1. Introduction

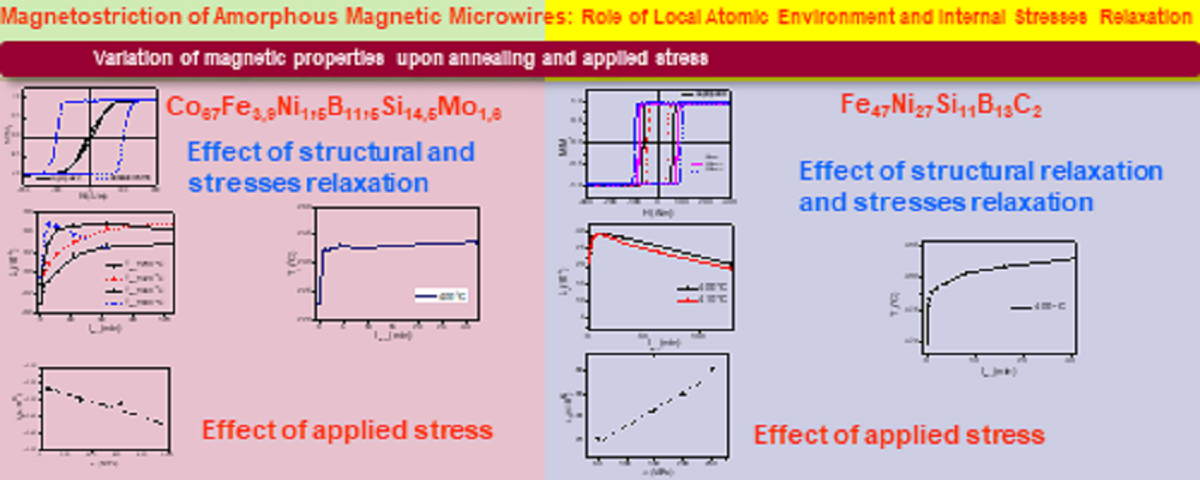

Magnetostriction,

λs, refers to the behavior of a magnetic material that undergoes either expansion or contraction in the direction of magnetization when exposed to a magnetic field [

1,

2]. The

λs can be either positive or negative, depending on whether the magnetostrictive effect leads to expansion or compression, respectively.

In amorphous alloys, magnetostriction is a phenomenon that relates to the deformation or change in shape of the material in response to an applied magnetic field. Unlike crystalline materials, amorphous alloys lack of long-range periodic atomic structure and instead have a disordered arrangement of atoms. In the absence of defects typical for crystalline materials (grain boundaries, dislocations, texture,…) the magnetoelastic anisotropy plays the determining role in magnetic softness of amorphous alloys [3-6]. The magnetoelastic anisotropy,

Kme, is determined by the magnetostriction coefficient, λ

s, as well as by the stress, σ, [

3,

4]. It is commonly accepted that in amorphous alloys the

λs is influenced by the chemical composition: for Fe-rich composition the

λs is positive (up to 40x10

-6) and large, while for Co-rich amorphous alloys

λs is negative (up to -5 10

-6). Consequently, nearly-zero

λs values have been achieved in Co

xFe

1-x (0≤x ≤1) or Co

xMn

1-x (0≤x ≤1) alloys 0,03 ≤x≤ 0,08 [3-5]. In such amorphous alloys with vanishing

λs values better magnetic softness is commonly reported [3-6].

However, magnetostriction of amorphous alloys is influenced by the local atomic environments, by the presence of clusters and even by stresses [7-9]. Thus, clusters are localized regions of atoms that exhibit different magnetic properties compared to the surrounding material. These clusters can arise due to variations in composition or local atomic arrangements within the amorphous structure. When an external mechanical stress is applied to an amorphous alloy with clusters, the magnetic moments within the clusters align with the stress direction, causing a local deformation or strain in the material. In the two-ion model, the strain experienced by one ion can affect the magnetic moment of the neighboring ion and vice versa. This coupling between strain and magnetism leads to changes in the magnetic properties of the material, including its magnetostriction [

7].

Research on amorphous magnetic wires has attracted considerable attention owing to unusual magnetic properties, such as magnetic bistability related to fast magnetization switching through the fast domain wall (DW) propagation, superior magnetic softness or the giant magnetoimpedance (GMI) effect [4, 10-12]. Such magnetic properties have been proposed for numerous applications in magnetic and/or magnetoelastic sensors and devices [4,8-10]. While the better magnetic softness and the highest GMI effect are commonly reported in magnetic wires with vanishing λs, spontaneous magnetic bistability is usually reported for magnetostrictive compositions of amorphous wires [4, 10-12].

One of the recent tendencies in amorphous materials is the development of low dimensional amorphous materials with enhanced physical (mechanical, corrosion) properties and biocompatibility [

4,

6,

11]. Therefore, studies of glass-coated microwires with unusual combination of physical properties, such as enhanced mechanical and corrosion properties, biocompatibility together with excellent magnetic softness with coercivities up to 2 A/m and high magnetoimpedance effect have attracted substantial attention [

4,

6,

11].

The peculiarity of glass-coated microwires is the presence of the glass-coating intrinsically related to the fabrication method [

4,

6,

11]. Such composite origin of glass-coated microwires is associated with high values of internal stresses in glass-coated microwires, discussed elsewhere [13-17]. Although there are several origins of the internal stresses in amorphous microwires, however the main contribution is related with the difference in thermal expansion coefficients of metallic alloy and glass coating [13-17].

The magnetostriction coefficient plays a significant role in determining the domain structure and hysteresis loop characteristics of glass-coated microwires. In compositions with low magnetostriction, the stress dependence of magnetostriction, whether applied or internal, becomes relevant. This stress dependence has been described as [

8,

9]:

Here, λs(σ) represents the magnetostriction coefficient under stress, λs(0) is the magnetostriction coefficient at zero stress, B is a positive coefficient of the order 10-10 MPa, and σ represents the applied or internal stresses. The change in magnetostriction can be attributed to the presence of applied stresses (σappl), internal stresses (σi), or both (σ).

Mechanical stresses play a significant role in modifying the magnetic properties of ferromagnetic materials. Alongside magnetic field and temperature, they are a crucial factor influencing magnetic properties. This phenomenon is commonly employed in stress and torsion sensors, where the variation in the material's magnetic properties is utilized for sensing purposes [5-8, 18-22]. Magnetostriction also has an impact on various inductive or transport magnetic effects [20-22].

Recently, studies of glass-coated magnetic microwires have attracted growing attention. Among the principal advantages of glass-coated microwires are the most extended diameters range from 100 nm [

13] up to 100 µm [

23]. Additionally, the presence of flexible, insulating and thin glass-coating together with extended diameters are beneficial for several technical applications [4, 24,25].

Similarly to thicker amorphous magnetic wires prepared by in-rotating water technique, magnetic bistability related to remagnetization by fast DW propagation is observed in Fe-and Fe-Ni- rich glass-coated microwires [

4,

6]. While almost unhysteretic loops with vanishing coercivity and high GMI effect are reported in Co-rich glass-coated microwires [4, 6].

As mentioned above, the λs of amorphous alloys is principally affected by the chemical composition. Thus, in most commonly studied amorphous Co1-xFex alloys high and positive λs (up to 40x10-6) is reported for Fe-rich compositions, while negative (up to -5 10-6) λs is observed in Co-rich amorphous alloys. Therefore, observed dependence of magnetic properties on chemical composition is commonly attributed to compositional dependence of λs.

As discussed above, the

λs in amorphous materials is affected by stress [

8,

9]. In the case of glass-coated microwires, the presence of a glass coating associated with a preparation method involving simultaneous solidification of a metallic alloy inside the glass coating leads to an elevated

σi -value (up to hundreds of MPa) [13-17].

In the case of low-magnetostrictive compositions, where λs (0) is approximately 10-7, and internal stresses are on the order of hundreds of MPa, the second term in Equation (1) becomes comparable to the first term. Consequently, the magnetostriction value and even sign can be substantially different from that of conventional amorphous materials. Therefore, the correct evaluation of λs - magnitude in glass-coated microwires becomes a crucial factor for adjusting the magnetic properties of glass-coated microwires and it is relevant for technological applications.

One of the most commonly used methods for evaluation of the λ

s in amorphous materials, is so called small angle magnetization rotation (SAMR) [8,9, 18]. The magnetostriction of conventional (bulk) magnetic materials usually can be measured by direct methods, such as strain gauge method or the capacitance method [

26,

27]. However, direct methods require use of the strain gauge or the movable electrode. Therefore, use of such direct methods for λ

s measurements in low dimensional amorphous materials, like amorphous ribbons or wires seems to be difficult. Therefore, indirect methods, like the SAMR method, Villari effect of stress dependence of hysteresis loop have been proposed for studied of amorphous low dimensional materials since the 80s [

8,

9,

18]. Some issues for use of indirect methods, like the stress dependence of the λ

s in amorphous materials and the influence of mechanical creep deformation of the sample can be successfully minimized using as short as possible keeping the sample under stress [

8].

In the case of glass-coated magnetic microwires, the use of direct methods for λ

s evaluation is even more difficult owing to composite origin of glass-coated microwires and substantially lower dimensionality. Therefore, recently SAMR method has been successfully adapted for magnetic microwires by improved resolution obtained in new experimental set-up [

28,

29].

Consequently, for glass-coated microwires with elevated internal stresses, studies of the magnetostriction coefficient are essentially relevant both from the point of view of applications and for understanding of the intrinsic properties (the degree of internal stresses relaxation, short range atomic order) of amorphous microwires. Accordingly, this paper presents the experimental results on the magnetostriction coefficient of glass-coated microwires of two different chemical compositions.

2. Materials and Methods

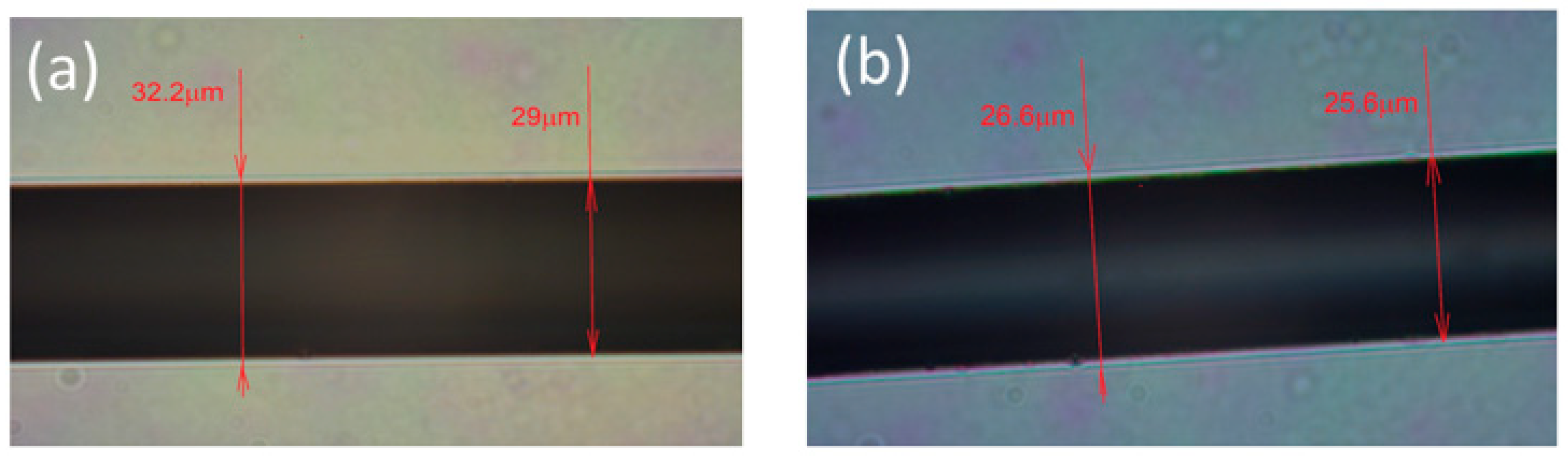

We studied Fe

47Ni

27Si

11B

13C

2 (metallic nucleus diameter,

d =29 µm, total diameter,

D=32.2 µm) and Co

67Fe

3.9Ni

1.

5B

11.

5Si

14.5Mo

1.6 (

d =25.6 µm,

D=26.6 µm) glass-coated microwires produced by Taylor-Ulitovsky technique [

4,

6,

15,

16,

30]. The preparation method of glass-coated microwires consists by melting of the ingot using a high frequency inductor be heating above its melting temperature, and then drawing of a glass capillary filled with the molten metallic alloy. The composite microwire is then wound onto a rotating pick-up bobbin [

4,

6,

30].

The metallic nucleus diameter,

d, has been controlled by the impedance measurements during the preparation [

4]. Additionally, an optical microscope Axio Scope A1 was used for the morphology analysis and evaluation of the d and D- values of prepared glass-coated microwires. From the images of prepared microwires (see

Figure 1a,b) we can clearly see that the metallic nucleus are rather homogeneous and confirm the d and D- values.

The SAMR method was used to evaluate λ

s in both microwires. This method consists in saturating the sample with an axial magnetic field, while the transverse magnetic field created by AC electric current causes the small angle magnetization rotation [

29,

30]. When a tensile stress is applied, the magnetization rotation angle decreases due to an increase in the magnetic anisotropy field

Hk, which leads to a decrease in the amplitude of the second harmonic of the electro-motive force,

EMF, induced in the pick-up coil. Tensile stress, σ, is created by a weight attached to the end of the microwire. The magnetostriction coefficient, λ

s, is then estimated from the

Hk(σ) dependence as:

where

μοM

s is the saturation magnetization

The SAMR method was also used for the evaluation of the λ

s (σ) dependence. The detailed description of the set-up developed for the λ

s evaluation in magnetic microwires is provided elsewhere [

30].

Hysteresis loops were measured using the fluxmetric method, previously successfully employed for high resolution measurements of axial hysteresis loops of magnetically soft microwires [

31]. The 5 cm long samples were placed inside a single layered pick-up coil located inside a 15 cm long solenoid producing an axial homogeneous magnetic field. For this geometry the influence of the demagnetizing field and hence shape magnetic anisotropy contribution or microwires are negligible. The hysteresis loops have been represented as the normalized magnetization, M/M

o versus magnetic field, H, being M– the magnetic moment at a given H and M

o -the magnetic moment at the maximum magnetic field amplitude, H

o. Such M/M

o(H) loops are useful for comparison of the soft magnetic properties of microwires with different chemical compositions and, therefore, with different saturation magnetization values.

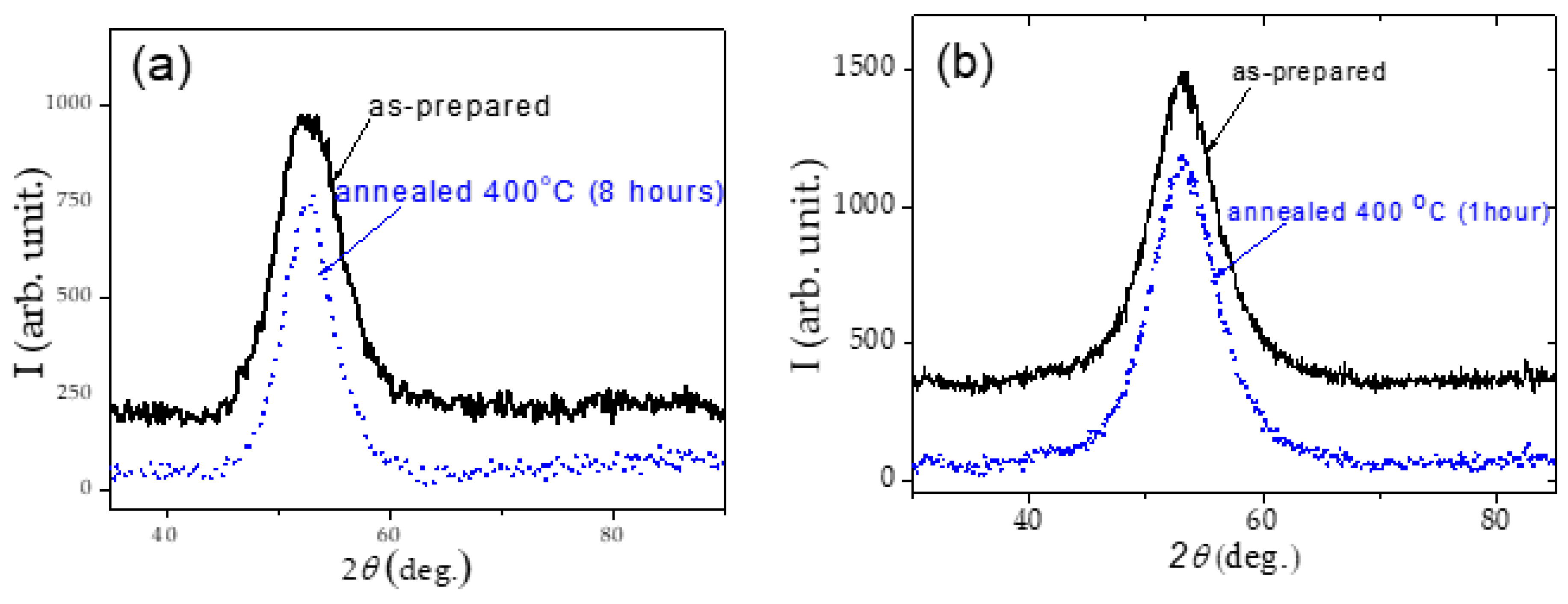

Amorphous structure of as-prepared and annealed samples have been proved by X-ray Diffraction (XRD) using a BRUKER (D8 Advance) X-ray diffractometer with Cu K

α (α=1.54 Å) radiation. XRD pattern of all the samples (as-prepared and annealed at 400

o C) present wide halo typical for amorphous alloys (see

Figure 2).

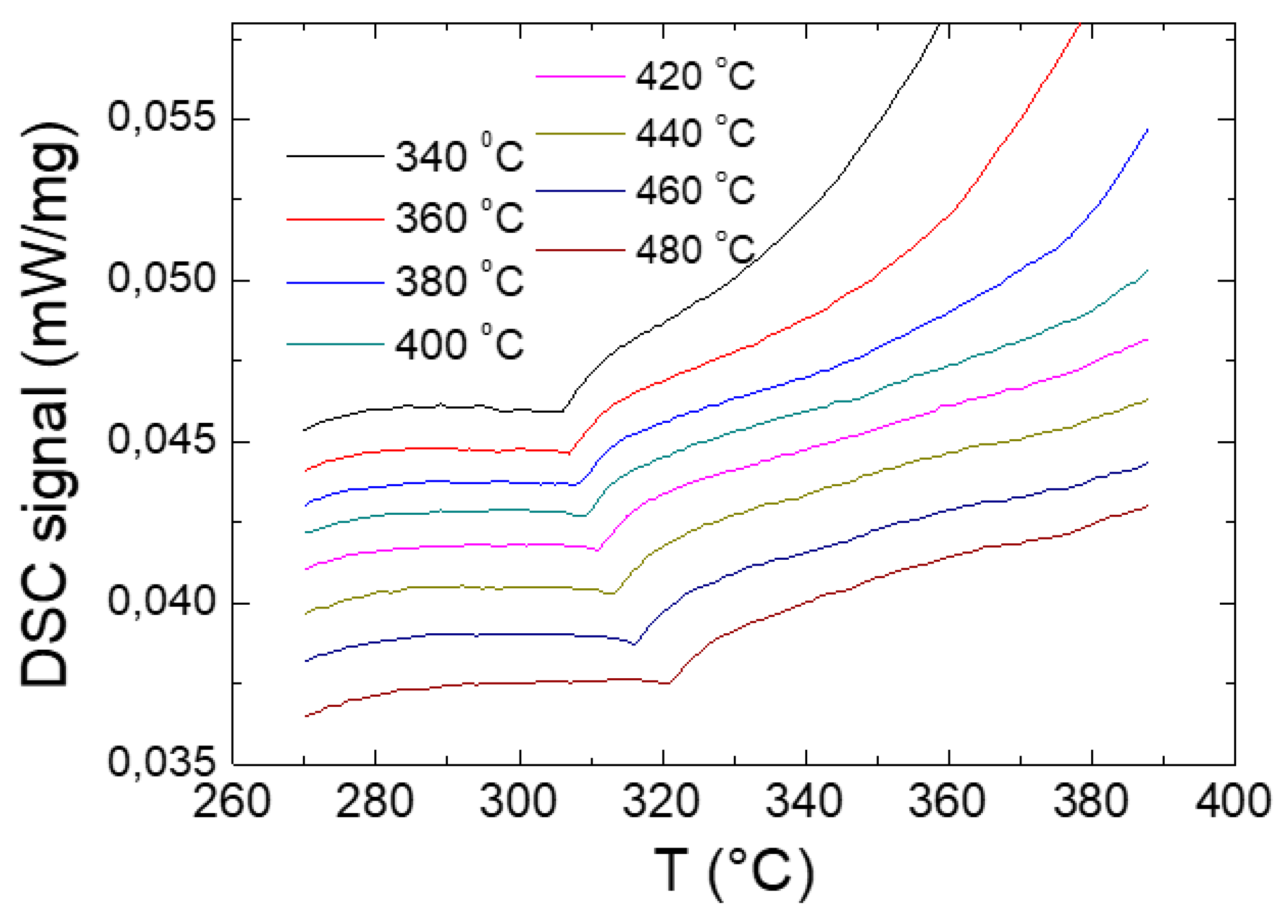

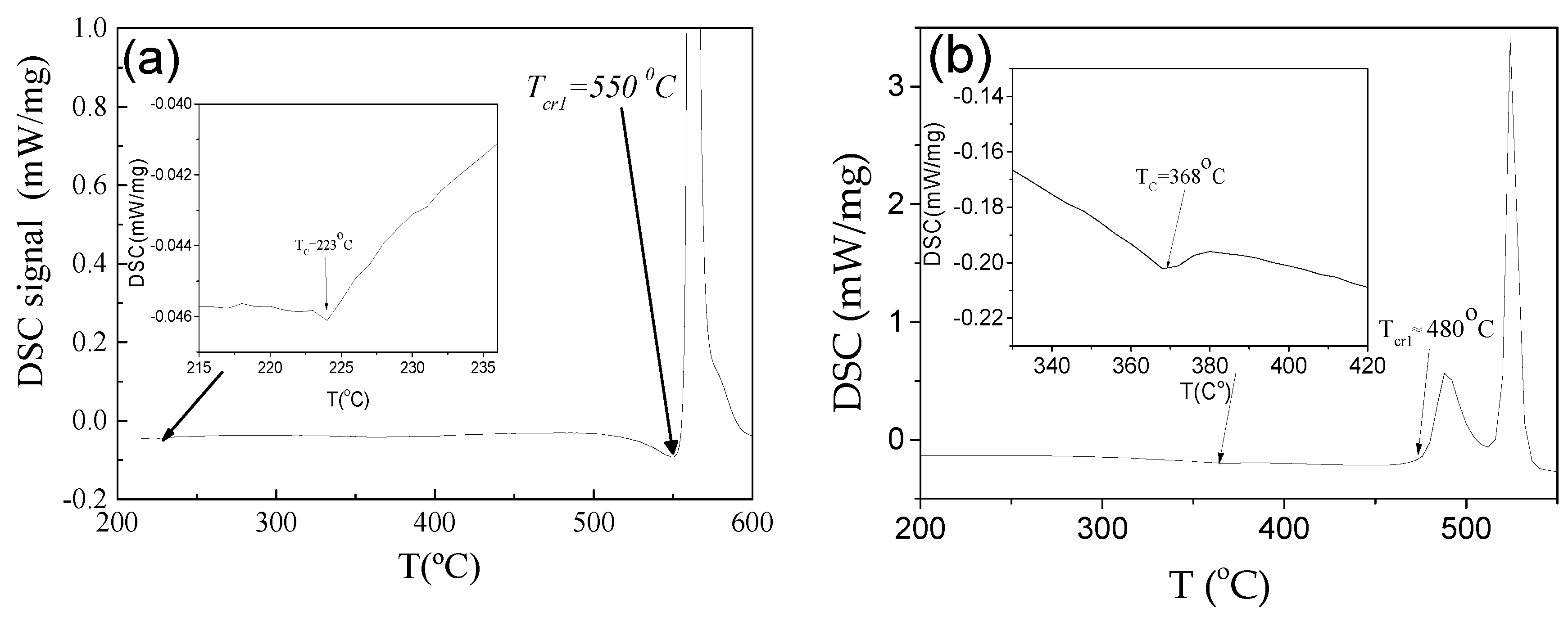

The crystallization and the Curie temperatures,

Tc, of both microwires have been evaluated using the Differential Scanning Calorimetry, DSC, method [

32]. We used DSC 204 F1 Netzsch calorimeter at a heating rate of 10 K/min (in Ar atmosphere).

The determination of the Curie temperature by the DSC method has been reported since more than 20 years [

32]. In particular, comparison of the

Tc –values obtained by the DSC with the

Tc obtained by the other commonly accepted methods for

Tc determination, such as temperature dependences of magnetization and electrical resistance, has proved that the turn on DSC curve actually corresponds to the Curie temperature

Tc. One of the examples of the change in the DSC signal in the vicinity of

Tc is provided in

Figure 3.

In the provided example it is shown that annealing of microwires leads to a change of the position and the shape of DSC peak in the vicinity of the

Tc: with increasing of the annealing temperature it shifts to higher temperatures. As- compared to the crystallization peak, the turn in the DSC curve in the vicinity of

Tc looks smaller. However, the use of standard software and a big amount of glass-coated tiny microwires makes it possible to increase the scale of DSC curves and determine

Tc quite accurately [

32,

33]. Thus, it was demonstrated that the accuracy of

Tc determining from DSC curves is about ±0.5 K, which makes this method among the most precise for

Tc determination [

32].

3. Experimental Results and Discussion

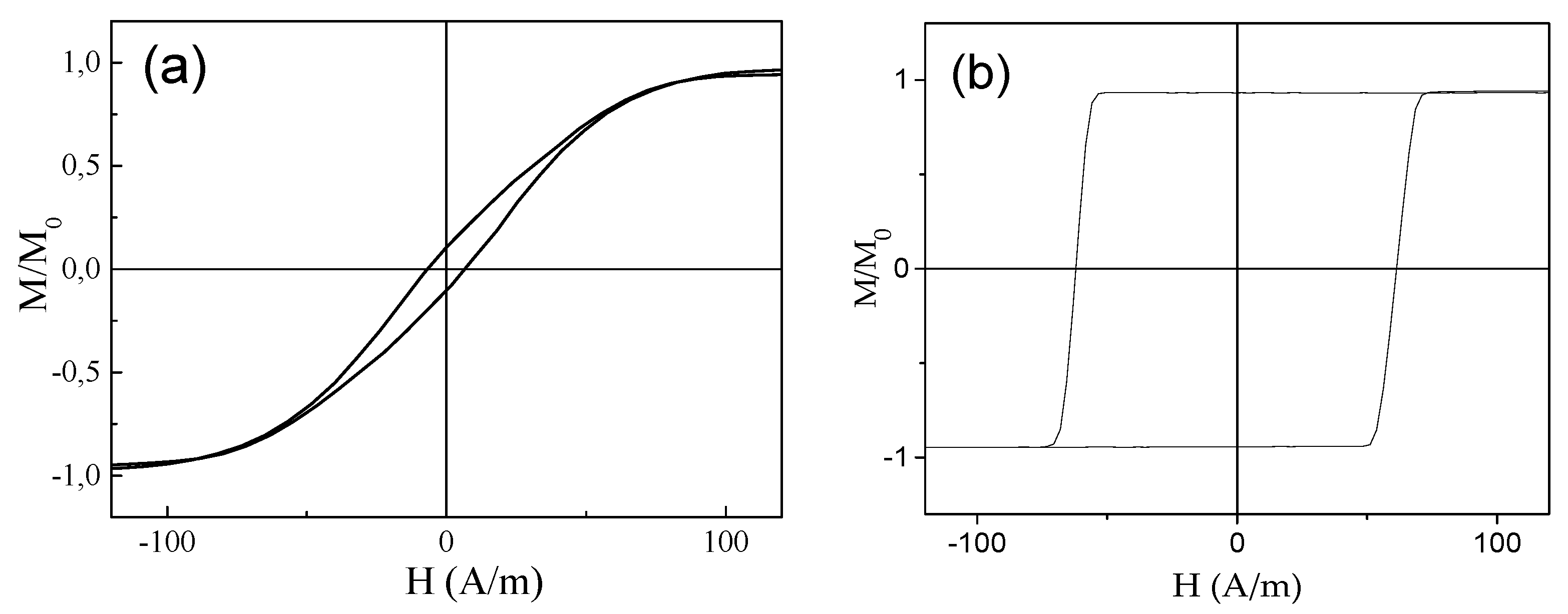

As can be observed from

Figure 4, studied microwires present rather different hysteresis loops. A linear and almost unhysteretic loop is observed for Co

67Fe

3.9Ni

1.

5B

11.

5Si

14.5Mo

1.6 microwire (see

Figure 4a), while a rectangular hysteresis loop is observed for Fe

47Ni

27Si

11B

13C

2 microwire (see

Figure 4b). The coercivity,

Hc, of Fe

47Ni

27Si

11B

13C

2 sample (H

c ≈61 A/m) is about, i.e., an order of magnitude higher than that for FeCo (

Hc ≈6 A/m).

The coercivity, Hc, of Fe47Ni27Si11B13C2 sample is about, 61 A/m, i.e., an order of magnitude higher than that for Co67Fe3.9Ni1.5B11.5Si14.5Mo1.6 microwire (Hc ≈6 A/m).

The observed difference in the hysteresis loop of studied microwires can be explained in terms of core-shell domain structure model confirmed experimentally in magnetic microwires with different magnetostriction coefficients [10,21, 34-38]. The domain structure of both families (Co-rich and Fe-rich) microwires was extensively studied either by magneto-optical Kerr effect or magneto-optical indicator film methods [34-38]. The core-shell domain structure model describes the domain structure of amorphous magnetic wires as consisting of an inner axially magnetized core surrounded by an outer shell with transverse magnetization. The outer shell of Fe-rich wires has a radial magnetization orientation, while a bamboo domain structure with a circular magnetization orientation is proposed for Co-rich wires [

10,

21,

38]. The difference in the outer shell domain structure is commonly explained considering the interplay of the magnetostriction and internal stresses and different

λs sign of Fe- and Co-rich magnetic wires. As mentioned above, the axial component of internal stresses arising during the microwires preparation is the largest [14-17]. Consequently, such axial internal stresses produce the transverse magnetic anisotropy in as-prepared Co-rich glass-coated microwires with negative λ

s. In contrast, axial magnetic anisotropy with rectangular hysteresis loops internal stresses appears in Fe-rich microwires with positive λ

s.

From DSC curves both crystallization,

Tcr1, and Curie,

Tc, temperatures can be evaluated (see

Figure 5).

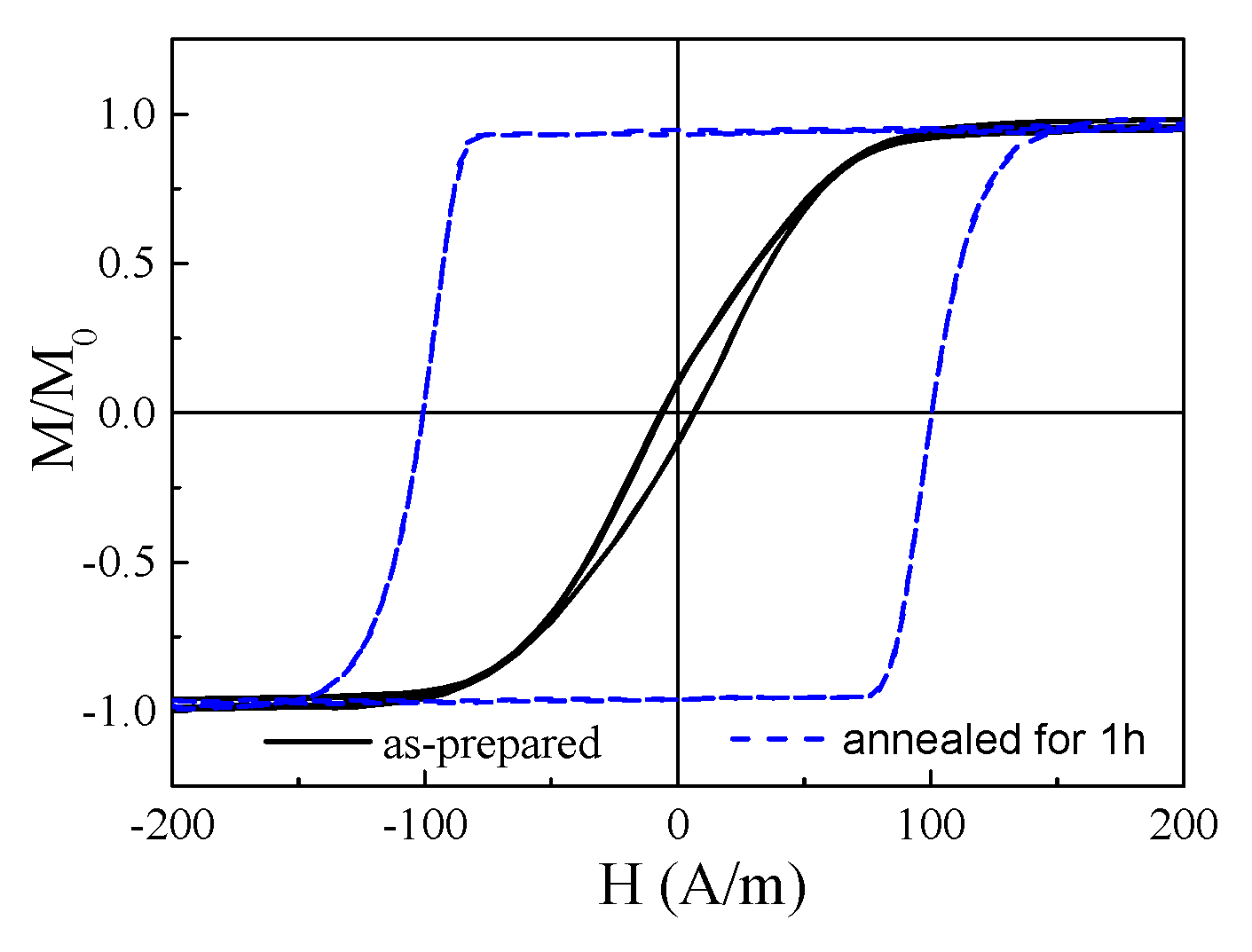

Accordingly, increase in Hc –value of Fe47Ni27Si11B13C2 sample must be related to different magnetoelastic anisotropy or fine structural rearrangements associated to annealing.

As mentioned in the introduction, in amorphous materials with vanishing λ

s, λ

s(σ) dependence can be relevant [

8]. Additionally, one of the main peculiarities of glass-coated microwires is the elevated magnetoelastic anisotropy,

Kme, related to the presence of glass-coating [

4,

7]. As discussed elsewhere [

4,

7],

Kme depends on the magnetostriction coefficient, λ

s, as well as on the total stresses,

σ =

σappl +

σi, (being

σappl and

σi as applied and internal stresses, respectively) as [

4,

7]:

It is commonly assumed that

λs -value and sign of amorphous materials are determined by the chemical composition of the alloys. Therefore, for the fixed composition of amorphous microwire it is expected that the annealing must be the common way allowing diminishing of

Kme and hence magnetic softening. However, even for the Fe

47Ni

27Si

11B

13C

2 microwire generally the opposite tendency is observed (see

Figure 6): some coercivity,

Hc, increasing is observed upon annealing at T

ann =410

oC. Selected

Tann is above Curie temperature,

Tc (

Tc ≈360

oC) and below the crystallization temperature,

Tcr (

Tcr ≈480

oC).

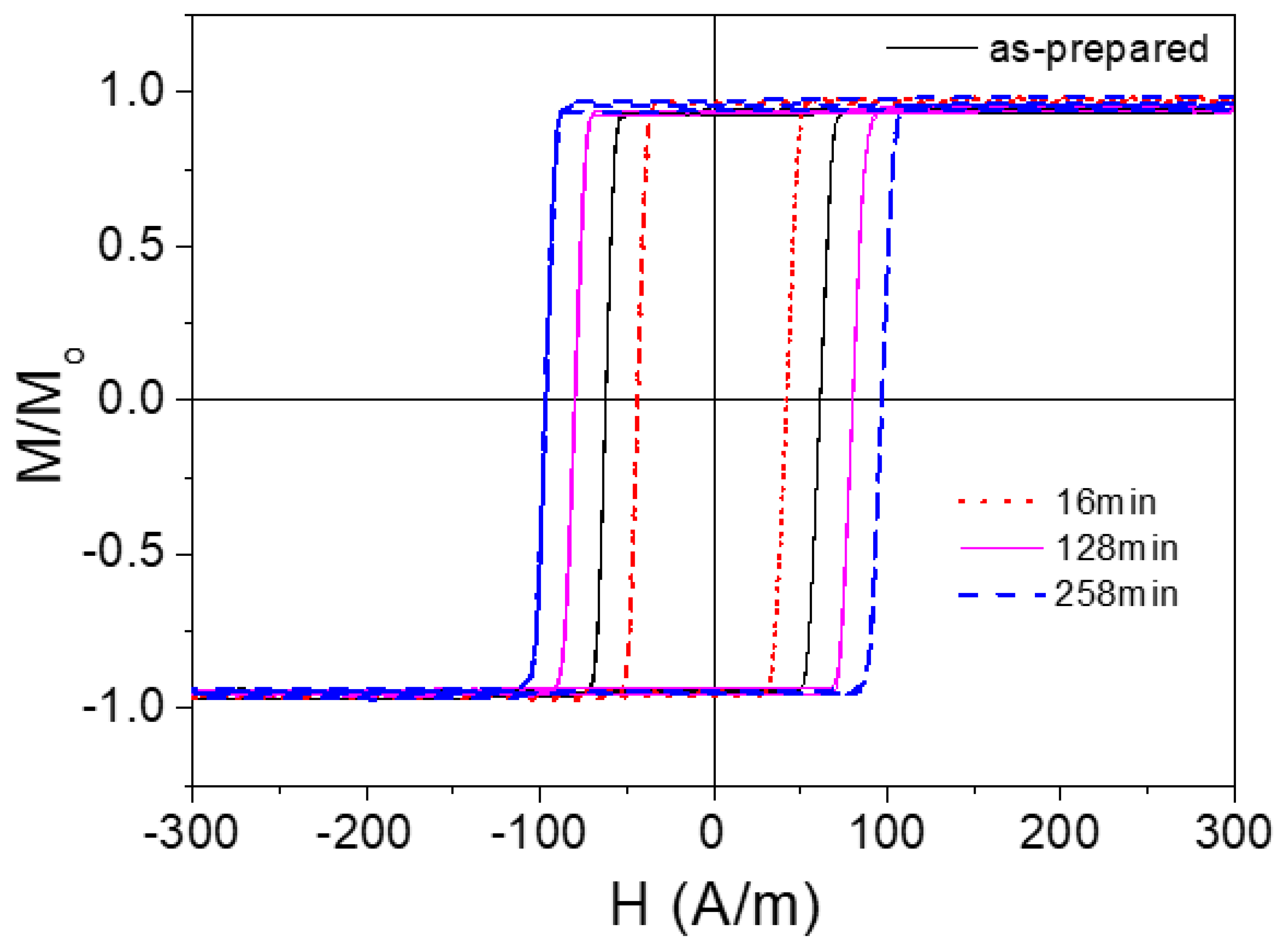

Similarly, substantial magnetic hardening is observed in Co

67Fe

3.9Ni

1.

5B

11.

5Si

14.5Mo

1.6 microwire after annealing (see

Figure 7). Similarly to Fe

47Ni

27Si

11B

13C

2 microwire, used

Tann >

Tc (

Tc ≈223

oC) and

Tann <

T Tcr (

Tcr ≈550

oC). The origin of magnetic hardening of amorphous materials upon annealing has been commonly discussed in terms of the directional ordering of atomic pairs or compositional and topological short- range ordering [39-43]. Accordingly, directional atomic pair ordering mechanism cannot explain observed magnetic hardening upon annealing of studied microwires.

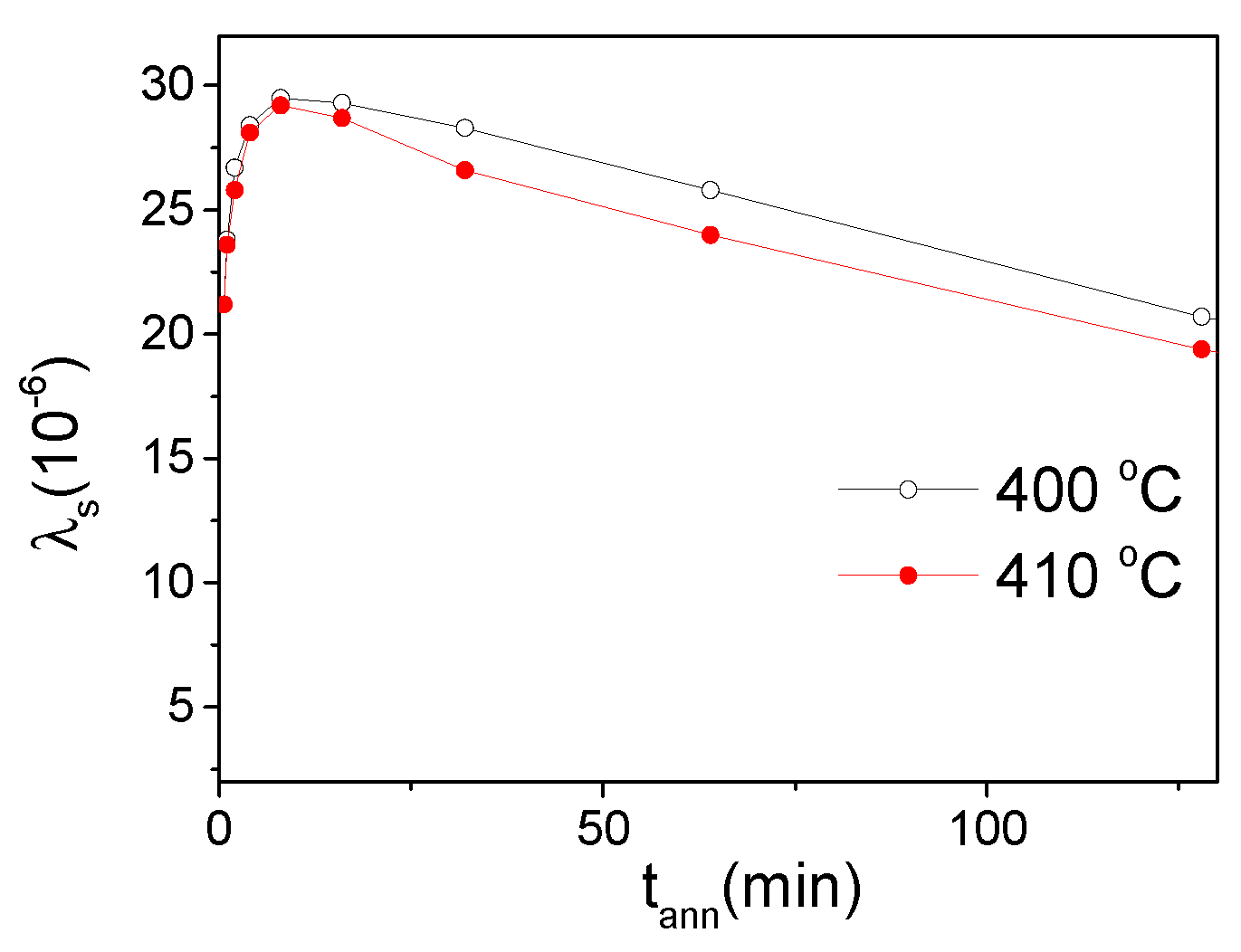

For better understanding of observed magnetic hardening of studied microwires upon annealing we analyzed the behaviour of

λs -value upon annealing. As can be appreciated from

Figure 8, an increase in

λs is observed in Fe

47Ni

27Si

11B

13C

2 microwire with annealing time,

tann, at

Tann>

Tc (

Tann =400 and 410

oC). Accordingly, some magnetic hardening of Fe

47Ni

27Si

11B

13C

2 microwire can be attributed to observed increase in

λs upon annealing.

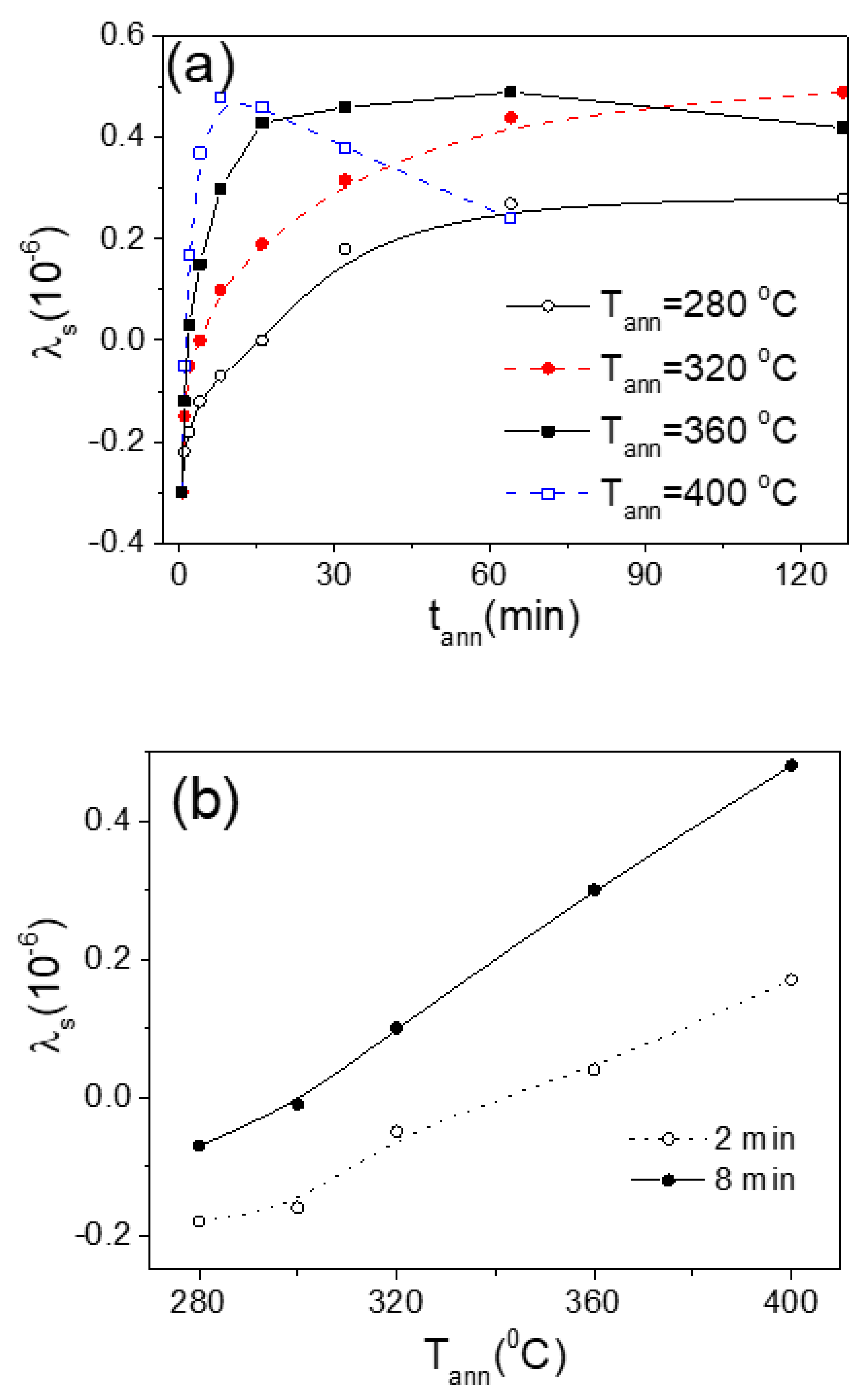

Similar tendency: an increase in

λs upon annealing is observed in Co

67Fe

3.9Ni

1.

5B

11.

5Si

14.5Mo

1.6 microwire (see

Figure 9): an increase of

λs –value is observed for all used

Tann. The most remarkable feature is that change not only

λs -value but also the sign upon annealing: after a few minutes of annealing

λs becomes positive. Such modification of

λs after annealing can explain the substantial change in the hysteresis loops of Co

67Fe

3.9Ni

1.

5B

11.

5Si

14.5Mo

1.6 microwire after annealing and magnetic hardening (see

Figure 7). As previously shown experimentally, magnetic hardening of Co-rich microwires after annealing is related to the change in domain structure consisting of increase of the volume of the inner axially magnetized core [4, 35].

Additionally,

λs is affected by both,

Tann and

tann (see

Figure 9 a,b)

. Temperature- time dependencies of various structural and magnetic parameters were previously discussed in terms of structural relaxation involving changes in the atomic short-range order [39-43]. As shown in

Figure 9b, an increase in

λs is affected by both

Tann and

tann. For

Tann <360

0C only an increase in

λs is observed for the whole measured

tann. However, for

Tann ≥360

0C an increase in

λs is followed by a decrease in

λs (see

Figure 9a). Similar influence of

Tann and

tann on

λs was previously reported for Co-Fe rich amorphous ribbons [

44] and quite recently in glass-coated microwires (but annealed at only one

Tann) [

45]. The appearance of the maximum on

λs(

tann) dependencies at elevated

Tann was explained by the contribution of two different processes [

44].

In the present case of glass-coated microwires, one of such processes must be associated with the internal stresses relaxation upon annealing. The other process must be related with aforementioned changes in in the atomic short-range order.

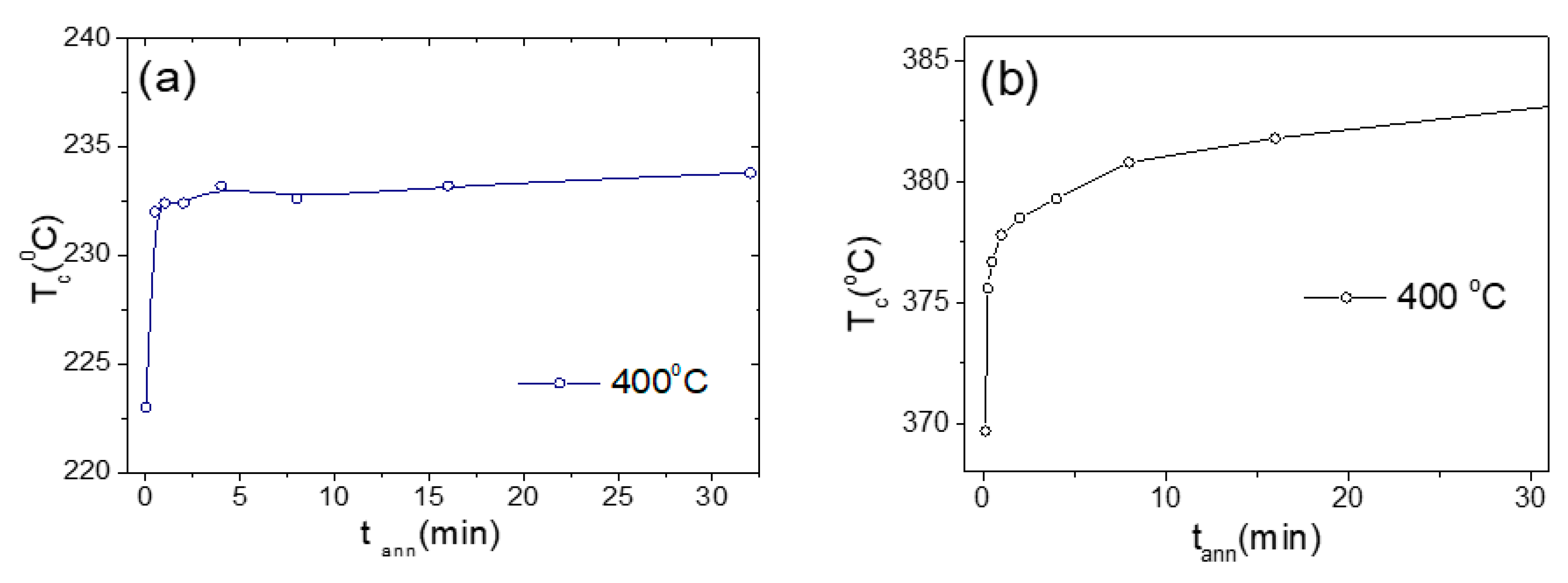

The Curie temperature,

Tc, is one of the most sensitive magnetic parameters to local structural rearrangements [46-50]. As shown in

Figure 10, substantial and monotonous increase in

Tc is observed for both studied microwires after annealing. Similar dependencies of

Tc upon annealing have been observed in various Fe-, Co- and Ni-rich amorphous alloys [46-48]. Such an increase in

Tc of amorphous alloys upon annealing has been commonly attributed to structural relaxation of amorphous alloys [46-48]. Since, the magnetostriction of amorphous alloys is linked to the local atomic order, such structural relaxation can be one of the origins of observed

λs evolution upon annealing.

From observed in

Figure 10 substantial

Tc(

tann) dependence, observed for both studied microwires, we can deduce that structural relaxation processes upon annealing occur in both studied microwires. The detailed description of various atomic mechanisms responsible for the changes in

Tc and other physical properties are provided elsewhere [

41,

42,

49]. Such mechanisms include diffusion of structural defects, topological and compositional short range atomic ordering and clustering [42,43, 49,50]. However, the determination of the local atomic structure in amorphous materials by direct methods is a long-standing problem in materials science. Most of the methods allow only average structural information. There are only very few direct observations of local atomic configurations of amorphous materials interpreted as the presence of clusters [

51,

52].

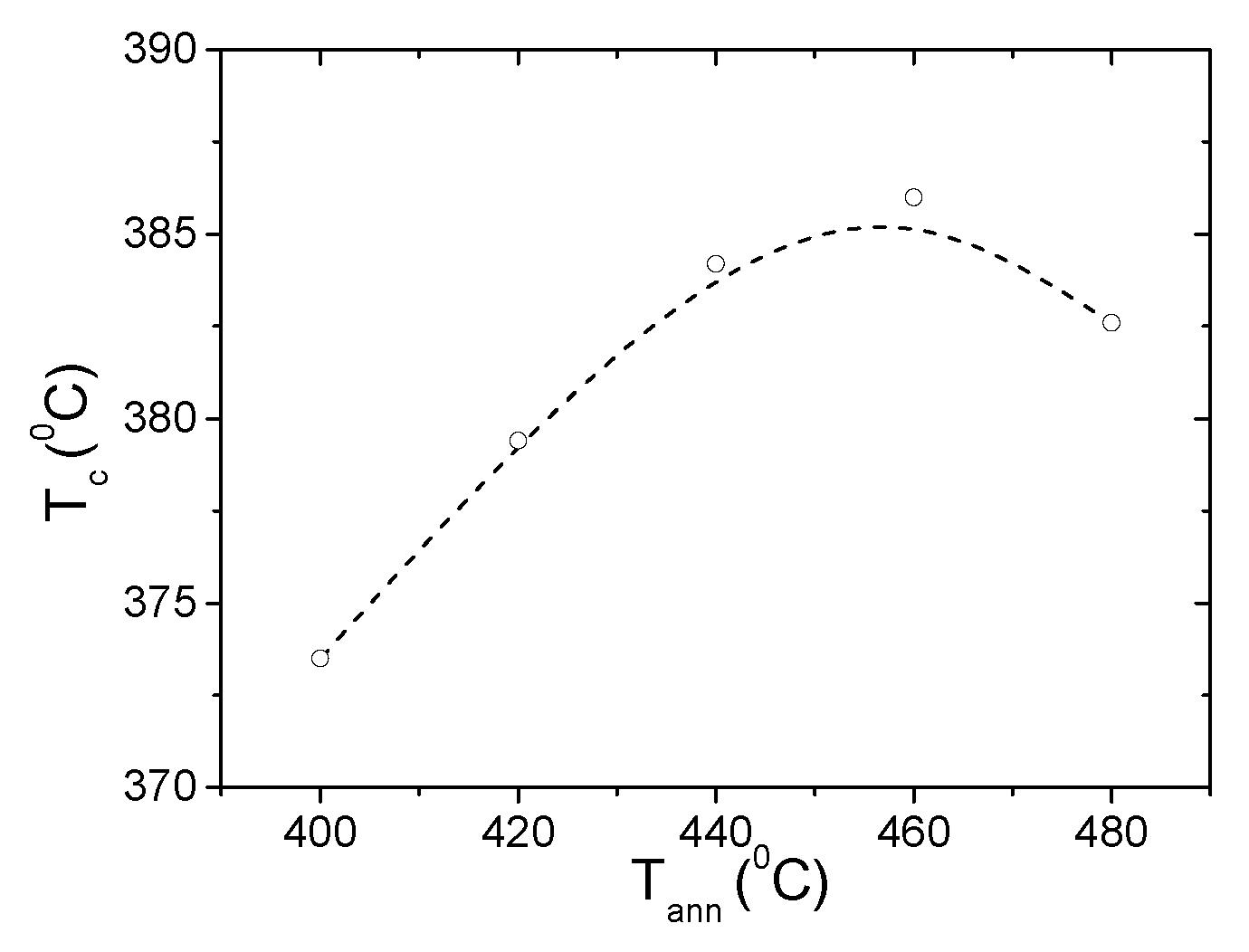

As mentioned above, one of the commonly involved mechanisms explaining magnetic hardening and magnetic field annealing induced anisotropy of amorphous materials with two or more ferromagnetic elements is atomic pairs ordering consisting of preferential reorientation of atomic pairs under the influence of the local magnetization [39-43,50]. Certainly, pair atomic ordering mechanism can be relevant for both studied microwires with the chemical composition consisting of more than two ferromagnetic elements. However, it is commonly assumed that such mechanism can be relevant for

Tann <

Tc. In the case of studied samples magnetic hardening is observed even upon annealing at

Tann >

Tc (see Figures 6,7). Provided in

Figure 11 dependence of

Tc on

Tann measured in the Fe

47Ni

27Si

11B

13C

2 microwire reflects the structural relaxation processes upon annealing at

Tann >

Tc and

Tann <

Tcr. Accordingly, various mechanisms previously discussed for amorphous alloys must be involved in observed dependencies of

Tc and

λs on annealing conditions.

On the other hand, structural relaxation should be also affected by the presence of mechanical stresses: transport processes including diffusion are affected by mechanical stresses [

53]. Thus, previously was reported that the devitrification process (in particular the

Tcr) and the structure of the crystalline phases are affected by the internal stresses produced by the glass-coating [

54,

55].

One of the peculiarities of glass-coated microwires is the composite structure and a higher level of internal stresses as-compared to the other amorphous materials associated with the presence of a glass-coating [6,13-17]. It is worth noting, that the internal stresses originated by the difference in the thermal expansion coefficients of metallic nucleus and the glass coating are the largest ones being an order of magnitude higher than the internal stresses related to the rapid melt quenching (typically present in conventional amorphous materials) [14-17]. Additionally, the internal stresses originated by the difference in the thermal expansion coefficients are mostly of tensile (axial) origin [14-17]. Therefore, the λs -value and stress-dependence can be rather different from conventional amorphous materials. Thus, one of the reasons for the λs modification upon annealing can be related to the internal stresses relaxation. Accordingly, we evaluated the stress dependence of λs in both studied microwires.

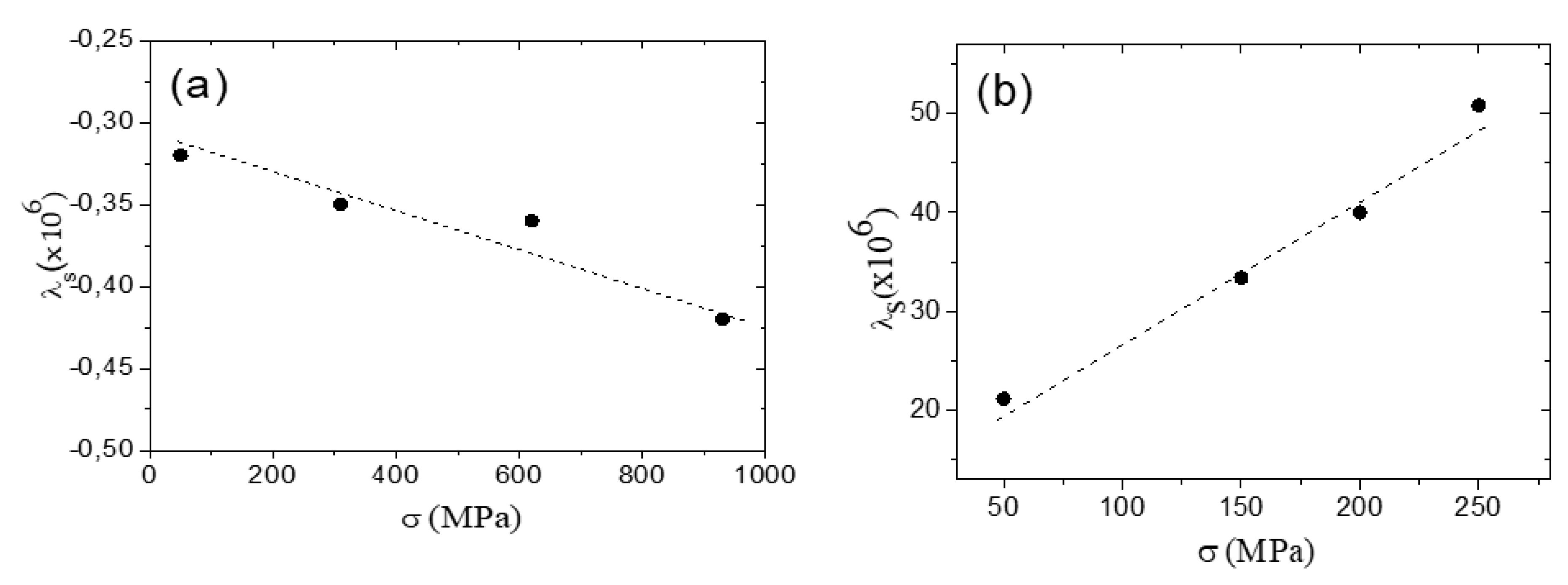

Similarly to Co-rich amorphous ribbons, a decrease in λ

s, well described as a linear λ

s(σ) dependence, is observed in Co

67Fe

3.9Ni

1.

5B

11.

5Si

14.5Mo

1.6 microwire (see

Figure 12a). Phenomenologically, observed λ

s(σ) dependence can be described by eq. (1) with a slope, B≈ 1.25 x 10

-7GPa, quite similar to the B-value, that was previously reported for Co-rich amorphous ribbons [

9].

A linear λ

s(σ) dependence, is also observed in Fe

47Ni

27Si

11B

13C

2 microwire, however an increase in λ

s is observed (see

Figure 12b). The value of B- coefficient, B ≈ -1.2 x 10

-5GPa is obtained for Fe

47Ni

27Si

11B

13C

2 microwire. Previously, negative but rather lower B-coefficient values were observed for annealed Co-rich amorphous materials with positive λ

s – values [

9]. However, recently an increase in λ

s upon application of tensile stress is also reported in Fe-Ni-rich microwires with positive λ

s [

45].

From observed λs(σ) dependencies we can assume that the internal stresses relaxation can explain only an increase in λs for Co67Fe3.9Ni1.5B11.5Si14.5Mo1.6 microwire and a decrease in λs for Fe47Ni27Si11B13C2 sample. Therefore, the processes involved in dependence of λs on thermal treatment conditions (Tann or tann) and on applied stress cannot be explained considering only elevated magnitude of internal stresses for studied microwires.

As mentioned above, the role of local atomic environments is essential for understanding of the magnetostriction coefficient and Curie temperature behavior in glass-coated microwires. Therefore, both internal stresses relaxation and structural (topological or compositional) relaxation upon annealing must be taken into account for interpretation of evolution of magnetostriction upon annealing and applied stresses. One more possible origin of λ

s(σ) dependencies in amorphous materials is so-called “morphic” effect, related to the variation of a saturation elastic constants with the magnetization direction [

56,

57]. However, the existence of such “morphic” effect is predicted for amorphous materials with nearly-zero λ

s –values [

56].

Most stress sensor applications ideally require materials that demonstrate significant reversible changes in magnetization when subjected to applied stress, while also exhibiting minimal magnetomechanical hysteresis. The dependence of magnetostriction on mechanical stress and annealing temperature can serve as a key starting point for determining the necessary treatment to use an adequate sensitive magneto-transport property, which is crucial for optimizing its sensitivity as a magnetostrictive stress sensor.