Submitted:

12 September 2023

Posted:

13 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

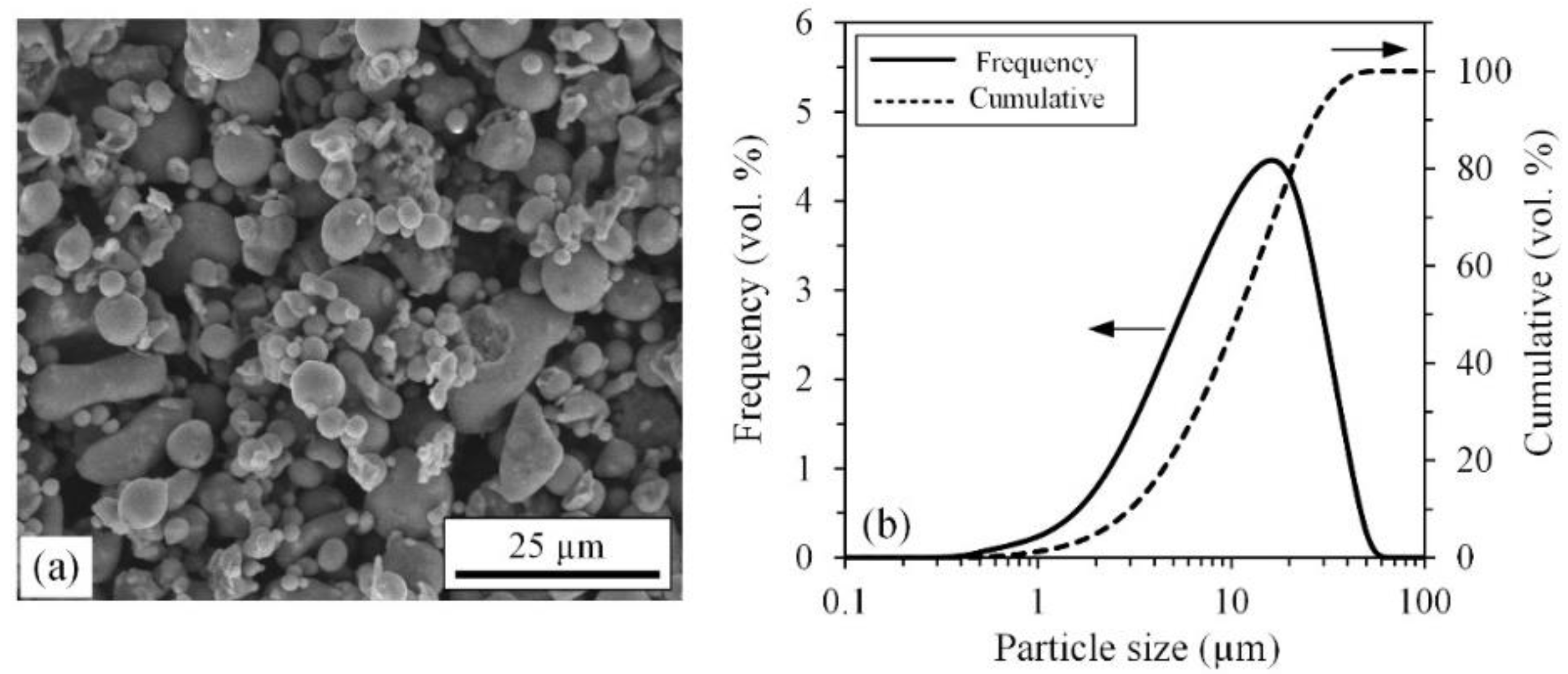

2.1. Feedstock formulation

2.2. Feedstock characterization

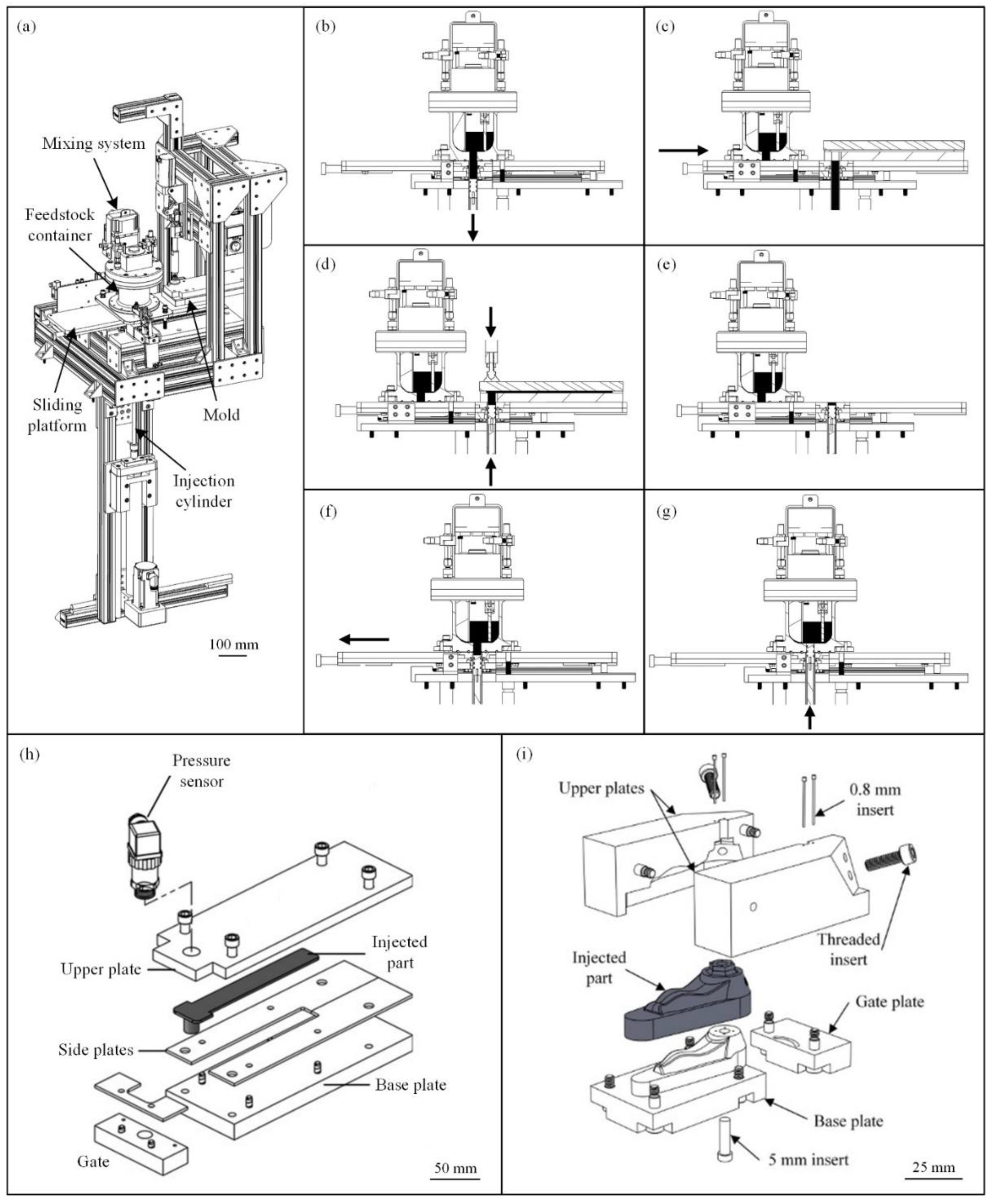

2.3. Real-scale injection

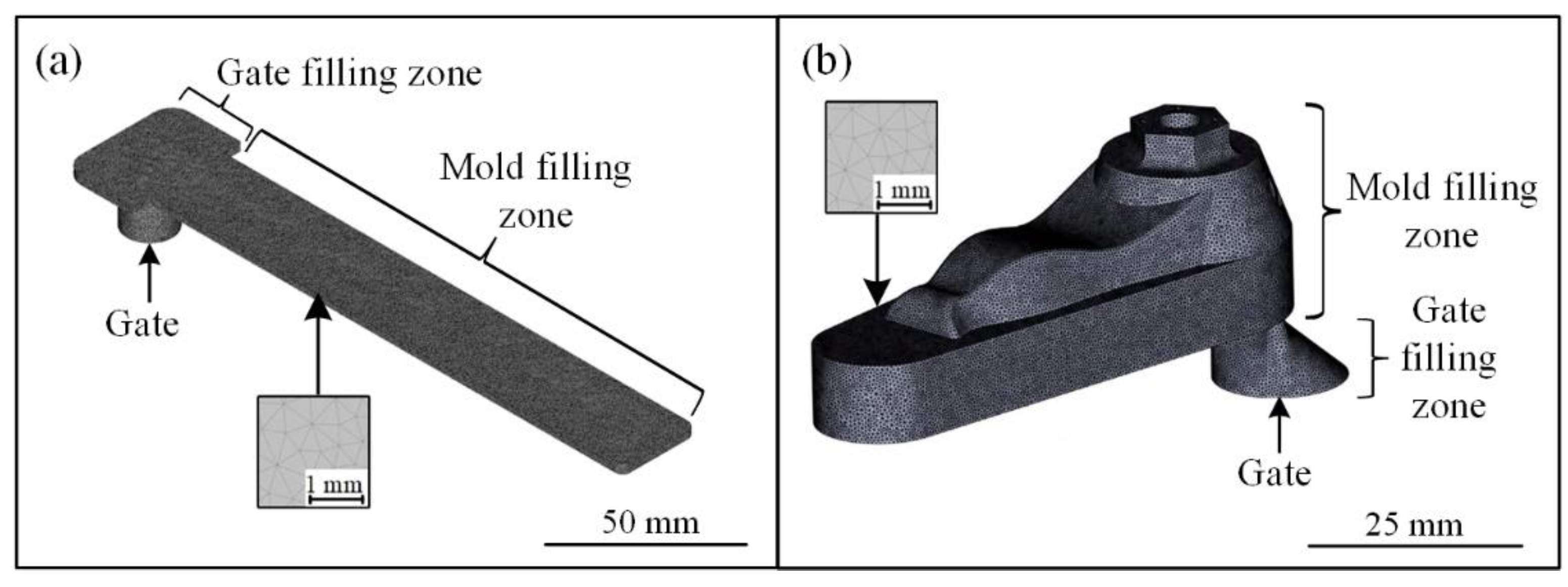

2.4. Numerical simulations

2.5. Powder segregation measurements

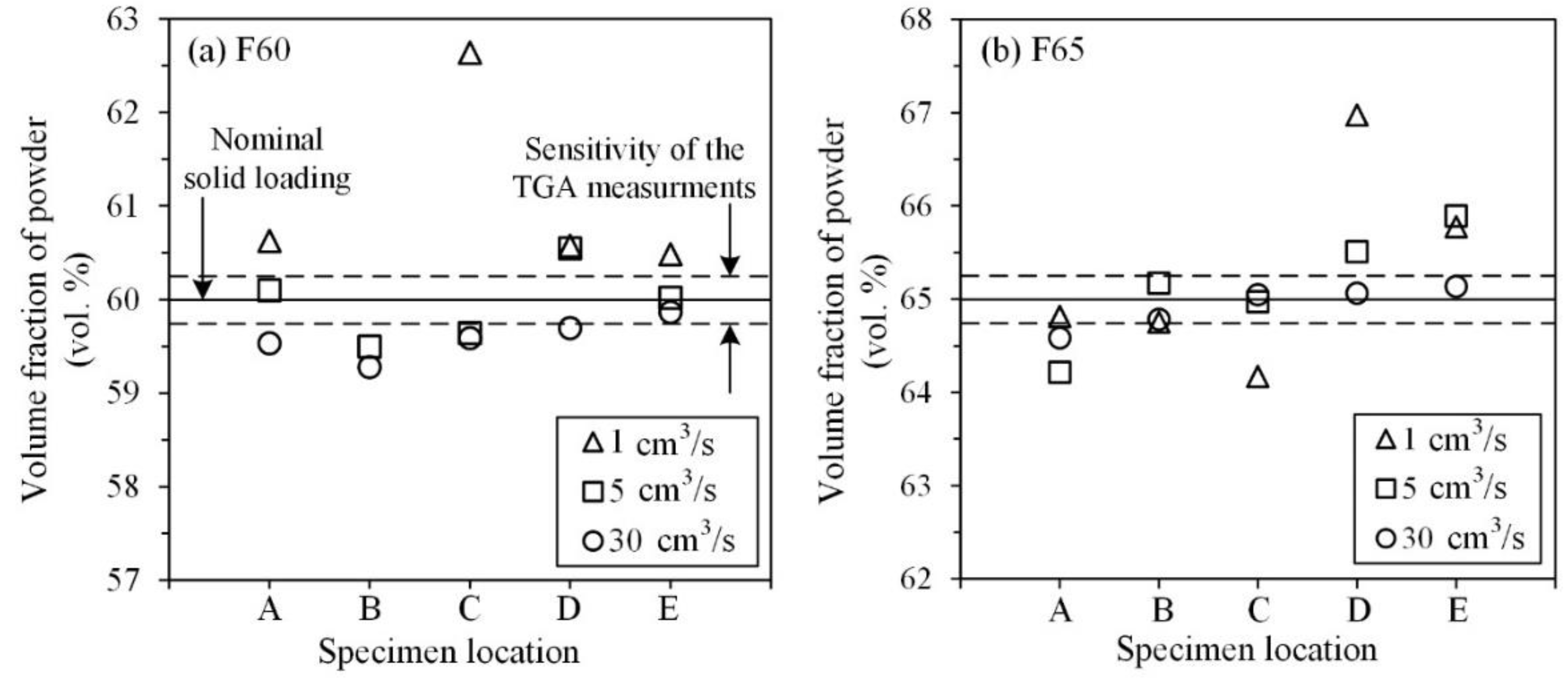

3. Results and discussion

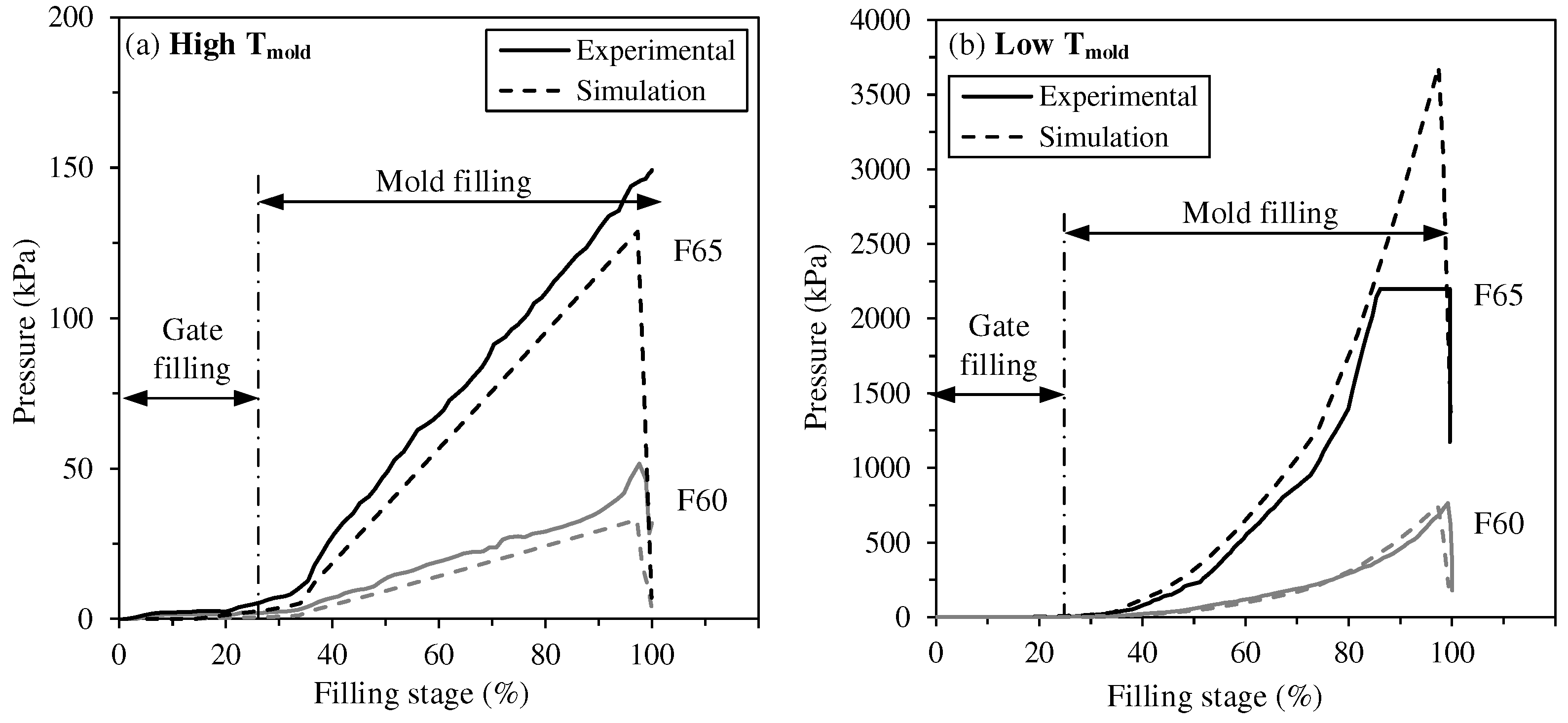

3.1. Influence of the mold and feedstock temperature on injection pressure

3.2. Influence of injection flow rate on pressure

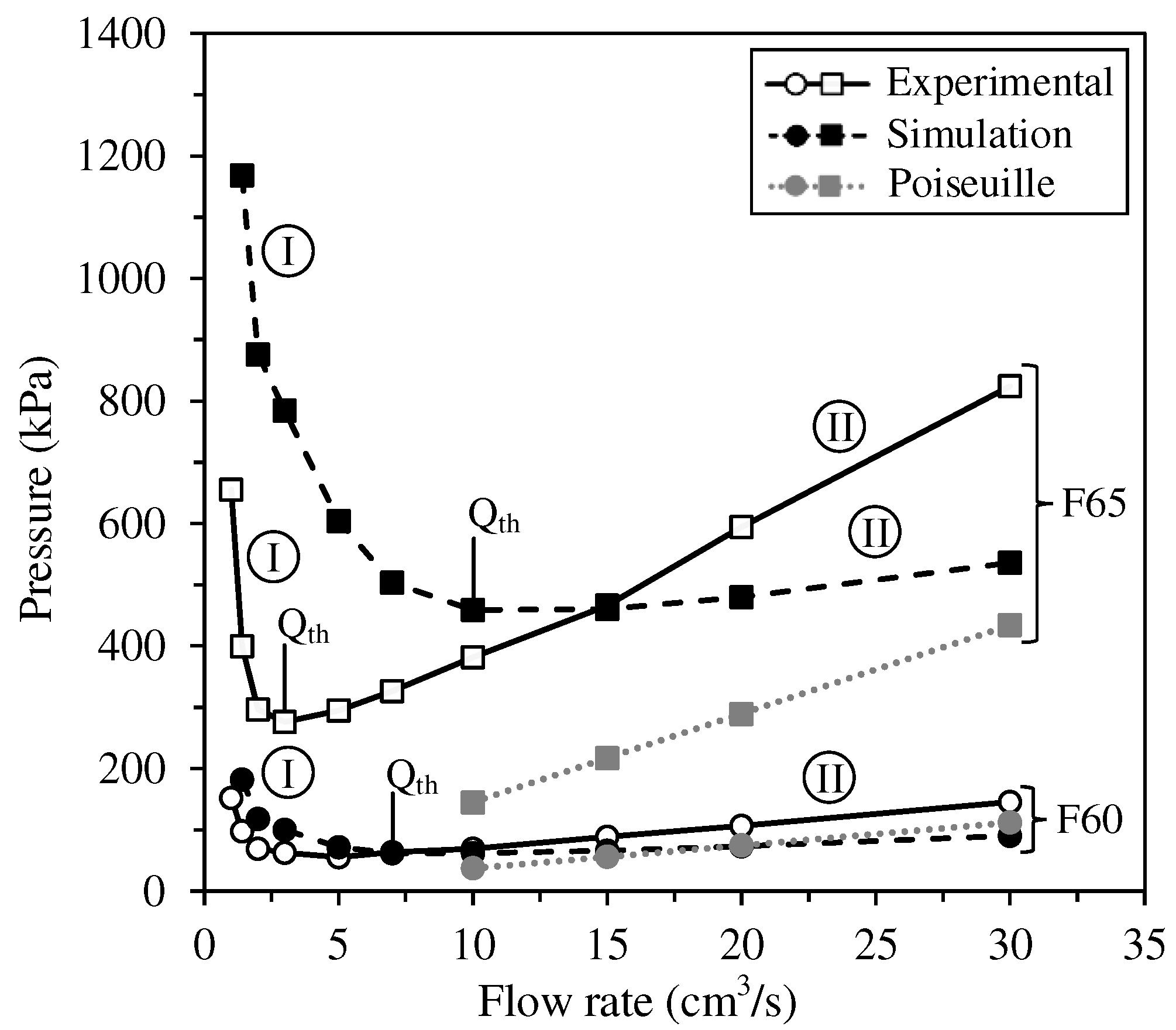

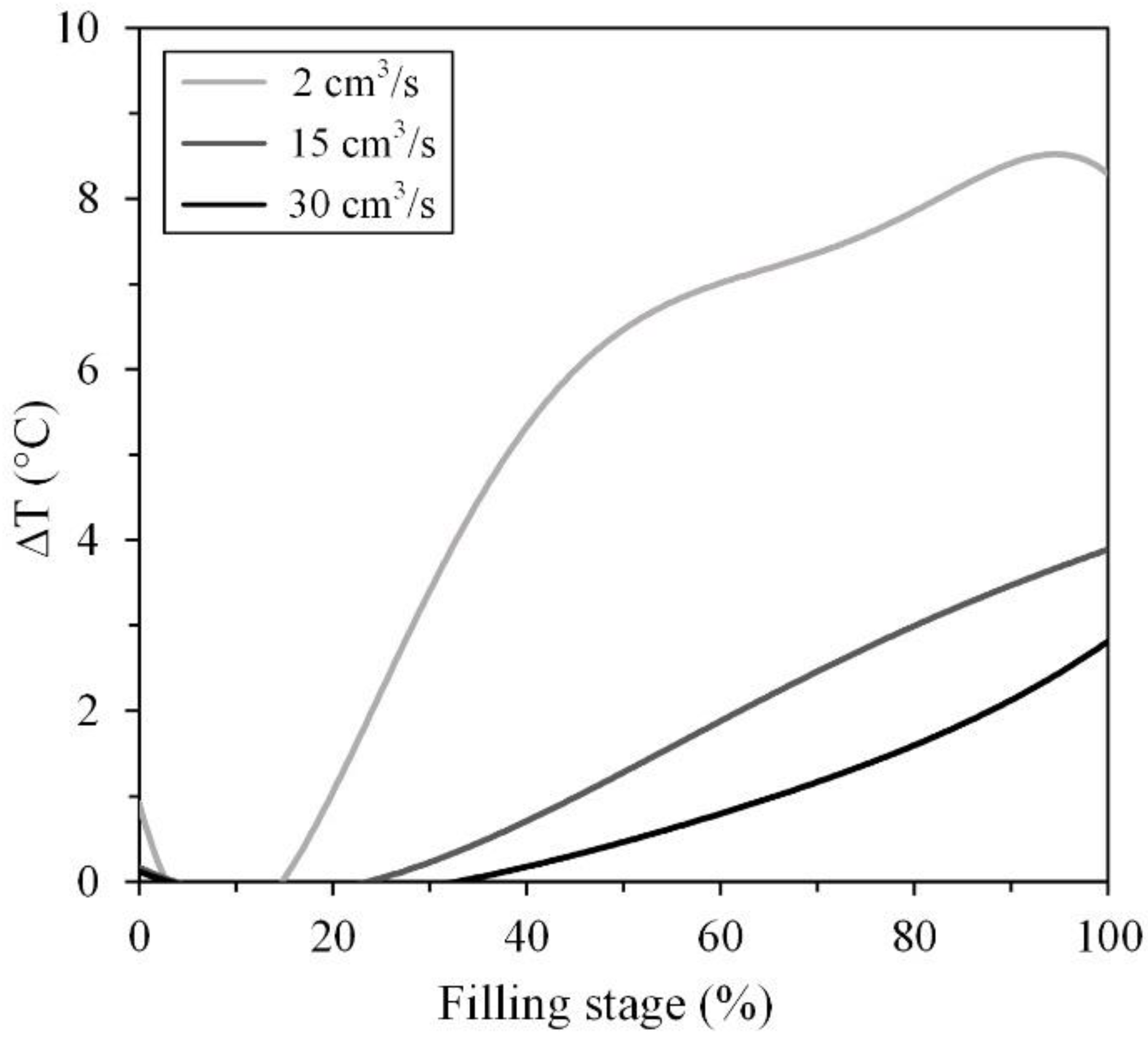

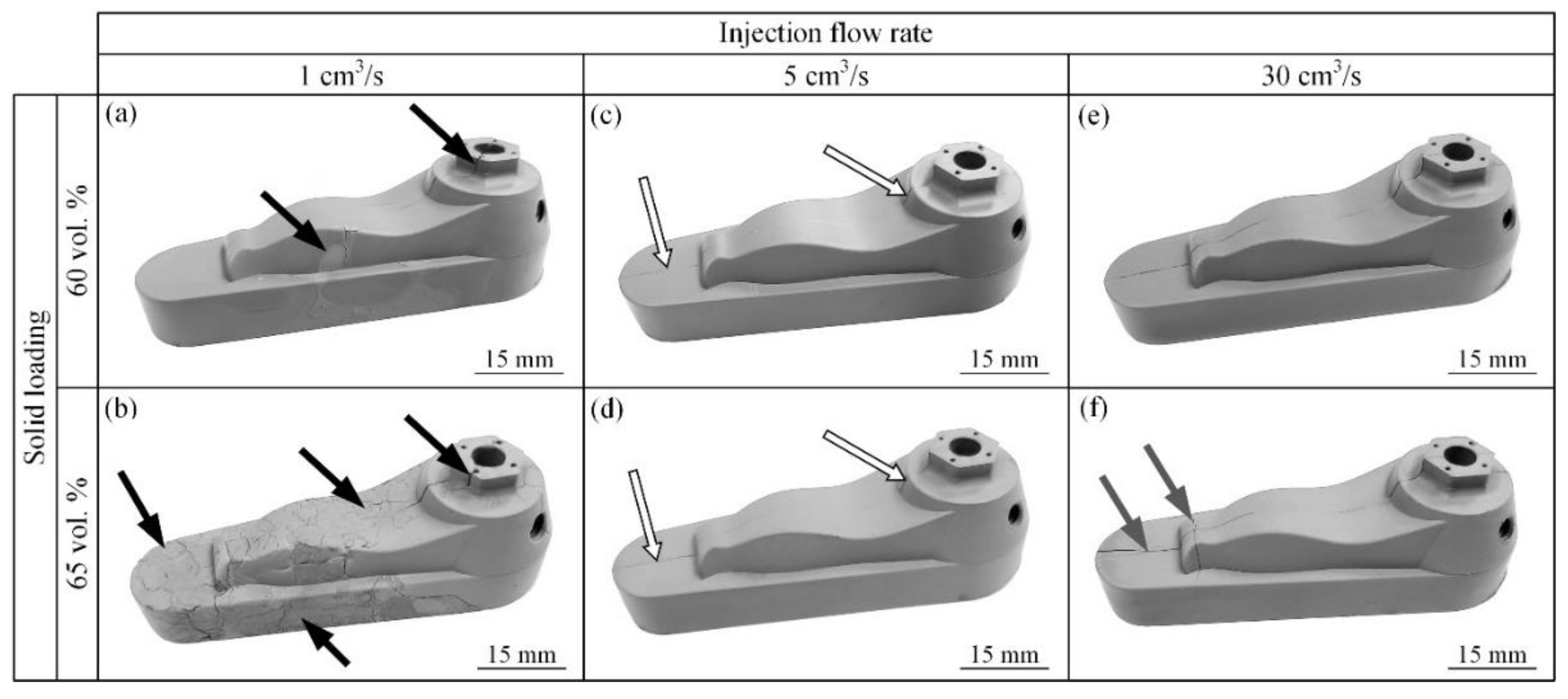

3.3. Influence of injection flow rate on green part quality

5. Conclusions

- An increase in mold temperature, feedstock temperature and/or a decrease in powder volume fraction produce a significant decrease in the in-cavity pressure, pointing to a strong correlation with the feedstock viscosity.

- The unexpected decrease in injection pressure observed during an increase in flow rate from 1 cm3/s to a flow rate threshold, Qth (7 and 3 cm3/s for the 60 and 65 vol. % of powder feedstocks, respectively), was in fact due to early solidification of the feedstock and not feedstock flow behavior. Using injection flow rates > Qth, the expected linear relationship between the pressure and feedstock flow was observed.

- The presence of visual defects was significantly reduced for injections at moderate flow rates, but an absence of the segregation phenomenon throughout green parts was seen when using high injection flow rates.

- The simulation model was able to capture the injection pressure only when the injection flow rate was maintained constant or when thermal transfer conditions were extreme (where solidification was promoted or avoided by decreasing or increasing the mold temperature). This suggests that the thermal behavior observed in the LPIM process (which is significantly different from the one seen in conventional HPIM) could not properly be taken into account in the model. Since this work represents, to the best of authors’ knowledge, the first experimental validation of the simulated pressure in LPIM, future works addressing this issue are thus needed to accuratly predict the numerical mold cavity pressure for LPIM feedstocks when different injection flow rates are used.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- González-Gutiérrez, J.; Stringari, G.B.; Emri, I. Powder injection molding of metal and ceramic parts, IntechOpen 2012; pp. 65-88. [CrossRef]

- Heaney, D.F. Handbook of metal injection molding, 2nd ed., Woodhead Publishing, 2019; pp. 1-656.

- Sulong, A.B.; Muhamad, N.; Arifin, A.; Yong, K.B. Optimizing injection parameter of metal injection molding processes using the feedstock of 16 μm stainless steel powder (SS316L), PEG, PMMA and stearic acid, J. Appl. Sci. Res., 2012, 8, 2998-3003.

- Demers, V. Low-pressure powder injection moulding review: enabling cost effective low and high volume PIM production, Powder Inject. Mould. Int., 2019, 13, 53-63.

- German, R.; Bose, A. Injection molding of metals ceramics, Metal Powder Industries Federation, Princeton, New Jersey, 1997; pp. 1-413.

- Costa, C.A.; Pasquali, F.M. Application of rapid tooling and rapid prototyping in low pressure injection molding process of ceramic parts, International Conference on Polymers and Moulds Innovations – PMI2014, Guimaraes, Portugal, 2014.

- Pompe, R.; Brandt, J. Goceram's MEDPIMOULD technology offers cost-effective PIM production, Met. Powder Rep., 2001, 56, 14-17.

- Zampieron, J.V.; Soares, J.P.; Mathias, F.; Rossi, J.L.; Ambrozio Filho, F. Low Pressure Powder Injection Moulding of Stainless Steel Powders, Key Eng. Mater., 2001, 189-191, 610-615. [CrossRef]

- Mangels, J.A.; Williams, R.M. Injection Molding Ceramics to High Green Densities, Am. Ceram. Soc. Bull., 1983, 62, 601-606.

- Peltsman, M.I.; Peltsman, I.D. Low pressure hot molding machine, Patent US 4416603, 1983.

- Mangels John, A. Low-pressure injection molding, Am. Ceram. Soc. Bull., 1994, 73, 37-41.

- Goncalves, A.C. Metallic powder injection molding using low pressure, J. Mater. Process. Technol., 2001, 118, 193-198. [CrossRef]

- Quevedo Nogueira, R.E.F.; Bezerra, A.C.; dos Santos, F.C.; Sousa, M.R.d.; Acchar, W. Low-Pressure Injection Molding of Alumina Ceramics Using a Carnauba Wax Binder: Preliminary Results, Key Eng. Mater., 2001, 189-191, 67-72. [CrossRef]

- Piotter, V.; Bauer, W.; Knitter, R.; Mueller, M.; Mueller, T.; Plewa, K .Powder injection moulding of metallic and ceramic micro parts, Microsyst. Technol., 2011, 17, 251-263. [CrossRef]

- Çetinel, F.A.; Bauer, W.; Knitter, R.; Haußelt, J. Factors affecting strength and shape retention of zirconia micro bending bars during thermal debinding, Ceram. Int., 2011, 37, 2809-2820. [CrossRef]

- Medvedovski, E.; Peltsman, M. Low pressure injection moulding mass production technology of complex shape advanced ceramic components, Adv. Appl. Ceram., 2013,111, 333-344. [CrossRef]

- Sardarian, M.; Mirzaee, O.; Habibolahzadeh, A. Influence of injection temperature and pressure on the properties of alumina parts fabricated by low pressure injection molding (LPIM), Ceram. Int., 2017, 43, 4785-4793. [CrossRef]

- Atre, S.V.; Park, S.J.; Zauner, R.; German, R.M. Process simulation of powder injection moulding: identification of significant parameters during mould filling phase, Powder Metall., 2007, 50, 76-85. [CrossRef]

- Muangwaeng, B.; Rojananan, S.; Rojananan, S. The Effect of Injection Parameters on Morphology in Metal Injection Moulding, Adv. Mater. Res., 2013, 802, 174-178.

- Walcher, H.; Knöpfle, C.; Maetzig, M. Influence of Process Parameter on the Quality of MIM Parts, European Congress and Exhibition on Powder Metallurgy, The European Powder Metallurgy Association, Shrewsbury, England, 2016.

- Huang, M.S.; Hsu, H.C. Influence of injection moulding and sintering parameters on properties of 316L MIM compact, Powder Metall., 2011, 54, 299-307. [CrossRef]

- Amin, S.Y. M.; Muhamad, N.; Jamaludin, K.R. Optimization of Injection Molding Parameters for WC-Co Feedstocks, J. Teknol., 2013, 63, 51-54. [CrossRef]

- Askari, A.; Momeni, V. Rheological investigation and injection optimization of Fe–2Ni–2Cu feedstock for metal injection molding process, Mater. Chem. Phys., 2021, 271, 1-10. [CrossRef]

- Yang, S.; Zhang, R.; Qu, X. Optimization and evaluation of metal injection molding by using X-ray tomography, Mater. Charact., 2015,104, 107-115. [CrossRef]

- Sardarian, M.; Mirzaee, O. Habibolahzadeh, A. Numerical simulation and experimental investigation on jetting phenomenon in low pressure injection molding (LPIM) of alumina, J. Mater. Process. Technol., 2017, 243, 374-380. [CrossRef]

- ASTM, B923–16: Standard Test Method for Metal Powder Skeletal Density by Helium or Nitrogen Pycnometry, ASTM International, West Conshohocken, PA, 2016.

- ASTM, D3418–15: Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry, ASTM International, West Conshohocken, PA, 2015.

- ASTM, E1269-11: Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry, ASTM International, West Conshohocken, PA, 2011.

- ASTM, D5930-17: Standard Test Method for Thermal Conductivity of Plastics by Means of a Transient Line-Source Technique, ASTM International, West Conshohocken, PA, 2017.

- Lamarre, S.G.; Demers, V.; Chatelain, J.-F. Low-pressure powder injection molding using an innovative injection press concept, Int. J. Adv. Manuf. Technol., 2017, 91, 2595-2605. [CrossRef]

- Lamarre, S.G.; Demers, V.; Chatelain, J.-F. A low-pressure powder injection molding machine and method, USA Patent (Patent No. 10,919,092), 2021.

- Ilinca, F.; Hétu, J.-F.; Derdoufu, A.; Stevenson, J. Metal injection molding: 3D modeling of nonisothermal filling, Polymer Eng. & Sci., 2002,42, 760-770. [CrossRef]

- Demers, V.; Fareh, F.; Turenne, S.; Demarquette, N.R.; Scalzo, O. Experimental study on moldability and segregation of Inconel 718 feedstocks used in low-pressure powder injection molding, Adv. Powder. Technol., 2018, 29, 180-190. [CrossRef]

- Malkin, A.I.; Isayev, A.I. Rheology: concepts, methods, and applications, Fourth ed., ChemTec Publishing 2022.

- Poh, L.; Della, C.; Ying, S.; Goh, C.; Li, Y. Powder distribution on powder injection moulding of ceramic green compacts using thermogravimetric analysis and differential scanning calorimetry, Powder Technol., 2018,328, 256-263. [CrossRef]

- Thornagel, M.; Schwittay, V.; Hartmann, G. Powder-binder segregation: PIM-simulation at breakthrough, Euro PM 2014 International Conference and Exhibition, European Powder Metallurgy Association (EPMA), Salzburg, Austria, 2014.

| Vol. % | |||||

|---|---|---|---|---|---|

| Feedstock | Powder | Paraffin wax | Carnauba wax | Stearic acid | Ethylene- vinyl acetate |

| F60 | 60 | 30 | 7 | 2 | 1 |

| F65 | 65 | 25 | 7 | 2 | 1 |

| Constituents | Melting point (°C) | Density (g/cm³) | Supplier |

|---|---|---|---|

| 17-4PH powder | ˃ 1404 | 7.69 | Epson Atmix Corp. |

| Paraffin wax | 59.0 | 0.90 | Sigma-Aldrich |

| Carnauba wax | 84.5 | 1.00 | Sigma-Aldrich |

| Stearic acid | 75.0 | 0.90 | Sigma-Aldrich |

| Ethylene vinyl acetate | 49.0 | 0.98 | Dupont |

| Fitted Coefficient | F60 | F65 |

| A | 5.574 | 7.819 |

| B | -3.987 E-1 | -5.569 E-1 |

| C | -4.136 E-2 | -7.336 E-2 |

| D | 5.850 E-2 | 6.149 E-2 |

| E | -5.047 E-1 | -1.967 E-1 |

| F | 1.169 E-4 | 2.645 E-4 |

| Sequence | Mold temperature (°C) |

Feedstock temperature (°C) | Flow rate (cm3/s) | Solid loading(vol. %) | Mold type |

| 1 | 30 | 90 | 15 | 60/65 | Rectangular |

| 40 | |||||

| 50 | |||||

| 2 | 40 | 80 | 15 | 60/65 | Rectangular |

| 90 | |||||

| 100 | |||||

| 3 | 40 | 90 | 1 | 60/65 | Rectangular |

| 2 | |||||

| 3 | |||||

| 5 | |||||

| 7 | |||||

| 10 | |||||

| 15 | |||||

| 20 | |||||

| 30 | |||||

| 4 | 40 | 90 | 1 | 60/65 | Complex shape |

| 5 | |||||

| 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).