3.1. Friction Modeling

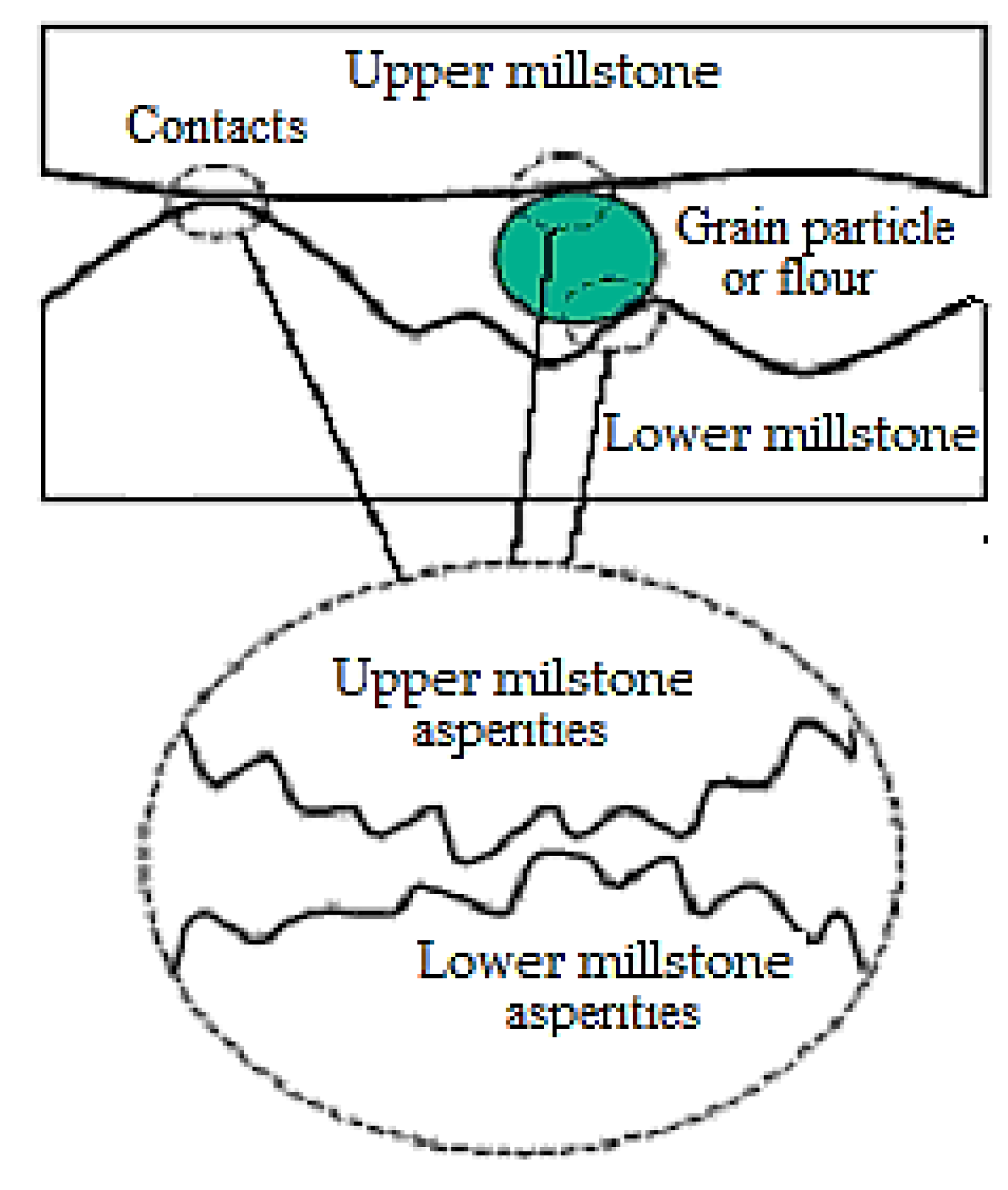

The development of a friction model was necessary considering that the total friction between the lower millstone, seeds, and upper millstone in the grinding process has three distinct friction force components [

15,

17].

The development of a friction model was necessary considering that the total friction between the lower millstone, seeds, and upper millstone in the grinding process has three distinct friction force components [

15,

17].

Thus, the frictional force between the lower millstone and the upper millstone,

Ffl-u is the first component, the frictional force between grain and upper millstone,

Ffg-u is the second component, and the frictional force between seeds and lower millstone,

Ffg-l is the third component. Each component of the friction force has an associated friction coefficient

μl-u, μg-u, and

μg-l), which are corresponding molecular and mechanical adhesion components, [

18].

The friction force components cumulated represent the friction force,

Ff, and can be written in the form:

where:

Ff – is the total friction force by sliding;

Fn – is the applied normal force;

C1 and

C2 – are constants which consider the contact’s number.

Through seeds density, the asperities distribution of the lower millstone, respectively of upper millstone, and rough contact modeling, the number of contacts can be evaluated [

19]. Also, for evaluation of the contacts, the lower millstone porosity is considered.

Figure 2 illustrates a schematic of the typical tool setup to measure friction between the upper millstone and grain (flour, which is on the pad), and between the lower millstone and grain (flour, which flows from the upper millstone) and below has a short presentation.

Experiments using different samples of lower millstones show distinctive endpoint traces, while the upper millstone gives unusable results.

If it is assumed that all the necessary energy for grinding is consumed by the friction between the upper millstone and lower millstone, then it can consider that this is roughly proportional linearly to the average

Ff. A way to highlight

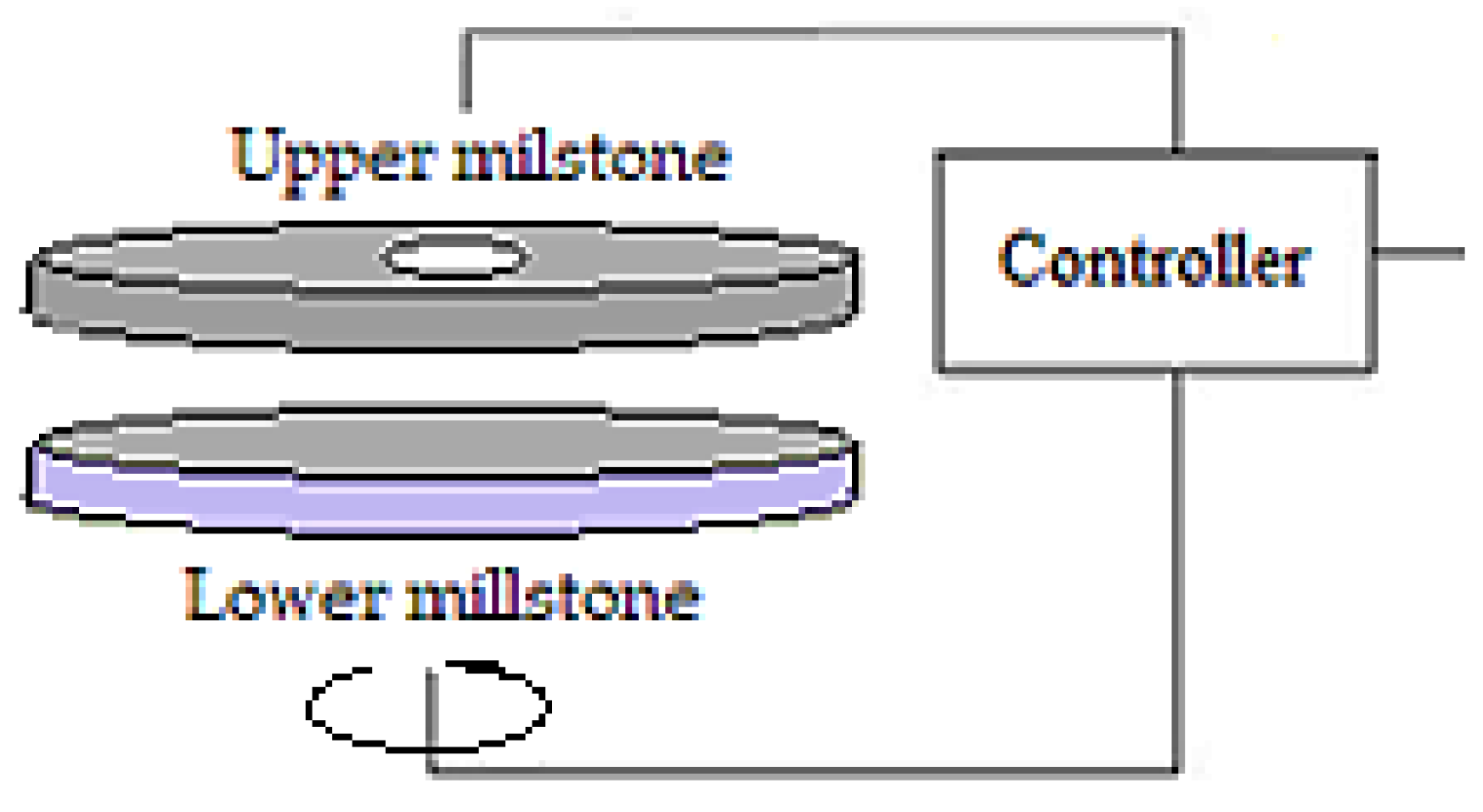

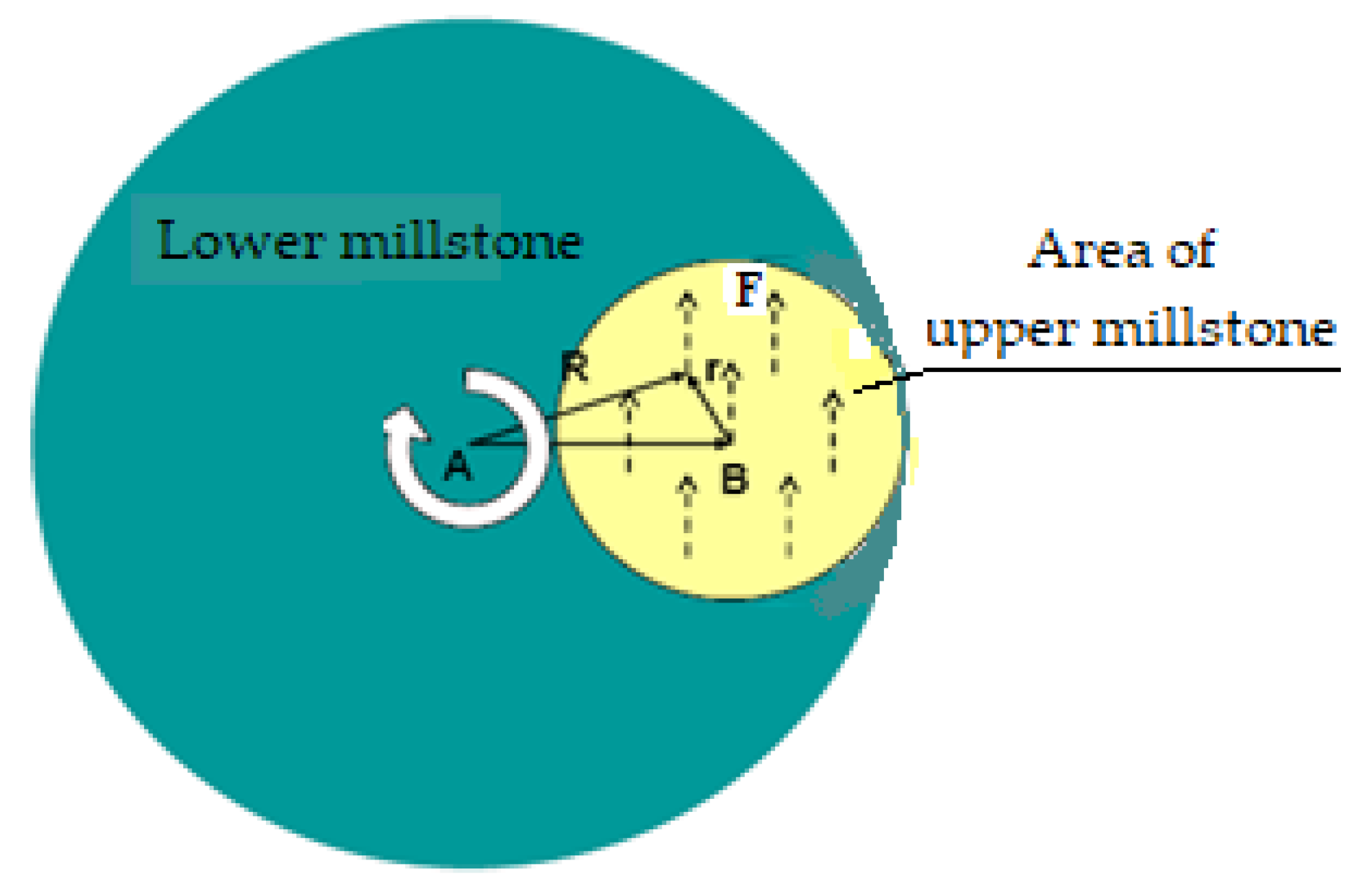

Ff exerted by the upper millstone on the lower one is shown in

Figure 3 (considering an area (the yellow one, for visualization) from the upper millstone in contact with the lower millstone, something that can be generalized over the entire surface of the upper millstone).

The Ff is periodically distributed on the contact surfaces of the upper millstone and of the lower one because the small flour particles are anchored and symmetrically distributed on each surface and the relative velocity between the two surfaces is constant. As a result, it is expected that the net torque of friction forces in ratio with the upper millstone is almost zero, while the net torque in relation to the lower millstone contributes and are added the small torques of these forces. This explains that lower millstone presents distinctive traces of endpoint and those from upper millstone are not useable.

Therefore, the traces during the grinding process provide us the information on friction evolution. To better understand the grinding process and to improve the endpoint monitoring of it, a model for evaluating friction is needed.

Below, is presented a friction model with two-factor (the standard deviation of the highest areas, σsd, and averaged material friction coefficient, μav), relatively simple, although can be considered more friction models. The goal is to understand the interactions between lower millstone with the physics model of the wafer (lower millstone with flour particle) in more detail, and on the basis of the experimental data, also additional factors will be considered.

The model admits that two factors are the cause change of

Ff, during the grinding process, namely: adherence of flour layer and surface topography variation (surface heights) [

20]. To characterize the

Ff between lower millstone and upper millstone, it is assumed as the

Ff is proportional linearly with the multiplication between the

μav and the

σsd, and the

Ff relation becomes:

where:

μav - it is obtained by averaging a weighted friction coefficient of material from friction exposed area;

β - empirical parameter dependent on the friction coefficients sensitive to the flour blanket and the materials used for the lower millstone and upper one.

For the σsd determination first, the lower millstone was discredited into cells on friction length size and was calculated as the average of the highest heights of each cell.

3.2. Experimental Procedure

At the beginning was performed a series of experiments to isolate the friction effects between the lower millstone material and the upper millstone. It is important to mention, that and here the frictional forces may be affected by individual flour particles in contact with the lower millstone asperities and of upper millstone.

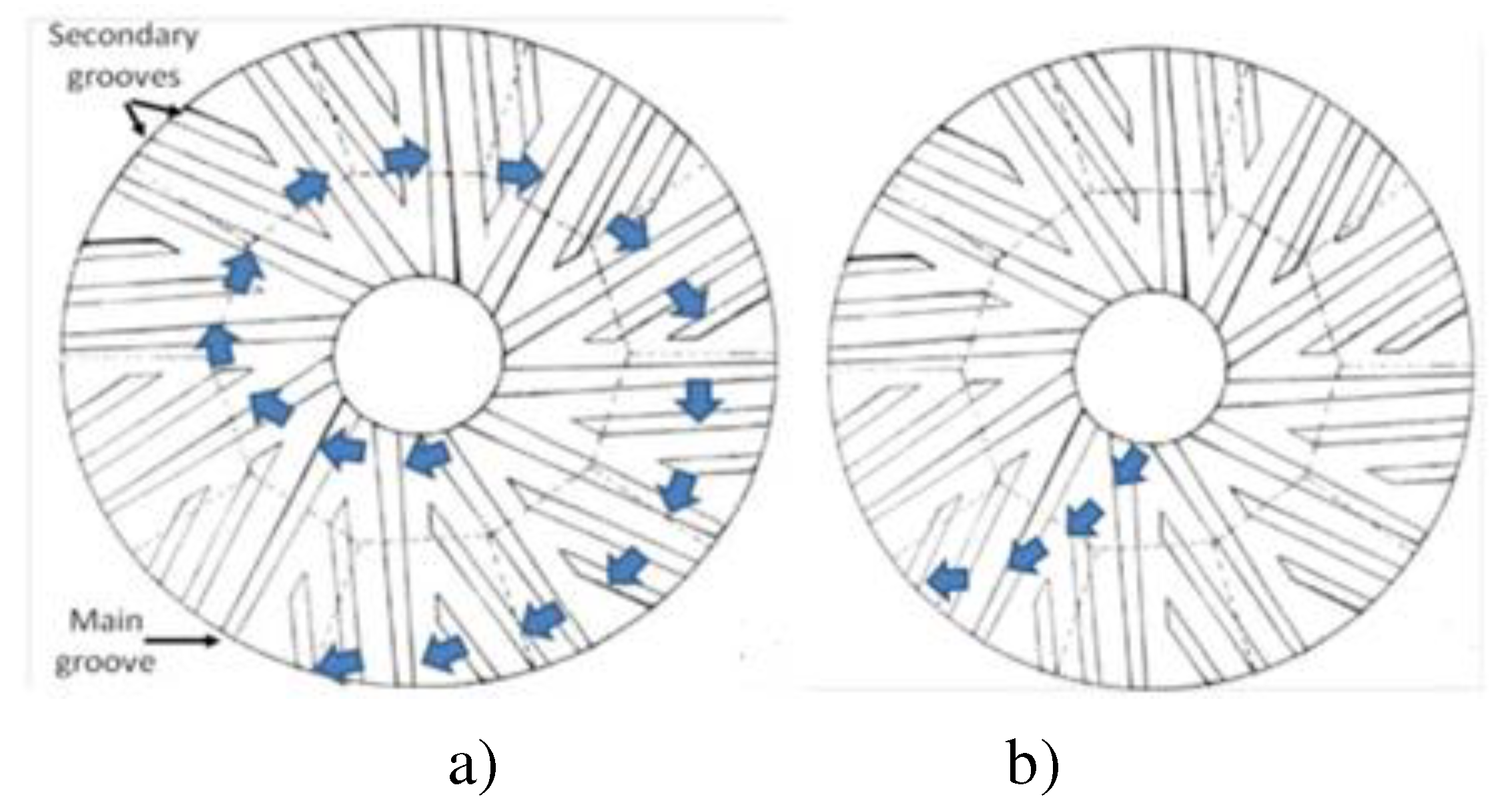

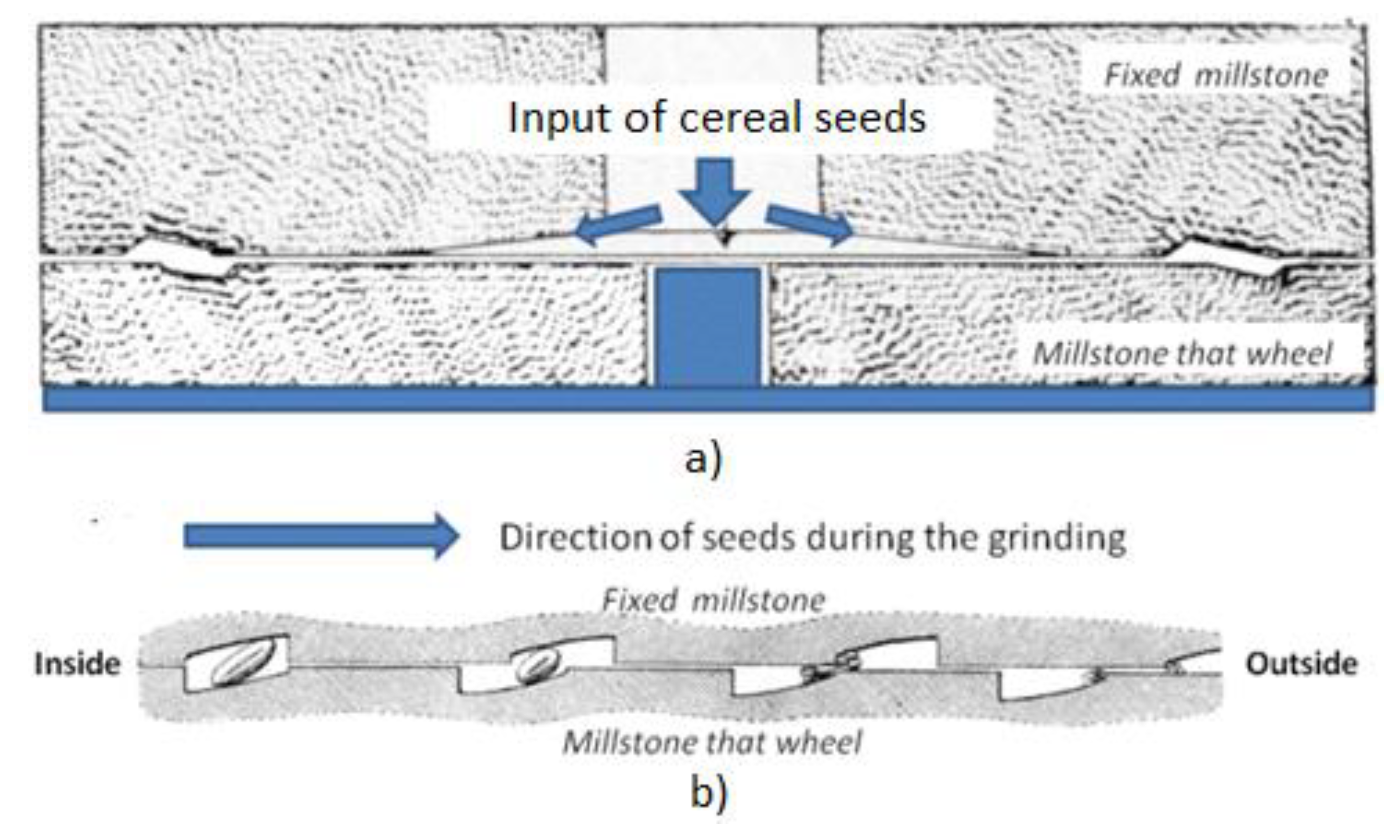

For this, the surface of the millstones must be foreseen by grooves organized radially to allow both the correct friction between the stone’s asperities and seeds (see

Figure 1) and the movement of seeds (

Figure 4). In particular, the main grooves that begin from the hole until the border of the millstone have the main function of cooling the stone, whereas the secondary grooves contribute to uniform distribute the product on the stone and help to eliminate the flour. As shown in

Figure 4, the movement of the seeds on every stone is different between the stones. On the upper millstone (

Figure 4a), in fact, seeds are inserted by the hole in the middle of this and move after a spiral path, whereas on the lower stone (

Figure 4b) they follow a route after a curve

.

Moreover, the hole has a trapezoidal section to allow a regular and uniform distribution of the seeds (

Figure 5a) on the one hand, and on the other hand because there is a distance between the two stones of about 10 mm in the center and much less at border (endpoint). Then, grains are grounded (by grain crushing and breaking) and displaced by the millstone until border and collected in externally, along the border (endpoint), in form of flour (

Figure 5b).

The grinding and movement of the grains towards the border, takes place by friction, according to the presentation above (see

Figure 1), which was analyzed by modeling, simulation and experimentally. The majority of grain crushing and breaking happens in the final part of the millstones where the distance between the stones is the very small.

With the help of micro-indentation and micro-scratch tests have been measured the micro-scale friction forces have been, and with a friction force sensor, with which, was the indenter equipped was measured lateral forces. The tests provide friction results from the interface between the lower millstone and the flour particle, respectively between the flour particle and upper millstone. Also, was measured the friction between a small section of material of the lower millstone and the upper one. Then, to create a scenario of more complex testing was translated over the substrate section from the material of lower millstone with impregnated flour particles.

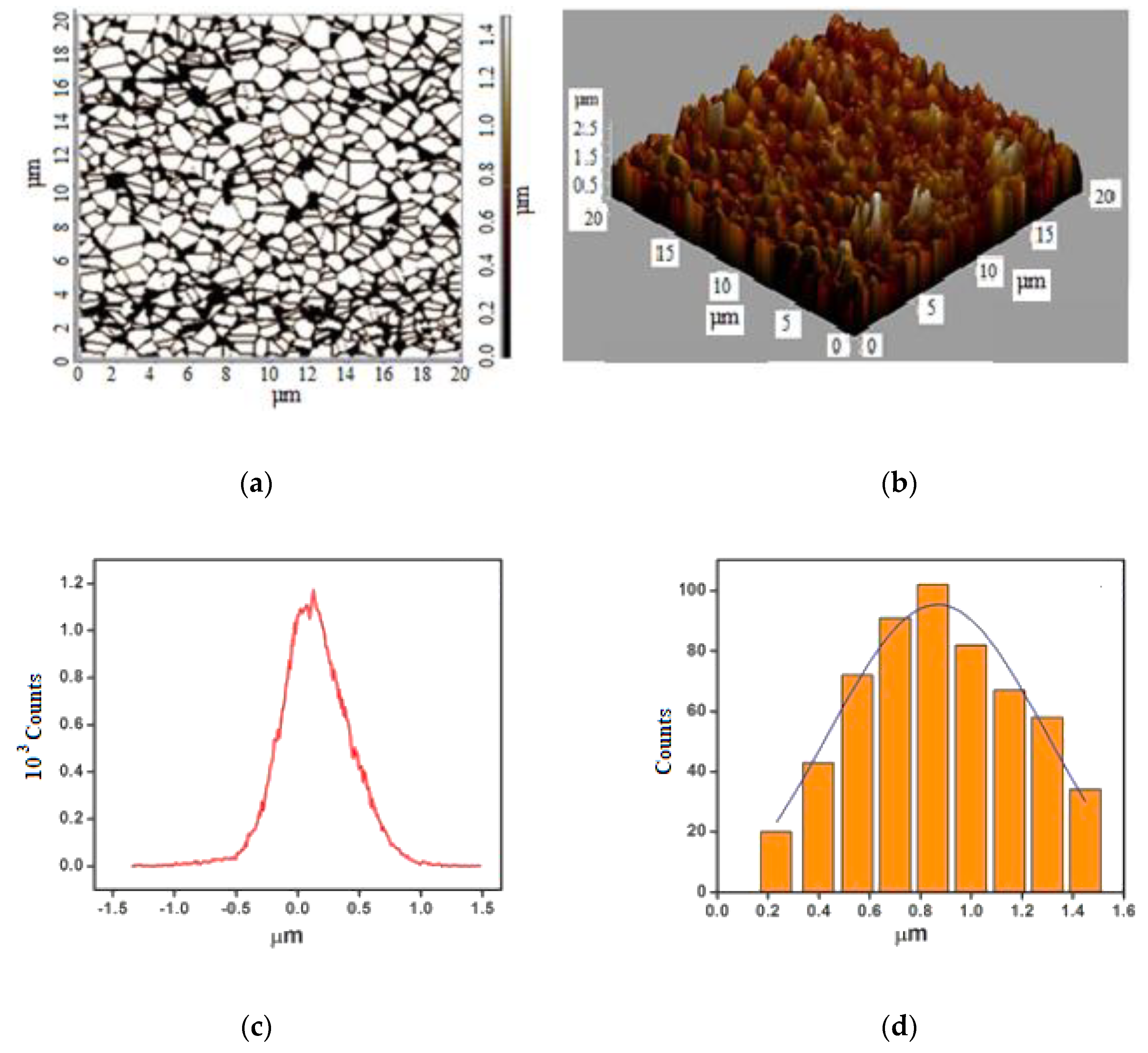

The frictional forces can be affected by the individual flour particles at contact with the asperities of the lower millstone and of the upper one. The Atomic Force Microscope (AFM) was used to measure the material’s asperities. The lower millstone structure is very porous, around 200 μm.

With the help of AFM was captured the regions between the opened pores, were to be able to measure the asperities of these regions at the micro-scale.

Figure 6 shows specific AFM images with data (

Figure 6a,b), along with the asperity histogram (

Figure 6c) and the distribution curve of the grinding stone ceramics grains size (

Figure 6d).

Examining the AFM images of ceramic from which the millstone is made,

Figure 4a shows the surface morphology of grains and grain boundary in a two-dimensional image of ceramic. It is noted that the AFM image of ceramic exhibits a compact structure with granular morphology, buffer layer, and flat grains with clear boundaries. A three-dimensional AFM image of the ceramic surface is presented in

Figure 5b shows, which exhibits the maximum peak height of the grain asperities of 2.52 µm within the scan area 20 µm × 20 µm, and

Figure 5c shows the three-dimensional surface roughness of grinding stone ceramic. The average and root mean square roughness were found to be 0.225 µm and 0.290 µm, respectively. The AFM analysis revealed the presence of the seeds with a wider size distribution in the ceramics material of the grinding stone taken into analysis. The average grain size estimated by the two-dimensional AFM image was found to be 0.620 µm out of 630 contacts as shown in the histogram of

Figure 5d.

To perform the friction measurements, it was used the pin/disc tribometer, on whose disc are fixed samples of a lower millstone, and on the articulated arm, the upper millstone samples are fixed. At the same time, the arm is provided with load sensors, and the friction is measured in simulated conditions of the grinding process by applying a normal load on the arm, to maintain in contact the lower and upper millstone samples.

This type of tribometer was used because it is the most suitable for measuring the frictional forces at the interface between the grinding stones and the cereal grains and then between these and the flour particles. The flour particles were obtained by fixing cereal grains between the circular pin with a diameter of 10 mm and the plate with a diameter of 80 mm, rotated at 60 rpm, which in the friction process will crumble until the flour powder is obtained. At the same time, the arm is provided with load sensors, and the friction is measured in simulated conditions of the grinding process by applying a normal load on the arm, to maintain the contact the lower and upper millstone samples and cereal grains particles.

Additionally, the friction work process is similar to the work process of a mill with grinding stones, and the samples are made of the material of the grinding stones with the same structure and morphology of the surface of the millstones (corundum ceramic). The distinction from the actual grinding process consists in the absence of the possibility of using a large number of cereal grains, just grain by grain, and their flour for measuring the frictional forces from the surface, forces that may differ relatively little from the real ones. The difference is due to the fact that first the grains are transformed into coarse flour particles and then into finer ones. Also, the contact area between the grinding stone samples used on the pin/disk tribometer differs from the actual contact area in the friction grinding mill, being much smaller. Precisely, this is proven by simulation and analytical modeling.

The difference is due to the fact that first the grains are transformed into coarse flour particles and then finer and finer, similar to those of grinding process in stone mill. Also, the contact area between the grinding stone samples used on the pin/disk tribometer differs from the actual contact area in the friction grinding mill, being much smaller.

In added, the effect of grinding on the flow ability of flour can be evaluated using flow indicators, as: frictional coefficient (in this paper), bulk density, and angle of repose, cohesive index, caking strength, and flour flow stability. Both, flow indicators and powder flow analysis showed that the flours from stone mill are cohesive. Based on the friction forces measured on the pin/disc tribometer, the friction coefficient was determined (with the help of the Amontons-Coulomb law), because it is one of the flow indicators by which the effect of grinding on the flour flow ability can be evaluated.

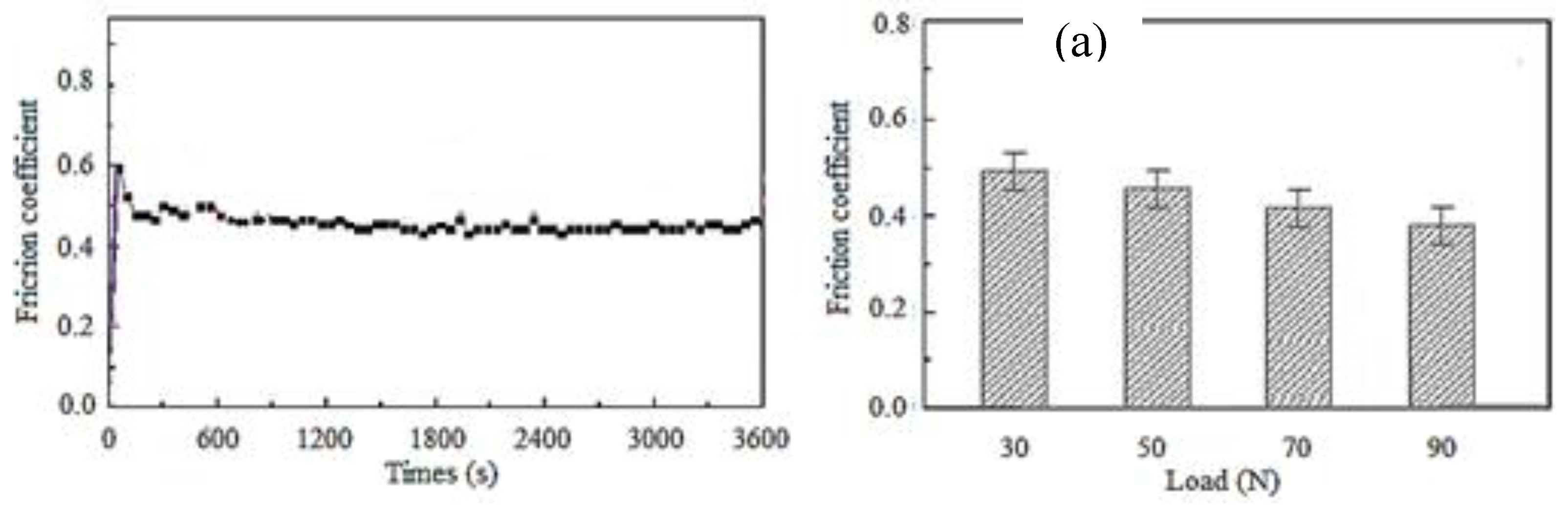

Thus, the variation of the friction coefficient over time and with the load at the sliding speed of 0.016 m/s is shown in

Figure 7.

It can be seen from

Figure 7a that the friction coefficient at sliding increases initially then slightly decreases until stabilizes relatively around a value, which apparently indicates that the friction pairs go through an essential friction running-in/accommodation process. This is because the flour film on the surface has not formed well at the beginning of the test, which could lead to relatively high friction coefficient, for a very short time. After the formation of the flour film, friction tends to decrease and friction coefficient stabilize (see

Figure 7a), while this decreases as the load increased (as average values, see

Figure 7b).

Therefore, the model for determining the friction force can explain the experimental phenomena through the obtained results. For example, for a normal contact force, F of 30 N (made by the weights placed on the arm of the pin/disc tribometer), a friction force, Ff ≈ 14.8 N, was experimentally obtained, while by using the analytical model based on the relationship/ equation (1) obtained Ff ≈ 14.6 N, and by the two-factor model (given by the relation/equation (2)), the friction force was Ff ≈ 15.2 N. So, it is found, a correlation good of the experimental results with those determined analytically (very close), which justifies the validation of the modeling, without identifying significant deficiencies in order to improve the model.

Instead, to develop a contact model was used the resulting asperities geometry was by measuring the asperities replicas of lower millstone using a profilometer. Also, the virtual micro-tribometer was used to simulate the contact under loads on the basis of the contact pressure prediction on asperity. All this was aimed the identifying areas, where the contact pressure caused grain material shear and delamination, in a well-controlled manner. At the same time, the modeling technique significantly influences flour quality, dough rheological properties, and bread characteristics. In added, it leads to ease of use and the system simplicity; higher concentrations of macro elements, micro elements, and polyphenols in flour; increased volume of the finished flour products and popularity with consumers. Precisely, these things are proven by simulation and analytical modeling of experimental results.