1. Introduction

Korea has distinct seasons, with cold and dry winters, hot and humid summers, and significant seasonal variations in external environmental conditions. As the scale of livestock farming increases, enclosed forced ventilation systems are used to adapt to external environmental changes and create suitable breeding conditions [

1,

2,

3] In enclosed facilities with high livestock stocking density, workers are exposed to higher concentrations of organic dust and harmful gases while engaging in agricultural activities. Especially, broiler houses are intensively used for raising chicken in enclosed spaces, and workers are consistently exposed to aerosols, including particulate matter and harmful gases, due to a higher frequency of barn management and harvesting operations compared to other livestock species [

4,

5]. The aerosols inside livestock facilities contain various bacteria, molds, and harmful gases, including ammonia, hydrogen sulfide, methane, acetaldehyde, formaldehyde, methylamine, and carbon monoxide [

6,

7,

8]. The aging of agricultural workers raises serious concerns about health issues resulting from the inhalation of aerosols. Elderly workers are consistently exposed to high levels of aerosols within the farm, which can lead to respiratory and immune system disorders, as well as conditions such as asthma [

6,

7,

8,

9,

10,

11] . Endotoxin-containing particulate matter (PM) with a diameter of 10 µm or less is prevalent in enclosed barns and housing facilities, and it can have a significant impact not only on livestock activity and productivity but also on the health of workers[

12,

13,

14,

15,

16,

17,

18,

19,

20] . The American Conference of Governmental Industrial Hygienists (ACGIH) categorizes particulate matter into inhalable, thoracic, and respirable fractions. Inhalable particulate matter consists of particles that can reach the respiratory system and potentially contain harmful substances. These particles have a penetration rate of 50% and an average aerodynamic diameter of around 100 µm. Thoracic particulate matter includes particles that can reach the bronchial and gas-exchange regions of the lungs. These particles have an average aerodynamic diameter of 10 µm. Respirable particulate matter comprises particles that can deposit in the gas-exchange regions of the lungs and may pose health risks. These particles have an average aerodynamic diameter of 4 µm. In addition, the Special Act on Fine Dust Reduction and Management (Korea Ministry of Government Legislation, 2019) defines PM10 as fine dust with an aerodynamic diameter of 10 µm or less and PM2.5 as fine particulate matter with a diameter less than 2.5 µm.

Previous research on aerosols within livestock facilities has primarily focused on concentration measurements at various locations and source tracking studies. To reduce the generation of fine dust and improve the working environment inside broiler houses, it is crucial to assess the status and characteristics of fine dust within the facility through field monitoring. There are methods for monitoring fine dust concentrations among workers in livestock facilities, including passive sampling using filters and gravimetric methods, as well as active sampling using optical scattering. Among passive sampling methods, gravimetric methods involve capturing airborne fine dust on filters to determine the mass concentration of fine dust. In active sampling, the optical scattering method involves shining light on suspended particulate matter in the air. When the light scatters, the amount of scattered light is measured to determine the concentration of particulate matter in real-time [

21,

22]. Previous research on field monitoring of aerosols in livestock facilities has predominantly utilized passive sampling to measure aerosol concentrations in representative areas inside the barn [

13,

14,

18,

23,

24,

25]. As the age of chicken increases, their activity level rises, resulting in higher indoor dust concentrations. Furthermore, extended use of litter material leads to the accumulation and drying of excrement, further elevating dust levels [

23,

26,

27]. Fine dust production varies with the season and the age of the chicken, with higher concentrations observed during the winter when maintaining minimal ventilation rates [

28]. Analysis of fine dust generated within the broiler house using Scanning Electron Microscope (SEM) revealed that feathers, feces, bedding material, and feed particles were the primary sources of dust [

18].

However, research on occupational environment, specifically analyzing aerosol concentrations through worker-centered monitoring has been quite rare. In recent times, although broiler farming has become larger in scale and more automated, workers continue to perform a significant portion of the tasks. Workers engage in various activities within broiler houses, including movement within the facility, feeding, and harvesting, culling of sick or unproductive chicken, management of feeding and watering systems, facility maintenance, and more. Depending on the type of task, workers may be exposed to different types and concentrations of aerosols. Therefore, for real-time analysis based on the type of task and workflow, it is crucial to utilize real-time active samplers to analyze the concentration and characteristics of fine dust exposure in the worker's occupational environment.

The aim of this study is to analyze the concentration and exposure characteristics of aerosols to which workers are exposed during management operations inside a tunnel-ventilated broiler house. To examine the structural characteristics of ventilation, regional concentration characteristics within the broiler house were measured using passive sampling methods with air samplers and filters. Furthermore, real-time aerosol concentrations according to particle size were measured along the workers' movement paths by utilizing an aerosol spectrometer installed at the workers' breathing height. Through video analysis, we aimed at distinguishing working characteristics and gain insights into the characteristics of worker-exposed aerosols within the broiler house.

2. Materials and Methods

2.1. Experimental farm

The target farms involved in the experiment consisted of five commercial broiler f houses commonly used in South Korea, utilizing forced ventilation systems for commercial broiler production. These experimental farms were needed t for access to the interior for equipment installation and regional aerosol concentration measurement.. To conduct real-time monitoring of the working environment during workers’ movement, workers were required to wear specially designed backpack-type equipment while performing tasks. Therefore, it was of utmost importance to engage cooperative commercial broiler farms. The farms selected for the experiment had an average capacity of 25,000 chickens each, with a similar stocking density of approximately 0.053 ㎡/head (

Table 1). These farms utilized wood shavings as bedding material and operated automatic feeding and watering systems. The farms utilized nearly identical tunnel and negative-pressure forced ventilation systems for air exchange. The ventilation systems regulated the ventilation rate by adjusting the output of ventilation fans installed on one end wall based on the environmental temperature. Open inlets were installed on the opposite side to allow fresh external air to enter in a negative-pressure manner. All farms operated under an All-in / All-out system, which facilitated disease control and production management. To ensure as consistent environmental conditions as possible, monitoring was conducted when the broilers were approximately four weeks old across all farms.

2.2. Aerosol collection and measurement

Spatial aerosol concentration distribution within the broiler houses was measured using passive samplers, while real-time active samplers were employed to measure the working environment along the workers' routes (

Figure 1a). For spatial concentration analysis, TSP (Total Suspended Particulate), PM-10 (particulate matter under 10µm), and PM-2.5 (particulate matter under 2.5µm) were measured through passive sampling. TSP was measured by fixing a PTFE (Polytetrafluoroethylene) filter (SKC Inc., USA, 2.0 μm, 37 mm) into a three-stage cassette, which was connected to a compact air sampler (AirChek TOUCH, SKC. Inc., USA) with an airflow rate of 2 L/min. PM-10 and PM-2.5 were measured by connecting PTFE filters to PEM impactors (Personal Environmental Monitor, SKC. Inc., USA), capable of capturing aerosols below 2.5 µm and 10 µm, respectively, and using a compact air sampler with an airflow rate of 4 L/min. For analyzing aerosol concentrations exposed to workers, an active sampling method was employed, which allowed real-time monitoring along the workers' routes, including size-segregated monitoring. To understand real-time aerosol concentration and size distribution, an Aerosol spectrometer (11-D, Grimm Inc., Germany) was utilized, measuring aerosol concentrations divided into 31 size bins ranging from 0.253 µm to 35.15 µm at 6-seconds intervals (

Figure 1b).

The filters used for capturing particulate matter were adequately dried for over 48 hours in a constant temperature and humidity chamber (KA33-73, Korea Ace Science Inc., Korea) before and after sampling. The dried filters were then weighed three times each using a microbalance (BM-22, AND weighing Inc., Japan) with a sensitivity of 0.001 mg, and the average value of these measurements was determined as the aerosol's weight. Blank filters, which were filters not used for any air sampling, were also prepared to correct the results. To calculate the aerosol concentration, Equation (1) was used, taking into account the weight difference of the filters before and after monitoring, as well as the error in filter weight due to sample collection, transportation, and pre-processing steps, while considering the weight of the blank filters.

Here, in the provided equations: represents the weight of the filter after sampling (µg). represents the weight of the filter before sampling (µg). represents the weight of the blank filter after sampling (µg). represents the weight of the blank filter before sampling (µg). signifies the total volume of the sample collection (m3). The flow rate (Q) is corrected to standard temperature and pressure (0 °C, 1 atm) and is calculated as shown in Equation (2). In this equation: Q represents the flow rate measured by the standard flow meterT and P represent the temperature (℃) and pressure (atm), respectively. t denotes the total sampling time (s). These equations were used to calculate and adjust the aerosol concentration based on various measurements and corrections.

2.3. Experimental procedure

2.4.1. Spatial aerosol distribution in broiler house

To analyze the spatial aerosol concentration within the tunnel-type forced ventilation broiler house, Total Suspended Particulate (TSP), PM-10, and PM-2.5 were measured (

Figure 2). The rearing area of the broiler house was divided into three sections: the inlet area near the air inlets, the middle area, and the outlet area near the exhaust fans. Monitoring devices were installed in these areas. During the experiment conducted in the summer season, the sidewall inlets were completely closed. Negative pressure was created by operating exhaust fans on one end wall, allowing fresh air to enter through the opposite side inlets. In all experimental farms, aerosol sampling was conducted for a total of 6 hours, primarily from 10 AM to 4 PM, covering the main working hours. The duration of fine dust measurements was set at 6 hours, considering the Time-Weighted Average Exposure Limit specified in the Occupational Safety and Health Act.

The direction of aerosol capture, physical characteristics of particles, and the flow rate near the sampling site can significantly impact concentration results. When dealing with fine dust particles, their size and weight can influence whether they settle due to gravity and humidity or continue to move primarily along the airflow. To selectively capture aerosols of the desired size and prevent the influence of dust deposition, the sampling direction was oriented downward, as depicted in

Figure 3. To analyze aerosol concentrations that affect workers, the sampling inlet was positioned at a height of 1.5 meters above the floor, which is the typical breathing height for workers. The air intake was placed at least 30 cm away from the structure that holds the equipment. This design was implemented to prevent any interference caused by the proximity of the intake to the structure holding the fine dust sampling equipment, as close proximity can lead to an underestimation of concentrations compared to real-time analysis results. To ensure stability during the 6-hour sampling period and to prevent equipment damage or tipping over, the monitoring devices were securely fastened and installed while avoiding the worker's path. Additionally, thorough disinfection and sanitation measures were conducted before installation to facilitate monitoring in commercial broiler farms.

To analyze the physical characteristics related to the generation and dispersion of aerosols, the filters used for aerosol collection were subjected to scanning electron microscopy (SEM) to examine the size and shape of the aerosols. The filters containing trapped fine dust were coated with a 10 nm-thick layer of platinum-palladium. An SEM-EDX (Supra 40VP, ZEISS Inc., Germany) was employed to analyze images of the fine dust at various resolutions.

2.4.2. Personal aerosol exposure by working conditions

To analyze the concentration and characteristics of fine dust to which workers are exposed inside commercial broiler houses, real-time measurement using an Aerosol spectrometer was conducted through active sampling along the work paths. Aerosol measurement points were strategically located within 30 cm from the workers' noses and mouths, at a height of 1.2 to 1.5 meters above the floor, using Tygon tubes. Aerosol measurements were taken during periods when general and frequent tasks were typically performed by workers, between 10:00 AM and 4:00 PM, when tasks such as broiler house management and maintenance are commonly carried out. For comparative analysis with real-time measurement data based on work types and work routes, video recording equipment (Hero 9 Black, GoPro Inc., USA) was installed near the entrance, allowing for comprehensive video documentation of the entire broiler house (

Figure 4). Work types were categorized into "Moving work," which involves tasks while moving for management purposes, and "Static work," which involves tasks performed in a stationary position for maintenance purposes.

3. Results

3.1. Spatial aerosol distribution

To understand the regional distribution of aerosol concentrations in the experimental broiler houses across the five selected farms, measurements of TSP, PM-10, and PM-2.5 were conducted at three locations along the length from the inlet to the exhaust. Measurements were taken from 10:00 AM to 4:00 PM. Temperature and humidity were monitored both inside and outside the livestock facilities (

Table 2). During the summer season, when external temperatures exceeded 30 degrees Celsius, full ventilation was achieved. In contrast, during the transitional season of autumn when external temperatures were around 20 degrees Celsius, approximately 5.2°C lower than the internal temperature, ventilation rates were reduced to less than 15% of the maximum capacity.

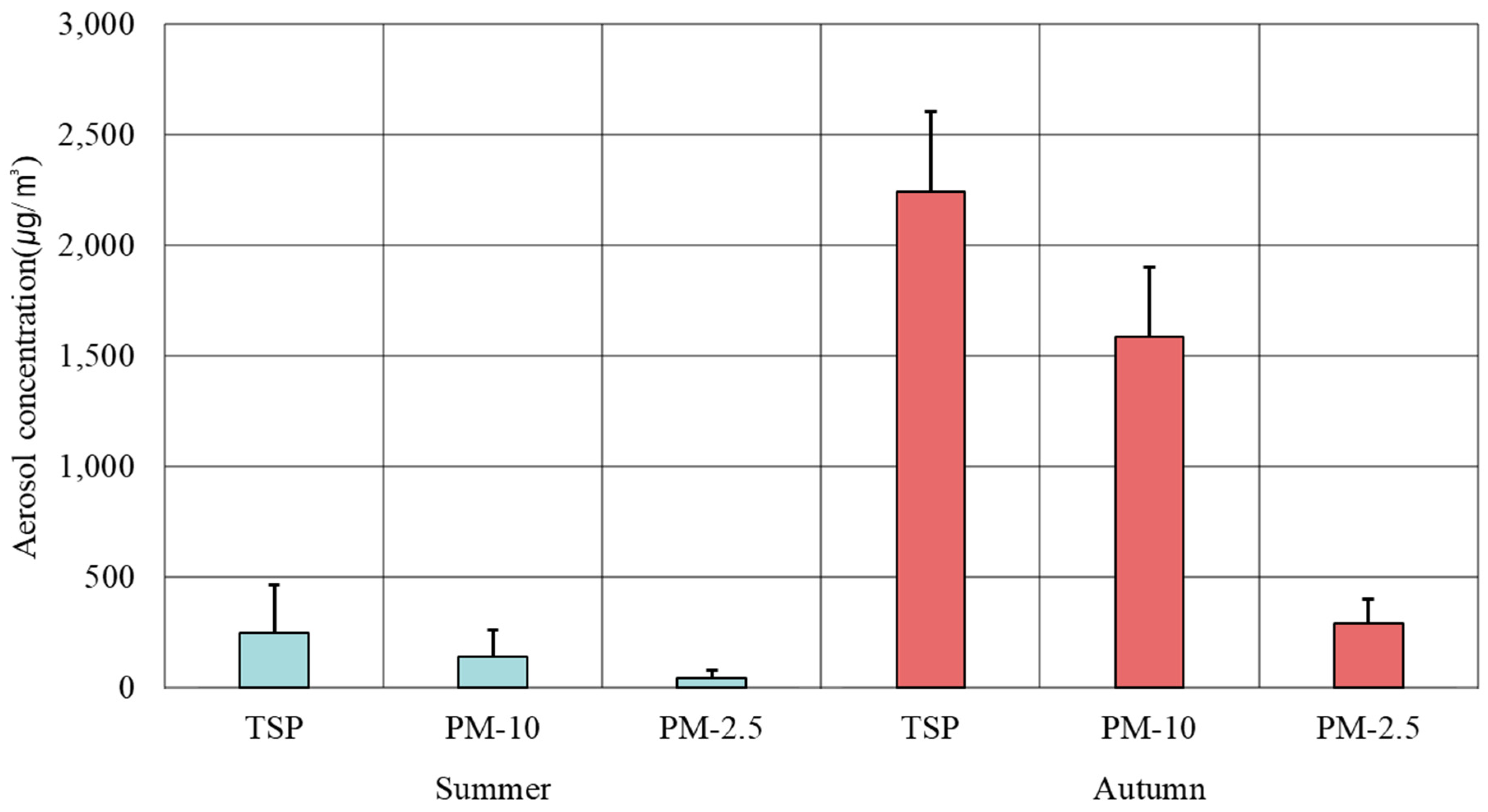

The average aerosol concentrations across all five farms were as follow: TSP 1,042 µg/m³, PM-10 718 µg/m³, and PM-2.5 137 µg/m³ (

Figure 5). Analyzing the data relative to particle size for each farm revealed that PM-10 accounted for 68.9% of the total aerosol concentration, while PM-2.5 accounted for 13.1%. This indicates a higher proportion of particles around 10 µm in size. This observation is attributed to mechanically generated particles from materials such as bedding (wheat straw) and feed particles, which tend to be around 10 µm in size [

29]. To confirm this, aerosol particles captured on filters were analyzed using SEM, showing that the captured fine particles were roughly 10 µm in size and exhibited a rounded shape, likely originating from sources like bedding material and feed. This finding aligns with previous research suggesting that particles generated from sources like feed and bedding exhibit similar size and shape characteristics [

18,

30,

31].

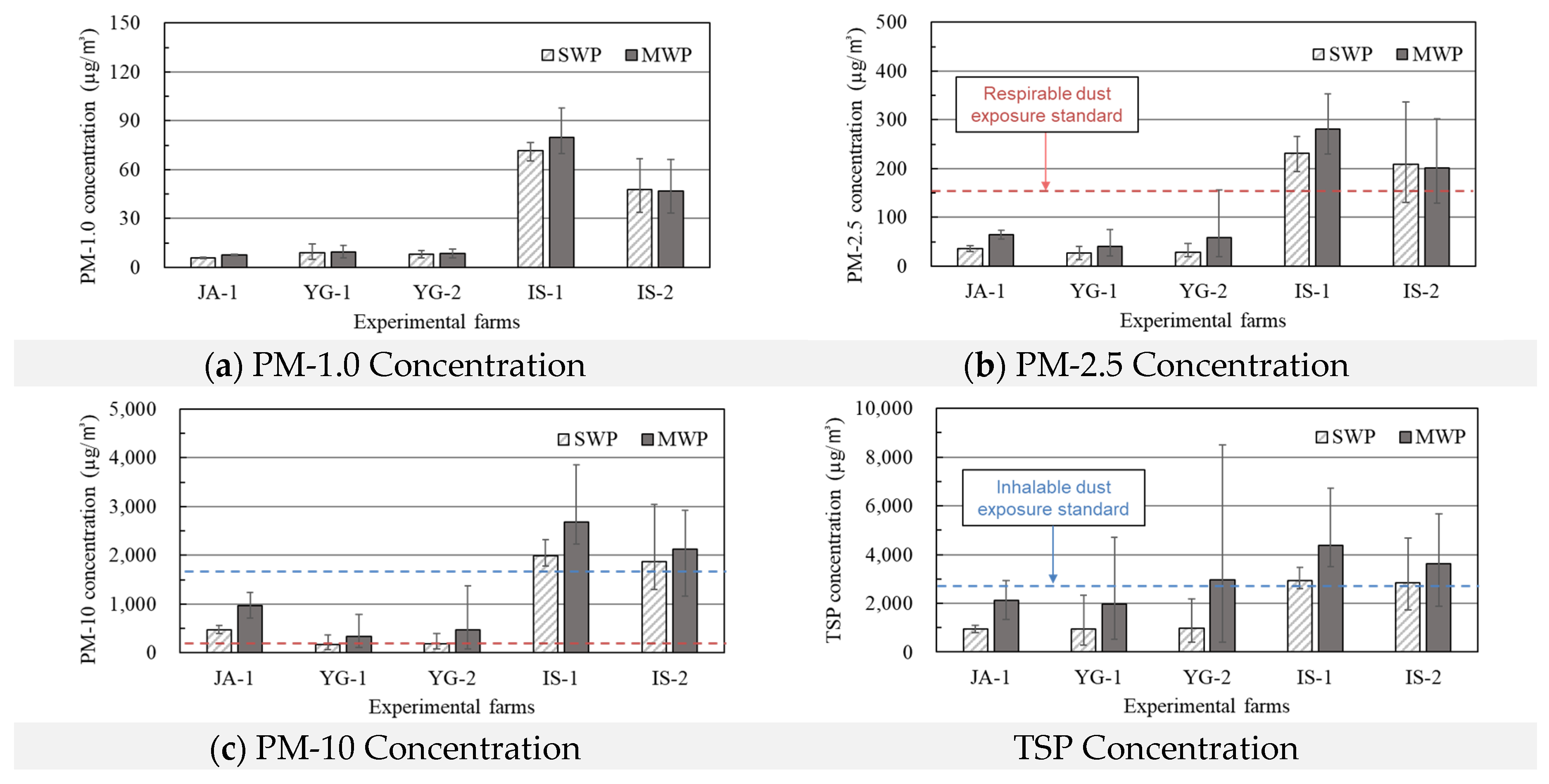

Seasonal analysis revealed that during the summer, maximum ventilation led to effective aerosol removal, resulting in average concentrations of TSP 244.4 µg/m³, PM-10 141.3 µg/m³, and PM-2.5 35.1 µg/m³. In contrast, during the autumn when ventilation was reduced to 15%, the average concentrations rose significantly to TSP 2,240 µg/m³, PM-10 1,583 µg/m³, and PM-2.5 289 µg/m³. This represents an 11.2-fold increase in PM-10 concentrations. There were variations in absolute concentrations measured between farms, primarily due to differences in farm management practices. These differences in fine dust concentrations among farms are influenced by various environmental factors, including ventilation systems, ventilation rates, management practices, stocking density, and other farm-specific conditions. In farms that employ closed-system housing for broiler, higher ventilation rates during the summer months led to lower fine dust concentrations, while lower ventilation rates in the autumn resulted in higher concentrations. Evaluating the measured aerosol concentrations in relation to occupational exposure limits for inhalable dust (with an average particle size of 100 µm) and respirable dust (with an average particle size of 4 µm), as suggested by Donham et al. (2000), revealed that during the summer, none of the farms exceeded the exposure limits for inhalable or respirable dust. However, during the autumn, IS-1 farm exceeded the inhalable dust limit by an average of 7.7% and up to 16.3%, while both IS-1 and IS-2 farms exceeded the respirable dust limits by an average of 127%, 35%, and up to 214%, 61.5%, respectively. Considering that field measurements captured PM-2.5, whereas respirable dust has a size of 4 µm or smaller, it is reasonable to assume that the actual exposure of farm workers to respirable dust may be higher than indicated by the measurements. This suggests a potential health risk for farm workers in terms of respiratory diseases related to exposure to respirable dust.

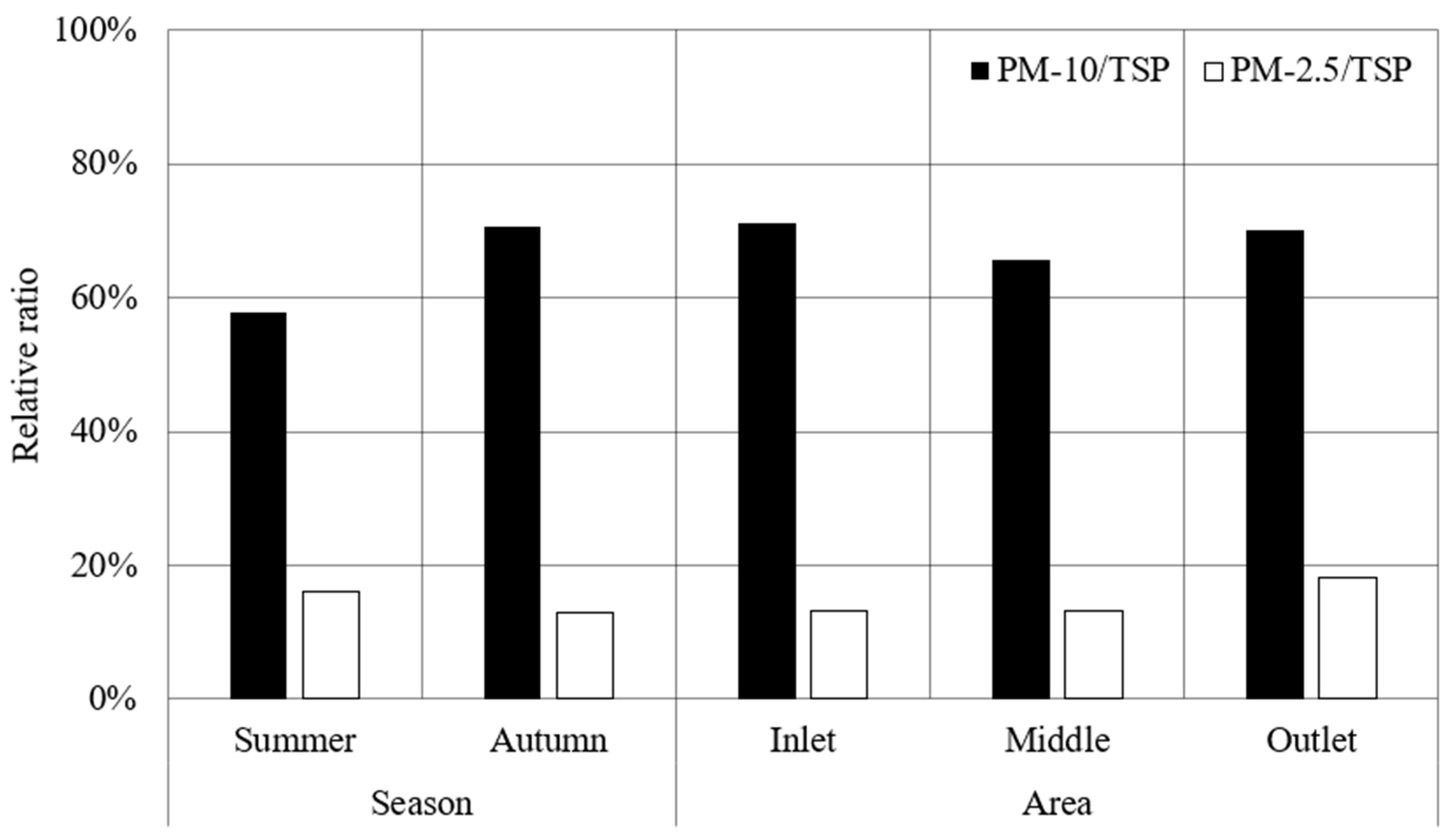

Due to variations in aerosol concentrations between experimental farms, a relative ratio analysis was conducted to effectively assess seasonal and location-based differences (

Figure 7). During the summer, when ventilation rates were high, aerosols with particle sizes around 10 µm were effectively expelled from the broiler house, representing 57.8% of TSP. In contrast, during the autumn, when ventilation rates significantly decreased, internally generated aerosols could not be expelled, and accumulated resulting in a higher relative ratio of 70.7%. Analyzing results based on measurement locations, PM-10 concentrations were relatively consistent, while PM-2.5 showed a slight increase in relative ratio of approximately 5.1%. The broiler farms where measurements were taken employed tunnel ventilation systems commonly used in Korea, where air flows longitudinally along the tunnel. As a result, the concentration of fine dust increased as it moved closer to the exhaust end due to the fine dust generated at the floor level.

3.2. Personal aerosol exposure by working conditions

To measure the exposure levels of workers to fine dust, we conducted real-time aerosol exposure analysis at five broiler farms with tunnel ventilation systems of similar scale and operation. Workers were tracked along their routes, and aerosol exposure levels at the height where workers were breathing were monitored. Real-time measurements of aerosol concentrations were taken at 6-seconds interval, and based on the results of particle size analysis and video analysis, we differentiated between the Moving work period, when workers were moving, and the Static work period, when they remained stationary. To reduce data errors, we calculated the concentration of the remaining data, excluding the front and back 10% of data for each of the two periods, as the concentration for that work period (

Figure 8). During the Static work period, workers were exposed to average concentrations of TSP 1,733 µg/m³, PM-10 942 µg/m³, and PM-2.5 106 µg/m³ of aerosols. In the Moving work period, the concentrations were higher, with TSP at 3,012 µg/m³, PM-10 at 1,318 µg/m³, and PM-2.5 at 129.2 µg/m³, showing 1.74 times, 1.40 times, and 1.22 times higher concentrations respectively, compared to the static work period. The higher concentration of fine dust during the Moving work period was attributed to an increase in chicken activity within the broiler house, leading to the significant generation of fine dust particles around 10 µm in size, such as feces, litter, and floor materials. Dust primarily caused by chemical sources, such as PM-1.0, showed relatively minor variations in concentration. When compared to the continuous monitoring standards for indoor dust in broiler workers' facilities, inhalable dust was found to increase by an average of 1.25 times and up to 3.5 times during movement, while respirable dust increased by an average of 1.2 times and up to 1.89 times. This indicates that workers are exposed to higher dust concentrations during periods of movement.

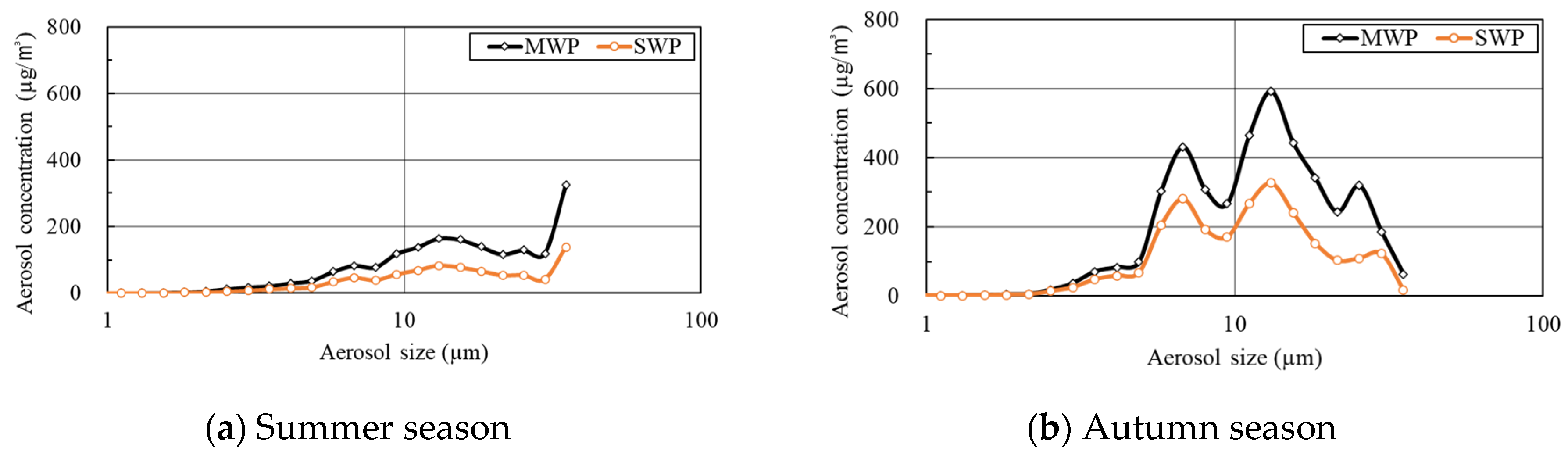

The analysis of aerosol concentrations by particle size to which broiler farm workers are exposed revealed a significant increase in aerosol concentrations around 10 µm during the Moving work period, confirming exposure to high aerosol levels during workers’ movement (

Figure 9). During the summer months with high ventilation rates, TSP increased by a substantial 2.46 times, and PM-10 increased by 2.13 times during the Moving work period. In contrast, during the relatively low-ventilation period in the autumn, TSP exhibited a relatively lower increase of 1.38 times, and PM-10 increased by 1.24 times. This indicates that, relative to the Static work period, autumn has a significantly lower increase in TSP by 3.0 times and PM-10 by 6.9 times, highlighting the substantial influence of ventilation rates on indoor fine dust concentrations. Therefore, when working within the broiler house, it is necessary to take measures to reduce indoor aerosol concentrations based on personal protective equipment and adequate ventilation, especially during entry or chronic exposure periods, even under normal circumstances.

To understand the correlation of aerosol concentrations between SWP and MWP, the combination of average concentrations to which workers are exposed during SWP and MWP was presented for all experimental periods based on video analysis (

Figure 10). As particle size increases, the graph's slope becomes steeper, indicating a larger increase in concentration during MWP. Based on the experimental results, the aerosol concentrations to which workers were exposed during MWP were found to be 1.76 times higher for particles larger than 10 µm, 1.29 times higher for particles ranging from 2.5 to 10 µm, and 1.11 times higher for particles smaller than 2.5 µm.

Figure 10 analyzes the increase in concentration between MWP and SWP for each particle size using an active sampler, the aerosol spectrometer. It can be observed that as particle size increases, the increase in concentration during MWP becomes more pronounced. These results can be utilized to apply weights when making standards for fine dust exposure for workers in broiler farms in the future. Instead of applying a uniform standard for fine dust exposure, factors such as the work environment and the type of work can be considered.

To assess the statistical significance of the particle size-specific fine dust concentrations between SWP and MWP for workers based on the aerosol concentration distribution along the broiler farm work routes, an independent sample t-test was conducted (

Table 3). The workers showed statistically significant differences between the work and movement periods. Specifically, during MWP when broiler activities increased, TSP and PM-10 exhibited extremely high significance levels with p-values below 0.001 each. However, for PM-1.0, the p-value was 0.098, indicating that there was no significant difference.

4. Conclusions

This research focused on analyzing the exposure concentrations of fine dust and aerosols in the air to workers in broiler farms. In particular, it improves upon previous studies by considering the characteristics of the working environment where workers continuously move inside broiler houses. It divides the analysis into spatial aerosol distribution and personal aerosol exposure, utilizing both passive and active samplers to measure aerosol concentrations.

The average aerosol concentrations were found to be within acceptable limits, with TSP at 1,042 µg/m³, PM-10 at 718 µg/m³, and PM-2.5 at 137 µg/m³. These values did not exceed the recommended exposure limits for inhalable dust (under 100 µm) at 2,400 µg/m³ and respirable dust (under 4 µm) at 160 µg/m³ in livestock facilities. However, when the analysis categorized the work into Static work period (SWP) and Moving work period (MWP) based on video analysis, it was revealed that aerosol concentrations during MWP exceeded the standards by up to 214%. Particularly, during MWP, the concentration was 1.74 times higher for TSP, 1.40 times higher for PM-10, and 1.22 times higher for PM-2.5 compared to SWP. This underscores the importance of paying attention to the working environment.

Aerosol concentrations varied depending on the nature of the work and ventilation rates. To mitigate the impact of aerosols with particle sizes around 10 µm that workers are exposed to during tasks, the use of personal protective equipment, proper operation of ventilation systems that can reduce physical fine dust, and the application of mist spraying devices are expected to play a significant role in promoting worker health and improving the working environment. The results of this study can be utilized to establish evaluation criteria for the effectiveness of personal respiratory protective equipment in reducing fine dust exposure. Additionally, they can be applied to develop and refine exposure standards for fine dust for different types of work and ventilation rates by applying them as weighting factors.

Acknowledgments

This work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry(IPET) and Korea Smart Farm R&D Foundation(KosFarm) through Smart Farm Innovation Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs MAFRA) and Ministry of Science and ICT(MSIT), Rural Development AdministrationRDA)421019-04.

References

- Kleven, S.H. Mycoplasmas in the Etiology of Multifactorial Respiratory Disease. Poult. Sci. 1998, 77, 1146–1149. [Google Scholar] [CrossRef] [PubMed]

- Wathes, C.M. Aerial Emissions from Poultry Production. Worlds. Poult. Sci. J. 1998, 54, 241–251. [Google Scholar] [CrossRef]

- Seo, I.H.; Lee, I.B.; Moon, O.K.; Kim, H.T.; Hwang, H.S.; Hong, S.W.; Bitog, J.P.; Yoo, J.I.; Kwon, K.S.; Kim, Y.H.; et al. Improvement of the Ventilation System of a Naturally Ventilated Broiler House in the Cold Season Using Computational Simulations. Biosyst. Eng. 2009, 104, 106–117. [Google Scholar] [CrossRef]

- Viegas, S.; Faísca, V.M.; Dias, H.; Clérigo, A.; Carolino, E.; Viegas, C. Occupational Exposure to Poultry Dust and Effects on the Respiratory System in Workers. J. Toxicol. Environ. Heal. Part A 2013, 76, 230–239. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.-R.; Kim, H.; Lee, K.; Chae, H.-S. Exposure to Dust and Organic Gas during Chicken Entrance and Shipment Tasks in Poultry Farms. J. Korean Soc. Occup. Environ. Hyg. 2014, 24, 471–477. [Google Scholar] [CrossRef]

- Donham, K.; Haglind, P.; Peterson, Y.; Rylander, R.; Belin, L. Environmental and Health Studies of Farm Workers in Swedish Swine Confinement Buildings. Occup. Environ. Med. 1989, 46, 31–37. [Google Scholar] [CrossRef]

- Olson, D.K.; Bark, S.M. Health Hazards Affecting the Animal Confinement Farm Worker. AAOHN J. 1996, 44, 198–204. [Google Scholar] [CrossRef]

- Bottcher, R.W. An Environmental Nuisance: Odor Concentrated and Transported by Dust. Chem. Senses 2001, 26, 327–331. [Google Scholar] [CrossRef]

- Moran, R.E.; Bennett, D.H.; Garcia, J.; Schenker, M.B. Occupational Exposure to Particulate Matter from Three Agricultural Crops in California. Int. J. Hyg. Environ. Health 2014, 217, 226–230. [Google Scholar] [CrossRef]

- Poole, J.A.; Romberger, D.J.; Wyatt, T.A.; Staab, E.; VanDeGraaff, J.; Thiele, G.M.; Dusad, A.; Klassen, L.W.; Duryee, M.J.; Mikuls, T.R. Age Impacts Pulmonary Inflammation and Systemic Bone Response to Inhaled Organic Dust Exposure. J. Toxicol. Environ. Heal. Part A 2015, 78, 1201–1216. [Google Scholar] [CrossRef]

- Castañeda, A.R.; Bein, K.J.; Smiley-Jewell, S.; Pinkerton, K.E. Fine Particulate Matter (PM2. 5) Enhances Allergic Sensitization in BALB/c Mice. J. Toxicol. Environ. Heal. Part A 2017, 80, 197–207. [Google Scholar] [CrossRef] [PubMed]

- Zuskin, E.; Mustajbegovic, J.; Schachter, E.N.; Kern, J.; Rienzi, N.; Goswami, S.; Marom, Z.; Maayani, S. Respiratory Function in Poultry Workers and Pharmacologic Characterization of Poultry Dust Extract. Environ. Res. 1995, 70, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Takai, H.; Pedersen, S.; Johnsen, J.O.; Metz, J.H.M.; Koerkamp, P.W.G.G.; Uenk, G.H.; Phillips, V.R.; Holden, M.R.; Sneath, R.W.; Short, J.L. Concentrations and Emissions of Airborne Dust in Livestock Buildings in Northern Europe. J. Agric. Eng. Res. 1998, 70, 59–77. [Google Scholar] [CrossRef]

- Donham, K.J.; Cumro, D.; Reynolds, S.J.; Merchant, J.A. Dose-Response Relationships between Occupational Aerosol Exposures and Cross-Shift Declines of Lung Function in Poultry Workers: Recommendations for Exposure Limits. J. Occup. Environ. Med. 2000, 260–269. [Google Scholar] [CrossRef] [PubMed]

- Radon, K.; Weber, C.; Iversen, M.; Danuser, B.; Pedersen, S.; Nowak, D. Exposure Assessment and Lung Function in Pig and Poultry Farmers. Occup. Environ. Med. 2001, 58, 405–410. [Google Scholar] [CrossRef]

- Banhazi, T.M.; Seedorf, J.; Laffrique, M.; Rutley, D.L. Identification of the Risk Factors for High Airborne Particle Concentrations in Broiler Buildings Using Statistical Modelling. Biosyst. Eng. 2008, 101, 100–110. [Google Scholar] [CrossRef]

- Wilson, D.J.; Gabriel, E.; Leatherbarrow, A.J.H.; Cheesbrough, J.; Gee, S.; Bolton, E.; Fox, A.; Fearnhead, P.; Hart, C.A.; Diggle, P.J. Tracing the Source of Campylobacteriosis. PLoS Genet. 2008, 4, e1000203. [Google Scholar] [CrossRef]

- Cambra López, M. Control of Particulate Matter Emissions from Poultry and Pig Houses, Universitat Politècnica de València, 2010.

- Adell, E.; Calvet, S.; Pérez-Bonilla, A.; Jiménez-Belenguer, A.; García, J.; Herrera, J.; Cambra-Lopez, M. Air Disinfection in Laying Hen Houses: Effect on Airborne Microorganisms with Focus on Mycoplasma Gallisepticum. Biosyst. Eng. 2015, 129, 315–323. [Google Scholar] [CrossRef]

- Li, Z.; Xiong, Y.; Wang, S.; Wang, C.; Ji, B.; Liu, Y.; Liang, C.; Tong, Q. Assessing Particulate Matter Concentration Level and Its Limit Exceedance Based on Year-Round Field Measurements of Different Laying Hen Building Systems. Biosyst. Eng. 2023, 226, 266–279. [Google Scholar] [CrossRef]

- Choi, Sang-In; An, Jeongun; Jo, Y.-M. Review of Analysis Principle of Fine Dust. J. Ind. Eng. Chem. 2018, 21, 16–23. [Google Scholar]

- Lee, Bok-Jin; Park, S.-S. Evaluation of PM10 and PM2.5 Concentrations from Online Light Scattering Dust Monitors Using Gravimetric and Beta-Ray Absorption Methods. J. Korean Soc. Atmos. Environ. 2019, 35, 357–369. [Google Scholar] [CrossRef]

- Kim, K.Y. Distribution of Concentration and Emission of Dust According to Types of Poultry Buildings in Korea. J. Environ. Heal. Sci. 2017, 43, 185–193. [Google Scholar] [CrossRef]

- Shin, S.-J.; Song, E.-S.; Kim, J.-W.; Lee, J.-H.; Gautam, R.; Kim, H.-J.; Kim, Y.-G.; Cho, A.-R.; Yang, S.-J.; Acharya, M. Major Environmental Characteristics of Swine Husbandry That Affect Exposure to Dust and Airborne Endotoxins. J. Toxicol. Environ. Heal. Part A 2019, 82, 233–243. [Google Scholar] [CrossRef] [PubMed]

- Seo, H.-J.; Oh, B.-W.; Kim, H.-C.; Sin, S.-J.; Seo, I.-H. Concentrations of Particulate Matter Exposed to Farm Workers in the Broiler Houses. J. Korean Soc. Agric. Eng. 2020, 62, 27–37. [Google Scholar] [CrossRef]

- Kwon, K.S.; Jo, Y.S.; Lee, I.B.; Ha, T.H.; Hong, S.W. Measurement of Dust Concentration in a Mechanically Ventilated Broiler House and Analysis of Dust Generation from Ground Beds. J. Korean Soc. Agric. Eng. 2014, 56, 31–43. [Google Scholar] [CrossRef]

- Fernández, A.P.; Demmers, T.G.M.; Tong, Q.; Youssef, A.; Norton, T.; Vranken, E.; Berckmans, D. Real-Time Modelling of Indoor Particulate Matter Concentration in Poultry Houses Using Broiler Activity and Ventilation Rate. Biosyst. Eng. 2019, 187, 214–225. [Google Scholar] [CrossRef]

- Choi, H.C.; Yeon, G.Y.; Song, J.I.; Kang, H.S.; Kwon, D.J.; Yoo, Y.H. Seasonal Dust Concentration and Characteristics of Windowless Broiler Building. J. Livest. Hous. Environ. 2005, 11, 197–206. [Google Scholar]

- Shen, D.; Wu, S.; Dai, P.Y.; Li, Y.S.; Li, C.M. Distribution of Particulate Matter and Ammonia and Physicochemical Properties of Fine Particulate Matter in a Layer House. Poult. Sci. 2018, 97, 4137–4149. [Google Scholar] [CrossRef]

- Heber, A.J.; Stroik, M.; Faubion, J.M.; Willard, L.H. Size Distribution and Identification of Aerial Dust Particles in Swine Finishing Buildings. Trans. ASAE 1988, 31, 882–887. [Google Scholar] [CrossRef]

- Pearson, C.C.; Sharples, T.J. Airborne Dust Concentrations in Livestock Buildings and the Effect of Feed. J. Agric. Eng. Res. 1995, 60, 145–154. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).