Submitted:

06 October 2023

Posted:

10 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

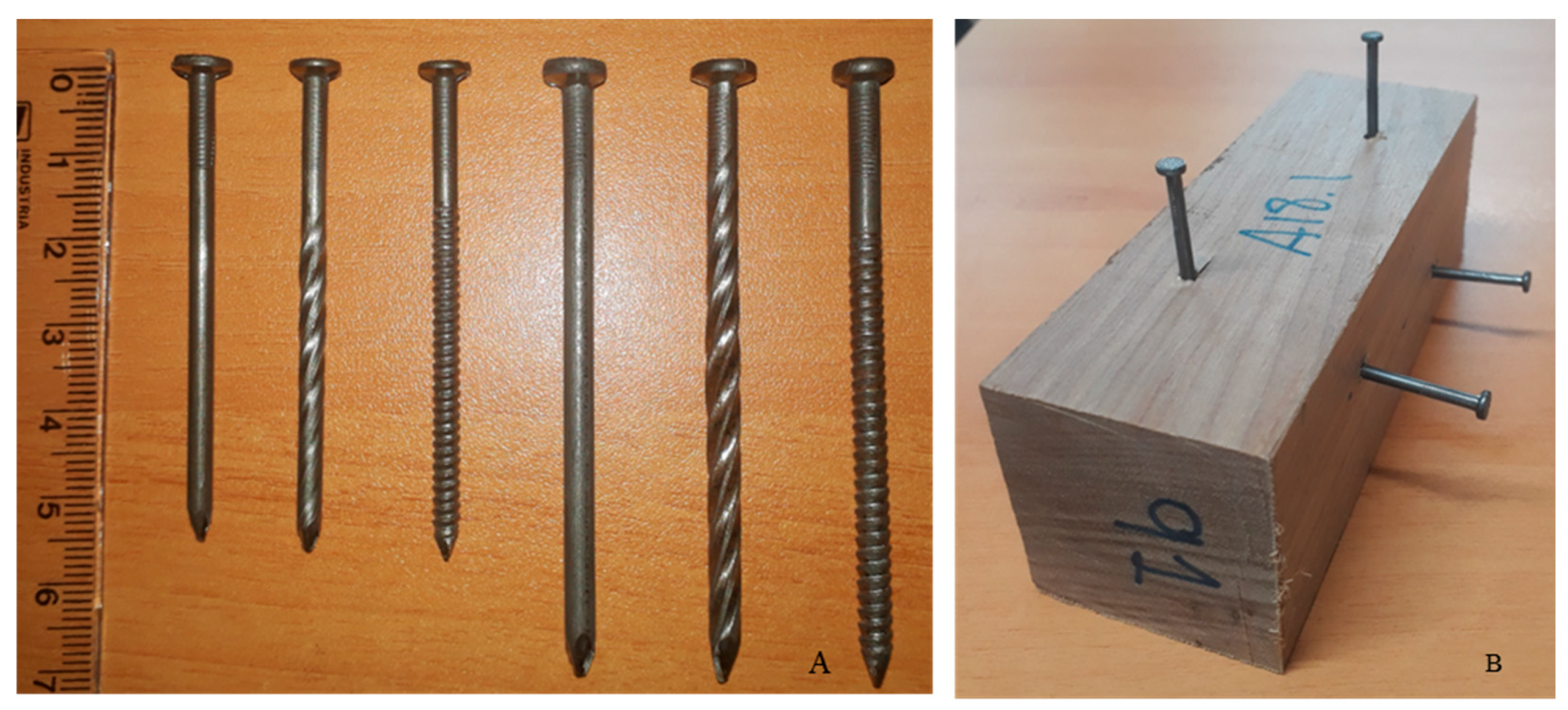

2.1. Specimens

2.2. Statistical Analysis

2.3. Theoretical Analysis

3. Results and Discussion

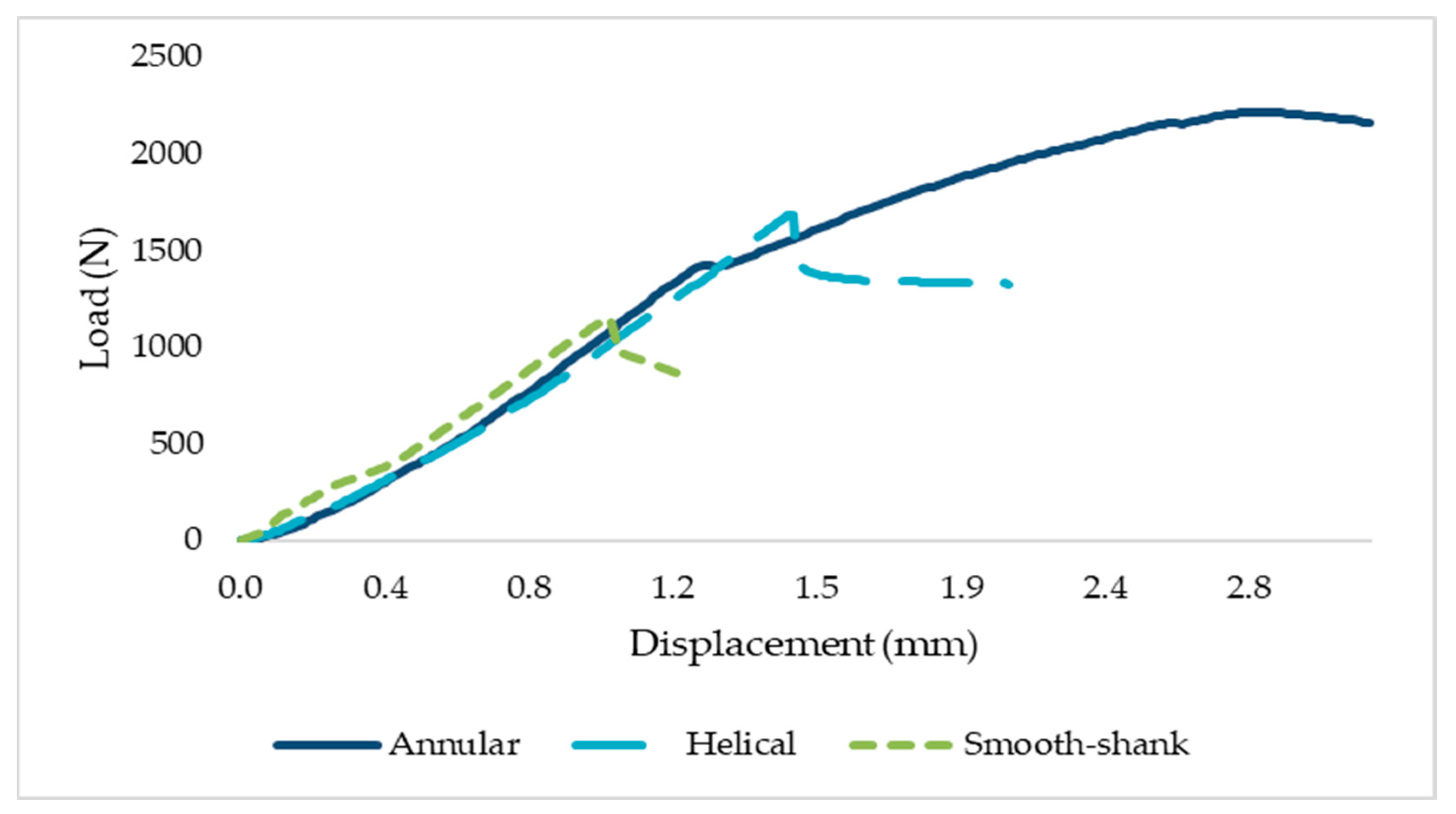

Withdrawal resistance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rammer, D. Fastenings. In Wood Handbook: Wood as an engineering material.; Ross., R.J., Ed.; U.S. Dept. of Agriculture, Forest Service, Forest Products Laboratory: Madison, 2021; pp. 8–28. [Google Scholar]

- De Paula, E.M.; De Souza Rocha, J. Extração de Pregos Em Madeiras Da Amazônia. Acta Amazon 1988, 3-4, 243–253. [Google Scholar] [CrossRef]

- Ruan, G.; Filz, G.H.; Fink, G. Shear Capacity of Timber-to-Timber Connections Using Wooden Nails. Wood Mater Sci Eng 2022, 17, 20–29. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Mohebby, B.; Elyasi, M. Bending Performances and Rolling Shear Strength of Nail-Cross-Laminated Timber. Wood Mater Sci Eng 2022, 17, 113–120. [Google Scholar] [CrossRef]

- Kim, K. Predicting Nail Withdrawal Resistance and Bearing Strength of Cross-Laminated Timbers from Mixed Species. Bioresources 2021, 16, 4027–4038. [Google Scholar] [CrossRef]

- Rammer, D.R.; Zelinka, S.L. Review of End Grain Nail Withdrawal Research; Madison, 2004.

- Mahdavifar, V.; Sinha, A.; Barbosa, A.R.; Muszynski, L.; Gupta, R. Lateral and Withdrawal Capacity of Fasteners on Hybrid Cross-Laminated Timber Panels. Journal of Materials in Civil Engineering 2018, 30. [Google Scholar] [CrossRef]

- Rammer, D.R.; Winistorfer, S.G.; Bender, D.A. Withdrawal Strength of Threaded Nails. Journal of Structural Engineering 2001, 127, 442–449. [Google Scholar] [CrossRef]

- Rammer, D.R.; Mendez, A.M. Withdrawal Strength of Bright and Galvanized Annulary Threaded Nails. Frame Building News 2008, 59–67. [Google Scholar]

- Theilen, R.D.; Bender, D.A.; Pollock, D.; Winistorfer, S.G. Lateral Resistance of Ring-Shank Nail Connections in Southern Lumber Pine Lumber. Faculty publications - Department of Mechanical and Civil Engineering 1998. Paper 32.

- Luszczki, G.E.; Clapp, J.D.; Davids, W.G.; Lopez-Anido, R. Withdrawal Capacity of Plain, Annular Shank, and Helical Shank Nail Fasteners in Spruce-Pine-Fir Lumber. For Prod J 2013, 63, 213–220. [Google Scholar] [CrossRef]

- Skulteti, M.J.; Bender, D.A.; Winistorfer, S.G.; Pollock, D.G. Withdrawal Strength of Ring-Shank Nails Embedded in Southern Pine Lumber. ASAE 1997, 40, 451–456. [Google Scholar] [CrossRef]

- Wills, B.L.; Winistorfer, S.G.; Bender, D.A.; Pollock, D.G. Threaded-Nail Fasteners - Research and Standardization Needs. Transactions of the American Society of Agricultural Engineers 1996, 39, 661–668. [Google Scholar] [CrossRef]

- Ogunrinde, O.; Gong, M.; Chui, Y.H.; Li, L. Flexural Properties of Downscaled Dowel-Type-Fastener Laminated Timber. International Journal of Scientific Research in Multidisciplinary Studies 2019, 5, 98–104. [Google Scholar]

- Shao, F.; Wang, Y.; Lian, W.; Benjeddou, O. Experimental and Numerical Investigation on Withdrawal Connectors Usage for Lateral Resistance of Timber Shear Wall´s Structure. Journal of Building Engineering 2021, 44, 103266. [Google Scholar] [CrossRef]

- Ahn, K.S.; Pang, S.J.; Oh, J.K. Prediction of Withdrawal Resistance of Single Screw on Korean Wood Products. Journal of the Korean Wood Science and Technology 2021, 49, 93–102. [Google Scholar] [CrossRef]

- Abdoli, F.; Rashidi, M.; Rostampour-Haftkhani, A.; Layeghi, M.; Ebrahimi, G. Withdrawal Performance of Nails and Screws in Cross-Laminated Timber (CLT) Made of Poplar (Populus Alba) and Fir (Abies Alba). Polymers (Basel) 2022, 14. [Google Scholar] [CrossRef]

- Ehlbeck J; Siebert W Axially Loaded Nails: Proposals for Supplement to the CIB Code, Int. Council Build. Res. Studies Documentation Working Commission W18A-Timber Struct. CIB-W18A/21-7-5; 1988.

- Blaß, H.; Uibel, T. Tragfähigkeit von Stiftförmigen Verbindungsmitteln in Brettsperrholz. 2007.

- American Wood Council (AWC) National Design Specification for Wood Construction 2018; Leesburg, 2018.

- Secco, R.D.S.; Procópio, L.C. A Importância Da Identificação Botânica Nos Inventários Florestais: O Exemplo Do “Tauari” (Couratari Spp. e Cariniana Spp. - Lecythidaceae) Em Duas Áreas Manejadas No Estado Do Pará. Acta Amazon 2008, 38, 31–44. [Google Scholar]

- Serviço Florestal Brasileiro - SFB Sistema de Cadeia de Custódia. Available online: https://sistemas.florestal.gov.br/scc/consultascc (accessed on 2 October 2023).

- Pimentel, T.S.; Wimmer, P.; de Carvalho, H.R.; Roitman, L.; Del Menezzi, C.H.S. Shear Bonding Strength of Some Amazonian Woods. Scientia Forestalis/Forest Sciences 2021, 49. [Google Scholar] [CrossRef]

- American Society for Testing and Materials - ASTM Standard Test Methods for Small Clear Specimens of Timber; West Conshohocken., 2000.

- Taj, M.A.; Kazemi Najafi, S.; Ebrahimi, G. Tragverhalten von Holzschrauben in Buchen-, Hainbuchen- Und Pappelholz Bei Scherbeanspruchung Und Auf Herausziehen. European Journal of Wood and Wood Products 2009, 67, 135–140. [Google Scholar] [CrossRef]

- Aytekin, A. Determination of Screw and Nail Withdrawal Resistance of Some Important Wood Species. Int. J. Mol. Sci 2008, 9, 626–637. [Google Scholar] [CrossRef] [PubMed]

- Teng, Q. Q.Z.; L.Z.; Z. Effect of Installed Angle on the Withdrawal Capacity of Self-Tapping Screws and Nails. In Proceedings of the Proceedings of the World Conference of Timber Engineering; Seoul, August 20, 2018.

- Ceylan, A.; Girgin, Z.C. Comparisons on Withdrawal Resistance of Resin and Phosphate Coated Annular Ring Nails in CLT Specimens. Constr Build Mater 2020, 238. [Google Scholar] [CrossRef]

- Li, X.; Ashraf, M.; Subhani, M.; Kremer, P. Pull-out Resistance of Self-Tapping Screws in Cross-Laminated Timber Made from Radiata Pine. In Proceedings of the Proceedings of International Structural Engineering and Construction; ISEC Press, 2020; Vol. 7, pp. 1–7. [CrossRef]

| Nail Shank Model | Equation1 | Unit | Authors |

|---|---|---|---|

| Smooth | W = 1380 G 5/2 D L | LB | AWC [20] |

| W = 54.12 G5/2 D L | N | Rammer [1] | |

| Helical | W = 36 x 10-2 G2 D L | N | Ehlbeck & Siebert [18] |

| W =29.6 G 1,28 D L | N | Rammer et al. [8] | |

| W = 0.117 D 0,6 L G 0,8 | N | Blass & Uibel [19] | |

| W = 1380 G 5/2 D L | N | AWC [20] | |

| W = 54.12 G5/2 D L | N | Rammer [1] | |

| Annular | W = 42.8 G 1.38 D L | N | Rammer et. al. [8] |

| W = 0.117 D 0,6 L G 0,8 | N | Blass & Uibel [19] | |

| W = 1800 G2 D L | LB | AWC [20] | |

| W = 77.57 G2 D L | N | Rammer [1] |

| Model/Diameter | Maximum load (N) | C.V. (%) |

|---|---|---|

| Smooth/2.8 mm | 1039.70 a | 15.7 |

| Smooth/3.5 mm | 1088.32 a | 19.7 |

| Helical/2.8 mm | 1330.10 b | 26.8 |

| Helical/3.5 mm | 1557.32 b | 23.5 |

| Annular/2.8 mm | 2050.09 c | 24.3 |

| Annular/3.5 mm | 2244.55 c | 25.4 |

| Nail Models | Experimental Values (N) | Ehlbeck & Siebert [18] | Rammer et. al. [8] | Blass & Uibel [19] |

AWC [20] | Rammer [1] |

|---|---|---|---|---|---|---|

| Smooth 2.8 mm | 1040 | - | - | - | 1452 | 1359 |

| (+40%)1 | (+31%) | |||||

| Smooth 3.5 mm | 1088 | - | - | - | 1815 | 1762 |

| (+67%) | (+62%) | |||||

| Helical 2.8 mm | 1330 | 1363 | 1528 | 1236 | 1452 | 1359 |

| (+2%) | (+15%) | (-6%) | (+9%) | (+2%) | ||

| Helical 3.5 mm | 1557 | 1704 | 1910 | 1413 | 1815 | 1762 |

| (+9%) | (+23%) | (-9%) | (+17%) | (+13%) | ||

| Annular 2.8 mm | 2050 | - | 2116 | 1236 | 2344 | 2936 |

| (+3%) | (-40%) | (+14%) | (+43%) | |||

| Annular 3.5 mm | 2245 | - | 2645 | 1413 | 2941 | 3671 |

| (+18%) | (-37%) | (+31%) | (+64%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions, or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).