Submitted:

04 October 2023

Posted:

09 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Recycling of specific electrical-electronic components from e-waste

1.3. Artificial lighting and MLCCs

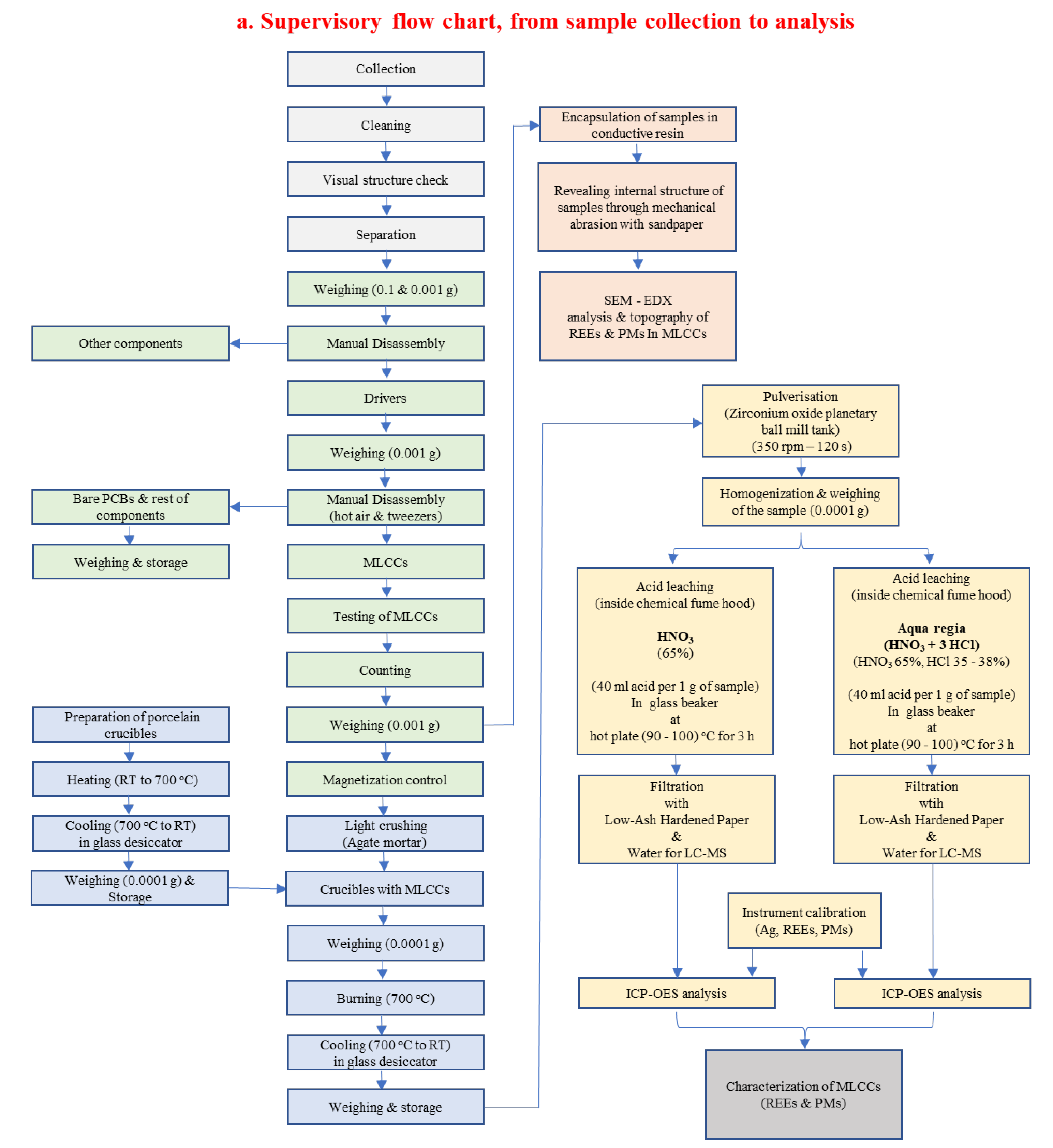

2. Materials and Methods

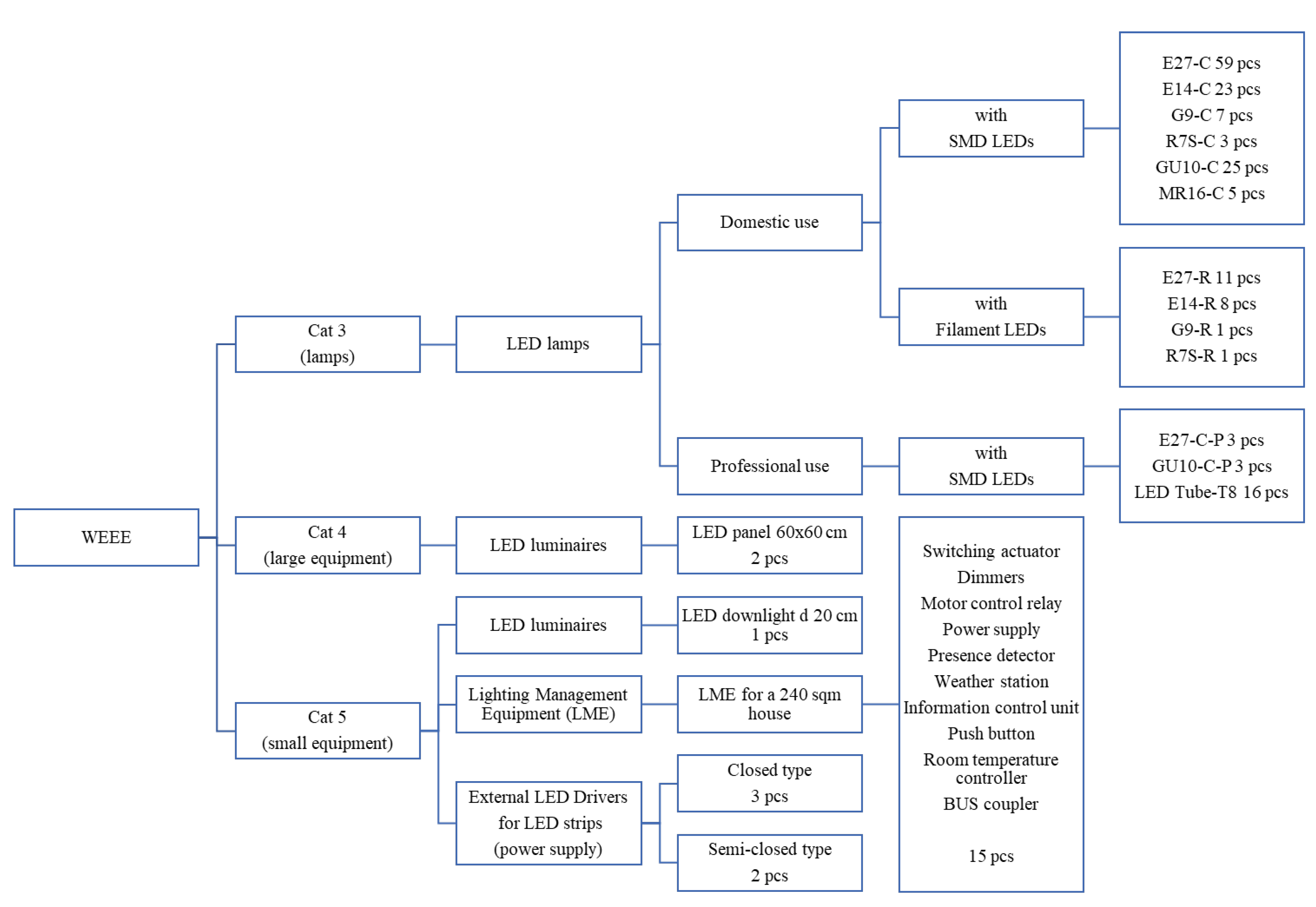

2.1. Materials

2.2. Methodology

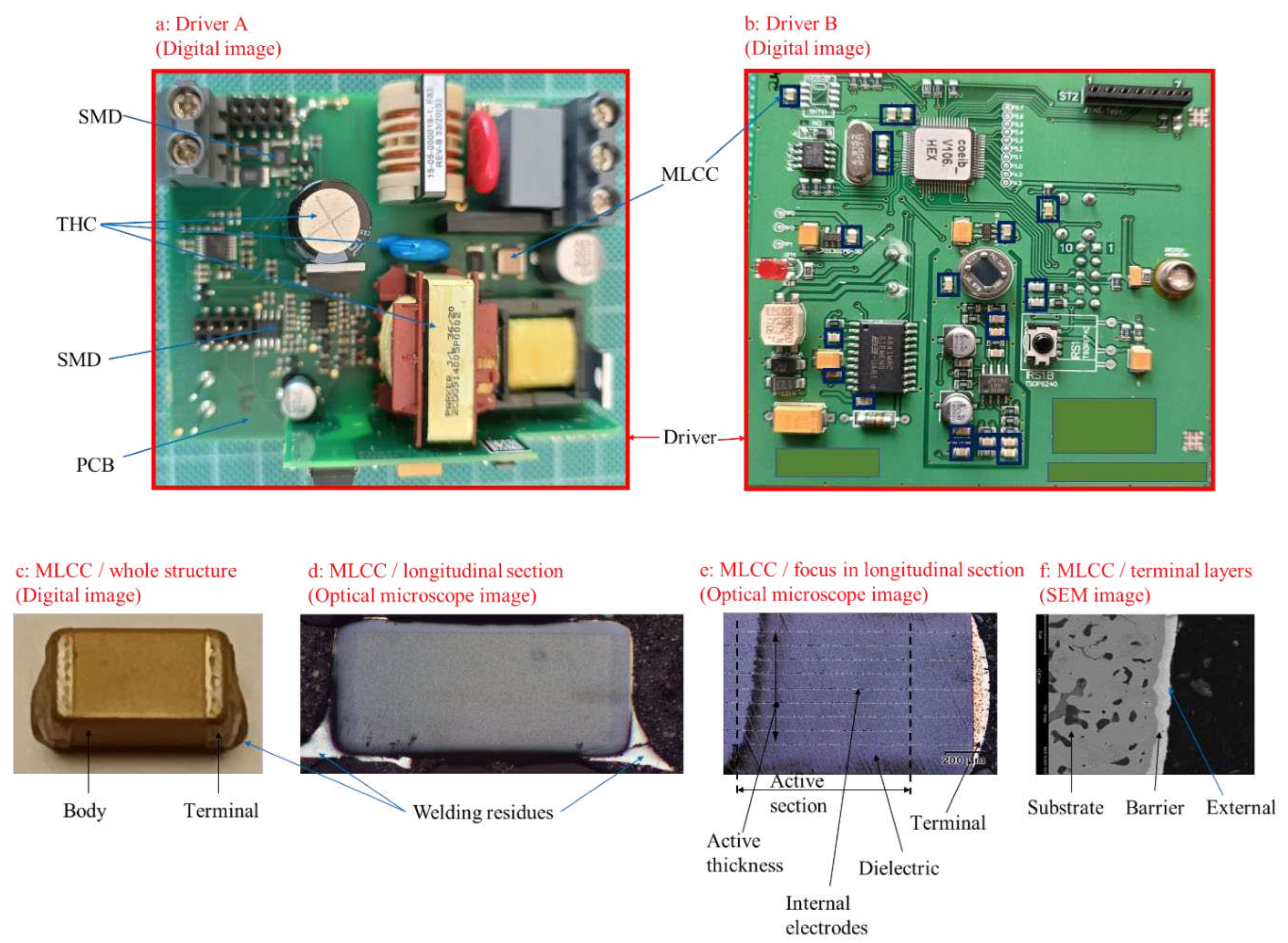

2.2.1. 1st stage - Collection and separation

2.2.2. 2nd stage - Disassembly and testing

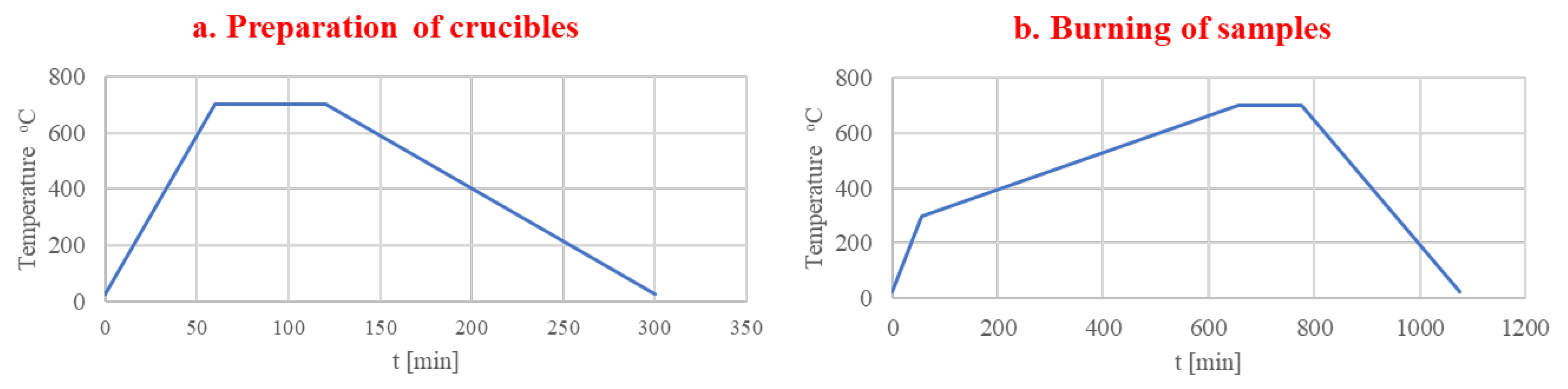

2.2.3. 3rd stage - Samples preparation

2.2.4. 4th stage - ICP-OES analysis

2.2.5. 5th stage - SEM-EDX analysis

2.2.6. 6th stage - Calculation of stored value

3. Results and Discussion

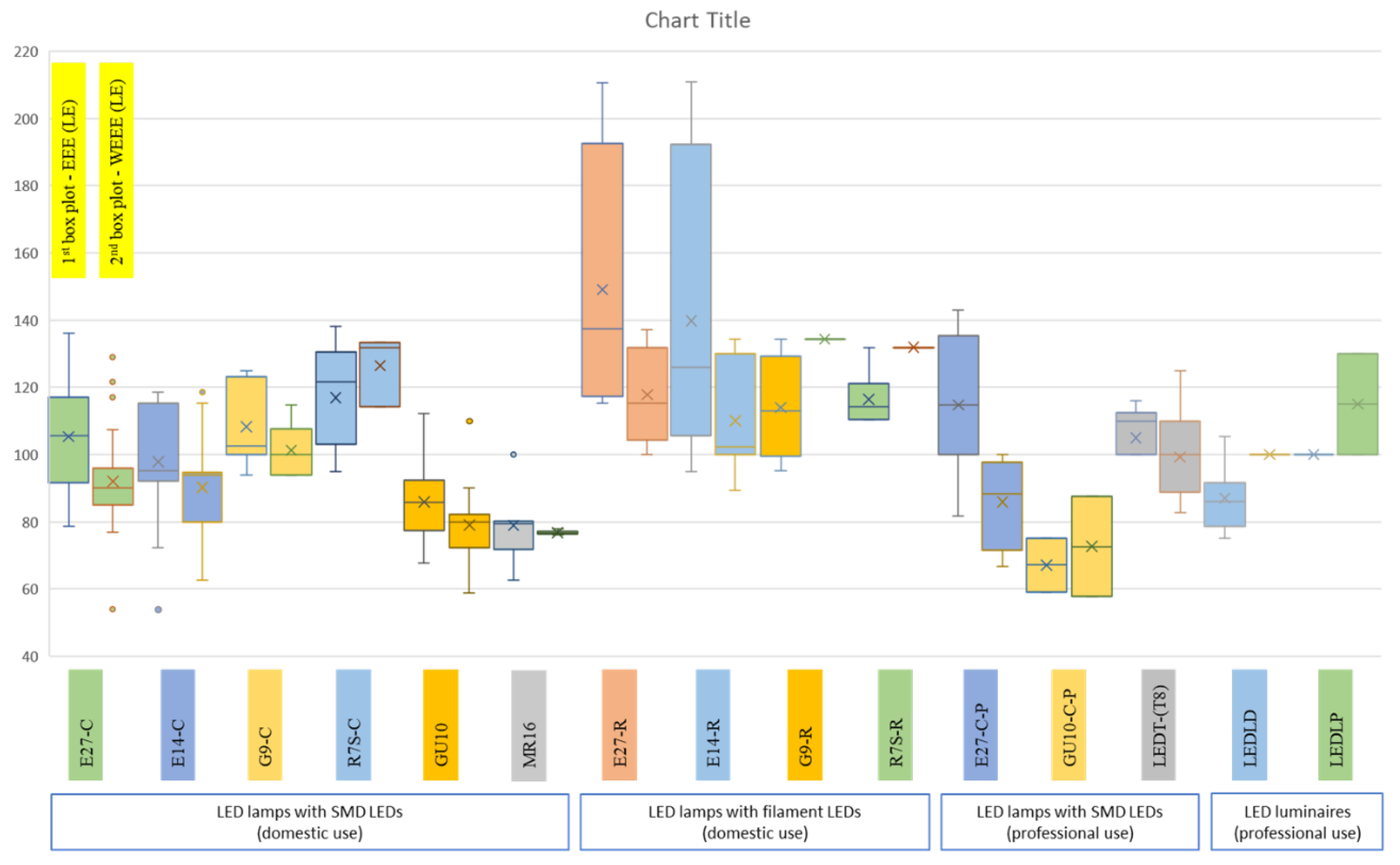

3.1. Estimation of the chronology of lighting equipment

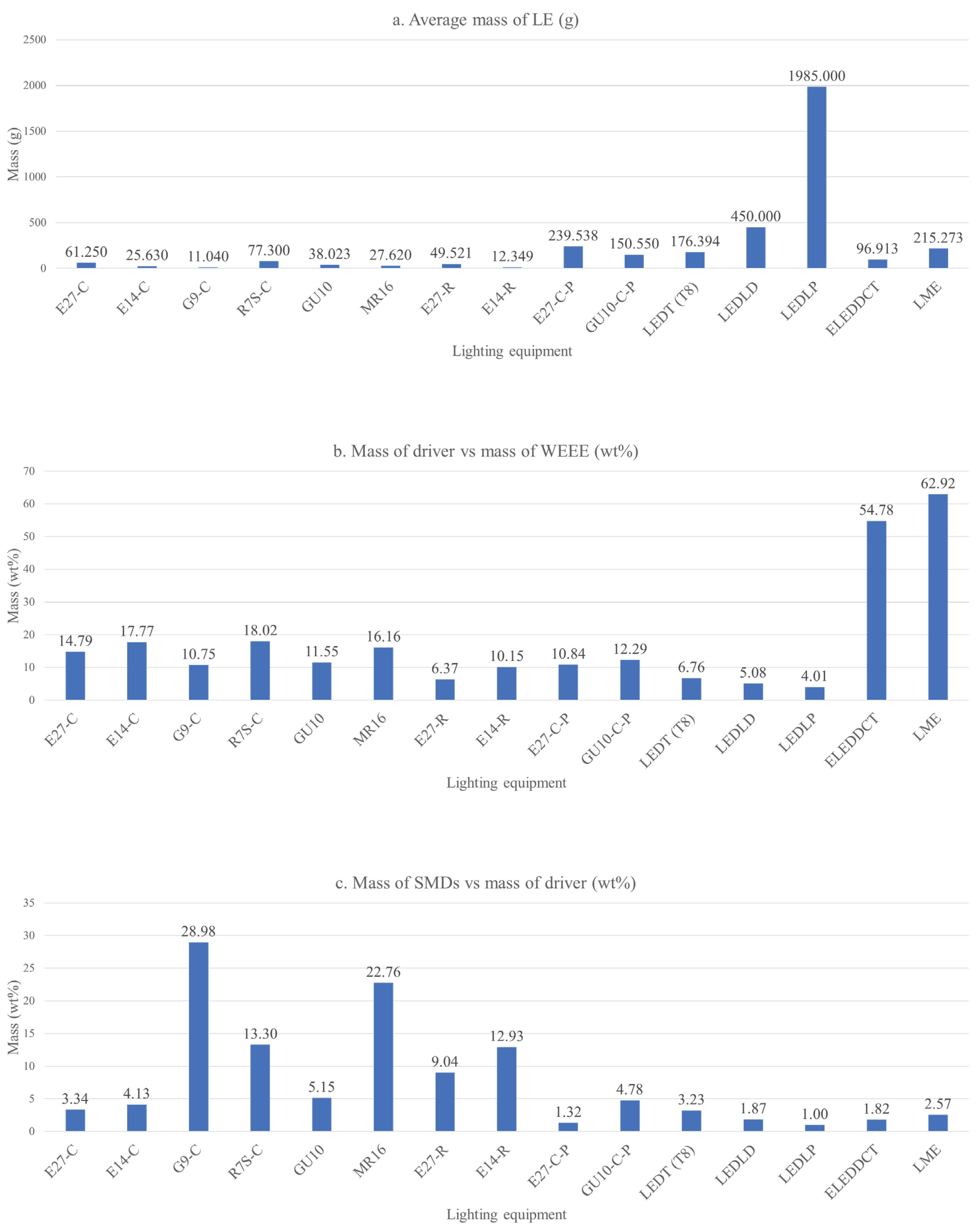

3.2. MLCCs in lighting equipment

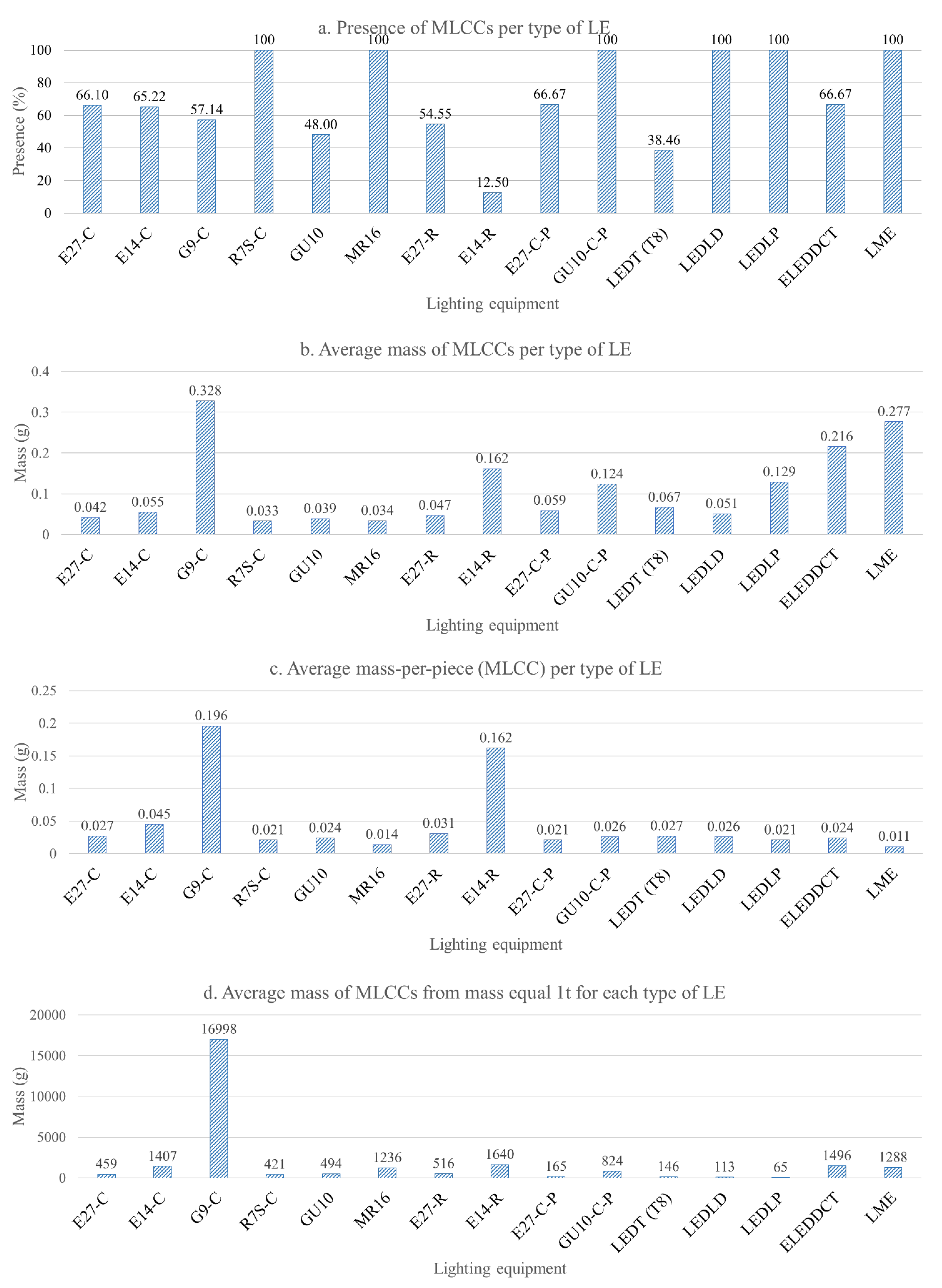

3.3. Characterisation of MLCCs from lighting equipment via ICP-OES analysis

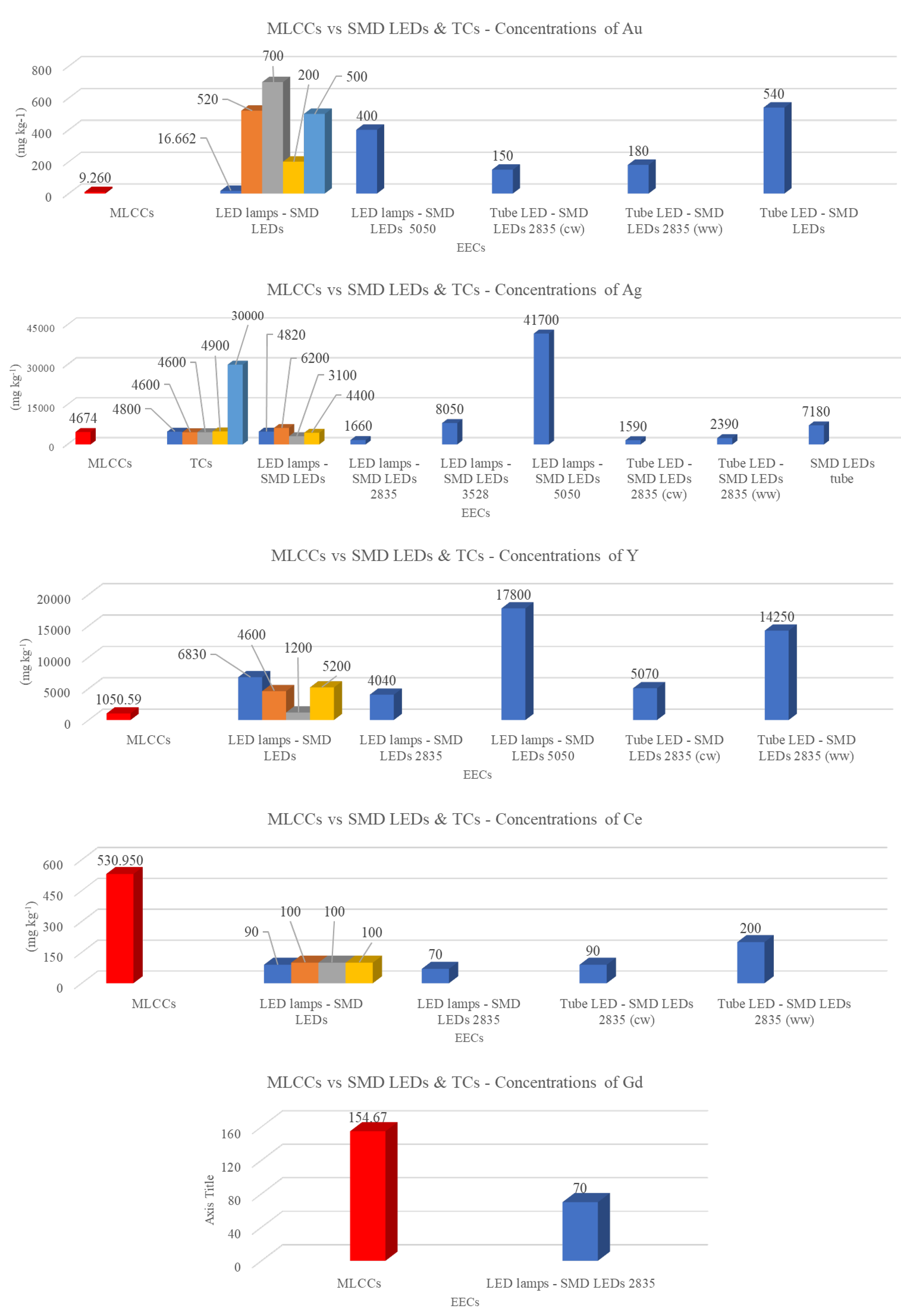

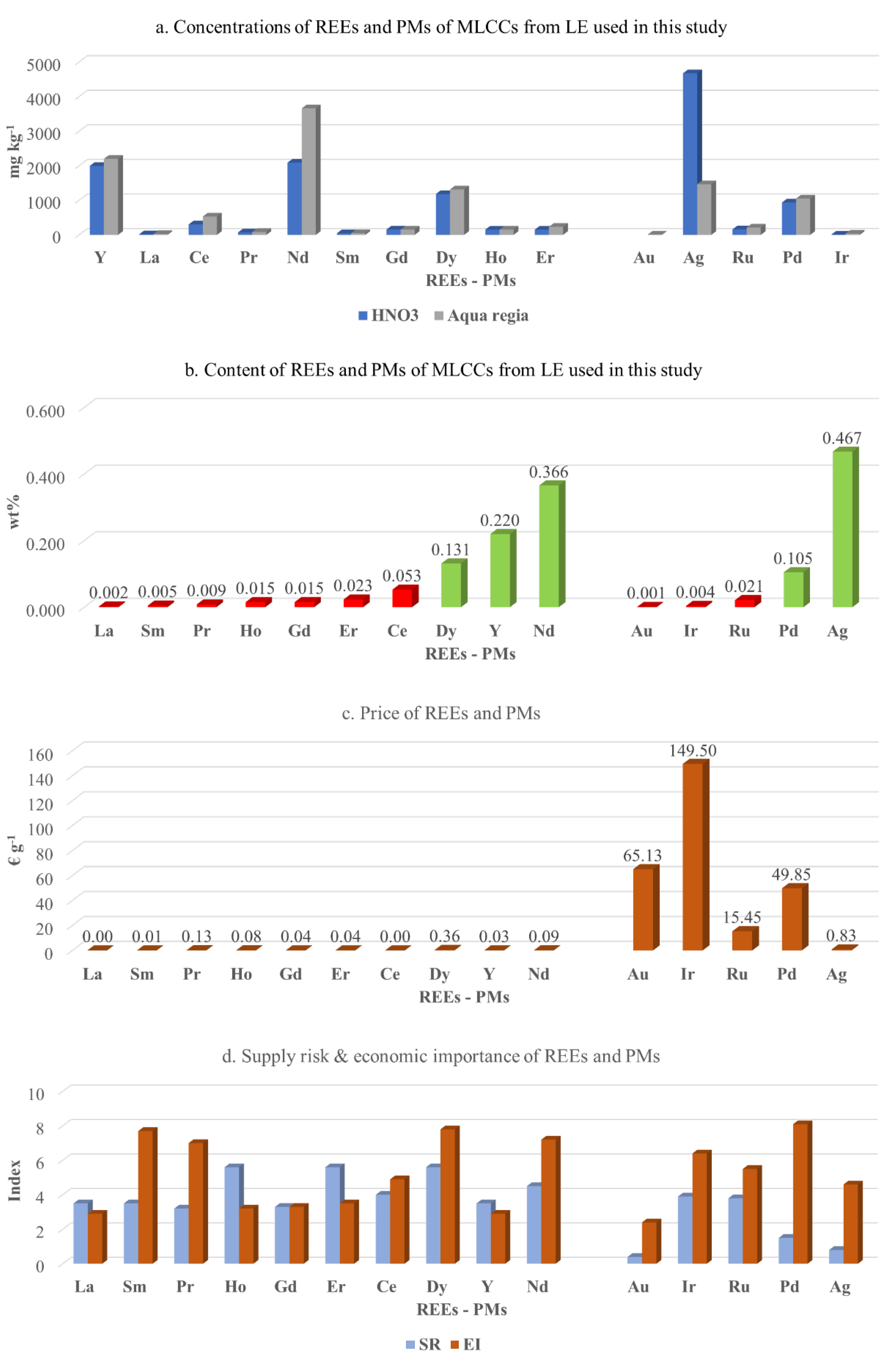

3.4. EDX analysis of MLCCs from lighting equipment

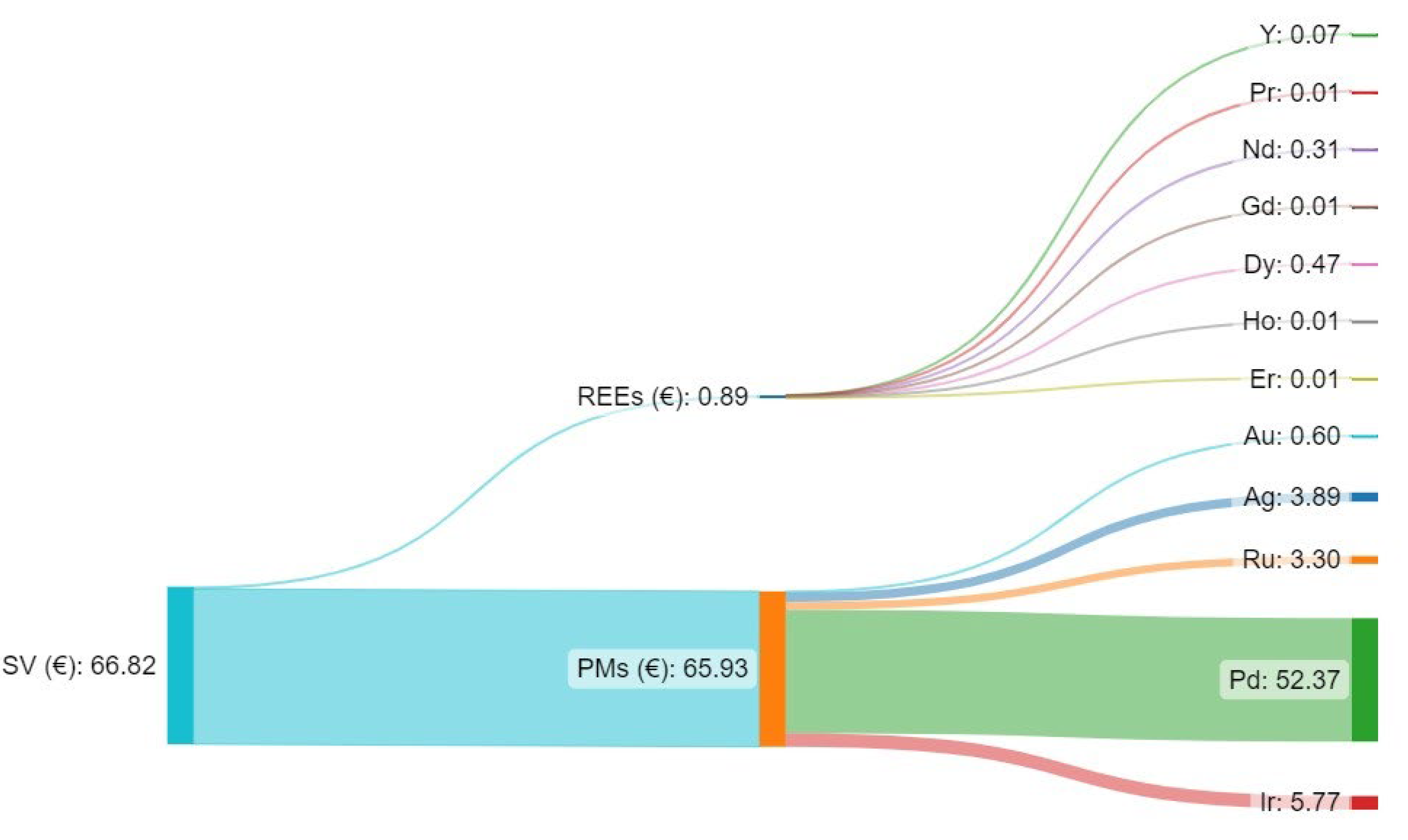

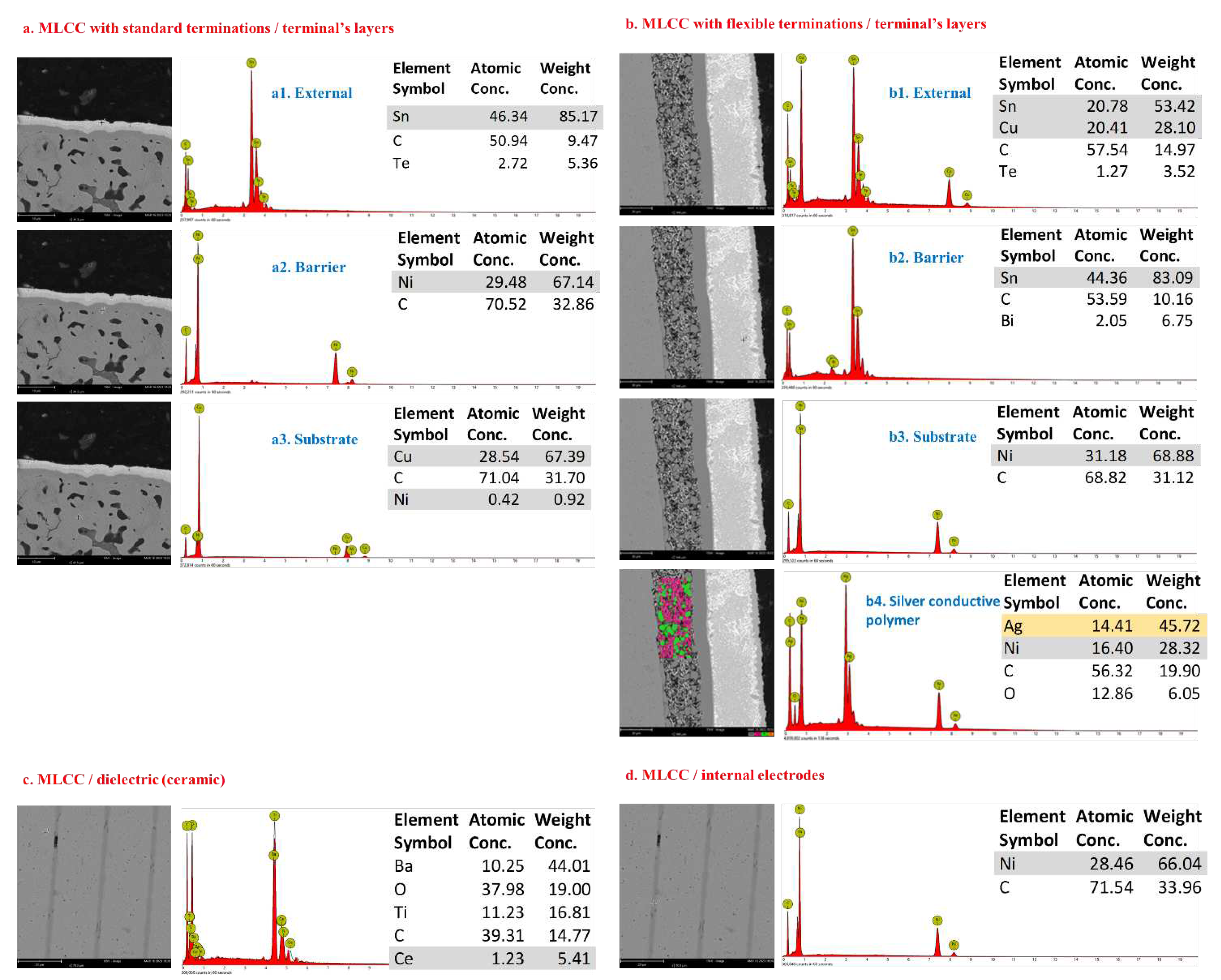

4. MLCCs as target components and their store value

4. Conclusions

Acknowledgements

Declaration of competing interest

Appendixes

References

- Birloaga, Ionela, Vasile Coman, Bernd Kopacek, and Francesco Vegliò. 2014. An advanced study on the hydrometallurgical processing of waste computer printed circuit boards to extract their valuable content of metals. Waste Management 34. Elsevier Ltd: 2581–2586. [CrossRef]

- Di Piazza, Simone, Grazia Cecchi, Anna Maria Cardinale, Cristina Carbone, Mauro Giorgio Mariotti, Marco Giovine, and Mirca Zotti. 2017. Penicillium expansum Link strain for a biometallurgical method to recover REEs from WEEE. Waste Management 60. Elsevier Ltd: 596–600. [CrossRef]

- Mir, Shaila, and Nikhil Dhawan. 2022. A comprehensive review on the recycling of discarded printed circuit boards for resource recovery. Resources, Conservation and Recycling 178: 106027. [CrossRef]

- Kaya, Muammer. 2016. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Management 57: 64–90. [CrossRef]

- Wani, Saima, and Shafquat Majeed. 2017. Rare-Earth nanomaterials for Bio-Probe applications. Applied Biological Research 19: 241. [CrossRef]

- Cardoso, Celso E D, Joana C Almeida, Cláudia B. Lopes, Tito Trindade, Carlos Vale, and Eduarda Pereira. 2019. Recovery of Rare Earth Elements by Carbon-Based Nanomaterials—A Review. Nanomaterials 9: 814. [CrossRef]

- Charles, Rhys G., Peter Douglas, Mark Dowling, Gareth Liversage, and Matthew L. Davies. 2020. Towards Increased Recovery of Critical Raw Materials from WEEE– evaluation of CRMs at a component level and pre-processing methods for interface optimisation with recovery processes. Resources, Conservation and Recycling 161. Elsevier: 104923. [CrossRef]

- Maurice, Ange A., Khang Ngoc Dinh, Nicolas M. Charpentier, Andrea Brambilla, and Jean Christophe P. Gabriel. 2021. Dismantling of printed circuit boards enabling electronic components sorting and their subsequent treatment open improved elemental sustainability opportunities. Sustainability (Switzerland) 13. [CrossRef]

- European Commission. 2023. Study on the Critical Raw Materials for the EU. [CrossRef]

- Gidarakos, E., and A. Akcil. 2020. WEEE under the prism of urban mining. Waste Management 102: 950–951. [CrossRef]

- Van Yken, Jonovan, Naomi J. Boxall, Ka Yu Cheng, Aleksandar N. Nikoloski, Navid R. Moheimani, and Anna H. Kaksonen. 2021. E-waste recycling and resource recovery: A review on technologies, barriers and enablers with a focus on oceania. Metals 11. [CrossRef]

- Gautam, Pushpa, Chhail K. Behera, Indrajit Sinha, Gospodinka Gicheva, and Kamalesh K. Singh. 2022. High added-value materials recovery using electronic scrap-transforming waste to valuable products. Journal of Cleaner Production 330. Elsevier Ltd: 129836. [CrossRef]

- Alam, Mohammed A., Leonard Zuga, and Michael G. Pecht. 2012. Economics of rare earth elements in ceramic capacitors. Ceramics International 38. Elsevier: 6091–6098. [CrossRef]

- Binnemans, K., and P. T. Jones. 2014. Perspectives for the recovery of rare earths from end-of-life fluorescent lamps. Journal of Rare Earths 32: 195–200. [CrossRef]

- Charles, Rhys Gareth, Peter Douglas, Ingrid Liv Hallin, Ian Matthews, and Gareth Liversage. 2017. An investigation of trends in precious metal and copper content of RAM modules in WEEE: Implications for long term recycling potential. Waste Management 60. The Authors: 505–520. [CrossRef]

- Smith, Lucy, Taofeeq Ibn-Mohammed, S. C.Lenny Koh, and Ian M. Reaney. 2018. Life cycle assessment and environmental profile evaluations of high volumetric efficiency capacitors. Applied Energy 220: 496–513. [CrossRef]

- De La Torre, Ernesto, Estefanía Vargas, César Ron, and Sebastián Gámez. 2018. Europium, yttrium, and indium recovery from electronic wastes. Metals 8. [CrossRef]

- Liu, Ya, Lingen Zhang, Qingming Song, and Zhenming Xu. 2020. Recovery of palladium and silver from waste multilayer ceramic capacitors by eutectic capture process of copper and mechanism analysis. Journal of Hazardous Materials 388: 122008. [CrossRef]

- Silva, Leandro H.de S., Agostinho A.F. Júnior, George O.A. Azevedo, Sergio C. Oliveira, and Bruno J.T. Fernandes. 2021. Estimating recycling return of integrated circuits using computer vision on printed circuit boards. Applied Sciences (Switzerland) 11. [CrossRef]

- Milinovic, Jelena, Francisco J. L. Rodrigues, Fernando J. A. S. Barriga, and Bramley J. Murton. 2021. Ocean-Floor Sediments as a Resource of Rare Earth Elements: An Overview of Recently Studied Sites. Minerals 11: 142. [CrossRef]

- Fischer, Andreas C., Fredrik Forsberg, Martin Lapisa, Simon J. Bleiker, Göran Stemme, Niclas Roxhed, and Frank Niklaus. 2015. Integrating MEMS and ICs. Microsystems and Nanoengineering 1: 1–16. [CrossRef]

- Prabaharan, G., S. P. Barik, and B. Kumar. 2016. A hydrometallurgical process for recovering total metal values from waste monolithic ceramic capacitors. Waste Management 52. Elsevier Ltd: 302–308. [CrossRef]

- Liu, Ya, Qingming Song, Lingen Zhang, and Zhenming Xu. 2021. Behavior of enrichment and migration path of Cu–Ag–Pd–Bi–Pb in the recovery of waste multilayer ceramic capacitors by eutectic capture of copper. Journal of Cleaner Production 287. Elsevier Ltd: 125469. [CrossRef]

- Wu, Changfa, Abhishek Kumar Awasthi, Wenqing Qin, Wei Liu, and Congren Yang. 2022. Recycling value materials from waste PCBs focus on electronic components: Technologies, obstruction and prospects. Journal of Environmental Chemical Engineering 10. Elsevier Ltd: 108516. [CrossRef]

- Kumari, Rima, and Sukha Ranjan Samadder. 2022. A critical review of the pre-processing and metals recovery methods from e-wastes. Journal of Environmental Management 320. Elsevier Ltd: 115887. [CrossRef]

- Niu, Bo, and Zhenming Xu. 2017. Application of Chloride Metallurgy and Corona Electrostatic Separation for Recycling Waste Multilayer Ceramic Capacitors. ACS Sustainable Chemistry and Engineering 5: 8390–8395. [CrossRef]

- Zhou, Jiazhi, Nengwu Zhu, Huangrui Liu, Pingxiao Wu, Xiaoping Zhang, and Zuqi Zhong. 2019. Recovery of gallium from waste light emitting diodes by oxalic acidic leaching. Resources, Conservation and Recycling 146: 366–372. [CrossRef]

- Niu, Bo, and Zhenming Xu. 2019. Innovating e-waste recycling: From waste multi-layer ceramic capacitors to Nb–Pb codoped and ag-Pd-Sn-Ni loaded BaTiO 3 nano-photocatalyst through one-step ball milling process. Sustainable Materials and Technologies 21. Elsevier B.V.: e00101. [CrossRef]

- Hernández, Víctor I., Domingo I. García-Gutiérrez, Juan A. Aguilar-Garib, and Román J. Nava-Quintero. 2021. Characterization of precipitates formed in X7R 0603 BME-MLCC during sintering. Ceramics International 47. Elsevier Ltd and Techna Group S.r.l.: 310–319. [CrossRef]

- Liu, Ya, Qingming Song, Lingen Zhang, and Zhenming Xu. 2021. Separation of metals from Ni-Cu-Ag-Pd-Bi-Sn multi-metal system of e-waste by leaching and stepwise potential-controlled electrodeposition. Journal of Hazardous Materials 408. Elsevier B.V.: 124772. [CrossRef]

- Xu, Junhua, Daobin Liu, Carmen Lee, Pierre Feydi, Marlene Chapuis, Jing Yu, Emmanuel Billy, Qingyu Yan, and Jean Christophe P. Gabriel. 2022. Efficient Electrocatalyst Nanoparticles from Upcycled Class II Capacitors. Nanomaterials 12: 1–13. [CrossRef]

- Buechler, Dylan T., Nadezhda N. Zyaykina, Cole A. Spencer, Emily Lawson, Natasha M. Ploss, and Inez Hua. 2020. Comprehensive elemental analysis of consumer electronic devices: Rare earth, precious, and critical elements. Waste Management 103. Elsevier Ltd: 67–75. [CrossRef]

- Kadota, Mitsuhiro, Hiroyuki Shoji, Atsushi Hatakeyama, and Keiji Wada. 2019. Output current ripple reduction of LED driver using ceramic-capacitor-input circuit and buck-boost converter. Electrical Engineering in Japan (English translation of Denki Gakkai Ronbunshi) 209: 26–34. [CrossRef]

- Hernández-López, Ana María, Juan Antonio Aguilar-Garib, Sophie Guillemet-Fritsch, Roman Nava-Quintero, Pascal Dufour, Christophe Tenailleau, Bernard Durand, and Zarel Valdez-Nava. 2018. Reliability of X7R multilayer ceramic capacitors during High Accelerated Life Testing (HALT). Materials 11. [CrossRef]

- Huang, Chien Ming, Jose A. Romero, Michael Osterman, Diganta Das, and Michael Pecht. 2019. Life cycle trends of electronic materials, processes and components. Microelectronics Reliability 99. Elsevier: 262–276. [CrossRef]

- Pankaj Kumar. 2018. Electronic waste - hazards, management and available green technologies for remediation - a review. International Research Journal of Environmental Sciences 7: 57–68.

- Sarvar, Mojtaba, Mohammad Mehdi Salarirad, and Mohammad Amin Shabani. 2015. Characterization and mechanical separation of metals from computer Printed Circuit Boards (PCBs) based on mineral processing methods. Waste Management 45. Elsevier Ltd: 246–257. [CrossRef]

- Panda, Rekha, Om Shankar Dinkar, Manis Kumar Jha, and Devendra Deo Pathak. 2020. Hydrometallurgical processing of waste multilayer ceramic capacitors (MLCCs) to recover silver and palladium. Hydrometallurgy 197. Elsevier: 105476. [CrossRef]

- Liu, Ya, Qingming Song, Lingen Zhang, and Zhenming Xu. 2021. Novel approach of in-situ nickel capture technology to recycle silver and palladium from waste nickel-rich multilayer ceramic capacitors. Journal of Cleaner Production 290: 125650. [CrossRef]

- Fu, Yutong, Yudong Hou, Beibei Song, Huarong Cheng, Xudong Liu, Xiaole Yu, Mupeng Zheng, and Mankang Zhu. 2022. Construction of lead-free dielectrics for high temperature multilayer ceramic capacitors and its inner electrode matching characteristics. Journal of Alloys and Compounds 903. Elsevier: 163995. [CrossRef]

- Liu, Xudong, Yudong Hou, Beibei Song, Huarong Cheng, Yutong Fu, Mupeng Zheng, and Mankang Zhu. 2022. Lead-free multilayer ceramic capacitors with ultra-wide temperature dielectric stability based on multifaceted modification. Journal of the European Ceramic Society 42. Elsevier Ltd: 973–980. [CrossRef]

- Andrade, Daniel Fernandes, Jeyne Pricylla Castro, José Augusto Garcia, Raquel Cardoso Machado, Edenir Rodrigues Pereira-Filho, and Dulasiri Amarasiriwardena. 2022. Analytical and reclamation technologies for identification and recycling of precious materials from waste computer and mobile phones. Chemosphere 286: 131739. [CrossRef]

- Bourgeois, Damien, Valentin Lacanau, Régis Mastretta, Christiane Contino-Pépin, and Daniel Meyer. 2020. A simple process for the recovery of palladium from wastes of printed circuit boards. Hydrometallurgy 191: 105241. [CrossRef]

- Mizuno, Youichi, Hiroshi Kishi, Kenji Ohnuma, Takanori Ishikawa, and Hitoshi Ohsato. 2007. Effect of site occupancies of rare earth ions on electrical properties in Ni-MLCC based on BaTiO3. Journal of the European Ceramic Society 27: 4017–4020. [CrossRef]

- Shen, Zhengbo, Xiaohui Wang, Huiling Gong, Longwen Wu, and Longtu Li. 2014. Effect of MnO2 on the electrical and dielectric properties of Y-doped Ba0.95Ca0.05Ti0.85Zr 0.15O3 ceramics in reducing atmosphere. Ceramics International 40. Elsevier: 13833–13839. [CrossRef]

- Gong, Huiling, Xiaohui Wang, Shaopeng Zhang, and Longtu Li. 2016. Synergistic effect of rare-earth elements on the dielectric properties and reliability of BaTiO3-based ceramics for multilayer ceramic capacitors. Materials Research Bulletin 73. Elsevier Ltd: 233–239. [CrossRef]

- Teverovsky, Alexander. 2018. Cracking Problems in Low-Voltage Chip Ceramic Capacitors. NASA Electronic Parts and Packaging Program: 1–73.

- Hong, Kootak, Tae Hyung Lee, Jun Min Suh, Seok Hyun Yoon, and Ho Won Jang. 2019. Perspectives and challenges in multilayer ceramic capacitors for next generation electronics. Journal of Materials Chemistry C 7. Royal Society of Chemistry: 9782–9802. [CrossRef]

- Patil, R. P., Chaitanya Hiragond, G. H. Jain, Pawan K. Khanna, V. B. Gaikwad, and Priyesh V. More. 2019. La doped BaTiO3 nanostructures for room temperature sensing of NO2/NH3: Focus on La concentration and sensing mechanism. Vacuum 166. Elsevier: 37–44. [CrossRef]

- Dash, Tapan, Sushree Subhadarshinee Mohapatra, Raj Kishore Mishra, and Binod Bihari Palei. 2020. Synthesis and analysis of structural properties of (Ba0.592Sr0.0406)TiO3compound. Materials Today: Proceedings 43. Elsevier Ltd: 362–365. [CrossRef]

- Delfini, Massimo, Mauro Ferrini, Andrea Manni, Paolo Massacci, Luigi Piga, and Antonio Scoppettuolo. 2011. Optimization of Precious Metal Recovery from Waste Electrical and Electronic Equipment Boards. Journal of Environmental Protection 02: 675–682. [CrossRef]

- Shanthi Bhavan, Jayesh, Jubin Joy, and Ashwath Pazhani. 2023. Identification and recovery of rare earth elements from electronic waste: Material characterization and recovery strategies. Materials Today Communications 36. Elsevier Ltd: 106921. [CrossRef]

- Laubertova, Martina, Marcela Malindzakova, Jarmila Trpcevska, and Nataša Gajić. 2019. Assessment of sampling and chemical analysis of waste printed circuit boards from weee: Gold content determination. Metallurgical and Materials Engineering 25: 171–182. [CrossRef]

- Kaliyaraj, Dhanalashmi, Menaka Rajendran, Vignesh Angamuthu, Annam Renita Antony, Manigundan Kaari, Shanmugasundaram Thangavel, Gopikrishnan Venugopal, Jerrine Joseph, and Radhakrishnan Manikkam. 2019. Bioleaching of heavy metals from printed circuit board (PCB) by Streptomyces albidoflavus TN10 isolated from insect nest. Bioresources and Bioprocessing 6. Springer Singapore. [CrossRef]

- Bobnar, Vid, Marko Hrovat, Janez Holc, and Marija Kosec. 2011. All-Ceramic Percolative Composites with a Colossal Dielectric Response. Ferroelectrics - Characterization and Modeling. [CrossRef]

- IEA.

- kafkas.gr. No Title.

- Sim, Jae-Kwan, K. Ashok, Yong-Ho Ra, Hong-Chul Im, Byung-Joon Baek, and Cheul-Ro Lee. 2012. Characteristic enhancement of white LED lamp using low temperature co-fired ceramic-chip on board package. Current Applied Physics 12: 494–498. [CrossRef]

- Gago Calderón, Alfonso, Luis Narvarte Fernández, Luis Miguel Carrasco Moreno, and Javier Serón Barba. 2015. LED bulbs technical specification and testing procedure for solar home systems. Renewable and Sustainable Energy Reviews 41: 506–520. [CrossRef]

- De Santi, C., M. Dal Lago, M. Buffolo, D. Monti, M. Meneghini, G. Meneghesso, and E. Zanoni. 2015. Failure causes and mechanisms of retrofit LED lamps. Microelectronics Reliability 55: 1765–1769. [CrossRef]

- Dillon, Heather E., Crysta Ross, and Rachel Dzombak. 2018. Environmental and Energy Improvements of LED Lamps over Time: A Comparative Life Cycle Assessment. LEUKOS 16: 229–237. [CrossRef]

- Richter, Jessika Luth, Leena Tähkämö, and Carl Dalhammar. 2019. Trade-offs with longer lifetimes? The case of LED lamps considering product development and energy contexts. Journal of Cleaner Production 226: 195–209. [CrossRef]

- Wehbie, Moheddine, and Vincent Semetey. 2022. Characterization of end-of-life LED lamps: Evaluation of reuse, repair and recycling potential. Waste Management 141: 202–207. [CrossRef]

- Liu, David Donhang. 2013. NASA Electronic Parts and Packaging Program Selection , Qualification , Inspection , and Derating of Multilayer Ceramic Capacitors with Base-Metal Electrodes.

- Tihtih, Mohammed, Jamal Eldin F.M. Ibrahim, Mohamed A. Basyooni, Redouane En-Nadir, Walid Belaid, Irina Hussainova, and István Kocserha. 2023. Development of Yttrium-Doped BaTiO3 for Next-Generation Multilayer Ceramic Capacitors. ACS Omega 8: 8448–8460. [CrossRef]

- Zhang, Weijun, Jinlun Yang, Fenglin Wang, Xingyu Chen, and Haijun Mao. 2021. Enhanced dielectric properties of La-doped 0.75BaTiO3-0.25Bi(Mg0.5Ti0.5)O3 ceramics for X9R-MLCC application. Ceramics International 47. Elsevier Ltd: 4486–4492. [CrossRef]

- Lakov, Lyuben, Mihaela Aleksandrova, and Vladimir Blaskov. 2020. Current trends in the development of high dielectric permittivity ceramics 10: 8–10.

- Duan, Ruijie, Jing Wang, Shenglin Jiang, Haiyan Cheng, Jiali Li, Aizhen Song, Beibei Hou, Danyang Chen, and Yuanxin Liu. 2018. Impact of La doping on performance of Na0.5Bi0.5TiO3-Ba0.7-xLaxSr0.3Sn0.1Ti0.9-0.25xO3 dielectric ceramics. Journal of Alloys and Compounds 745. Elsevier B.V: 121–126. [CrossRef]

- Sasikumar, S., T. K. Thirumalaisamy, S. Saravanakumar, S. Asath Bahadur, D. Sivaganesh, and I. B. Shameem Banu. 2020. Effect of neodymium doping in BaTiO3 ceramics on structural and ferroelectric properties. Journal of Materials Science: Materials in Electronics 31. Springer US: 1535–1546. [CrossRef]

- Paunović, Vesna, Vojislav V. Mitić, Miloš Đorđević, Miloš Marjanović, and Ljubiša Kocić. 2017. Electrical characteristics of Er doped BaTiO3 ceramics. Science of Sintering 49: 129–137. [CrossRef]

- KYOCERA-AVX. No Title.

- Andooz, Amirhossein, Mohammad Eqbalpour, Elaheh Kowsari, Seeram Ramakrishna, and Zahra Ansari Cheshmeh. 2022. A comprehensive review on pyrolysis of E-waste and its sustainability. Journal of Cleaner Production 333. Elsevier Ltd: 130191. [CrossRef]

- Costis, Sophie, Kristin K. Mueller, Lucie Coudert, Carmen Mihaela Neculita, Nicolas Reynier, and Jean Francois Blais. 2021. Recovery potential of rare earth elements from mining and industrial residues: A review and cases studies. Journal of Geochemical Exploration 221. Elsevier B.V.: 106699. [CrossRef]

- Brewer, Aaron, Alice Dohnalkova, Vaithiyalingam Shutthanandan, Libor Kovarik, Elliot Chang, April M. Sawvel, Harris E. Mason, et al. 2019. Microbe Encapsulation for Selective Rare-Earth Recovery from Electronic Waste Leachates. Research-article. Environmental Science and Technology 53. American Chemical Society: 13888–13897. [CrossRef]

- Ueberschaar, Maximilian, Julia Geiping, Malte Zamzow, Sabine Flamme, and Vera Susanne Rotter. 2017. Assessment of element-specific recycling efficiency in WEEE pre-processing. Resources, Conservation and Recycling 124: 25–41. [CrossRef]

- ISE.

- umicore. No Title.

- Keimasi, Mohammadreza, Michael H. Azarian, and Michael Pecht. 2007. Isothermal aging effects on flex cracking of multilayer ceramic capacitors with standard and flexible terminations. Microelectronics Reliability 47: 2215–2225. [CrossRef]

- Vogel, G. 2015. Avoiding flex cracks in ceramic capacitors: Analytical tool for a reliable failure analysis and guideline for positioning cercaps on PCBs. Microelectronics Reliability 55. Elsevier Ltd: 2159–2164. [CrossRef]

- Bookhagen, B., D. Bastian, P. Buchholz, M. Faulstich, C. Opper, J. Irrgeher, T. Prohaska, and C. Koeberl. 2020. Metallic resources in smartphones. Resources Policy 68. Elsevier Ltd: 101750. [CrossRef]

- Cenci, Marcelo Pilotto, Frederico Christ Dal Berto, Bianca Wurlitzer Castillo, and Hugo Marcelo Veit. 2020. Precious and critical metals from wasted LED lamps: characterization and evaluation. Environmental Technology (United Kingdom) 43: 1870–1881. [CrossRef]

- Niu, Bo, Zhenyang Chen, and Zhenming Xu. 2017. Recovery of Valuable Materials from Waste Tantalum Capacitors by Vacuum Pyrolysis Combined with Mechanical-Physical Separation. ACS Sustainable Chemistry and Engineering 5: 2639–2647. [CrossRef]

- Niu, Bo, Zhenyang Chen, and Zhenming Xu. 2017. Application of pyrolysis to recycling organics from waste tantalum capacitors. Journal of Hazardous Materials 335: 39–46. [CrossRef]

- Chen, Zhenyang, Bo Niu, Lingen Zhang, and Zhenming Xu. 2018. Vacuum pyrolysis characteristics and parameter optimization of recycling organic materials from waste tantalum capacitors. Journal of Hazardous Materials 342. Elsevier B.V.: 192–200. [CrossRef]

- Zhan, Lu, Fafa Xia, Qiuyu Ye, Xishu Xiang, and Bing Xie. 2015. Novel recycle technology for recovering rare metals (Ga, In) from waste light-emitting diodes. Journal of Hazardous Materials 299: 388–394. [CrossRef]

- DODBIBA, Gjergj, Hiroki OSHIKAWA, Josiane PONOU, Yonggu KIM, Kazutoshi HAGA, Atsushi SHIBAYAMA, and Toyohisa FUJITA. 2019. Treatment of Spent LED Light Bulbs for Recycling of Its Components: A Combined Assessment in the Context of LCA and Cost-Benefit Analysis. Resources Processing. [CrossRef]

- Cenci, Marcelo Pilotto, Frederico Christ Dal Berto, Eduardo Luis Schneider, and Hugo Marcelo Veit. 2020. Assessment of LED lamps components and materials for a recycling perspective. Waste Management 107. Elsevier Ltd: 285–293. [CrossRef]

- Zhan, Lu, Zhengyu Wang, Yongliang Zhang, and Zhenming Xu. 2020. Recycling of metals (Ga, In, As and Ag) from waste light-emitting diodes in sub/supercritical ethanol. Resources, Conservation and Recycling 155: 104695. [CrossRef]

- Oliveira, Rafael Piumatti, Amilton Barbosa Botelho Junior, and Denise Crocce Romano Espinosa. 2020. Characterization of Wasted LEDs from Tubular Lamps Focused on Recycling Process by Hydrometallurgy. In , 317–325. [CrossRef]

- Vinhal, Jonathan Tenório, Rafael Piumatti de Oliveira, Jorge Luis Coleti, and Denise Crocce Romano Espinosa. 2022. Characterization of end-of-life LEDs: Mapping critical, valuable and hazardous elements in different devices. Waste Management 151: 113–122. [CrossRef]

- Niu, Bo, Zhenyang Chen, and Zhenming Xu. 2017. Method for recycling tantalum from waste tantalum capacitors by chloride metallurgy. ACS Sustainable Chemistry and Engineering 5: 1376–1381. [CrossRef]

| Au wt% |

Ag wt% |

Pd wt% |

Y wt% |

Specific (MLCCs or WEEE) |

Analytical technique | Ref. |

|---|---|---|---|---|---|---|

| < 0.0001 | 1.69 | Yes 1 | ICP-OES | [51] | ||

| 0.01 | 0.13 | 0.05 | No | MP-AES | [22] | |

| 3.48 | 1.24 | No | XRF, ICP-MS |

[26] * | ||

| 1.99 | 1.10 | No | SEM-EDS | [28] | ||

| (0.3 & 0.8) | Yes 2 | ICP-MS | [7] | |||

| (205-968) mg L-1 |

(38-193) mg L-1 |

OoQL | Yes 3 | ICP-AES | [43] | |

| 1.08 | 0.14 | Yes 4 | AAS | [38] | ||

| 5.01 | 0.95 | No | XRF, ICP-AES |

[18] * [23] * |

||

| 68.92 | Yes 5 | TEM-EDXS | [29] | |||

| 2.02 | 0.35 | Yes 6 | ICP-AES | [30] *, [39] * |

||

| < 1 | (1-20) | < 1 | No | - | [24] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).