Submitted:

12 September 2023

Posted:

13 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

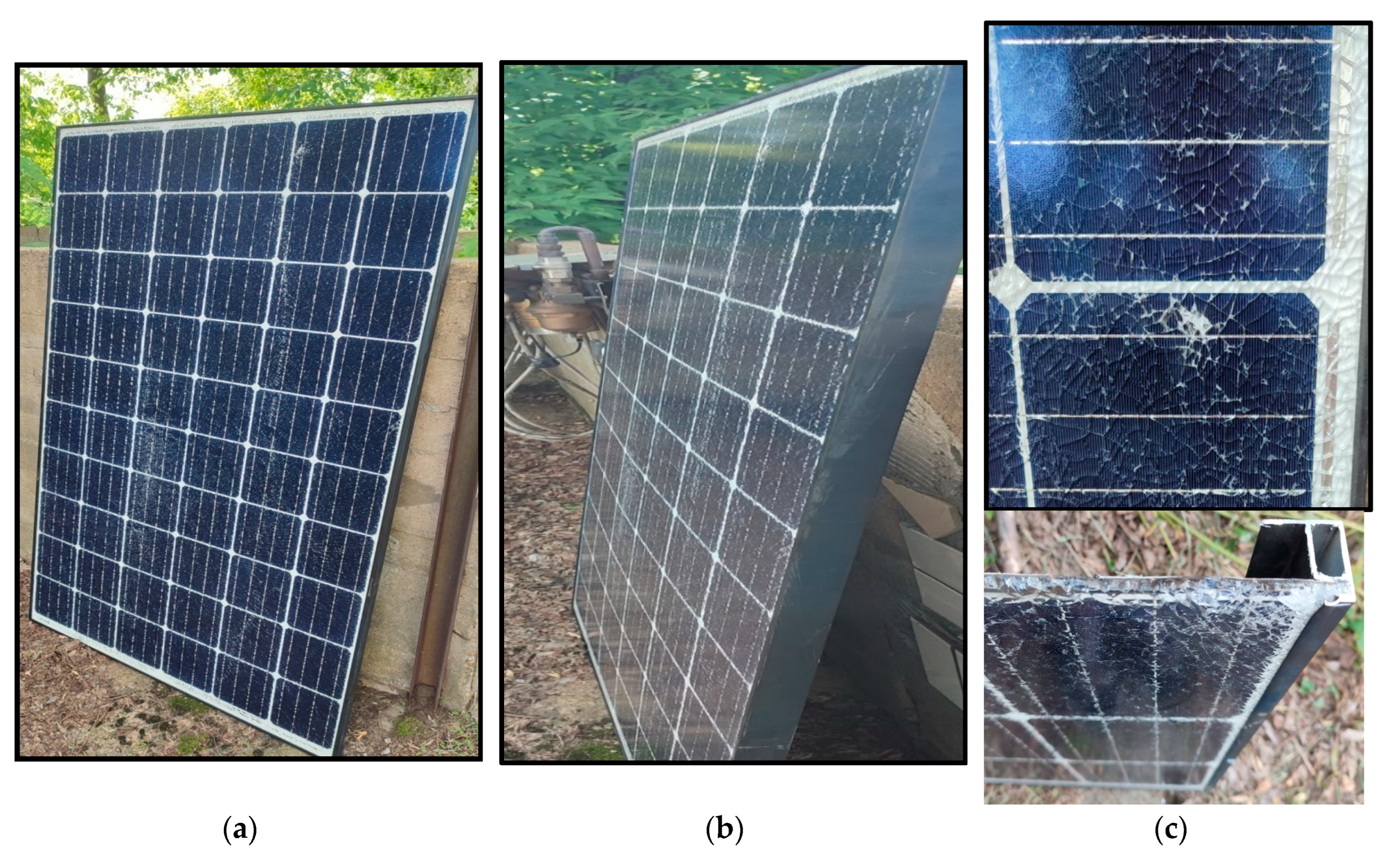

2.1. Properties of the photovoltaic panel

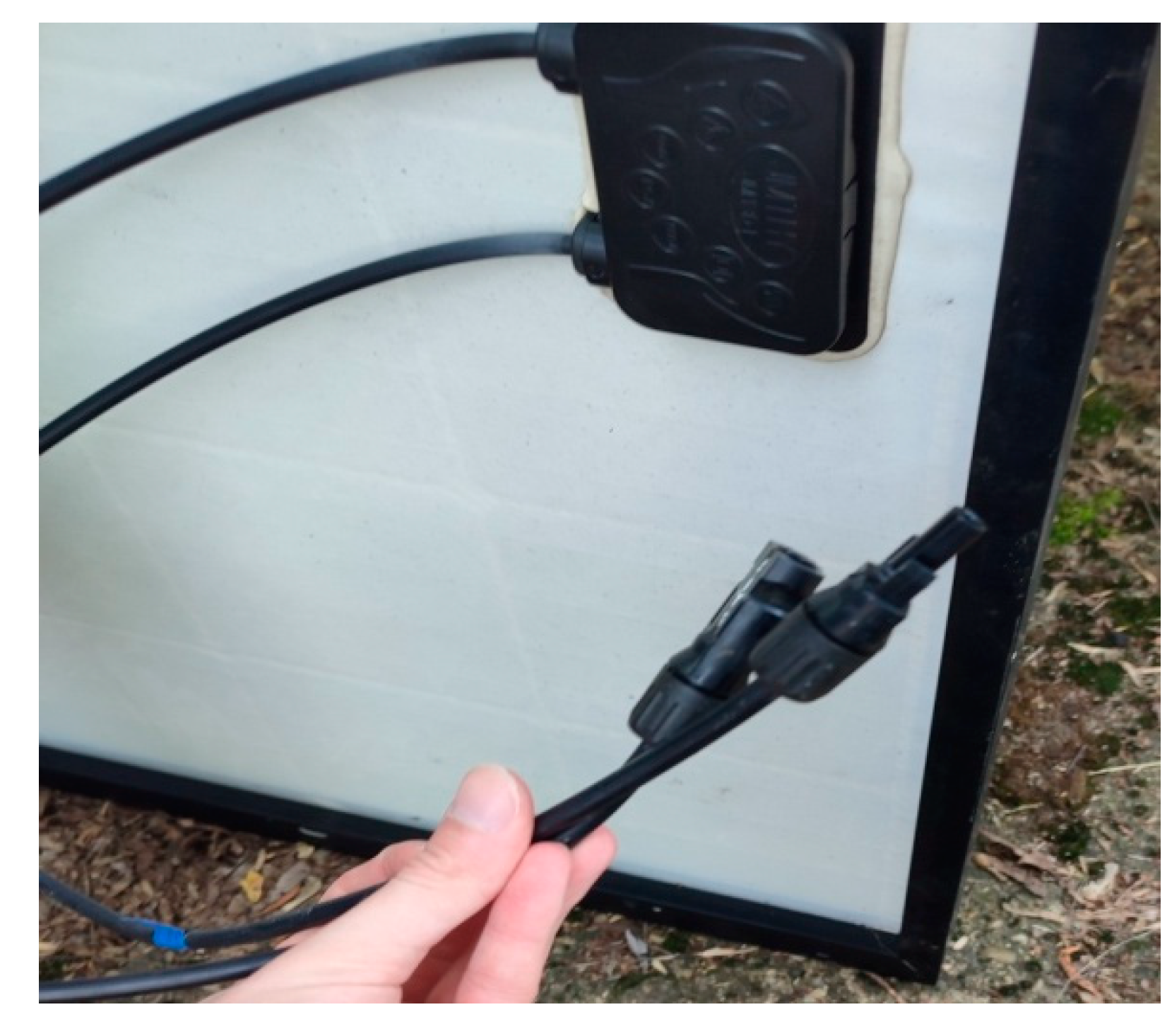

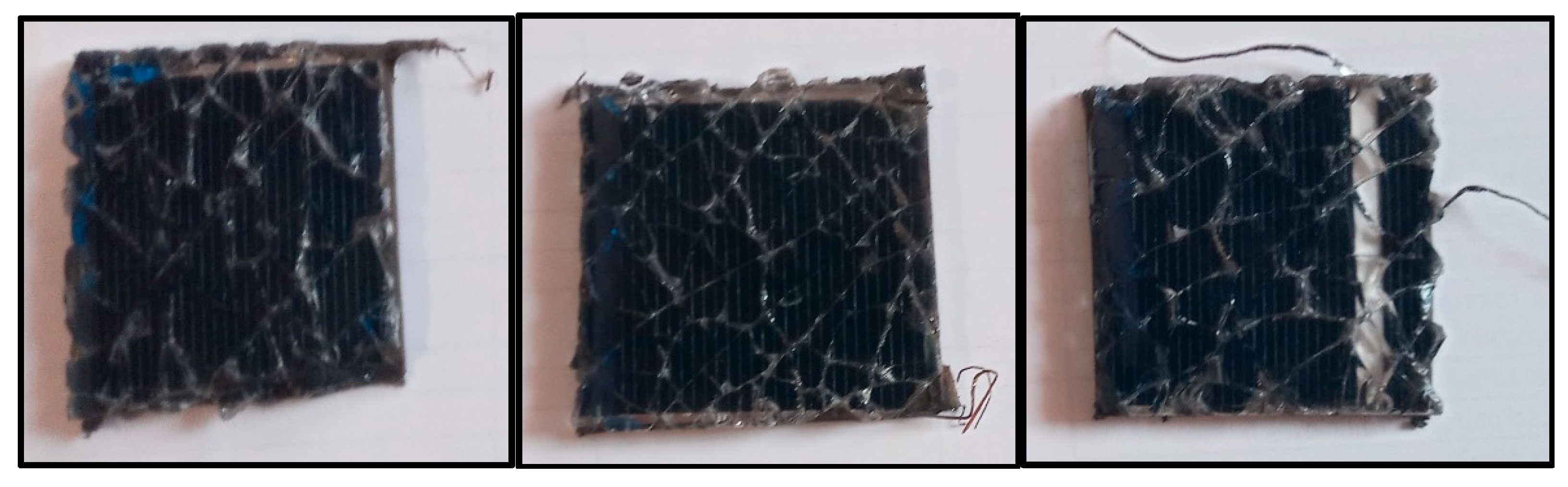

2.2. Dismantling a monocrystalline photovoltaic panel

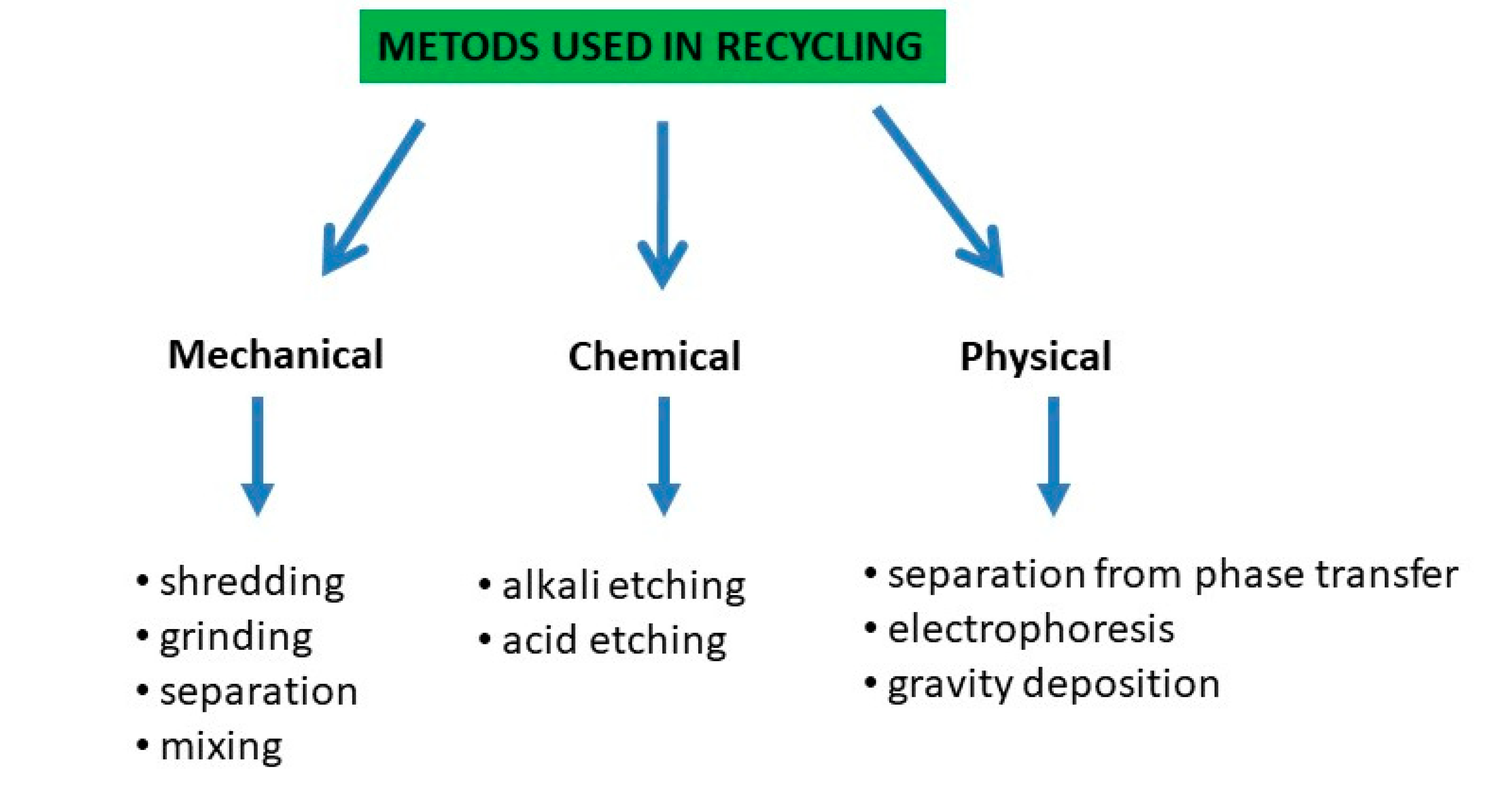

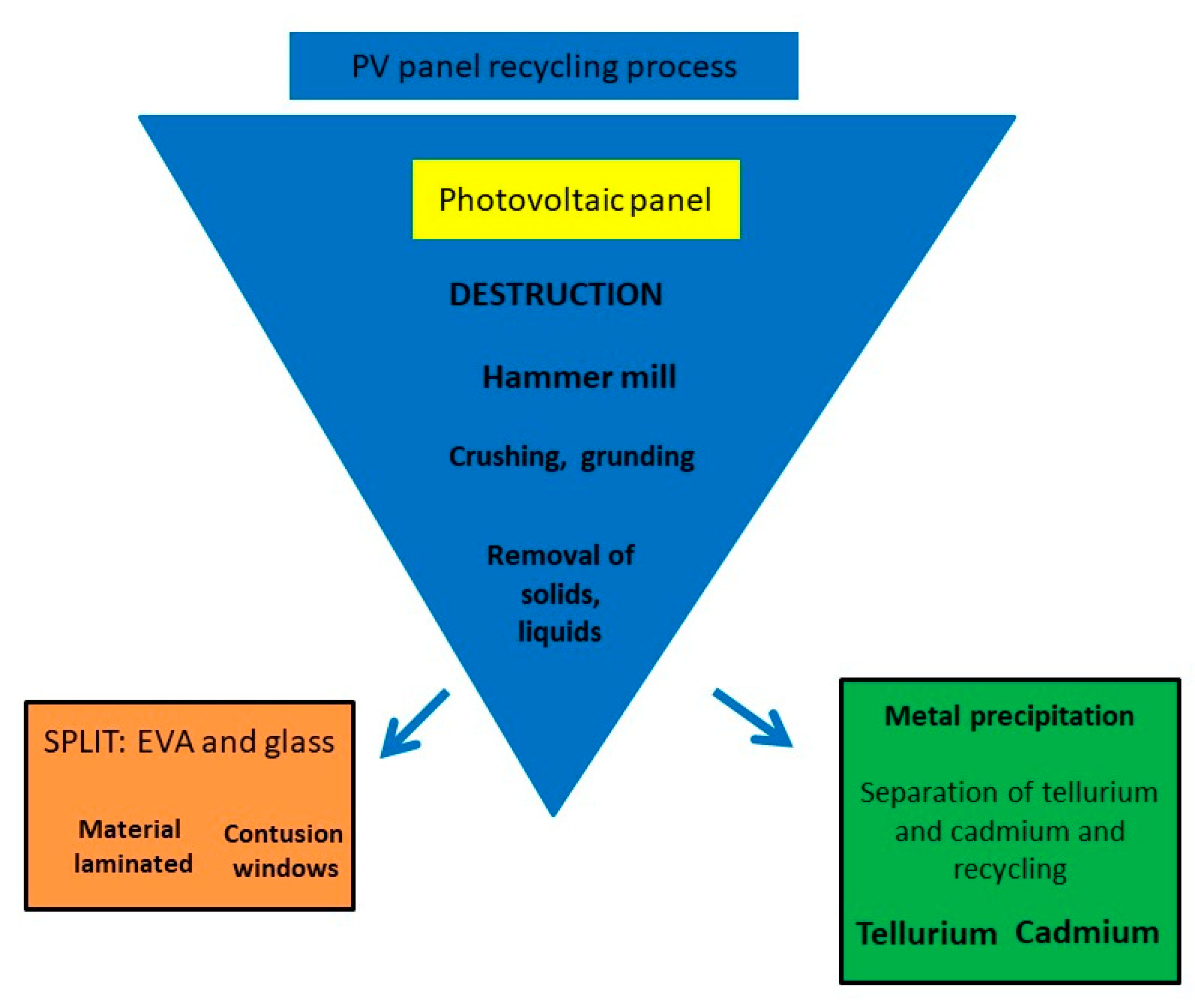

2.3. Methods used when analyzing the recyclability of materials used to build a photovoltaic module

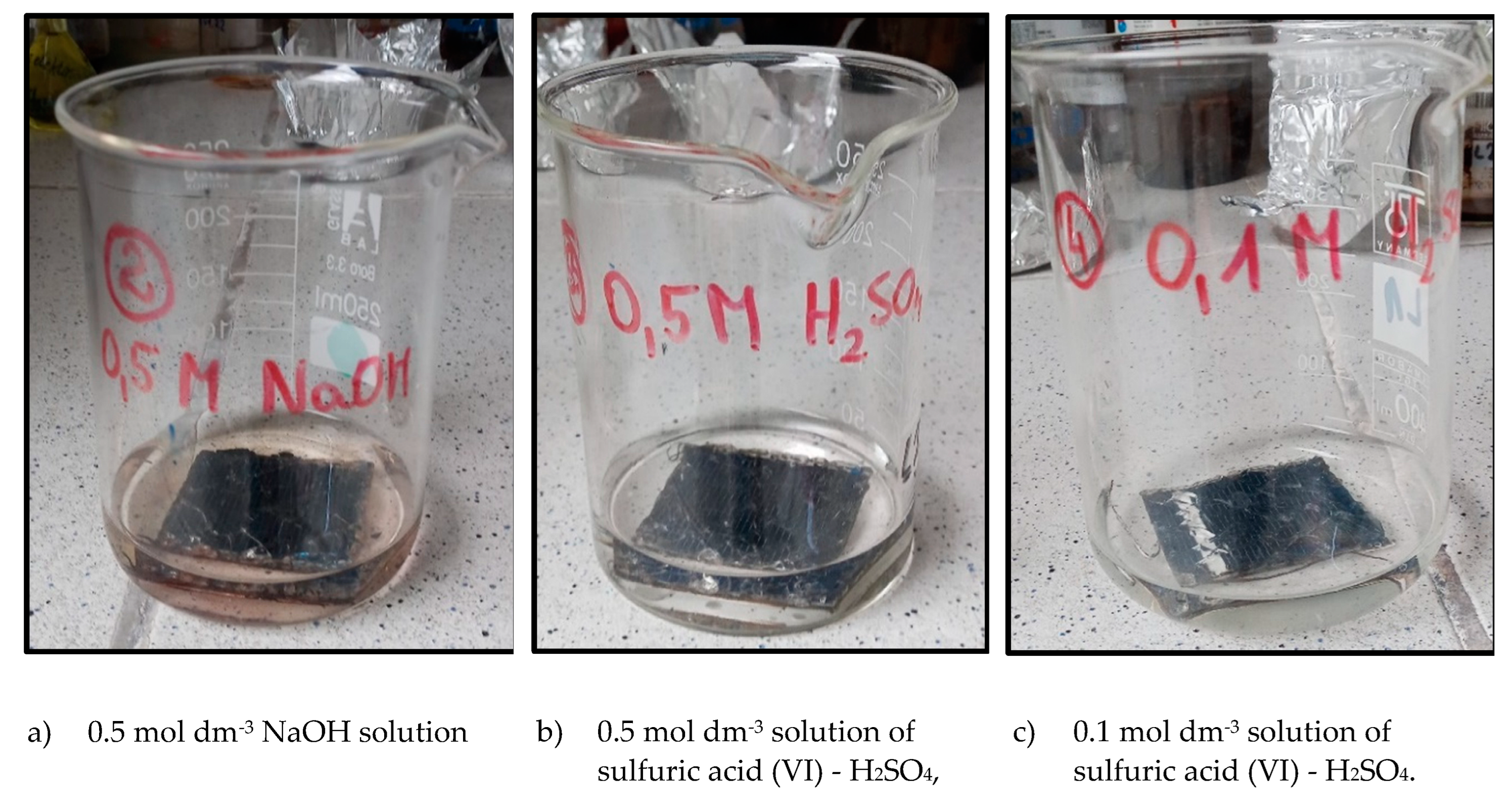

2.4. Chemical methods

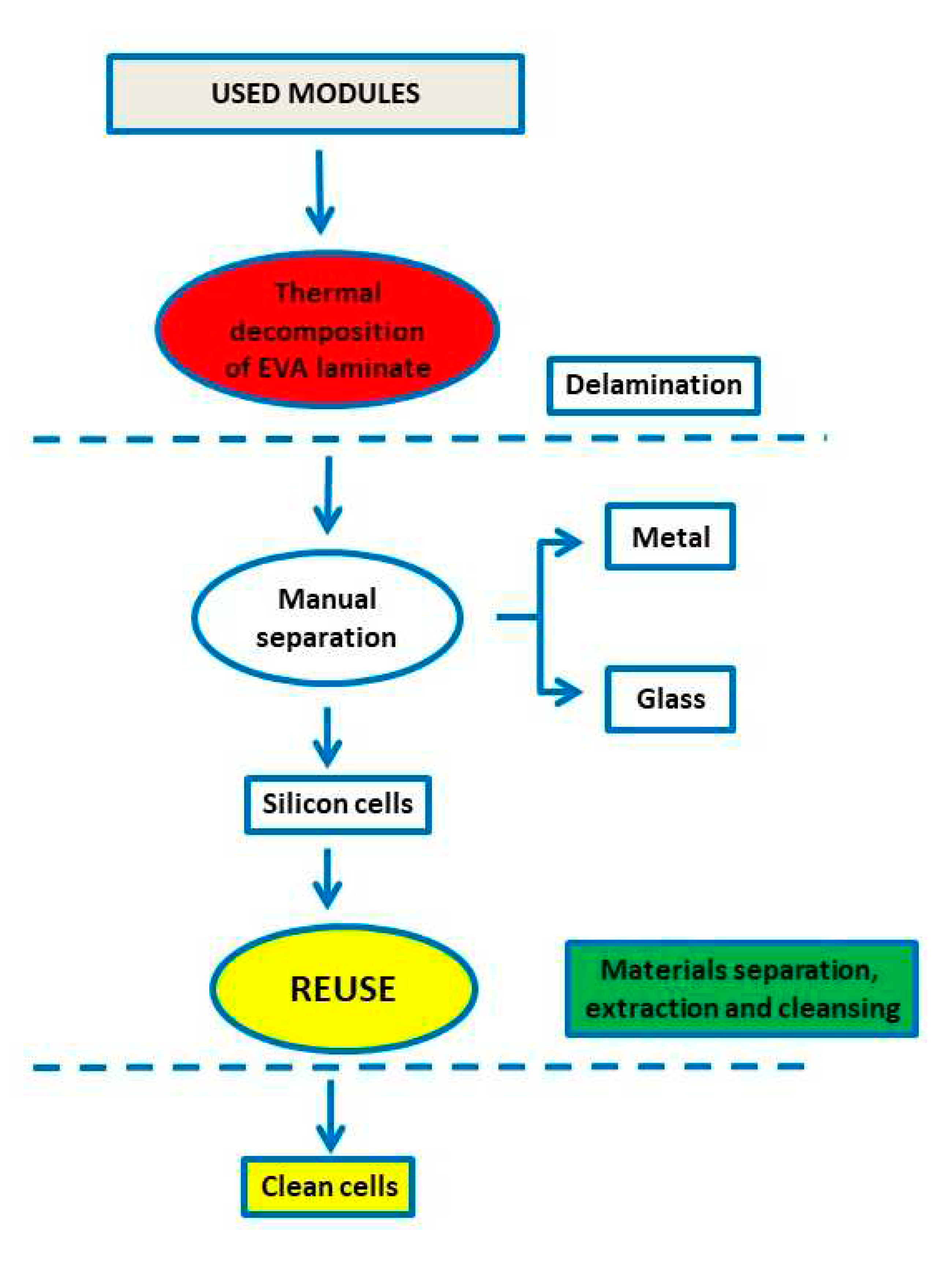

2.5. Thermal method

3. Results and discussion

3.1. Analysis of the change in mass of PV module samples

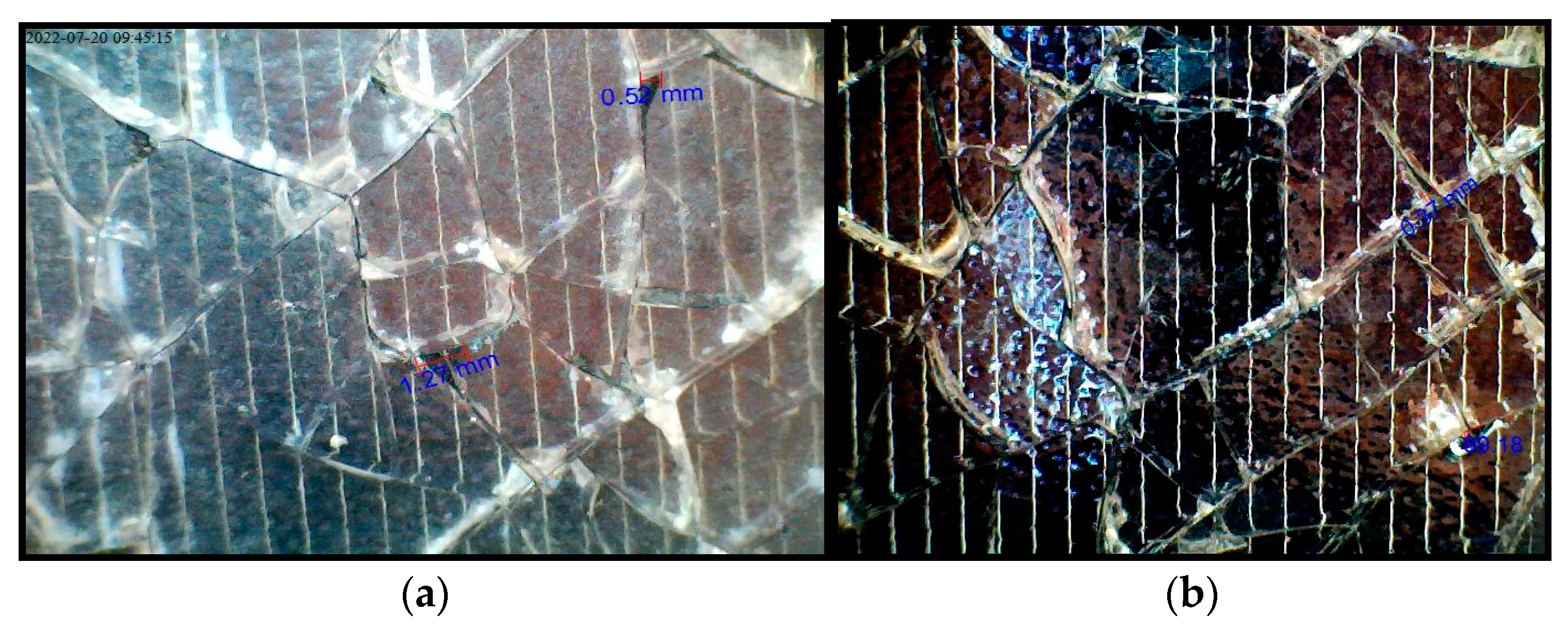

3.2. Structural analysis of PV module samples after exposure in solutions

3.3. Analysis of thermal treatment of PV module Samales

4. Conclusions

- the number of used photovoltaic modules is increasing in Poland and around the world, which generates problems with electronic waste management,

- proper waste management and storage depends on the degree of raw material recovery and the type of recovered materials,

- the conducted research has proven that the disassembly of the photovoltaic module, i.e. the separation of individual layers (glass - EVA foil - crystalline silicon) is very difficult and requires special tools, at the same time the use of mechanical methods, i.e. mills, grinding, grinding, separation, is associated with a large energy consumption;

- as a result of exposure of module elements in acidic solutions, the solution penetrated the material and caused changes in the sample in the form of cracks and plasticization of the sample;

- after exposure of the module samples for 34 days, an increase in mass was observed both in the solution of 0.5 mol dm-3 NaOH, as well as in 0.1 mol dm-3 and 0.5 mol dm-3 H2SO4, which may result from the phenomenon liquid absorption through EVA foil. After drying the samples, a weight loss of 0.0585 g was observed in an alkaline solution (0.5 mol dm-3 NaOH) and from 0.0016 g and 0068 g in solutions of 0.1 mol dm-3 and 0.5, respectively. mol dm-3 H2SO4;

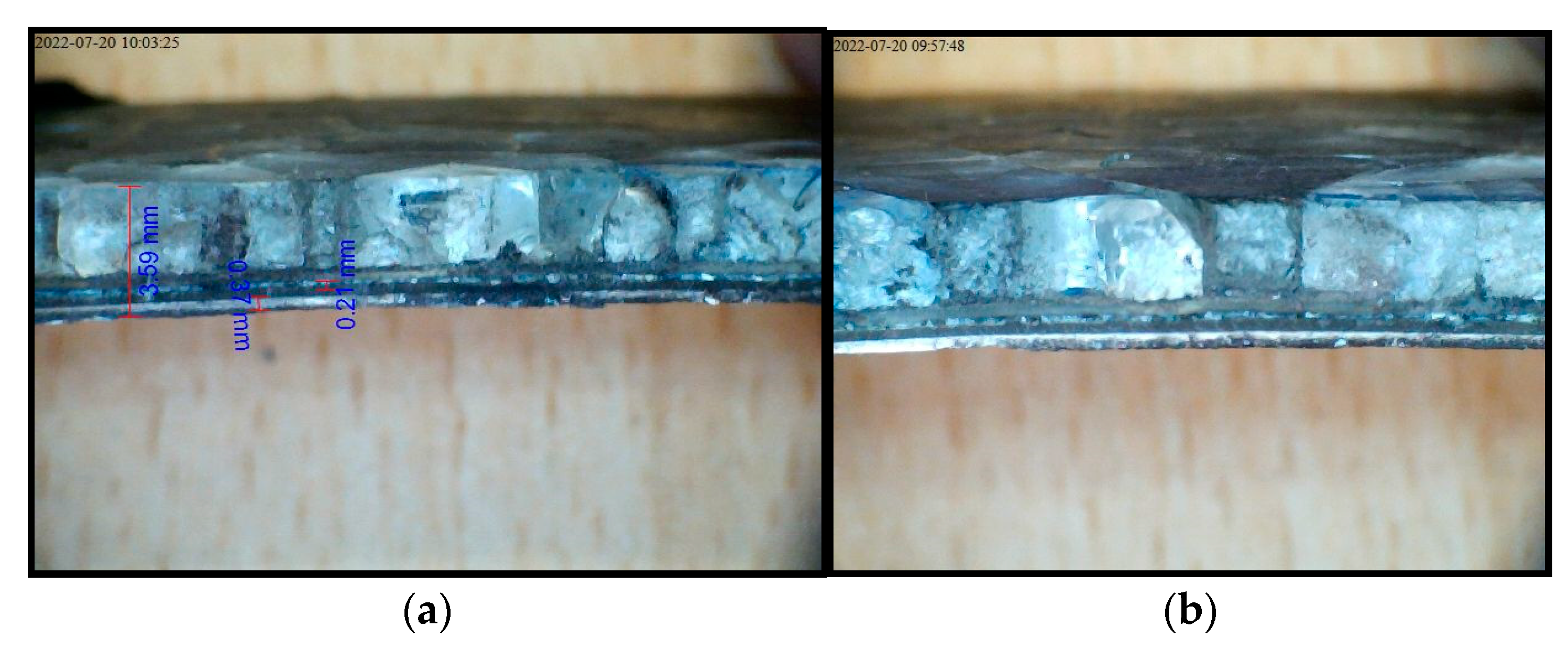

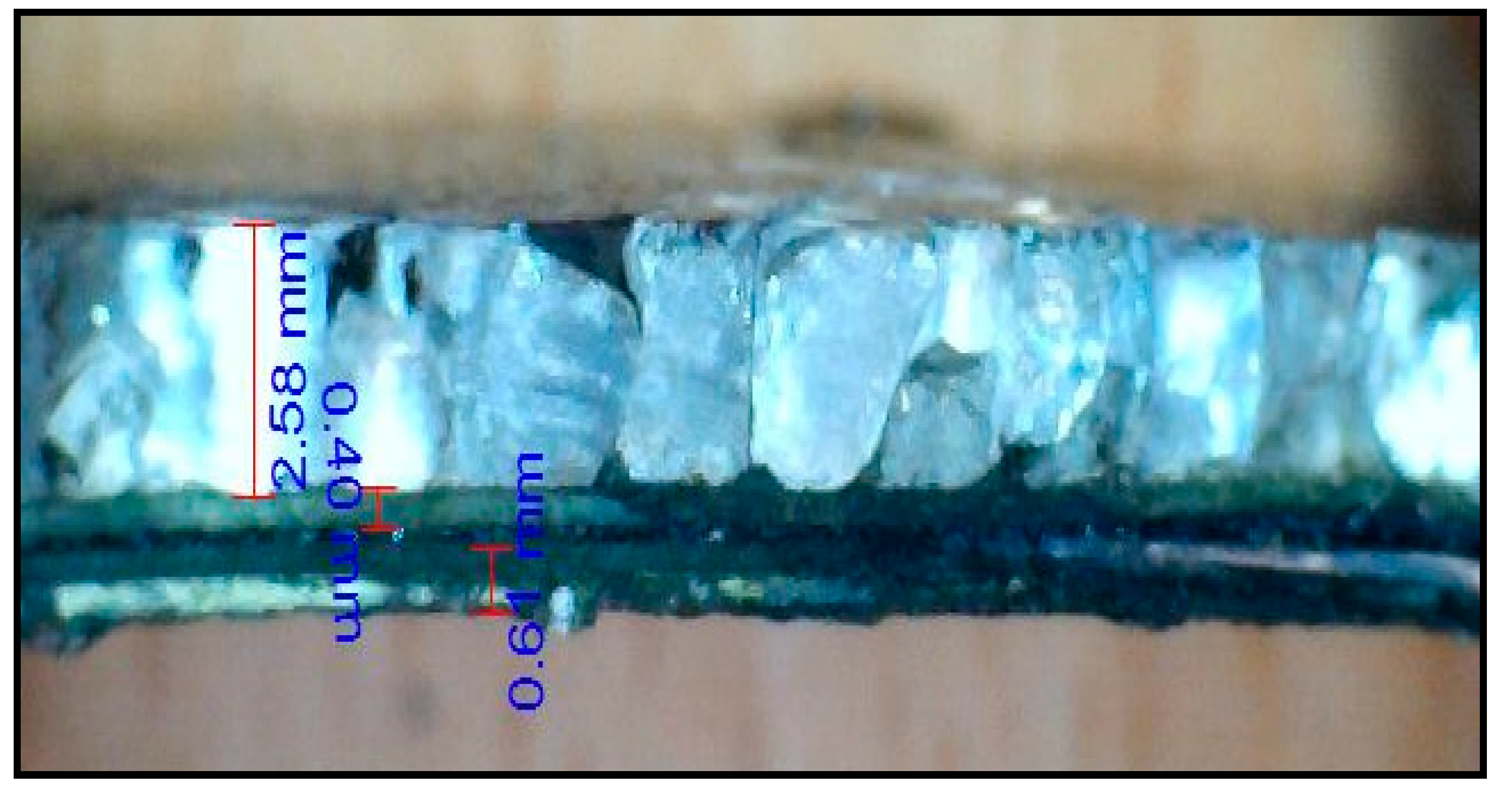

- the phenomenon of swelling of material samples was supported by the analysis of the thickness of the samples: after exposure, the total thickness of the module was estimated at approx. 3.59 mm (crystalline silicon: approx. 0.37 mm, EVA foil: approx. 0.21 mm, tempered glass: and glass pane: approx. 3.00 mm), according to the manufacturer, the panel thickness is 3.2 mm;

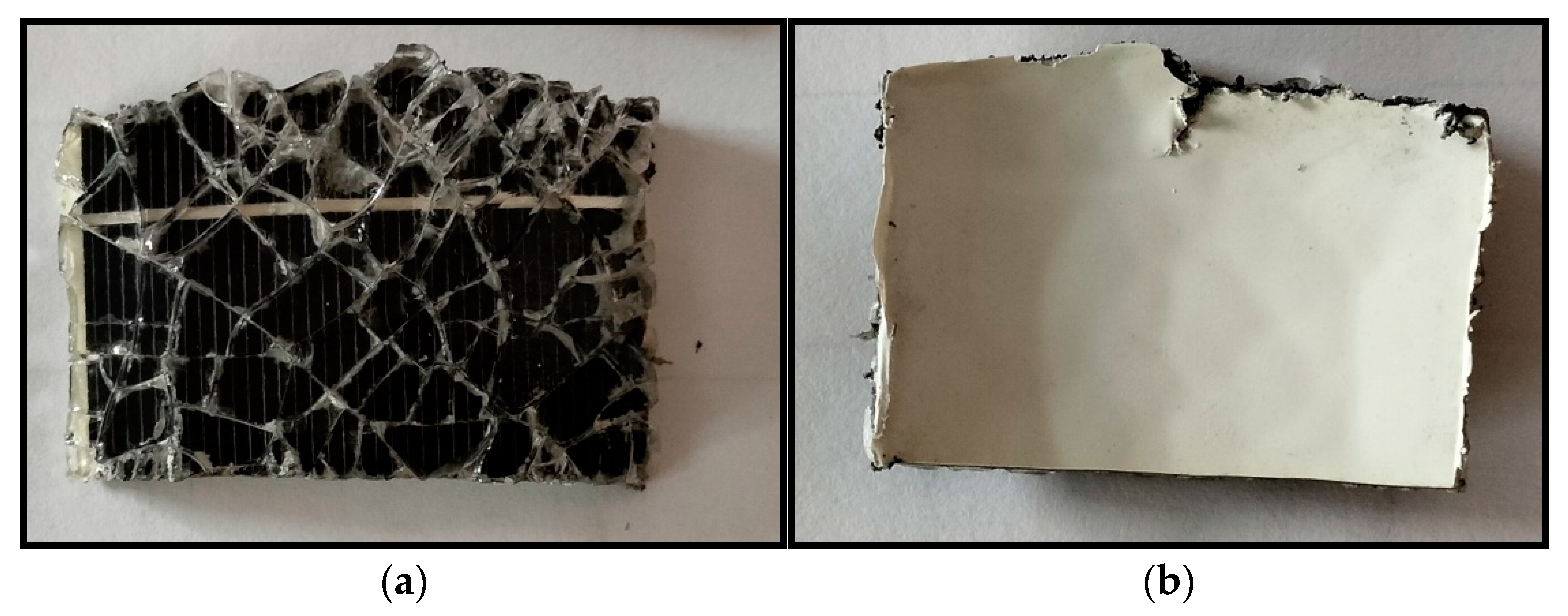

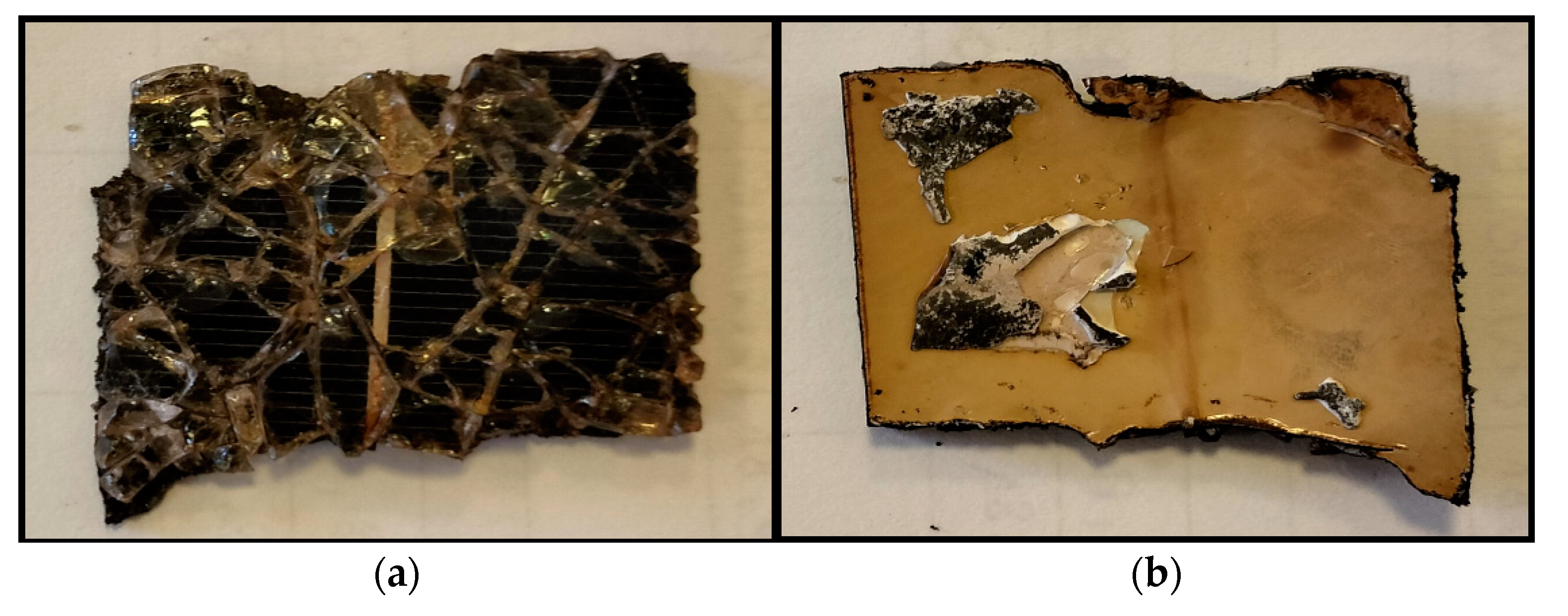

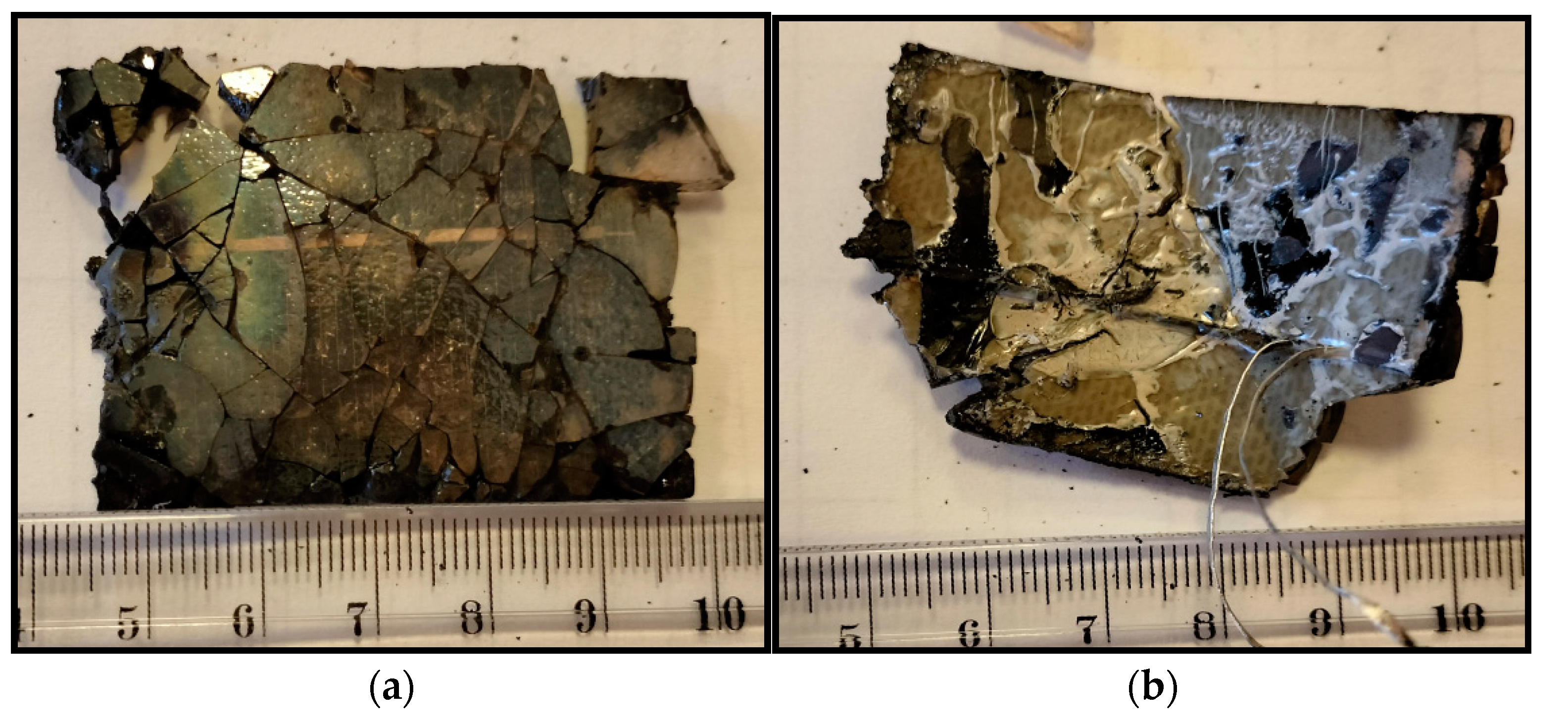

- after thermal treatment of the panel at a temperature of 500oC, the bottom layer of the panel was melted, the glass was in the form of crumbs, which resulted from previous damage to the panel. Bus bars were intact and easily accessible.

Author Contributions

Funding

References

- www.flixenergy.pl/-recyklingu-modulow-pv-zagrozenie-w-przyszlosci-czy-potencjalny-biznes,dn.05.03.2022.

- End-of- live management Solar Photovoltaic Panels, IRENA International Renewable Energy Agency (access August 2023).

- www.evertiq.pl/news/28867,dn.06.03.2022.

- Stowarzyszenie Technologii Ekologicznych Silesia, Sprawdzone metody gospodarowania odpadami komunalnymi, in polish (access August 2023).

- Postępowanie z odpadami komunalnymi po przetworzeniu w instalacjach mechaniczno-biologicznego przetwarzania odpadów komunalnych (MBP), Departament Środowiska, Najwyższa Izba Kontroli, in polish (access August 2023).

- www.energetyka24.com/recykling-w-fotowoltaice-czy-poradzimy-sobie-ze-starymi-panelami-analiza, in polish (access August 2023).

- Adam Mroziński, Wydział Inżynierii Mechanicznej, Uniwersytet Technologiczno Przyrodniczy, Bydgoszcz, Nr 5/2010,Recykling ogniw fotowoltaicznych,dn.30.03.2022.

- Ewa Radziemska, Piotr Ostrowski, Tomasz Seramak, Obróbka chemiczna krzemowych ogniw słonecznych jako najważniejszy etap w recyklingu modułów fotowoltaicznych,dn.30.03.2022.

- Technologia monokryształów i cienki warstw, (access August 2023).

- www.sites.google.com/site/profesorjanczochralski/in-the-news, (access August 2023).

- www.centrumnaukiec1.pl/aktualnosci/monokrysztaly-jana-czochralskiego, (access August 2023).

- Jing Tao, Suiran Yu, ELSEVIER, Review on feasible recycling pathways and technologies of solar photovoltaic module, (access August 2023).

- End-of- live management Solar Photovoltaic Panels, IRENA International Renewable Energy Agency (access August 2023).

- Jing Tao, Suiran Yu, ELSEVIER, Review on feasible recycling pathways and technologies of solar photovoltaic module, (access August 2023).

- SolarWorld AG | www.pvinfo.pl (access August 2023).

- Anna Kuczyńska- Łażewska, Technologie recyklingu zużytych odpadowych modułów fotowoltaicznych I i II generacji, (access August 2023).

- Dyrektywa Parlamentu Europejskiego I Rady 2012/19/UE z dnia 4 lipca 2012 r. w sprawie zużytego sprzętu elektrycznego i elektronicznego (WEEE).

- Raport o funkcjonowaniu systemu gospodarki zużytym sprzętem elektrycznym i elektronicznym w 2017 roku, (access August 2023).

- Europejski Trybunał Obrachunkowy, Działania UE dotyczące odpadów elektronicznych i wyzwania w tej dziedzinie 2021, (access August 2023).

- Raport Gospodarka elektrodpadami. Wyzwania na lata 2019-2023. Analiza sytuacji na rynku gospodarowania zużytym sprzętem elektrycznym i elektronicznym oraz rekomendacje, (access August 2023).

| Technology | PV module type | Advantages and disadvantages |

|---|---|---|

| Filtration | Crystalline silicon | capable of filtering small-sized particles contamination must be reduced before filtration |

| Spinning | Crystalline silicon | high silicon recovery content time-consuming process submicron SiC particles cannot be removed |

| Separation with phase transfer | Crystalline silicon | very high silicon recovery and no use of aggravating liquid very economical |

| Electrophoresis and gravity deposition | Crystalline silicon | very effective in the separation of Si, Al2O3 aluminum impurities in silicon |

| Electric field | Crystalline silicon | effective in the separation of silicon and SiC no use of toxic substances Pre-treatment is needed to eliminate contaminants from the metal |

| Al–Si alloying | Crystalline silicon | elimination of SiC meticulous process |

| Hydrobromination | Crystalline silicon | recovery of high-purity silicon without SiC removal |

| Supercritical water | Crystalline silicon | obtaining silicon from oily waste after silicon ingot processes |

| Sedimentation and leaching | Crystalline silicon | separation of silicon and SiC using physical methods a much easier process and not too complicated |

| Mono crystal Czochralski process | Crystalline silicon | mono crystal recovery reducing boron, which facilitates efficiency |

| Electrokinetic separation | Crystalline silicon | high efficiency of removing iron fragments from waste no chemical additives are used |

| Hydrometallurgy (oxidation, evaporation, reduction by inorganic substances) | CIGS | obtaining high-purity selenium |

| Hydrometallurgy (dissolution, filtering, electroplating, extraction) |

CIS | application of typical hydro-metallurgical processes and use of chemicals recovery of pure indium further development of technology |

| Continent | Number of e-waste production [million tons] | Number of e-waste production per capita [kg] | Number of e-waste recycled [million tons] | Number of e-waste recycled [%] |

|---|---|---|---|---|

| Africa | 2.9 | 2.5 | 0.03 | 0.9 |

| America | 13.1 | 13.3 | 1.2 | 9.4 |

| Asia | 24.9 | 5.6 | 2.9 | 11.7 |

| Europe | 12 | 16.2 | 5.1 | 42.5 |

| Oceania | 0.7 | 16.1 | 0.06 | 8.8 |

| 0.5 mol dm-3 NaOH | 0.5 mol dm-3 H2SO4 | 0.1 mol dm-3 H2SO4 | |

|---|---|---|---|

| m0 | 14.7422 g | 16.7304 g | 16.5919 g |

| mzal | 142.6702 g | 152.2068 g | 187.4988 g |

| m3 | 138.0130 g | 148.6846 g | 183.4708 g |

| m4 | 14.9688 g | 16.9590 g | 16.8485 g |

| m5 | 14.6837 g | 16.736 g | 16.5851 g |

| m6 | 122.9970 g | 131.7030 g | 166.5834 g |

| 0.5 mol dm-3 NaOH | 0.5 mol dm-3 H2SO4 | 0.1 mol dm-3 H2SO4 | |

|---|---|---|---|

| mn | 46.0325 g | 51.0224 g | 44.4226 g |

| mn+p | 60.8585g | 67.9300 g | 61.1760 g |

| m after drying | 60.7162 g | 67.7544 g | 61.0077 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).