Recently, studies of persimmon fruits have mainly focused on their biophysiological functions, including antioxidant, lipid-lowering, prevention of atherosclerosis, antitumor and antiviral activity [

1,

2]. Despite this, thousands of tons of persimmon fruits are thrown away annually due to large production volumes, high quality standards and consumer expectations related to shape, size and color [

3]. In addition, persimmon has a limited shelf life; it is a seasonal fruit that is perishable and difficult to store and transport [

4,

5]. It is usually hard during harvesting, but after a week or two of storage under normal conditions it becomes hard and soft; the more time passes, the more difficult it becomes to hold it in your hands [

6]. This is reflected in the total number of post-harvest losses, which can reach 20% of the total annual volume of its production [

7,

8].

Poor post-harvest processing, microbial contamination and high respiratory rate are some of the factors responsible for the short shelf life of perishable products. Therefore, effective preservation of these goods is necessary in order to reduce damage and extend the shelf life.

Preservation is considered as an action exerted on a perishable commodity to preserve its consumer properties for a long time [

9].

Currently, the available opportunities for involving surplus persimmons as raw materials for the production of canned products, including products that can be obtained as a result of its drying, are being intensively studied.

In this review, we aim to compile an updated and brief overview of the potential use of persimmons in the development of products from its drying.

Natural drying of persimmons

Dehydration of persimmons in the air is the oldest and easiest way to dry persimmons; it is finished at a humidity of about 50% (when semi-dry persimmons are obtained) or it is carried to a water content of 35% and below [

10,

11].

The production and consumption of semi-dried (dried) persimmons is traditionally in Asian countries, such as South Korea, China and Japan, with various processing methods to obtain a new high-quality and stable product with good sensory properties [

12,

13].

In Azerbaijan (and neighboring Georgia), ripe hard fruits are taken for drying persimmons in this traditional way. They are carefully peeled off without affecting the stems, for which they are then tied with strong threads so that they do not touch each other. Ready-made "garlands" are suspended under a canopy (

Figure 1 A). Some manufacturers, during drying, periodically slightly crush the fruits with their fingers to give a better shape and accelerate the appearance of sugar plaque (

Figure 1 B). It takes about a month to dry the fruits, but sometimes they are left hanging on a string until March.

Bundles of dried persimmon tied with threads (

Figure 1) are sold in the markets in Georgia at a fairly low price - from 3.5 lari (

$1.1) per 1 kg. However, the prices for dried persimmon without seeds (which is made from the "Khachiya" variety) are twice as high, they start from 7.5 lari (

$ 2.3) per 1 kg. For comparison, the cost of prunes, also popular in Georgia, starts from 10 lari per 1 kg (

$ 3.03).

Prices for dried persimmons and prunes in Azerbaijan are almost the same as in Georgia.

Here, shelves with dried persimmons are approached much less often than shelves with dried apricots, grapes, plums. And partly this is also determined by the fact that, despite the fact that in most cases dried persimmon is in the form of whole fruits without skin, its appearance is constantly changing in detail.

Farmers prefer to sell dried persimmon not immediately, but after it is covered with a white fluffy coating consisting of small sugar crystals that have appeared on its surface. However, this increases the risk of contamination of the product by microorganisms [

14].

Despite the fact that this method is consolidated, studies have been conducted concerning changes in the qualitative characteristics of the target product depending on the persimmon variety used and the region of its cultivation. In particular, this concerns the work of Spanish authors on the identification of physico-chemical and microstructural changes during drying by this method of persimmon fruits of the “Rojo Brillante” variety, collected in two stages of maturity [

15]. The fruits of the first stage of maturity weighed about 195.3 g, which was lower than the fruits that reached the second stage of maturity (252.0 g). The humidity level of 50%, at which persimmon is considered semi-dry, was reached after 21 and 28 days for fruits weighing 195.3 g and 252.0 g, respectively. During drying, there was a slight darkening, which was reflected in the deterioration of color. The removal of water led to a significant decrease in the content of soluble tannin - on the 28th day of drying, the fruits were no longer tart.

Natural drying of whole persimmons under a canopy is traditionally used in Asian countries (China, South Korea and Japan) as a method of obtaining a product with good taste and nutritional properties, which is often eaten and produced on an industrial scale. The standard way to prepare this dried product is to remove the sepals and skin, followed by hanging the fruit on threads. In China and Japan, dried fruits are kneaded closer to the end of the drying process in order to evenly distribute the moisture in the fruit and shape the finished product [

16].

González et al. [[

1] used this method to dry Rojo Brillante persimmons, comparing the properties of non-astringent and astringent fruits, some of which were pretreated with CO2 to eliminate astringency. After 20 days, a natural decrease in the content of soluble tannins was observed; at the same time, astringent and non-astringent fruits had similar values (20-30 mg/100 g). In addition, the color of the pulp of astringent fruits remained orange, while darkening was observed in non-astringent fruits. Thus, no processing is required to reduce the astringency.

Villena et al. [

17] analyzed the physicochemical and microstructural changes during such drying of Rojo Brillante persimmons harvested at the early stage of maturity (S1) and the last stage of maturity (S2). The loss of water caused shrinkage, which led to the formation of a secondary epidermis and gelation of the inner pulp. Compared to S2 fruits, S1 fruits had a thicker epidermis and a smaller volume of the gel-forming area inside, which led to the production of tougher fruits. Microstructural analysis demonstrated the destruction of parenchyma after drying both in the secondary epidermis and in the pulp, with S1 showing a faster rate of destruction than S2. Consequently, the characteristics of the dried persimmon depended on the state of maturity at harvest.

Dehydration under a canopy or in the sun is one of the most common ways to dry persimmon fruits [

1]; however, it is unhygienic: the drying time increases to several weeks with uncontrolled humidity [

18].

The successful dewatering process depends on a slow and steady supply of heat, which guarantees uniform drying [

9]. Modern and sophisticated drying methods include either drying in drying machines [

20,

21], or drying in the sun with the intensification of the process using solar air heaters [

22,

23].

Drying persimmons with the concentration of solar energy using solar air heaters

On an industrial scale, solar drying is used for drying persimmons, which leads to an increase in shelf life [

24] and a decrease in microbial attack [

25], better quality and permanent nutritional properties [

26,

27]. Hanif et al. [

28] and Senadeera et al. [

24] reported that an increase in slice thickness and a decrease in drying temperature affect vitamin C in persimmon fruits. They concluded that persimmons need to be dried at temperatures below 50 °C and a slice thickness of 1.0 cm in order to obtain a higher vitamin C content.

Another study showed that an increase in the drying temperature led to a decrease in fungal infection by up to 22.1%, and honey reduced the aflatoxin content in dried fruits better than aloe vera gel [

29]. Similarly, the exogenous use of 10.0% persimmon peel extract helped preserve the nutritional and mineral composition of persimmon fruits. Moreover, the peel extract can effectively preserve nutritional value compared to commercially available synthetic preservatives [

26,

30]. Bolek and Obuz [

31] treated fruit samples with sodium metabisulfite before drying, then dried at different temperatures and found the greatest amount of rehydration and ascorbic acid at 50 °C. Moreover, the control treatments had the maximum activity of mesophilic aerobic bacteria during storage, while the treated samples had the lowest activity of these bacteria, which suggests an antimicrobial effect of sodium metabisulfite.

Blanching time and drying temperature significantly affect the moisture loss per hour and drying time. The shortest drying time and the highest rehydration values were obtained with a blanching time of 5 minutes [

26].

Pretreatment of persimmons with nitrogen and carbon dioxide showed that both treatments contribute to the preservation of texture and nutritional qualities after three weeks of storage; fruits treated with nitrogen had a better appearance, and those treated with carbon dioxide had a better taste [

32].

Sun-dried persimmons (for 12 hours at a temperature of 60 ° C) contained fewer polyphenols than fresh fruits, while differences in the content of trace elements, minerals and dietary fibers in them were insignificant [

27].

Persimmon from pretreatment with citric acid had the highest content of dry matter, glucose, fructose and vitamin C. And the sulfur treatment significantly affected the physico-chemical characteristics and aromatic compounds of dried fruits - after such treatment, about 45 aromatic compounds were found in them [

3].

The individual and interactive effects of various temperatures, as well as natural and artificial preservatives on the drying kinetics and organoleptic characteristics of the Fuyu persimmon variety collected in the experimental garden of the Peshawar Agricultural University, Khyber Pakhtun-Hawa, Pakistan (34.02° North latitude, 71.48° East longitude, height 359.0 m) were studied [

34]. The collected fruits were washed, blanched at a temperature of 70 ° C in warm water and placed for drying on trays of a solar dryer. Two factors were included in the study: drying temperature and food preservatives (two natural and three artificial). Three temperature conditions (40, 45 and 50°C) and five preservatives were tested - 25% honey solution, 25% aloe vera solution, 2% sodium benzoate solution (C

7H

5NaO

2), 1% potassium metabisulfite solution (K

2S) and 2% citric acid solution (C

6 H

8 O

7). An experimental site was created equipped with a convection dryer with forced solar radiation, a flat plate solar radiation collector, a drying cabinet and a fan (

Figure 2).

The drying time was approximately 13.0 hours. Comparison of drying temperatures showed that 8.2% of moisture was lost per hour at 50 °C, then 6.8% at 45 ° C, and a minimum (6.1%) was recorded at 40 °C. The data on preservatives showed that the greatest moisture loss (7.8%) per hour in persimmons treated with 2% citric acid solution, and the least moisture loss (6.4%) was recorded when using a 1% solution of potassium metabisulfite. In general, the greatest moisture loss (9.3%) was recorded at a drying temperature of 50 °C when treated with 2% citric acid solution, and the smallest (6.1%) - at a temperature of 40 ° C when treated with 25% honey solution. Individual and interactive effects of drying temperature and preservatives were expressed in the effect on the pH of dried persimmons. The highest (6.32) and lowest (6.13) pH values were observed at drying temperatures of 45°C and 50°C, respectively. The sugar and vitamin C content, as well as the acidity, were highest in the samples from pretreatment with citric acid solution and drying at 50 °C.

Figure 2.

Experimental plot for solar drying of persimmon fruits [

34].

Figure 2.

Experimental plot for solar drying of persimmon fruits [

34].

Thus, the temperature of the air used in the drying process is one of the main factors affecting the drying speed. Excessively high temperature during drying can damage the product or create an undesirable situation of "cementation". In addition, when the temperature rises, the useful properties of chemical components are either completely destroyed or significantly reduced. Therefore, restrictions should be placed on the drying temperature of most food products.

On the other hand, by increasing the temperature, it is possible to speed up the drying process and increase the hygienic purity of the product.

The use of special devices with a forced change of factors affecting the intensity of drying

Persimmon Chips

Although the apparent constancy of the persimmon masses of natural and artificial drying can create the illusion of the economic benefits of natural drying, the functionality of natural drying is much lower, especially with regard to using the potential to create new types of products with predetermined properties.

In recent years, crispy fruit snacks have become increasingly popular among modern consumers [

35]. However, persimmon snacks obtained by natural drying are unlikely to satisfy the needs of consumers who want to eat a crispy snack.

A crispy product rich in biologically active compounds is obtained by freeze-drying [

1]. Also, biologically active compounds with this method are preserved better than with other drying methods. However, freeze drying is a very time-consuming, energy-consuming and expensive process [

36]. In addition, before freeze-drying, processing is necessary to reduce the astringency, since tart samples retain a high content of soluble tannins and, therefore, have excessive astringency [

37]. Persimmon chips dried using a combination of hot air drying and a microwave oven were similar in color, texture, taste and general acceptability to freeze-dried chips [

38].

Since each drying process has inherent disadvantages, the combination of several methods is a practical strategy for the production of high-quality dried products, which can overcome the existing gap in quality [

39]. Microwave drying is fast and highly efficient; however, the main problems are high operating costs and difficulties with process control caused by rapid and uneven heating, which leads to heat leakage during drying [

40].

The fruits used in the production of chips should be hard enough to be peeled and shredded using electric vegetable cutters. In small industries, for this purpose, a Hitrees abrasive peeling machine (with a capacity of up to 1000 kg per shift) and other machines can be used (

Figure 3 A) and an electric vegetable cutter “Robot couple cl 50 ultra” with a capacity of 5 kg of fruit/min (

Figure 3 B); it is equipped with a volumetric hopper-a receiver with an area of 139 cm

2.

Soluble tannins are responsible for the astringency of persimmon fruits, and Gonzalez et al. [

1] reported that consumers' perception of astringency correlates with the content of soluble tannins in persimmon snacks.

Hard persimmon is usually tart, and its slices, coming into contact with oxygen in the air, quickly darken.

Taking this into account, the Research Institute of Fruit and Tea Growing of the Ministry of Agriculture of the Republic of Azerbaijan has developed a technology for producing natural chips, which allows almost completely preserving the color of persimmon slices, as well as improving their taste [

41].

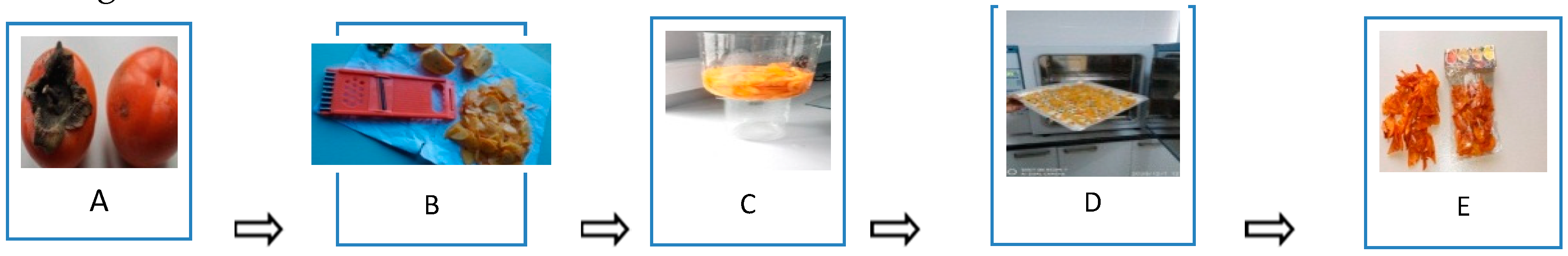

Figure 4 shows its essence in a visual form.

The fruits (

Figure 4,

A) are first washed, then the peduncle is removed from each of them along with the cup, after which they are cut into independent slices (depending on the size of the fruit, there may be 4 or 8 slices).

The amount of waste generated after such treatment is insignificant and does not exceed 20 g for every 1 kg of feedstock.

The resulting slices are chopped into slices 2-3 mm thick, immediately dropping them into a pre-prepared mixture prepared from 1 part citric acid, 2 parts table salt and 40 parts water (

Figure 4,

B;

Figure 4,

C). When using an electric vegetable cutter for this purpose, this mixture is poured into a receptacle sliced fruit.

With each repetition of this operation, a little new portion of it is added to the aqueous mixture of citric acid and table salt. The mixture remaining after processing four batches of slices is used to prepare other canned fruit.

The processed slices are carefully removed with a slotted spoon and laid out on the grates to drain the excess amount of syrup.

Slices treated with an acid-salt mixture are laid out on extruded grids with square-shaped cells measuring 5 × 5 mm (it is on the grids, and not on aluminum baking trays, to which the slices stick during their further drying) in one layer. One grid size of 35 cm x 35 cm can fit 600 g of processed slices.

Nets with slices are placed on mobile racks and loaded into a drying chamber (

Figure 4,

D). Drying is carried out at a temperature of 70...72 ° C and finish after 3 hours, when the residual water content in the product decreases to 11%.

The yield of dried slices from 1 kg of Hiakume persimmon (fruit weight 268 g; unused parts – a peduncle with a cup of 2.7 g and 3 seeds – 3.3 g) is 216 ± 0.4 g. To make the slices crispy, they are dried in the microwave to moisture of 5-6%.

Dried slices are packed in plastic bags with fasteners (

Figure 4,

E), in which they perfectly retain their original characteristics (including color) for six months or more.

This can also be seen from

Figure 5, which captures the appearance of three samples of persimmon chips of the aforementioned after 6 months of their storage at a temperature no higher than 10° C.

It shows that all three samples with a well-preserved color of the raw material, but still chips from slices that were soaked in a mixture with number 1 before drying (which consisted of 1 part citric acid, 2 parts table salt and 40 parts water), with a more attractive appearance. The study of their chemical composition showed that the advantage is again with the sample number 1, since more vitamin C was preserved in it than in the other two samples, and less polyphenols, among which tart forms predominate.

Thus, pretreatment of persimmon slices with stabilizing solutions and a combination of hot air drying and microwave drying allows you to get high-quality snacks from persimmons, while saving energy and time.

100% dried persimmon

The effect of four drying methods on the total amount of biologically active compounds in persimmon and the bioavailability of the total content of phenols in vitro (TPC) was studied. The results showed that vacuum drying with ultrasound, infrared drying and hot air drying increased the bioavailability of TPC. However, the bioavailability of lyophilized samples did not differ significantly from that of fresh persimmons. The increase in bioavailability was due to the heat treatment used during drying, since biologically active compounds are released from food products under the influence of heat. Thus, ID and HAD showed the highest bioavailability, since these are drying methods with the highest heat load [

42].

Park and his colleagues [

43] conducted experiments on drying persimmons in the form of wafer-like slices; at 60 ° C it took 12 hours.

The processing of persimmons before drying with hot steam led to the fact that after drying it became more tart than before drying [

44].

It is considered that due to the strong varietal differences between varieties, it is in vain to look for one common way to prepare them for drying. For one group of varieties, a method of preparation is suitable, providing only for peeling the fruit from the skin. Fruits of other varieties are better first cut into slices, then dried, and in one case directly, in the other - after aging in solutions that help improve the taste and texture of dried persimmons [

14].

It is clear that it is easier to work with hard persimmons - to segment, distribute slices into trays, and so on. However, this is a period when their astringency has not yet decreased and is at its peak; it is difficult to get the best dried fruits from raw materials that are not fully ripe and have not yet acquired their best taste.

In addition, hard persimmons have to be peeled off before they are dried, which leads to losses and a decrease in the yield of the target product. In the total mass of not quite ripe and still hard persimmons of different varieties, the pulp itself accounted for from 49.70 to 85.79% [

45], the rest is waste in the form of peel from its cleaning.

Another thing is aged softened persimmon, which becomes so tasty and tender that the need for peeling disappears by itself. After any processing aimed at violating its integrity (in this case, processing is only possible manually), it does not change its original color for a long time. Taking it in your hand, you can cut it with a sharp knife several times in the direction from the tip to the cup, leaving the slices attached with their base to the cup, then slightly push them apart and give the fruit the appearance of an open flower and dry in this form.

Figure 6 reflects the main elements of the drying technology of aged softened persimmon fruits developed at the Research Institute of Fruit and Tea Growing of the Ministry of Agriculture of the Republic of Azerbaijan [

46,

47,

48].

Preparation of aged softened fruits for drying, according to this technology, is as follows.

First, each such fruit (

Figure 6 A) is carefully washed under the tap and cut with a sharp knife crosswise from their tip to the very base into 4-8 approximately equal slices, leaving them attached with their lower end to the base of the fruit, where the cup is located, and put on a lattice baking sheet. Then these not completely independent lobules are pushed apart until large spaces are formed between them and the fruit takes the form of an open flower with 4-8 "petals" (

Figure 6,

B).

Drying of aged softened persimmons in this form is carried out in one layer at 70-72 ° C for 9.5-10.5 hours to a humidity of 24%.

Dried fruits (

Figure 6,

C) are divided manually into parts, each of which may consist of two lobules connected to each other at the base (

Figure 6,

D), while the peduncles and cups are removed. The slices are packed in plastic bags with fasteners (

Figure 6, E). Plastic boxes with hinged lids can also be used for this purpose.

The resulting 100% dried persimmon is stored at a temperature no higher than 10 ° C in order to better preserve its initial color, which is almost the same as that of the raw material.

The shelf life of 100% dried persimmon is 6 months. This is the period after which a white plaque appears on the slices, consisting of sugar crystals (

Figure 7).

The yield of the finished product from 1 kg of aged unsullied (seedless) persimmon “Khachiya" (fruit weight 205.5 g) was 284 g; waste from cleaning dried fruits (calyx, peduncle) was 15 g.

The yield of the finished product from 1 kg of poorly pollinated (1-2 seeds) aged persimmon “Hiakume" (fruit weight 290 g) was 280 g.

From the table devoted to the results of the biochemical evaluation of finished samples, it can be seen that in 100% dried persimmon “Hachiya” the concentration of simple sugars and polyphenols is much higher than in 100% dried persimmon “Hiakume”, which can serve as a reason to recommend them to different groups of the population.

Conclusion

Thus, in recent years, there has been an increase in persimmon production in the world and, at the same time, there has been an increased interest in studying the composition of nutrients and biologically active substances of this fruit and after-harvest technologies.

Of particular interest in an attempt to reduce losses is the involvement of excess persimmons in drying.

A review of the current state of affairs in this area has shown that the available opportunities for more complete use of the functionality of technologies for drying persimmon fruits have been studied many times and continue to be studied now. Of particular interest are some recent developments aimed at improving the organoleptic properties of dried persimmons and the search for those hygienic standards and forms in which they should be presented to the consumer.

Using the example of some new developments, it can be seen that adhering to the principle “first come the hard fruits of the period of their mass collection, then – aged, softened”, the duration of the season of production of products from drying persimmons can be extended.

References

- González CM, Gargia AL, Llorca E, Hemando I, Atienzar P, Bermejo A, et al. Carotenoids in dehydrated persimmon: antioxidant activity, structure, and photoluminescence. LWT, 2021, 142, 111007. [CrossRef]

- Hafizov GK. Nutritional value and taste qualities of persimmon fruits (review). Web of Scholar. 2016, 1(1): 54-57 (in Russ.).

- Gea-Botella S, Agulló L, Martí N, Martínez-Madrid MC, Lizama V, MartínBermudo F, et al. Carotenoids from persimmon juice processing. Food Res. Int. 2021, 141, 109882. [CrossRef]

- Méndez DA, Fabra M J, Falcó I, Sánchez G, Aranaz P, Vettorazzi A, et al. Bioactive extracts from persimmon waste: influence of extraction conditions and ripeness. Food Funct. 2021, 12, 7428–7439. [CrossRef]

- Gafizov GK. An overview of the latest advances in technologies applied to persimmon fruits in order to preserve their quality after harvest. Austrian J of Technical and Natural Sciences. 2016, 3-4: 61-67 (in Russ.).

- Hafizov GK, Hafizov S.G. Biochemical features of persimmon fruit storage under normal and refrigerated conditions. Austrian J of Technical and Natural Sciences. 2015, 7-8: 10-17 (in Russ.).

- Heras RM-L, Amigo-Sánchez JC, Heredia A, et al. Influence of preharvest treatments to reduce the seasonality of persimmon production on color, texture and antioxidant properties during storage. CyTA - J. of Food. 2016, 14: 333–339. [CrossRef]

- Senica M, Veberic R, Grabnar JJ, et al. Selected chemical compounds in firm and mellow persimmon fruit before and after the drying process. J. Sci. Food Agric. 2015, 96: 3140–3147. [CrossRef]

- Hafizov GK. The effect of the method of initial processing with the addition of sorbic acid as a preservative, as well as the temperature and duration of storage of pomegranate juice on the safety of anthocyanins. APRIORI. Series: Natural and Technical Sciences. 2015, 4: 15 (in Russ.).

- Kim J-H, Chung IK, Kim HY, Kim K-M. Comparison of the quality of dried persimmon (Diospyros kaki THUNB.) treated with medicinal plant extracts and food additives. Int. J. Food Sci. Nutr. 2018, 6: 1991–1998. [CrossRef]

- Kang W, Kim J, Oh S. et al. Physcochemical characteristics of Sangju traditional dried persimmons during process. J. Korean Soc. Int. J. Food Sci. Nutr. 2004, 33: 386–391 (In Korean).

- Gardeli C, Evageliou V, Poulos C, et al. Drying of fennel plants: oven, freeze drying, effect of freeze-drying time, and use of biopolymers. Dry. Technol. 2010, 28: 542–549. [CrossRef]

- Li B. A brief introduction to postharvest research and utilization of persimmon (Diospyros kaki) in China: Ancient time to today. Acta Hortic. 2013, 996: 373–378. [CrossRef]

- Hafizov GK. Analysis of the reasons for the low demand for dried persimmons on the market of low humidity products. International Scientific and Practical Conference World science. 2016, Vol. 3, № 3 (7): 22-27 ( in Russ.).

- Vilhena NQ, Gil R, Llorca E, et al. Physico-chemical and microstructural changes during the drying of persimmon fruit cv. Rojo Brillante harvested in two maturity stages. Foods. 2020, 9, 870. [CrossRef]

- Sugiura A, Taira S. Dried persimmon production in Japan. Acta Hortic.2009, 833, 71–76. [CrossRef]

- Vilhena NQ, Gil R, Llorca E, Moraga G, Salvador A. Physico- chemical and microstructural changes during the drying of persimmon fruit cv. Rojo Brillante harvested in two maturity stages. Foods. 2020, 9, 870. [CrossRef]

- Khademi O, Farrokhzad Y, Khangholi S. Impact of different pre-treatments and drying methods on quality and antioxidant properties of dried persimmon (Diospyros kaki L.) slices. Int J of Postharvest Technology and Innovation. 2019, 6(2): 137–150. [CrossRef]

- Mohamed AH, Ragab M, Siliha H, Haridy LA. Physicochemical, microbiological and sensory characteristics of persimmon fruit leather. Zagazig J of Agricultural Research. 2018, 45(6): 2071–2085. [CrossRef]

- Prosapio V, Norton I. Influence of osmotic dehydration pre-treatment on oven drying and freeze drying performance. Lwt. 2017, 80: 401–408. [CrossRef]

- Baeghbali V, Ngadi M, Niakousari M. Effects of ultrasound and infrared assisted conductive hydro-drying, freeze-drying and oven drying on physicochemical properties of okra slices. Innovative Food Science & Emerging Technologies. 2020, 63: 102313. [CrossRef]

- Seerangurayar T, Al-Ismaili AM, Jeewantha LJ, Al-Nabhani A. Experimental investigation of shrinkage and microstructural properties of date fruits at three solar drying methods. Solar Energy. 2019, 180: 445–455. [CrossRef]

- Rabha D, Muthukumar P, Somayaji C. Energy and exergy analyses of the solar drying processes of ghost chilli pepper and ginger. Renewable Energy. 2017, 105: 764–773. [CrossRef]

- Senadeera W, Adiletta G, Önal B, Di Matteo M, Russo P. Influence of different hot air drying temperatures on drying kinetics, shrinkage, and colour of persimmon slices. Foods. 2020, 9(1): 101. [CrossRef]

- Khademi O, Farrokhzad Y, Khangholi S. Impact of different pre-treatments and drying methods on quality and antioxidant properties of dried persimmon (Diospyros kaki L.) slices. Int J of Postharvest Technology and Innovation. 2019, 6(2): 137–150. [CrossRef]

- Doymaz İ. Evaluation of some thin-layer drying models of persimmon slices (Diospyros kaki L.). Energy conversion and management. 2012, 56: 199–205. [CrossRef]

- Park H-W, Oh S-I, Cho M-G, Kim C-W, Lee U. The comparison of quality characteristics of dried persimmons manufactured by solar drying method in Yecheon. J of Korean Society of Forest Science. 2018, 107(4): 422–427.

- Hanif M, Khattak MK, Ali SA, Khan M, Ramzan M, Amin M, et al. Impact of drying temperature and slice thickness on retention of vitamin c in persimmons (Diospyros kaki L.) dried by a flat plate solar collector. Pak J Food Sci. 2015, 25: 66–70.

- Hanif M, Khattak MK, Rehman MU, Ramzan M, Amin M, Aamir M, et al. Effect of drying temperature and natural preservatives on reducing aflatoxins in solar dried persimmon (Diospyros kaki L). Proc Pak Acad Sci. 2015, 52: 361–365.

- Kim I-D, Lee J-W, Kim S-J, Cho J-W, Dhungana SK, Lim Y-S, et al. Exogenous application of natural extracts of persimmon (Diospyros kaki Thunb.) can help in maintaining nutritional and mineral composition of dried persimmon. African Journal of Biotechnology. 2014, 13(22). [CrossRef]

- Bolek S, Obuz E. Quality characteristics of Trabzon persimmon dried at several temperatures and pretreated by different methods. Turkish J of Agriculture and Forestry. 2014, 38(2): 242–249. [CrossRef]

- Bibi N, Khattak AB, Mehmood Z. Quality improvement and shelf life extension of persimmon fruit (Diospyros kaki). Journal of food engineering. 2007, 79(4): 1359–63. [CrossRef]

- Karakasova L, Babanovska - Milenkovska F, Lazov M, Karakasov B, Stojanova M. Quality properties of solar dried persimmon (Diospyros kaki). J of Hygienic Engineering and Design. 2013, 4(1): 54–59.

- Khaliq A, Li WF, Ali S, Shah ST, Ma ZH, Mao J, Niaz Y, Chen BH, Haq IU, Al-Yahyai R, Ahmed MAA, Al-Ghamdi AA, Elshikh MS, Zuan ATK. Thin layer drying kinetics and quality dynamics of persimmon (Diospyros kaki) treated with preservatives and solar dried under different temperatures. PLoS One. 2022, 17(3):e0265111. [CrossRef]

- Jia Y, Khalifa I, Hu L, Zhu W, Li J, Li K, et al. Influence of three different drying techniques on Persimmon Chips’ characteristics: A comparison study among Hot-Air, combined Hot-Air-Microwave, and Vacuum-Freeze Drying techniques. Food Bioprod. Process. 2019, 118: 67–76. [CrossRef]

- Orak H, Aktas T, Yagar H, İsbilir SS, Ekinci N, and Sahin FH. Effects of Hot Air and Freeze Drying methods on antioxidant activity, colour and some nutritional characteristics of strawberry tree (Arbutus Unedo L) fruit. Food Sci. Technol. Int. 2012. 18, 391–402. [CrossRef]

- González CM, Llorca E, Quiles A, Hernando I, and Moraga G. An in vitro digestion study of tannins and antioxidant activity affected by drying "Rojo Brillante" persimmon. Lwt. 2022. 155, 112961. [CrossRef]

- Jia Y, Khalifa I, Hu L, Zhu, W, Li J, Li K, et al. Influence of three different drying techniques on persimmon chips’ characteristics: A comparison study among Hot-Air, combined Hot-Air-Microwave, and Vacuum-Freeze drying techniques. Food Bioprod. Process. 2019, 118: 67–76. [CrossRef]

- Pu Y-Y, Sun D-W. Combined Hot-Air and Microwave-Vacuum drying for improving drying uniformity of mango slices based on hyperspectral imaging visualisation of moisture content distribution. Biosyst. Eng. 2017, 156: 108–119. [CrossRef]

- Cheng WM, Raghavan GSV, Ngadi M, and Wang N. Microwave power control strategies on the drying process. Development and evaluation of new microwave drying system. J. Food Eng. 2006, 76: 188–194. [CrossRef]

- Hafizov GK. Research of functional and technological properties of persimmon fruits as an object of drying. Earth Sciences. 2021. 10(3): 118-127. [CrossRef]

- Kayacan S, Karasu S, Akman PK, Goktas H, Doymaz I, and Sagdic O. Effect of different drying methods on total bioactive compounds, phenolic profile, in vitro bioaccessibility of phenolic and HMF formation of persimmon. Lwt. 2020. 118, 108830. [CrossRef]

- Park Y-S, Jung S-T, Kang S-G, et al. Drying of persimmons (Diospyros kaki L.) and the following changes in the studied bioactive compounds and the total radical scavenging activities. LWT, 2006, 39: 748-755. [CrossRef]

- Hafizov G. Influence of the method of preparation for drying and various modes of air-thermal heating on some qualitative indicators of dehydrated persimmons. Eurasian Scientific Association. 2021, 6-2(76): 97-102. (in Russ.). [CrossRef]

- Hafizov GK, Abdullayeva NM. Selection of dried fruit varieties of oriental persimmon and determination of the optimal drying method. Agricultural science. 2014, 10: 14-17 (in Russ.).

- Hafizov SG, Hafizov GK. New products from drying persimmon fruits: manufacturing technologies and their prospects. Eurasian Scientific Association. 2022, 1(83): 126-134. (in Russ.). [CrossRef]

- Hafizov GK, Mammadov N.A. Technology of obtaining a food product from aged softened persimmon: functionality and prospects of commercialization. Modern Economy Success. 2017, 1: 25-46 (in Russ.).

- Hafizov GK, Kurbanov IS, Abubekirov GS, Gafizov SG. A method for obtaining a food product from aged softened persimmon. Patent SU No. 2552360 C2, Application No. 2013145512/13: filed 10.10.2013: published 10.06.2015 (in Russ.).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).