1. Introduction

Today, manufacturers can meet the requirements for oils and greases used in industry thanks to modern additives. Currently used base oils are only the main component, while additives improving the lubricating properties of lubricants are chemical compounds that participate in tribochemical reactions. They can be divided into: anti-seize, anti-wear and friction modifiers [

1,

2,

3]. Increasingly stringent requirements are being placed on lubricating oils, as less oil is currently used in machinery and equipment, but at higher pressures and higher thermal loads. Therefore, modern equipment requires the use of only the highest quality oils. Oil additives improving the properties of lubricants have been used for a long time, and despite this, research is still being carried out to improve the used additives [

4,

5,

6,

7]. Despite the addition of a number of different enriching agents, the problem of preventing or slowing down the microbiological decomposition of petroleum products is still present. This is because many species of bacteria and fungi have the ability to grow in petroleum products, which are a source of carbon and energy. Therefore, the life activity of microorganisms causes the decomposition of hydrocarbons and oil additives, and the release of water, sulfur compounds, and surface-active substances into fuels and lubricating oils [

8,

9,

10,

11]. The result is changes in the chemical composition of petroleum products and the values of some physical parameters, such as flash point, acid number or viscosity.

The aim of the work was to determine the effect of ecological agents added to lubricating oil on selected operating parameters of an internal combustion engine. The point is to check whether oils with ecological additives may have a negative impact on the operation and operating parameters of a piston engine as a result of improper lubrication. Further research is to answer whether it will be possible to replace harmful biocides with environmentally friendly, e.g. effective microorganisms. Oil with these additives may have a positive effect on slowing down microbiological decomposition in lubricating oils used in internal combustion engines.

If the internal combustion piston engine is properly used, the deterioration of its technical condition is caused primarily by all kinds of of mechanical and chemical impurities, i.e. solid foreign bodies and chemically active substances that cause corrosion.

Such impurities are partly a natural residue of petrochemical processes, and partly get into oils during distribution (transport, storage and transfer). The harmfulness of mechanical impurities in lubricant results mainly from their hardness and resistance to compression [

12,

13]. Microbial contamination is a serious problem in petroleum products, which includes both automotive, aviation and marine fuels, transformer and engine oils, as well as lubricants and oil emulsions. With the development of industry and the broader automotive industry, including aviation and ships, it turned out that the problem of microbial contamination is still valid and is becoming more and more common. Studies have shown that the life activity of microorganisms can lead to disruption of operation and even damage to internal combustion engines [

3,

5,

14].

Goof quality oil must be clear and transparent. Microbial growth can often contribute to cloudiness and darkening. The most obvious and easily recognizable consequence of microbial activity is the formation of sediments, visible as solid particles, which are a mixture of living and dead cells and inorganic by-products [

15,

16].

One of the currently used methods of combating microorganisms in petroleum products are biocides, which are pesticides used, among others, to combat or limit the development of microorganisms in petroleum products. Unfortunately, most biocides also destroy beneficial organisms and cause adverse changes in the composition of microorganisms. Despite a number of benefits resulting from the use of biocides, there are currently strong trends to limit their use. They are caused by the fear of the harmful effects of these highly concentrated substances on the environment [

17,

18,

19]. Therefore, one of the methods of combating microorganisms, taking into account the aspects of environmental protection, is the use of effective microorganisms (EM). EMs are used in horticulture, environmental protection, medicine, industry and many other areas of the economy with positive results. The principle of operation of EM is based solely on natural processes, they are not genetically modified and completely environmentally friendly. Effective microorganisms are most commonly used in water treatment, sewage treatment and water reservoirs. This technology is also used in waste incineration plants, which significantly reduces the emission of dangerous dioxins. In addition, another solution may be silver, which has long been used for protective and healing purposes [

20,

21,

22,

23,

24,

25]. These additives were added in the form of non-ionic and ionic silver. Non-ionic silver, i.e. colloidal silver. It has a yellow color because the silver particles that are dispersed in the water block the light passing through them. Ionic silver is silver solution. Ionic silver is as transparent as water.

So far, the focus has been on chemical and physical testing of lubricating oil without and with these additives. The tests were carried out on new and used oil. The most favorable results were obtained when effective microorganisms in the form of ceramic tubes were used, mainly due to fact in this case the additive in this form does not contain water. In further studies, it is planned to check the oils in terms of microbiology, which will allow for a full assessment of the possibility of replacing harmful biocides by these additives.

3. Results

Before the tests of the parameters of the internal combustion engine and the composition of the exhaust gases were carried out, each oil, starting with pure oil and then with each of the additives, worked in the engine under the same conditions. Each of the tests lasted 100 hours of engine operation, not including breaks, of which 80 hours at idle and the the remaining 20 hours at 50% of the total load, which was 20 kW. After the oil had been used in the assumed period, the parameters of engine operation and exhaust gas composition were measured. The obtained results made it possible to draw graphs and then assess the impact of ecological additives to the lubricating oil on the technical condition of the tested engine. Each measurement of operating parameters and exhaust gas composition was performed three times. However, the article presents the average results for each case. They are presented in the tables and the form of graphs in

Figure 6,

Figure 7,

Figure 8 and

Figure 9.

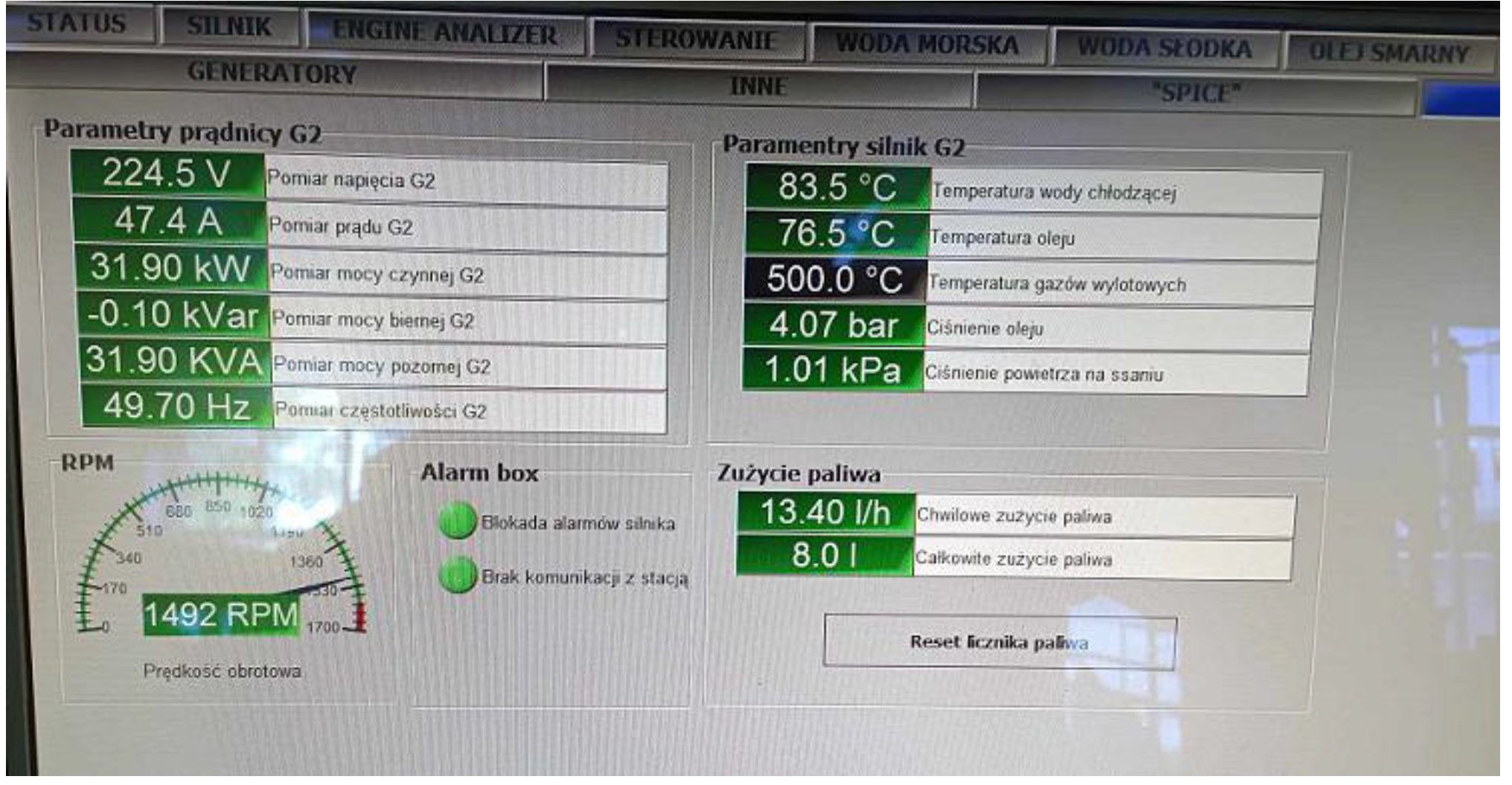

In addition, in order to better illustrate the obtained results, the measured parameters and their values are listed in

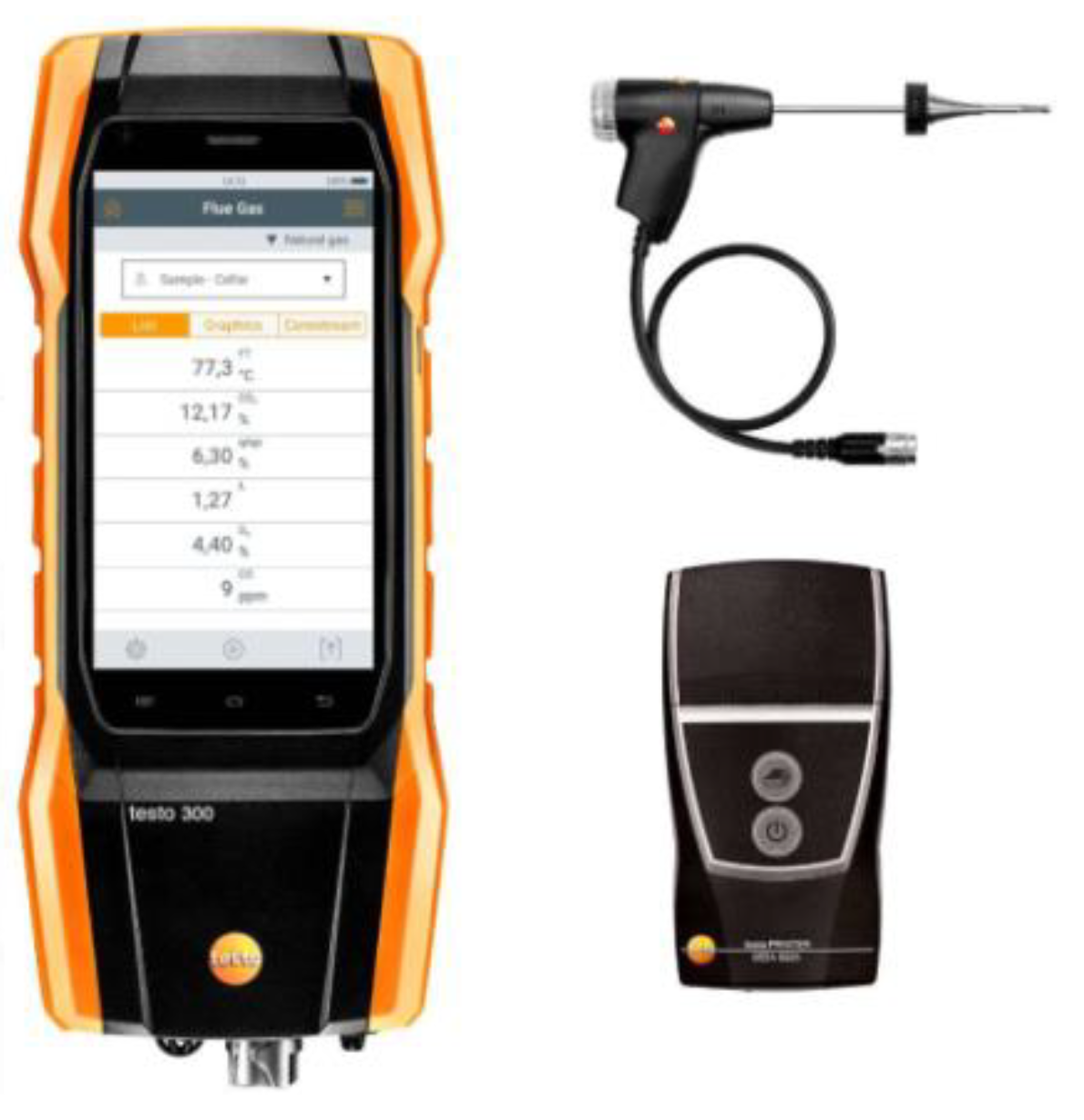

Table 4. The results of this work were read using a control and measurement system cooperating with a running engine (

Figure 5).

Figure 5.

Sample view of the control and measurement system cooperating with a running engine.

Figure 5.

Sample view of the control and measurement system cooperating with a running engine.

The operating conditions of a marine engine and its emission of pollutants in exhaust gases are shaped by the so-called external conditions, which include: sailing in waters with limited water depth and in channels, sailing in storms, changes in hull immersion (e.g. as a results of increased loading or changes in density water). The engine operating conditions are also affected by changes in the movement of the vessel (starting, accelerating, braking) set by the crew.

Motor oil is also used in automotive internal combustion engines. The oil works there in various conditions, where the most difficult are urban ones (acceleration, deceleration, driving in a traffic jam, various weather conditions).The test stand does not reflect the above-mentioned conditions that take place during the operation of the internal combustion engine being the equipment of marine and land means of transport.

Another limitation was the equipment of the test stand with a device loading the engine. The tested motor worked with a 3-phase synchronous generator. The maximum load power was 40 kW, therefore it was decided to test at zero and 50% engine load, which was 20 kW. Another limitation was the test time of 100 hours, which does not fully reflect the total oil exploitation time in real conditions. In further studies, it is planned to use oil with these additives in real operating conditions.

There is also no previous research on the subject discussed in the article, because the agents used in the tested oils are used, for example, in wastewater treatment (effective microorganisms) or elimination of some bacteria (silver ions). This may be a limitation, but the authors undertook this research, assuming that since in other liquids, such as water or sewage, it is possible to limit the growth of microorganisms by means of effective microorganisms or silver ions, such an effect may also occur in petroleum products.

Statistical analysis was performed for a significance level of 98%. The obtained results for the assumed significance level do not show any significant errors, because they fall within the lower and upper confidence intervals.

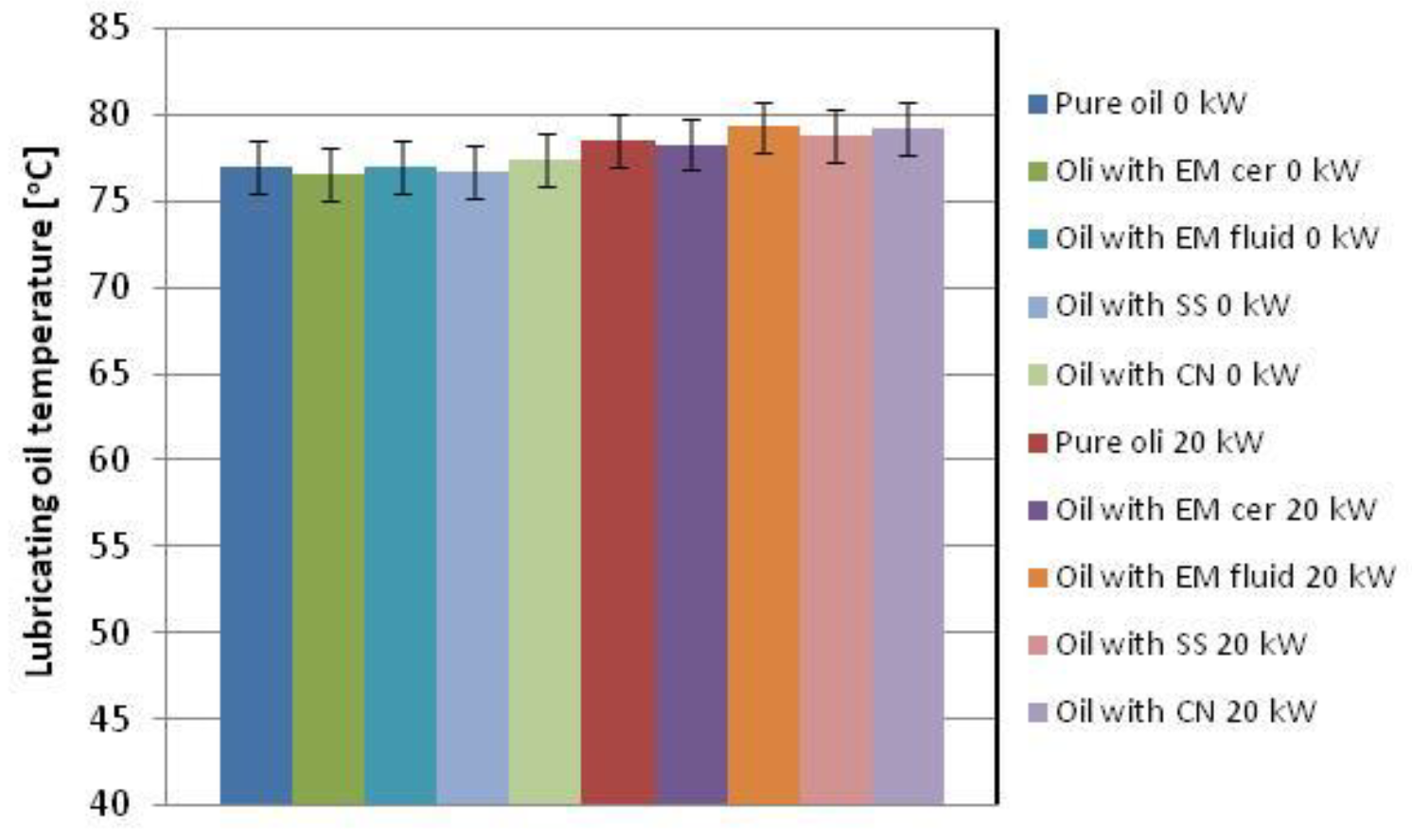

Analyzing the results obtained, it can be seen in

Figure 6 and 7, that lubricating oil temperature and pressure for both 0 kW and 20 kW load, for pure oil and oil with any kind of additives are very close to each other. The oil temperature rises when its parameters are not correct for the engine, or the engine is overloaded. There were no such effects in this case. The oil pressure values also confirm that the oil additives do not adversely affect engine operation, because the lack of excessive pressure increase means that the oil filter is working properly and the oil parameters are within normal limits.

Figure 6.

Lubricating oil temperature of pure oil and oil with additives.

Figure 6.

Lubricating oil temperature of pure oil and oil with additives.

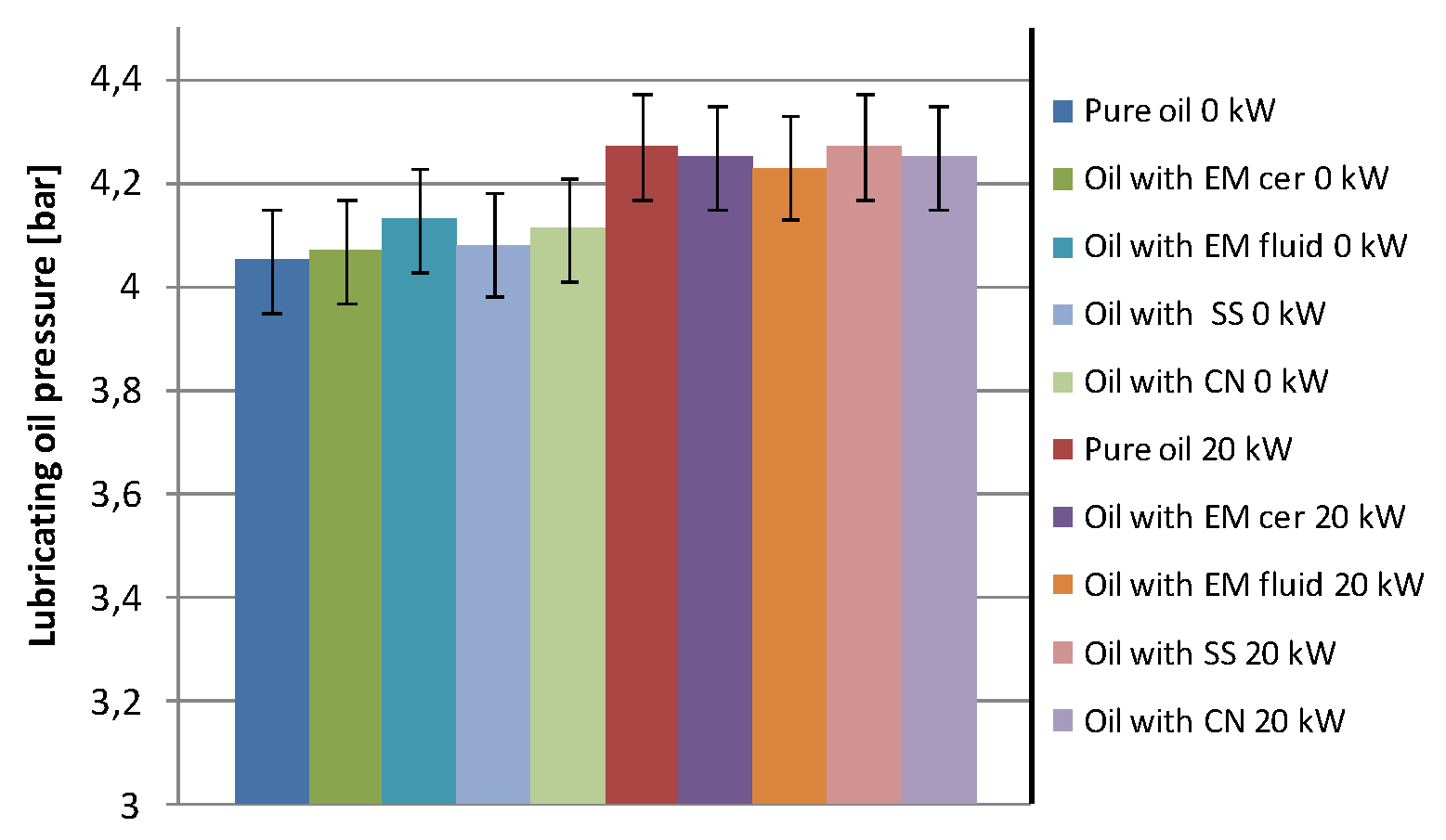

Only the addition of effective microorganisms in liquid form, due to its composition (mainly water and molasses), slightly affected the resistance of the filter, which could have contributed to a slight increase in oil pressure. This was the case when the engine was idling, which we no longer observe when the engine is under load. It is likely that the load on the engine causes the oil filter to work more efficiently and has less effect on the oil pressure. Other additives do not show such effects.

Figure 7.

Lubricating oil pressure of pure oil and oil with additives.

Figure 7.

Lubricating oil pressure of pure oil and oil with additives.

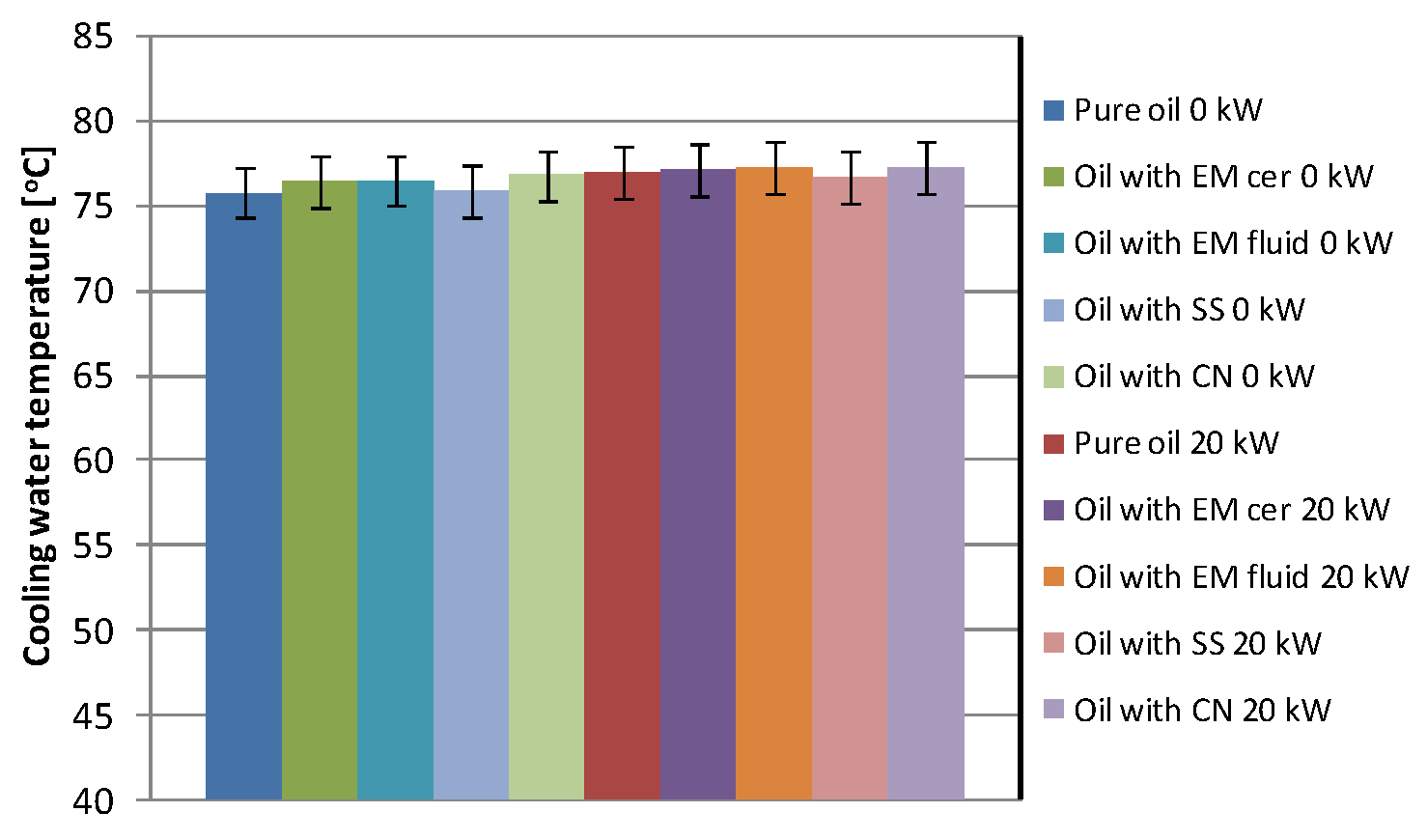

The graph in

Figure 8 for cooling water temperature also shows that the additives, regardless of their type, do not have a negative effect on the cooling performance of the engine at idle (0 kW) and under load (20 kW).

Figure 8.

Cooling water temperature of pure oil and oil with additives.

Figure 8.

Cooling water temperature of pure oil and oil with additives.

Their presence in the oil does not cause overheating of the walls, because the results are very similar to the operation of the engine with oil without these additives.

Each result does not differ by more than 2% compared to engine operation with clean oil. The greatest increase occurred for the addition of effective microorganisms and colloidal s, but still it is not so high as to have a harmful effect on the tested internal combustion engine.

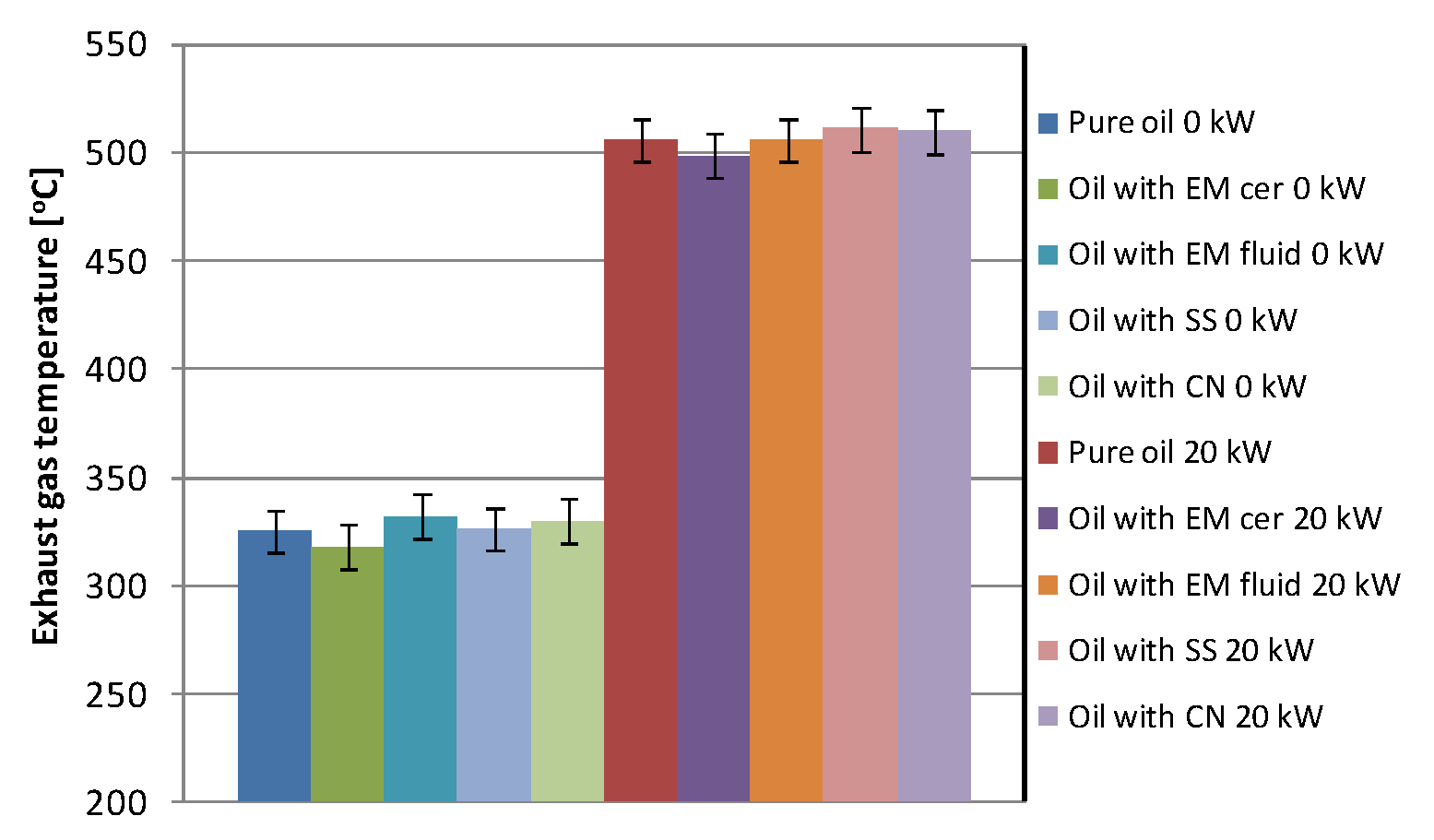

In

Figure 9 it is shown, as for the previously presented parameters, that additives do not adversely affect the technical condition of the engine. All obtained temperatures are close to each other, the resulting differences are also within the previously adopted confidence interval. Due to the fact that the other parameters are normal, no negative impact on the exhaust gas temperature, which is one of the carriers of diagnostic information of the internal combustion engine, was noticed either.

Figure 9.

Exhaust gas temperature of pure oil and oil with additives.

Figure 9.

Exhaust gas temperature of pure oil and oil with additives.

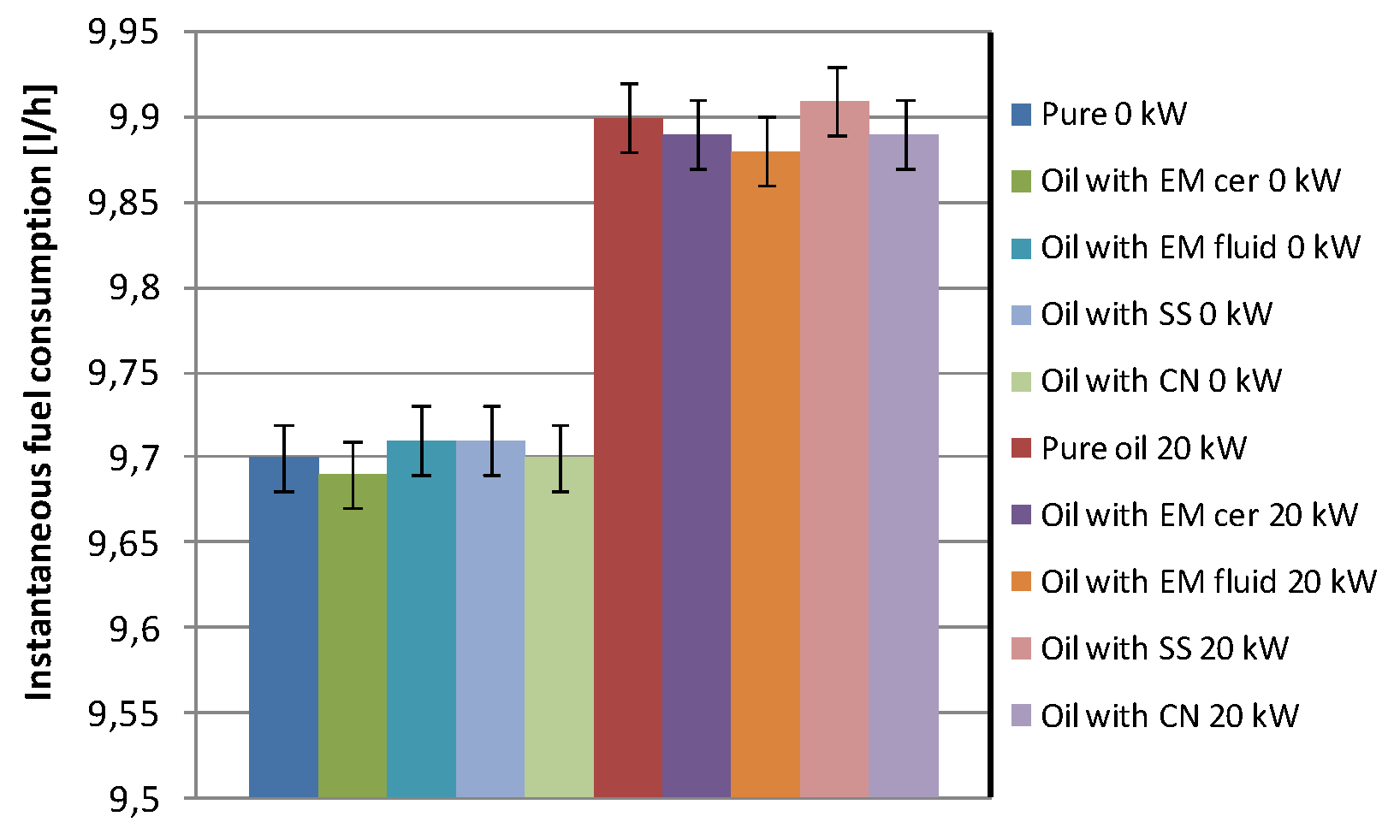

As for the instantaneous fuel consumption, it is shown in

Figure 10. This graph also shows that the engine was running properly. All the results obtained confirm that each of the additives has a small impact on fuel consumption, because each of the results does not exceed 2% compared to the reading obtained for pure oil.

Figure 10.

Instantaneous fuel consumption of pure oil and oil with additives.

Figure 10.

Instantaneous fuel consumption of pure oil and oil with additives.

In addition to the selected operating parameters presented above, the influence of oil additives on the exhaust gas composition was additionally measured. Due to the fact that the engine comes from the last century (production of this engine series started in 1966), the exhaust gas composition can be an important source of information about the technical condition of the engine [

34,

35,

36]. Figures 11–14 show the most important components of the exhaust gas, which are of greatest importance due to the toxicity of the exhaust gas. The tests were carried out with a load of 20 kW, after 90 hours of engine operation. Each measurement was performed three times, and as in the case of operating parameters, the average of these measurements is presented in the article. The presented graphs are only supplementary, because in a fully operational engine there should be no oil burning in the engine. In this particular engine, this phenomenon most likely took place, hence the different results of the exhaust components when mixed with additives.

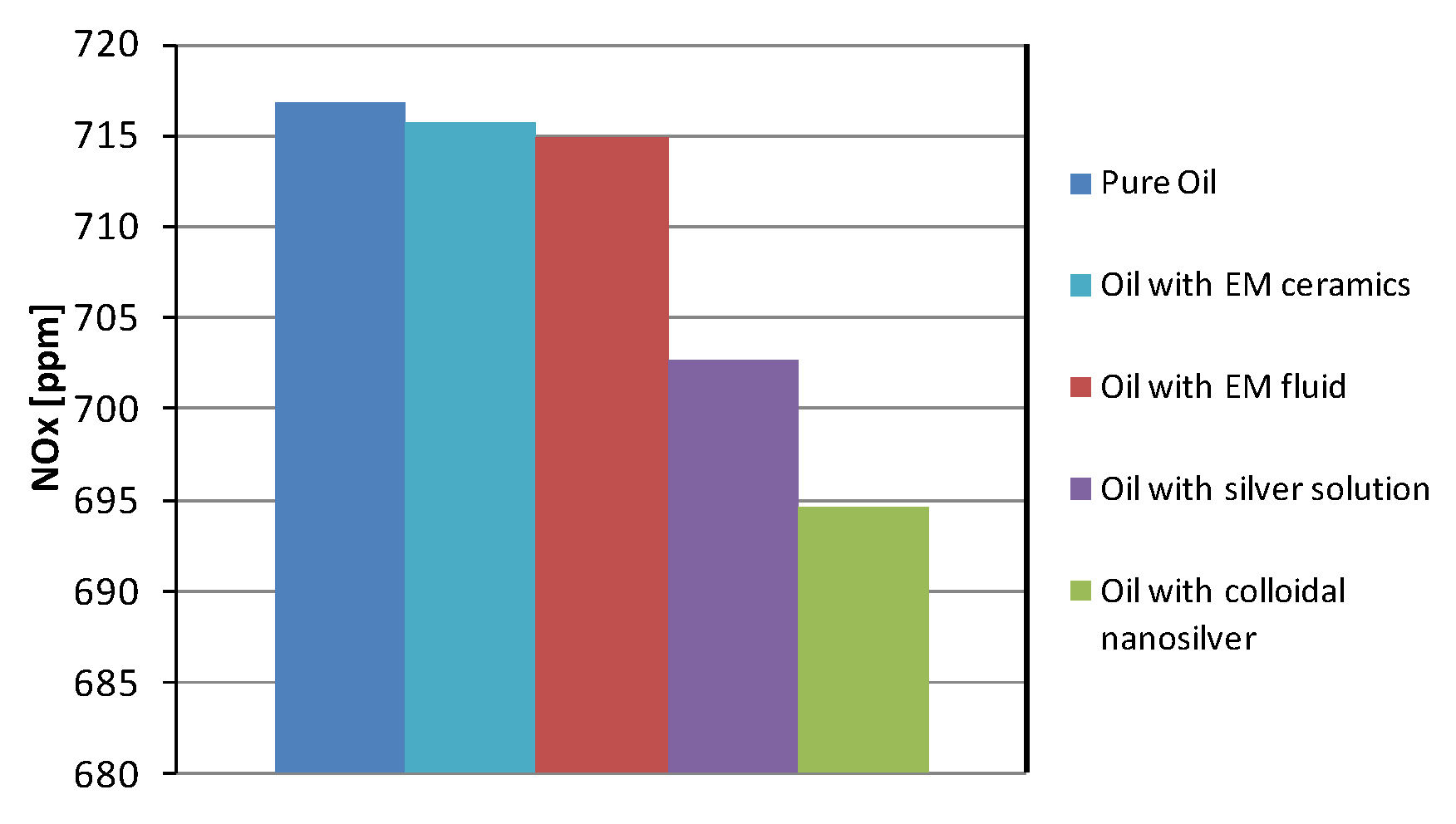

Figure 11 shows the NO

x content in the exhaust gas. Effective microorganisms cause a slight reduction of NO

x, while silver solution and colloidal nanosilver significantly reduce the amount of NO

x in the exhaust gas. This is particularly important and worth further research as NO

x gases react with oxygen in the atmosphere, ground-level ozone (O

3) forms corrosive nitric acid and toxic organic nitrates. The presence of these substances in the air causes serious health problems for people and contributes to the formation of acid rain and the deterioration of water and air quality. In addition, these attenuated environmental conditions negatively impact agriculture by killing plant tissues and reducing plant growth rates [

34]. If these results are confirmed in tests after adding silver to the fuel, it is necessary to check the chemical reactions that may occur between silver ions and nitrogen oxides in order to reduce the emission of nitrogen oxides to the atmosphere.

Figure 11.

Instantaneous fuel consumption of pure oil and oil with additives.

Figure 11.

Instantaneous fuel consumption of pure oil and oil with additives.

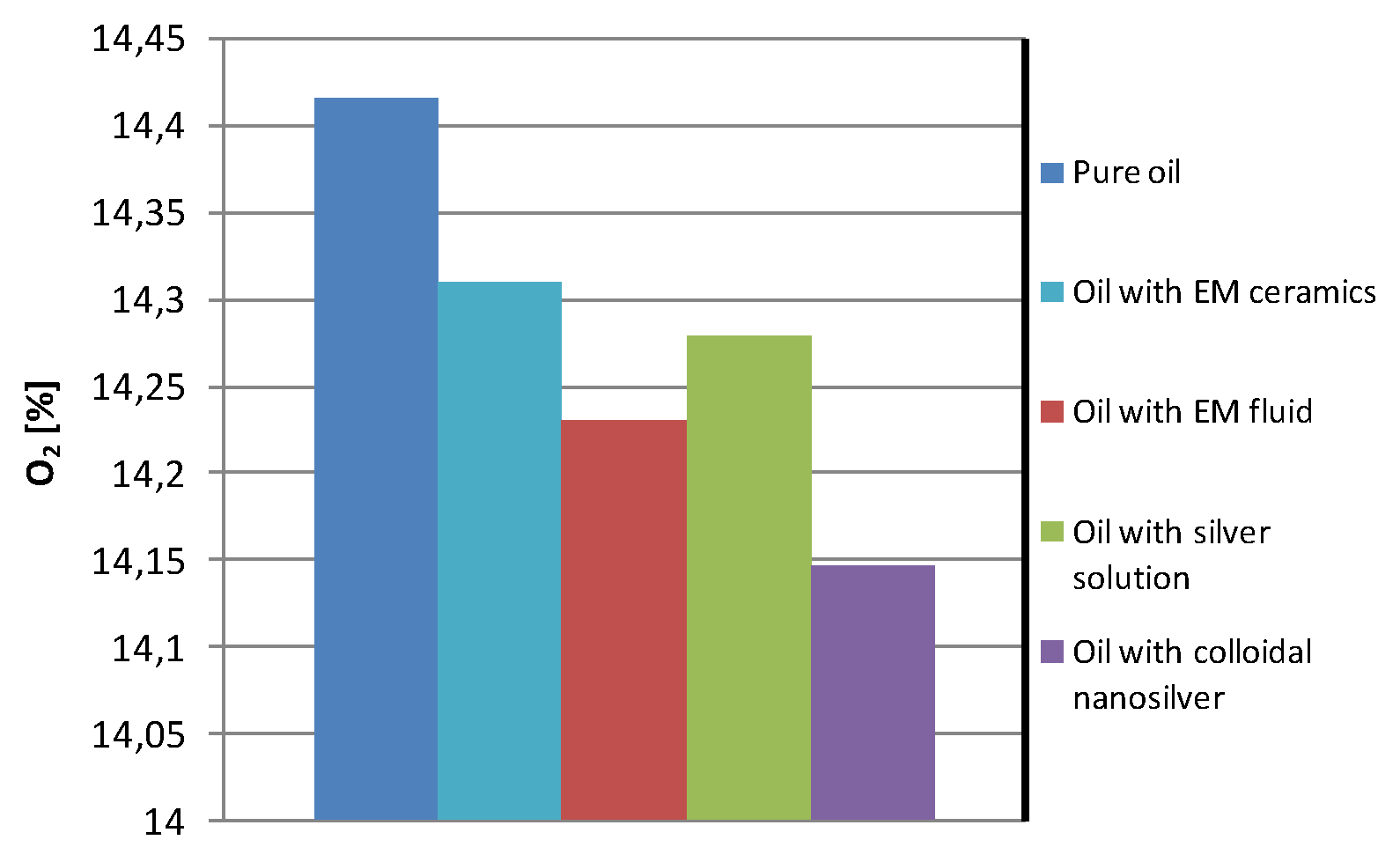

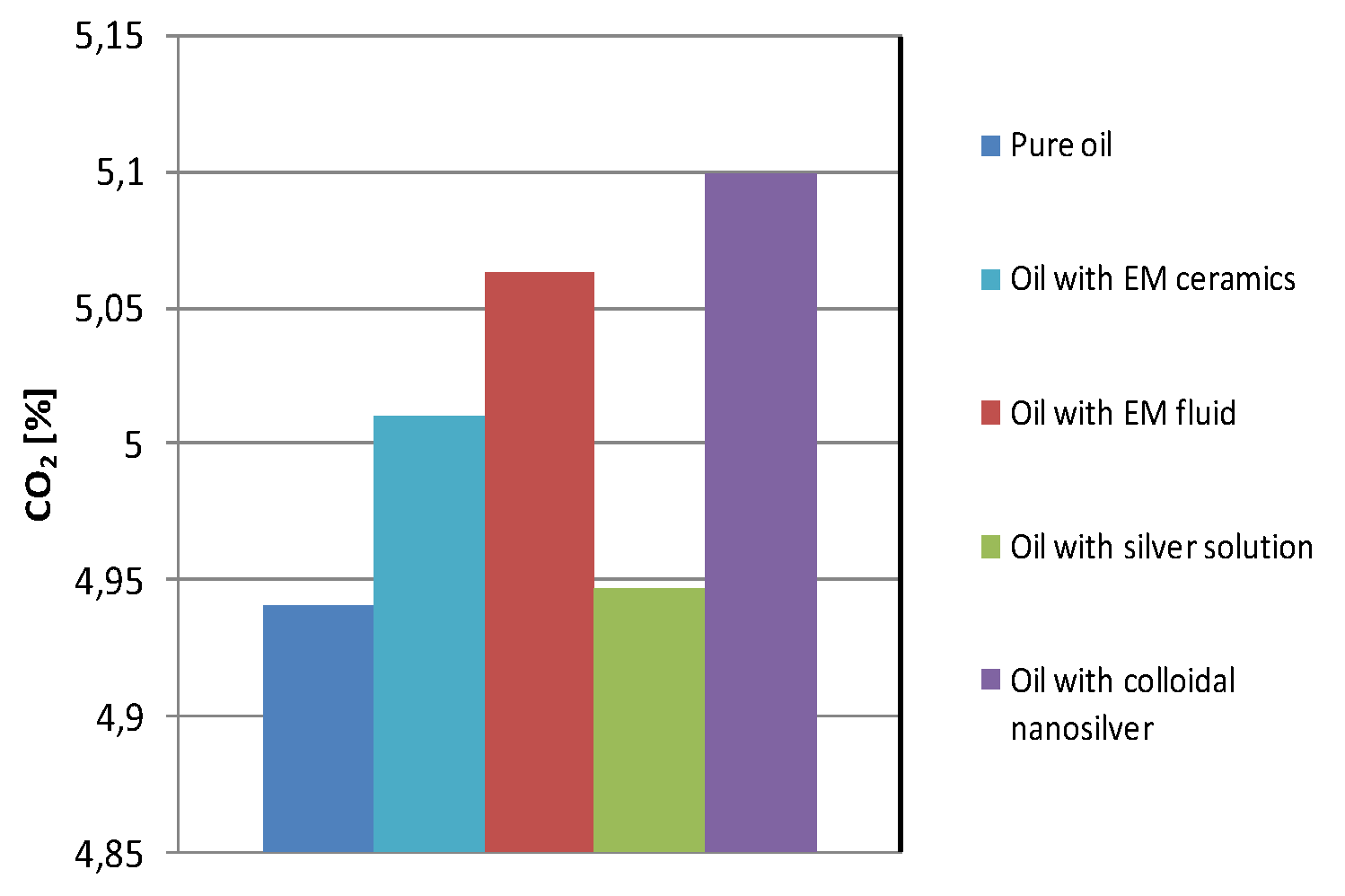

Unfortunately, for other exhaust gas components, i.e. O

2, CO and CO

2, the obtained results are more different compared to NO

x. The best result was obtained for the silver solution additive, where CO decreased from 294 ppm to 293 ppm. For O

2 the content is similar to that for pure oil (

Figure 12) and amounts to approx. 14.3%, and for CO

2 the result is the same as for pure oil.

For effective microorganisms and colloidal nanosilver, minimal reduction of oxygen was obtained, especially for effective microorganisms, while the content of CO and CO

2 is slightly high er (

Figure 13 and

Figure 14) than the results obtained for pure oil. For effective microorganisms, the CO content increases by about 1 ppm, for colloidal nanosilver by 1.5 ppm. As far as CO

2 is concerned, the biggest difference compared to pure oil was obtained for the colloidal nanosilver additive, for which the value of CO

2 was higher by approx. 0.2% compared to pure oil.

These results also confirm that the additives used do not cause deterioration of the technical condition of the engine, nor excessive fuel consumption, nor significantly increase the toxicity of exhaust gases. In the next part of the research, it is planned to add these ecological agents to the fuel and study the direct effect on the composition of the exhaust gases and the fuel consumption of the engine.

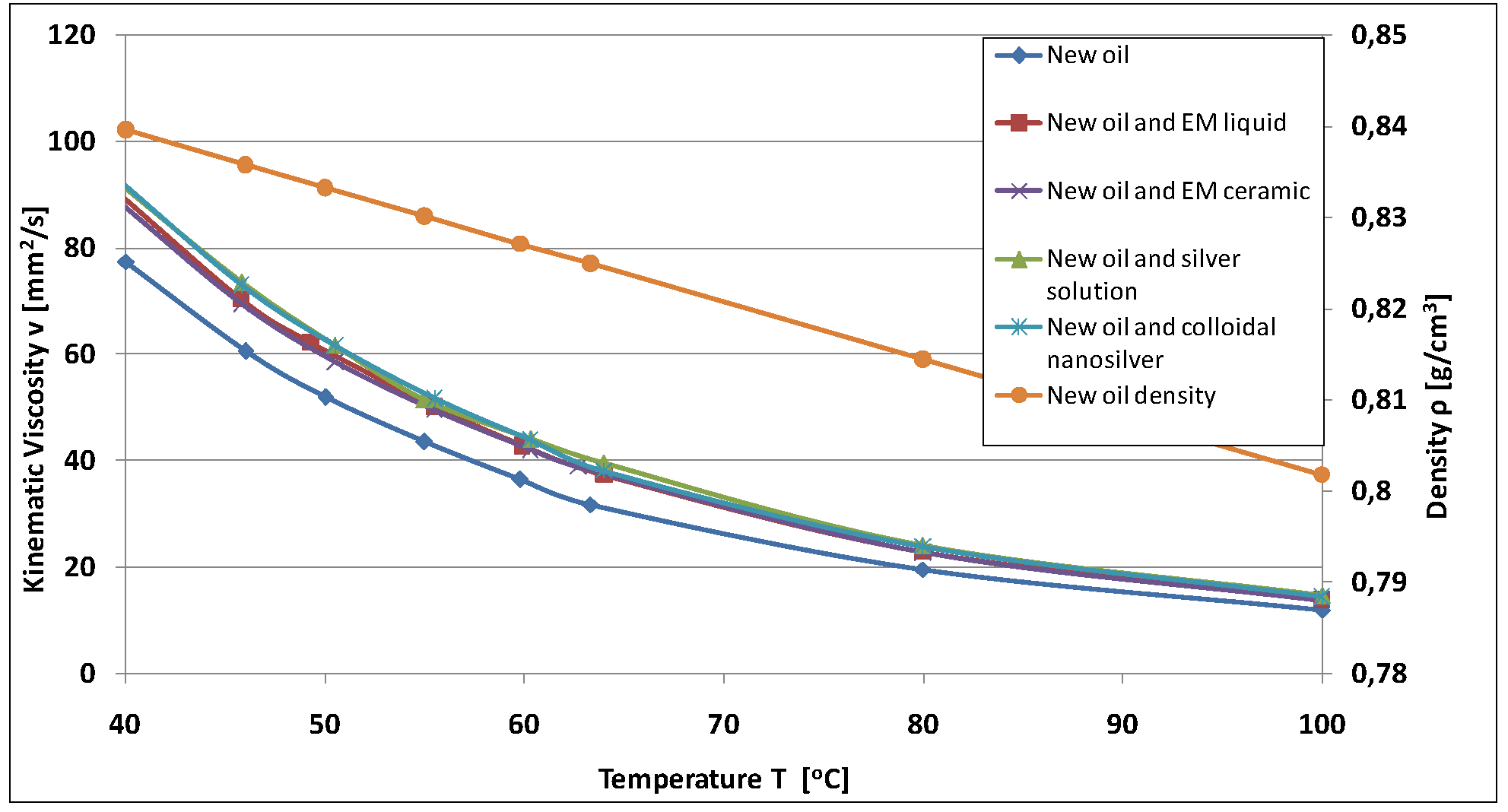

In order to complete the obtained results, the article also presents in

Figure 15 and 16 comparison of kinematic viscosity new and used oil with and without additives. These graphs present the impact of each of the additives on the kinematic viscosity of the engine oil samples. Each sample of pure oil and oil with additives was tested three times, at the temperature of 40

oC to 100

oC. To determine the kinematic viscosity, first the dynamic viscosity was read. Additionally, the density curve for new oil in the same range is also shown. This density made it possible to determine the kinematic density. Analyzing the obtained results, it can be observed in

Figure 15 that the kinematic viscosity of pure fresh oil is 77.42 mm

2/s at 40

oC and 12.95 mm

2/s at 100

oC. The addition of effective microorganisms to the oil in the liquid and ceramic form shows a similar course, but for microorganisms in liquid form, the viscosity value is higher in the lower temperature range compared to the course with the addition of ceramic tubes. Effective microorganisms cause a unconsiderable increase in the kinematic viscosity in the oil compared to oil without such an additive and is equal for liquid effective microorganisms - 89.56 mm

2/s at 40

oC, and for ceramic tubes – 90.15 mm

2/s at 40

oC. At a temperature of 100

oC, we have, respectively: 15.75 mm

2/s and 15.68 mm

2/s.

As for the outcomes obtained for colloidal nanosilver and silver solution, the courses are very similar to each other, while the greater number of effective microorganisms results in an even higher value of kinematic viscosity than that obtained for pure new oil. The value of the determined viscosity for the additive of colloidal nanosilver and silver solution at 40 oC is 92.65 mm2/s and 93.17 mm2/s, respectively, while for 100 oC - 16.56 mm2/s and 15.43 mm2/s.

Moreover, the graph shows that the kinematic viscosity most similar to that of pure oil was obtained with a ceramic microorganisms added, therefore the behavior of the oil with ceramic tubes should be checked in further tests.

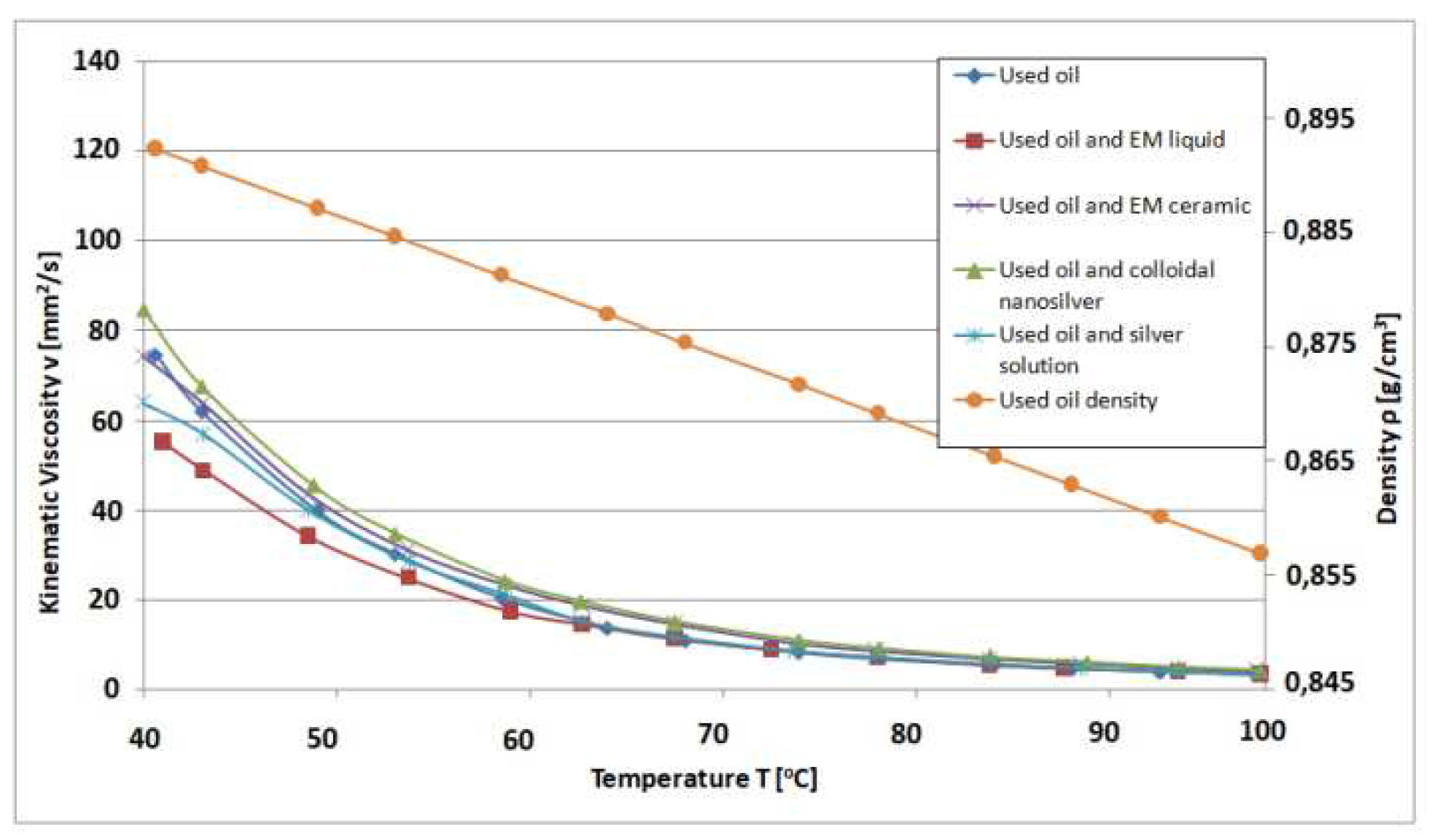

In

Figure 16 we can see changes in kinematic viscosity from temperature for used and used oil samples also with the addition of liquid effective microorganisms, in the form of ceramic tubes and colloidal nanosilver and silver solution.The density curve for used oil was also shown, in order to better visualize the results obtained. This density made it possible to determine the kinematic density. The viscosity courses are presented in the temperature range from 40 - 100

oC. In order to illustrate the obtained results better, the viscosity curve for the new oil has been added. Kinematic viscosity value of used oil with no additives is 70.52 mm

2/s at 40

oC and 6.75 mm

2/s at 100

oC. The lowest viscosity value was obtained for the addition of EMs in the liquid form, which means that this form of microorganisms does not have a positive effect on the oil parameters. For this additive, the kinematic viscosity is 57.16 mm

2/s at 40

oC and 6.58 mm

2/s at 100

oC.

Similar values as for used oil can be seen for oil with ceramic pipes and are respectively (75.42 mm2/s at 40 oC and 6.43 mm2/s at 100 oC). The situation is different for the addition of colloidal nanosilver and silver solution. The values obtained for colloidal nanosilver are higher for both used and new oil without additives. The following results were obtained for this addition: 85.08 mm2/s at 40 oC and 5.82 mm2/s at 100 oC, while for silver solution, the results are different and are as follows: 63.92 mm2/s at 40 oC and 5.39 mm2/s at 100 oC. The results obtained for used oil confirm that the additives of effective microorganisms, colloidal nanosilver and silver solution affect the parameters of used oil. The best results were obtained for effective microorganisms in the form of ceramic tubes.

In order to confirm the obtained results, the article also presents selected other oil parameters, which are presented in

Table 5 and

Table 6. Tables show a comparison of the parameters of fresh and used oil without additives, with those in which the additives of effective microorganisms and silver compounds were added. Also, analyzing the data from the tables, it can be concluded that the best additive for new oil are ceramic effective microorganisms. As for silver, they adversely affect the parameters of both new and used oil.

In further research it will also be checked, among others the effect of additives on the elemental composition of the oil and whether there is rheological shear thinning. These tests will check whether molasses has a negative effect on the performance of the engine oil.

4. Discussion

This work shows the value comparison of the lubricating oil temperature and pressure, cooling water and exhaust gas temperature as well as instantaneous fuel consumption of pure oil with oil after adding to fresh oil effective microorganisms in liquid and ceramic tubes form. In addition, silver solution and colloidal nanosilver were added to fresh in the same proportions as for effective microorganisms in liquid form.

Analyzing the results obtained, it can be seen, that for pure oil, both at 0 kW and 20 kW, the lubricating oil temperature is similar to that read for liquid effective microorganisms and colloidal nanosilver and is eqauls 77 oC. Adding of the effective microorganisms in ceramics form and silver solution to the oil causes the lubricating oil temperature is lower by 0.5 oC compared to pure oil. The analysis of the chart shows that the temperature of the lubricating oil does not reveal negative changes in the engine.

The oil pressure values also confirm that the oil additives do not adversely affect engine operation, because the lack of excessive pressure increase means that the oil filter is working properly and the oil parameters are within normal limits. Only the addition of effective microorganisms in liquid form, due to its composition (mainly water and molasses), slightly affected the resistance of the filter, which could have contributed to a slight increase in oil pressure of about 2%.

The additives, regardless of their type, do not have a negative effect on the cooling performance of the engine at idle and under load. Their presence in the oil does not cause overheating of the walls, because the results are very similar to the operation of the engine with oil without these additives.

No negative impact on the exhaust gas temperature, which is one of the carriers of diagnostic information of the internal combustion engine, was noticed either. All obtained temperatures are close to each other, the resulting differences are also within the previously adopted confidence interval, which means, that additives do not adversely affect the technical condition of the engine.

In addition to the selected operating parameters presented, the influence of oil additives on the exhaust gas composition was additionally measured. The presented graphs are only supplementary, because in a fully operational engine there should be no oil burning in the engine.

Effective microorganisms cause a slight reduction of NOx, while silver solution and colloidal nanosilver significantly reduce the amount of NOx in the exhaust gas. If these results are confirmed in tests after adding silver to the fuel, it is necessary to check the chemical reactions that may occur between silver ions and nitrogen oxides in order to reduce the emission of nitrogen oxides to the atmosphere.

For other exhaust gas components, i.e. O2, CO and CO2, the obtained results are more different compared to NOx. The best result was obtained for the silver solution additive, where CO decreased from 294 ppm to 293 ppm. For O2 the content is similar to that for pure oil and amounts to approx. 14.3%, and for CO2 the result is the same as for pure oil. For effective microorganisms and colloidal nanosilver, minimal reduction of oxygen was obtained, especially for effective microorganisms, while the content of CO and CO2 is slightly higher than the results obtained for pure oil.

In the future, it is planned to add these ecological agents to the fuel and study their direct impact on the composition of exhaust gases and fuel consumption by the engine. Further tests will also include physical, chemical and microbiological tests of lubricating and diesel oils.

5. Conclusions

The article presents research on the impact of ecological agents added to lubricating oil on selected operating parameters of an internal combustion engine. In addition, some chemical compounds in the exhaust gas composition are presented in order to supplement the obtained results.

Analyzing the results obtained, it can be seen, that for pure oil, the lubricating oil temperature is similar to that read for liquid effective microorganisms and colloidal nanosilver. Adding of the effective microorganisms in ceramics form and silver solution to the oil causes the lubricating oil temperature is lower compared to pure oil. The analysis of the chart shows that the temperature of the lubricating oil does not reveal negative changes in the engine.

The additives, regardless of their type, do not have a negative effect on the cooling performance of the engine at idle and under load. Their presence in the oil does not cause overheating of the walls, because the results are very similar to the operation of the engine with oil without these additives. Each result does not differ by more than 2% compared to engine operation with clean oil.

The obtained results also confirm that each of the additives has a small effect on fuel consumption, as each of the results does not exceed 2% in relation to the result obtained for pure oil, which means that the engine is working properly.

Effective microorganisms cause a slight reduction of NOx, while silver solution and colloidal nanosilver significantly reduce the amount of NOx in the exhaust gas.

For other exhaust gas components, i.e. O2, CO and CO2, the obtained results are more different compared to NOx. The best result was obtained for the silver solution additive, where the CO content is lower. For O2 the content is similar to that for pure oil and for CO2 the result is the same as for pure oil. For effective microorganisms and colloidal nanosilver, minimal reduction of oxygen was obtained, especially for effective microorganisms, while the content of CO and CO2 is slightly higher than the results obtained for pure oil.

The test results are satisfactory and will be continued, as they confirm that the additives used do not cause deterioration of the technical condition of the engine, excessive fuel consumption, and do not significantly increase the toxicity of exhaust gases.

In the future, it is planned to add these ecological agents to the fuel and study their direct impact on the composition of exhaust gases and fuel consumption by the engine. Further tests will also include physical, chemical and microbiological tests of lubricating and diesel oils. Research will focus directly on problems related to determining the possibility of using oils and fuels with ecological additives without losing properties.

Based on the obtained results, it can be concluded that the additives used, and in particular the effective microorganisms in the form of ceramic tubes, may be a good alternative to some currently used enriching additives, which may contribute to the protection of the natural environment.