Submitted:

07 October 2023

Posted:

08 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental

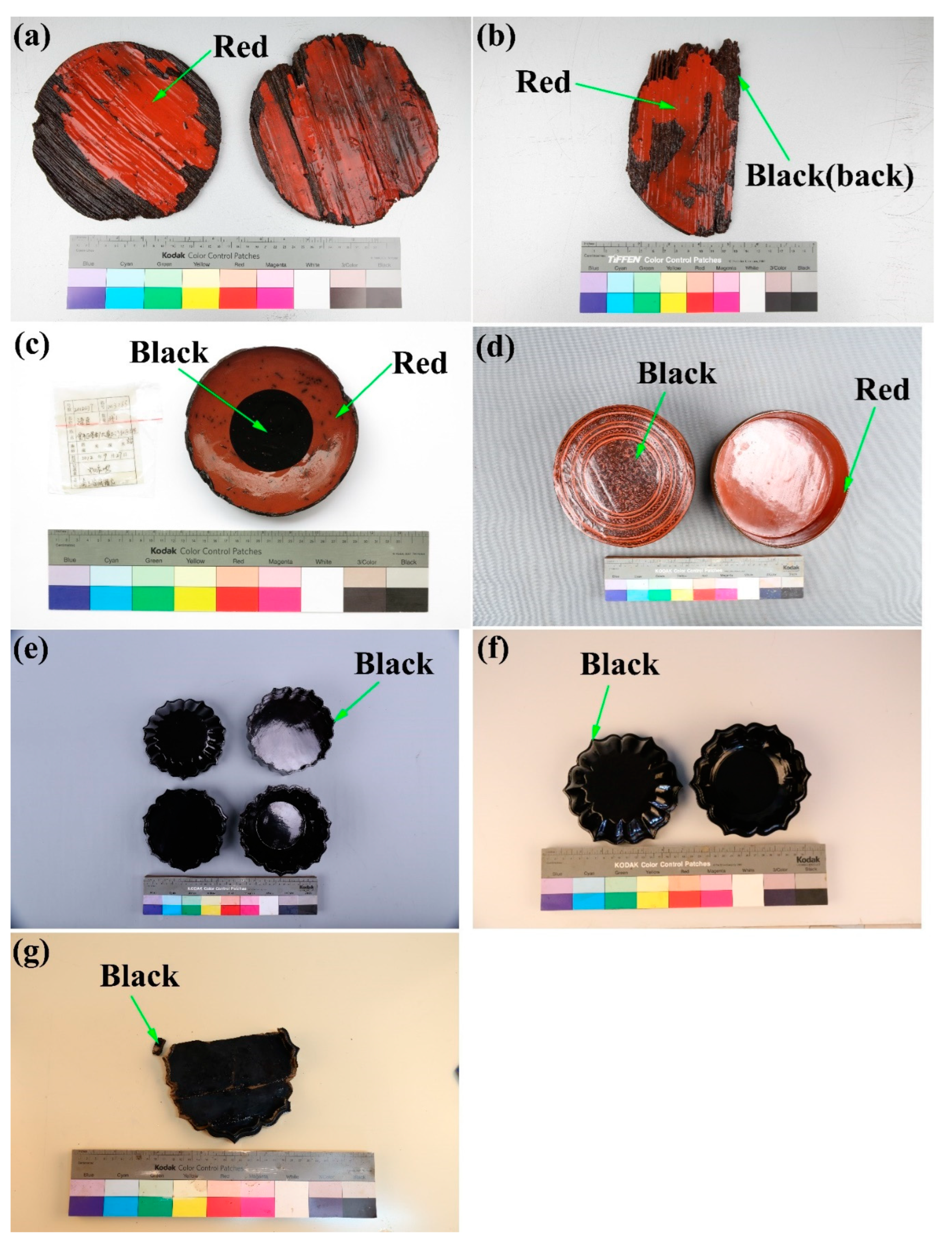

2.1. Archaeological samples

2.2. Analysis methods

2.2.1. Cross-section observations

2.2.2. Raman spectroscopy

2.2.3. Thermally assisted hydrolysis and methylation pyrolysis coupled with gas chromatography/ mass spectroscopy (THM-Py-GC/MS)

3. Results and discussion

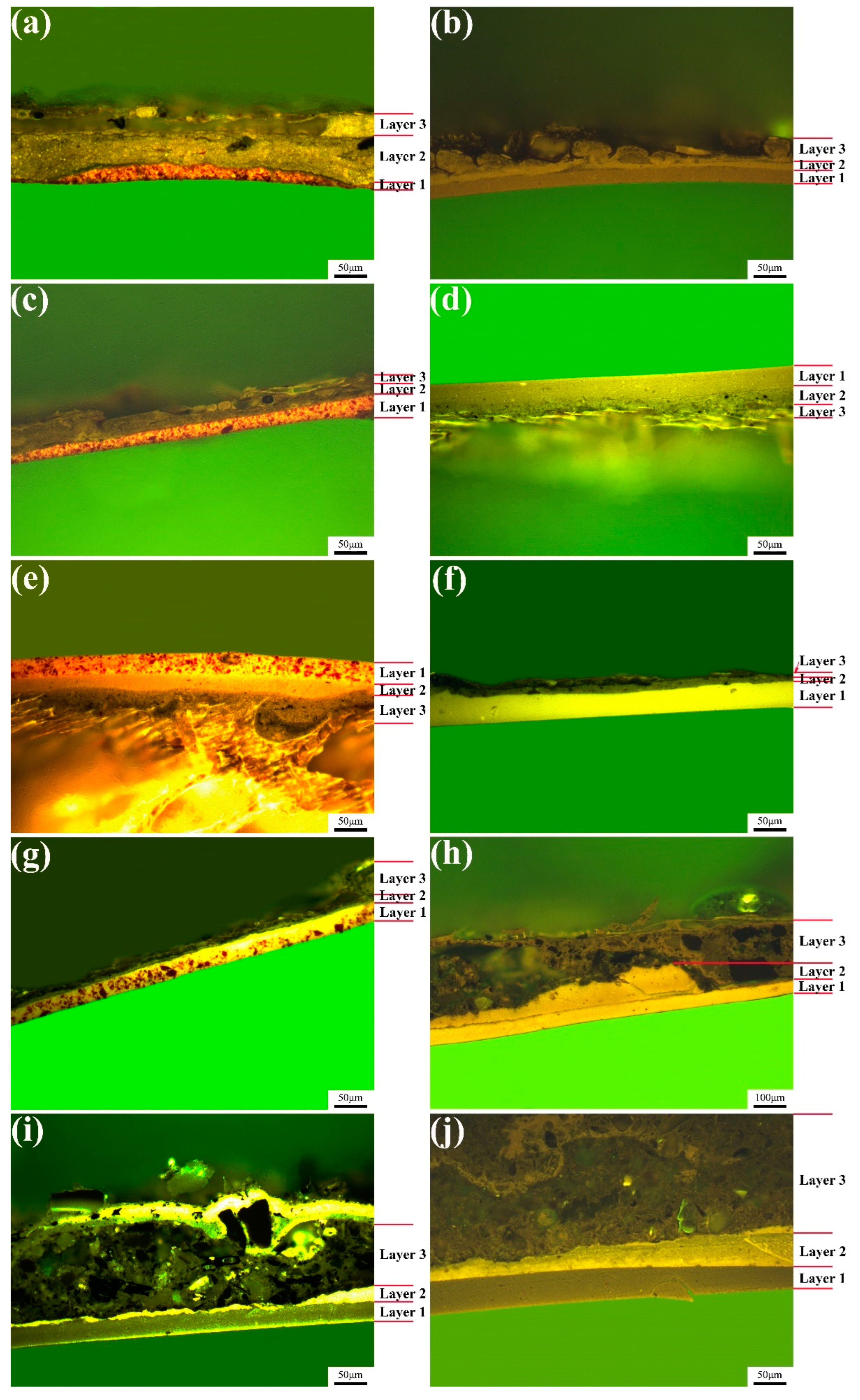

3.1. Cross-sectional analysis

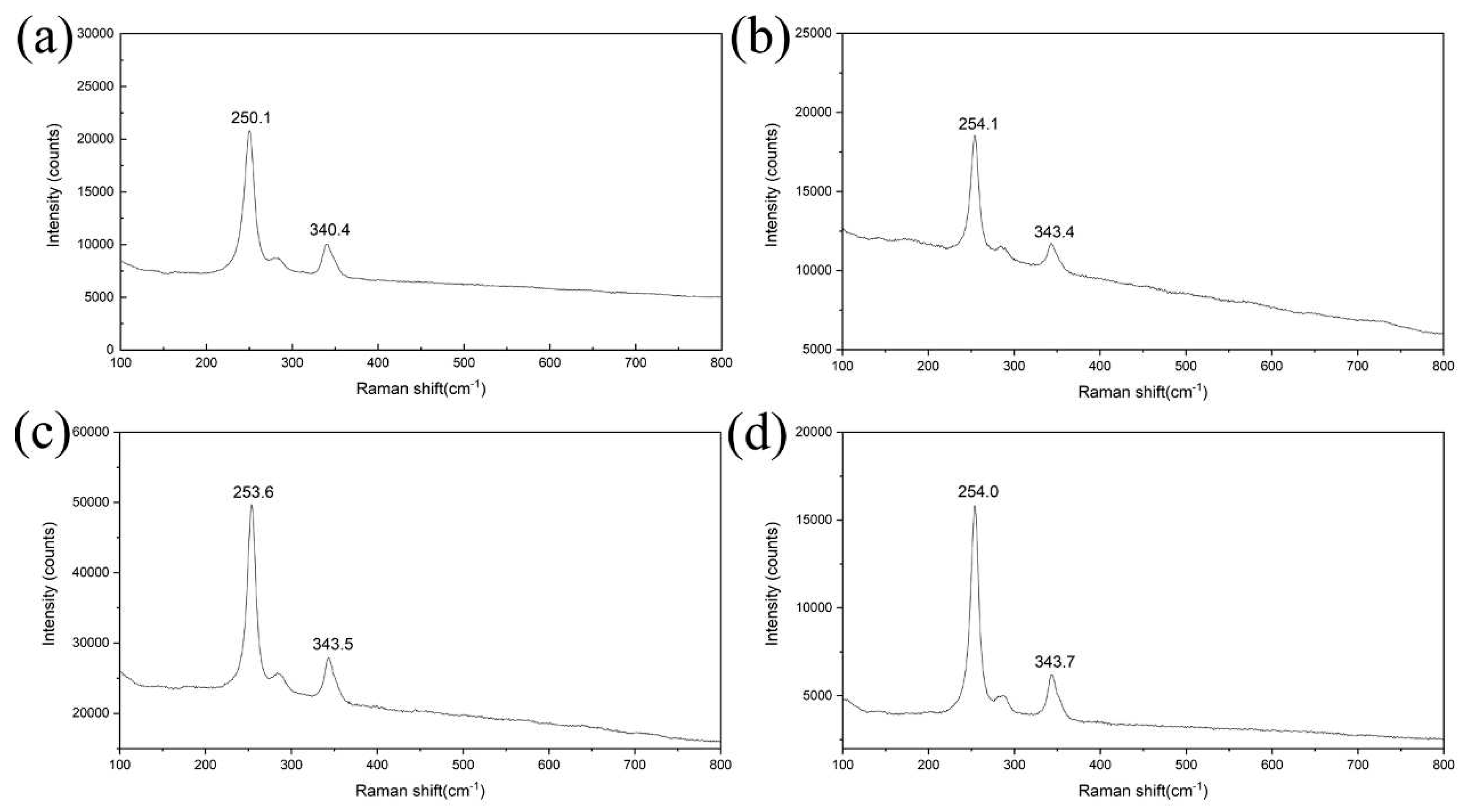

3.2. Pigment analysis

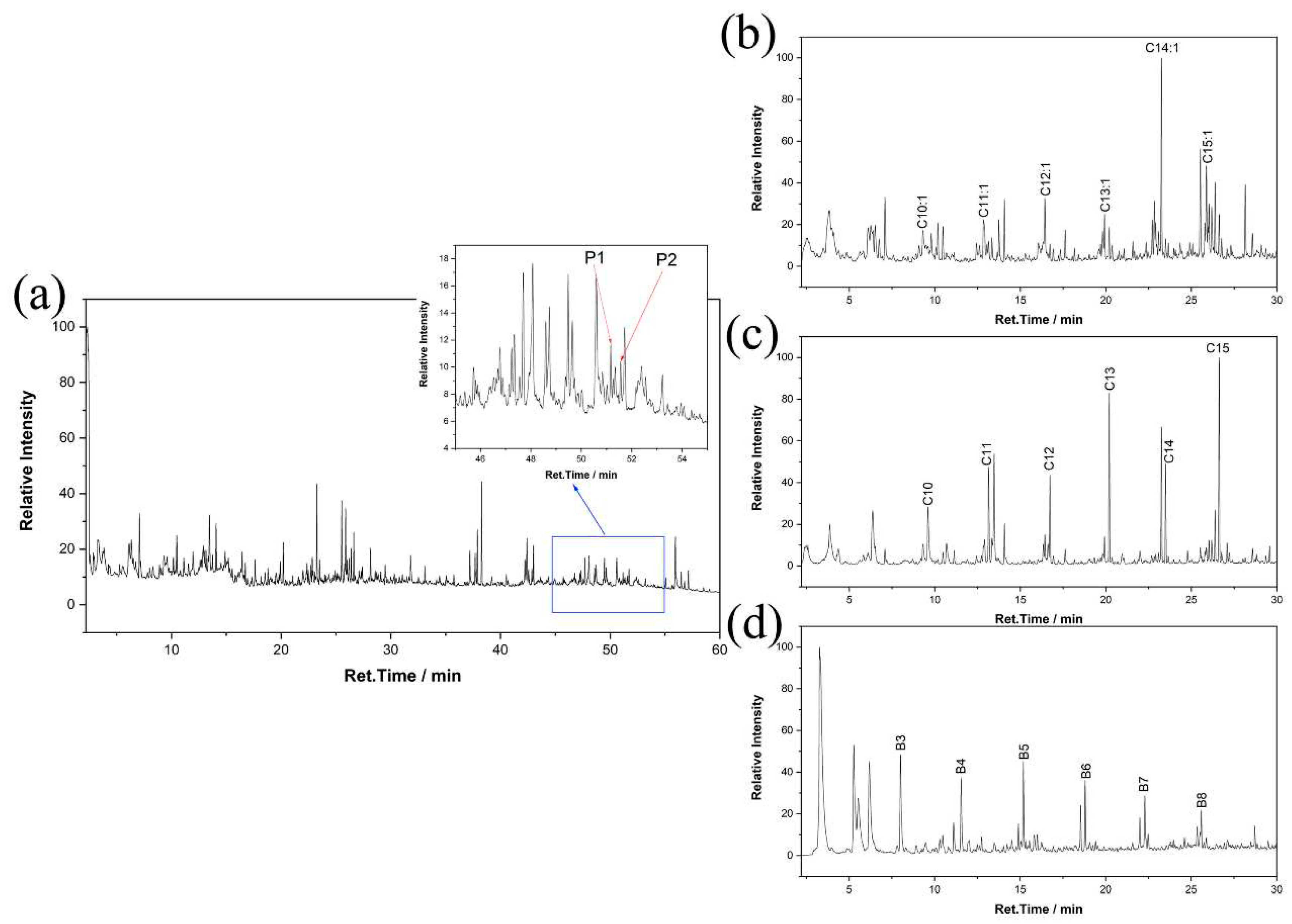

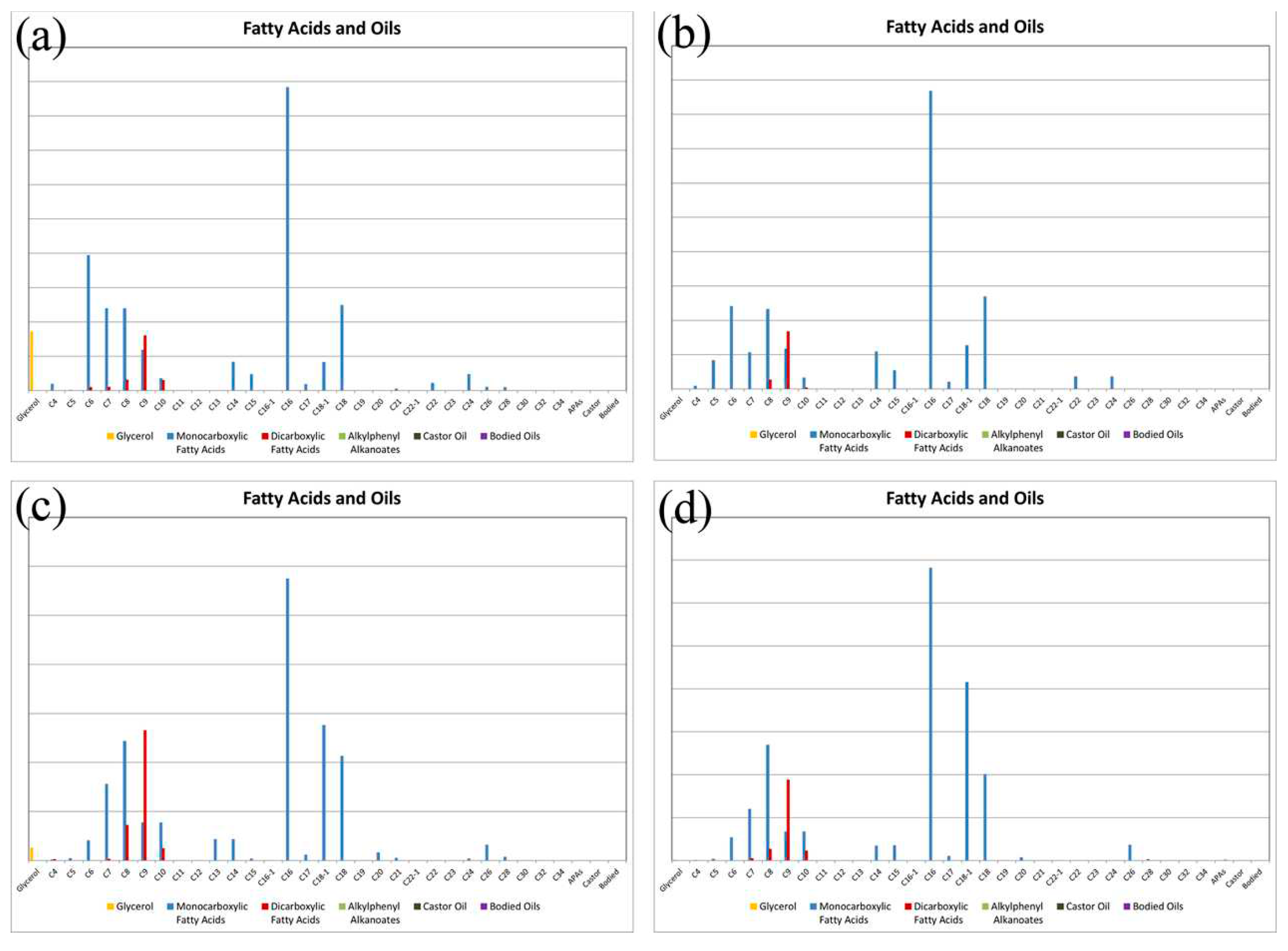

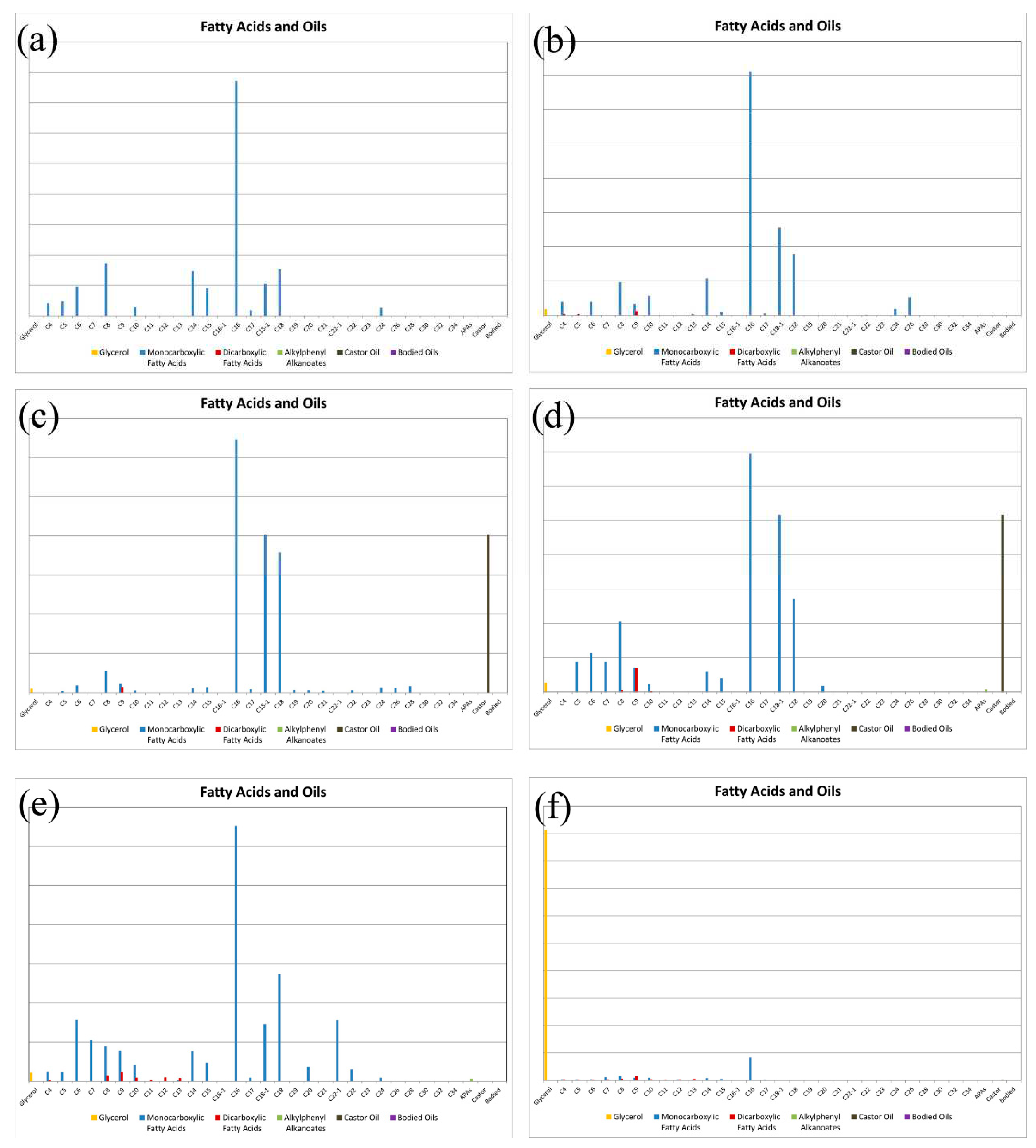

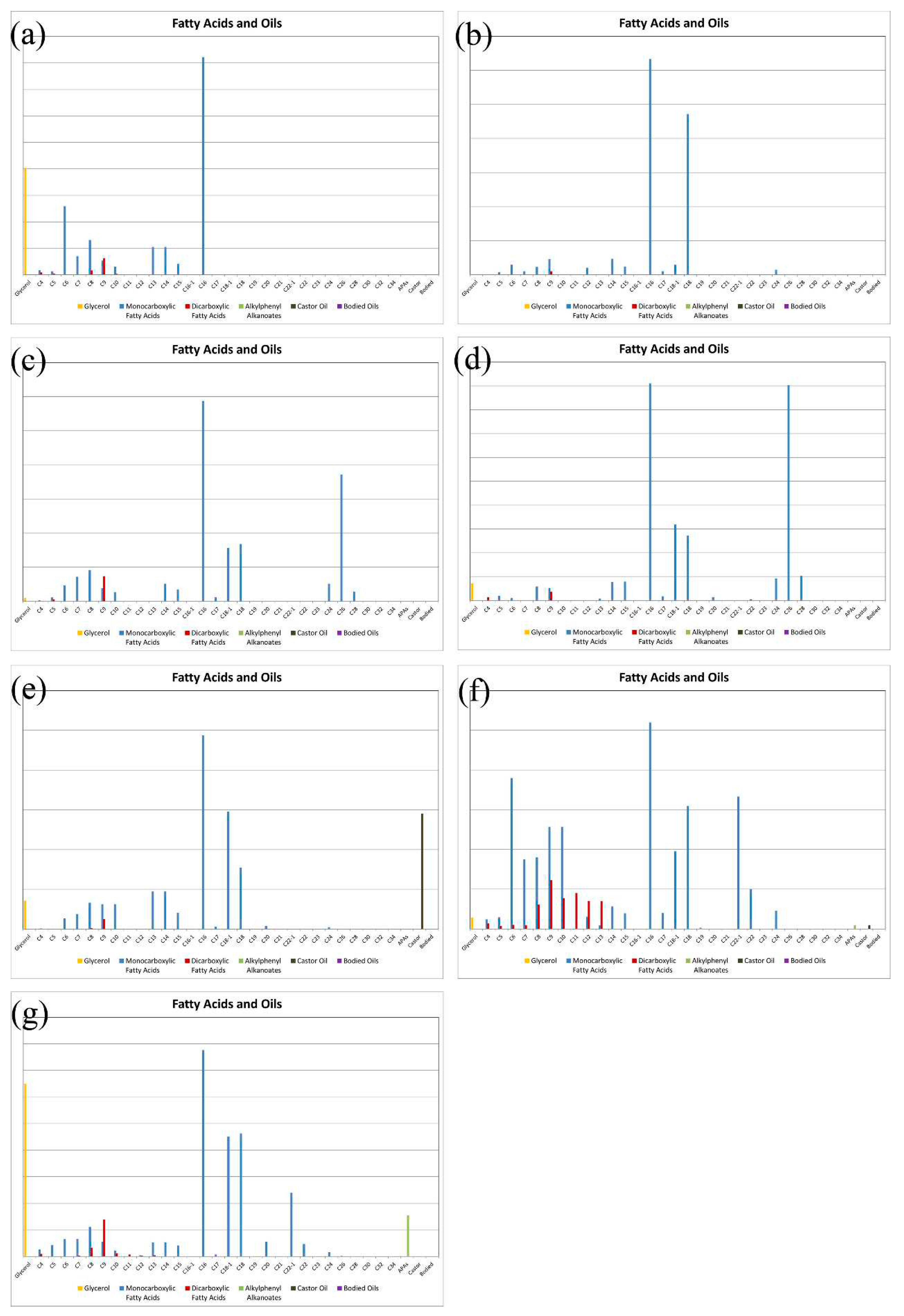

3.3. Lacquer film analysis

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Niimura, N.; Miyakoshi, T.; Onodera, J.; Higuchi, T. Characterization of Rhus vernicifera and Rhus succedanea lacquer films and their pyrolysis mechanisms studied using two-stage pyrolysis-gas chromatography/mass spectrometry. J. Anal. Appl. Pyrolysis 1996, 37, 199–209. [Google Scholar] [CrossRef]

- N. Niimura, T. Miyakoshi, J. Onoderra, T. Shiguchi. Structural studies of Melanorrhoea usitate lacquer film using two-stage pyrolysis/gas chromatography/mass spectrometry. Rapid Communications in Mass Spectrometry 1996, 10, 1719–1724. [Google Scholar] [CrossRef]

- Tamburini, D.; Bonaduce, I.; Colombini, M.P. Characterization and identification of urushi using in situ pyrolysis/silylation–gas chromatography–mass spectrometry. J. Anal. Appl. Pyrolysis 2015, 111, 33–40. [Google Scholar] [CrossRef]

- Kumanotani, J. Urushi (oriental lacquer) — a natural aesthetic durable and future-promising coating. Prog. Org. Coatings 1995, 26, 163–195. [Google Scholar] [CrossRef]

- Lu, R.; Kamiya, Y.; Miyakoshi, T. Applied analysis of lacquer films based on pyrolysis-gas chromatography/mass spectrometry. Talanta 2006, 70, 370–376. [Google Scholar] [CrossRef]

- Sung, M.; Jung, J.; Lu, R.; Miyakoshi, T. Study of historical Chinese lacquer culture and technology – Analysis of Chinese Qin-Han dynasty lacquerware. J. Cult. Heritage 2016, 21, 889–893. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, B.; Jiang, L.; Wu, J.; Sun, G. Natural lacquer was used as a coating and an adhesive 8000 years ago, by early humans at Kuahuqiao, determined by ELISA. J. Archaeol. Sci. 2018, 100, 80–87. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, Y.; Zhang, B.; Li, L. Study of colored lacquerwares from Zenghou Yi Tomb in Early Warring States. New J. Chem. 2021, 45, 9434–9442. [Google Scholar] [CrossRef]

- Zhao, Y.; Tang, Y.; Tong, T.; Sun, Z.; Yu, Z.; Zhu, Y.; Tong, H. Red lead degradation: monitoring of color change over time. New J. Chem. 2016, 40, 3686–3692. [Google Scholar] [CrossRef]

- Watson, A.Y.; Valberg, P.A. Carbon Black and Soot: Two Different Substances. Am. Ind. Hyg. Assoc. J. 2001, 62, 218–228. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, L.; Zhao, X.; Yang, J.; Zhang, M.; Wang, Y. Characterization of the materials and techniques of a birthday inscribed lacquer plaque of the Qing Dynasty. Heritage Sci. 2020, 8, 1–10. [Google Scholar] [CrossRef]

- Ma, X.; Shi, Y.; Khanjian, H.; Schilling, M.; Li, M.; Fang, H.; Cui, D.; Kakoulli, I. Characterization Of Early Imperial Lacquerware From The Luozhuang Han Tomb, China. Archaeometry 2015, 59, 121–132. [Google Scholar] [CrossRef]

- de Oliveira, L.F.; Edwards, H.G.M.; Frost, R.L.; Kloprogge, J.T.; Middleton, P.S. Caput mortuum: spectroscopic and structural studies of an ancient pigment. Anal. 2002, 127, 536–541. [Google Scholar] [CrossRef] [PubMed]

- Karpova, E.; Nefedov, A.; Mamatyuk, V.; Polosmak, N.; Kundo, L. Multi-analytical approach (SEM-EDS, FTIR, Py-GC/MS) to characterize the lacquer objects from Xiongnu burial complex (Noin-Ula, Mongolia). Microchem. J. 2017, 130, 336–344. [Google Scholar] [CrossRef]

- Wang, X.; Zhen, G.; Hao, X.; Zhou, P.; Wang, Z.; Jia, J.; Gao, Y.; Dong, S.; Tong, H. Micro-Raman, XRD and THM-Py-GC/MS analysis to characterize the materials used in the Eleven-Faced Guanyin of the Du Le Temple of the Liao Dynasty, China. Microchem. J. 2021, 171, 106828. [Google Scholar] [CrossRef]

- Tamburini, D.; Sardi, D.; Spepi, A.; Duce, C.; Tinè, M.R.; Colombini, M.P.; Bonaduce, I. An investigation into the curing of urushi and tung oil films by thermoanalytical and mass spectrometric techniques. Polym. Degrad. Stab. 2016, 134, 251–264. [Google Scholar] [CrossRef]

- Honda, T.; Lu, R.; Sakai, R.; Ishimura, T.; Miyakoshi, T. Characterization and comparison of Asian lacquer saps. Prog. Org. Coat. 2008, 61, 68–75. [Google Scholar] [CrossRef]

- Tamburini, D.; Pescitelli, G.; Colombini, M.P.; Bonaduce, I. The degradation of Burmese lacquer (thitsi) as observed in samples from two cultural artefacts. J. Anal. Appl. Pyrolysis 2017, 124, 51–62. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, Z.; Zhou, S.; Wei, S. Comparative study of the materials and lacquering techniques of the lacquer objects from Warring States Period China. J. Archaeol. Sci. 2019, 114, 105060. [Google Scholar] [CrossRef]

- Yuasa, K.; Honda, T.; Lu, R.; Hachiya, T.; Miyakoshi, T. Analysis of Japanese ancient lacquerwares excavated from Jōmon period ruins. J. Anal. Appl. Pyrolysis 2015, 113, 73–77. [Google Scholar] [CrossRef]

- Wei, S.; Pintus, V.; Pitthard, V.; Schreiner, M.; Song, G. Analytical characterization of lacquer objects excavated from a Chu tomb in China. J. Archaeol. Sci. 2011, 38, 2667–2674. [Google Scholar] [CrossRef]

- Wang, X.; Hao, X.; Zhao, Y.; Tong, T.; Wu, H.; Ma, L.; Shen, X.; Tong, H. Systematic study of the material, structure and lacquering techniques of lacquered wooden coffins from the Eastern Regius Tombs of the Qing Dynasty, China. Microchem. J. 2021, 168, 106369. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, Z.; Zhou, S.; Wei, S. Comparative study of the materials and lacquering techniques of the lacquer objects from Warring States Period China. J. Archaeol. Sci. 2019, 114, 105060. [Google Scholar] [CrossRef]

- Jin, P.; Hu, Y.; Ke, Z. Characterization of lacquer films from the middle and late Chinese warring states period 476–221BC. Microsc. Res. Tech. 2017, 80, 1344–1350. [Google Scholar] [CrossRef]

- Tamburini, D.; Bonaduce, I.; Ribechini, E.; Gallego, C.; Pérez-Arantegui, J. Challenges in the data analysis of Asian lacquers from museum objects by pyrolysis gas chromatography/mass spectrometry. J. Anal. Appl. Pyrolysis 2020, 151, 104905. [Google Scholar] [CrossRef]

- Niimura,, N. Determination of the type of lacquer on East Asian lacquer ware. International Journal of Mass Spectrometry 2009, 284, 93–97. [Google Scholar] [CrossRef]

- Schilling, M.R.; Heginbotham, A.; van Keulen, H.; Szelewski, M. Beyond the basics: A systematic approach for comprehensive analysis of organic materials in Asian lacquers. Stud. Conserv. 2016, 61, 3–27. [Google Scholar] [CrossRef]

- X. Hao, M.R. Schilling, X. Wang, H. Khanjian, A. Heginbotham, J. Han, S. Auffret, X. Wu, B. Fang, H. Tong. Use of THM-PY-GC/MS technique to characterize complex, multilayered Chinese lacquer. Journal of Analytical and Applied Pyrolysis 2019, 140, 339–348. [Google Scholar] [CrossRef]

| Sample | Color | Layer 1 (μm) | Layer 2 (μm) | ||

|---|---|---|---|---|---|

| Average | Standard deviation | Average | Standard deviation | ||

| 1 | red | 21.6 | 2.89 | 56.7 | 8.84 |

| 2 | black | 21.6 | 1.34 | 28.1 | 11.84 |

| red | 19.2 | 5.28 | 22.7 | 10.44 | |

| 3 | black | 40.8 | 6.15 | - | - |

| red | 29.9 | 0.84 | 23.0 | 3.20 | |

| 4 | black | 39.0 | 3.92 | 11.7 | 1.74 |

| red | 27.6 | 2.69 | 5.1 | 0.97 | |

| 5 | black | 43.8 | 2.45 | 78.9 | 20.67 |

| 6 | black | 31.6 | 1.94 | 9.9 | 4.59 |

| 7 | black | 45.3 | 5.75 | 35.1 | 10.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).