1. Introduction

Additive manufacturing (AM) technologies have developed intensively over the past decades and are now an essential part of efficient industrial production. 3D-printing no longer serves only as a technology for prototype or small batch production. As a manufacturing technology, the type of 3D-printing not only affects the design of the component along with the material used, but also the development time, functionality, safety, reliability, durability, efficiency, ecological footprint and recyclability [

1]. The working principles of various 3D-printing technologies have enabled the emergence of new methods and procedures for component design. The design of a part is no longer adapted only to traditional manufacturing methods, but also to its application and functionality. It is important that research and development for AM continues to come up with innovative and sophisticated component design methods corresponding to current design advances, due to the increasing number of input requirements for part design and manufacturing [

2,

3].

Manufacturing technology, operating costs, waste management, etc. are limiting factors that influence the component design process, even if they are not directly related to its functionality. Currently, the final design is a compromise that takes into account all specific factors of the product life cycle [

4]. Traditional manufacturing technologies are one of the limiting factors that has a significant impact on product design. Their technological design principles do not always achieve the optimum part properties for a given application. Modern AM (Design for Additive Manufacturing - DfAM) technologies make it possible to implement an innovative component design process. The design of a design is determined only by the application and the specific requirements of the designer for the component [

5]. Based on the new knowledge and understanding of the capabilities of DfAM, the following construction methods were introduced [

6]:

Topology Optimization (TO),

Generative Design (GD),

Multiscale Structure Design) (MSD),

Multimaterial Design (MD),

Parts Consolidation) (PC),

Design for Mass Customization (DfMC),

Lattice Structures (LS),

Thermal Issues in Design (TIiD).

Among the above-mentioned design methods, TO is used in the research due to the ever-increasing development of that type of DfAM, especially in the automotive industry but also in other industries. The principles of TO have been known for several decades. The method provides optimal designs of components that are very complex in terms of geometry and are not manufacturable or difficult to manufacture by traditional manufacturing methods (chip machining, casting). It was with the advent of additive manufacturing technologies that it began to be applied to a greater extent in the component design process [

7,

8,

9]. Currently, TO is implemented in the development of components that have the optimum strength, mass and dynamic parameters for a specific function. The resulting design is characterized by organic shapes that are only manufacturable by 3D-printing [

10,

11]. The above method of construction (TO) is a set of mathematical iterations that work on the principle of removing and distributing material in a defined space of the original shape of the part [

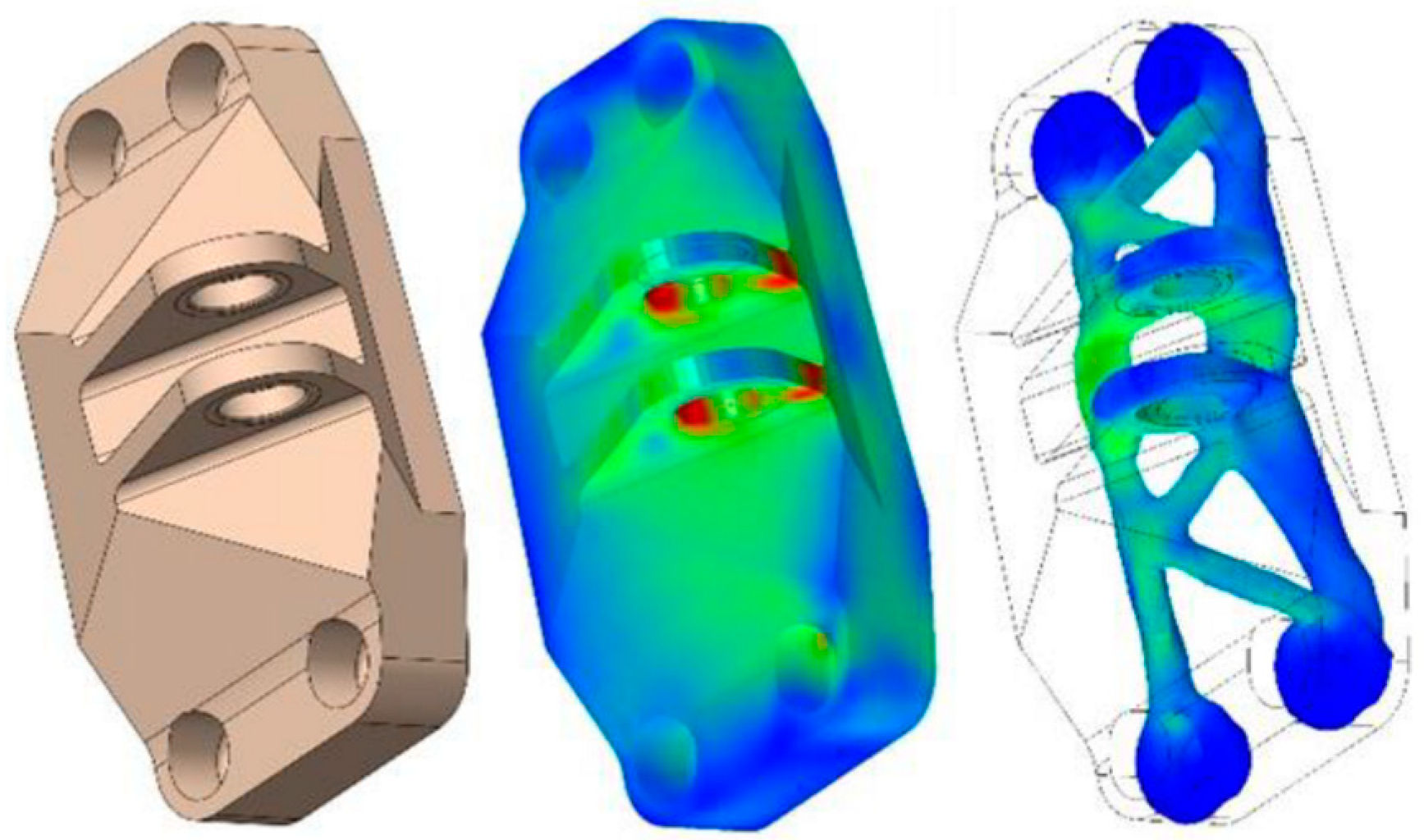

12]. The optimization is based on predefined conditions - load, functional elements of the part that must be preserved (contact surfaces, holes, etc.), links, limiting space (original shape of the part). Often TO is confused with the GD method. The main difference is that TO upgrades the design of an existing component and the GD method creates a new component with an optimal design. The optimization itself is preceded by a strength check of the part using the finite element method. The strength check results in stress and strain maps that serve as input to the optimization process (

Figure 1) [

13].

Today, there are several innovative CAD software on the market that allow designers to use the full production potential and capabilities of additive manufacturing technologies, many of which include TO tools. One of them is the 3DExperience software, whose licenses are available at the research institute of the Faculty of Mechanical Engineering. The software includes two optimization modules:

Structural Generative Design (SGD) – mass optimization,

Flow Generative Design (FGD) – shape optimization with respect to pressure losses.

In the SGD module, the optimization process can be based on different strategies. The TO strategies used are:

maximize the stiffness for a given part weight,

minimize the weight while respecting the constraints,

maximize the value of the lowest natural frequency for a given weight of the part.

For strategies 1 and 3, it is necessary to define the desired weight of the optimized part. The disadvantage of these strategies (especially strategy 1) is that the predefined desired weight may not be the lowest possible weight of the component at which the strength requirements are satisfied. Optimization by strategy 2 requires the determination of a limiting factor, such as:

maximum allowable stress,

maximum allowable deformation,

maximum/minimum wall thickness,

manufacturing technology.

In this strategy, the material is removed as long as the optimization conditions of the TO are met. A schematic representation of the whole optimization process is shown in

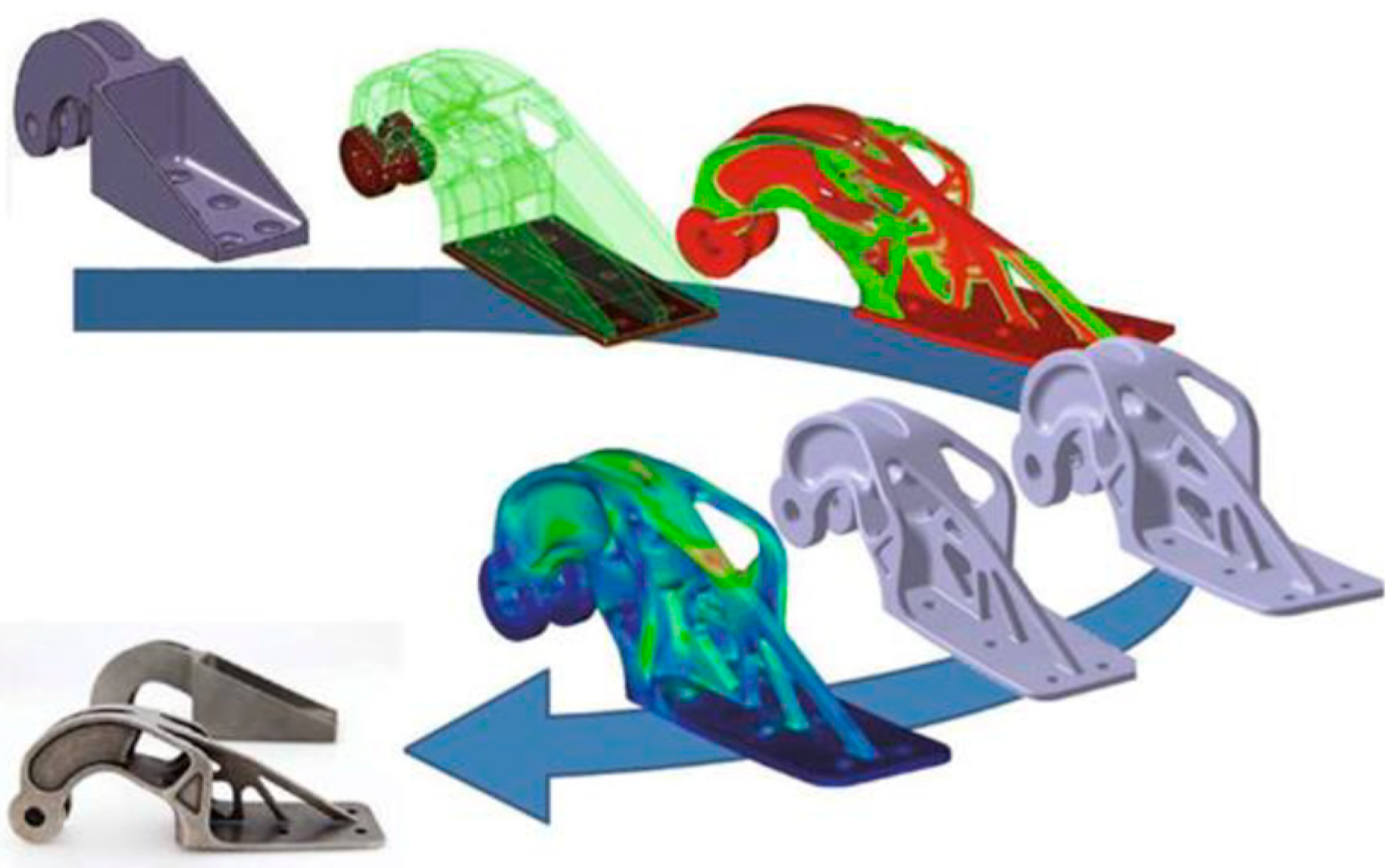

Figure 2 [

15].

The aim of the research activity is to develop, apply and evaluate the effectiveness of an innovative methodology for the design of mobile machine components intended for AM in comparison with traditional design procedures, based on the acquired know-ledge in the field of AM and DfAM methods. The specific aim is to minimize the time required not only to reduce the product development stage but also to manufacture it efficiently, especially for geometrically shape-intensive components, often with the requirement to reduce their weight while maintaining the required strength parameters. To achieve the final result of the research, the following sub-objectives are specified:

to develop a sophisticated design methodology for the construction of mobile machine parts intended for AM based on the current state of the art,

application of the proposed design methodology for shape and weight optimization,

validation of the proposed component manufacturing methodology by evaluating its effectiveness.

2. Materials and Methods

2.1. Traditional method of component designing

To evaluate the effectiveness of the new construction methodology, it is necessary to define the traditional construction procedures. The construction procedure used in companies specialized in the development of mobile machines serves as a comparative benchmark.

2.1.1. Design process by traditional design method

In companies using CAD software in the development of component construction, whose modules and tools do not use the principles of innovative construction methods, the development of the component construction is an iterative process, consisting of two, maximum three iterations of the design solution. The two-iteration development process of the component construction is composed of the following operations:

- 2.

first iteration of the design solution:

material selection,

design of the structure,

design validation by strength,

analysis of strength check results – failure to meet strength requirements;

- 3.

second iteration of the design solution:

analysis of the original design and strength check,

modification of the design,

validation of the new design by strength check,

analysis of strength check results – meeting strength requirements;

- 4.

postprocessing:

analysis of tolerance chain,

manufacturability analysis,

optimization of the final design for production.

The development of the design of a new component, from the given production line, presented in the research consists of two iterations of the design solution, which, based on the data obtained, takes one designer two weeks, i.e. 75 hours.

2.1.2. Applying the traditional method of designing to research

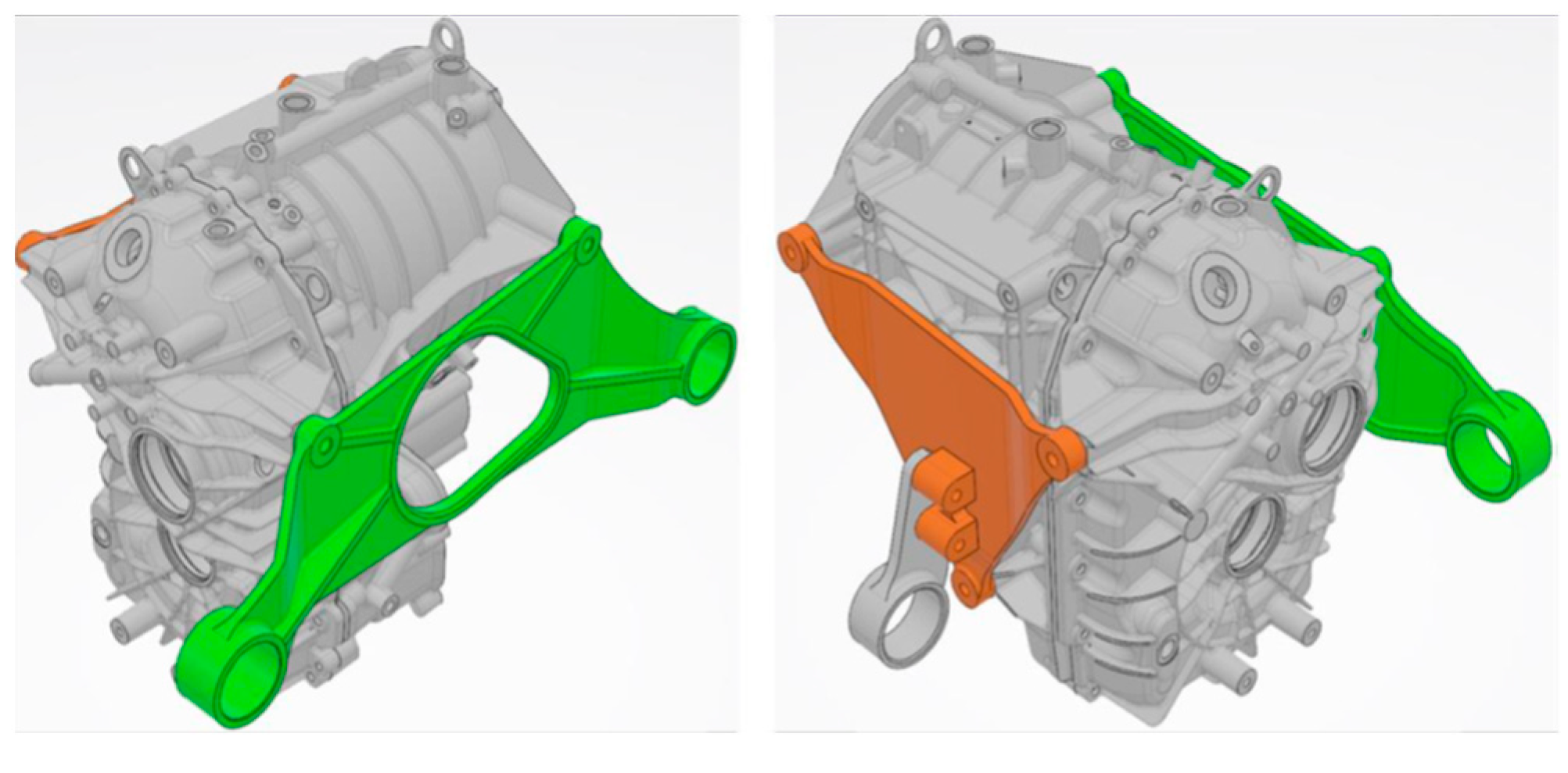

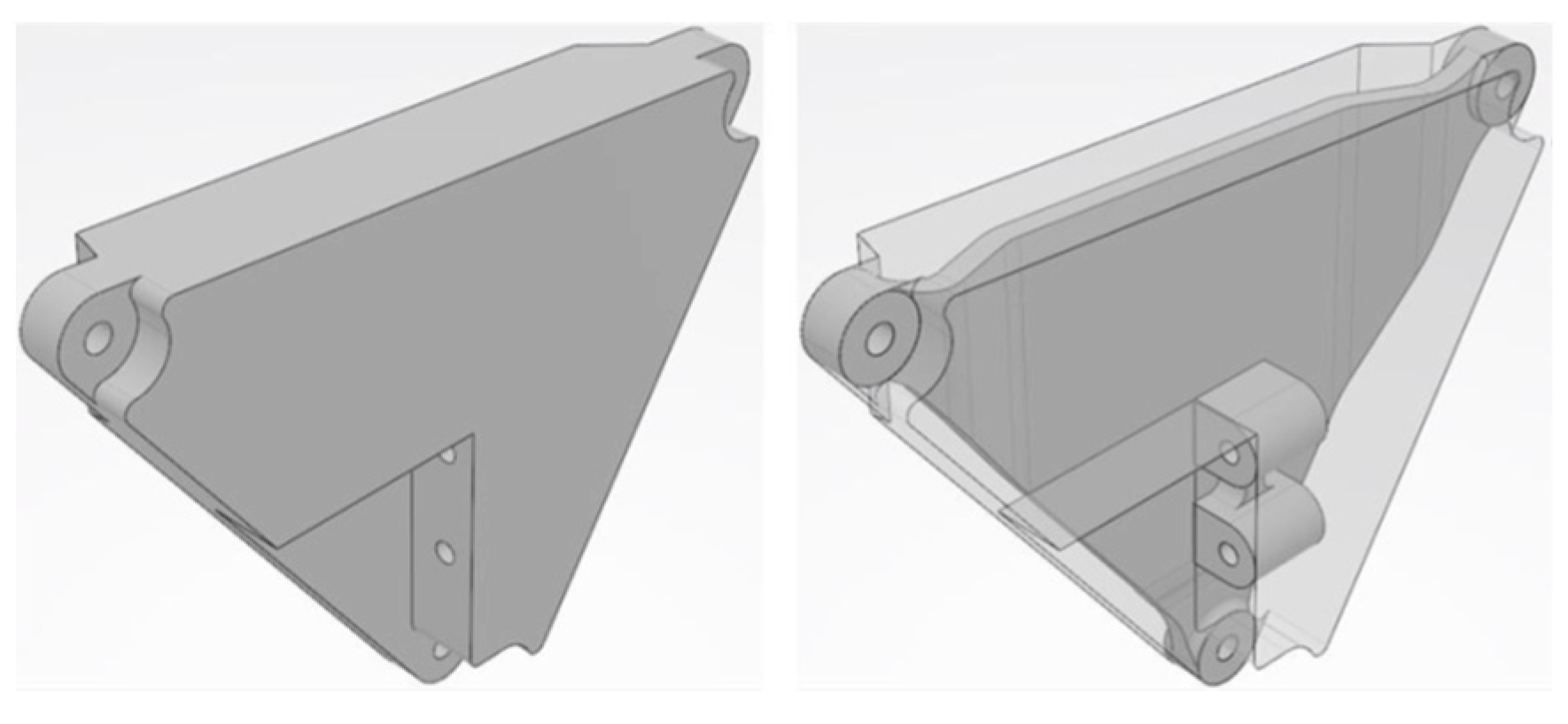

From the traditional design approach, the first iteration was implemented on the electric motor mounts. The assembly of the brackets and the electric motor is shown in

Figure 3.

The weight of the front bracket is 1.9 kg and the weight of the rear bracket is 1.124 kg. However, this design did not meet the strength requirements. The material used was aluminum alloy EN AW-7022 with a yield strength of 370 MPa. In some loading situations, the maximum stress values were 476 MPa and 481 MPa for the front and rear brackets, respectively.

The traditional design method no longer proposed a second iteration of the design that would take into account the strength test results of the first iteration. Instead, the decision was taken to apply CAD software to the development of the components, which includes modules and tools that use the principles of innovative design methods. The TO method in the SGD module of the 3DExperience software was used to develop the component design. The whole procedure serves as a template for the development of a sophisticated design methodology for shape and weight optimization of mobile machine components, which is described in detail in the following section of the research.

2.2. TO designing procedure

The proposed procedure for the development of the design of the electric motor mounts using the TO method in the SGD module of the 3DExperience software consists of five main stages:

2.2.1. Pre-preparation for TO

Part of the TO pre-preparation is the creation of the shape of the object for optimization, definition of its functional elements, creation of the Body (volume in CAD software) of the optimization object, creation and assignment of the material profile.

2.2.1.1. Object shape creation for optimization

The first thing to do is to create an optimization object. The object can be either an existing component or the maximum allowed building volume, the so-called semi-finished product. In this case, the existing components, i.e. the first iterations of the design of the electric motor holders, did not meet the strength requirements. Therefore, the holder blanks were created. The semi-finished volume is the maximum allowable build volume that the future component can occupy. The design of the blank is designed to avoid collision with the frame, interior and other components of the passenger car. The designs of the holder blanks and their comparison with the first iterations of the bracket design are shown in

Figure 4 and

Figure 5. The individual semi-holders were created as separate

Bodies.

2.2.1.2. Defining the functional elements of an object for optimization

Functional elements are those parts of the optimization object volume that are to be preserved after TO. The individual functional elements have been created as separate Bodies. The shape of the Body of the functional elements has a significant impact on the quality of the mesh and thus on the progress of the individual simulations that are part of the TO. Therefore, the shapes of the Bodies of the functional elements were designed to follow the contour of the shape of the semi-finished product with a certain distance.

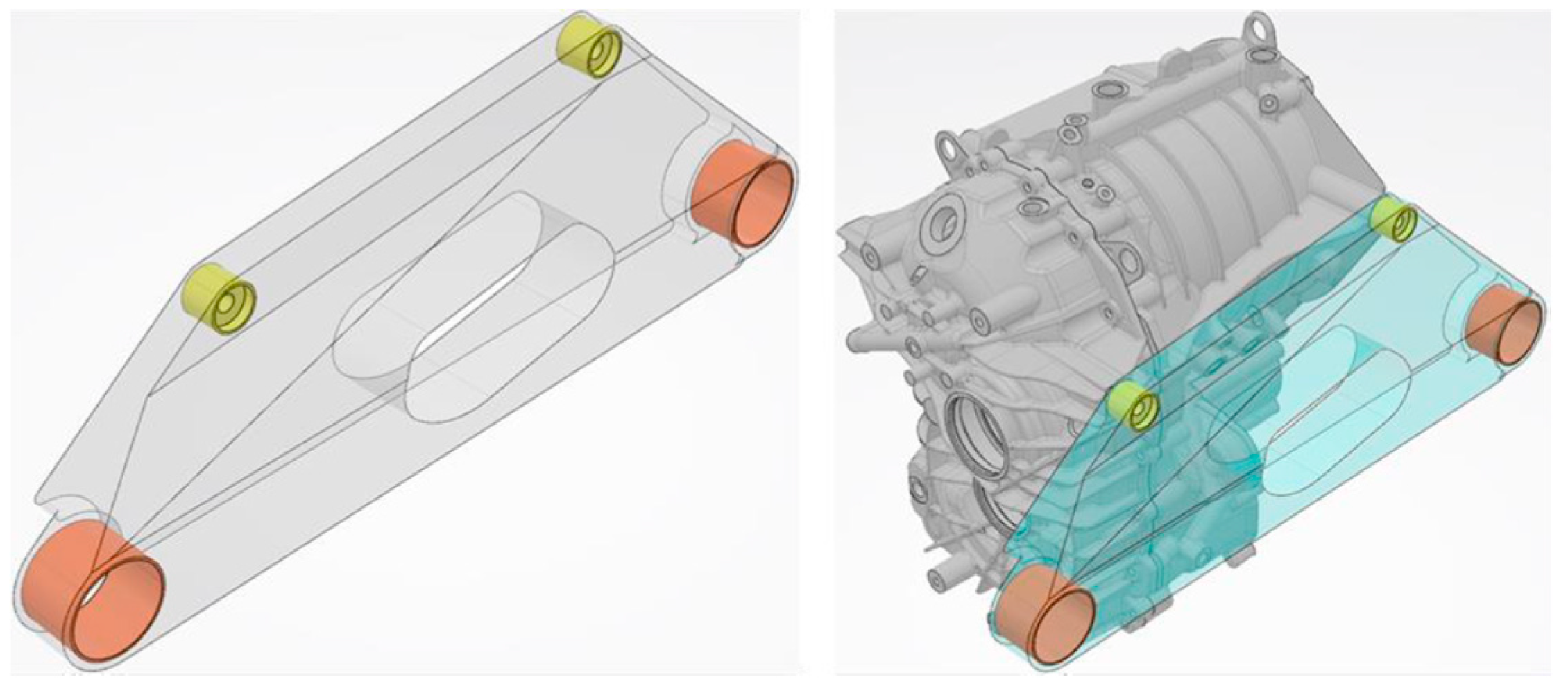

In the case of the front bracket, the following object functional elements were retained for optimization (

Figure 6):

through-holes and recesses for screws (marked in yellow),

the holes for the silent blocks (shown in orange).

In the case of the rear bracket, the following functional elements of the optimization object were retained (

Figure 7):

through-holes for screws (marked in yellow),

the threaded holes for the rear arm attachment (shown in orange).

2.2.1.3. Creating the Body object for optimization

By linking the Body of the blank with the Body of the functional elements, the Body of the optimization object is created, which was used in the next steps of the optimization process. The Partition Design Space function is used to create the Body object for optimization.

2.2.1.4. Create and assign a material profile to the optimization object

In order for a material profile to be usable for a TO, three parameters need to be defined:

density – 𝜌,

Young's modulus – 𝐸,

Poisson's number – 𝜇.

Aluminum alloy AlSi10Mg, which is suitable for fabrication by additive manufacturing using DMLS or SLM technologies, was selected for the structural design of electric motor mounts by TO method. Its parameters are:

density: 𝜌=2650 𝑘𝑔.𝑚-3,

Young's modulus: 𝐸=66 𝐺𝑃𝑎,

Poisson's number: 𝜇=0.325,

yield stress: 𝑅𝑒=260 𝑀𝑃𝑎.

2.2.2. TO

The TO process in the SGD module of the 3DExperience CAD software consists of the following sequential steps:

defining the TO strategy,

definition of the optimization object and its functional elements,

definition of force loads, constraints and their assignment to load cases (Load Cases),

mesh creation,

initial strength check of the optimization object,

definition of optimization conditions,

TO,

concept generation,

strength check of the generated concepts.

2.2.2.1. TO strategy

In the SGD module, TO can follow three different strategies as mentioned earlier (Chapter 1):

maximize the stiffness with respect to the specified component mass,

minimize the weight while respecting the constraints,

maximize the value of the lowest natural frequency for a given component weight.

In the development of the electric motor mounts, the objective was set to achieve the lowest possible weight at which the components meet the strength requirements. Therefore, the strategy TO no. 2 Minimize the weight while respecting the specified constraints was chosen.

2.2.2.2. Object to be optimized and its functional elements

The user selects from the list of all available Bodies whose internal structure contains partitions, i.e. the Body of the Optimization Object. In the next step, it is necessary to select which volumes of the optimization object are to be preserved and which are to be optimized. The software also informs the user of the masses of the individual volumes. The total weight of the front bracket blank is 12.776 kg, of which the weight of the functional volumes is 0.188 kg (1.46 %) and the weight of the optimized volume is 12.589 kg (98.54 %). The total weight of the rear bracket blank is 6.668 kg, of which the weight of the functional volumes is 0.198 kg (2.96 %) and the weight of the optimized volume is 6.471 kg (97.04 %).

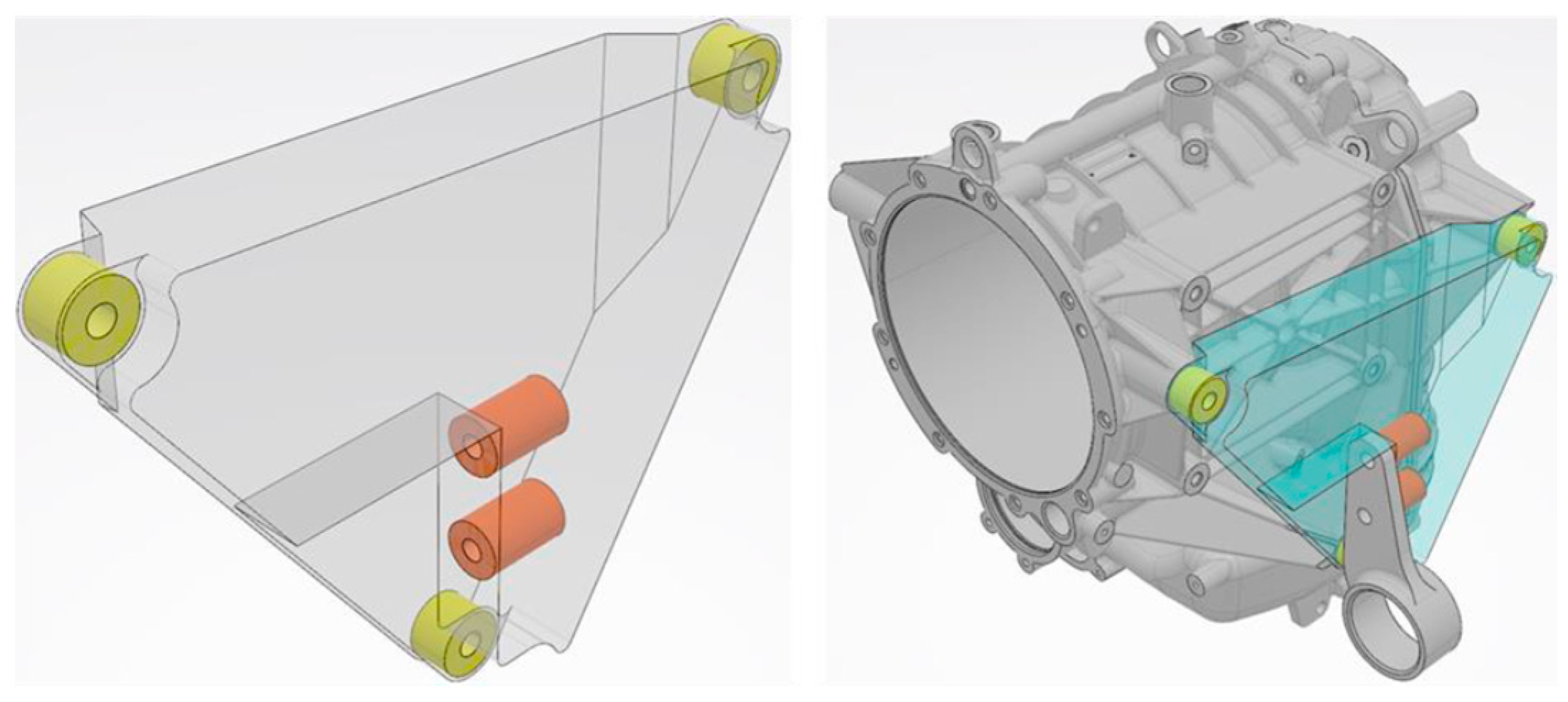

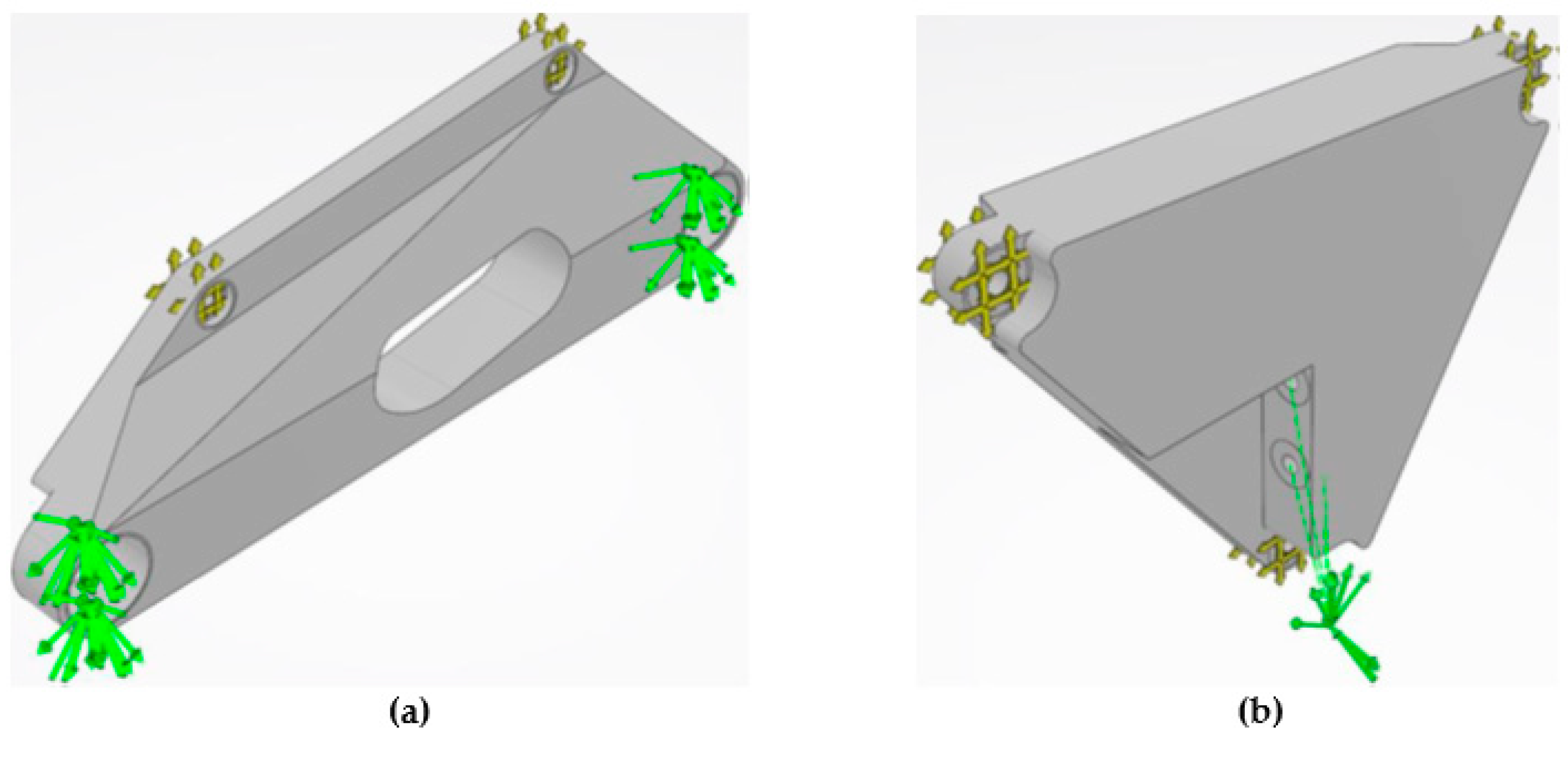

2.2.2.3. Definition of load situations

The loads acting on the components were obtained from measurements performed on a real vehicle during thirty load situations. The individual load situations represent conditions that may occur during vehicle handling, driving or collision. The measured forces were in the silentblocks (

Figure 8 position 1,2 and 3) through which the electric motor with brackets is attached to the vehicle frame. These forces are then applied to the inner circumference of the front bracket hubs and the rear arm hubs, from which the force effects are transferred to the rear bracket. All thirty load situations are represented in the software by load cases. A load case consists of the applied force effects (force, moment, ...) and the constraints.

For the front holder, the load case includes (

Figure 9a):

- ○

two rotational links (Rotate type),

- ○

four sliding links (Slide type).

For the rear holder, the load case includes (

Figure 9b):

- ○

three rotating links (Rotate type),

- ○

six sliding links (Slide type).

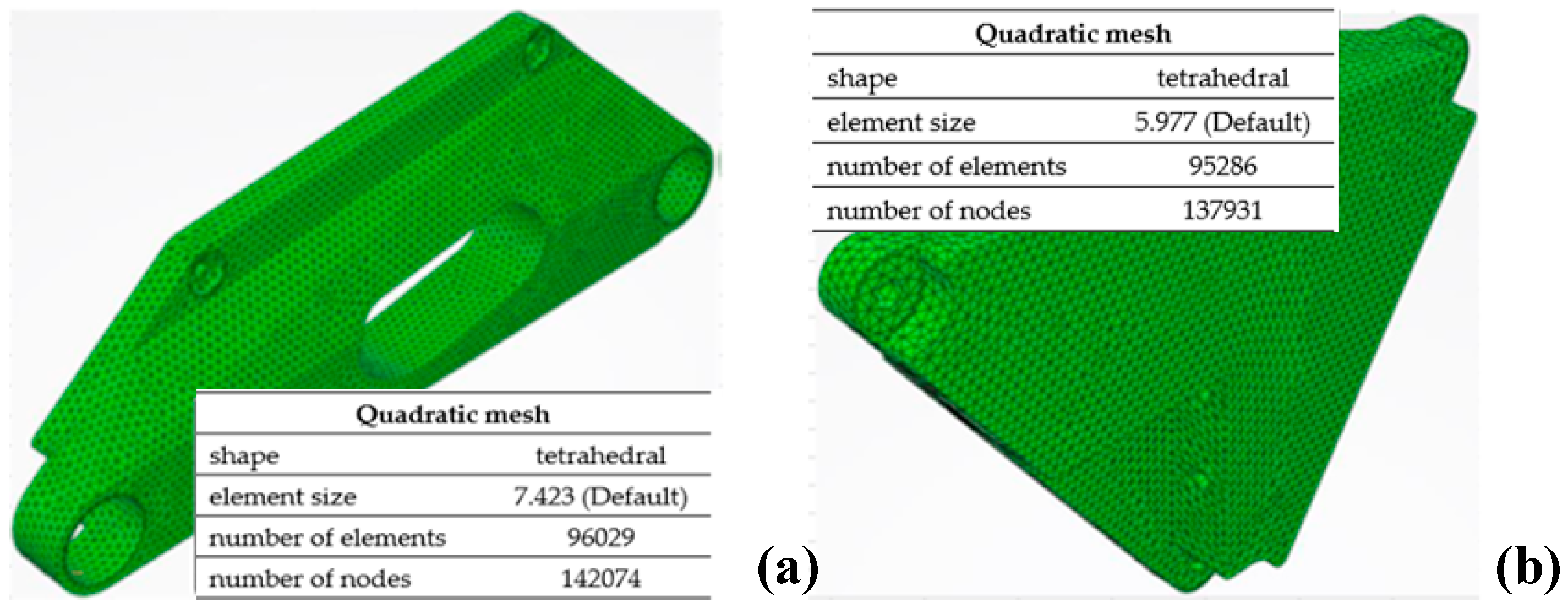

2.2.2.4. Creating a mesh

Based on the results obtained from the analysis of the

mesh influence on the progression and outcome of the TO, a quadratic

mesh configuration with a default number of elements (

Automatically deducated quadratic mesh option) was used for both holders. The quadratic

mesh network with default number of elements of the front holder is shown in

Figure 10a and that of the rear holder in

Figure 10b. The shapes of the

Body function elements were designed to follow the contours of the shape of the blank with some distance to avoid certain qualitative errors of the

mesh.

2.2.2.5. Initial strength check of the object for optimization

The initial strength check is used to demonstrate the optimization potential of the object to be optimized. Its result serves as input to the TO. Based on the stress map, the material is removed or reorganized in the blank volume. The value of the maximum stress from the input strength check must be lower than the value of the allowable stress in the optimization condition. For the purpose of evaluation and analysis, 30 stress situations with strength control were performed.

After analyzing the results of the input strength control, it was decided that the parts will be optimized only for the ten most unfavorable-greater load situations. This accelerated the entire development process. The most unfavorable load situations did not develop only on the basis of voltage values, but also on the basis of the sizes of the individual components of the acting forces.

2.2.2.6. Definition of optimization conditions

A single optimization condition, i.e. the maximum allowable stress, was defined for the TO of the electric motor holders. In order to be able to run the optimization process at all, it is necessary that the value of the maximum allowable stress is greater than the stress values obtained during the initial strength check of the semi-finished product. On the other hand, it should not be greater than the yield strength or ultimate strength of the material used. On the basis of consultations with companies using additive SLM technology for the production of dynamically stressed mobile machine components made of aluminum alloy AlSi10Mg, it was found that the maximum stress value (reduced Von Mises stress) of the static strength analysis should be in the range of 90 MPa - 110 MPa. Compliance with this condition will achieve the required service life of the components. A maximum allowable stress value of 100 MPa was set as the optimization condition for the TO of both motor holders.

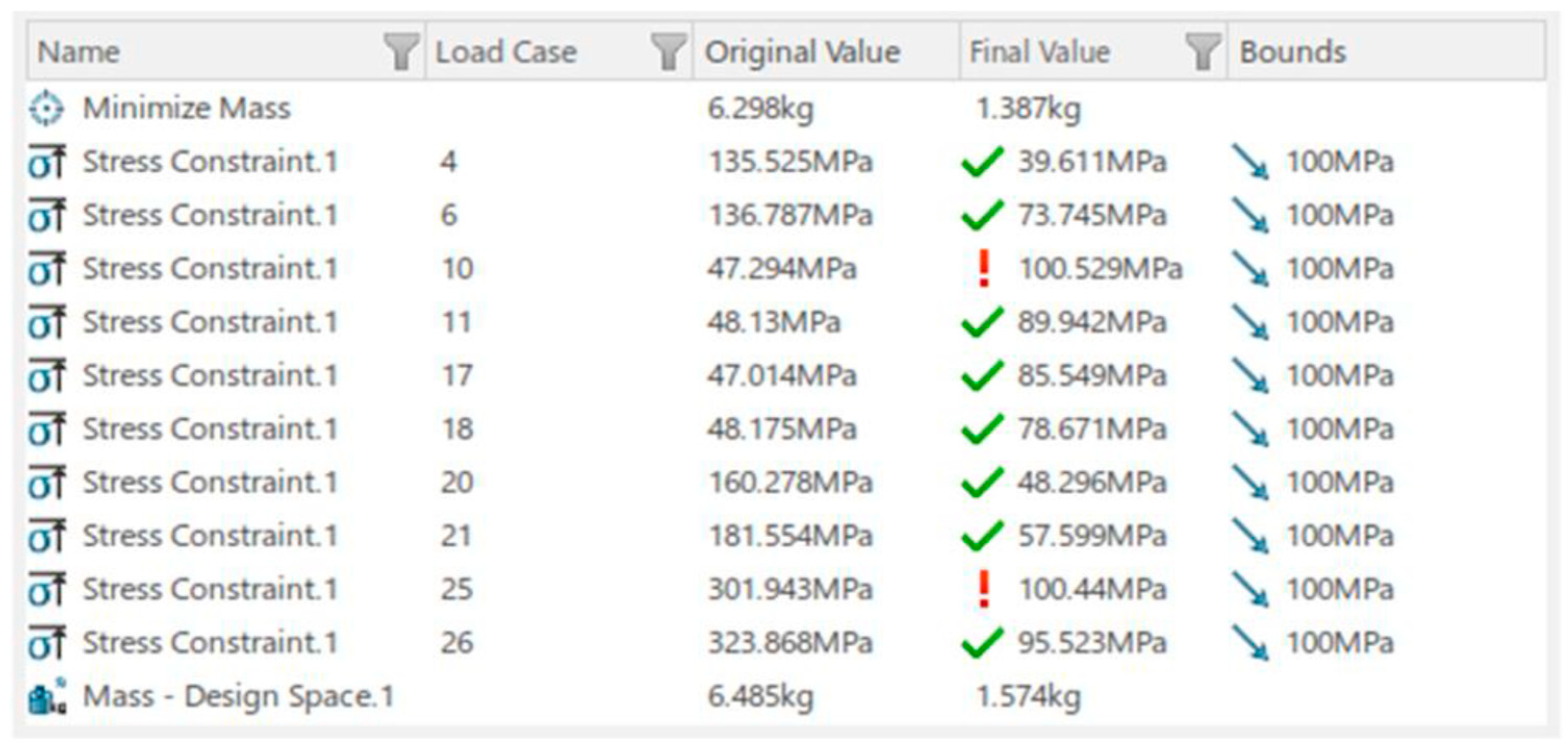

2.2.2.7. TO

The TO of the front mount lasted 3 hours and 2 minutes. The optimization converged to a solution that satisfied the optimization conditions after 120 iteration cycles were performed. The results of the TO of the front holder are shown in

Figure 11. The software evaluated the failure to meet the optimization requirement for two

load cases. The stress values exceeded the maximum allowable stress value by 0.5%. However, after analyzing the results, it was concluded that the optimization condition was satisfied in all ten load cases. The achieved mass of the front bracket concept was 1.574 kg (

Figure 11 labeled as

Mass - Design Space.1: Final Value), i.e. 12.3% of the weight of the holder.

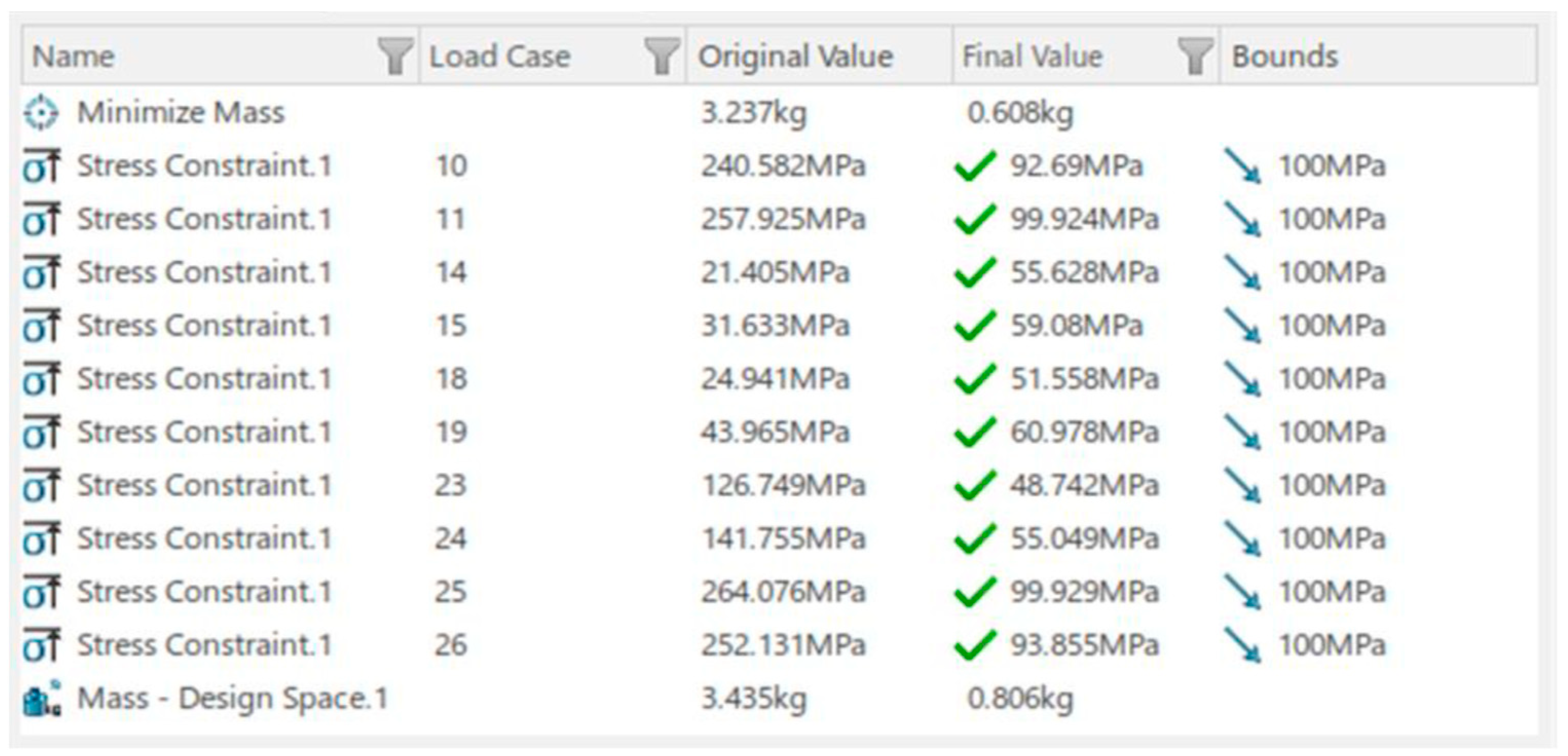

The TO of the rear holder lasted 1 hour and 32 minutes. In this case, the optimization converged to a solution that satisfied the optimization conditions after only 52 iteration cycles had been performed. The results of the TO of the rear holder are shown in

Figure 12. The optimization condition was satisfied in all

load cases. The achieved mass of the rear bracket was 0.806 kg (

Figure 12 labeled as

Mass - Design Space.1: Final Value), i.e. 12.1% of the mass of the holder.

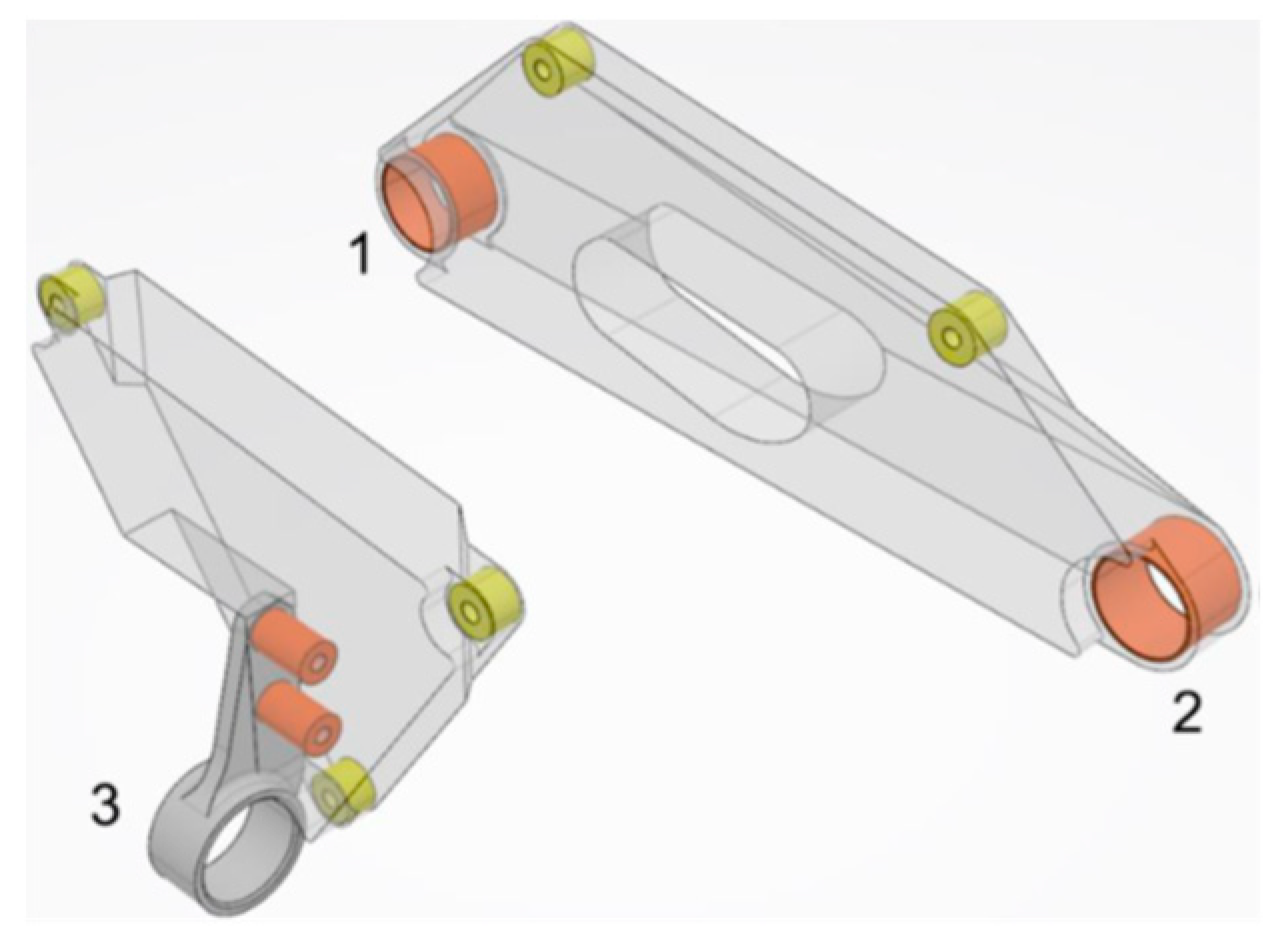

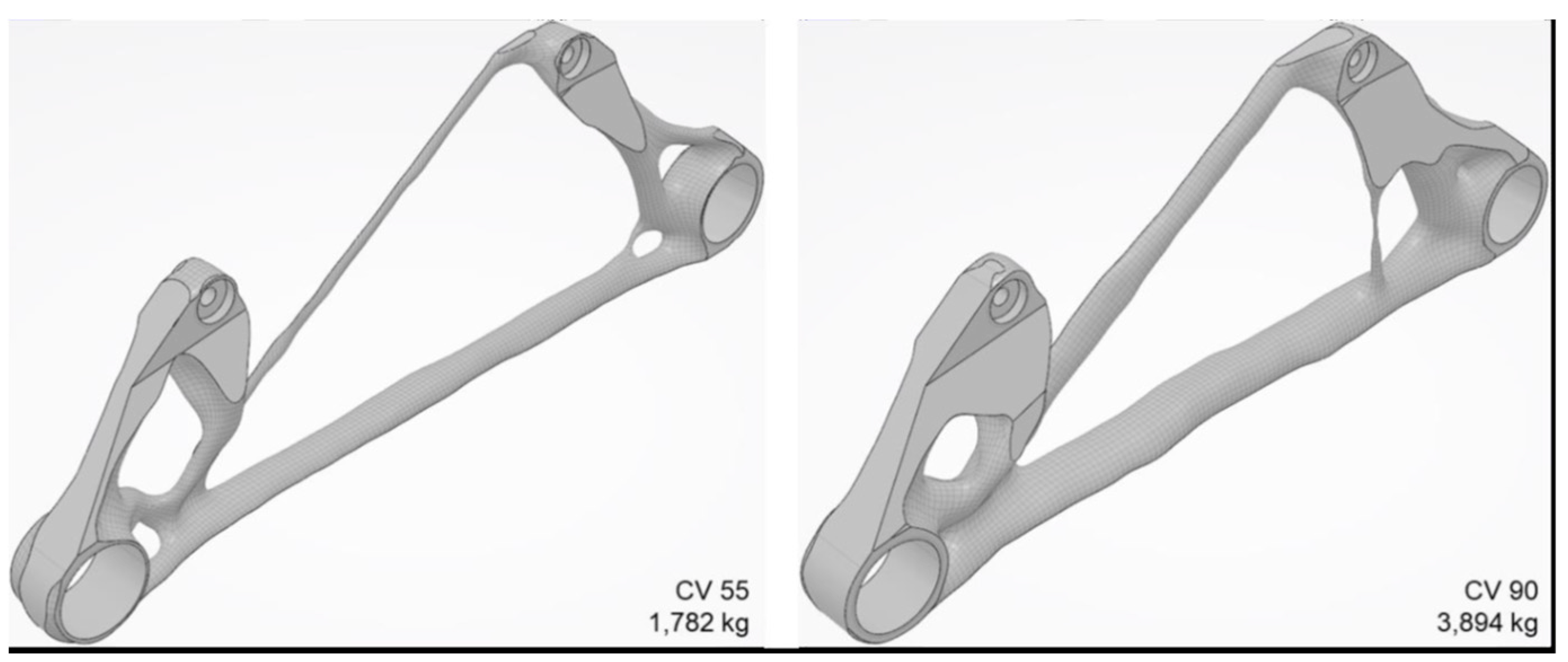

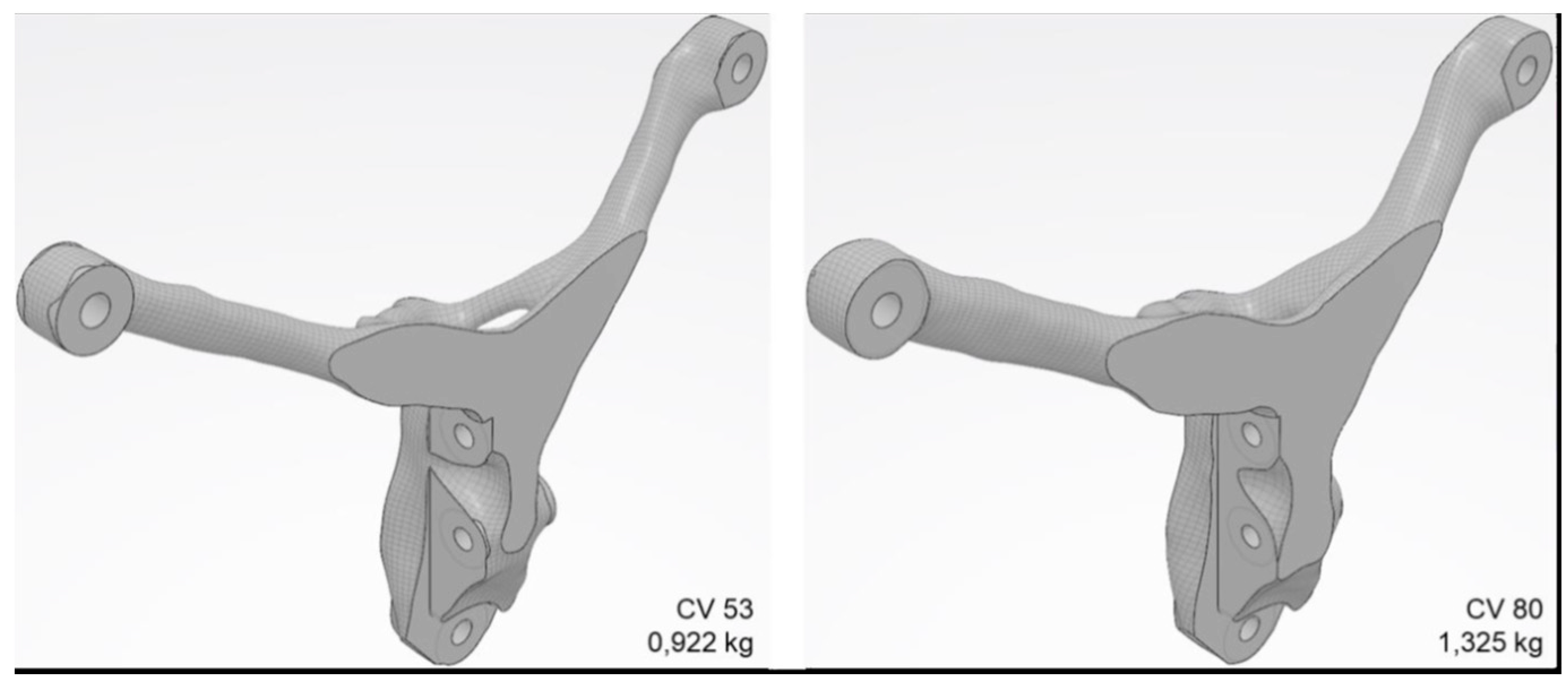

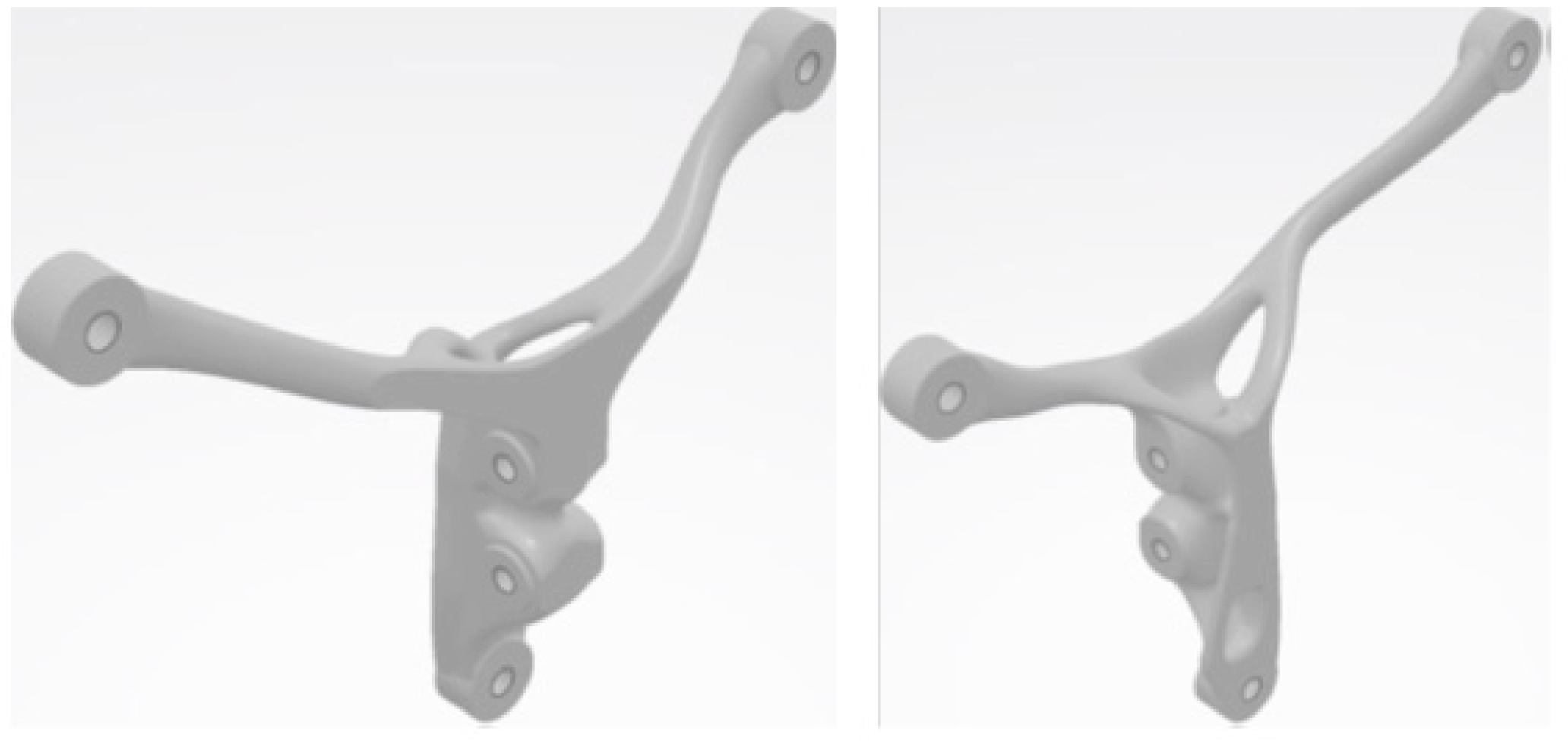

2.2.2.8. Concept generation

The concept generation process is used to materialize the results of the TO. The

Cutting Value (CV) parameter has the greatest influence on the generated shape. It is an informative parameter whose value describes the amount of mass retained after the optimization process. By changing the parameter, material is removed or added with respect to the TO result. Two concepts have been generated for the two holders. One concept was generated with a CV parameter such that its mass is closest to the mass of the concept after the last iteration of the TO (

Figure 11 and 12 labeled as

Mass - Design Space.1: Final Value, respectively). The CV value of the front holder and the rear holder was set to 55 and 53, respectively. The second concept was generated with a higher CV parameter value (CV value: front bracket - 90, rear bracket - 80). The generation of two concepts with different CV parameter value allows to analyze the influence of the parameter on the weight, design concept and strength of the generated concepts. From

Figure 13 and

Figure 14, it can be seen that the weight of the generated concepts with the CV parameter, where the weight is closest to the weight after the last iteration of TO, is larger than that shown in

Figure 11 and

Figure 12, respectively. This is because the software adds material at certain locations in order to generate a concept with a nice continuous shape without defects.

2.2.2.9. Robustness check of generated concepts

The strength check of the generated raw front and rear holder concepts for all ten load cases was used to validate the strength of their design and the accuracy of the TO results.

The raw generated front bracket concept with CV 55 did not meet the strength requirements for all load cases (two load cases). However, after analyzing the results, it was concluded that with minor modifications to the design in postprocessing, these relatively high stresses could be avoided. The strength checks proved the accuracy of the TO results. The generated concepts are suitable for use as templates for the final design of components within the postprocessing.

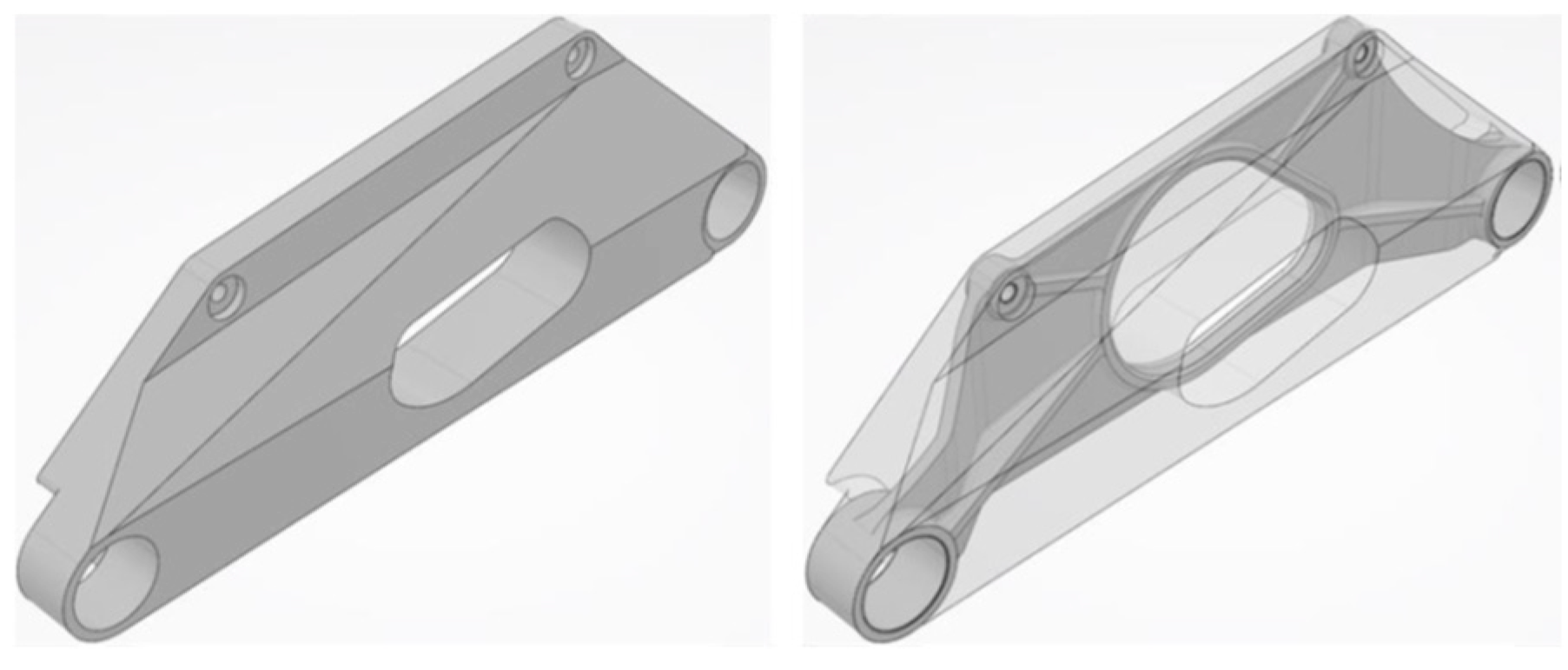

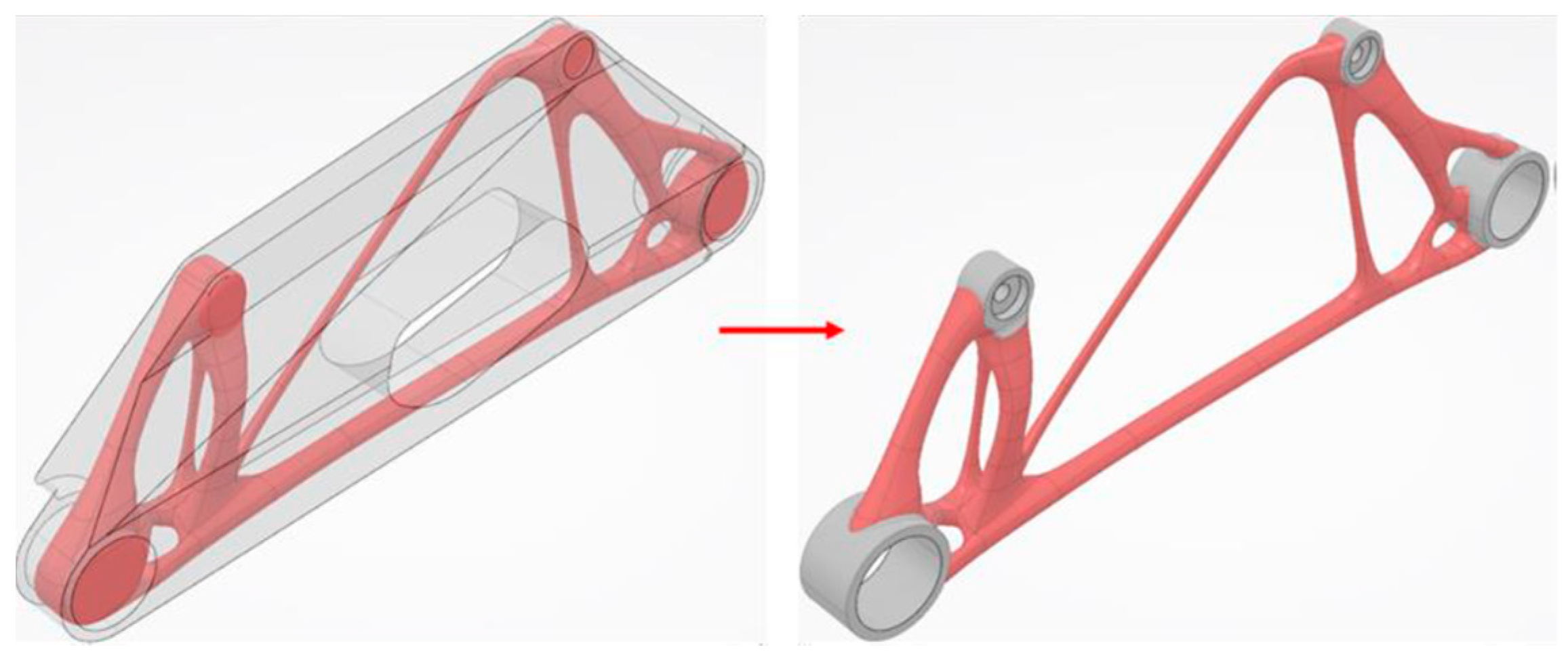

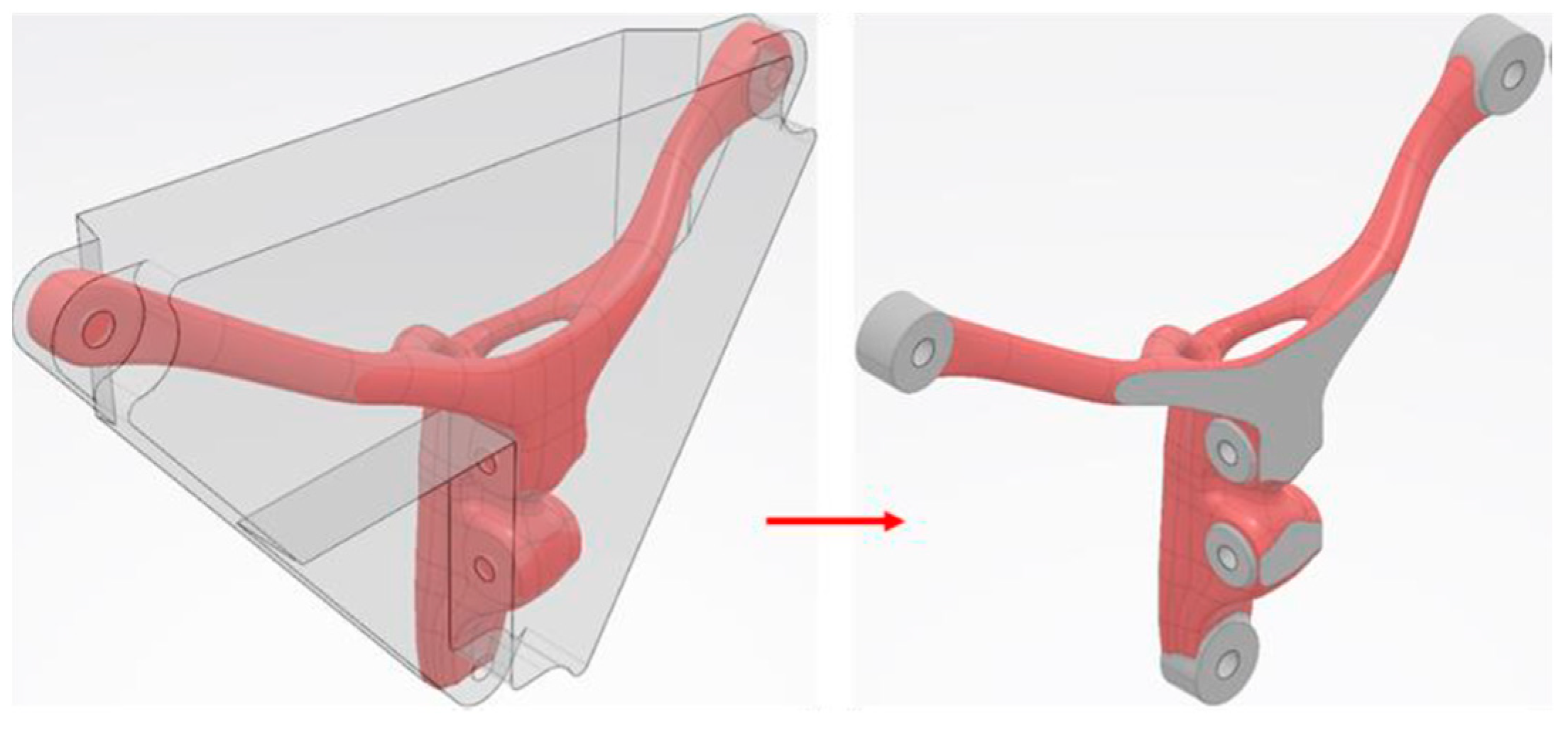

2.2.3. Postprocessing –- creation of the final design

In postprocessing, the complicated design of the generated and validated concepts is reconstructed, and functional elements are implemented in the final design.

The SGD module has functions and tools for the reconstruction of complex geometry using

NURBS surfaces [

17]. These are general surfaces whose geometry is controlled by control points. Such surfaces can be connected to each other to form larger units, thus creating the final design of the component. The individual design elements of the concepts are modeled as separate planar entities by the

IMA - Tube drawing and

IMA - Cylinder functions. The final design of the front and rear holder was obtained by trimming the blanks with the final

NURBS-flat

Split function and implementing the functional elements into the trimmed volume by

Boolean operations (

Figure 15 and

Figure 16).

2.2.4. Validation of the final design

To validate the correctness of the final design of the front and rear holder, strength tests were performed for all thirty loading situations. A linear mesh with an element size of 2 mm was used for the front holder and a linear mesh with an element size of 1.5 mm was used for the rear holder. These are the same mesh configurations that were used in the validation of the generated bracket concepts (Chapter 2.2.2.9). The strength tests proved the correctness of the front and rear electric motor bracket design. In neither load case do the stresses (Von Mises type) exceed the maximum allowable stress value of 100 MPa. All the conditions imposed on the design of the bracket construction have been fulfilled.

2.2.5. Final design - preparation for 3D-printing

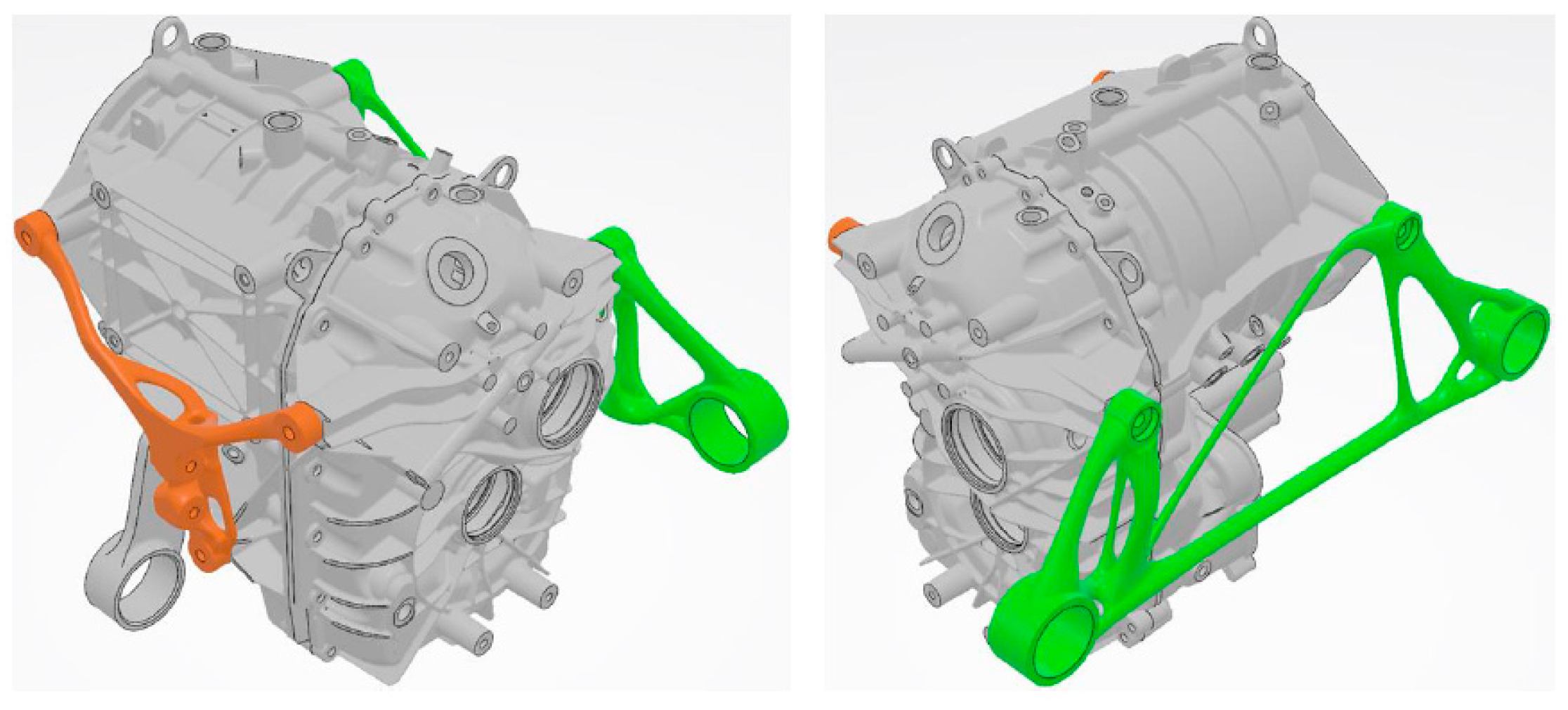

The weight of the final design of the optimized front holder is 1.714 kg. A detailed view of the front holder design of the electric motor is shown in

Figure 17. The weight of the final design of the rear holder is 0.783 kg. A detailed view of the rear electric motor holder design is shown in

Figure 18. The electric motor assembly with optimized front and rear holder is shown in

Figure 19.

Before the actual additive manufacturing with SLM technology, it is necessary to perform 3D-printing and cooling simulation of the component. This will highlight the behavior of the components throughout the manufacturing process. Based on the results, manufacturing inaccuracies can be predicted, which can be eliminated by changing the design (so called component pre-deforming) or eliminated in the manufacturing finishing operations. Areas that are prone to deformation during 3D-printing or during cooling after the manufacturing process shall be reinforced with supports. These supports are then removed mechanically or by vibration. Additional material shall be applied to functional surfaces which are subject to high demands in terms of precision and roughness. Precision chip machining is used to remove the additive and thus achieve the required precision and roughness of the functional surfaces.

3. Results

Table 1 shows the duration times for each stage of the development of the electric motor bracket design by the TO method using the

3DExperience software. These are the times that can be achieved with ideal inputs, ideal operation of the software and ideal outputs from the optimization process. However, real-world use has shown that it is often necessary to rework the inputs (blanks, partitions) to improve the input strength optimization results, and it is often necessary to change the optimization conditions to ensure that the optimization process is working properly and thus obtain usable concepts of the optimized parts. This nature of the software and the TO method itself is accounted for by the reliability coefficient 𝑘𝑠𝜖〈1.3〉. The coefficient interval was defined based on the experience gained by applying the method and software to the development of several components. The comparison of the development time of the electric motor brackets with the TO method and the development time with traditional design methods is shown in

Table 2.

It is clear that the implementation of the TO method into the process of designing the optimal design of electric motor holders has significantly reduced the development time. A weight saving was also achieved compared to the first iteration of the design of the electric motor holders, which additionally did not undergo a strength check.

4. Discussion

The application of the proposed design methodology in practice confirmed its effectiveness at the component development stage. Its implementation in the component design process demonstrated significant savings in development time and component weight. The principles of TO have been known for a long time, but the method has not been used in practice on a large scale. This is due to the relative difficulty of operating optimization software, its reliability and the lack of trained and experienced personnel. In order to ensure the efficiency and reliability of the implementation of optimization software in the development of new components, it is necessary to develop variants of the design methodology that will be tailored for the design process of a specific product line.

Author Contributions

Conceptualization, P.H. and Martin N.; methodology, L.G. and A.K.; software, A.K. and Miroslav N.; validation, P.H. and V.Ch.; formal analysis, P.H. and Martin N.; investigation, L.G. and V.Ch.; resources, V.Ch.; data curation, Miroslav.N.; writing—original draft preparation, P.H. and Martin N.; writing—review and editing, P.H. and L.G.; visualization, V.Ch.; supervision, L.G.; project administration, L.G.; funding acquisition, L.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Chadha, U.; Abrol, A.; Vora, N.P.; Tiwari, A.; Shanker, K.S.; Selvaraj, S.K. Performance evaluation of 3D printing technologies: a review, recent advances, current challenges, and future directions. Progress in Additive Manufacturing 2022, 7, 853–886. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Rangappa, S.M.; Karfidov, A.; Gorbatyuk, S.; Anish, K.; Mrityunjay, D.; Siengchin, S. A comprehensive review on 3D printing advancements in polymer composites: technologies, materials, and applications. The International Journal of Advanced Manufacturing Technology 2022, 121, 127–169. [Google Scholar] [CrossRef]

- Mazurkievic, I.; Gulan, L.; Izrael, G. Mobilné pracovné stroje: teória a konštrukcia základných modulov; Nakladateľstvo STU: Bratislava, Slovakia, 2013; 301p. [Google Scholar]

- Kumar, S.; Gopi, T.; Harikeerthana, N.; Gupta, M.K.; Gaur, V.; Krolczyk, G.M.; Wu, C. Machine learning techniques in additive manufacturing: a state of the art review on design, processes and production control. Journal of Intelligent Manufacturing 2023, 34, 21–55. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, Y.F. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyping Journal 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Lampeas, G. Revolutionizing Aircraft Materials and Processes; Pantelakis, S. , Tserpes, K., Eds.; Publisher: Springer Nature Switzerland AG: Switzerland, 2020; 405p. [Google Scholar]

- Jun, Z.; Yuechao, Z.; Zhenyu, F. Topology optimization for additive manufacturing with self-supporting constraint. Structural and Multidisciplinary Optimization 2021, 63, 2341–2353. [Google Scholar]

- Meng, L.; Zhang, W.; Quan, D.; Shi, G.; Tang, L.; Hou, Y.; Breitkopf, P.; Zhu, J.; Gao, T. From Topology Optimization Design to Additive Manufacturing: Today’s Success and Tomorrow’s Roadmap. Archives of Computational Methods in Engineering 2020, 27, 805–830. [Google Scholar] [CrossRef]

- Zegard, T.; Paulino, G.H. Bridging topology optimization and additive manufacturing. Struct. Multidiscip. Optim. 2016, 53, 175–192. [Google Scholar] [CrossRef]

- Mirzendehdel, A.M.; Suresh, K. Support structure constrained topology optimization for additive manufacturing. Comput.-Aided Des. 2016, 81, 1–13. [Google Scholar] [CrossRef]

- Nieto, D.M.; Sánchez, D.M. Design for Additive Manufacturing: Tool Review and Case Study. Applied Science, 2021, 11, 1571. [Google Scholar] [CrossRef]

- Baotong, L.; Wenhao, T.; Senmao, D.; Jun, H. A generative design method for structural topology optimization via transformable triangular mesh (TTM) algorithm. Structural and Multidisciplinary Optimization 2020, 62, 1159–1183. [Google Scholar]

- FE Training. Available online: https://www.fetraining.net/topology-optimization-part-1/ (accessed on 18 September 2023).

- Sun, H.; Ma, L. Generative Design by Using Exploration Approaches of Reinforcement Learning in Density-Based Structural Topology Optimization. Designs 2020, 4, 10. [Google Scholar] [CrossRef]

- SPRINGER LINK. Available online: https://link.springer.com/article/10.1007/s11831-019-09331-1 (accessed on 18 September 2023).

- Gulanová, J.; Lonek, S.; Gulan, L. Comparison of two different approaches of a class-A surface creation and quality verification. Computer-aided design and applications 2018, 15, 757–763. [Google Scholar] [CrossRef]

Figure 1.

Topology optimization of the part [

14].

Figure 1.

Topology optimization of the part [

14].

Figure 2.

Topology optimization process [

16].

Figure 2.

Topology optimization process [

16].

Figure 3.

First iteration of the design solution for electric motor holders.

Figure 3.

First iteration of the design solution for electric motor holders.

Figure 4.

Object for optimization - front holder blank.

Figure 4.

Object for optimization - front holder blank.

Figure 5.

Object for optimization - rear holder blank.

Figure 5.

Object for optimization - rear holder blank.

Figure 6.

Functional elements for optimization - front holder blank.

Figure 6.

Functional elements for optimization - front holder blank.

Figure 7.

Functional elements of the object for optimization - rear holder blank.

Figure 7.

Functional elements of the object for optimization - rear holder blank.

Figure 8.

Hubs for the silentblocks of the front holder blank (1, 2) of the rear arm (3).

Figure 8.

Hubs for the silentblocks of the front holder blank (1, 2) of the rear arm (3).

Figure 9.

Schematic representation of all 30 load cases of the blanks: (a) front holder, (b) rear holder.

Figure 9.

Schematic representation of all 30 load cases of the blanks: (a) front holder, (b) rear holder.

Figure 10.

Network of a quadratic mesh with default number of elements: (a) front holder blank, (b) rear holder blank.

Figure 10.

Network of a quadratic mesh with default number of elements: (a) front holder blank, (b) rear holder blank.

Figure 11.

Results of TO front holder blank.

Figure 11.

Results of TO front holder blank.

Figure 12.

Results of the TO rear holder blank.

Figure 12.

Results of the TO rear holder blank.

Figure 13.

Front holder concepts generated.

Figure 13.

Front holder concepts generated.

Figure 14.

Rear holder concepts generated.

Figure 14.

Rear holder concepts generated.

Figure 15.

Trimming of the front holder blank with the final NURBS-plate and implementation of the functional elements.

Figure 15.

Trimming of the front holder blank with the final NURBS-plate and implementation of the functional elements.

Figure 16.

Trimming of the rear holder blank with the final NURBS-plate and implementation of the functional elements.

Figure 16.

Trimming of the rear holder blank with the final NURBS-plate and implementation of the functional elements.

Figure 17.

Final design of the optimized front electric motor holder.

Figure 17.

Final design of the optimized front electric motor holder.

Figure 18.

Final design of the optimized rear electric motor holder.

Figure 18.

Final design of the optimized rear electric motor holder.

Figure 19.

Electric motor with optimized holders.

Figure 19.

Electric motor with optimized holders.

Table 1.

Development time of electric motor holders by TO method.

Table 1.

Development time of electric motor holders by TO method.

| Development time of electric motor holders by topological optimization method |

|---|

| Stages |

Job description |

Front

holder |

Rear

holder |

| Time (h) |

|---|

| pre-preparation for topological optimization |

- -

creating an object for optimization - -

creation of functional elements of the optimization object - -

creation of a material profile and assignment to the optimization object |

3 |

3 |

| topological optimization |

- -

defining the optimisation strategy - -

defining the object for optimisation - -

defining the functional elements of the optimisation object |

0.25 |

0.25 |

- -

definition of force loads and constraints and their assignment to load cases - -

creating a MESH - -

Initial strength check of the object for optimization |

2 |

2 |

- -

definition of optimization conditions - -

topological optimization |

3 |

1,5 |

- -

generation of concepts - -

strength check of generated concepts |

1 |

1 |

| postprocessing |

- -

reconstruction of the complex geometry of the generated and validated concept through NURBS surfaces - -

implementation of functional elements of the final design |

4 |

4 |

| validation of the final design |

- -

strength check of the final component design |

1 |

1 |

| preparation for production |

- -

allowances for finishing after 3D-printing |

1 |

1 |

| |

|

total development time under ideal conditions

(rounded to whole hours) |

15 |

14 |

| |

|

method reliability coefficientks

|

3 |

| |

|

total development time under realistic conditions |

46 |

41 |

Table 2.

Comparison of design methods for the development of electric motor holders.

Table 2.

Comparison of design methods for the development of electric motor holders.

| Comparison of design methods |

|---|

| Method of construction |

Development time (h) |

Weight of holders (kg) |

Front

holder |

Rear

holder |

Front

holder |

Rear

holder |

Front

holder |

Rear

holder |

| traditional |

75 |

1,9 |

1,124 |

| topological optimization |

Ideal conditions |

Real conditions |

1,714 |

0,783 |

| 15 |

14 |

46 |

41 |

| savings when using the topological optimization method |

80% |

82% |

39% |

45% |

10% |

30% |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).