1. Introduction

The focus of construction activity is to develop a system for minimizing the waste of all types of resources. Despite various methods and means available for finding a solution to this issue of reducing the waste, though not fully eradicate the same, a simple tool to adopt will help the construction industry to have a better control on the waste being generated [

1]. Wastage in terms of labour may occur not only with the usage of the materials and machineries by the labours, but also connected with the activities of the various stakeholders associated with the construction. Any particular tool or a system, before it is being adopted in a project has to be made easily understandable by all the persons associated with the project at all levels.

While this study focusses on implementing a suitable tool to be adopted easily by the labours who are directly involved in the construction, analysis of the various setbacks of achieving the goal of implementing the Lean tool should pave a better path not only by means of adopting the Lean principle, but to reap the benefits of totally solving the setbacks developed by the various stakeholders during the stages of the Lean tool implementing [

2]. This study not only gives a methodology of adopting the Lean tool but also helps in developing a clear path for all the stakeholders to achieve the result of adopting the Lean tool considered in the research for various cost category of projects during pandemic period.

Labour productivity has long since been taken into consideration for various researches [

3,

4,

5]. [

6] has studied the result of the independent systems of LPS, who are the self-interested stakeholders thus focusing only on the subcontractors’ effect on implementing the LPS. [

7] had done the research on the effects of LPS on society based organisational connections within the construction workers. Again, [

8] have done their research work on the effects of the societal subcontract and LPS Involvements in the activity labour flow of activities in multistorey development projects.

While cost reduction, improvement of work flow, reduction of variations and setting up of buffers for completing the projects on time had been the focus for a certain period of research and implementation, there had been many challenges in implementation of the various lean tools which are mainly done for enhancing the quality of the project in execution and improving the project management process during implementation and delivery stages and also to reduce various types of wastages [

9]. While various tools such as 5S, mapping of values, work standardization have mostly more of the external factors controlling them while the Last Planner System method in executing a project through lean is more influenced by internal factors associated with the direct executor of the project, the labour. Not only it is the labour who is involved but also the various stakeholders such as the vendors, sub-contractors, Architects, Structural and MEP consultants also have a direct control on the last planner system. The last planner system tool is mainly concentrated with the activities in the execution of the project of the worker who is last in line in the planning and project management. The Last Planner who is mostly the foreman is unable to make his system flow run smoothly during the course of execution of the project as most of his inputs are received from various stakeholders associated with the project. Many hurdles and setbacks are faced by the last planner in achieving his goal set for the project. These hurdles and setbacks may not only be created within the project, but also formed by the nature such as cyclones, unseasonal rainfall, pandemic etc., The impact of different stakeholders may also vary at times since they occur not at the same time but at different staggered periods during the course of executing the project by the Last planner’s made-in plan [

10]. A better coordinated system among the stakeholders associated with the last planner and a well-defined system and procedure to overcome the natural hurdles becomes the need of the project, particularly during any long-term pandemic period for effecting a smooth work flow in his system. Though such systems can be implemented in the contract conditions during the tendering process, the cost associated with adopting and following such systems and procedures may vary drastically. Hence it becomes imperative that only after the project is in execution stage of certain level, new tools, systems and procedures are implemented in accordance with the already set procedures [

11]. Such tools have high cost implications and mainly need the support and approval of the top management since they are the one who control the cost flow of the project.

Though different researches have been done on the enactment of the Last Planner System to improve the flow of work, reduce cost and wastage, improve labour productivity there is a gap in connecting and making responsible all the stakeholders in the combined achievement of the target through the Lean tool implementation, particularly during pandemic. This research is more specific and concentrates on both the setbacks and the positive factors faced by the Last Planner during the application of the last planner system during COVID-19 pandemic period and provides a deep insight into the coordination and communication process between the management and the stakeholders of the project with the Last Planner [

12]. Any new tool or a system initially during the adoption stage face various challenges and doubts in the starting period itself. The research study initially started with observing the process of the project management being followed in the four case studies such as the frequency of meetings being conducted, mode of communication being followed, flow of instructions given in the work flow process, stakeholders input method for executing various activities of the project and status of implementation of project management tool, if any in the project. Questionnaires involving various factors of the implementation of the last planner tool have been circulated and ranking done among eight factors associated with the project management and the priority is set for such factors to be followed both during the pandemic and post pandemic periods. The responses received for the questionnaires also are connected with all the stakeholders of the project in all the four case studies which are being distributed evenly. Every case study project is unique not only by relating them by means of cost incurred in the project but also various inputs received from various sources, project management methodology being adopted, follow up actions being implemented and the procedures set for executing the various activities to be executed. A consensus on the responses has to be reached based on the questionnaire responses which is done either through ranking or prioritising method. Ultimately through statistical analysis and graphs, a system to be adopted for the various category of projects based on the cost [

13]. The performance index calculated for the various categories of project implementation is also found for various factors in relation to the various cost category of housing accommodation projects ranging from less than 50 crores to above 150 crores.

2. Literature Review

The Last planner system is a method of lean principle. It is a system based on the product plans made that promotes effective communication among workers while also increasing plan dependability [

14]. The Last planner system views the plans made and the means of organizing as a combined process, opposed to the current project plans made, which views plans made and the steps taken to review the plans separately [

15] According to [

16], the LPS emphasises combining plans made and the review of the products made rather than guiding and adapting (cybernetic model) in the traditional project management technique.

The integrated method employed in the LPS improves plan dependability and reduces task variance throughout project execution [

17,

18]. [

19] discovered that the LPS technique decreases variance in scheduled activities, enhances project performance, and contributes to a 35% increase in productivity when compared to a similar project not handled by the LPS method. This conclusion is supported by research from [

20,

21]. These studies indicate that the LPS technique enhances planning dependability and job completion quality. This demonstrates the LPS’s ability to efficiently manage the manufacturing process on projects. The frontline supervisor is referred to as the final planner [

22].

The LPS is built on five major components: (1) Initial main plan (2) combined programs made in phases for planning, (3) Immediate process plans made, (4) Activity plans on weekly basis and (5) review and studying. [

23,

24] all go into great detail on these processes. The LPS promotes the creation of a coordinated executing relationship and the timely completion of construction projects via the use of these features. However, the Last planner system is always reviewed with respect to the plans made in phases with respect to the Gantt chart-based programme [

25]. Furthermore, [

26] contended on an emphasis on the overall completion of plans in terms of percentage in Last planner evaluation which may direct subcontractors to alter the results. Nonetheless, the LPS method allows stakeholders undertaking work to participate to the plans made in phases in order to build a solid plan, which separates it from the standard project management approach.

A case study taking cost into consideration to improve upon the process of construction by using methodologies of Lean Management [

27]. Time, Cost and Quality are the three main important factors which have got a more deviation effect on most of the construction projects. In this research, a project site of Poland has been taken for consideration and the activity of column concreting has been taken. [

28] have used the factor of compatibility in their research to find the labour productivity by means of analysing in a clustered manner. Not only by means of calculating the time taken by a mason in completing a task is taken as a means of finding the productivity of that mason in a quantitative approach method, the interpersonal relationship between the workers in a crew also provide a qualitative approach in determining the productivity.

The advanced metrics for construction planning [

29]. Combining the Last Planner System with the conventional methodology used for the metrics study so as to find out the outcome of the project schedule. Dashboard and a framework are used to study the planning in production planning and it is found that in the two construction projects considered for the study, it is the reverse option of first making the tasks ready and then starting to remove the hurdles and a sense of commitment towards the critical tasks. [

30] have made a comparative analysis of planning with the CPM, LPS and Locations Based Techniques in three countries such as USA, Finland and Brazil. It was initially found in the research that though the above methods focus on schedules, there is no focus on the similarities and differences in these methods.

The barriers in adopting the Lean principles in the construction field through the means within Jordan construction industry [

31]. Lean construction improves the end result in the project execution. The study aims in identifying the barriers to such lean tools with the help of questionnaire with 30 barriers distributed to 326 persons. The main response of the respondents includes the non-support of top management, low knowledge of lean, absence of training and openness were the main barriers in adopting to lean construction. Other barriers were also identified such as the resistance to adopt to change, nil incentives and nil motivation, very low wages and less adaptation of design and build concept [

32]. Ultimately few suggestions to overcome the barriers were given which were, to take an effort to adopt to change, spread the knowledge of lean by government and educational institutions, conduct many training programmes in lean. Other limitations in this research include the non-usage of LPS, no interviews conducted, model to use the factor analysis too.

The effect of completion of public construction projects in a systematic way in four categories of time, cost, quality and customer satisfaction [

33]. By means of conducting interviews and a thorough study of the four construction projects by the Norwegian commissioner, it was found that the systematic way had a very high impact of positiveness on the side of completion of the project with low cost and within the time frame schedule. Though only the building commissioner’s perspective way of thinking has been taken into account, the other stakeholders connected such as the design team, contractor’s team and client views were only limited and not fully taken into account [

34]. Since it is very systematic, the time taken in error corrections is less and savings in the energy. Both the planning and the construction to go simultaneously and issues on technical systems corrected early.

The conflicts arising out of the expert contractors who use the Last Planner System in building information modelling, thereby improving the planning process with the execution process correlating both LPS an BIM processes [

35]. Using the LPS technique, the best technique was found by using the LPS technique after studying the plans of the expert contractors by applying on various tasks of the construction project. By using this approach, the time delay of the project is reduced since the conflict with respect to the time of the expert contractors was minimized [

36]. Ultimately it was concluded that this research reaped out the benefits of LPS to motivate the contractors and consultants, decrease the delays caused due to huge wastage of time, high costs and bad quality.

The qualitative approach as having many similar characteristics which includes, combining the researcher with the participant, non-artificial development, information being passed based on some subject, a specific reasoned way of communicating the matter [

37]. In a way, the researcher projects the qualitative approach as the method which gives utmost importance to creating an approach to meaningfully know the science related to the society connected with the human in order to pave a way for the thought process of the people.

Study of the project execution method. While the traditional project management, by using the CP method focusses on splitting the overall activities into various sub activities, giving floats to non-critical activities, it does not consider the flow of matters and materials [

38]. [

39] In today’s highly speed construction process, these two flows are very essential and this is done with the aid of Last Planner System. The discussions and the responsibilities are effectively managed in this means of lean tool in construction. After a thorough study of various literatures, it is found that a systematic training of last planner system is very much essential and the various factors such as taking action on subcontracts, results of PPC, assessment matrix etc., also improves the LPS. Since the LPS flow is from the top to the bottom, delegation of authority is seen to be an important factor to evolve the full benefits of Last Planner System. The barriers are also found in the enactment of the last planner system in this research.

The application of Last Planner System in the Real Estate construction projects. As the Indian Real Estate is improving at a fast pace at 6 to 8% at present and is expected to reach around 13% in the year 2025 [

40]. The real challenges faced by the real estate sector in India are the non-availability of highly skilled labour, cost and time increasing heavily over the budget, very less productivity of labours and above all high generation of wastes. Hence waste reduction is considered to be highly important which will not only reduce the cost and time, but also will definitely increase the productivity, by stabilizing the flow management. To conclude the research, it is found that wastes are generated by interconnecting previous activity with the current activity. As and when project progresses, the percentage plan complete improves. Future research is recommended with applying Just-in-time concept in the project for effective monitoring and control.

The effect of autonomy-based agents on Last Planner System, who are the self-interested stakeholders. This paper particularly focusses on the subcontractors’ effect on the method of implementing the LPS in a Texas project [

41]. Qualitative interviews in eight projects were conducted and found that the behaviour of the subcontractors has affected the LPS project performance. Ultimately it was concluded that the behaviour of the independent agents affected the enactment of Last Planner System in projects. This behaviour in turn affected the labour productivity in construction. Further research paves a way to address this behavioural issue and study performed in other places also. Resource allocation and tracking manpower with buffers have to be done to address this issue.

Figure out if Last Planner System can assist in overcoming the risky effects of the Design-Bid-Build concept of the procurement [

42]. Nine interviews were conducted with different stakeholders such as the Architect, engineer and the construction contractor. By adopting various strategies such as the alliance contract and risk management techniques, the hurdles were overcome. Also, the interviews conducted revealed that building a lean culture was enabled using LPS by means of good proper communication, visualise the facts, openness and interaction with good relations. Most of the interview results state that the Design-Bid-Build concept has got a high negative impact on the construction projects. Though LPS adaptation helps in supporting such high systems, the lean culture in such type of projects can be improved by the above said means.

Research on the uses of adopting the Last Planner System in the project in the area of Addis Ababa [

43]. Road Project has been taken into consideration. By the use of super decision model, a more important of tool of lean construction which is the LPS has been taken into account mainly to improve the production output and decrease the waste. The barriers to adopt the LPS has been found out and it was known that only the critical path method-based project planning with push planning methodology is being used and there was no weekly plan and look ahead schedule. The barriers included the labour oriented, work environment, stakeholder’s views, materials related and exogenous matters. If the above barriers are overcome, LPS gives the major benefits such as less time and cost, good quality and claims. By means of various questionnaires, surveys, interviews and discussions, data was collected and the barriers grouped into 5 categories among 38 barriers. Finally, the criteria are measured for the benefits reaped out of the benefits of Last Planner system.

3. Research Method

Quantitative based study contains the accumulation, tabulation, summary made and review of the results based on numbers [

44]. The Usefulness of Quantitative Approaches and Methods in Researching Problem-Solving. Qualitative research is a fully questionable and different approach in the way of interpretation which aims to get the in-depth into the detailed means and approaches which get through in a specific phenomenon connected with the society at large with a subject oriented approach with the participating members.

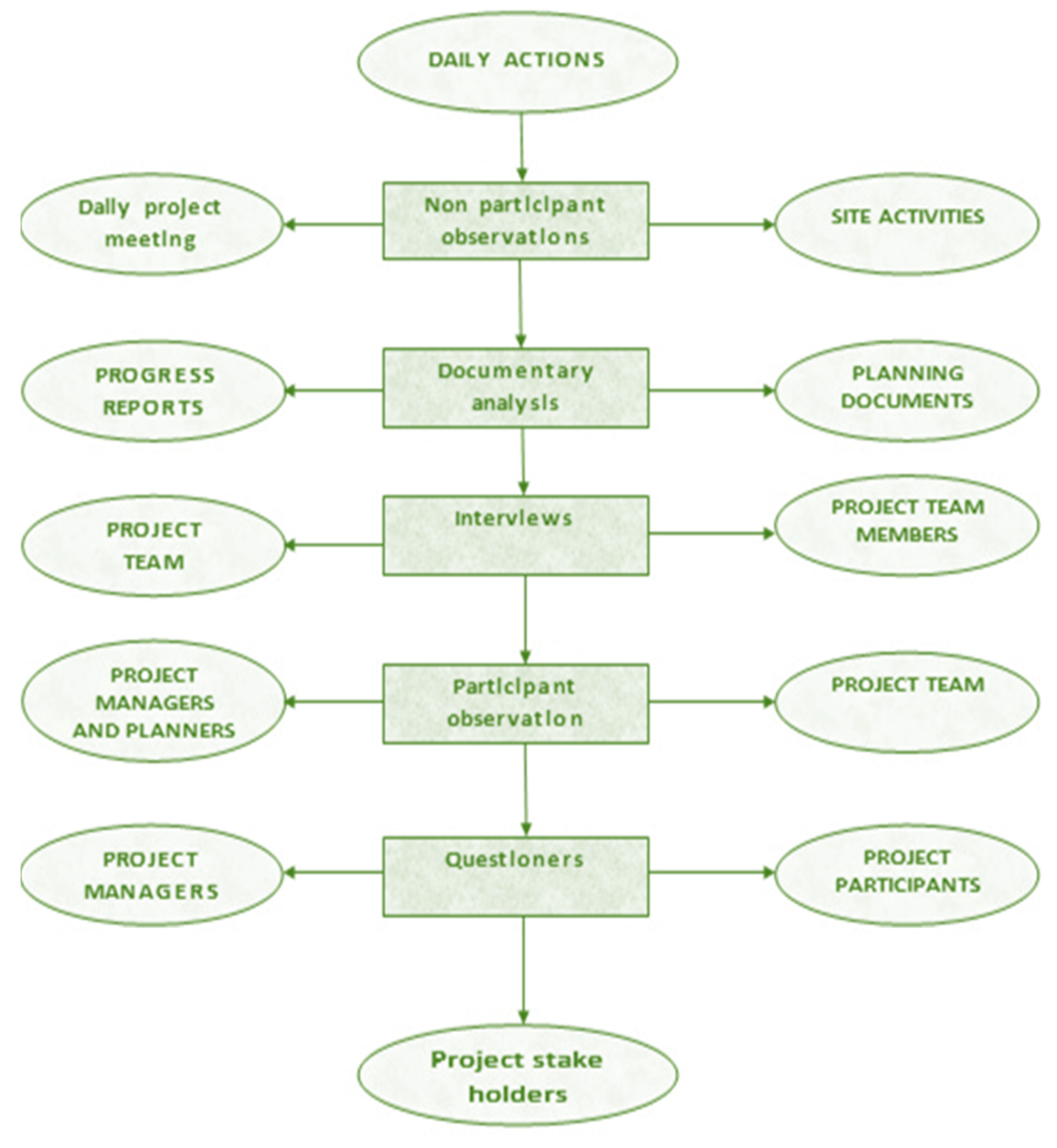

The entire process is split into three stages to get the expected result. The first stage is the Last Planner System (LPS) mobilization stage where it has to be implemented. In order to get a detailed report on this stage, the method of project execution is first studied mostly by external observation of the method of arranging the main resources and how they are being organized and allocated, the frequency of the meetings conducted in the project, team cooperation and the method of works executed as a team in the project, the way of behavior and the method of flow of information and finally the knowledge and process of setting up the Last Planner system (LPS). Then the next stage is the working stage, wherein the LPS is started to be implemented by identifying the list of unfinished tasks through the designated last planner and finding out the reasons for the low percentage plan completion (PPC) of the tasks. There may be various stakeholders in a project who impact the last planner at different stages of the project. Impact also may be different for different activities being executed by the same last planner. Since these are the one who impact the low PPC of a task, the first step in the third stage of identifying the reasons for the backlog of activities from the various stakeholders. Questionnaire survey process is being chosen as a tool and also the last planner system of implementation in various circumstances. In order to find out the areas wherein the LPS is being applied and the method of its application and the hurdles and setbacks faced by the agency responsible for implementation. The Questionnaire survey was then conducted with all the main persons involved in the project and developed through factors such as methodology of implementation of LPS, LPS implementation output through execution phase, LPS implementation during the design phase, quality of implementation, hurdles faced during implementation of the lean tool, positive factors effecting the implementation, benefits derived out of the enactment of the Last Planner System and negative factors affecting the LPS implementation were ranked in a scale from 1 to 5. These data were then analysed through calculating the priority index for all the responses received by ranking method with points. It was made in such a way that the entire team of persons directly involved in the project were taken into consideration as given in the

Figure 1.

Ranges were set for the factor which had to be given more importance for effective implementation of the Last Planner System for various categories of project based on the project cost. Cost analysis was done to find out the savings incurred in the project in four stages such as executing the project in normal conditions, LPS implementation normal conditions, implementation of Last planner system during the covid-19 pandemic period and finally the after effect of the implementation of the Last Planner System after the decrease in the spread of covid-19 pandemic in the projects. Any research analysis need to be validated for future use in projects and the statistical approach was used to validate the responses received from various stakeholders by finding out the regression factor.

3.1. Data Collection

The researcher contacted the contractor and enquired if the Last Planner System could develop the process of progress in all the project. However, initially, the contractor had some restrictions to team up with the process of enquiry, but when the project progressed, the contractor showed his interest. The data gathered was in three stages of analysis viz., Mobilisation stage, working stage and conclusion stage. In the mobilisation stage of working, the data which was collected involving the ideas of the non-member and the meetings being conducted is done. In the working stage, the data is gathered with the usage of the members’ idea while participating and the investigating sort of analysis of the activities status of completion. In the conclusion stage, questionnaire survey is conducted with eight factors related to project management during pandemic period.

3.1.1. Case Study 1

The project under consideration was one of the research scholars family accommodation in Chennai, Tamil Nadu, India. During the mobilisation stage the outcome of the various activities were analysed and tabulated in

Table 1. In the working stage the major activities were constantly reviewed and the percentage plan complete (PPC) is calculated and explained in

Table 2.

>Questionnaire survey was conducted with the main stakeholders in four parts. The first part involved on receiving a broader outlook of the gain of the LPS process of development. The second part focused mainly on the exterior parts of the implementation process. The third part mainly concentrated on the premium process of the working of the LPS development. The final part existed on the main usages and good results of working implementation of the Last Planner System.

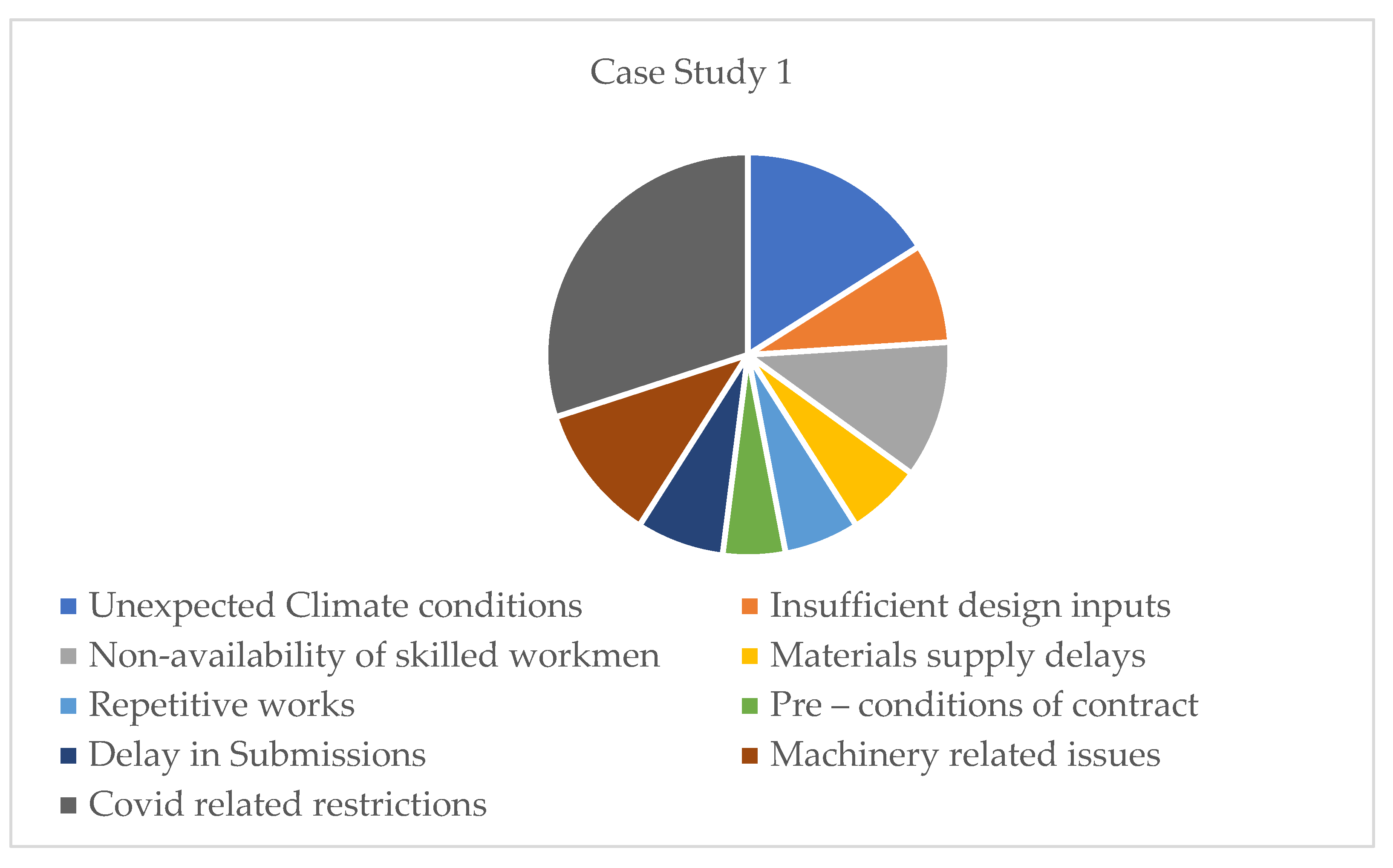

Common reasons for unfinished tasks were found out and tabulated in

Table 3 and the same has been furnished in

Figure 2.

3.1.2. Case Study 2

The project under consideration was two residential blocks Ganga and Yamuna for the teaching staff in a university in Chennai, Tamil Nadu, India. There were four contractors working at various activities of the project. In the Mobilization stage through the non-participants point of view, following information were collected from the site activities of the four contractors and tabulated in

Table 4. In the working stage the task completion status of the major activities was reviewed and the percentage plan complete (PPC) is calculated in

Table 5.

>Questionnaire survey was conducted with the main stakeholders and the activity-based persons to estimate the utility of the Last Planner System.

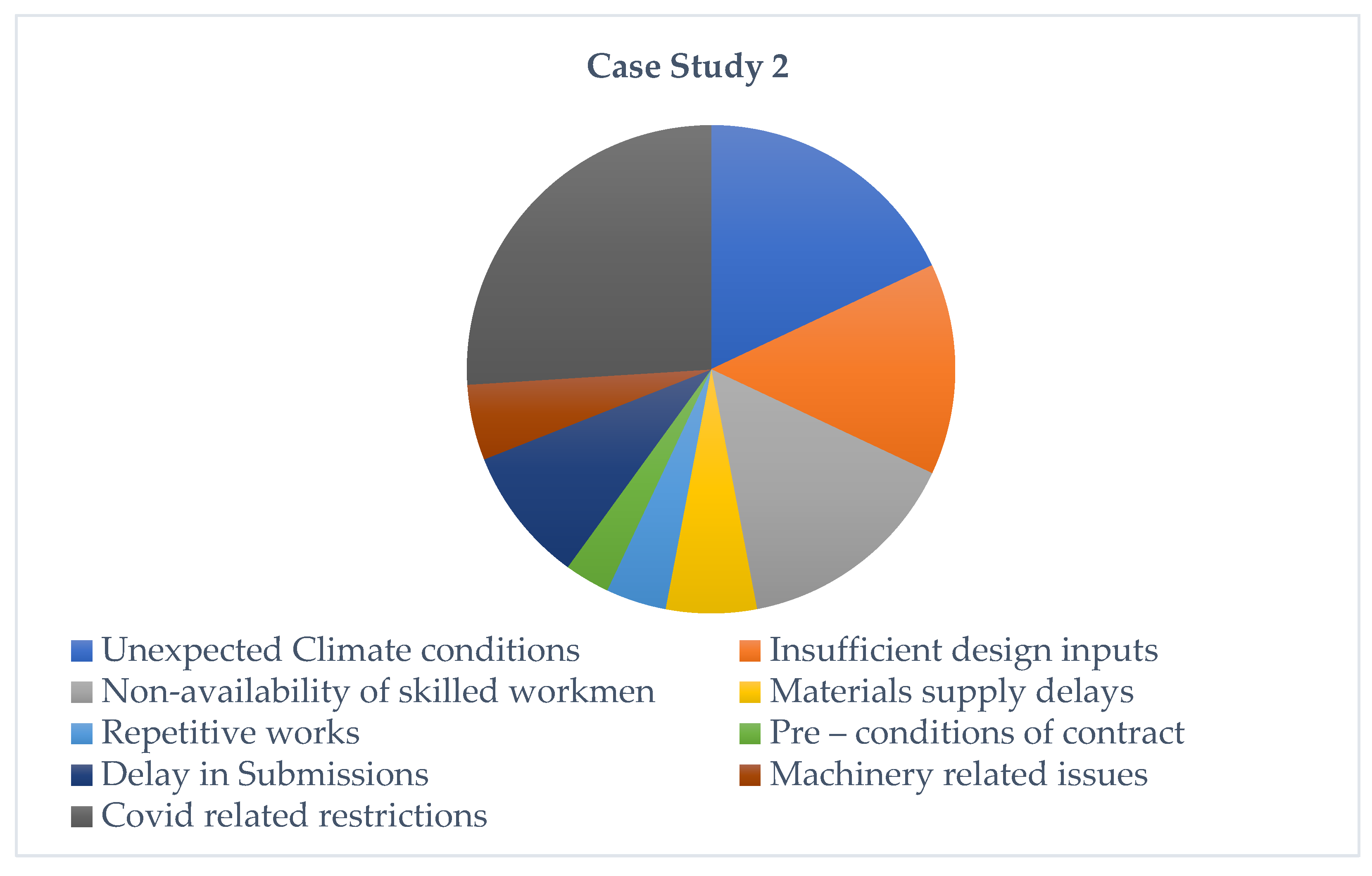

The common reasons for the unfinished activities were extracted and tabulated in

Table 6 and these quantum of reasons are projected in

Figure 3.

3.1.3. Case Study 3

The project under consideration was hostel building for the student inmates to reside in Chennai, Tamil Nadu, India which was executed by two different contractors. The contractors had the same plan of action and the objective for the project. The prime contractor (CONTR 1) with a staff strength of 150 and the other contractor (CONTR 2) comprised of 65 staff members. In the Mobilization stage following information regarding the work methodology were collected from the Non-involved participants from the site activities of the two contractor and tabulated in

Table 7. In the working stage the major activities were constantly reviewed and the percentage plan complete (PPC) of the items of works executed was calculated as given in

Table 8.

Questionnaire study and analysis were restricted to the members who were involved in the tasks to study the utility of LPS method of implementation

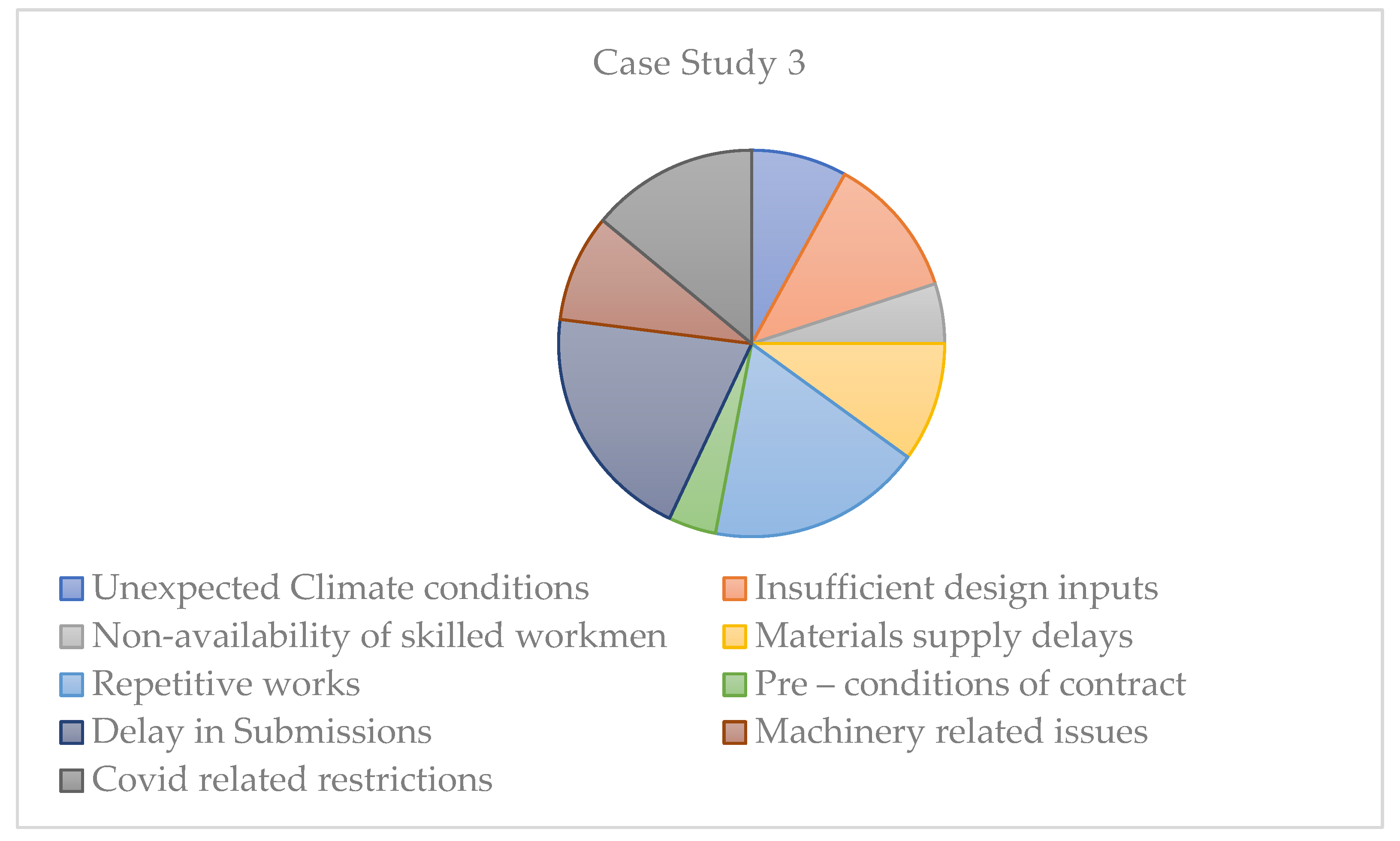

The common factors for the unfinished tasks were studied and tabulated in

Table 9 and the details of the same has been furnished in

Figure 4.

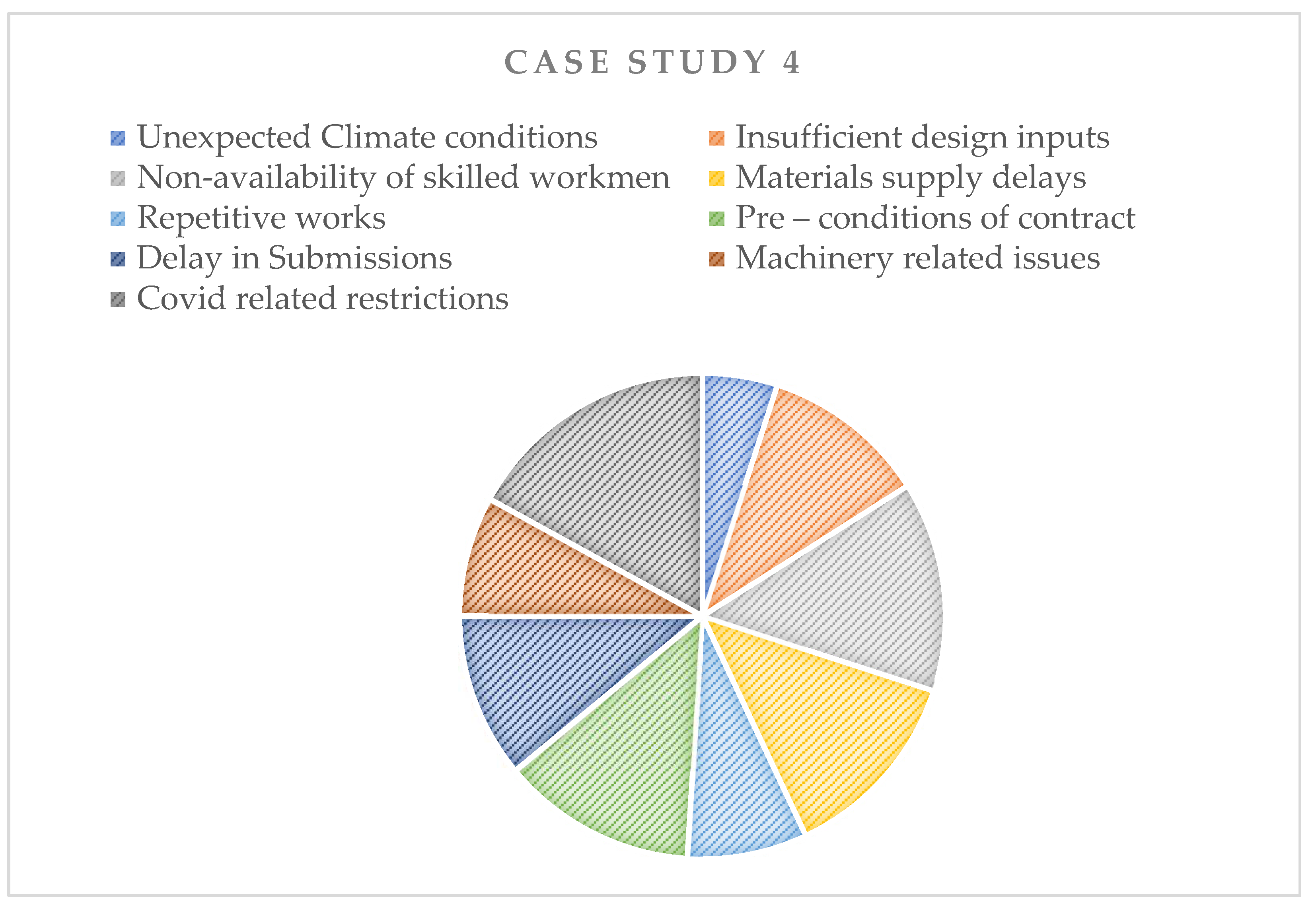

3.1.4. Case Study 4

The project is oriented towards the construction of proposed hostel for the female students in Chennai, Tamil Nadu, India with all amenities. The works are being executed by one main contractor. In the Mobilization stage following information were collected through interview with the main contractor and tabulated as given in

Table 10. In the working stage the major activities were constantly reviewed and the percentage plan complete (PPC) was calculated in

Table 11.

>Questionnaire study and analysis were conducted among the various stakeholders who were involved in the tasks to study the LPS implementation.

The common reasons for the incomplete works were found out and tabulated in

Table 12 and these reasons are given in

Figure 5.

4. Results and Discussion.

The prime goal in the research is to implement the Last Planner System, by first studying the existing project management method. Initially while observing the method of project management, every case study was unique in the project management system being followed. The time taken to make the project team adopt this lean tool of Last Planner System was also different among the four case study projects taken into consideration, while the challenges faced during the pandemic period by implementing the Last planner system was also observed and then the process of implementing the lean tool was started in a sequential manner. The responses while implementing the last planner system was also done in such a way that the entire project team was also acquainted with the changes being made in the already existing project management system. Since the pandemic was an unexpected one and the rules being framed for executing different activities were changing based on the time taken for executing a particular activity and the inputs being received from various stakeholders were different, a common consensus in setting up a standard operating procedure for the various team members was a highly challenging one. The results thus obtained from giving the inputs to accustom to the ways and means of a common and unique project management system had varying responses from all the project team members. Hence the eight factors had to be set up to scrutinize the results and also the responses to the last planner system. The eight factors covered a wide range of the implementation of the lean tool, LPS. Hence to accommodate the above factors, questionnaires were circulated amongst the stakeholders of all the four projects taken in the case study. The fifty-five questions set in the questionnaire covered areas such as means of execution of the project, methodology of project management, details of LPS implementation in the project load analysis phase and execution phase of the project, Analysis of LPS implementation in the project, Hurdles faced during implementation of LPS, Positive factors and finally the benefits arrived out of implementing the Last Planner System. The responses were received in a scale of 1 to 5 from various respondents which covered equally all the stakeholders of the project. The responses were graded through the factors as follows:

5 – Highly Acceptable, 4 – Acceptable, 3 – Acceptable only on certain occasions, 2 – Unacceptable, 1 – Highly Unacceptable.

Any response thus received through the questionnaire had to be analysed to discuss on the results and to understand the depth to which the enactment of the last planner system has reached the project team members. To achieve this an indexing method either through arithmetical calculation or through graphical method will suit the requirement. In this research study, the arithmetical calculation method was found to be both faster and appropriate in judging the responses received from the participants of the fifty-five questionnaire. Hence the Priority Index Method was used to analyse the responses as given in Equations 1 and 2:

Priority Index Method (PI)

Ō = Weighted average

PI = Priority Indices of Importance

𝑘 = Maximum points on Likert scale

∑R = Total number of respondents

Average PI = Points derived / Total number of questions.

Overall, PI = Sum of the average PIs for a factor of all projects / Total number of Projects.

The next step is the grading of the priority index to install upon a theory which will bring into an easy approach towards any new lean tool implementation. The results of the priority index were thus divided as follows:

Highly Acceptable Points – 0.7 and Above

Acceptable Points – 0.6 – 0.69

Acceptable to certain extents – 0.59 and below

The questionnaire survey was conducted by dividing the stakeholders in four individual teams comprising of contractor’s member (53%), client’s engineers (15%), PMC staff (10%), Vendor’s persons (14%) and consultant’s engineers (8%). This is done in this manner because the last planner system implement or belonged to the contractor’s group members and the persons working with the last planner on a daily basis for executing the activities assigned to him also belonged to the contractor. Hence a maximum weightage was given to the respondents belonging to the contractor’s team which is 53%. The order of priority for the number of persons to whom the questionnaire was distributed was made in such a way based on the involvement and the daily requirement of such stakeholder.

The analysis of the Last Planner System was then done by circulating the questionnaire with 55 questions which cover the optimization of arranging the required inputs during pandemic to the above respondents covering wide range of eight factors as given below. The responses were then analyzed for all factors of all the four case study projects by observing the response receive from maximum number of the respondents who had given their opinion against the highly unacceptable question in a particular factor. This way, the order of importance given to all the respondents was in an equivalized and a balanced manner.

3.1. Execution of the project

The questions related to the working and completing of the activities in the project in implementing the last planner system is given in

Table 13. All factors are interlinked with this factor as any variation in any of the other seven factors will have a deep impact on this factor of execution. It was observed that 63% of the respondents had agreed that there was a cordial relationship between the engineers of the project in the below 50 crore project category. Contradictory to that it was found that 65% of the respondents expressed that there was not a safe and efficient environment exist in the site premises in case study 2 and so required action to be taken to improve the safety measures in this project which falls under the 50 – 100 crore project categories.

5.2. Methodology of project management

The questions regarding the methodology of project management with respect to the implementation of the last planner system is given in

Table 14. This factor also varies with each and every activity and mostly on a day to day basis depending on both the quantum and the time taken to receive the required resource among the labour, material, plant & machinery and the cost allocation of the activity. Though there was an acceptance of 73% of respondents for the fact that the covid-19 sort of pandemic system compliance which is prepared based on the standard operating procedure (SOP) to be integrated with the initial plan made for the future projects under the more than 150 crore project category. While 36% of the respondents in both the 50 – 100 crore project and 100 – 150 crore project categories that the payment made to the labours was not satisfactory with the way of working by the labours. This fact needs to be addressed so that the labours work efficiency and the productivity is improved.

5.3. LPS implementation in the design phase

The questions regarding the enactment of the last planner system in the design phase is given in

Table 15. Design phase forms a basis for the execution phase. While this design phase is a continuous phasefor most of the projects, the input given from the design phase to the execution phase must go simultaneously since any delay in the design phase will not only have an adverse effect on the particular activity associated with the design but also to the entire project also. There was a very high acceptance rate of 83% for the fact that the LPS implementation during the design stage reduces the output creation time making it easy for the fast completion of the project. But there was a huge impact of the changes being made during the activities completion phase of the project in the design as responded by majority persons for the 100 – 150 crore project value category and this has to be reduced so that there is no frequent change in the LPS implementation due to the change in design.

5.4. LPS implementation in the construction phase

The questions regarding the construction phase implementation of the lean tool is given in

Table 16. For any project, safety is the prime important factor for which more weightage has to be given since the quality, cost and the time taken for the project are all connected directly with the safety parameter factor of the particular project. The environment and safety measures during implementation of LPS in the construction phase were efficiently taken care as accepted by 81% of the respondents, but the benchmarking of activities under more than 150 crore project category was impossible as only 28% of the respondents agreed to this and hence this factor needs to be concentrated for high value projects.

5.5. Analysis of LPS implementation

Questions were also framed directly related to the LPS implementation as given in

Table 17. This factor is also crucial in not only understanding the effect of carrying out of the last planner system but also to correct mistakes if any and also forms an input for the future projects also. In the implementation of LPS in the construction phase the skill of percentage plan complete and schedules of the project were very effective with an acceptance rate of 85%, but the feedback of the LPS experimental implementation was very poor in the 50 – 100 crore project categories with only 18% acceptance and hence this factor needs to be concentrated more.

5.6. Hurdles in LPS implementation

The hurdles in implementing the LPS implementation were framed as questions as given in

Table 18. These hurdles also again form a varying factor in all the four case study taken into consideration. Among all the hurdles of the projects taken into consideration, availability of skilled workers was a major hurdle in implementation of LPS since the understanding of the procedure of LPS by less skilled workers was not so easy. Around 91% had accepted this fact. On the same hand, in the same project category under less than 50 crores value, availability of covid vaccines for all age category and also frequently changing covid-19 restrictions by the government lead to a major hurdle and hence this has to be given more concentration and adopting to fast changing government policies during any pandemic in the future.

5.7. Quality of LPS implementation

The quality of this LPS implementation was framed as questionnaire as given in

Table 19. There exists no compromise on the quality of the system in any project since any deviation from the expected quality will have an adverse effect directly on the cost of the project. Without any support from the top management implementation of any new method is impossible. This was reflected in the fact that 93% of the respondents agreed to this that there was sufficient support from the top management during all stages of the application of the last planner system in the four case studies taken into consideration for implementation. Also acceptance of the procedure by the last planner gained more weightage when compared with the adjusting to the situation of the implementation. It was only in the fact that maintaining sufficient human resource in the 50 – 100 crore project category was difficult throughout the LPS implementation period while other resources such as materials, plan and machinery and even the cost had no major effect to undergo any change if required. Hence this factor of quality maintenance has to be concentrated more in the 50 – 100 crore project category.

5.8. Benefits in LPS implementation

The benefits arising out of the LPS implementation were framed as a questionnaire as given in

Table 20. The responses received through the factor associated with the benefits will definitely have a positive effect on the involvement of the stakeholders of any project. While there were responses related to benefits were many, the procedural implementation adopted in Last Planner System and the logistics in the project site which also went simultaneously had a huge number of positive response in the questionnaire. The improvement in the site logistics was accepted by 87% of the respondents. Risk assessment factor which is varying and also independent of any implementation though seem to be a major benefit, it is only in the above 150 crore project category the risk assessment was not supposed to reduce by LPS implementation and has to be considered individually.

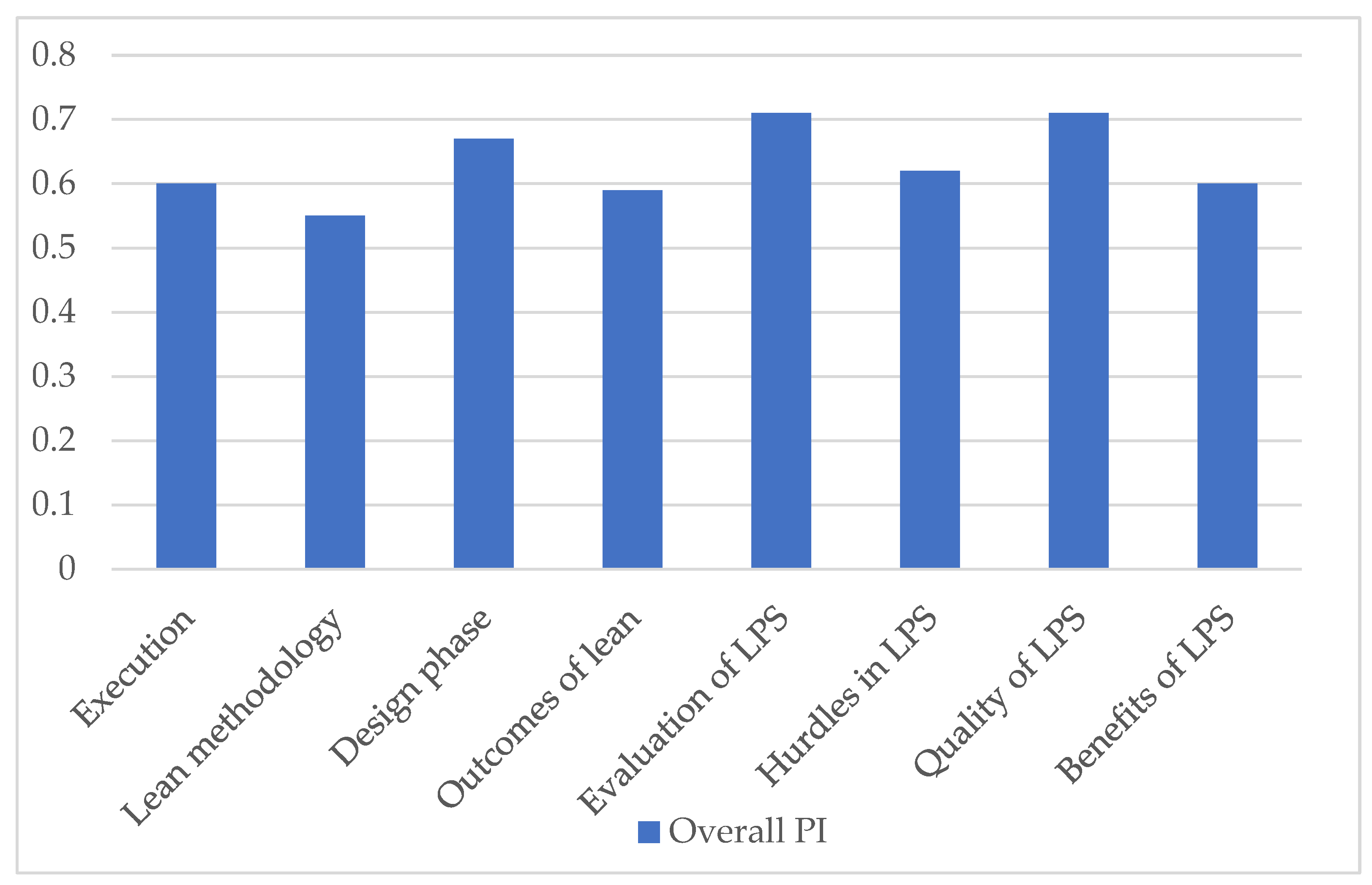

5.9. Result analysis of questionnaire

The responses received from all the four case studies for the eight factors were analysed and the overall priority index was calculated and tabulated in

Table 21 and the same has been figured out as a bar chart in

Figure 6. It was observed that while executing projects during pandemic, more emphasis has to be given for the methodology of lean tool application and its implementation means.

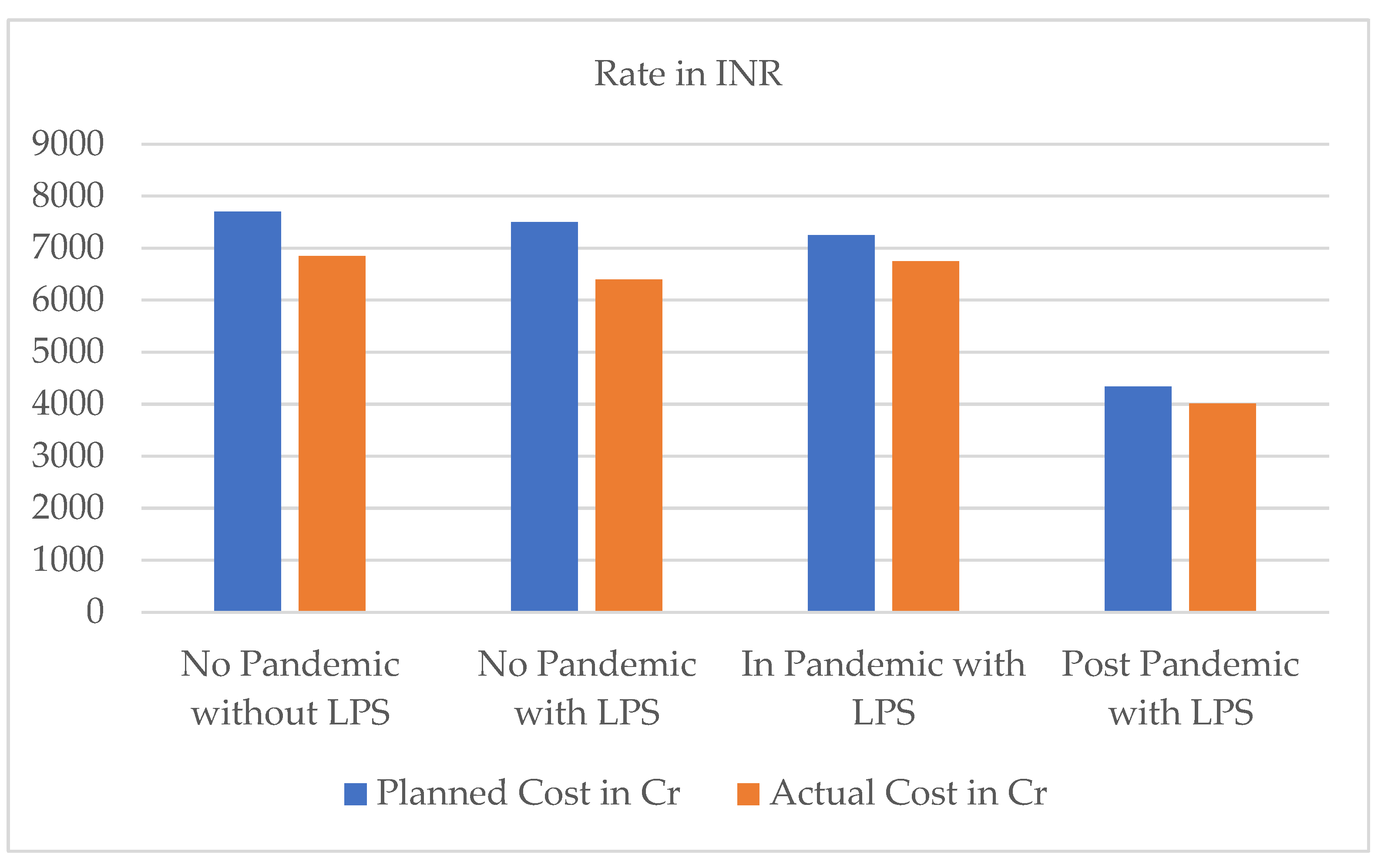

6. Cost benefits in LPS implementation

This Any project with or without implementation of a lean tool system has to be cost effective. This is not only considered in acquiring the estimated profit for the project but also is a crucial factor for the growth of the organization as a whole. To reap the benefits out of the control in the cost, the planned cost vs actual cost incurred in all the four case studies was found over four consecutive periods. The first period was considered before implementation of the Last Planner System under normal conditions, the second period was considered during the enactment of the last planner system under normal conditions, the third period was considered in the enactment of the LPS during the pandemic period and the fourth period was considered in the enactment of LPS during the post pandemic period. Each time frame was spread over a few months. The gap between the cost worked out in the planning stage and the exact cost in a particular month by executing some activities during the particular month was found out. It was found that the variation in all the four case studies, the actual cost was less than the planned cost during the pre-implementation of the Lean tool, which is the Last Planner System. The reasons were found to be that of avoiding Material Shortages, Remobilization of labours only during the requirement stage, allocating funds for unexpected Medical and Sanitation expenses to overcome the impact of the pandemic, etc., Though there was increase in the profit percentage by implementing the Last Planner System, the pandemic impact influenced the profit. But this was overcome by adopting certain factors among the eight as mentioned above to improve the profit during pandemic situation upon implementation of LPS as given in the

Table 22 and

Figure 7.

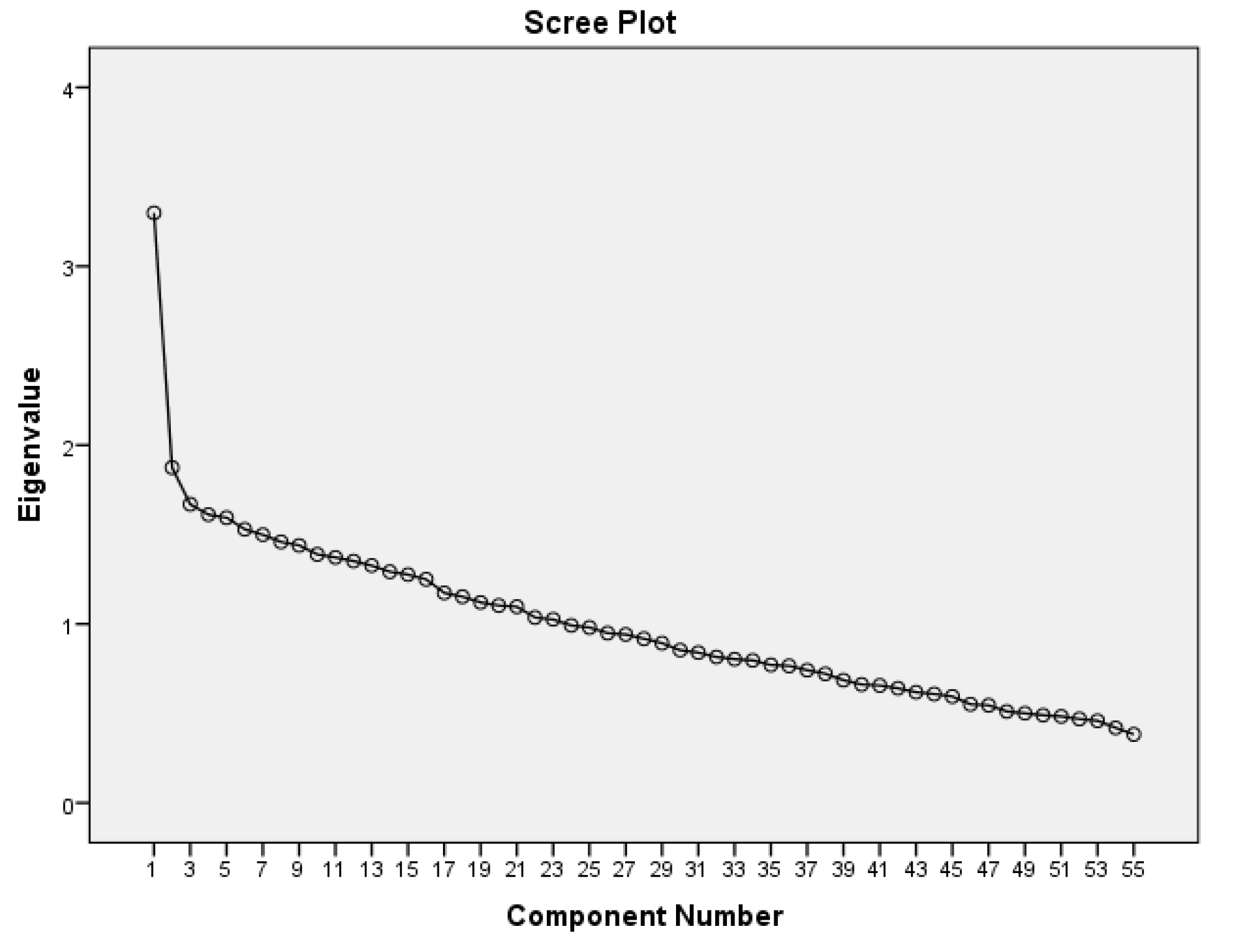

7. Validation

The questionnaire responses were then clubbed into a single format received from all the four case study projects for validating the responses through statistical analysis. The responses were received from the various stakeholders who were involved in similar type of residential accommodation project since some of the stakeholders may be involved in not only the case study under consideration but also with any additional project. Moreover, the questions which were framed were put in order such that the respective project were first studied prior to the employment of the last planner system proceeding towards enactment of the Last Planner system during normal conditions, then during the pandemic period and finally analyzing the results of implementation of the LPS during the post pandemic period. The questions were relatively grouped according to the timeframe as mentioned above. Fifty-five Questions were circulated among 100 respondents of various categories of stakeholders such as contractors, clients, consultants, skilled workmen, field engineers etc., in each case study. Reliability and validity tests were conducted to find out the existence of inner consistent factor of the respondents and the relationship among the responses. The Cronbach’s Alpha value was found to be 0.820. Hence the reliability of the questions existed since the value is greater than 0.7. Hence it was observed that there was a relation between the responses received from various category respondents. Further the KMO and Bartlett’s Test was also conducted as a validity test to find out the relationship between the variables received in the responses. On the statistical analysis, the Kaiser-Meyer-Olkin Measure of adequacy value of the sample and the Sig value also was found. The factor analysis done for the eight domains of the questions framed was analysed for their association. Among the domains the type of association existed is found by factor analysis. There were both dependent variable which are the questions framed among the eight domains and the independent variable being the respondents. Since there existed a correlation among the dependent and the independent variable, it was found that the Kaiser-Meyer-Olkin Measure of adequacy value of sample was 0.766 and the Sig value was found to be 0.000. The total variance was also explained using the Eigen values. It was found that the Eigen values for twenty-two out of the fifty-five questions had a value greater than one as given in the graph below. This meant that the fifty-five questions were separated into twenty-two components. Since the KMO Value is greater than 0.7, there exists a relationship among these twenty-two components.

Figure 8 shows the details of questions which were framed into components.

8. Conclusions

The goal of the study deals with the effects by enacting the Last Planner System of Lean construction tool in four projects in pandemic period. As such, the study focussed on initially observing the methodology of project management and execution of the projects taken into consideration and then implementing the lean based tool which is the Last Planner System in the four residential accommodation projects. While implementing the Last Planner System, the reason for implementing this system was brought out to all the stakeholders (Clients, Contractors, Consultants, Vendors, Supervisors) highlighting the impact of both the internal and external factors causing a huge impact in all the activities of the project. The Last Planner System was implemented in all the four projects wherein all the enabling tasks such as resource allocation, periodic meetings, proper communication among the project team members were taken care. Covid-19 pandemic also came as an unexpected and also a different sort of interruption while implementing the system, but this was overcome through effective coordination of setting up of Standard Operating Procedures with the Last Planner and the stakeholders. The current study highlights the eight factors which must be considered for various category of projects based on the project values starting with below 50 crores moving towards projects ranging from 50 crores to 100 crores, moving on to projects ranging from 100 crores to 150 crores and finally projects ranging above 150 crores. The main factor which was common for all the category of projects during application of the Last Planner System during pandemic period is the factor related to the work methodology to be adopted. This factor also can be relied upon as an important factor for which high level of care to be taken care while execution, since the resources and inputs received for all the category of projects is common. These factors were brought out through responses of various stakeholders and then validated through the reliability and factor analysis. Even if the factors are evaluated through priority index method for adoption in housing accommodation projects, future study can be made for executing commercial and industrial projects by implementing last planner or any other lean tool for improving the impact of stakeholders in executing the projects during pandemic period.

Author Contributions

Conceptualization, S.S; methodology, S.S.; software, S.S.; validation, S.S.; formal analysis, S.S.; investigation, S.S.; resources, S.S.; data curation, S.S.; writing—original draft preparation, S.S and T.C.M..; writing—review and editing, S.S and T.C.M..; and supervision, S.S and T.C.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the author.

Acknowledgments

I am thankful to Prof. Dr. T.Ch.Madhavi, Civil Engineering Department, SRM Institute of Science and Technology. Ramapuram, Chennai- 600089, Tamil Nadu, India for her motivation and support for the research work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Patel Dhruvkumar Shaileshbhai.; Pitroda, J. R. Application of Last Planner System in Construction of Real Estate Projects. ECS Transactions 2022, 107 (1), 6019-6026. [CrossRef]

- Natalie M. Scala.; Vincent Schiavone.; Hylton Olivieri.; Olli Seppänen.; Thais da.; Alves, C.L.; Min Liu.; Ariovaldo Denis Granja. Comparative Analysis of Planning with the Critical Path Method, Last Planner System, and Location Based Techniques in Brazil, Finland, and the United States. Engineering Management Journal 2022, 1-20. [CrossRef]

- Omar Zegarra.; Luis F. Alarcón. Variability propagation in the production planning and control mechanism of construction projects. Production Planning & control 2017, 1-20. [CrossRef]

- Abdul Mannan Hussain, S.M.; Vamsi Krishna, B.; Ranjith Kumar, V. Application and Analysis of Last Planner System in The Construction Industry. International Journal of Research in Engineering & Technology 2014, 2, (6), 33-44.

- Daniela D. Viana.; Carlos T. Formoso.; Eduardo L. Isatto. Understanding the theory behind the Last Planner System using the Language Action Perspective: two case studies. Production Planning & control 2016, 1-13. [CrossRef]

- Emmanuel Itodo Daniel.; Christine Pasquire.; Graham Dickens.; Herman Glenn Ballard. The relationship between the Last Planner System and collaborative planning practice in UK construction. Engineering, Construction and Architectural Management 2017, 24(3), 1-25. [CrossRef]

- Vitaliy Priven.; Rafael Sacks. Effects of the Last Planner System on Social Networks among Construction Trade Crews. Journal of Construction Engineering and Management 2015, 141(6), 04015006. [CrossRef]

- Vitaliy Priven.; Rafael Sacks. Impacts of the Social Subcontract and Last Planner System Interventions on the Trade-Crew Workflows of Multistory Residential Construction Projects. Journal of Construction Engineering and Management 2016, 142(7), 04016013. [CrossRef]

- Ramkumar, R.; Saranya, K.; Saravanan, P.; Srinivasa Perumal, K.P.; Ramshankar, P.; Yamunadevi, V.; Ganeshan, P. Dynamic mechanical properties and thermal properties of madar fiber reinforced composites. Materials Today: Proceedings 2022, 51(1), 1096-1098. [CrossRef]

- Luis A. Salazar.; Paz Arroyo.; Luis F. Alarcón. Key Indicators for Linguistic Action Perspective in the Last Planner® System. Sustainability, 2020, 1-29. [CrossRef]

- Gao Shang.; Low Sui Pheng. The Last Planner System in China’s construction industry A SWOT analysis on implementation. International Journal of Project management 2014, 1-13.

- Olli Seppanen.; Glenn Ballard.; Sakari Pesonen. The Combination of Last Planner System and Location-Based Management System. Lean Construction Journal 2010, 43-54.

- Bassam A. Tayeh.; Khalid Al Hallaq. Techniques and benefits of implementing the last planner system in the Gaza Strip construction industry. Engineering, Construction and Architectural Management 2019, 26(7), 1421-1436. [CrossRef]

- Yicheng Shena.; Katarzyna Julia Zygmunta.; Søren Wandahl. Reducing variability of workforce as a tool to improve plan Reliability. Procedia Engineering 2017, 172, 969 – 976. [CrossRef]

- Emmanuel Itodo Daniel.; Christine Pasquire.; Graham Dickens. Development of Approach to Support Construction Stakeholders in Implementation of the Last Planner System. Journal of Management in Engineering 2019, 35(5), 04019018. [CrossRef]

- Lena E. Bygballe.; Sanne K. Sand-Holm.; Ceyda Pakoglu.; Fredrik Svalestuen. Challenges of Performance Measurement in Lean Construction and the Last Planner System: A Norwegian Case. Lean Construction Journal 2022, 24-40.

- Marion M. Russell.; Min Liu.; Gregory Howell.; Simon M. Hsiang. Case Studies of the Allocation and Reduction of Time Buffer through Use of the Last Planner System. Journal of Construction Engineering and Management 2015, 141(2), 04014068. [CrossRef]

- Mughees Aslam.; Zhili Gao.; Gary Smith. Development of Innovative Integrated Last Planner System (ILPS). International Journal of Civil Engineering 2020, 1-15. [CrossRef]

- Brad W. Wambeke.; Min Liu.; Simon M. Hsiang. Using Last Planner and a Risk Assessment Matrix to Reduce Variation in Mechanical Related Construction Tasks. Journal of Construction Engineering and Management 2012, 138(4), 491-498. [CrossRef]

- Jose L. Fernandez-Solis.; Vishal Porwal.; Sarel Lavy.; Ali Shafaat.; Zofia K. Rybkowski.; Kiyoung Son.; Nishi Lagoo. Survey of Motivations, Benefits, and Implementation Challenges of Last Planner System Users. Journal of Construction Engineering and Management 2013, 139(4), 354-360. [CrossRef]

- Patrick Dallasega.; Erwin Rauch.; Marco Frosolini. A Lean Approach for Real-Time Planning and Monitoring in Engineer-to-Order Construction Projects. Buildings 2018, 8(3), 38. [CrossRef]

- Luai M. El-Sabek.; Brenda Y. McCabe. Framework for Managing Integration Challenges of Last Planner System in IMPs. Journal of Construction Engineering and Management 2018, 144(5), 04018022. [CrossRef]

- Vladimír Bureš.; Andrea Stropková. Labour Productivity and Possibilities of its Extension by Knowledge Management Aspects. Procedia - Social and Behavioral Sciences 2014, 109, 1088 – 1093. [CrossRef]

- Glenn Ballard.; Hajnalka Vaagen.; William Kay.; Bill Stevens.; Mauricio Pereira. Extending the Last Planner System® to the Entire Project. Lean Construction Journal 2020, 42-47.

- Seongkyun Cho.; Glenn Ballard. Last Planner and Integrated Project Delivery. Lean Construction Journal 2011, 67-78.

- Yong-Woo Kim.; Glenn Ballard. Management Thinking in the Earned Value Method System and the Last Planner System. Journal of Management in Engineering 2010, 26 (4), 223-228. [CrossRef]

- Piotr Nowotarskia.; Jerzy Pasáawskia.; Jakub Matyja. Improving Construction Processes Using Lean Management Methodologies – Cost Case Study. Procedia Engineering 2016, 161, 1037 – 1042. [CrossRef]

- Laura Florez.; Jean C. Cortissoz. Using workers compatibility to predict labor productivity through cluster analysis. Procedia Engineering 2017, 196, 359 – 365. [CrossRef]

- Farook R. Hamzeh.; Ghali El Samad.; Samir Emdanat. Advanced Metrics for Construction Planning. Journal of Construction Engineering and Management 2019, 145(11), 04019063. [CrossRef]

- Natalie M. Scala.; Vincent Schiavone.; Hylton Olivieri.; Olli Seppänen.; Thais da.;. Alves, C. L.; Min Liu.; Ariovaldo Denis Granja. Comparative Analysis of Planning with the Critical Path Method, Last Planner System, and LocationBased Techniques in Brazil, Finland, and the United States. Engineering Management Journal 2022, 35(3), 237-256. [CrossRef]

- Cristian Huaman-Orosco.; Andrews A. Erazo-Rondinel.; Rodrigo F. Herrera. Barriers to Adopting Lean Construction in Small and Medium-Sized Enterprises—The Case of Peru. Buildings 2022, 12(10), 1637. [CrossRef]

- Ann Francis, Albert Thomas. Exploring the relationship between lean construction and environmental sustainability: A review of existing literature to decipher broader dimensions. Journal of Cleaner Production 2020. 252, 119913. [CrossRef]

- Teresa Beste.; Ole Jonny Klakegg. Strategic change towards cost-efficient public construction projects. International Journal of Project Management 2022, 40, 372–384. [CrossRef]

- Fernanda, S.; Bataglin.; Daniela D. Viana.; Carlos T. Formoso.; Iamara R. Bulhoes. Model for planning and controlling the delivery and assembly of engineer-to-order prefabricated building systems: exploring synergies between Lean and BIM. Can. J. Civ. Eng. 2019, 47, 168-177. [CrossRef]

- Adib Amany.; Katayoon Taghizade.; Esmatullah Noorzai. Investigating conflicts of expert contractors using the last planner system in building information modeling process. Journal of Engineering, Design and Technology 2020. 18 (6), 1381-1402. [CrossRef]

- Daniel Pérez.; Camilo Lagos.; Luis Fernando Alarc. Key Last Planner System Metrics to Assess Project Performance in High-Rise Building and Industrial Construction Projects. J. Constr. Eng. Manage 2022, 148(1), 04021179. [CrossRef]

- Mahyar Habibi Rad.; Mohammad Mojtahedi.; Michael J. Ostwald.; Suzanne Wilkinson. A Conceptual Framework for Implementing Lean Construction in Infrastructure Recovery Projects. Buildings 2022, 12(3), 272. [CrossRef]

- Krishnaraja, A. R.;Kulanthaivel, P.;Ramshankar, P.; Vincent Herald Wilson.; Ponnusamy Palanisamy.; Vivek, S.; Sampathkumar, V.; Ganeshan, P.; Sashikkumar, M. C.; Raja, K.; Senthil Kumaran Selvaraj.; John Rajan, A.; Jose, S. Performance of Polyvinyl Alcohol and Polypropylene Fibers under Simulated Cementitious Composites Pore Solution. Advances in Materials Science and Engineering 2022, 2022, 9669803. [CrossRef]

- Nitin D More.; Yogita Fulse. Study of Last Planner System in Construction Industry. Journal of Emerging Technologies and Innovative Research 2021, 8(8), 502-510.

- Patel Dhruvkumar Shaileshbhaia.; Pitroda, J. R. Application of Last Planner System in Construction of Real Estate Projects. ECS Transactions 2022, 107 (1) 6019-6026. [CrossRef]

- Jorge L. Rincón.; Jos_e L. Fernández-Solís.; Sarel Lavy.; Jing Du. Effect of Autonomous Agents on Last Planner System Performance in Texas. Journal of Management in Engineering 2019, 35(1), 04018050. [CrossRef]

- Sergei Kortenko.; Lauri Koskela.; Patricia Tzortzopoulos.; Shervin Haghsheno. Can Last Planner System Help to Overcome the Negative Effects of Design-Bid-Build?. Proc. 29th Annual Conference of the International Group for Lean Construction 2021, 787- 796 . [CrossRef]

- Zenawi Mehari Limenih.; Belachew Asteray Demisse.; Abenezer Tariku Haile. The Usefulness of Adopting the Last Planner System in the Construction Process of Addis Ababa Road ProjectsAdvances in Civil Engineering 2022, 2022, 7846593. [CrossRef]

- Sina Moradi.; Piia Sormunen. Lean and Sustainable Project Delivery in Building Construction: Development of a Concetual Framework. Buildings 2022, 12(10), 1757. [CrossRef]

Figure 1.

Process of involvement of project team.

Figure 1.

Process of involvement of project team.

Figure 2.

Percentage of reasons for non-completion of tasks.

Figure 2.

Percentage of reasons for non-completion of tasks.

Figure 3.

Quantum of reasons for unfinished activities.

Figure 3.

Quantum of reasons for unfinished activities.

Figure 4.

Reasons for unfinished works in percentage.

Figure 4.

Reasons for unfinished works in percentage.

Figure 5.

Percentage of reasons for incomplete works.

Figure 5.

Percentage of reasons for incomplete works.

Figure 6.

Questionnaire result analysis.

Figure 6.

Questionnaire result analysis.

Figure 8.

Components of questionnaire.

Figure 8.

Components of questionnaire.

Table 1.

Project management method.

Table 1.

Project management method.

| Site Activities |

Outcomes |

Present scheduling exercise in terms

of labour and material planning |

Labour and materials were not adequately available as per the schedule |

| Frequency of site inspection meetings |

Daily site meetings are not taking place regularly |

| Site coordination |

Work is appropriately planned but not

accurately coordinated within various

disciplines. |

| Communication and relationships |

No proper communication channel and

appropriate coordial relationship between

the project participants |

Table 2.

Status of tasks completion.

Table 2.

Status of tasks completion.

| Weeks |

Number of

Finished Tasks |

Number of

Unfinished Tasks |

Total Tasks |

PPC % |

| 21/05/2020 to 27/05/2020 |

8 |

3 |

11 |

72.72 |

| 28/05/2020 to 04/06/2020 |

11 |

1 |

12 |

91.67 |

| 05/06/2020 to 11/06/2020 |

9 |

2 |

11 |

81.81 |

| 12/06/2020to 18/06/2020 |

9 |

1 |

10 |

90.00 |

| Total |

37 |

7 |

44 |

84.05(Average) |

Table 3.

Reason for non-completion of tasks.

Table 3.

Reason for non-completion of tasks.

| Cause of Unfinished Task |

Causes % |

| Unexpected climate conditions |

16 |

| Insufficient design inputs |

8 |

| Non-availability of skilled workmen |

11 |

| Materials supply delays |

6 |

| Repetitive works |

6 |

| Pre – conditions of contract |

5 |

| Delay in submissions |

7 |

| Machinery related issues |

11 |

| Covid related restrictions |

30 |

Table 4.

Project working method.

Table 4.

Project working method.

| Area of Study |

Contractor 1

(CONTR 1) |

Contractor 2

(CONTR 2) |

Contractor 3

(CONTR 3) |

Contractor 4

(CONTR 4) |

Current schedule

formation and

period of project

meets. |

Project meets

organized as

per

requirement. |

Weekly project

meetings

conducted. |

Daily project

meetings conducted |

Two times a week,

meetings organized |

Information flow

methods. |

No

information

flow methods

adopted. |

No information

flow methods

adopted. |

Information flow

methods adopted. |

By means of walkie

talkie information

flow kept |

Lean information

know how

|

No

information

know how on

lean methods |

No information

know how on

lean methods.

|

Know how exists on

lean methods but

not had

implemented |

No knowledge of lean

information |

Project

management. |

Project in charge

finished the tasks in

Main office and the

project engineer

completed task in

the site. |

Compelled way of

managing when

task moved from

top management |

Task correctly

planned but not

rightly organized |

Despite of a senior

executive posted, the

different opinions in

the low level is seen

which obstructed the

project execution |

Table 5.

Status of activities completion.

Table 5.

Status of activities completion.

| Weeks |

Number of

Finished Tasks |

Number of

Unfinished Tasks |

Total Tasks |

PPC % |

| 26/10/2020 - 1/11/2020 |

9 |

3 |

12 |

75.00 |

| 02/11/2020 - 08/11/2020 |

7 |

7 |

14 |

50.00 |

| 09/11/2020 - 15/11/2020 |

10 |

4 |

14 |

71.40 |

| 16/11/2020 - 22/11/2020 |

7 |

5 |

12 |

58.30 |

| 23/11/2020 - 29/11/2020 |

11 |

4 |

15 |

73.30 |

| 30/11/2020 - 06/12/2020 |

8 |

4 |

12 |

66.70 |

| 07/12/2020 - 13/12/2020 |

6 |

7 |

13 |

46.20 |

| Total |

58 |

34 |

92 |

63.10(Average) |

Table 6.

Reason for non-completion of activities.

Table 6.

Reason for non-completion of activities.

| Cause of Unfinished Task |

Causes % |

| Unexpected climate conditions |

18 |

| Insufficient design inputs |

14 |

| Non-availability of skilled workmen |

15 |

| Materials supply delays |

6 |

| Repetitive works |

4 |

| Pre – conditions of contract |

3 |

| Delay in submissions |

9 |

| Machinery related issues |

5 |

| Covid related restrictions |

26 |

Table 7.

Work methodology.

Table 7.

Work methodology.

| Site Project Tasks |

Contractor-1 |

Contractor-2 |

Current process of

schedule – interval of

project venue

meetings. |

Meetings are conducted

as and when the

requirements come |

Communication

meets are held every

week |

Project management:

activity controller

.

|

The resident manager

and the project

engineers are the

responsible persons |

Charge and site

engineers are made

responsible for

handling site activities |

Information

passing

mechanism. |

No information passing

mechanism used.

|

No information passing

mechanism used. |

Project control

mechanisms in place. |

No project control

mechanism.

|

No project control

mechanism |

Knowledge of Lean / LPS

|

No knowledge of lean

construction techniques.

|

Not aware of Last

Planner System

method. |

Table 8.

Status of tasks completion.

Table 8.

Status of tasks completion.

| Weeks |

Number of

Finished Tasks |

Number of

Unfinished Tasks |

Total Tasks |

PPC % |

| 29/05/2021 to 05/06/2021 |

7 |

6 |

13 |

53.84 |

| 06/06/2021 to 12/06/2021 |

3 |

5 |

8 |

37.50 |

| 13/06/2021 to 19/06/2021 |

2 |

7 |

9 |

22.22 |

| 20/06/2021 to 26/06/2021 |

3 |

4 |

7 |

42.85 |

| 27/06/2021 to 03/07/2021 |

4 |

5 |

9 |

44.44 |

| 04/07/2021 to 10/07/2021 |

4 |

4 |

8 |

50.00 |

| 11/07/2021 to 17/07/2021 |

3 |

4 |

7 |

42.85 |

| Total |

56 |

50 |

106 |

49.34(Average) |

Table 9.

Reason for unfinished completion of work activities.

Table 9.

Reason for unfinished completion of work activities.

| Cause of Unfinished Task |

Causes % |

| Unexpected climate conditions |

8 |

| Insufficient design inputs |

12 |

| Non-availability of skilled workmen |

5 |

| Materials supply delays |

10 |

| Repetitive works |

18 |

| Pre – conditions of contract |

4 |

| Delay in submissions |

20 |

| Machinery related issues |

9 |

| Covid related restrictions |

14 |

Table 10.

Outcome of site activities.

Table 10.

Outcome of site activities.

| Site Activities |

Outcomes |

Present scheduling exercise in terms

of labour and material planning |

Labour and materials were not adequately available as per the schedule |

| Frequency of site inspection meetings |

Daily site meetings are not taking place regularly |

| Site coordination |

Work is appropriately planned but not

accurately coordinated within various

disciplines. |

| Communication and relationships |

No proper communication channel and

appropriate coordial relationship between

the project participants |

Table 11.

Status of tasks completion.

Table 11.

Status of tasks completion.

| Weeks |

Number of

Finished Tasks |

Number of

Unfinished Tasks |

Total Tasks |

PPC % |

| 24/04/2022 - 30/04/2022 |

8 |

6 |

4 |

57.14 |

| 01/05/2022 - 07/05/2022 |

8 |

7 |

15 |

53.33 |

| 08/05/2022 - 14/05/2022 |

7 |

5 |

12 |

5833 |

| 15/05/2022 - 21/05/2022 |

8 |

7 |

15 |

53.33 |

| 22/05/2022 - 28/05/2022 |

5 |

6 |

11 |

45.45 |

| 29/05/2022 - 04/06/2022 |

7 |

5 |

12 |

58.33 |

| Total |

43 |

36 |

78 |

54.32(Average) |

Table 12.

Reason for incompletion of tasks.

Table 12.

Reason for incompletion of tasks.

| Cause of Incomplete Tasks |

Causes % |

| Unexpected climate conditions |

5 |

| Insufficient design inputs |

11 |

| Non-availability of skilled workmen |

14 |

| Materials supply delays |

13 |

| Repetitive works |

8 |

| Pre – conditions of contract |

13 |

| Delay in submissions |

11 |

| Machinery related issues |

8 |

| Covid related restrictions |

17 |

Table 13.

Analysis of execution of the project.

Table 13.

Analysis of execution of the project.

| S.No |

Analysis of Execution |

| 1 |

By means of effective control capabilities, the labours had easy approach to the work spot management. |

| 2 |

In the site, there exists cordial understanding among the site execution persons |

| 3 |

There exists a clear understandable communication among the activities performers. |

| 4 |

In the activity, an executable safe and healthy environment for the activity exists |

| 5 |

The collaboration in the site allows and develops project events to be associated with new trends |

| 6 |

The project managers follow the progress and allocation of works by using new project management tools |

| 7 |

At the site, the project management personnel admit the hard work of labours in the work spot |

| 8 |

The weather condition was favourable at all times during the execution |

Table 14.

Analysis of methodology.

Table 14.

Analysis of methodology.

| S.No |

Methodology |

| 1 |

There prevails a request to mark the status of increment in the work on this activity |

| 2 |

There exists a process of management commitment, taking care of all workers during a pandemic |

| 3 |

The level of satisfaction of payment made to the workers in the work spot was good. |

| 4 |

A deep correlation between the operations and the benefits at the project place prevails |

| 5 |

The process of materials selection and approvals was satisfactory |

Table 15.

Analysis of design phase.

Table 15.

Analysis of design phase.

| S.No |

Analysis of Design Phase |

| 1 |

LPS provide for better improvement in technology |

| 2 |

The design with analysis addresses solvable construction issues |

| 3 |

The LPS implementation in the design phase decreases the period and cost of construction |

| 4 |

There exists good interaction with the design members during implementation. |

| 5 |

The design clubbed with last planner helps to control waste and unwanted activities |

| 6 |

There prevails a huge impact due to changes and delay in issue of the drawings during execution |

Table 16.

Analysis of construction phase.

Table 16.

Analysis of construction phase.

| S.No |

Construction Phase Analysis |

| 1 |

There exists an increase in the safety and environmental problems during construction |

| 2 |

There is an increase in the quality and final finish of the product |

| 3 |

Many aids in finding the barriers within project execution is admitted |

| 4 |

Main importance is given to addition of value during construction |

| 5 |

Reasonable benchmarks made in the product output periods after construction |

| 6 |

There prevails a provision of aid to reduce the movement of site materials during construction |

| 7 |

The implementation system helps to benchmark work methodologies. |

Table 17.

LPS implementation analysis.

Table 17.

LPS implementation analysis.

| S.No |

LPS Implementation Analysis |

| 1 |

LPS was more active in this project plan. |

| 2 |

The results obtained from the experimental implementation was satisfactory when compared to the previous projects |

| 3 |

The weekly work plans and PPC are very much needed to reach the profit goal |

| 4 |

Huge difficulty in implementing of LPS exists. |

Table 18.

Hurdles in LPS implementation.

Table 18.

Hurdles in LPS implementation.

| S.No |

Hurdles in LPS Implementation |

| 1 |

The system leads to improper management and poor-quality control leading to rework |

| 2 |

Many deviations in specifications, additions in quantities and variations in cost is found. |

| 3 |

The contactor’s involvement is found to be satisfactory. |

| 4 |

Many changes in design occurs due to LPS implementation |

| 5 |

Reasonable availability of vaccination during pandemic restriction period exists. |

| 6 |

There prevails an acceptance of endorsements |

| 7 |

Availability of skilled workers is a major concern. |

| 8 |

Risks of non-availability of required materials and machineries exists. |

Table 19.

Quality of LPS implementation.

Table 19.

Quality of LPS implementation.

| S.No |

Quality of LPS Implementation |

| 1 |

Quality education and showing a good responsibility to last planner members prevails |

| 2 |

There is an improvement in the working of the stakeholders |

| 3 |

A Positivity in criticizing the people to make changes occurs. |

| 4 |

There is a difficulty in acquiring the accurate human resource |

| 5 |

Aid received from the top management is good. |

| 6 |

Adaptation to negativity to acquire changes is dynamic. |

| 7 |

Mostly face to face interactions exists with the vendors for all the planned activities |

| 8 |

The weather condition is favourable at all times during the execution |

Table 20.

Benefits of LPS implementation.

Table 20.

Benefits of LPS implementation.

| S.No |

Benefits of LPS Implementation |

| 1 |

Means of controlling during LPS implementation and solving issues related to hurdles occurs often. |

| 2 |

There is a reduction in the part completion of activities and to avoid irrelevant information flow. |

| 3 |

It is easy in formulating viewing thoughts and reducing the effect on the management |

| 4 |

Forming a better judgable and dependable policy is easy. |

| 5 |

Implementing and handing over of all the project related activities and lean principles adoption is satisfactory. |

| 6 |

The implementation establishes project activities and gets along with lean principles |

| 7 |

There prevails a major development in construction framework |

| 8 |

There is no huge requirement of skilled labours |

| 9 |

Decreases the problems of risk assessment |

| 10 |

Better handing over project activities on time prevails. |

Table 21.

Result analysis of questionnaire.

Table 21.

Result analysis of questionnaire.

| Factors |

Overall PI |

| Execution |

0.6 |

| Lean methodology |

0.55 |

| Design phase |

0.67 |

| Outcomes of lean |

0.59 |

| Evaluation of LPS |

0.71 |

| Hurdles in LPS |

0.62 |

| Quality of LPS |

0.71 |

| Benefits of LPS |

0.6 |

Table 22.

Cost analysis through last planner system implementation.

Table 22.

Cost analysis through last planner system implementation.

| Time frame |

Planned Cost in Cr |

Actual Cost in Cr |

Profit in % |

Remarks |

| Stage 1 |

7700 |

6850 |

11.03 |

No pandemic without LPS |

| Stage 2 |

7500 |

6400 |

14.67 |

No pandemic with LPS |

| Stage 3 |

7250 |

6752 |

06.87 |

In pandemic with LPS |

| Stage 4 |

4340 |

4009 |

07.61 |

Post pandemic with LPS |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).