Submitted:

03 October 2023

Posted:

03 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experiment

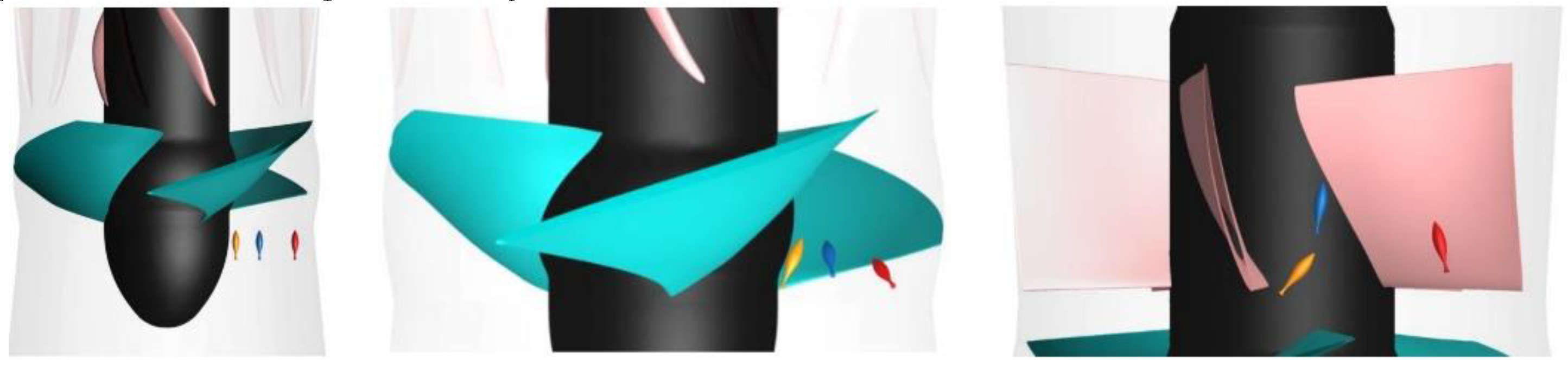

2.1. Experimental device and experimental fish

2.2. Experimental Scheme

2.3. Experimental Results and Analysis

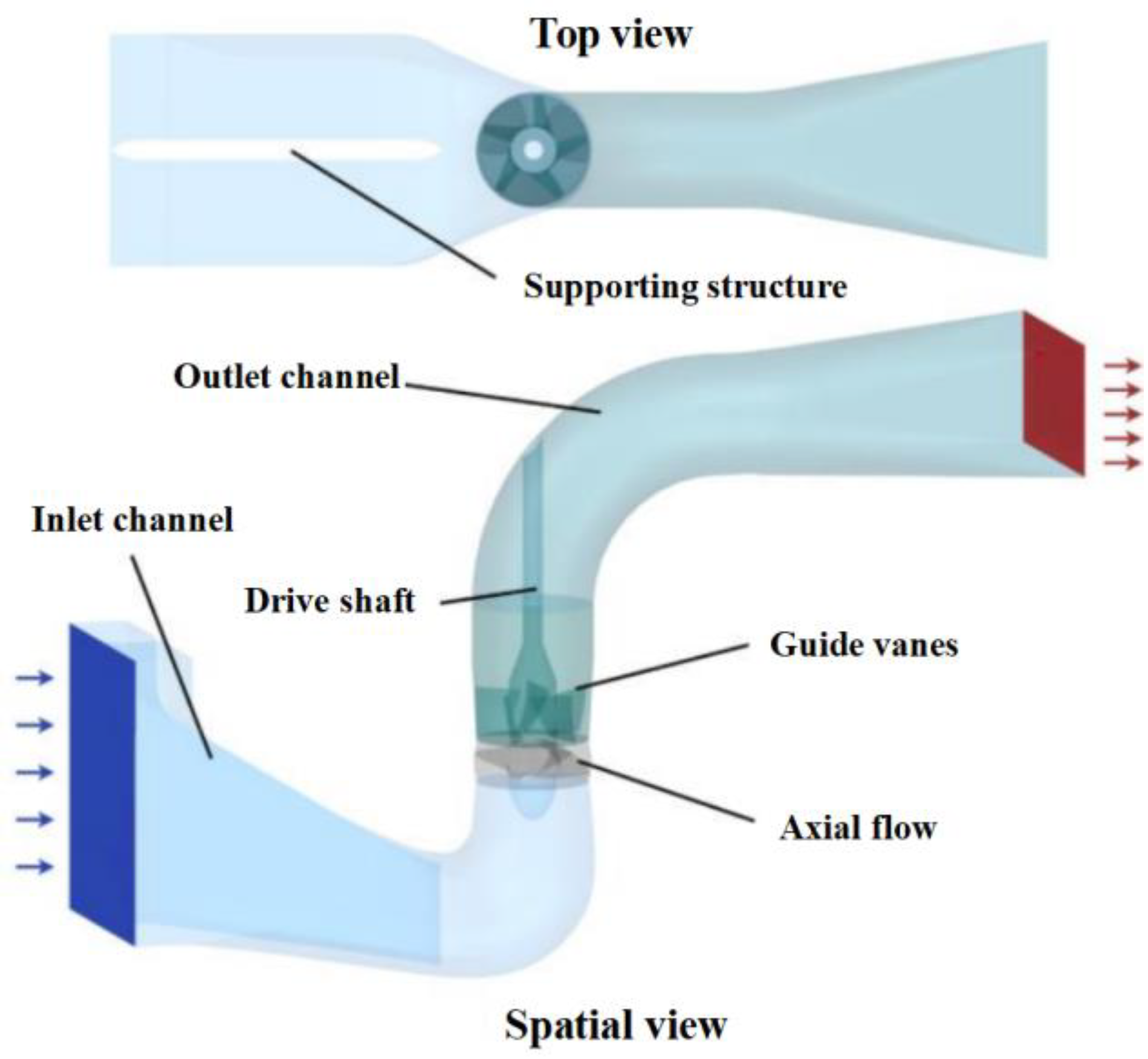

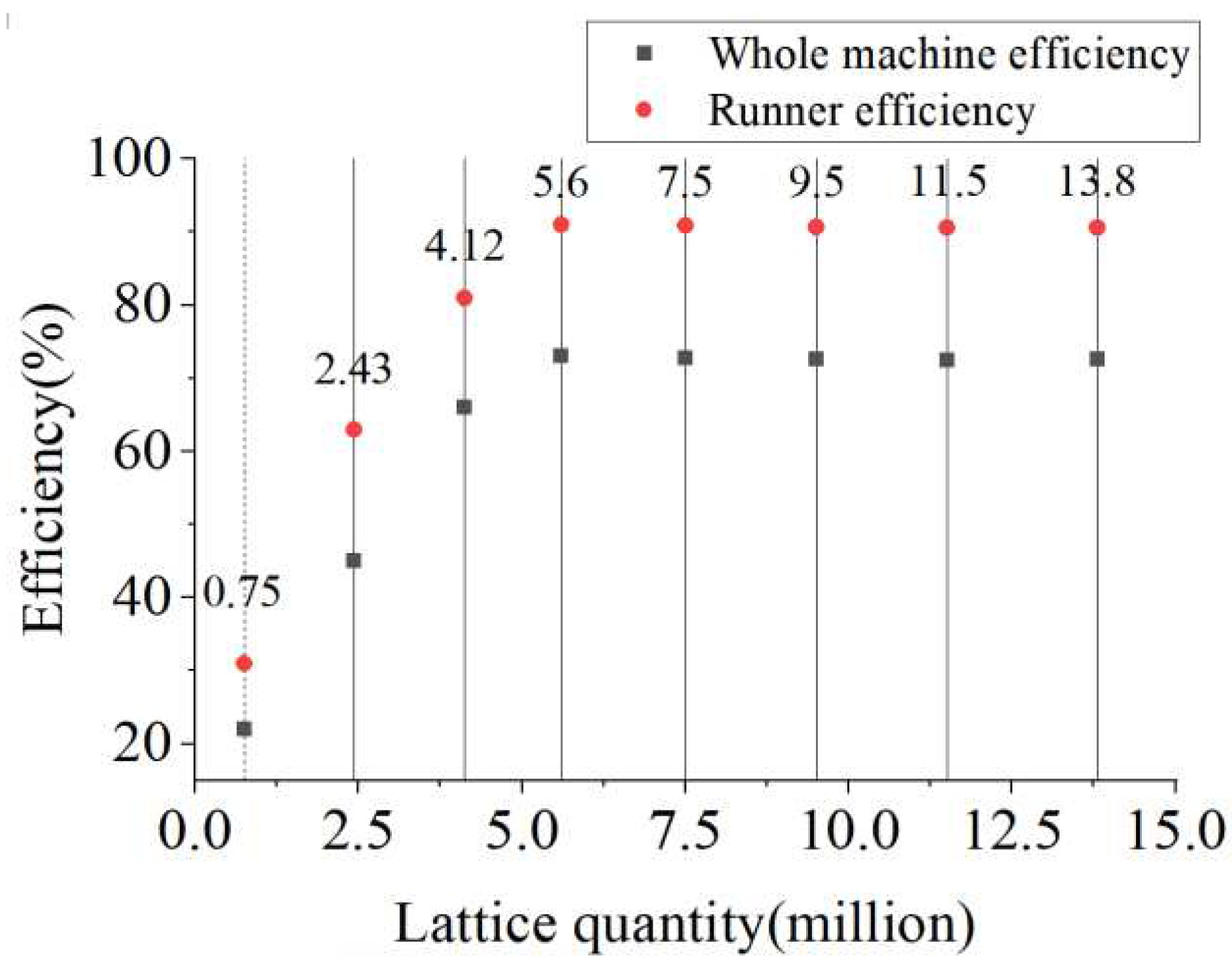

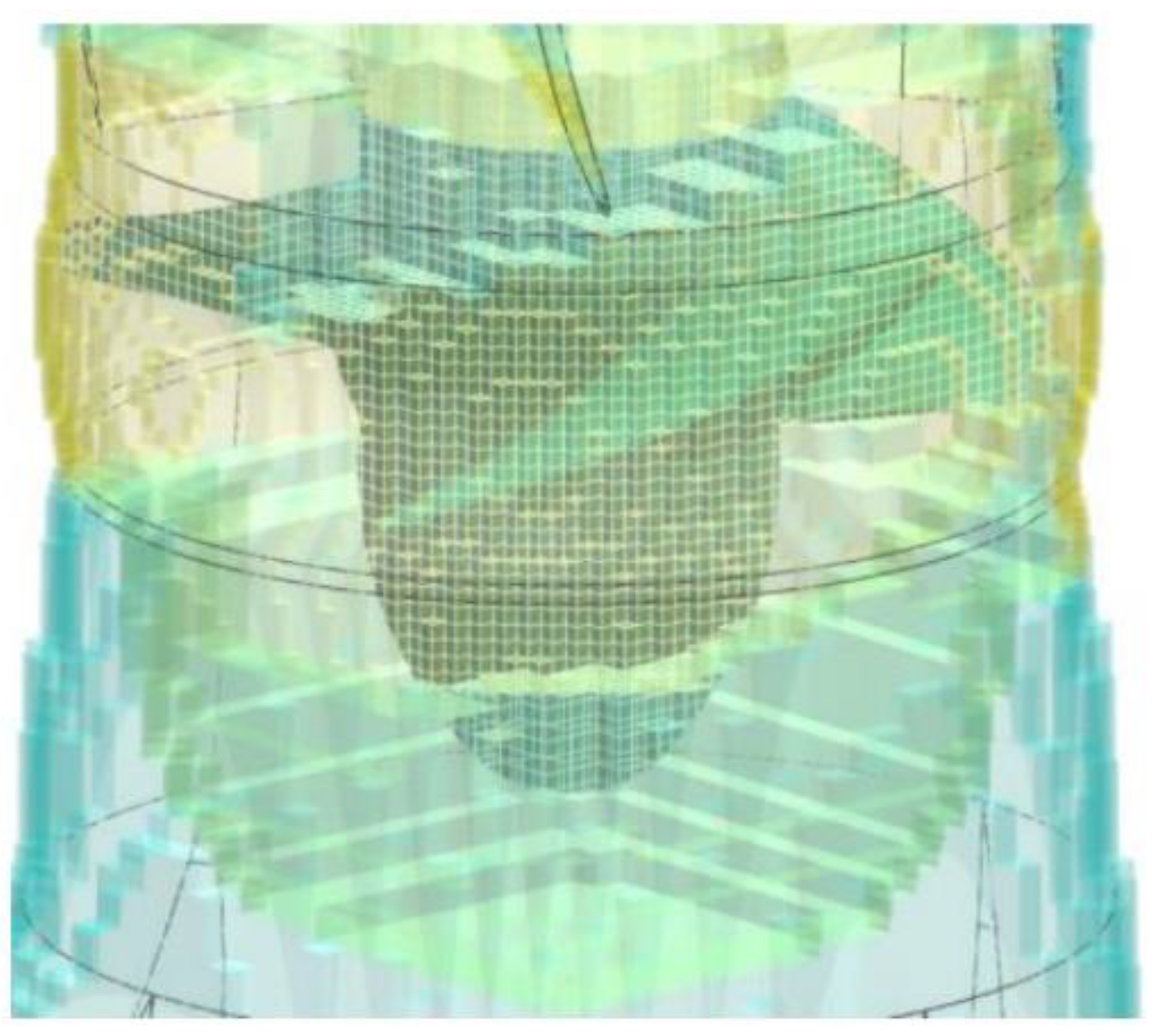

3. Numerical simulation method and main parameters of the model

3.1. IB-LBM method

3.2. Model geometric structure and parameters

3.3. Evaluation method of blade impact probability

4. Optimal design and hydraulic performance analysis of fish-friendly axial flow pump

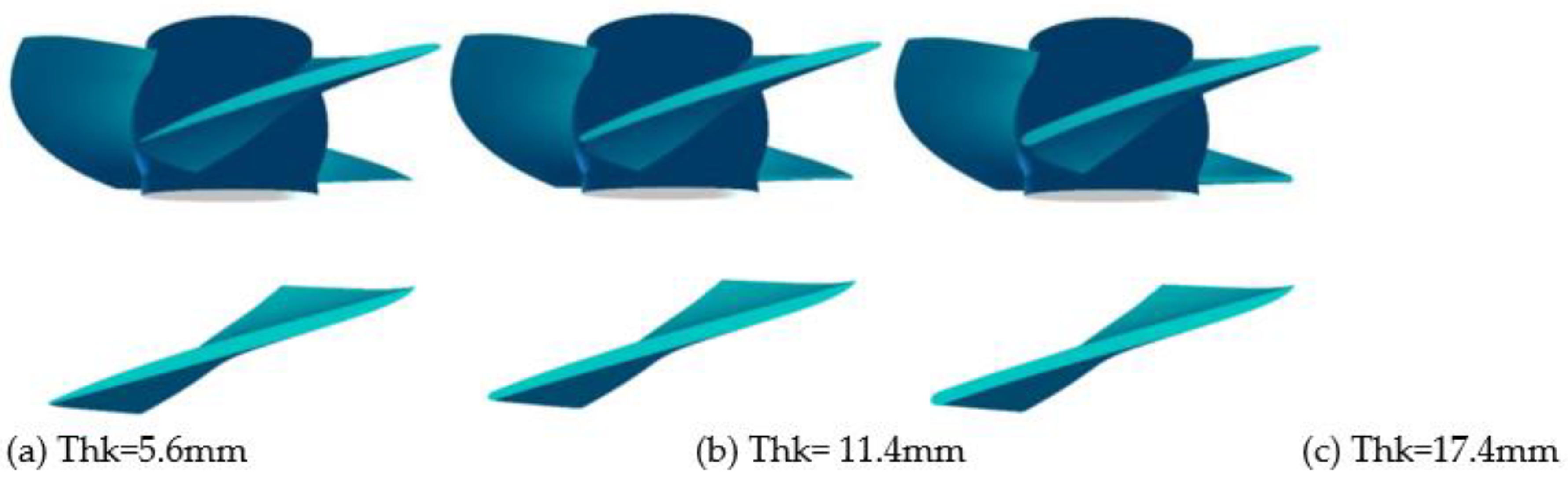

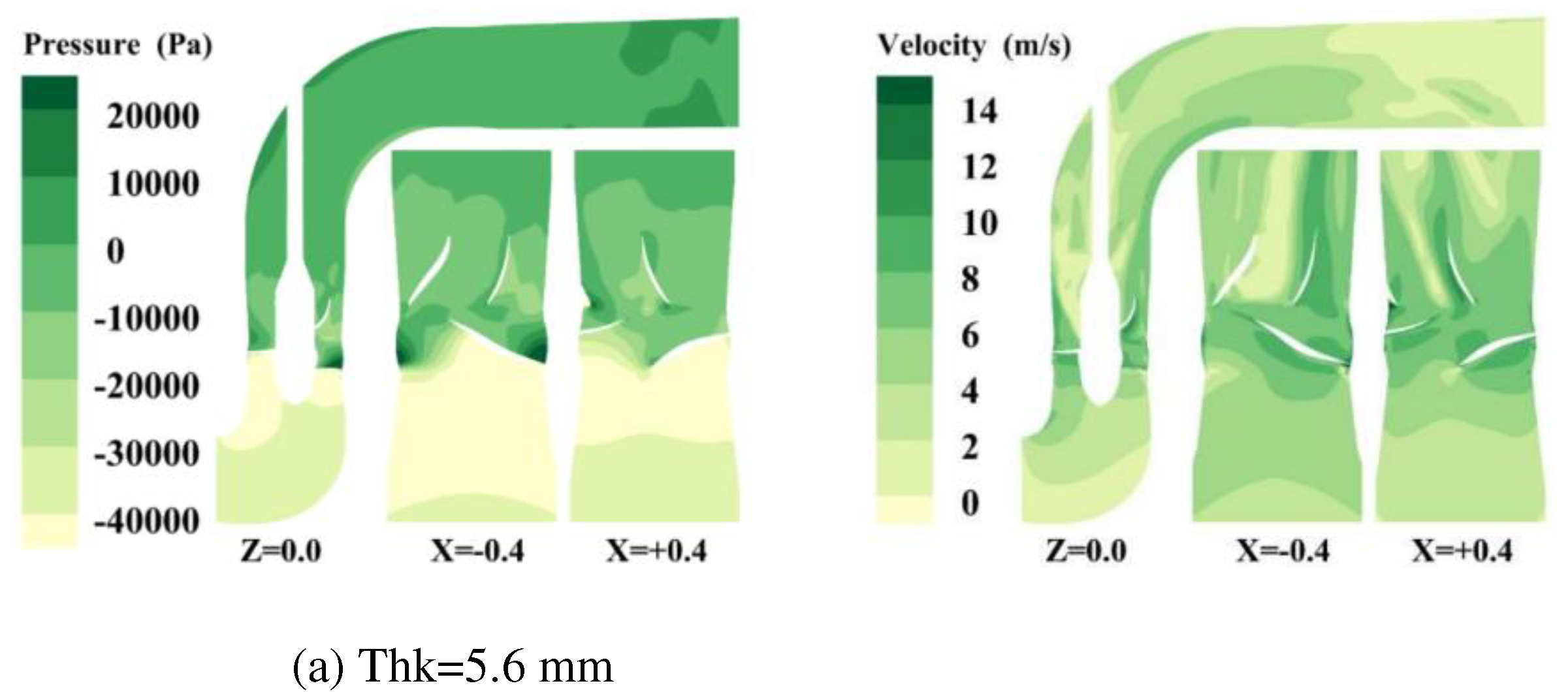

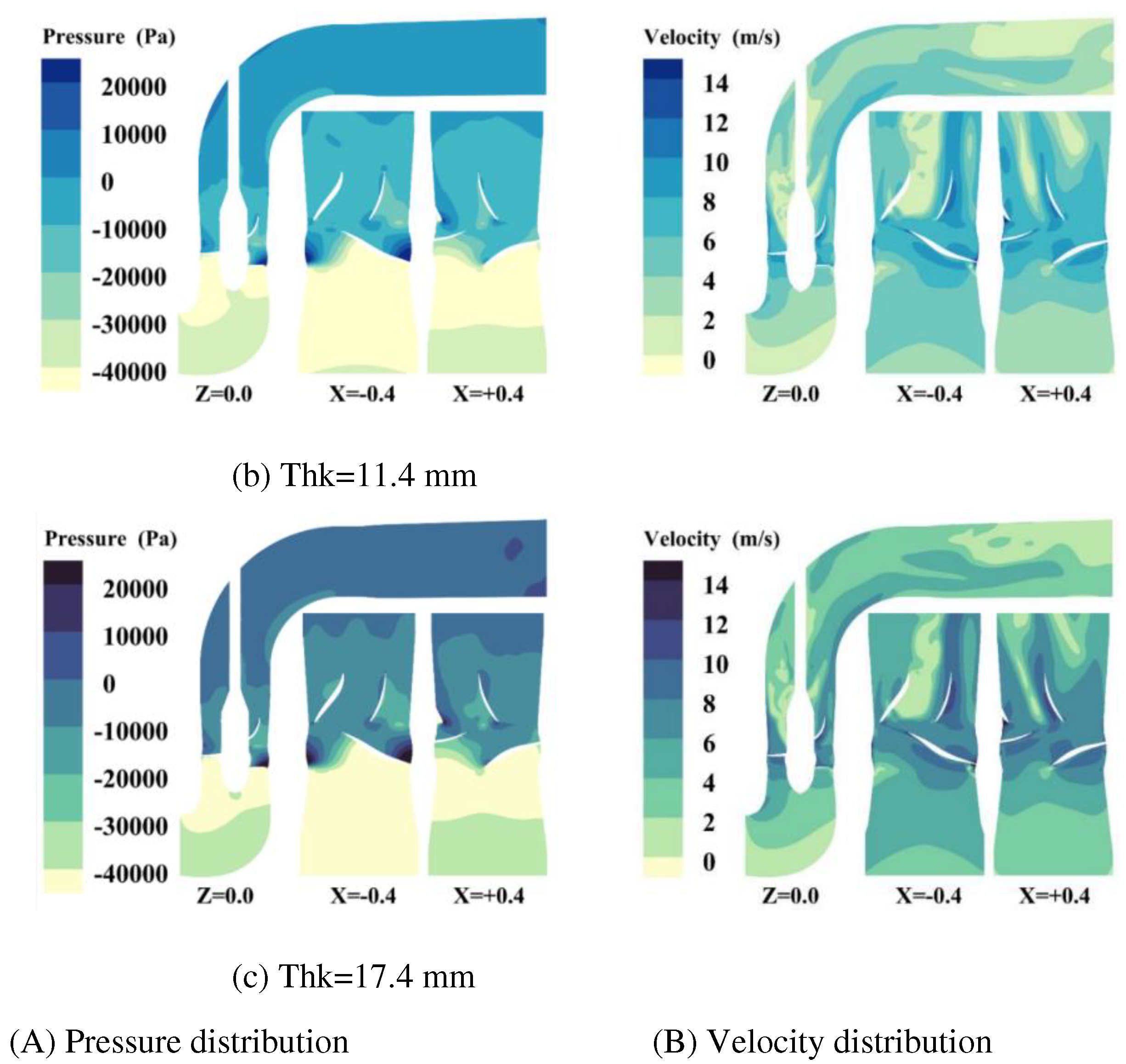

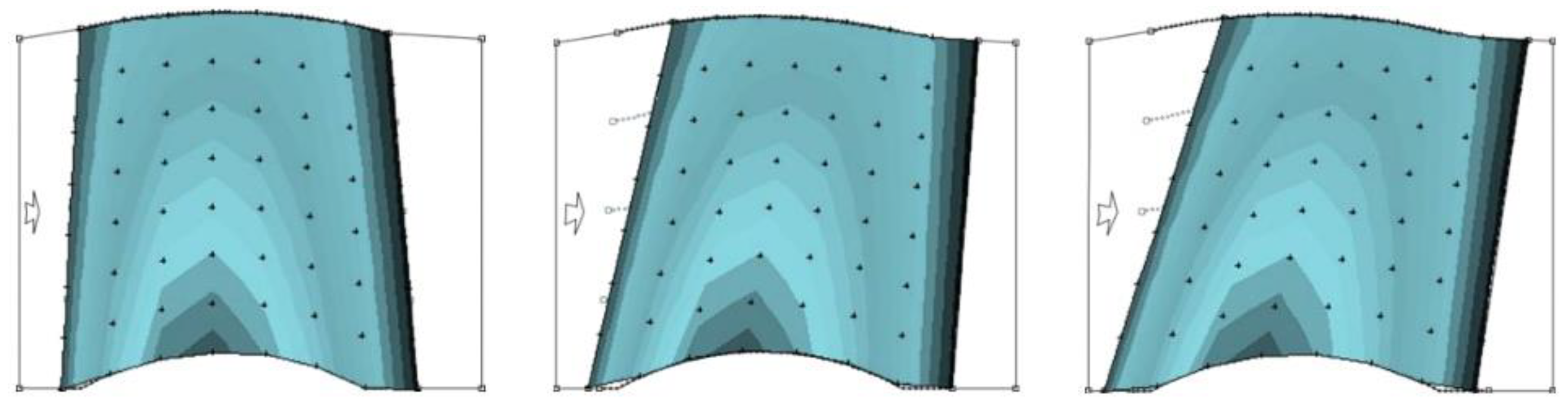

4.1. Optimal design of leading edge thickness of blade

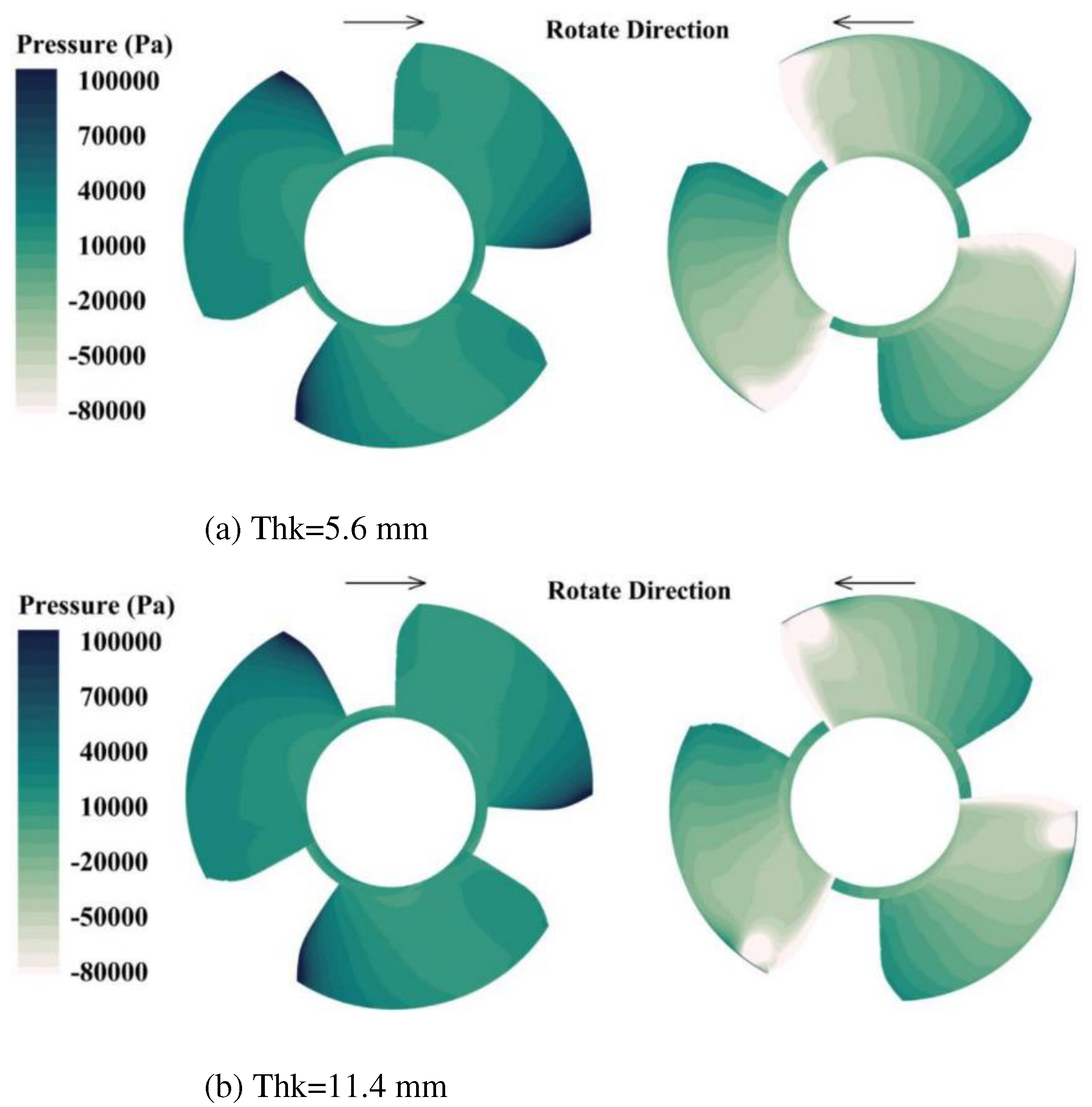

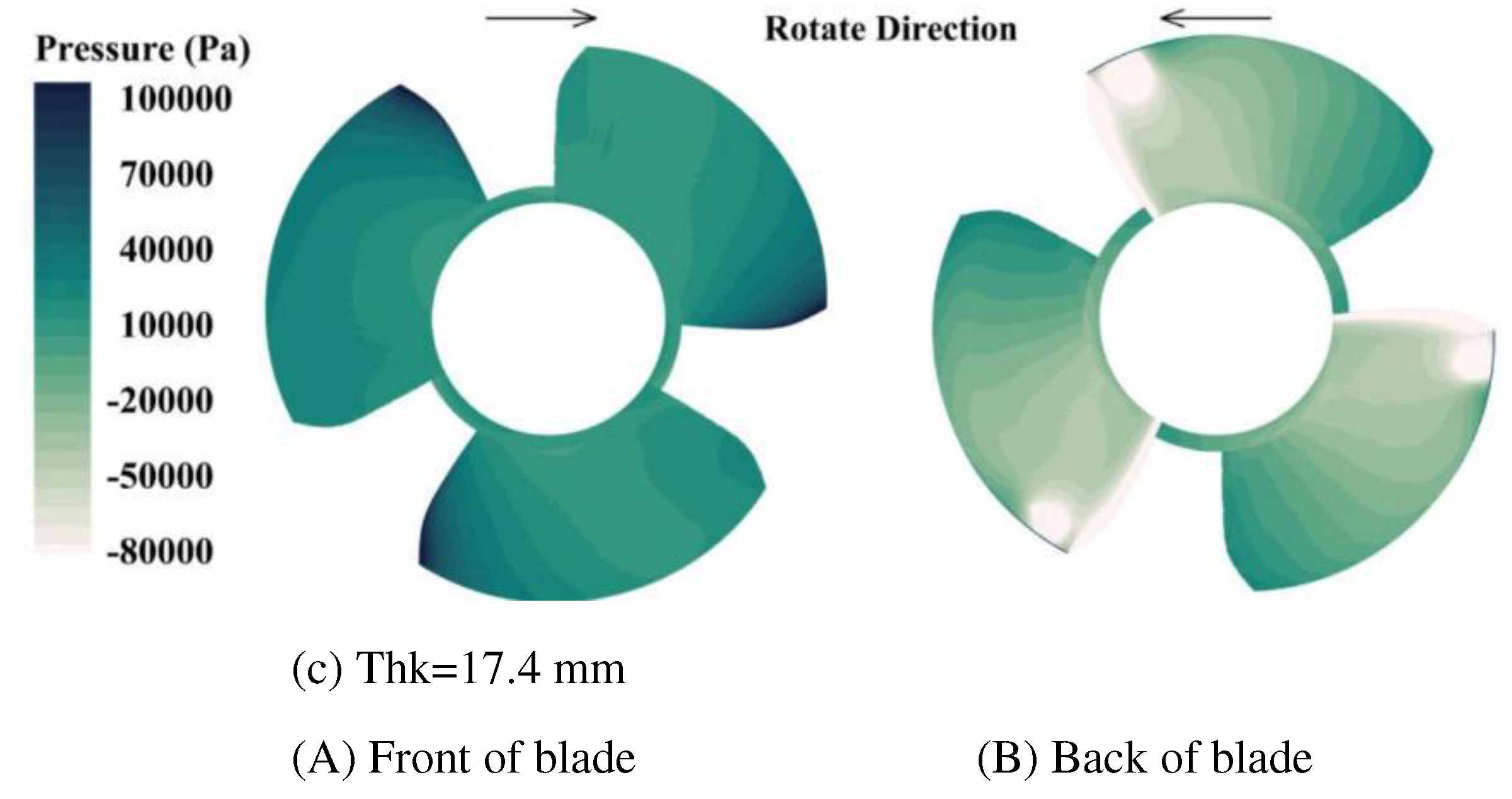

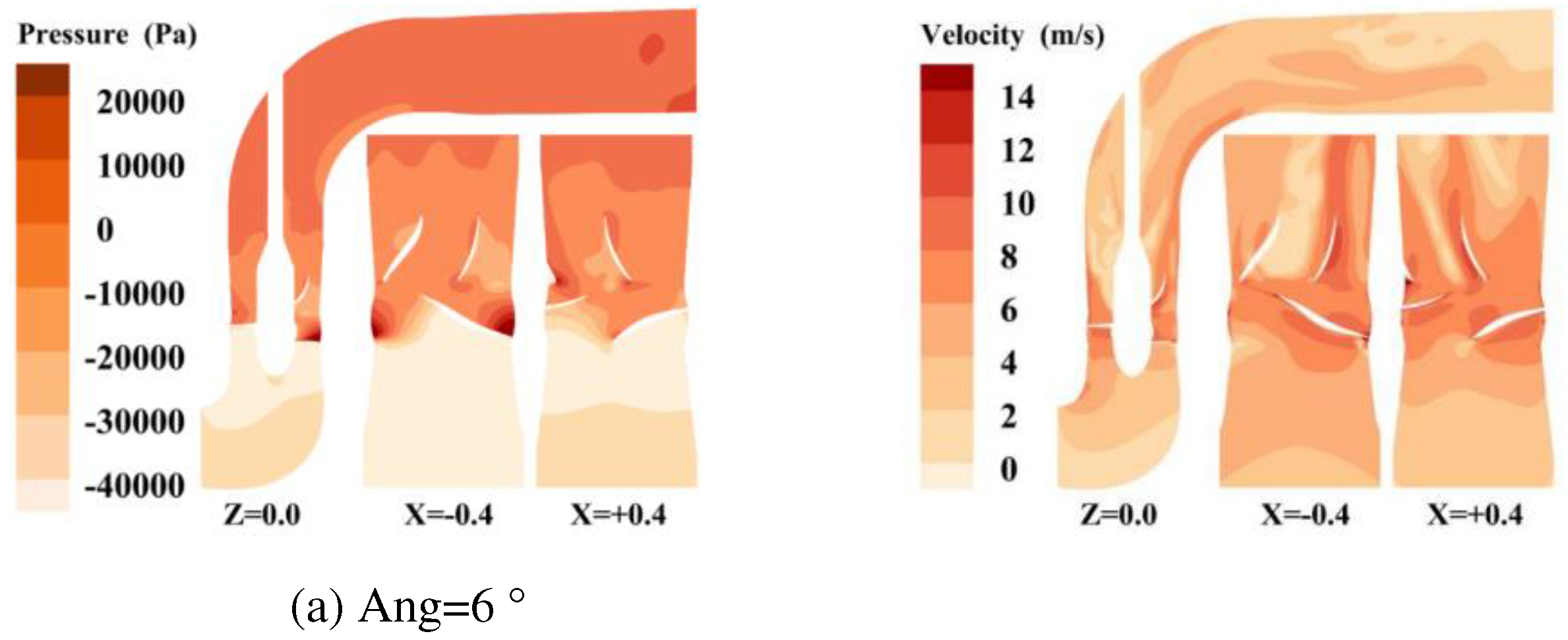

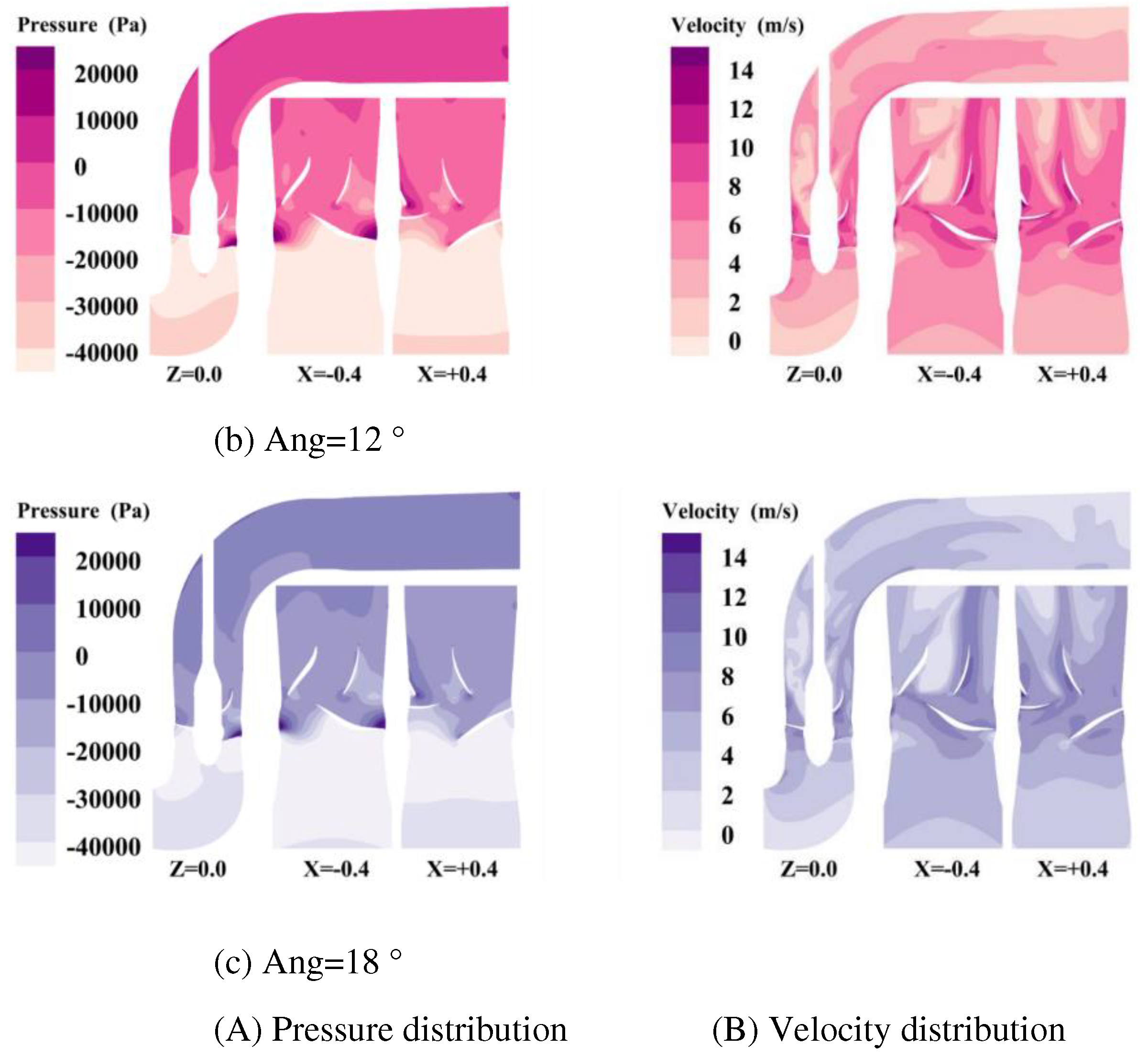

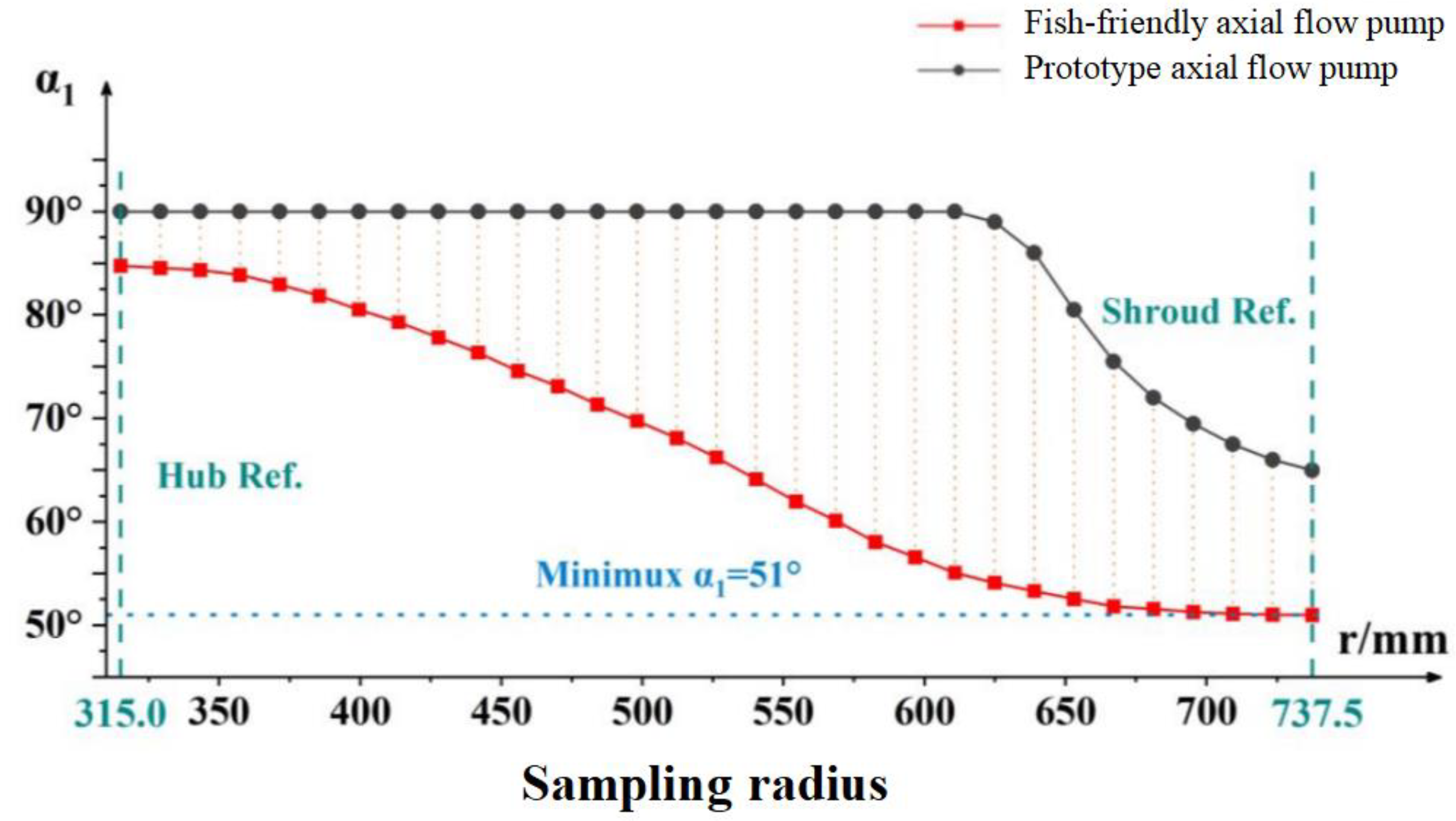

4.2. Optimal design of leading edge guiding characteristics of blade

5. Fish-passing performance analysis of fish-friendly axial flow pump

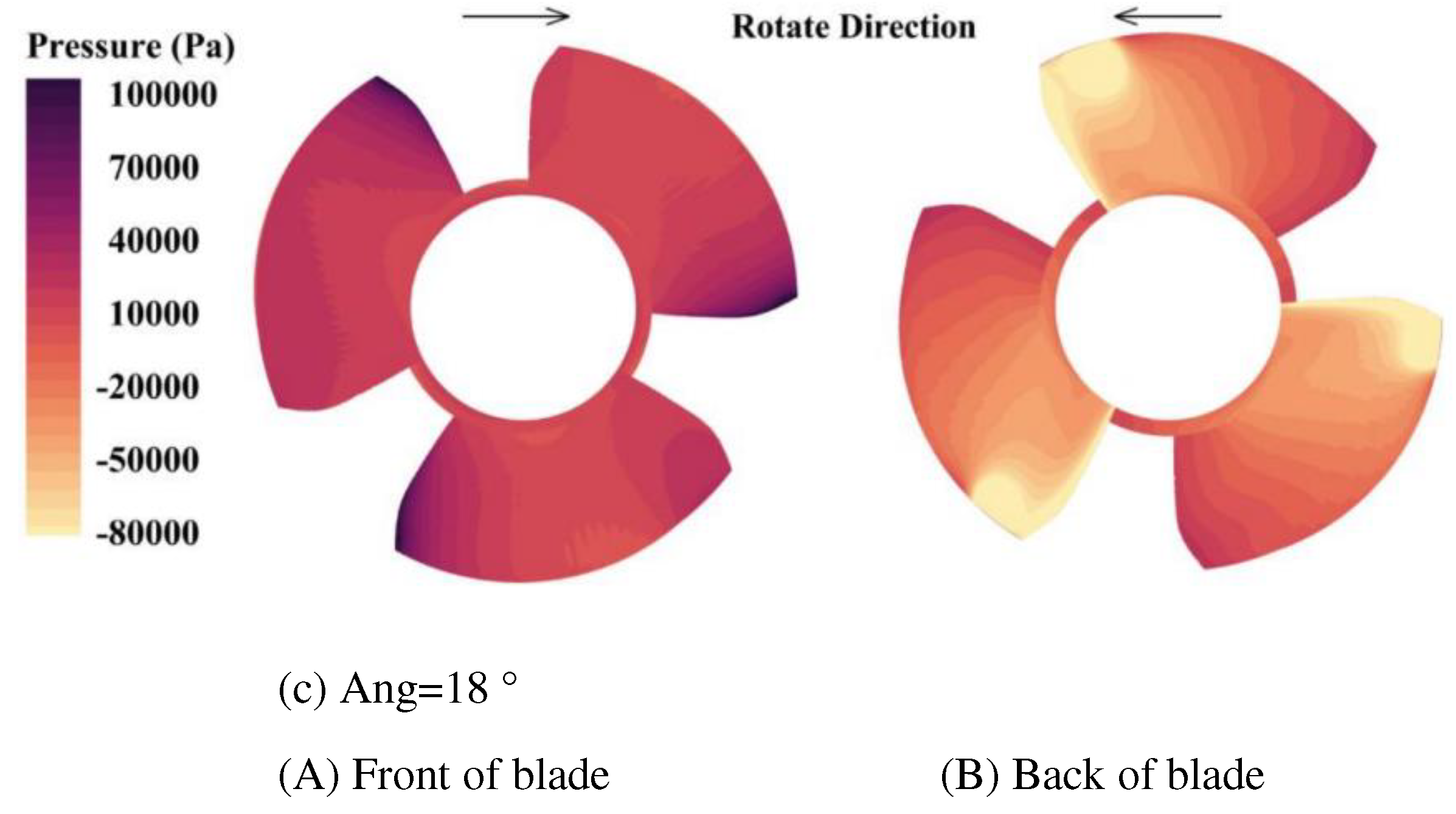

5.1. Analysis on the behavior trajectory of Fish through Axial flow pump

5.2. Comparative analysis on the mortality of fish subjected to blade impact

5.3. Comparative analysis of fish subjected to pressure and shear damage

6. Conclusion

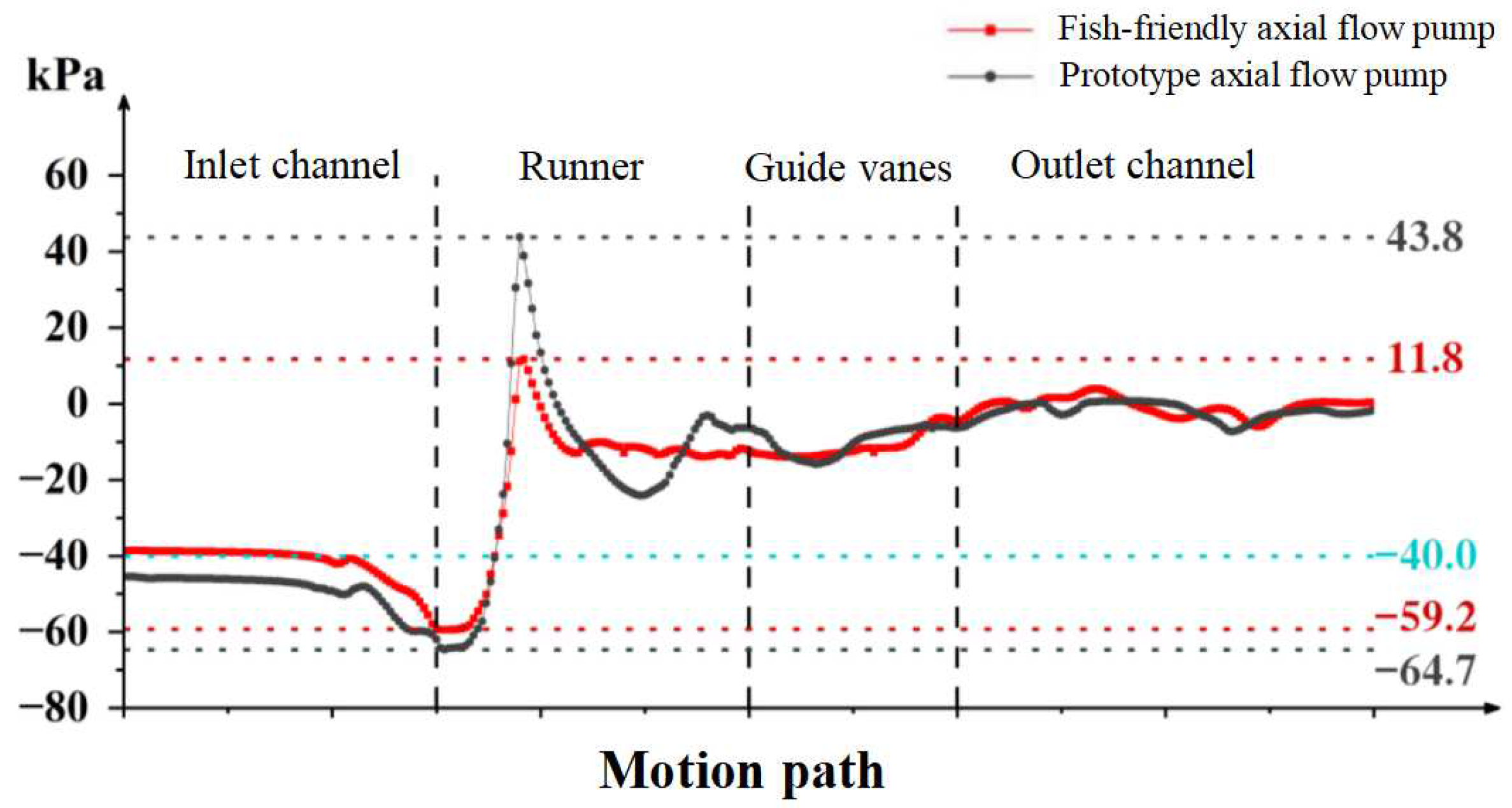

- Using the experiment device which is suitable for simulating the internal pressure of hydraulic machinery, the survival conditions of different species of fish under different pressure thresholds are obtained. Several typical pressure thresholds that fish may bear in the axial flow pump were simulated, and the damage situation and damage mechanism of fish after pressure injury were further studied. The survival threshold of wild crucian carp and yellow catfish is -40kPa. Other fish species should not be subjected to negative pressure. Therefore, this paper establishes -4kPa as the low-pressure damage threshold, which is used as a reference to analyze the probability of fish damage caused by hydraulic turbines.

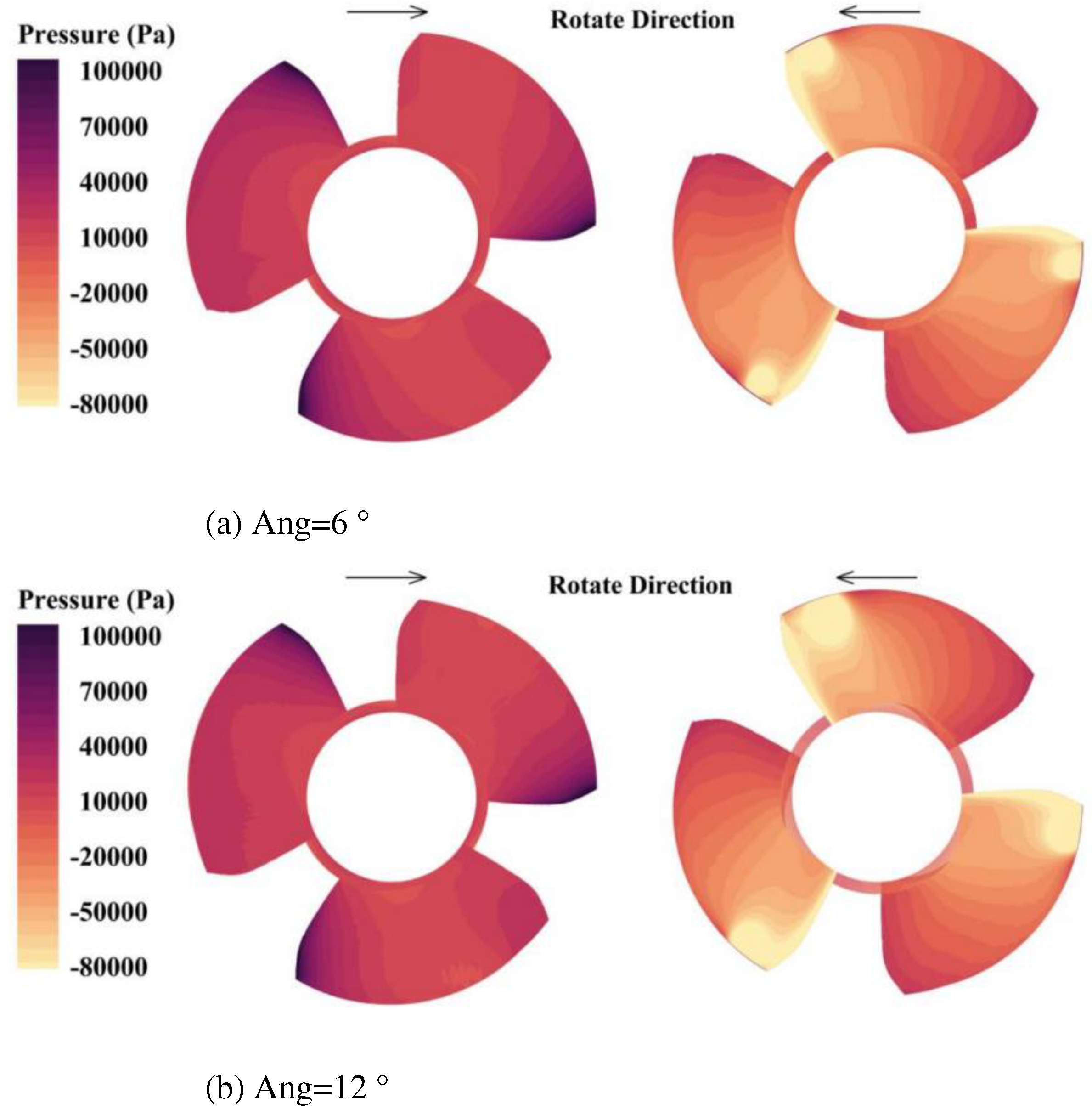

- Based on the runner design method and blade impact model of the axial flow pump, a fish-friendly axial flow pump is designed. The structural design of the axial flow pump runner is guided by the variables in the blade impact model, and the fish-friendly runner with high hydraulic performance and low impact mortality is obtained by using hydraulic performance, pressure, and shear rate damage as criteria. The runner whose leading edge thickness is 11.4mm is determined. This scheme can reduce the impact probability of the blade on the fish, ensure that the efficiency of the original runner is 98.4%, and have a more fish-friendly suction chamber negative pressure level than the 17.4mm runner. The runner with an inlet cutting angle of 18 ° is determined. The hydraulic performance, guiding effect, negative pressure performance, and velocity gradient performance of this scheme are better than those of 12 ° runner.

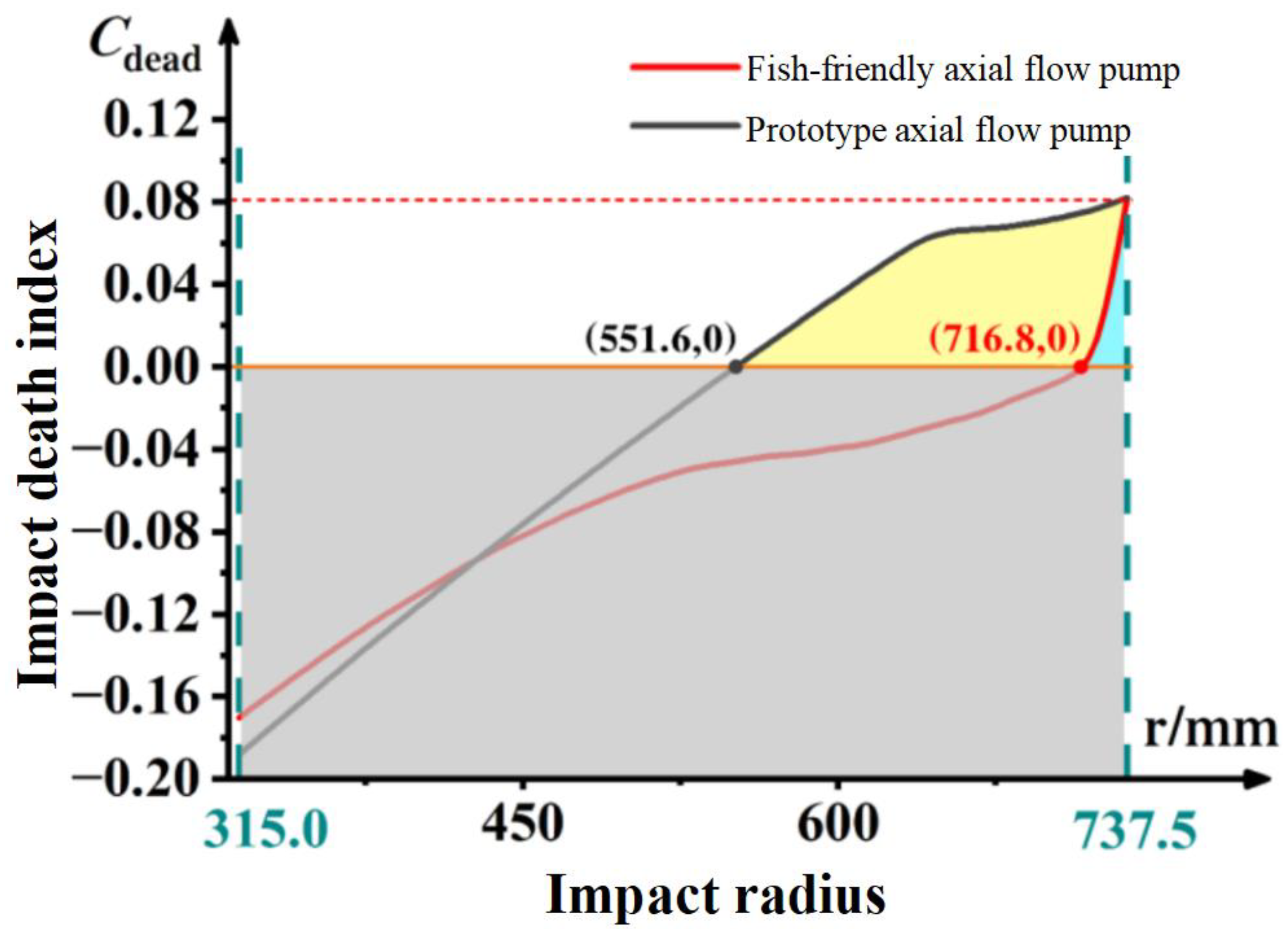

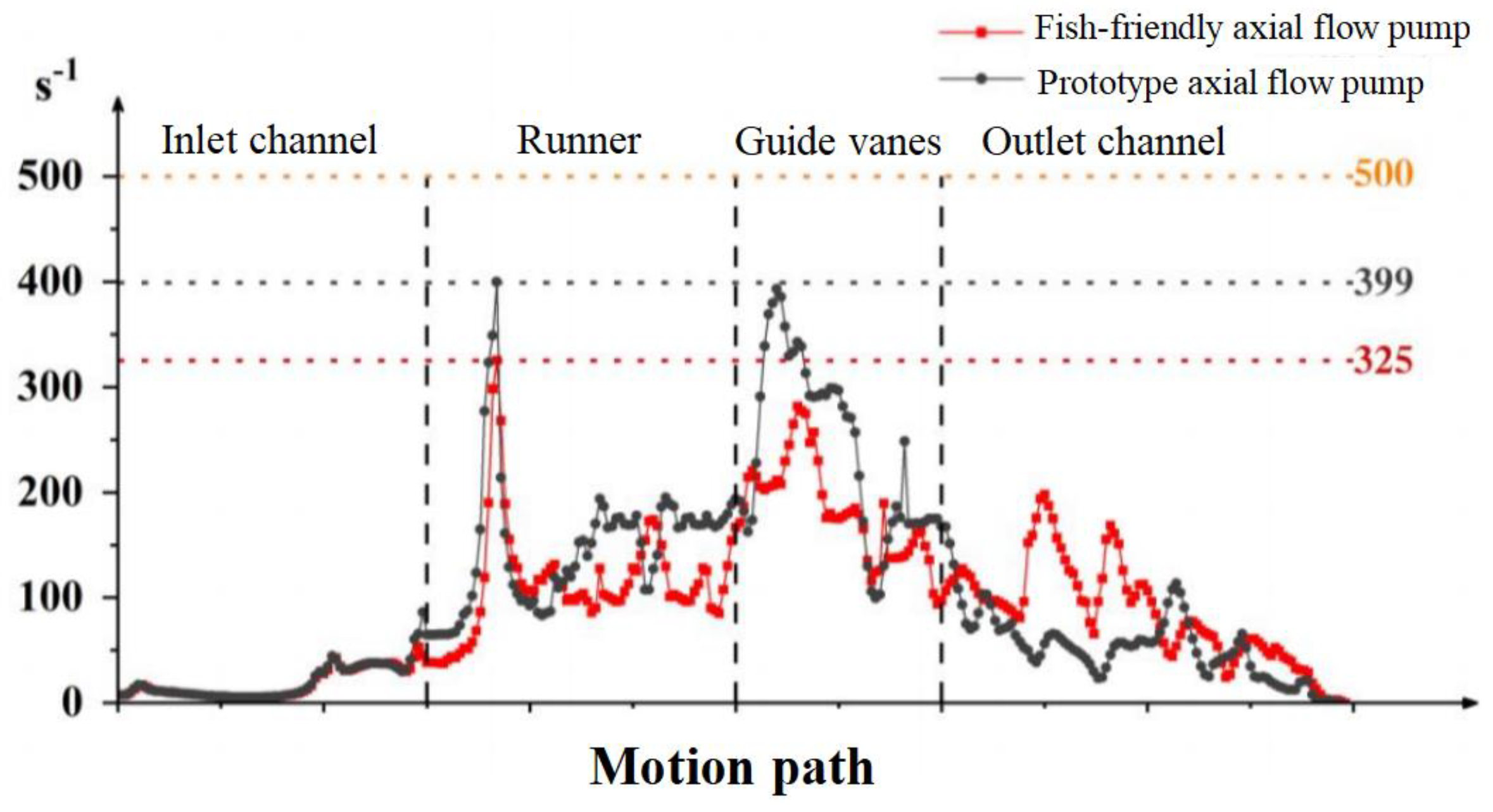

- Based on the efficient boundary calculation ability of the moving object of the LES-IB-LB method, the upward trajectory of three fish through the axial flow pump is simulated. The fish-passing performance of the prototype pump and fish-friendly axial flow pump were qualitatively and quantitatively analyzed. It is calculated that when the impact radius is less than 716.8 mm, the impact between the fish and the runner will not cause death. The ratio of total impact mortality of axial flow pump runner before and after optimization is close to 7:1. The pressure damage analysis shows that the average negative pressure on the body surface of the fish passing through the fish-friendly axial flow pump is higher than the survival threshold -40 kPa, and the negative pressure is lower than -40 kPa only in 0.13 s of the runner, while the lowest negative pressure -59.2 kPa is still higher than -64.7 kPa of the prototype axial flow pump, so the fish-friendly axial flow pump can reduce the negative pressure damage of fish. The shear damage analysis shows that the fish will not be damaged by shear in the prototype pump and the fish-friendly pump.

Corresponding author

Foundation Item

Nomenclature

| the relaxation time, s | |

| Pimpact | the probability of impact between the fish and the blade |

| tfish | the time for the fish to pass through the leading edge of the blade |

| hfish | the correction coefficient of the effective length of the fish |

| tblade | the time for the blade to walk through a leaf spacing |

| Cdead | the fish impact death index |

| Lfish | the length of the fish body, m |

| D | the thickness of the leading edge of the blade, m |

| Vs | the impact velocity |

References

- Thompson, A.M., Glasgow, J., Buehrens, T., et al. 2011. Mortality in juvenile salmonids passed through an agricultural Hidrostal pump. Fish. Manag. Ecol. 18 (4), 333–338. [CrossRef]

- Liu, C. Global migratory fish is facing extinction crisis. Ecological economy, 2021, 37 (01): 5-8.

- Liu, X. Research on the predicament and countermeasures of domestic fish road development. Guangxi Quality Supervision Guide, 2018, 1 (06): 24.

- Amaral S.V. Development and application of fish-friendly hydraulic turbine. KuaiBao of Water Conservancy and Hydropower, 2012: 33 (4): 34-37.

- Abernethy, C.S., Amidan, B.G., Eada, G.F. Simulated passage through a modified kaplan turbine pressure regime: A Supplement to ‘Laboratory Studies of the Effects of Pressure and Dissolved Gas Supersaturation on Turbine-Passed Fish. European Journal of Operational Research, 2002,73(1): 1-16. [CrossRef]

- Yang, C.X., Zheng, Y., Zhang, Y.Q., et al. Review on design and research of fish-friendly hydraulic turbines. Engineering Science, 2018,20(03): 96-101.

- Aode, M., Ma, X.j., Liu, Y. New concept of parent fish turbine design. Water Resources and hydropower Letters, 2001(4): 1-5.

- Shao, Q., Li, H.F., Wu, Y.L., et al. Simulation test of Pressure gradient Change in hydraulic machinery on fish damage. Chinese Journal of Mechanical Engineering, 2002(10): 7-11.

- Shao, Q., Li, M., Wu, Y.L., et al. Stress damage simulation of carp and grass carp in hydraulic machinery. Chinese Journal of Engineering Thermophysics, 2003(06): 954-957.

- Cada G. F., Bevelhimer, M. S. 2011. Attraction to and avoidance of instream hydrokinetic turbines by freshwater aquatic organisms. Oak Ridge Nati onalLaboratory,May. [CrossRef]

- Abernethy C.S., Amidan B.G. Laboratory studies of the effects of pressure and dissolved gas supersaturation on turbine-passed fish. office of scientific & technical information technical reports, 2001. [CrossRef]

- Cada, G., Loar, J., Garrison, L., et al. Efforts to reduce mortality to hydroelectric turbine-passed fish: Locating and Quantifying Damaging Shear Stresses. Environmental Management, 2006,37(6): 898-906. [CrossRef]

- Neitzel, D.A., Rishmond, M.C., Dauble, D.D., et al. Laboratory studies on the effects of shear on fish. Reports, 2000. [CrossRef]

- Neitzel, D.A., Dauble, D.D., Cada, G.F., et al. Survival estimates for juvenile fish subjected to a laboratory-generated shear environment. Transactions of the American Fisheries Society (1900), 2004,133(2): 447-454. [CrossRef]

- Lai X.D., Digital design and manufacture of vane fluid machinery. 2007.

- Lai X.D., Xu Y. Dynamic analysis and application of vane hydromechanical. 2017.

- Cook T.C., Hecker G.E., Faulkner H.B., et al. Development of a more fish-tolerant turbine runner, advanced Hydropower turbine project. Development of a More Fish Tolerant Turbine Runner - Advanced Hydropower Turbine Project, 1997.

- Hogan T.W., Cada G.F., Amaral S.V. The status of environmentally enhanced hydropower turbines. Fisheries, 2014, 39(4): 164-172. [CrossRef]

- Franke G.F., Webb D.R., Fisher R.K. Development of environmentally advanced hydropower turbine system concepts. Office of Scientific & Technical Information Technical Reports, 1997.

- Liao C.L., Lu L., Li T.Y., et al. Advance on the research and application of fish friendly turbine; Proceedings of the Proceedings Of The 35TH IAHR World Congress Vols I And II, 2013, 2013.

- Brown S. Innovations in turbine design and fish protection at Wanapum. International Journal on Hydropower & Dams, 2006, 13(4): 71-72.

- Loiseau F., Davidson R.A., Ouston M. Fish environment & new turbines design; proceedings of the 23rd IAHR Symposium-Yokohama, October 2006.

- David T., Mahar J.R. A cost effective and environmentally sustainable approach to retrofitting existing dams for hydroelectric power generation. Waterpower, 2009.

- Li H.F., Wu Y.L., Wang Z.W., et al. Experimental study on a new environment-friendly upflow turbine. Journal of Hydropower, 2002, 1 (1): 89-95.

- Pan, Q., Zhang, D.S., Shi, W.D. Optimization design of fish-friendly axial flow pump based on blade impact model. Transactions of the Chinese Society for Agricultural Machinery,2015,46(12):102-108.

- Pan, Q., Shi, W.D., Zhang, D.S., et al. Fish-friendly design and fish survival prediction of axial flow pumps for pumping stations. Journal of Drainage and Irrigation Machinery Engineering, 2017,35(001): 42-49. [CrossRef]

- Halliday I., Hammond L.A., Care C.M., et al. Lattice Boltzmann equation hydrodynamics. Physical Review E, 2001, 64(1): 18-20. [CrossRef]

- Chikatamarla S.S., Karlin I.V. Lattices for the lattice Boltzmann method. Physical Review E, 2009, 79(4). [CrossRef]

- Wu J.Y., Cheng Y.G., Zhang C.Z., et al. A high precision immersion boundary-lattice Boltzmann fluid-solid coupling scheme is used to simulate the free settlement motion of a two-dimensional rigid body. Journal of Sichuan University (Engineering Science Edition), 2016, 48 (1): 29-34.

- Li S.Y., Cheng Y.G., Zhang C.Z. IB-LB coupling scheme simulates 3-D transient flow of tubular turbine. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2016, 44 (01): 122,127.

- Li J. Study on damage mechanism of passing fish in tubular turbine; Xi’an University of Technology, 2020.

- Zhu G.J., Li J., Feng J.J. Research on casualty characteristics of fish in tubular turbine based on IB-LBM method. Journal of Physics Conference series, 2020, 1549(4): 42135. [CrossRef]

- Quaranta E., Wolter C. Sustainability assessment of hydropower water wheels with downstream migrating fish and blade strike modeling. Sustainable energy technologies and assessments, 2021, 43(1). [CrossRef]

- Stoltz U., Geiger F., Tuhtan J. A., et al. Influence of operation modes and fish behavior on fish passage through turbines; proceedings of the 30th IAHR Symposium on Hydraulic Machinery and Systems (IAHR), Electr Network, F 2021Mar 21-26, 2021.

- Mueller M., Sternecker K., Milz S., et al. Assessing turbine passage effects on internal fish injury and delayed mortality using X-ray imaging. Peer J, 2020, 8(1): 18-20. [CrossRef]

- Saylor R., Sterling D., Bevelhimer M.S., et al. Within and among fish species differences in simulated turbine blade strike mortality: Limits on the Use of Surrogacy for Untested Species. Water, 2020, 12(3). [CrossRef]

- Amaral, S.V., Watson, S.M., Schneider, A.D., et al., 2020. Improving survival: injury and mortality of fish struck by blades with slanted, blunt leading edges. EcoHydraul. 5(2), 175–183. [CrossRef]

- Klopries, E.M., Schüttrumpf, H., 2020. Mortality assessment for adult European eels (Anguilla Anguilla) during turbine passage using CFD modeling. Renew. Energy 147, 1481–1490. [CrossRef]

| Experimental laber | Fish species | Pressure threshold(Mpa) | Increase pressure time(s) | Increase pressure rate(kpa/s) | The number of abnormal fish | The number of dead fish | The proportion of dead fish(%) | The proportion of surviving fish(%) |

|---|---|---|---|---|---|---|---|---|

| 0C | Cultured crucian carp | 0.101 | 0 | 0 | 3 | 0 | 0 | 100 |

| 0W | Wild crucian carp | 6 | 18 | 18 | 82 | |||

| 0Y | Yellow catfish | 0 | 3 | 3 | 97 | |||

| 1C | Cultured crucian carp | 0.34 | 24 | 13.6 | 18 | 20 | 20 | 80 |

| 1W | Wild crucian carp | 6 | 18 | 18 | 82 | |||

| 1Y | Yellow catfish | 0 | 4 | 4 | 96 | |||

| 2C | Cultured crucian carp | 0.68 | 48 | 13.6 | 17 | 72 | 72 | 28 |

| 2W | Wild crucian carp | 3 | 19 | 19 | 81 | |||

| 2Y | Yellow catfish | 1 | 8 | 8 | 92 |

| Experimental laber | Fish species | Pressure threshold(Mpa) | Increase pressure time(s) | Increase pressure rate(kpa/s) | The number of abnormal fish | The number of dead fish | The proportion of dead fish(%) | The proportion of surviving fish(%) |

|---|---|---|---|---|---|---|---|---|

| 0C | Cultured crucian carp | 0.101 | 0 | 0 | 3 | 0 | 0 | 100 |

| 0W | Wild crucian carp | 6 | 18 | 18 | 82 | |||

| 0Y | Yellow catfish | 0 | 3 | 3 | 97 | |||

| 3C | Cultured crucian carp | -0.02 | 6 | 3.33 | 12 | 76 | 76 | 24 |

| 3W | Wild crucian carp | 6 | 6 | 6 | 94 | |||

| 3Y | Yellow catfish | 2 | 13 | 13 | 87 | |||

| 4C | Cultured crucian carp | -0.04 | 12 | 3.33 | 0 | 100 | 100 | 0 |

| 4W | Wild crucian carp | 1 | 19 | 19 | 81 | |||

| 4Y | Yellow catfish | 6 | 37 | 37 | 63 | |||

| 5C | Cultured crucian carp | -0.08 | 24 | 3.33 | 0 | 100 | 100 | 0 |

| 5W | Wild crucian carp | 18 | 78 | 78 | 22 | |||

| 5Y | Yellow catfish | 15 | 70 | 70 | 30 |

| Parameter | Value |

|---|---|

| Rated headb Hr (m) | 6.0 |

| Rated speed nr (r/min) | 300 |

| Rated discharge Qr (m3/s) | 8.0 |

| Runner diameter D1 (mm) | 1475 |

| Number of runner blade Nb | 3 |

| Number of guide vane Ngv | 5 |

| Leading edge thickness of blade | Discharge | Head | Average pressure at inlet and outlet of runner | Shaft power | Runner efficiency | Machine efficiency | ||

|---|---|---|---|---|---|---|---|---|

| Thk(mm) | Q(m3/s) | H(m) | P1(kPa) | P0(kPa) | ΔP(kPa) | N(kw) | η(%) | η(%) |

| 5.6 | 8.01 | 6.01 | -44.5 | 14.3 | 58.8 | 523.4 | 90.12 | 75.68 |

| 11.4 | 8.02 | 5.91 | -45.9 | 11.9 | 57.9 | 518.8 | 89.38 | 74.50 |

| 17.4 | 8.02 | 5.83 | -47.3 | 9.8 | 57.1 | 514.8 | 88.87 | 73.59 |

| Blade cutting angles | Discharge | Head | Average pressure at inlet and outlet of runner | Shaft power | Runner efficiency | Machine efficiency | ||

|---|---|---|---|---|---|---|---|---|

| Ang(°) | Q(m3/s) | H(m) | P1(kPa) | P0(kPa) | ΔP(kPa) | N(kw) | η(%) | η(%) |

| 6 | 8.02 | 5.91 | -45.9 | 11.9 | 57.9 | 518.8 | 89.38 | 74.50 |

| 12 | 8.01 | 5.95 | -46.0 | 12.2 | 58.3 | 529.6 | 88.20 | 72.62 |

| 18 | 8.02 | 5.90 | -44.8 | 12.8 | 57.6 | 523.0 | 88.33 | 71.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).