 03.19 (14) | 02.51 (37) | 06 (28) |

| 530 | 2 | 00.93 (37) | 02.70 (19) | 04.00 (56) | 13 (38) | |

| 544 | 3 | 00.60 (32) | 03.08 (17) | 02.96 (45) | 06 (40) | |

| 11. am | 662 | 2 | 00.84 (37) | 02.83 (19) | 03.39 (55) | 12 (42) |

| 679 | 3 | 00.65 (35) | 03.03 (20) | 03.11 (47) | 07 (38) | |

| 12. pm | 749 | 2 | 00.76 (24) | 02.91 (13) | 03.39 (32) | 12 (31) |

| 758 | 3 | 00.72 (26) | 02.93 (15) | 03.38 (36) | 06 (38) | |

| 01. pm | 777 | 3 | 00.78 (31) | 02.87 (17) | 3.55 (41) | 34 (38) |

| 02. pm | 754 | 2 | 01.12 (33) | 02.61 (18) | 04.25 (46) | 13 (37) |

| 748 | 3 | 00.95 (28) | 02.74 (16) | 03.90 (40) | 06 (38) | |

| 03. pm | 670 | 2 | 01.08 (32) | 02.64 (18) | 04.16 (45) | 12 (38) |

| 508 | 3 | 00.94 (27) | 02.71 (15) | 03.96 (37) | 06 (36) | |

| 04. pm | 534 | 1 | 01.97 (29) | 02.69 (16) | 03.97 (40) | 12 (35) |

| 517 | 2 | 01.00 (29) | 02.67 (16) | 04.08 (40) | 09 (37) | |

| 500 | 3 | 00.45 (38) | 03.30 (22) | 02.36 (53) | 06 (39) | |

| 05. pm | 344 | 1 | 00.80 (53) | 03.01 (31) | 03.16 (73) | 24 (48) |

| 326 | 2 | 00.59 (32) | 03.11 (19) | 02.89 (44) | 10 (38) | |

| 312 | 3 | 00.36 (30) | 03.45 (19) | 01.95 (38) | 06 (38) | |

| 06. pm | 37 | 1 | 00.62 (28) | 03.06 (16) | 03.03 (38) | 25 (35) |

| 34 | 2 | 00.20 (25) | 03.74 (13) | 01.16 (35) | 09 (47) | |

| 42 | 3 | 00.04 (34) | 04.05 (19) | 00.29 (46) | 02 (55) |

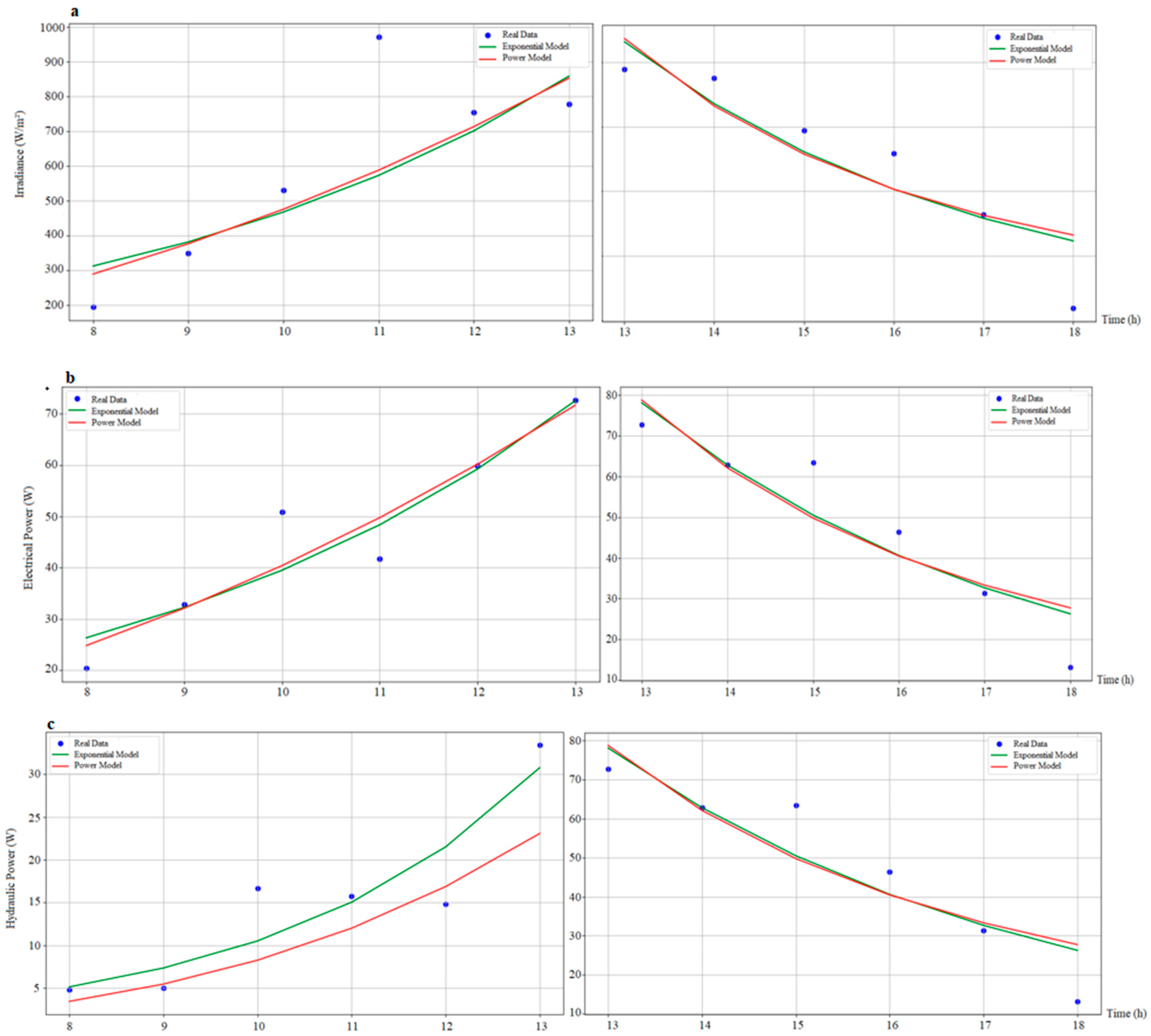

4.2. Modeling of PVWP System Using Experimental Data

PVWPS model

| Increasing Irradiance Trend | |||||

| Model | Software Tools | a | b | R² | |

| Irradiance Vs Time | Exponential | Python | 62,093 | 0,202 | 0,86 |

| Exponential | R | 62,092 | 0,202 | 0,86 | |

| Power | Python | 2,874 | 2,219 | 0,9 | |

| Power | R | 2,874 | 2,22 | 0,9 | |

| Electrical Power Vs Time | Exponential | Python | 5,185 | 0,203 | 0,88 |

| Exponential | R | 5,185 | 0,203 | 0,88 | |

| Power | Python | 0,262 | 2,188 | 0,88 | |

| Power | R | 0,262 | 2,188 | 0,88 | |

| Hydraulic Power Vs Time | Exponential | Python | 0,293 | 0,358 | 0,82 |

| Exponential | R | 0,293 | 0,358 | 0,82 | |

| Power | Python | 0,001 | 3,917 | 0,62 | |

| Power | R | 0,001 | 3,917 | 0,62 | |

| Decreasing Irradiance Trend | |||||

| Model | Software Tools | a | b | R² | |

| Irradiance Vs Time | Exponential | Python | 22539,772 | -0,251 | 0,82 |

| Exponential | R | 22539,772 | -0,251 | 0,82 | |

| Power | Python | 10939913,381 | -3,679 | 0,78 | |

| Power | R | 3378000 | -3,245 | 0,77 | |

| Electrical Power Vs Time | Exponential | Python | 1328,821 | -0,218 | 0,85 |

| Exponential | R | 1328,793 | -0,218 | 0,84 | |

| Power | Python | 295836,902 | -3,209 | 0,81 | |

| Power | R | 298100 | -3,21 | 0,81 | |

| Hydraulic Power Vs Time | Exponential | Python | 8165,452 | -0,423 | 0,95 |

| Exponential | R | 8165,454 | -0,423 | 0,95 | |

| Power | Python | 243140608,495 | -6,158 | 0,95 | |

| Power | R | 12560000 | -5,038 | 0,92 | |

- Electrical Power & IrradianceEP= 5,185*EXP(0,203*t)G= 62,093*EXP(0,202*t)G= EP* 11,975* EXP(-0,001*t)

- Hydraulic Power & Electrical PowerHP = 8165,452*EXP(-0,423*t)EP= 5,185*EXP(0,203*t)EP= HP*0.0006332 * EXP (0.626 * t)

| Increasing Irradiance Trend | ||||||

| Time | Real Data | PP Exponential Model | Power Model | |||

| Irradiance Vs Time | 08:00 | 196 | 313 | 290 | Exponential Model | |

| 09:00 | 350 | 382 | 377 | RMSE | 79,09 | |

| 10:00 | 530 | 468 | 476 | MAE | 73,83 | |

| 11:00 | 671 | 573 | 588 | Power Model | ||

| 12:00 | 754 | 701 | 713 | RMSE | 66,68 | |

| 01:00 | 777 | 858 | 852 | MAE | 62,33 | |

| Electrical Power Vs Time | 08:00 | 20,38 | 26,31 | 24,79 | Exponential Model | |

| 09:00 | 32,85 | 32,23 | 32,08 | RMSE | 05,97 | |

| 10:00 | 50,90 | 39,48 | 40,39 | MAE | 04,30 | |

| 11:00 | 41,72 | 48,36 | 49,76 | Power Model | ||

| 12:00 | 59,84 | 59,25 | 60,19 | RMSE | 05,92 | |

| 01:00 | 72,71 | 72,59 | 71,71 | MAE | 04,25 | |

| Hydraulic Power Vs Time | 08:00 | 04,84 | 05,14 | 03,45 | Exponential Model | |

| 09:00 | 05,01 | 07,35 | 05,47 | RMSE | 04,00 | |

| 10:00 | 16,69 | 10,51 | 08,26 | MAE | 3,15 | |

| 11:00 | 15,75 | 15,04 | 12,00 | Power Model | ||

| 12:00 | 14,81 | 21,51 | 16,87 | RMSE | 5,75 | |

| 01:00 | 33,43 | 30,77 | 23,08 | MAE | 4,41 | |

| Decreasing Irradiance Trend | ||||||

| Time | Real Data | PP Exponential Model | Power Model | |||

| Irradiance Vs Time | 01:00 | 777 | 863 | 873 | Exponential Model | |

| 02:00 | 751 | 671 | 664 | RMSE | 111,05 | |

| 03:00 | 589 | 522 | 515 | MAE | 93,83 | |

| 04:00 | 517 | 406 | 406 | Power Model | ||

| 05:00 | 327 | 316 | 325 | RMSE | 119,49 | |

| 06:00 | 38 | 2446 | 264 | MAE | 99,33 | |

| Electrical Power Vs Time | 01:00 | 72,71 | 78,10 | 78,78 | Exponential Model | |

| 02:00 | 62,85 | 62,81 | 62,11 | RMSE | 07,94 | |

| 03:00 | 63,42 | 50,50 | 49,77 | MAE | 06,29 | |

| 04:00 | 46,40 | 40,61 | 40,46 | Power Model | ||

| 05:00 | 31,37 | 32,66 | 33,31 | RMSE | 08,98 | |

| 06:00 | 13,18 | 26,26 | 27,73 | MAE | 07,24 | |

| Hydraulic Power Vs Time | 01:00 | 33,43 | 33,40 | 33,59 | Exponential Model | |

| 02:00 | 19,49 | 21,88 | 21,28 | RMSE | 02,33 | |

| 03:00 | 18,95 | 14,33 | 13,92 | MAE | 01,77 | |

| 04:00 | 08,84 | 09,39 | 09,35 | Power Model | ||

| 05:00 | 04,02 | 06,15 | 06,44 | RMSE | 02,47 | |

| 06:00 | 03,15 | 04,03 | 04,53 | MAE | 01,88 | |

5. Conclusion

Abbreviations

| AI | Artificial Intelligence |

| BDC | Brushed Direct Current |

| DC | Direct Current |

| HEexp | Experimental Hydraulic Efficiency |

| HEmod | Modeling Hydraulic Efficiency |

| HPPT | Hydraulic Power Point Tracking |

| IncCond | Incremental Conductance |

| MBE | Mean Bias Error |

| MPPT | Maximum Power Point Tracking |

| P&O | Perturb and Observe |

| PV | Photovoltaic |

| PVWPS | Photovoltaic Water Pumping System |

| R&D | Research and Development |

| RMSE | Root Mean Square Error |

References

- Vafaeipour, M., Hashemkhani, Z.S., Morshed, V.M.H, Derakhti, A. and Keshavarz, E. M. (2014). Assessment of regions priority for implementation of solar projects in Iran: new application of a hybrid multi-criteria decision-making approach. Energy Conversion and Management.86,653–663.

- Moumen, M. (2014). Guide D’Irrigation Localize De L’Agriculteur. Maroc: FAO, Office Régional de la Mise en Valeur Agricole Doukkala.

- Akihiro, Oi.T., Anwari, M., and Taufik, M. (2009). Modeling and simulation of photovoltaic water pumping system. Proc. 3rd Asia Int. Conf. Modelling & Simulation. pp. 497-502. Bali, Indonesia. https://doi.org/10.1109/AMS.2009.85. [CrossRef]

- Khan, A. Md. T., A. Md. Rishad, S. I. Ahmed, and S. I. Khan. (2012). Design and performance analysis of water pumping using solar PV. Proc. 2nd International Conference on the Developments in Renewable Energy Technology (ICDRET). pp. 1–4. Dhaka, Bangladesh, 5-7 January.

- Sefriti, B., and I. Boumhidi. (2015). Neural network incremental conductance MPPTalgorithm for photovoltaic water pumping system. Proc. 10th International Conference on Intelligent Systems: Theories and Applications (SITA). pp. 1–6. Rabat, Morocco, 20-21 October.

- Essam, E. A., A. M. Zaki, and M. M. El-Sotouhy. (2017). Design and control of a standalone PV water pumping system. Journal of Electrical Systems and Information Technology (JESIT), 4(2): 322–337.

- Almeida, R. H., Ledesma, J. R., Carrêlo, I. B., Narvarte, L., Ferrara, G., Antipodi, L. (2018). A new pump selection method for large-power PV irrigation systems at a variable frequency. Energy Convers Manage, 174:874–85. https://doi.org/10.1016/j.enconman.2018.08.071. [CrossRef]

- Hamidat, A., B. Benyoucef, and T. Artani. (2003). Small-scale irrigation with photovoltaic water pumpingsystem in Sahara regions. Renewable Energy, 28(3): 1081–1096.

- Hamidat, A., and Benyoucef, B. (2008). Mathematic models of photovoltaic motor-pump systems. Renewable Energy, 33, 933–942.

- Protogeropoulos, C., and S. Pearce. (2000). Laboratory evaluation and system sizing charts for a ‘second generation’ direct PV-powered, low cost submersible solar pump. Solar Energy, 68(5): 453–474.

- Kashyap, M., S. Chanana, and A. J. Singh. (2013). Solar powered pmdc motor drive. Proc. Conference on Advances in Communication and Control Systems (CAC2S), Dehradun, 18-22 April 2013.

- Harkani, A., El Aissaoui, A., Fihri Fassi, H., El Kacimi, O. (2019). Performance Study of a Standalone Direct Pumping Photovoltaic System Used for Drip Irrigation, CIGR journal. 21 (3): 114-122.

- Zhounian, L., Qian, L., An, Z., Wenjie, Z., Hailiang, X., AND Dazhuan, W. (2020). Improving Reliability of Pumps in Parallel Pump Systems Using Particle Swam Optimization Approach. IEEE Access. 8: 58427- 58434.

- Koor, M., Vassiljev, A., Koppel, T. (2015). Optimization of pump efficiencies with different pumps characteristics working in parallel mode. Advances in Engineering Software. 101: 69-76.

- Katan, R.E., Agelidis, V.G., and Nayar, C.V. (1996). Performance analysis of a solar water pumping system. Proc. the IEEE int. conf. on power electronics, drives, and energy systems for industrial growth (PEDES). pp. 81–87. New Delhi, India.

- Zahab, E.A., Zaki, A.M., and El-sotouhy. M.M. (2017). Design and control of a standalone PV water pumping system. Journal of Electrical Systems and Information Technology (JESIT), 4 (2), 322-337. http://dx.doi.org/10.1016/j.jesit.2016.03.003. [CrossRef]

- Jafar, M. (2000). A model for small-scale photovoltaic solar water pumping. Renewable Energy, 19,85–90.

- de Blas MA, Torres JL, Prieto E, Garcıa A. Selecting a suitable model for ́ characterizing photovoltaic devices. Renew Energy 2002;25:371–80.

- Ahonen, T., Tamminen, J., Ahola, J., Viholainen, J., Aranto, N. and Kestilä, J. (2010). Estimation of pump operational state with model-based methods. Energy Conversion and Management.51(6), 1319–1325. http://dx.doi.org/10.1016/j.enconman.2010.01.009. [CrossRef]

- Kalaiselvan, A., Umashankar, S., Paramasivam, S., and Norbert, H. Real Time Simulation of Variable Speed Parallel Pumping System. Proc. 9th International Conference on Applied Energy, ICAE2017, Cardiff, UK, pp. 2102- 2108, 21-24 August 2017.

- Zhang, Z., Kusiak, A., Zeng, Y., and Wei, X. (2016). Modeling and optimization of a wastewater pumping system with data-mining methods. Applied Energy, 164, 303-311. https://doi.org/10.1016/j.apenergy.2015.11.061. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).