1. Introduction

The increasing global concern regarding environmental impact has spurred the formulation of governmental policies aimed at fostering effective waste management procedures. These policies play a pivotal role in diminishing the society's burden of pollutants. Consequently, there arises a pressing need to devise and refine waste recovery protocols, particularly in the domain of organic waste. This particular waste category has been recognized as a promising resource, capable of transforming into valuable substances facilitated by microorganisms. Against this backdrop, the current doctoral research project delineates a strategic blueprint for formulating a methodology centered around Digital Twins. This methodology is geared towards enhancing both production and service systems, with a specific focus on addressing existing and forthcoming challenges within the waste management sector, particularly in the context of organic waste recovery processes.

Incorporating the utilization of solid waste is integral to the formulation of strategies aimed at fostering a sustainable environment and society. This endeavor aligns with the overarching goals of the millennium objectives. In Colombia, the use of the putrescible fraction of municipal solid waste (MSW) has increased in recent years. In fact, according to ECLAC et al [

1], Roughly 12.9% of the total generated solid waste finds utilization within the country, amounting to approximately 3 kg per inhabitant per month. Among the available options, composting emerges as the predominant choice. Nonetheless, the efficacy of these processes faces challenges due to the nascent state of source separation procedures. Delving into the efficiency of composting processes, authors such as Vargas Pineda, Trujillo González, & Torres Mora [

2] carried out a series of experiences where they found that of all the organic matter disposed for composting, only 60% was transformed into compost, and the rest was emitted into the atmosphere in the form of water vapor and CO

2. The stated indicates why tools and methodologies to improve production systems and services such as Digital Twin should be sought.

Digital Twin is a burgeoning technology rooted in the concept of creating a virtual and dynamic replica of a physical object or system. This replication, enriched by data gleaned from real-world systems through sensors, allows for the capture of information and facilitates responses to a multitude of stimuli. The concept of Digital Twin is composed of a physical system in real space, a digital system in virtual space, and the connections that link the virtual space with the real one [

3]. Digital Twins offer concrete advantages to companies, not only by opening doors to novel revenue streams but also by aiding in addressing critical strategic queries. Leveraging the advancements in technology brings forth enhanced flexibility, agility, and cost efficiency, enabling companies to embark on their Digital Twin journey with reduced initial investment and quicker realization of value compared to previous possibilities. The pivotal consideration might not be whether to initiate the integration of Digital Twins, but rather where to commence to derive optimal value within the shortest feasible timeframe, all while maintaining a competitive edge in the market. What will be the first step and how to start the Digital Twin generation? [

4].

Numerous research initiatives underscore the significant role of Digital Twins in bolstering intelligent industrial systems, thereby contributing to a spectrum of decision-making processes. However, considerable resources and time are required to create a Digital Twin of a particular process [

5]. With the effective application of tools such as the Digital Twin, greater operating efficiency in composting processes is expected, as well as a decrease in processing times and in the amount of waste to be disposed of [

6]. The application of Digital Twin in Latin America offers important opportunities for a sustainable environmental development [

7].

Considering the comprehensive array of factors outlined earlier, this document aims to introduce a methodology for the implementation of Digital Twins. This proposed methodology encompasses the presentation of a definition, an architectural structure, and a framework for these components.

2. Materials and Methods

2.1. Digital Twins, Definitions and Characteristics

One of the cornerstone tools within Industry 4.0, hinging on simulation, is the Digital Twin. This technology emerges as a transformative force in the simulation and analysis of industrial processes, offering the potential to fully harness the advantages of digital plant transformation. Digital Twins are dynamic digital portrayals of devices and processes constituting a production or service workflow. They remain in active connection with the authentic system they replicate through the utilization of "Cyber-Physical Systems" (CPS). By integrating real-time data sourced from the operational plant, historical records of activities, and the application of Machine Learning methodologies, it becomes feasible to develop a meticulously accurate model. This model mirrors the behavior of the authentic system with a remarkable level of precision. [

8].

Digital Twins fabricate a virtual representation of a physical entity, orchestrating the simulation of the entity's behavior through data-driven techniques. They exhibit attributes including real-time synchronization, accurate correspondence, and elevated fidelity, facilitated by real-virtual feedback loops, fusion analysis of data, iterative decision-making for optimization. This framework fosters the synergy between the material realm and the realm of information, thereby amplifying or extending the capacities of the physical entity [

9]. Although the term "Digital Twin" was initially coined in the 1970s, its contemporary connotation traces its roots to a pivotal presentation by Michael Grieves in 2002. Grieves expounded on how a virtual rendition of a product could profoundly contribute to the adept management of the product's life cycle [

9].

Seventeen years have elapsed since Dr. Grieves introduced the term in 2003, and the past five years have borne witness to the swift evolution of the Digital Twin concept. Nevertheless, until recently, a standardized definition and a universally embraced creation and implementation process remained absent. Distinct industries and various fields of application have adopted diverse viewpoints and methodologies. Through meticulous examination, it becomes evident that the Digital Twin is progressively transitioning from its nascent phase to a period of rapid advancement. Researchers are now delving into practical applications and technological facets within the industrial domain.

The original vision that set out to fully understand and reflect every aspect of the physical twin still has a long way to go. The fields of application of the Digital Twin are widely distributed, showing great vitality [

10]. In fact, Authors such as Jia et al. [

11] carry out a bibliographical review where it is shown that a standard definition of Digital Twin has not yet been reached, but rather multiple definitions according to the general vision of the authors; A summary of these definitions is presented below:

Table 1.

Some definitions and reference models of the Digital Twin1.

Table 1.

Some definitions and reference models of the Digital Twin1.

| Author |

Proposed definition |

| Grieves et al [12] |

The Digital Twin is a set of virtual information constructs that fully describes a potential or actual physical product manufactured from the micro atomic level to the macro geometric level. |

| Tao et al [13] |

The Digital Twin combines the physical entity with the high-fidelity virtual counterpart and the two parts of the business with each other throughout the life cycle, it also integrates and converges data from multiple sources to generate a more accurate and complete information. |

| Zhuang et al. [14] |

The Digital Twin refers to the process and method of describing and modeling the characteristics, behavior, formation process, and performance of physical entity objects using digital technology. |

2.2. Waste management

The environmental problem caused by inadequate waste management and deficient disposal of solid waste has acquired great importance within government policies in recent years [

15]. Considering this context, comprehensive Solid Waste Management Plans (SWMPs) have been devised and enacted by local environmental authorities. This document encompasses a multitude of essential policies, among which is the imperative to conduct waste classification procedures for materials generated by the community. This sorting process is crucial to ensure proper disposal aligned with the specific waste type and its potential for utilization.

In addition to the considerations, pinpointing the utilization mechanisms of organic waste necessitates a meticulous selection procedure. This task is not always performed by the cleaning companies that secure contracts for waste disposal in individual cities. It becomes imperative, however, to introduce strategies aimed at fostering a culture of recycling and source separation. These strategies must, in turn, be intertwined with a feasible management program catering to distinct waste categories [

16].

The consumption and production processes are directly related to the generation of solid waste [

17]. Alcides J. Padilla and Juan C. Trujillo [

18] reveal that only 3.6% of Colombians perform recycling. Comparatively, this level of recycling at source is below that of a middle-income country such as Brazil, which reached 7.3% in 2006, and even below lower-middle-income countries such as the Philippines, which in 2006 reached a percentage of 28% and Malaysia that reached a percentage of 9% in 2012; However, in recent years Malaysia has experienced a progressive growth in recycling and source separation, projecting a rate of 25% by 2020 Trujillo [

18].

Population growth has generated an increase of waste generation in the country. The production of organic solid waste per inhabitant is around 0.7 kg/families per day [

19]. generating an environmental problem. In this regard, it is stated that the direct causes of the origin of the environmental problem of solid waste can be specified in: (i) the concentration of the population in cities; (ii) industrialization that favors the appearance of durable materials, and (iii) new consumption habits [

20]. For this reason, the sustainable management of municipal waste is necessary in the impact phases such as planning, design, operation and closure of places and disposal sites.

In Colombia, 11 million tons of solid waste are produced per year [

21] and by weight, 65% of all the waste that’s generated corresponds to organic solid waste [

22].

In the Latin American context, the coverage and quality of solid waste management is lower than the provision of other services, since in most countries there are no public policies and national plans for solid waste management. On average, in some cities in the region 70% of all the waste produced is collected (50-70% in small cities and 85-90% in large ones), which indicates that 30% of the waste produced is not collected. This could represent between 20 and 25 million tons a year that end up in the streets, clandestine dumps, and water sources.

2.3. Methodological development

Throughout Colombia's history, waste management practices have predominantly revolved around recycling, serving as a means for families without alternative avenues to secure income. This underscores the largely manual and craft-based nature of these processes, leading to substantial challenges in their ultimate disposal. However, there exist industrial procedures capable of bestowing added value upon waste, exemplified by the production of organic fertilizers.

Technological tools are ever-present, consistently reshaping the way various activities are conducted, influencing societal perceptions of reality and modes of communication. Manufacturing is not exempt from these technological advancements. In fact, the emergence of Industry 4.0 is a testament to this phenomenon. Industry 4.0 is ushering in a wave of fresh paradigms that are redefining manufacturing practices and service delivery norms. The industry 4.0 has been considered a new industrial stage in which various emerging technologies are converging to provide digital solutions [

23]. This global transformation entails a process of digital integration and intelligent engineering, representing the evolution towards the next echelon of manufacturing. In this new phase, machines are poised for redefinition in terms of their communication abilities and their execution of distinct functions [

24].

Industry 4.0 tools, including the Digital Twin, provide a profound capacity to delve into the internal dynamics of various systems. They illuminate the intricate interplay between different components within the system and even project the future behavior of the corresponding physical entity. Importantly, these insights are not just informative but also actionable, thereby benefiting stakeholders, users, and other parties invested in the system [

7]. The augmented understanding of system operations, coupled with the ongoing accumulation of data, culminates in heightened efficiency within production processes. This perpetual feedback loop propels these processes to an elevated tier of intelligence, ushering in a new era of sophisticated operations.

Following this overarching overview, specific inquiries of critical examination come to the forefront, such as:

Is the incorporation of Digital Twin technology conducive to enhancing the efficiency of organic waste management processes?

What challenges do structural components like sensors, servers, and other technological tools pose for the implementation of Digital Twins, particularly in smaller industries?

Can a methodology be devised that mitigates the expenses associated with implementing Digital Twin prototypes?

To what extent can the integration of Digital Twins be realistically achieved in waste recovery processes, considering their predominantly manual nature?

These and related questions will progressively emerge throughout the research endeavor, serving as guiding beacons to steer this academic exploration toward the accomplishment of the proposed objectives.

Considering the context outlined above, various variables come into play that could impact the feasibility of implementing Digital Twins in production processes. Some of these variables are contingent upon the social and technological landscape specific to the region. Understanding these relationships is of paramount significance for the analysis and formulation of a Digital Twin application methodology.

Consequently, the overarching goal of this research process can be summarized as follows:

To formulate a methodological framework for the implementation of Digital Twins, with the intention of enhancing production and service systems, particularly within the context of the waste management industry.

To evaluate the feasibility and effectiveness of this proposed methodology in areas characterized by high population density.

Considering the objectives stated above, the following general research hypothesis has been posited:

“With the development and application of a comprehensive methodology for the integration of Digital Twins into the processes involving the utilization of organic waste in Colombia, it is possible to enhance the efficiency of these processes, quantifiable through various Key Performance Indicators (KPIs).”

In the results section of this research, a proposal for the definition of Digital Twins is presented. Drawing from the unique characteristics of Digital Twins within the realm of improving production systems and services, particularly those associated with organic waste utilization, an architectural framework, a conceptual structure, and a practical methodology are developed to facilitate their practical application.

3. Results

3.1. Digital Twin Definition

Despite its conceptual origins dating back to the 1970s, there has been an absence of a formal or universally accepted definition, along with a standardized creation and implementation process for Digital Twins. Various industries and fields of application have crafted distinct definitions, viewpoints, and methodologies that align with their specific application contexts. This divergence underscores the diverse and evolving nature of Digital Twins as a concept [

10]. In light of this situation, it becomes pertinent to craft a comprehensive and meticulously structured definition of Digital Twins. Such a definition should encompass the distinctive features of the application context, capture methodological nuances, and yield a comprehensive vision of its overarching framework. This effort aims to provide clarity and coherence in understanding the multifaceted nature of Digital Twins.

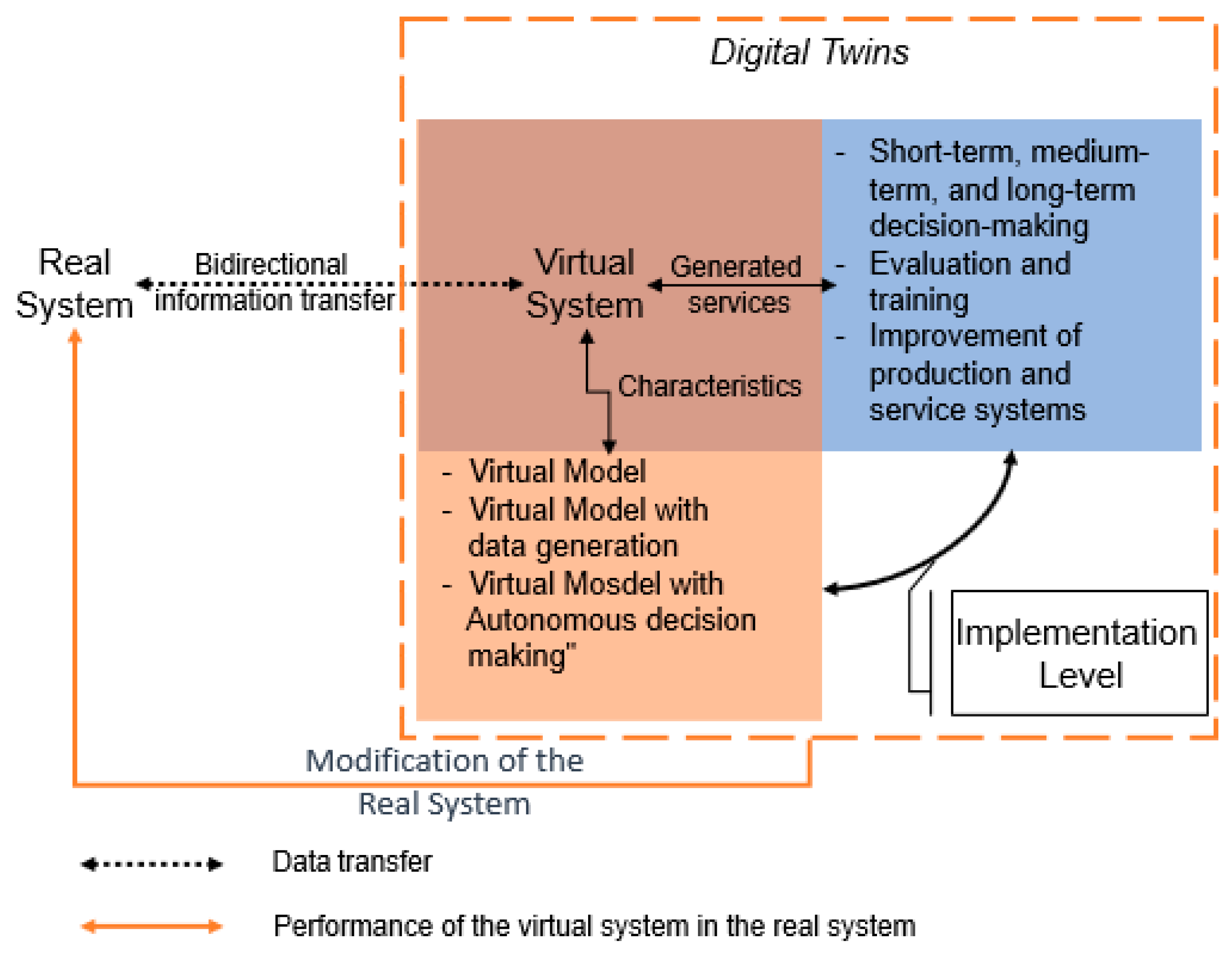

A Digital Twin is a dynamic method for creating a real-time representation of an actual system that continuously interacts with and provides feedback from the real-world system. It harnesses a suite of technologies, including autonomous learning tools, Data Mining, sensors, and other components inherent to Industry 4.0, to generate proactive and predictive insights from real systems in a virtual space. The utility of a Digital Twin can vary based on its level of implementation and the predefined objectives. It can serve as a decision-making tool spanning short, medium, and long-term horizons, function as an assessment and training instrument, or emerge as a pivotal resource for optimizing production systems. A proposed schematic definition of Digital Twins is shown in

Figure 1.

Indeed, the development of a Digital Twin should be methodically planned, adhering to essential project management principles. Much like in the simulation of discrete events, the application of a Digital Twin should not be haphazard; rather, it necessitates careful deliberation based on several critical factors. These considerations encompass an in-depth understanding of the study system and an assessment of the problem's significance in relation to the potential solutions offered by this tool.

Building upon the previously discussed concepts, it can be affirmed that virtually every real system can find its counterpart in the virtual realm. This connection is established through the unidirectional transfer of information (data) at its fundamental stage or evolves into a bidirectional relationship at its most advanced state. The virtual counterpart, or Digital Twin, exhibits specific characteristics and offers services that correspond to the level of implementation. This spectrum can range from a basic virtual replica to a sophisticated intelligent decision-making system, driven by the continuous generation and acquisition of data. The chosen level of implementation is intricately tied to the predefined objectives established during the methodological application of the Digital Twin.

At a more advanced level of development of a DT, it can be used to make decisions and to modify the real system, therefore generating a feedback loop that is predictive and constant, as well as improving the studied systems; All of which is dependent on the level of implementation and the objectives of the Digital Twin itself that is to be developed.

3.2. Architecture and Framework

Considering the substantial volume of data generated through the interaction between the physical twin and its virtual counterpart, it becomes imperative to establish a set of mechanisms to facilitate effective information management. The architecture supporting this process encompasses an extensive array of tools, processes, models, and mechanisms designed specifically for efficient data handling and management. This comprehensive framework is essential for ensuring that the wealth of information generated is effectively utilized and harnessed for the intended purposes.

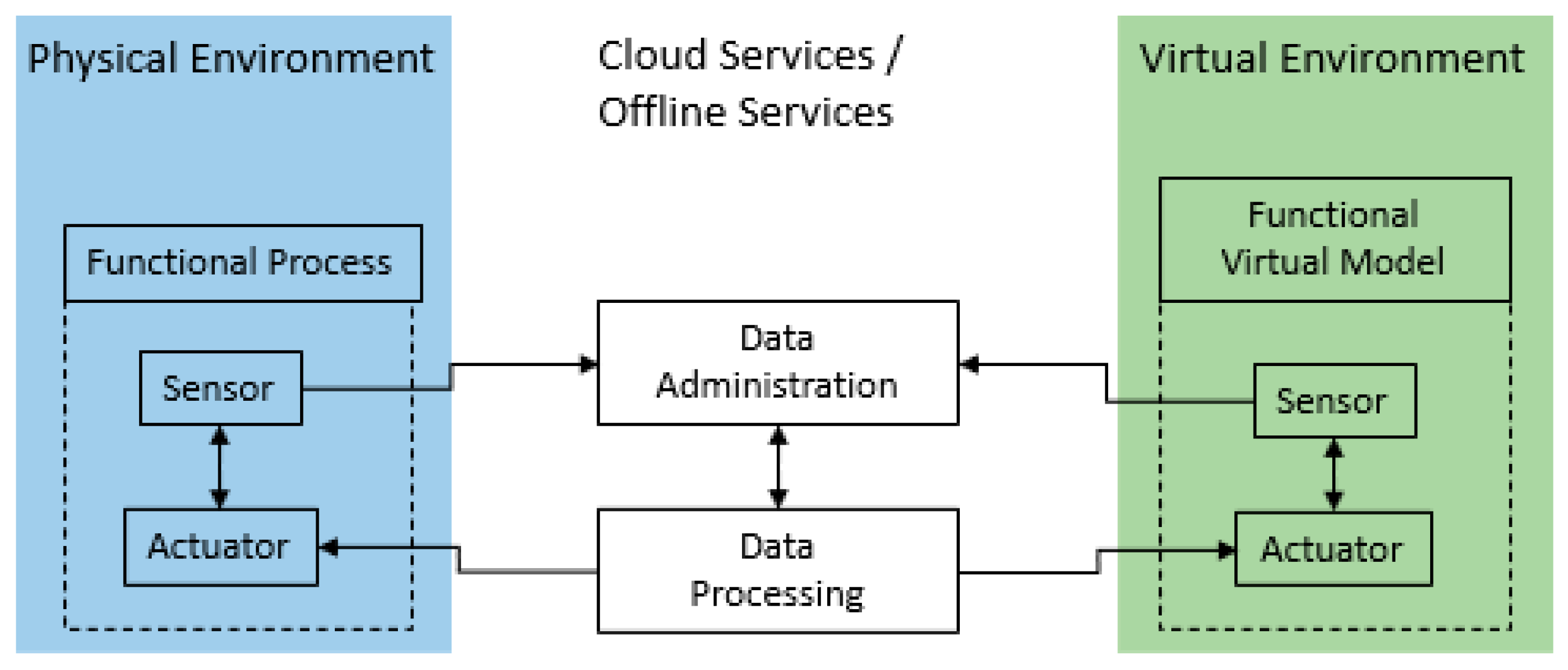

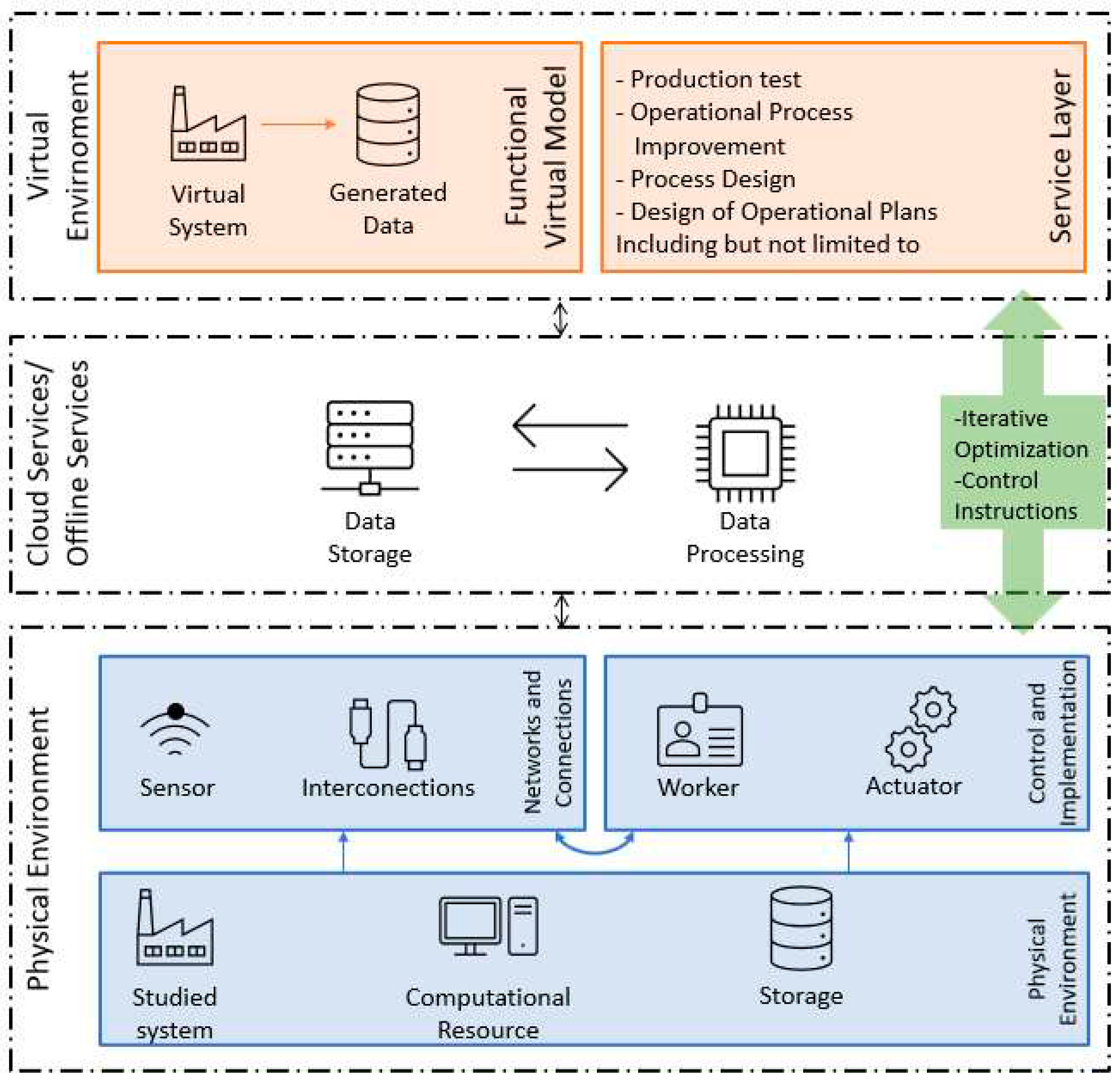

The proposed architecture is structured around three fundamental layers, each serving distinct roles in the Digital Twin framework. These layers consist of:

Physical Environment Layer: This layer deals with the representation of the actual, physical system. It encompasses structural and functional elements that articulate the underlying processes, capture data from the physical system, and execute actions based on the data processed and collected.

Virtual Environment Layer: In contrast, the virtual environment layer mirrors the real-world system in a digital realm. It too comprises structural and functional components that describe the system's processes, capture data from the virtual representation, and undertake actions based on the processed and collected data.

Communication and Data Transfer Layer: This layer facilitates the seamless exchange of data between the physical and virtual counterparts. It plays a pivotal role in ensuring that data flows efficiently between the two environments, enabling them to stay synchronized and responsive to changes in real-time.

Figure 2.

Proposed architecture.

Figure 2.

Proposed architecture.

The proposed Framework is intricately rooted in the architecture delineated earlier, comprised of three fundamental elements: the physical environment, the virtual environment, and the online and offline services responsible for information processing.

Initially, data from the real-world system is gathered through a combination of sensors and manual inputs. Subsequently, this information undergoes storage and processing using various logical-mathematical tools. These processed data are then modeled and utilized within the virtual system. Importantly, this feedback loop allows information from the virtual system to influence and optimize the performance of the real system, thereby enhancing its overall functionality. This iterative process forms the core of the Framework's operations.

Figure 1.

Digital Twin framework proposed for the improvement of production and service systems.

Figure 1.

Digital Twin framework proposed for the improvement of production and service systems.

3.3. Methodological proposal

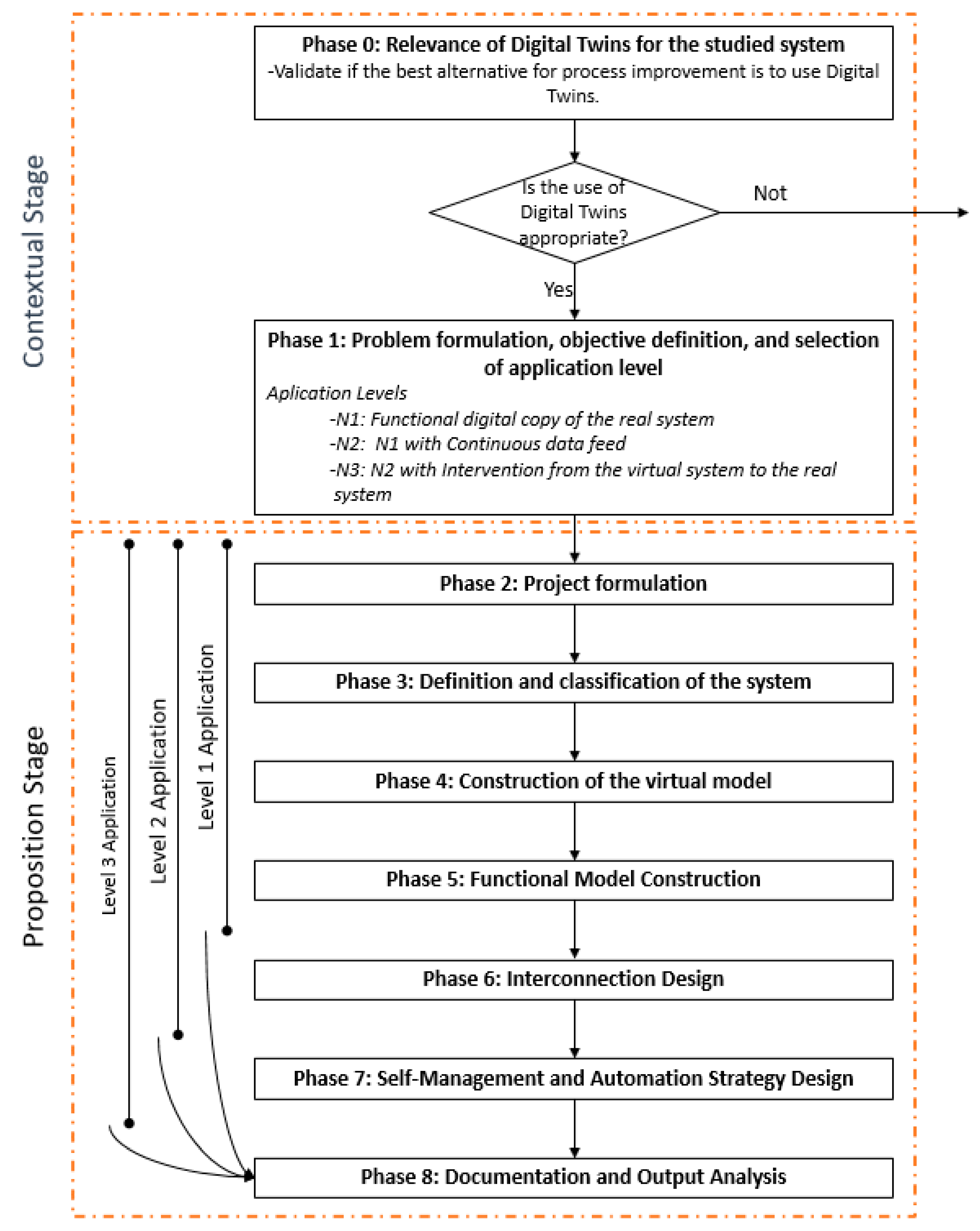

The proposed methodology comprises a series of pivotal phases for the creation of Digital Twins. It commences by establishing the significance of this tool, progressing through the structured definition of objectives and sought-after services. The process culminates in the development of a functional Digital Twin that aligns with the predetermined project objectives and services, as illustrated in

Figure 4.

Figure 4.

Methodological proposal developed for the implementation of Digital Twins.

Figure 4.

Methodological proposal developed for the implementation of Digital Twins.

The proposed methodology is structured into two distinct stages: the contextual stage and the purposeful stage.

In the contextual stage, the primary aim is to formulate the project for applying and implementing Digital Twins. This phase encompasses several crucial steps:

Defining Relevance: The initial step involves establishing the significance of employing a Digital Twin for the specific application case at hand.

Problem Formulation: Next, it becomes essential to articulate the problem clearly. The objectives and the level of application and implementation are contingent upon the precise understanding of the problem.

The purposeful stage is delimited by the predetermined level of application, which, in turn, hinges on the objectives set during the contextual stage. This methodology posits three levels of application:

Level 1 - Digital Copy: The simplest level involves the creation of a digital replica of the real system.

Level 2 - Constant Data Feed: The second level introduces increased complexity by continuously receiving data from the actual system.

Level 3 - Real-Virtual Interaction: At the highest level, a distinctive feature emerges: the virtual system intervenes in the operation of the real system, forming a closed loop of information and action.

The purposeful stage initiates during the project formulation phase and progresses through several phases:

System Evaluation and Classification: The first step is to assess and classify the system under study.

Project Phase: This phase involves detailed project planning and design.

Virtual System Construction: Subsequently, a virtual system is constructed, and a functional model is integrated to replicate the real system's behavior.

Integration of Real and Virtual Systems: The integration of the virtual and functional system is achieved. This integration enables the design of interconnections between the real and virtual systems.

Self-Management and Automation Strategies: Finally, self-management and automation strategies are proposed, closing the feedback loop. These strategies allow for the analysis of generated information concerning the operation, functioning, and enhancement of the studied system.

While the results presented in this document focus on systems related to organic waste management, it's important to note that the methodology's principles and general framework have the potential to be applied to any production process that is amenable to improvement and optimization.

4. Conclusions

In this article, a comprehensive methodology for the implementation of Digital Twins in the field of waste management has been presented, specifically focusing on improving production and service systems. The urgent need to address current challenges in urban solid waste management, particularly about organic waste, has been emphasized, given the growing urban population and the inadequacy of current practices.

Research has demonstrated that Digital Twins technology, within the context of Industry 4.0, can play a pivotal role in optimizing waste management processes. Digital Twins offer the ability to create real-time virtual representations of physical systems, facilitating simulation, experimentation, and informed decision-making. This is essential for enhancing the efficiency of waste management processes and addressing challenges related to organic waste management.

A significant contribution of this article has been the proposal of a comprehensive definition of Digital Twins that underscores their capacity to generate proactive and predictive insights from real systems in a virtual space. Additionally, a three-layer architecture for Digital Twins has been presented, encompassing the physical environment, the virtual environment, and the data communication and transfer layer. This architecture provides a solid foundation for the effective management of information generated by Digital Twins.

The proposed methodology has been divided into two stages, the contextual stage, and the specific-purpose stage, offering a structured approach to implementing Digital Twins. This methodology has the potential to significantly enhance waste management processes, particularly in densely populated areas.

Ultimately, a research hypothesis has been formulated positing that through the development and application of this comprehensive methodology for integrating Digital Twins into processes involving organic waste in Colombia, it is possible to improve the efficiency of these processes, which can be measured through various key performance indicators (KPIs).

As areas for future research, the article suggests conducting comparative analyses, exploring the integration of machine learning and artificial intelligence, evaluating the scalability of the methodology, and applying Digital Twins in critical real-time decision-making situations. Collectively, this article makes a valuable contribution to the field of waste management and the application of Digital Twins technology in this context.

5. Future work

For future research endeavors, the following avenues are recommended:

Comparative Analysis: Conduct a comparative study to assess the proposed methodology against similar approaches. This can provide valuable insights into the strengths and weaknesses of different methodologies.

Machine Learning and AI Integration: Explore the incorporation of machine learning and artificial intelligence techniques into the methodology. These advanced technologies can enhance the capabilities of Digital Twins and contribute to more robust decision-making processes.

Scalability Assessment: Evaluate the scalability of the methodology to determine its effectiveness in handling larger and more complex systems or scenarios. Under-standing the limits of its scalability can guide its application in various contexts.

Real-Time Critical Decision-Making: Investigate the application of Digital Twins in critical decision-making situations in real-time. Assess how Digital Twins can contribute to swift and informed decision-making in high-stakes scenarios.

These future research directions can help further refine and expand the applicability of the proposed methodology for Digital Twins in diverse contexts and applications.

6. Acknowledgments

The authors would like to express their sincere gratitude to Universidad Nacional de Colombia campus Manizales, for their support and resources in conducting this re-search. We also wish to thank the Faculty of Engineering and Architecture for their support of the doctoral program in Industrial Engineering and Organizations. This article is part of the doctoral thesis entitled "Methodological Proposal for Improving Production and Service Systems in the Waste Industry through the Use of a Digital Twin. Application in High-Population Density Areas," developed within the framework of the doctoral program. We are grateful to the Ministry of Science, Technology, and Innovation for their financial support of this research, and to all participants and collaborators who made this study possible.

Furthermore, we would like to acknowledge that this article derives from the presentation titled "Digital Twin application methodology for the improvement of production and service systems. Application to waste management processes" at the "Sustainable Smart Cities and Territories International Conference" held in the city of Manizales, Colombia, from 21st to 23rd June 2023. We are thankful to the conference organizers for providing us with the opportunity to share our research findings with the academic community at this esteemed event.

References

- Comisión Económica para América Latina y el Caribe (CEPAL), Departamento Nacional de Planeación (DNP), Compromiso Empresarial para el Reciclaje (CEMPRE) Colombia, «Encuesta A Municipios Sobre Gestión De Residuos Sólidos Domiciliarios 2019 Colombia,» CEPAL, Bogotá, 2021.

- Vargas Pineda, O. I.; Trujillo González, J. M.; Torres Mora, M. A. El compostaje, una alternativa para el aprovechamiento de residuos orgánicos en las centrales de abastecimiento. Orinoquia 2019, 23. [Google Scholar] [CrossRef]

- M. Grieves, «Digital Twin: Manufacturing Excellence through Virtual Factory» White paper Michael W. Grieves, LLC. Dassault Systeme., pp. 1-7, 2014.

- Parrott y L. Warshaw, «Industry 4.0 and the digital twin, Manufacturing meets its match» About Deloitte University Press, 2017.

- Gao, Y.; Chang, D.; Chen, C.-H.; Xu, Z. Design of digital twin applications in automated storage yard scheduling. Advanced Engineering Informatics 2022. [Google Scholar] [CrossRef]

- Marmolejo, L. F.; Oviedo, É. R.; Jaimes, J. C.; Torres, P. Influencia de la separación en la fuente sobre el compostaje de residuos sólidos municipales. Agronomía Colombiana 2010, 28, 319–328. [Google Scholar]

- Botín-Sanabria, D.; Mihaita, A.-S.; Peimbert-García, R.; Ramírez-Moreno, M.; Ramírez-Mendoza, R.; Lozoya-Santos, J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022. [Google Scholar] [CrossRef]

- Instituto Tecnológico de Informática, «DIGITAL TWINS: Gemelos Digitales en la transición a la Industria 4.0,» 20 Octubre 2018. [En línea]. Available online: https://www.iti.es/proyectosidi/proyecto-gemelos-digitales-industria-4-0/.

- Li, L.; Lei, B.; Mao, C. Digital twin in smart manufacturing. Journal of Industrial Information Integration 2022. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. Journal of Manufacturing Systems 2021, 346–361. [Google Scholar] [CrossRef]

- Jia, W.; Wang, W.; Zhang, Z. From simple digital twin to complex digital twin Part I: A novel modeling method for multi-scale and multi-scenario digital twin. Advanced Engineering Informatics 2022. [Google Scholar] [CrossRef]

- M. Grieves y J. Vickers, «Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems» de Transdisciplinary Perspectives on Complex Systems, Berna, Springer, 2017, pp. 85-113.

- F. Tao y M. Zhang, «Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing» IEEE, p. 20418–20427, 2017.

- Zhuang, C.; Liu, J.; Xiong, H.; Ding, X.; Liu, S.; Weng, G. Connection, architecture and trends of product digital twin. Comput. Integr. Manuf. Syst. 2017, 23, 753–768. [Google Scholar]

- E. F. Avendaño Acosta, Panorama actual de la situación mundial, nacional y distrital de los residuos sólidos. Análisis del caso Bogotá D.C. Programa basura cero, Bogotá D.C., 2015.

- L. Rodríguez Gutiérrez, «La generación de residuos orgánicos en Cundinamarca y sus mecanismos de aprovechamiento en la generación de energías limpias» Universidad Cooperativa de Colombia, 2020.

- Pandey, R. S. A. K. M. Exploring linkages between sustainable. Journal of Cleaner Production 2017, 49–59. [Google Scholar]

- Padilla, A. J.; Trujillo, J. C. Waste disposal and households’ heterogeneity. Identifying factors shaping attitudes towards source-separated recycling in Bogotá, Colombia. Waste Management 2018, 74, 16–33. [Google Scholar]

- Torres, S.C.; Miranda, J.P.R. Modelo de aprovechamiento sustentable de residuos sólidos orgánicos en Cundinamarca, Colombia. Univ. Salud 2017, 19, 116. [Google Scholar] [CrossRef]

- C. Montes Cortés, Estudio de los residuos sólidos en Colombia, Bogotà D.C.: Universidad Externado de Colombia, 2018.

- WWF, «¿Por qué seguimos sin reciclar en Colombia?,» 17 Mayo 2022. [En línea]. Available online: https://www.wwf.org.co/?363591/Por-que-seguimos-sin-reciclar-en-Colombia.

- DANE, «Cuenta ambiental y económica de flujos de materiales – residuos sólidos 2017-2018,» Bogotá, 2020.

- Frank, A. G.; Santos Dalenogar, L.; Ayala, N. F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. International Journal of Production Economic 2019, 15–26. [Google Scholar] [CrossRef]

- Muhuri, P. K.; Shukla, A. K.; Abraham, A. Industry 4. Engineering Applications of Artificial Intelligence 2019, 218–235. [Google Scholar] [CrossRef]

- K. Alam y A. El Saddik, «C2PS: A Digital Twin Architecture Reference Model for the Cloud-Based Cyber-Physical Systems» IEEE, p. 2050–2062, 2017.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).