Submitted:

21 September 2023

Posted:

26 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

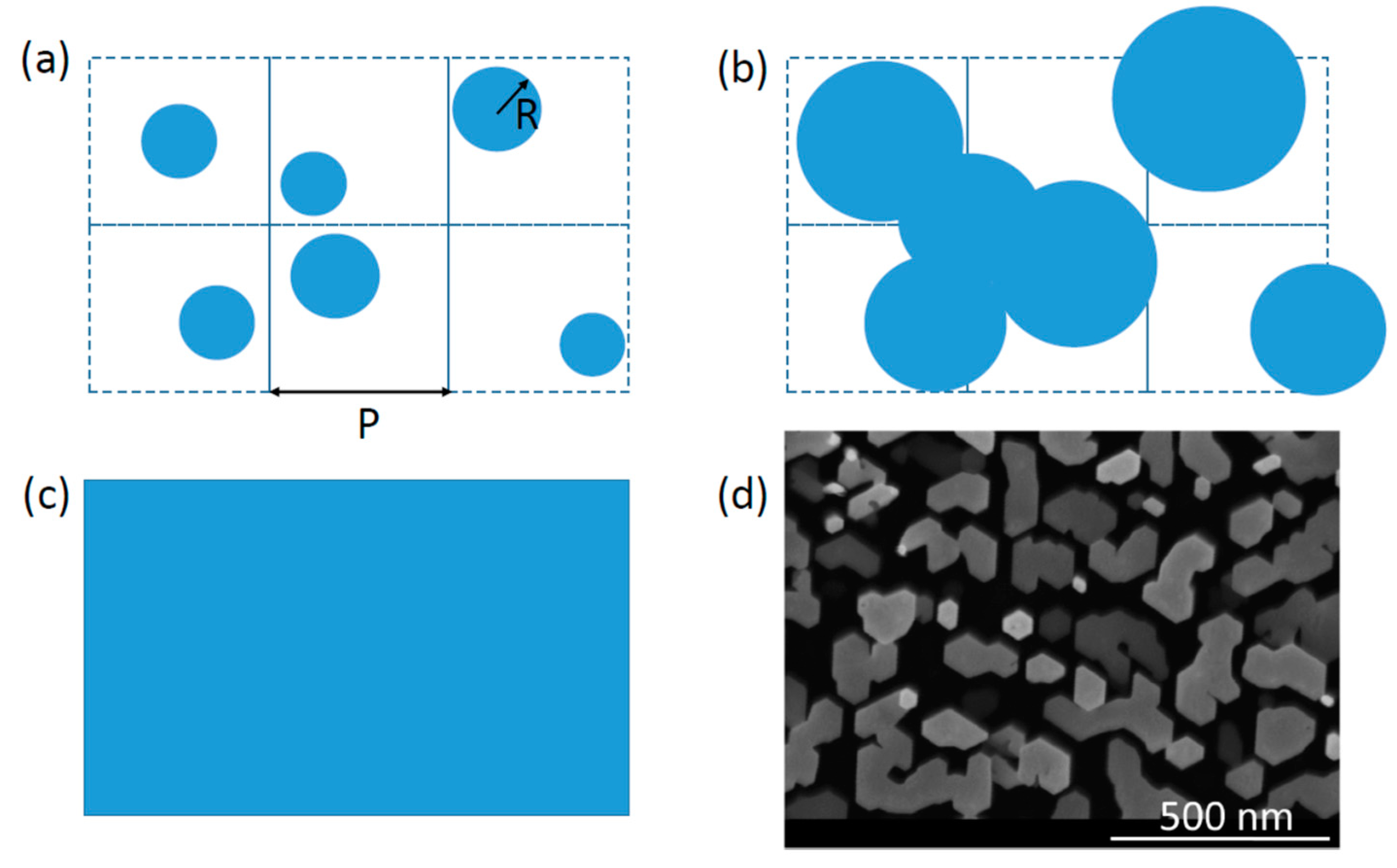

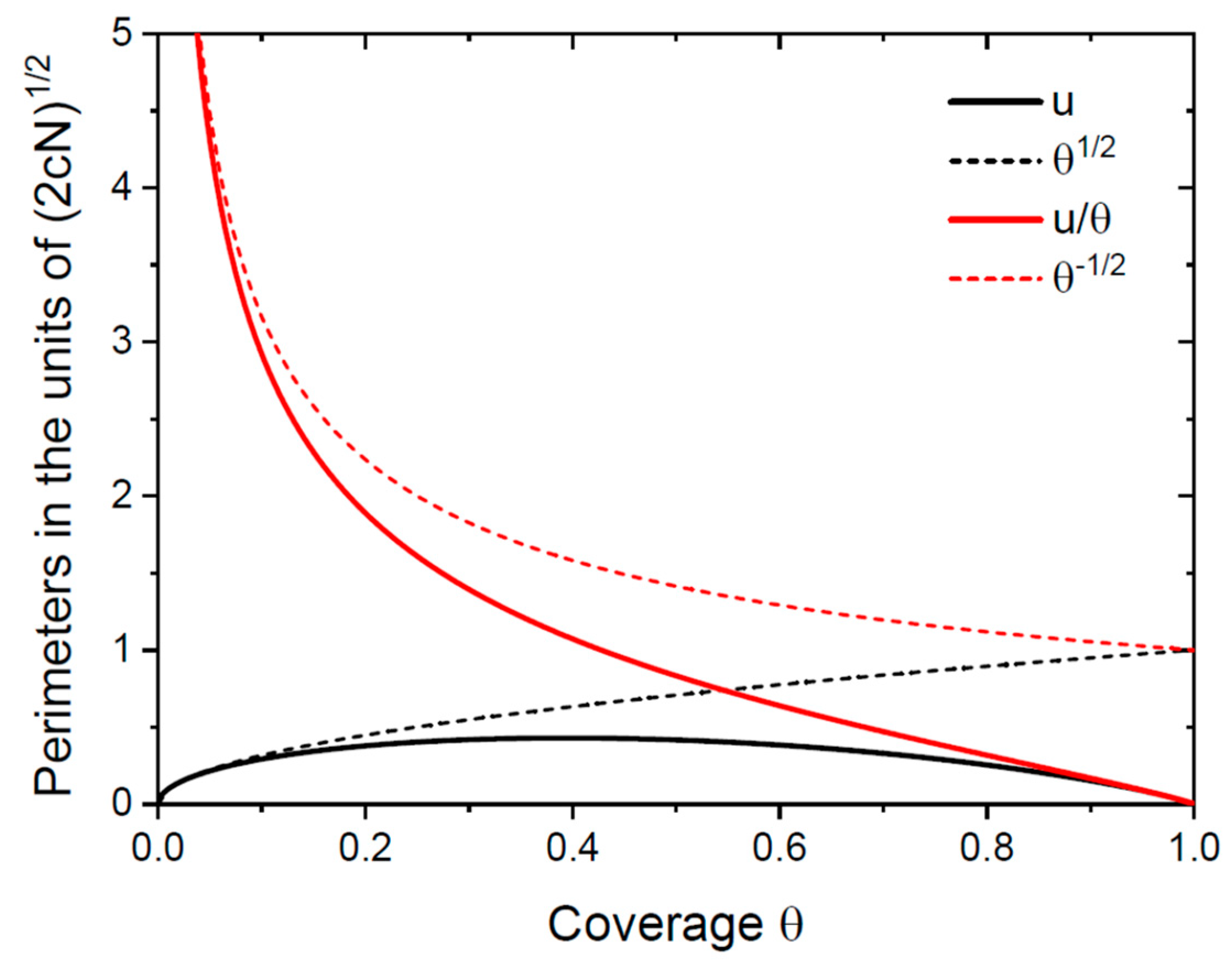

2. Model

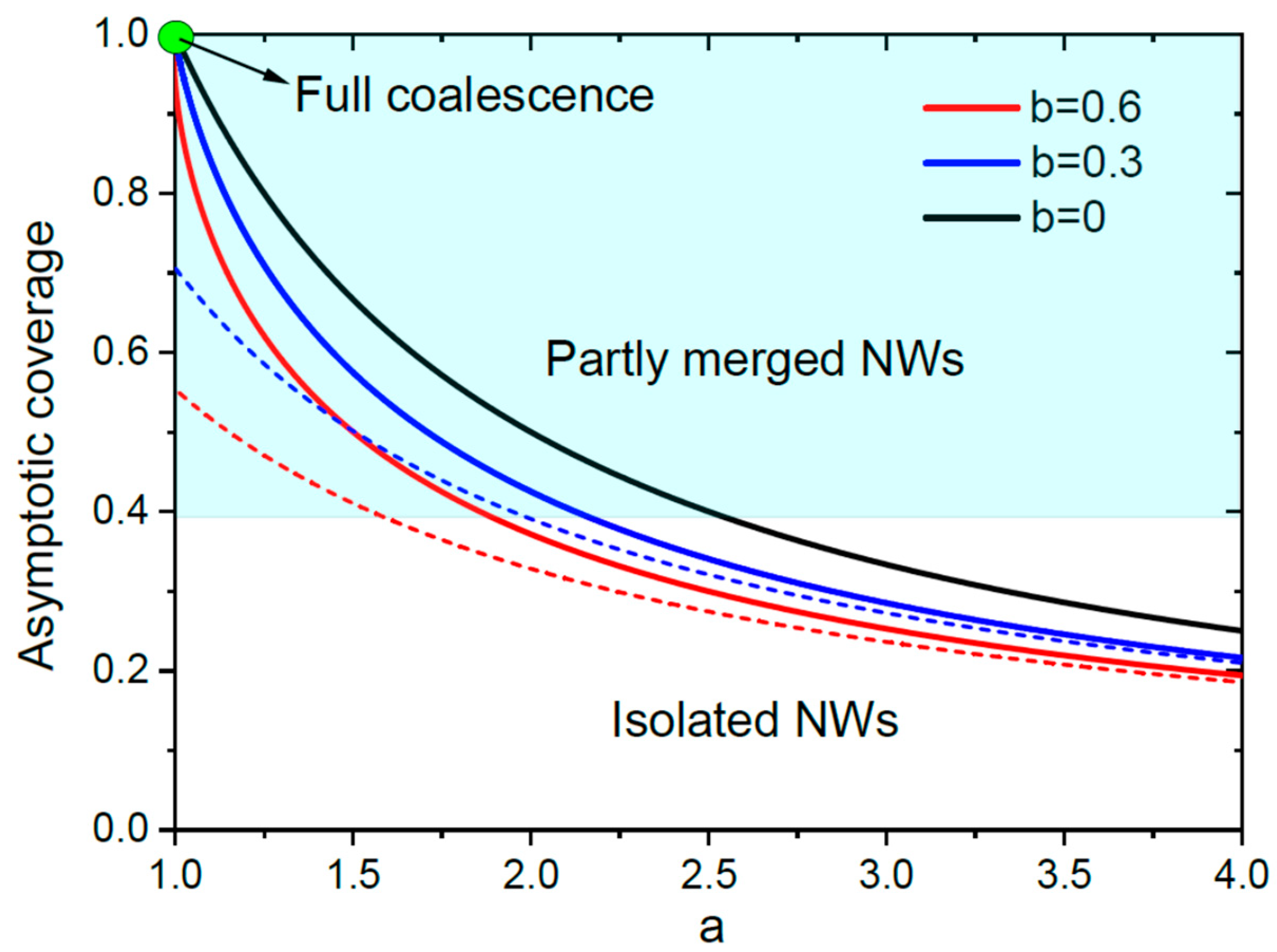

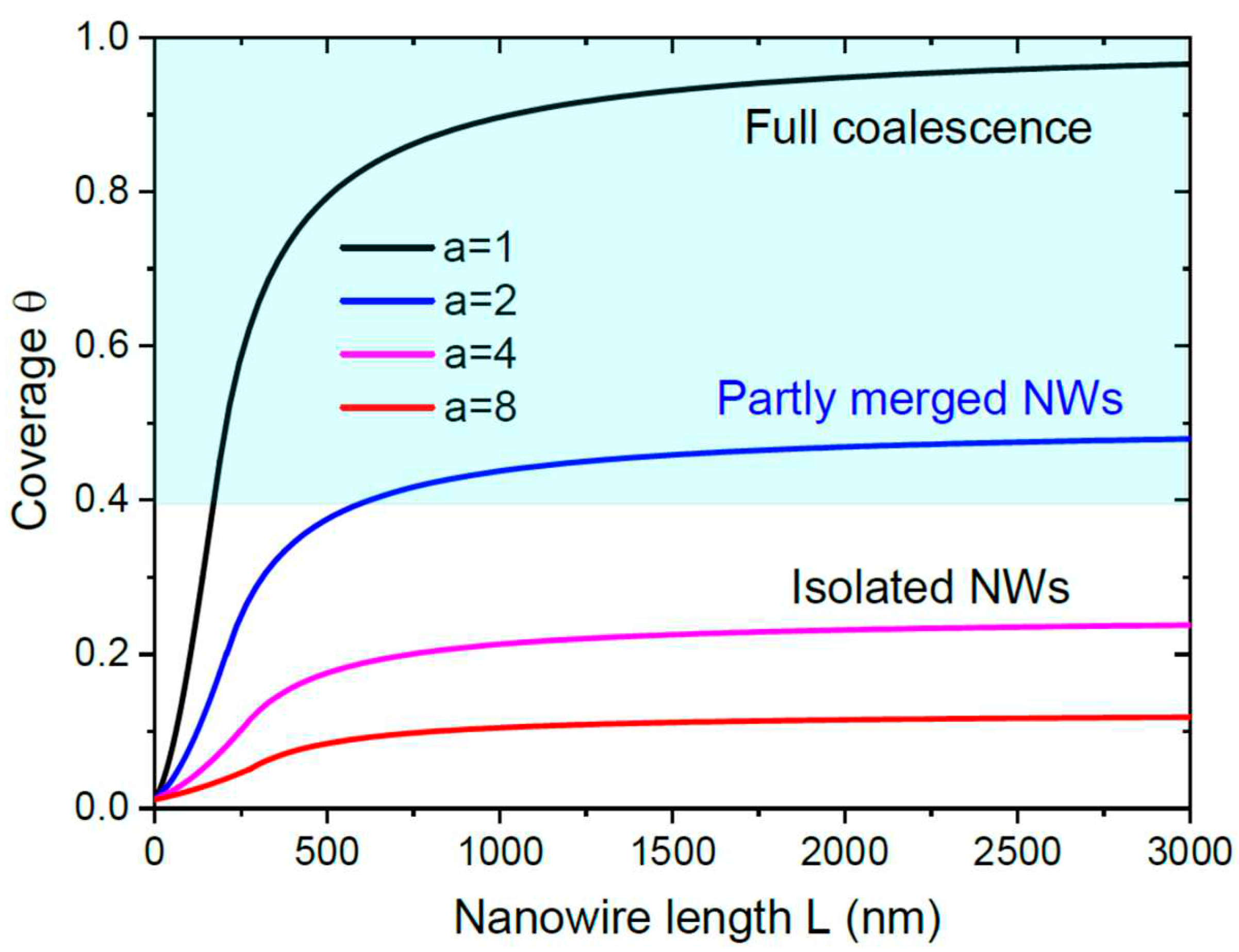

3. Results and discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- McIntyre, P. C.; Fontcuberta i Morral, A. Semiconductor nanowires: to grow or not to grow? Mater. Today Nano 2020, 9, 100058. [Google Scholar] [CrossRef]

- Wagner, R. S.; Ellis, W. C. Vapor-liquid-solid mechanism of single crystal growth. Appl. Phys. Lett. 1964, 4, 89. [Google Scholar] [CrossRef]

- Colombo, C.; Spirkoska, D.; Frimmer, M.; Abstreiter, G.; Fontcuberta i Morral, A. Ga-assisted catalyst-free growth mechanism of GaAs nanowires by molecular beam epitaxy, Phys. Rev. B 2008, 77, 155326. [Google Scholar] [CrossRef]

- Dubrovskii, V. G.; Glas, F. Vapor–liquid–solid growth of semiconductor nanowires, In: N. Fukata, R. Rurali (eds) Fundamental Properties of Semiconductor Nanowires. Springer, Singapore, 2020. [CrossRef]

- Tomioka, K.; Ikejiri, K.; Tanaka, T.; Motohisa, J.; Hara, S.; Hiruma, K.; Fukui, T. Selective-area growth of III-V nanowires and their applications, Mater. Res. 2011, 26, 2127. [Google Scholar]

- Sanchez-Garcia, M. A.; Calleja, E.; Monroy, E.; Sanchez, F. J.; Calle, F.; Muñoz, E.; Beresford, R. J. The effect of the III/V ratio and substrate temperature on the morphology and properties of GaN- and AlN-layers grown by molecular beam epitaxy on Si(1 1 1). J. Cryst. Growth 1998, 183, 23. [Google Scholar] [CrossRef]

- Dubrovskii, V. G.; Consonni, V.; Geelhaar, L.; Trampert, A.; Riechert, H. Scaling growth kinetics of self-induced GaN nan-owires. Appl. Phys. Lett. 2012, 100, 153101. [Google Scholar] [CrossRef]

- Glas, F. Critical dimensions for the plastic relaxation of strained axial heterostructures in free-standing nanowires. Phys. Rev. B 2006, 74, 121302 (R). [Google Scholar] [CrossRef]

- Chuang, L. C.; Moewe, M.; Chase, C.; Kobayashi, N. P.; Chang-Hasnain, C.; Crankshaw, S. Critical diameter for III-V nanowires grown on lattice-mismatched substrates. Appl. Phys. Lett. 2007, 90, 043115. [Google Scholar] [CrossRef]

- Dubrovskii, V. G.; Sibirev, N. V.; Zhang, X.; Suris, R. A. Stress-driven nucleation of three-dimensional crystal islands: from quantum dots to nanoneedles. Cryst. Growth Des. 2010, 10, 3949. [Google Scholar] [CrossRef]

- Kaganer, V. M.; Fernández-Garrido, S.; Dogan, P.; Sabelfeld, K. K.; Brandt, O. Nucleation, growth, and bundling of GaN nanowires in molecular beam epitaxy: Disentangling the origin of nanowire coalescence. Nano Lett. 2016, 16, 3717. [Google Scholar] [CrossRef]

- Fernández-Garrido, S.; Kaganer, V. M.; Hauswald, C.; Jenichen, B.; Ramsteiner, M.; Consonni, V.; Geelhaar, L.; Brandt, O. Correlation between the structural and optical properties of spontaneously formed GaN nanowires: a quantitative evaluation of the impact of nanowire coalescence. Nanotechnology 2014, 25, 455702. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Lin, Y.; J. Creighton, R.; Figiel, J. J.; Wang, G. T. Nanowire-templated lateral epitaxial growth of low-dislocation density nonpolar a-plane GaN on r-plane sapphire. Adv. Materials 2009, 21, 2416. [Google Scholar] [CrossRef]

- Conroy, M.; Zubialevich, V. Z.; Li, H.; Petkov, N.; Holmes, J. D.; Parbrook, P. J. Ultra-high-density arrays of defect-free AlN nanorods: A “space-filling” approach. ACS Nano 2016, 10, 1988. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.; Zhao; S, Liu; X.; Mi, Z. Study on the coalescence of dislocation-free GaN nanowires on Si and SiOx. J. Vac. Sci. Tech. 2014, B 32, 02C114.

- Le, B. H.; Zhao, S.; Liu, X.; Woo, S. Y.; Botton, G. A.; Mi, Z. Controlled coalescence of AlGaN nanowire Arrays: An architecture for nearly dislocation-free planar ultraviolet photonic device applications. Adv. Materials 2016, 28, 8446. [Google Scholar] [CrossRef] [PubMed]

- Mandl, B.; Dey, A. W.; Stangl, J.; Cantoro, M.; Wernersson, L. E.; Bauer, G.; Samuelson, L.; Deppert,K. ; Thelander, C. Self-seeded, position-controlled InAs nanowire growth on Si: A growth parameter study. J. Cryst. Growth 2011, 334, 51. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Phillips, M. R.; Ton-That, C. Coalescence of ZnO nanowires grown from monodisperse Au nanoparticles. CrystEngComm 2015, 17, 4987. [Google Scholar] [CrossRef]

- Lotty, O.; Hobbs, R.; O’Regan, C.; Hlina, J.; Marschner, C.; O’Dwyer, C.; Petkov, N; Holmes, J. D. Self-seeded growth of germanium nanowires: Coalescence and Ostwald ripening. Chemistry of Materials 2013, 25, 215. [Google Scholar] [CrossRef]

- Sabelfeld, K.; Kablukova, E. Stochastic model and simulation of growth and coalescence of spontaneously formed GaN nanowires in molecular beam epitaxy. Comput. Mater. Sci. 2016, 125, 284. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, X.; Wang, Z. Size effect on the spontaneous coalescence of nanowires. Nanotechnology 2019, 30, 245601. [Google Scholar] [CrossRef]

- Chi, C.-Y.; Chang, C.-C.; Hu, S.; Yeh, T.-W.; Cronin, S. B.; Dapkus, P. D. Twin-free GaAs nanosheets by selective area growth: Implications for defect-free nanostructures. Nano Lett. 2013, 13, 2506. [Google Scholar] [CrossRef]

- Yuan, X.; Pan, D.; Zhou, Y.; Zhang, X.; Peng, K.; Zhao, B.; Deng, M.; He, J.; Tan, J. H. H.; Jagadish, C. Selective area epitaxy of III–V nanostructure arrays and networks: Growth, applications, and future directions. Appl. Phys. Reviews 2021, 8, 021302. [Google Scholar] [CrossRef]

- Ramanandan, S. P.; Tomić, P.; Morgan, N. P.; Giunto, A.; Rudra, A.; Ensslin, K.; Ihn, T.; Fontcuberta i Morral, A. Coherent hole transport in selective area grown Ge nanowire networks. Nano Lett. 2022, 22, 4269. [Google Scholar] [PubMed]

- Morgan, N. P.; Dubrovskii, V. G.; Stief, A.-K.; Dede, D.; Sanglé-Ferriere, M.; Rudra, A.; Piazza, V.; Fontcuberta i Morral, A. From layer-by-layer growth to nanoridge formation: Selective area epitaxy of GaAs by MOVPE. Cryst. Growth Des. 2023, 23, 5083. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Jiang, H.; Lau, K. M. Coalescence of planar GaAs nanowires into strain-free three-dimensional crystals on exact (001) silicon. J. Cryst. Growth 2016, 454, 19. [Google Scholar] [CrossRef]

- Oehler, F.; Cattoni, A.; Scaccabarozzi, A.; Patriarche, J.; Glas, F.; Harmand, J. C. Measuring and modeling the growth dynamics of self-catalyzed GaP nanowire arrays. Nano Lett. 2018, 18, 701. [Google Scholar] [CrossRef]

- Dubrovskii, V. G. Theory of MBE growth of nanowires on reflecting substrates. Nanomaterials 2022, 12, 253. [Google Scholar] [CrossRef]

- Dubrovskii, V. G. Theory of MOCVD growth of III-V nanowires on patterned substrates. Nanomaterials 2022, 12, 2632. [Google Scholar]

- Cirlin, G. E.; Dubrovskii, V. G.; Sibirev, N. V.; Soshnikov, I. P.; Samsonenko, Yu. B.; Tonkikh, A. A.; Ustinov, V. M. The diffusion mechanism in the formation of GaAs and AlGaAs nanowhiskers during the process of molecular-beam epitaxy. Semiconductors 2005, 39, 557. [Google Scholar] [CrossRef]

- Johansson, J.; Magnusson, M. H. From diffusion limited to incorporation limited growth of nanowires, J. Cryst. Growth 2019, 525, 125192. [Google Scholar]

- Consonni, V.; Dubrovskii, V. G.; Trampert, A.; Geelhaar, L.; Riechert, H. Quantitative description for the growth rate of self-induced GaN nanowires. Phys. Rev. B 2012, 85, 155313. [Google Scholar]

- Glas, F. Vapor fluxes on the apical droplet during nanowire growth by molecular beam epitaxy. Phys. Status Solidi B 2010, 247, 254. [Google Scholar] [CrossRef]

- Dubrovskii, V. G.; Sibirev, N. V.; Cirlin, G. E.; Bouravleuv, A. D.; Samsonenko, Yu. B.; Dheeraj, D. L.; Zhou, H. L.; Sartel, C.; Harmand, J. C.; Patriarche, G.; Glas, F. Role of non-linear effects in nanowire growth and crystal phase. Phys. Rev. B 2009, 80, 205305. [Google Scholar] [CrossRef]

- Kolmogorov, A. N. On the statistical theory of the crystallization of metals. Bull. Acad. Sci. URSS (Cl. Sci. Math. Nat.) 1937, 3, 355. [Google Scholar]

- Hertenberger, S.; Rudolph, D.; Bichler, M.; Finley, J. J.; Abstreiter, G.; Koblmüller, G. Growth kinetics in position-controlled.

- and catalyst-free InAs nanowire arrays on Si(111) grown by selective area molecular beam epitaxy. J. Appl. Phys. 2010, 108, 114316. 2010; 108, 114316.

- Dubrovskii, V. G. Modeling catalyst-free growth of III-V nanowires: empirical and rigorous approaches. Nanomaterials 2023, 13, 1253. [Google Scholar] [CrossRef]

- Panciera, F.; Baraissov, Z.; Patriarche, G.; Dubrovskii, V. G.; Glas, F.; Travers, L.; Mirsaidov, U.; Harmand, J. C. Phase selection in self-catalyzed GaAs nanowires. Nano Lett. 2020, 20, 1669. [Google Scholar] [CrossRef]

- Kim, W.; Dubrovskii, V. G.; Vukajlovic-Plestina, J.; Tütüncüoglu, G.; Francaviglia, L.; Güniat, L.; Potts, H.; Friedl, M.; Leran, J.-B.; Fontcuberta i Morral, A. Bistability of contact angle and its role in achieving quantum-thin self-assisted GaAs nanowires.

- Nano Lett. 2018, 18, 49.

- Olszewski, K.; Sobanska, M.; Dubrovskii, V. G.; Leshchenko, E. D.; Wierzbicka, A.; Zytkiewicz, Z. R. Geometrical selection of GaN nanowires grown by plasma-assisted MBE on polycrystalline ZrN layers. Nanomaterials 2023, 13, 2587. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).