1. Introduction

Currently, the solid waste management system is one of the most important problems in the world. The generation of solid waste has been increasing day by day as a result of rapid population growth, rapid industrialization and economic development, which has caused the emergence of various social problems related mainly to health and the environment [

1]. Solid Waste Management is made up of an entire chain of processes among which we can mention: waste collection from the point of generation (homes, companies, shopping centers, etc.), transportation, treatment, segregation and final disposal of waste [

2]. Municipal Solid Waste Management is one of the main functions of local institutions in developing countries and its optimal performance will depend mainly on the level of knowledge that organizations may have in relation to the production of solid waste.

The segregation or classification of solid waste is considered by many researchers as one of the most important pillars of the Solid Waste Management System [

3]. Solid waste consists of a series of materials that in most cases are recyclable, such as: paper, cardboard, glass, plastic, rubber, ferrous and non-ferrous metals, which could be reused in various industrial processes. In turn, organic waste can be treated to generate biogas and biofertilizers. However, due to poor waste management and inadequate collection practices that are currently present in most cities, they have generated serious social, health and environmental problems, as well as economic, resource and energy losses [

4]. Additionally, as a result of this poor waste management, the recycling percentage is minimal and the amount of waste that reaches landfills or areas established for landfills exceeds their capacity, generating a negative impact on society and the world. that surrounds us.

Within the wide spectrum of problems related to environmental protection, solid waste management occupies one of the most important places within environmental management policies, where the main objective is to establish mechanisms that allow this process to be carried out in an efficient manner efficient and compatible with the environment and public health [

5]. Waste sorting has become a crucial mission to sustain global economic growth, reduce poverty levels and preserve the environment. For this reason, it is very important to have efficient solid waste classification processes, with the aim of improving environmental and health conditions, job creation, the emergence of new services and the economic level of many families that depend on the current economic activities related to the sector.

Given this situation, there is a need to develop an effective system that allows the possibility of making significant changes in the solid waste classification process at the source in order to minimize the problem. Currently, every government in the world is planning to build smart cities or trying to transform existing cities into smart cities [

6]. The collection and classification of solid waste is a crucial point for the environment and its impact on society, which is why the use of technologies such as the Internet of Things (IoT) and Artificial Intelligence could help implement solutions that allow the provision of services related to this problem. Although there is a large number of developments related to the classification of materials and/or waste through image recognition from Convolutional Neural Networks, optical and spectrophotometry techniques, among other related techniques, such as those proposed by [

7,

8,

9,

10,

11,

12],which, despite being efficient in the classification process, require cameras and robust hardware, generating a higher implementation cost compared to the method proposed in this article and which in most cases may not be suitable for the dirty conditions to which any ecological point will be subjected.

In view of the above, this article presents as a demonstration the development of a prototype of an ecological point which carries out a basic waste separation process, through the design of a capacitive sensor with low manufacturing cost, with sufficient capacity and sensitivity to facilitate the classification process of various types of solid waste in the source such as: glass, plastic, metal and organic waste mainly, through the use of Machine Learning algorithms, in order to optimize the separation processes of recyclable and non-recyclable waste at the source. For the particular case in Colombia, it is regulated by Resolution 2184 of the Ministry of Environment and Sustainable Development of December 26, 2019 [

13].

2. Materials and Methods

In the particular case of Colombia, according to the Ministry of Environment, the generation of estimated solid waste derived from domestic activities would be close to 26,975 tons/day. And the total accumulated in one year, adding industrial and commercial waste, the amount of solid waste would be around 11.6 million tons per year [

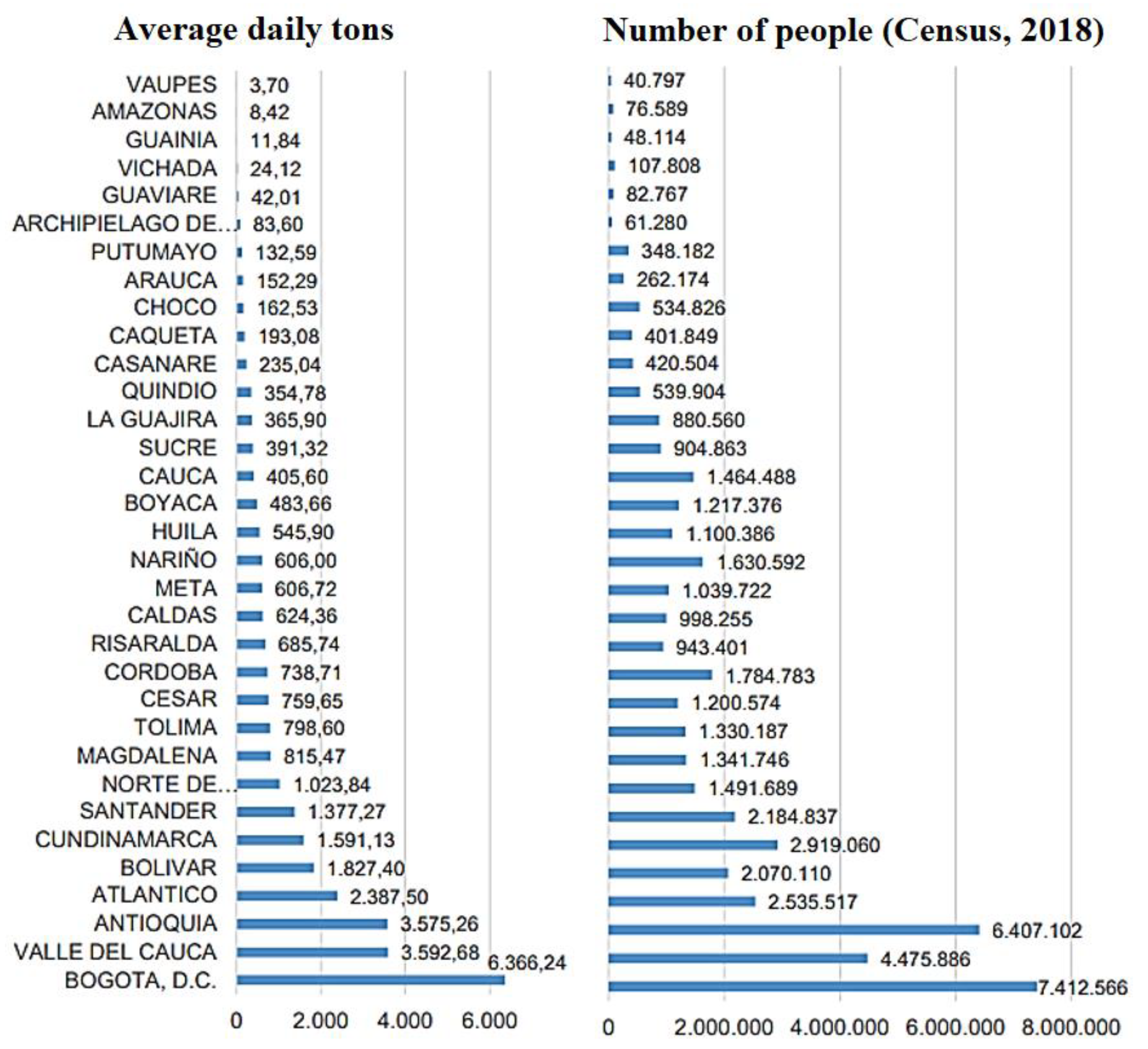

14]. In

Figure 1, it is possible to see that most of the departmental distribution of the country’s waste disposal (51.41%) is concentrated in the Capital District and 3 departments, Bogotá, DC (6,366.24 Ton/day, 20.55%), Valle del Cauca (3,592.68 Ton/day, 11.60%), Antioquia (3,575.26 Ton/day, 11.54%) and Atlántico (2,387.50 Ton/day 7.71%). In accordance with the trend exposed for the 2017 period in the 2017 Final Disposal Report, it can be seen that these 3 departments and the Capital District also had the highest concentration of disposed waste. Although awareness campaigns, environmental education programs and legislative documents have been carried out in this regard for years, it is estimated that the recycling percentage only reaches 17%. In the particular case of plastic, it is stated that only 7% is recycled [

15].

Although progress has been made in Colombia in the organization of people who literally live off garbage, an expression that since 1986 has been changing to “solid waste recyclers”, the creation of trade union organizations has been achieved. Cooperatives and NGOs in the main cities and at the national level, representations such as the National Association of Recyclers (ANR) [

16]. These entities report that in the country there are between 50 to 60 thousand families who make a daily living from the job of collecting recyclable waste, highlighting that this activity has become a family dynamic, because children must help their parents. in this work, or even if they are very young, their parents must accompany them at night, given the insecurity of leaving them alone in the house. This work is regularly carried out between 6:00 am and 10:00 pm and generates income between

$200 to

$300 thousand Colombian pesos per month, equivalent to approximately 44 and 66 dollars [

17].

Although recycling is a very important activity for the environmental sustainability of the country, it continues to present very low income, where it can be mentioned as an example that, in 2019, only 1.3 million tons of waste were used. about 30 million produced[18]. However, one of the main reasons why recyclers have low economic income, despite the high volume of products that can be collected, is due to the inadequate classification process at the source, which generates contamination between the waste and the inadequate disposal of the same, which means that the material has to be discarded due to its contamination and consequently an economic loss as well as the opportunity to use it [

15].

It is evident that, to improve indicators such as SDG 12 – Responsible production and consumption, as well as SDG 1 – End poverty in all its forms throughout the world, it is necessary to generate contributions from engineering through the development of innovative technological solutions, with the capacity to carry out the solid waste classification process at the source in an efficient and systematized manner, through the so-called “Smart Ecological Points”, which would be consistent (in the case of Colombia), with Resolution 2184 of the Ministry of Environment and Sustainable Development of December 26, 2019, which came into force as of January 1, 2021, in which it is determined that, to carry out the separation of solid waste at the source,From now on, only three colors will be implemented for the classification of solid waste, as can be seen in

Figure 2 [

13].

On the other hand, in decree 349 of 2014, which regulates the imposition and application of the Environmental Comparative in the Capital District, the following is expressed: “Culture of waste reduction and separation at the source”. It is oriented towards training and raising awareness among citizens who use sanitation services, through massive campaigns on the benefits of recycling, separation at the source and the differentiated disposal of solid waste. Differentiated interventions are included according to type of user: schools and universities, homes, residential complexes, businesses and commercial premises and industries [

19]. Although the pedagogical nature of the construction of environmental culture is highlighted in the responsibility of separation at the source, this is not currently applied by society and that is why it must be kept in mind in paragraph 2 of article 94 of Law 1801 of 2016, better known as the Police Code, which has seen the need to establish type 3 fines (16 SMDLV), for those people or institutions that do not separate at the source or do so incorrectly.

In view of the above, promoting the design and implementation of Smart Ecological Points could be considered a great contribution to the Comprehensive Solid Waste Management Plans (PGIRS) that each municipality in Colombia is committed to developing and continuing to strengthen the formulation of projects for the use of solid waste and develop separation programs at the source (homes, companies, commercial environments, etc.), through the companies that provide collection, use and treatment services for the public cleaning service, with the aim of improve environmental and health conditions, the generation of employment, the emergence of new services and the economic level of many families that currently depend on economic activities related to the sector, thereby generating the possibility of contributing to the implementation of measures necessary for the economic and social reactivation of the country, derived from the pandemic and post-pandemic context, and in turn contributing to Sustainable Development.

Additionally, the proposed technological solution would allow, in the short, medium and long term, to optimize the logistics processes of the route and frequency of waste collection at ecological points, taking into account that the system could have the capacity to send via GRPS or WiFi, to the cloud, information on the current status of each container, allowing us to identify when each ecological point has reached its storage capacity and in this way, the company can schedule the collection at each ecological point along its route. In turn, through the use of the Internet of Things (IoT), an updated record could be kept in the cloud, with statistics on the weight, types of waste, place, day of the week and times of day in which a greater generation of waste, among other parameters, in such a way that through the use of data analytics and Machine Learning algorithms, it is possible to generate new knowledge and identify patterns related to this social dynamic, which will allow in the not too distant future the creation of new development programs of more efficient environmental culture [

6]. Aspects that would be addressed in greater detail in future manuscripts.

It is very important to mention that Solid waste management is a fairly broad field, which includes the following processes: waste collection from the point of generation, waste transportation, waste treatment, waste classification and finally waste disposal [

20]. When talking about the correct way to separate waste, the best known method implemented by institutions and at the domestic level is the manual classification method, which consists of depositing the waste in different containers taking into account their material, this method is supported by pedagogy programs that instruct people on the subject [

21].

Garbage classification and environmental monitoring technology has developed rapidly in recent years. The combination of the Internet of Things and environmental technology has become a trend. In the process of growth of cities, it has in turn generated considerable growth in environmental pollution and solid waste management, causing enormous environmental and social problems [

22]. The current urban area commonly applies the strategy of “mixed collection, centralized transportation, centralized processing”, commonly known as three-segment management for recycling and garbage disposal, which has proven to be ineffective in treating massive waste [

23]. Below is a chronological description of some of the most representative works at an international level related to the use of technology aimed at the classification and management of solid waste, which were identified during the review process in various bibliographic sources.

2.1. Some developments in the international environment

In [

24], presents an overview of modern air classification devices, their operating principles, features and parameters such as cut size, cleaning and recovery. Additionally, it mentions various gravitational and centrifugal classifiers, including those with vertical and horizontal air currents, cascade classifiers, fluidized bed separators, inertial, vortex, rotor classifiers, etc. The choice of classifier type and designs is related to the technological requirements (performance, cleanliness, etc.) and the properties of the materials to be classified.

In [

25], a waste classification mechanism supported by eddy currents has been proposed. The separation process takes place in two stages, first the strongly conductive particles are separated at the top of the drum, and then the remaining indecisive and poorly conductive particles are separated at the bottom of the magnetic drum. The dynamic eddy current separator with permanent magnets separates small non-ferrous metal particles from two-component non-ferrous metal mixtures. The material is sent along a conveyor belt with a series of sensors underneath. These sensors locate different types of metal which are then separated by a system of rapid air jets that are linked to the sensors.

In [

26], an electrostatic separation or induction classification method was proposed to classify granular mixtures due to electrical forces, which act on particles whose average size is approximately 5 mm. In this case, three different electrostatic separation processes are used for the processing of different types of mixtures: (i) electrostatic roll separator, used to classify mixtures containing metal/plastic particles (copper/PVC for example), (ii) electrostatic plate separator, used to classify mixtures containing metal/metal particles (copper/lead for example) and (iii) free fall electrostatic separator, used to classify mixtures of plastic/plastic particles (PVC/PE ).

In [

27], an indirect classification method has been proposed to classify solid waste by using an optical sensor and a mechanical separation system. In this system, the color, shape and dimension of waste are used for waste separation. The mechanical sorting device consists of a compressed air nozzle that is controlled by a computer, The target particles that were recognized by the sensor are expelled from the main waste stream.

In [

28], the X-ray fluorescence method has been proposed for material segregation. This method determines the elemental composition of various materials with X-ray fluorescence. Based on this analysis, objects with specific elements can be detected and can be separated from the material stream. With classification systems you can treat materials such as glass, ceramics, metals, minerals, plastics.

In [

29], it makes use of one of the important methods currently used to separate post-consumer polymers/plastics based on FT-IR spectroscopy and hyperspectral imaging.

In [

30], an effective segregation system has been developed for the separation of different types of plastics. The concepts of NIR spectroscopy and multivariate analysis have been used, designed and implemented using the Raspberry Pi system to segregate the plastics. The computational algorithms and GUI were developed using Python. This system can differentiate between five types of plastics.

In [

31], a smart solid waste container has been developed for an efficient and dynamic waste management system. This paper presents the implementation and execution of an integrated detection system and algorithm for solid waste container to automate the solid waste management process. The integrated detection system is designed using a rule-based decision procedure to provide an automatic and efficient container status monitoring system.

In [

32], an automated recognition system is proposed that uses a deep learning algorithm in Artificial Intelligence to classify objects as biodegradable and non-biodegradable, where the system, once trained with an initial data set, can identify objects in real time and classify them with almost precision. Biodegradable waste is used to generate energy, enrich the soil and act as food for animals. This process does not harm the earth making it valuable, ecologically safe and helps us protect our environment, our rich ecosystem and human inhabitants in the future.

In [

33], carried out a preliminary study to apply a non-destructive testing technique using microwaves (300MHz) for solid waste classification. The experiment demonstrated that the vertical incidence of plane waves between air and different compositions of solid waste generated different reflection coefficients. The experiment also showed that metal had the highest reflection coefficient, while wood and paper had a lower reflection coefficient.

In [

23], presents the implementation of an IOT-based solid waste management system for smart cities, which allows remote monitoring of garbage containers by the municipal organization. The proposal focuses on keeping urban areas clean by rationalizing the expenses and time necessary to do so. With the help of this waste control device, the waste control department sends the vehicle to pick up the container as soon as they receive an alert SMS through the GSM module that could be located in the container.

In [

34], designed a smart waste management system using a sensor system, microcontroller, GSM/GPRS. Ultrasonic sensor and force sensor are used to detect the level and weight of waste respectively. An Android application was also developed to tell the user the location of the nearest container.

In [

20], has proposed a smart waste management system using the Internet of Things, in which the data collected by the sensor is transmitted to a remote server where it is stored for further processing. Based on this data, routes to collect containers from different locations are decided. This system also predicts factors such as traffic congestion, the speed at which containers fill, leading to an improvement in collection efficiency.

In [

35], focuses on using the IGOE framework to automate the process of identifying, locating and collecting solid waste. The data is stored in a database for analysis and operation in waste management. The focus is on making the system portable and cost-effective.

In [

36], propose an architectural solution based on IoT to address the problems faced by the current solid waste management system. By proposing a complete IoT based system, the process of tracking, collecting and managing solid waste can be easily automated and monitored efficiently. The system uses sensors to collect information from garbage containers, which are sent to a gateway using LoRa technology. The gateway collects data from multiple garbage bins and sends it to the cloud over the Internet using the MQTT (Message Queue Telemetry Transport) protocol.

In [

37], considered the use of a technique that combines hyperspectral imaging technology and a neural network-based algorithm for the identification and separation of different types of plastics from electronic waste (e-plastics). Although recent technological developments in computing power allow big data to be handled in a relatively reasonable time, a manageable number of neurons must be used to realize real-time sorting applications for plastic recycling. The prototype presented a successful result to identify three different common types of electronic plastics with a very high accuracy rate.

In [

38], suggest a system in which garbage containers are equipped with a low-cost integrated device, placing them in various locations in the city. The status of the garbage level and the location of the garbage container are sent to the cloud. The cloud-based system allows you to organize the solid waste management process through the use of a mobile application, in order to monitor and control the collection of solid waste as a service. The mobile application makes it easy for waste collection drivers to go to the garbage bins using the dynamic and shortest route.

In [

7], propose the design of a bottle recycling machine (BRM), through which it is possible to collect used bottles and classify them using a machine learning algorithm. After classification, the system has a separation mechanism for recycling used bottles. The system makes use of a raspberry-PI connected with a camera and interactive audiovisual system. In order to detect plastic bottles, the system used a machine learning algorithm.

In [

34], different mobile technologies for tracking waste containers are analyzed and used as a prospective means to improve waste management. Mobile technologies such as GPS tracking based on mobile networks for weather prediction and route design, GPRS for real-time data transmission and communication with vehicles, Bluetooth for worker monitoring, and RFID for container tracking and weighing were proposed. RFID, GPS, GPRS and GIS along with camera technologies are integrated for intelligent container and truck monitoring system.

In [

39], a new CNN architecture was designed known as capsule neural network (Capsule-Net) aimed at solid waste management, in the separation of plastic and non-plastic materials. Capsule-Net was evaluated using 2 different data sets. The first data set considered the use of materials collected from public places and the second data set, materials collected from a private environment. The proposed architecture with capsule-Net provided an accuracy of 96.3% and 95.7% for data set 1 and 2 respectively.

In [

40], explored the performance of CNN-based waste type classifiers (VGG-16, ResNet-50, MobileNet V2 and DenseNet-121) in waste type classification of 9,200 municipal solid waste images. The waste type can be identified directly from the waste type classifier or derived from the waste element class. The derived classifiers outperformed their corresponding direct classifiers in the experiment.

In [

41], Convolutional Neural Networks such as VGG, Resnet, Efficientnet, etc. to carry out waste classification processes such as metal, plastic and paper. The test accuracies that were obtained during the training process by using Resnet101, EfficientNet-B0 and EfficientNet-B1, on the data set of 6640 images taken from the internet were 92.43%, 90.02% and 91 .53% respectively. The data set comes from Stanford’s Trashnet data set and images collected on the Internet.

In [

42], proposes a solid waste classification and recycling algorithm based on deep learning technology, and uses convolution neural network to construct a garbage intelligence simultaneous interpretation and classification algorithm, which improves the accuracy and speed of garbage image recognition . The algorithm is compared with the traditional BP neural network algorithm. The simulation results show that the algorithm is 30% faster than the traditional algorithm.

In [

43], The plastic sorting system of the waste processing line is considered. Two main residue recognition methods are applied in two separation stages: spectrometry and computer vision.

2.2. Some related works developed in Colombia

In [

44], UTS students developed a prototype of an automated basket, which encourages taking care of the environment and facilitates the recycling process. Through sensors, the bin notifies when it is full, sending an alert to the web application so that the person in charge of managing the ecological point can carry out the corresponding emptying.

In [

45], presents the development of a control system for the recognition and classification of recyclable waste. The system carries out the identification and correct classification of recyclable materials such as plastic, paper, glass and metal through the use of capacitive, inductive and force sensors to achieve the identification of a sample of the most common waste found in ecological points.

In [

46], a sensor was presented for the recognition of materials through capacitance. The sensor uses a Colpitts oscillator in which one of its capacitors is replaced by two parallel plates where the different materials are placed, these generate frequency changes which are transformed into voltage for subsequent reading and processing of the embedded system.

2.3. The trash

They are all those wastes that do not represent a commercial value, which require special treatment for their final disposal, which is why they generate disposal costs that cannot be reincorporated by the economic-productive cycle [

42]. These waste generate negative environmental impacts, which is why they must be minimized.

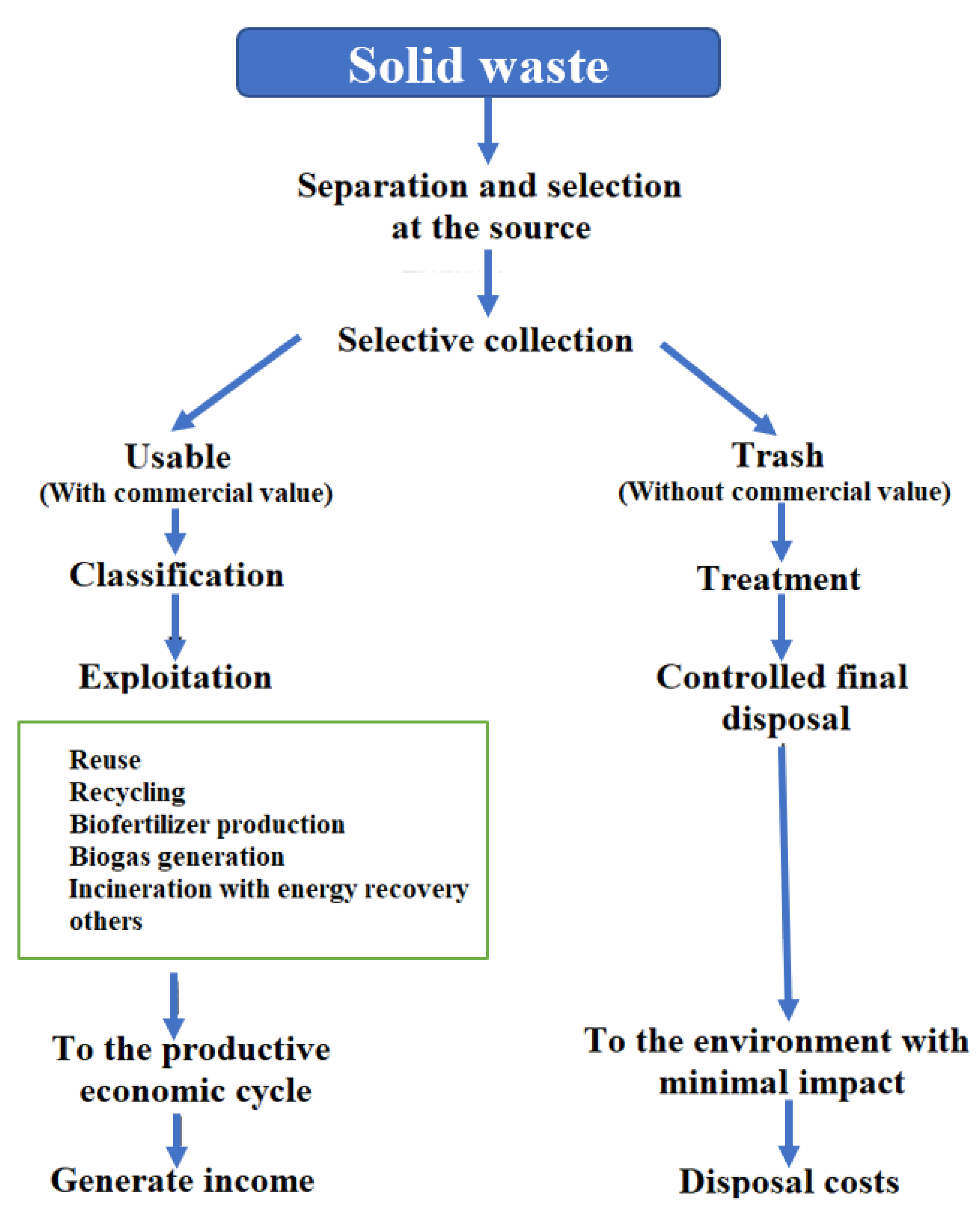

Figure 3 shows the general solid waste classification scheme.

2.4. Recycling

Recycling is the process of collecting and processing materials that would otherwise be discarded as garbage and turning them into new products. Recycling is a process that benefits the community and the environment. Among the main benefits of recycling, we can mention [

47]:

Reduces the amount of waste sent to landfills and incinerators.

Helps conserve natural resources such as wood, water and minerals.

It increases economic security by promoting a source of raw materials and income for people linked to the sector.

Pollution reduction.

Energy saving

It helps create jobs in the recycling industries and the manufacturing of products derived from recycled material.

Some of the common products that can be manufactured with recycled content can be mentioned:

In Resolution 2184 of 2019, mention is made of the following benefits of carrying out recycling and classification processes of solid waste [

13]:

Environmental benefits:The amount of waste taken to final disposal is reduced, avoiding the associated environmental impacts, such as the generation of greenhouse gases and impacts on soil, water and air resources.

Social benefits:The working condition of professional recyclers is improved, their work is dignified, work groups and environmental projects are strengthened and promoted. The health risks of the personnel who collect and manipulate waste are reduced.

Economic benefits:By taking advantage of solid waste as raw material for new products, final costs are reduced and it becomes alternatives for new businesses and a source of employment.

There are two general types of recycling operations: internal and external [

25]. Internal recycling is the reuse in a manufacturing process of materials that are a waste product of that process. Internal recycling is common in the metals industry, for example. The manufacturing of copper tubes results in a certain amount of waste in the form of tube ends and trimmings, This material is melted again to give it another use. Another form of internal recycling is seen in the distillation industry, where, after distillation, spent grain mash is dried and processed into edible livestock feed. External recycling corresponds to the recovery of materials from a product that has worn out or has become obsolete. An example of external recycling is the collection of old newspapers and magazines to make new paper products.

2.5. Ecological point

An ecological point is defined as a special area or space, clearly delimited and marked, composed of containers of different colors, with the aim of encouraging and raising awareness among people to act responsibly in the solid waste separation process [

15]. An ecological point facilitates the classification of solid waste, because it has special containers to properly deposit the different recyclable materials and organic waste. It is important to mention that the use of color in recycling containers is considered a mechanism that helps guide people in the correct identification and classification of the type of waste that should be deposited in each of them.

2.6. Current regulations for ecological points Colombia

The Ministry of the Environment issued Resolution No. 2184 of 2019, which came into force as of January 2021, which establishes the new color code (white, black and green) for garbage containers and recycling bins. and bags that are used in the separation of waste. The new code must be adopted throughout the national territory and in coherence with the Comprehensive Solid Waste Management Plans (PGIRS) and the National Circular Economy Strategy established in the National Development Plan. The types of ordinary solid waste that must be classified according to the assigned color are described below:

White color: To deposit usable waste such as plastic, bottles, cans, glass, metals, paper, tetrapack, textiles and cardboard.

Black color: To deposit unusable waste such as toilet paper, sanitary waste, diapers, sweeping waste, napkins, papers and cardboard contaminated with food, metallic papers, among others.

Green color: To deposit usable organic waste such as food scraps, agricultural waste, etc.

Additionally, Resolution 2148 of 2019 establishes the Single National Format for the Presentation of the Program for the Rational Use of Plastic Bags, which is a management instrument regulated by Resolution 0668 of April 28, 2016, aimed at guaranteeing the presentation homogeneous information from plastic bag distributors in the country, chain stores, large commercial stores, chain supermarkets, among others. On the other hand, in the solid waste classification process, the so-called “special or dangerous” waste arises, among which we can mention:

Electrical equipment and appliances.

Cell phones.

Used oils

Used tires

Computers and peripherals

Batteries or accumulators

Bulbs and luminaires

Expired medications

Pesticides

Lead acid batteries

According to current regulations, this type of waste must be deposited in those places called: Ecolecta, Ecopunto, Recipunto and Puntos Azules. Below is a list of the most relevant regulations related to the treatment and collection of this type of waste:

Law 1672 of 2013.”By which the guidelines are established for the adoption of a public policy for the comprehensive management of waste electrical and electronic equipment (WEEE) and other provisions are dictated.”

Decree 284 of 2018.”By which Decree 1076 of 2015, Sole Regulatory of the Environment and Sustainable Development Sector, is added in relation to the Comprehensive Management of Waste Electrical and Electronic Devices (WEEE) and other provisions are issued.”

Decree 4741 of 2005.”By which the prevention and management of waste or hazardous waste generated within the framework of comprehensive management is partially regulated”

Agreement 565 of 2014. “Through which the installation of delivery and collection points for waste or hazardous waste from the consumption of dangerous products or substances in Bogotá DC is promoted”

Law 565 of 2014.”Through which the installation of delivery and collection points for waste or hazardous waste from the consumption of dangerous products or substances in Bogotá DC is promoted”

District Agreement 634 of 2015.”By which regulations are established for the generation, collection and adequate treatment or use of used vegetable oil and other provisions are dictated.”

Resolution 316 of 2018.”By which provisions related to the management of used cooking oils are established and other provisions are issued.”

Finally, there is another regulation of great value, related to the PGIRS or comprehensive solid waste management plan, which is independent for each region of the country. Decree 2981 of 2013, which regulates the provision of public cleaning services, indicates that: “In the case of ordinary waste and when the PGIRS establishes utilization programs, the collection of waste destined for final disposal must be carried out separately from those with the possibility of use, implementing separation processes at the source and differentiated presentation of waste.” It also indicates that “Within the framework of the PGIRS, “The municipality must consider the articulation of the waste utilization project with the other components of the public sanitation service, such as the presentation of waste separated at the source, selective collection and transportation, awareness-raising and training in separation at the source.” Additionally, it mentions that “It is the duty of users to carry out separation at the source when selective collection of usable solid waste is carried out, in accordance with the conditions established by the respective Comprehensive Solid Waste Management Plans-PGIRS and the Benefit Program. from service”[

5].

Although manual classification of solid waste is the most used method worldwide, there are other methods supported by the use of technology that seek to carry out the same process. These methods are classified as direct and indirect and are used in various sectors according to the need for classification [

41]. Direct methods make use of the physical properties of the waste, such as electrical conductivity, magnetic susceptibility, or density. These methods seek to separate heavy waste from organic waste, as well as ferrous metals from non-ferrous metals. Normally this method is used in the first stage of solid waste classification. Indirect methods are related to the use of sensors for the identification and classification of the different types of materials that make up the solid waste resulting from the direct separation process. These methods are used in a later stage of the process in which the direct methods were considered, since at this stage a more specialized identification of materials is required [

49]:

Classification based on eddy current: It is used for the identification of ferrous materials. It consists of passing the waste through two coils, a transmitter coil that generates a primary magnetic flux, a parasitic current flows towards the waste opposing the secondary flow generated by the receiving coil, the latter is the one that is measured to detect the type of waste.

Laser-induced breakdown spectroscopy: The method is used for the identification of plastic, metals and wood. It uses a solid-state neodymium-doped yttrium aluminum garnet laser, a spectral range spectrometer, and a processing unit for rapid data analysis. In the process, the waste is exposed to the laser, thereby generating a heating process in the form of plasma, which is analyzed by the spectrometer and thereby identifies the composition of the material.

Classification based on X-rays: The method makes use of a high-intensity X-ray beam, facilitating an analysis of the atomic density of the material. There are two times of X-ray based classification, dual energy X-ray transmission and X-ray fluorescence.

Optical classification: This method uses a camera to analyze the shape, size, color and texture of the material.

Classification based on spectral images: This method uses image processing and spectral reflectance measurement.

2.7. Design of the proposed capacitive sensor

For the construction of the proposed capacitive sensor, the use of aluminum sheets was considered, which were extracted from beer cans, taking into account the ease of having this resource as a reusable material and in coherence with the general objective of the project. It is very important to mention that beer or soda cans can be made of steel or aluminum, which depends on the application and the region in which it is manufactured, where one type of metal or another may be more common. In most cases, cans are made with aluminum (as in this particular case), because this material helps keep drinks fresh and protected from air, light and safety hazards (bacteria, viruses, chemicals and physical hazards), as well as to guarantee their quality levels [

50].

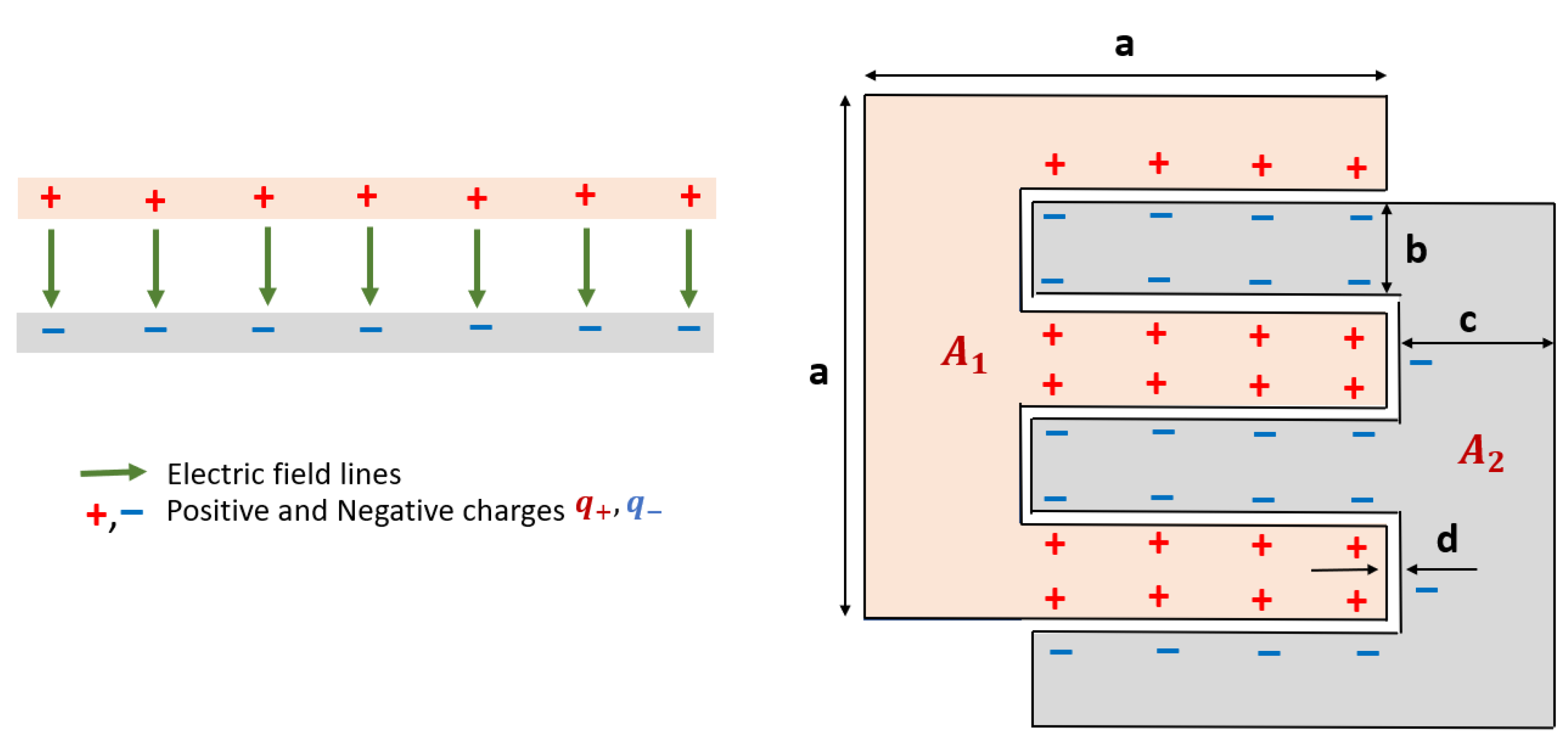

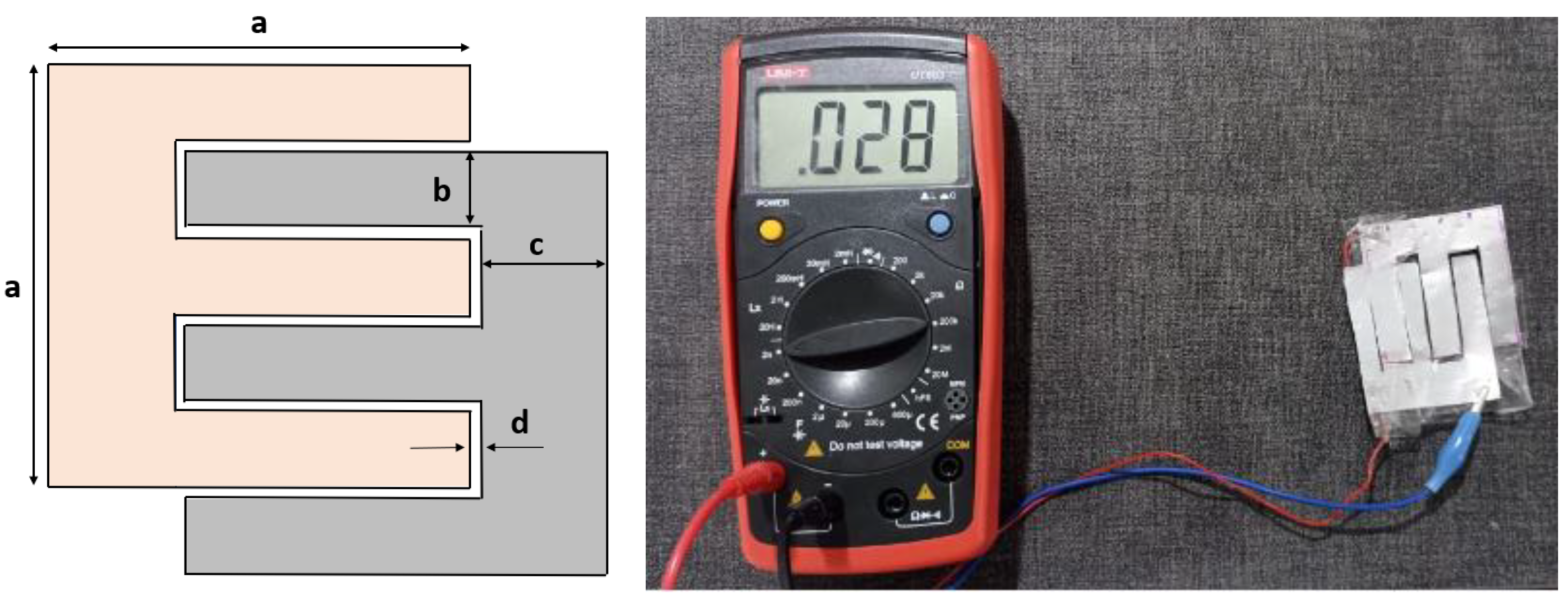

For the particular case, a non-traditional capacitive sensor (MNT) was proposed, which is made up of two E-shaped plates, which is inspired by the shape of a resistive humidity sensor, where the area of the plates (

) and the number of slots that interlock between the plates is the same, separated from each other by a distance (d).

Figure 4 presents the proposed diagram for the MNT sensor, which is given by the dimensions a, b, c and d. Additionally, the way in which the positive and negative electric charges are distributed on the plates that are part of the capacitive sensor, the electric field lines and their similarity from an analytical point of view with a parallel plate capacitor of area (A) and separation (d).

The capacitance value for the MNT capacitive sensor

can be calculated from equation (1):

2.8. Architecture of the ecological point prototype

An ecological point is an infrastructure designed for the correct disposal of solid waste, with a special focus on its classification and efficient management. These points play an essential role in promoting sustainable practices and reducing environmental pollution. One of the key components in waste management is proper separation, and eco-points make this task easier by providing specific containers for different types of waste.

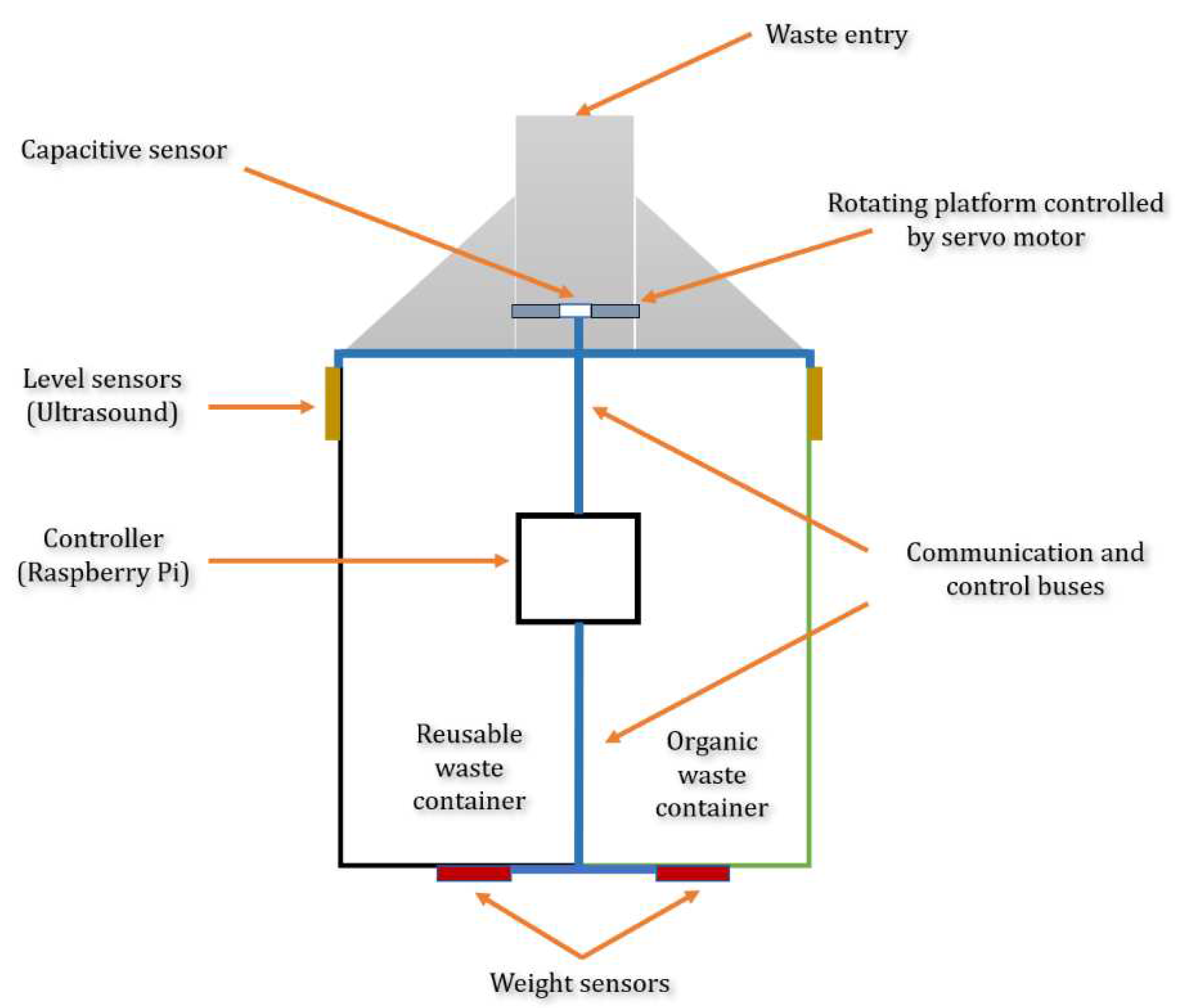

The ecological point prototype that has been developed using Raspberry Pi is an outstanding example of the technology applied to waste management. This system mainly consists of two containers: one for organic waste and the other for reusable waste. Most impressive is the integration of a capacitive sensor connected to a rotating platform controlled by a servo motor. After reading the capacitance of the introduced residue, the platform rotates clockwise or counterclockwise, depending on the result of the classification carried out by a Machine Learning algorithm. This allows the waste to be deposited in the corresponding container in an automated and precise manner.

Figure 5 shows the diagram that describes the prototype of the ecological point that was developed.

In addition, the system incorporates two HC-SR04 ultrasound sensors that function as waste level detectors in each container. Also included are two XS-112 load cells with a capacity of up to 50 kg each, connected to HX711 modules. This allows the measurement of the weight of the containers, providing information on their fill level. All of this complex infrastructure is managed by a Raspberry Pi, which not only reads the capacitance and controls the rotating platform, but also records and monitors the weight and level of each container to identify when they are full. This prototype demonstrates that, with existing technology in the environment, it is possible to play a fundamental role in the efficient management of solid waste, thus promoting more sustainable and environmentally friendly practices.

3. Results

For the development of the experiment, a digital Capacitance and Inductance meter (LCR) brand UNI-T series UT603 was used, which has a tolerance percentage of 1%, through which the capacitance measurement in pF was carried out for each of the proposed sensors, under each of the established conditions, according to the type of material or waste for subsequent identification and classification. In turn, an Electronic SF-400 series digital scale was used, which has a maximum capacity of 5kg, with a sensitivity level of 1g.

It is important to mention that the MNT sensor was covered with a layer of plastic (polypropylene) during the manufacturing and design stage in order to protect the sensor from the environment to which it will be subjected and at the same time maintain a constant separation distance between the plates, having Keep in mind that these are without any type of contact between them. In view of the above, a value of was considered to estimate the capacitance value.

Figure 6 presents a capacitance value

that the LCR delivers for the prototype that was implemented of the MNT Sensor, when it is free of residue, accompanied by the proposed diagram. From equation (1), the capacitance value

is calculated according to the sensor dimensions that were considered at the discretion of the researchers for its construction (a=5 cm, b=0.9 cm, c=1.5 cm and d=0.1 cm).

In equations (2 - 4) the result of this process is presented accompanied by the absolute error () and the relative error () in contrast with the result obtained experimentally, where it can be seen that the theoretical value and the one obtained experimentally, as in the previous case, are very similar to each other, with low absolute and relative error levels. In view of the above, it could be said that the mathematical expression proposed for the type of sensor is consistent with the results obtained experimentally, thereby allowing us to establish a reference point of great importance for future research in which we wish to use the proposed model. or make some variation in terms of design or dimensions.

Figure 7 presents some of the results obtained during the measurement campaigns, in the presence of reusable waste such as: plastic, glass and metal, as well as various types of organic waste. For the sampling campaign, a number of 100 samples were established, distributed in 25 records for each of the four types of waste or materials (plastic, glass, metal and organic). In

Table 1 and

Table 2, the mean, standard deviation and confidence intervals are presented for each characteristic, according to the type of material or waste used during the sampling campaign.

3.1. Classification of solid waste with MNT sensor using Machine Learning algorithms

For the training and evaluation process of the different processes related to data analytics, training, testing and validation of the proposed model, use was made of the cluster of libraries (sklearn, matplotlib, pandas, numpy and scipy mainly) and other resources in Python that are available in the Anaconda tool – Jupyter Notebook version 6.5.4. To carry out adequate conditioning of the data in order to minimize biases during the model training process, a process of adjustment and normalization of the data was carried out using the “RobustScaler” technique, which is part of the sklearn library. . Additionally, for the training and testing process of each of the proposed classification models, the “train_test_split” function was used.

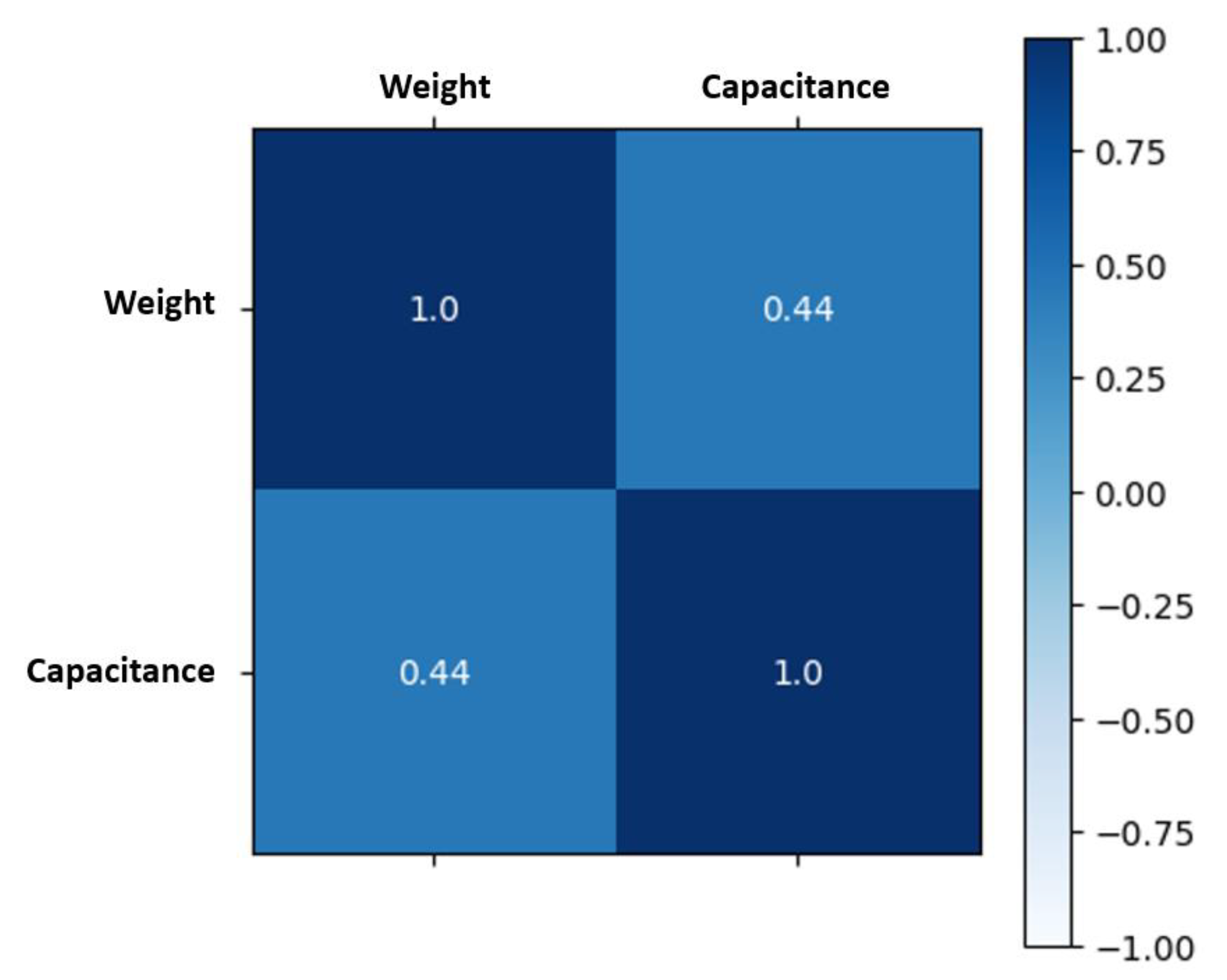

Figure 8 shows the correlation matrix of the two characteristics under study, where it is possible to show a correlation factor of 0.44 between Weight and Capacitance. An aspect that can be considered relatively low and therefore consider that the two characteristics are Independent of each other, a result that is very important to consider when carrying out the classification process and analysis of results of the proposed Machine Learning model.

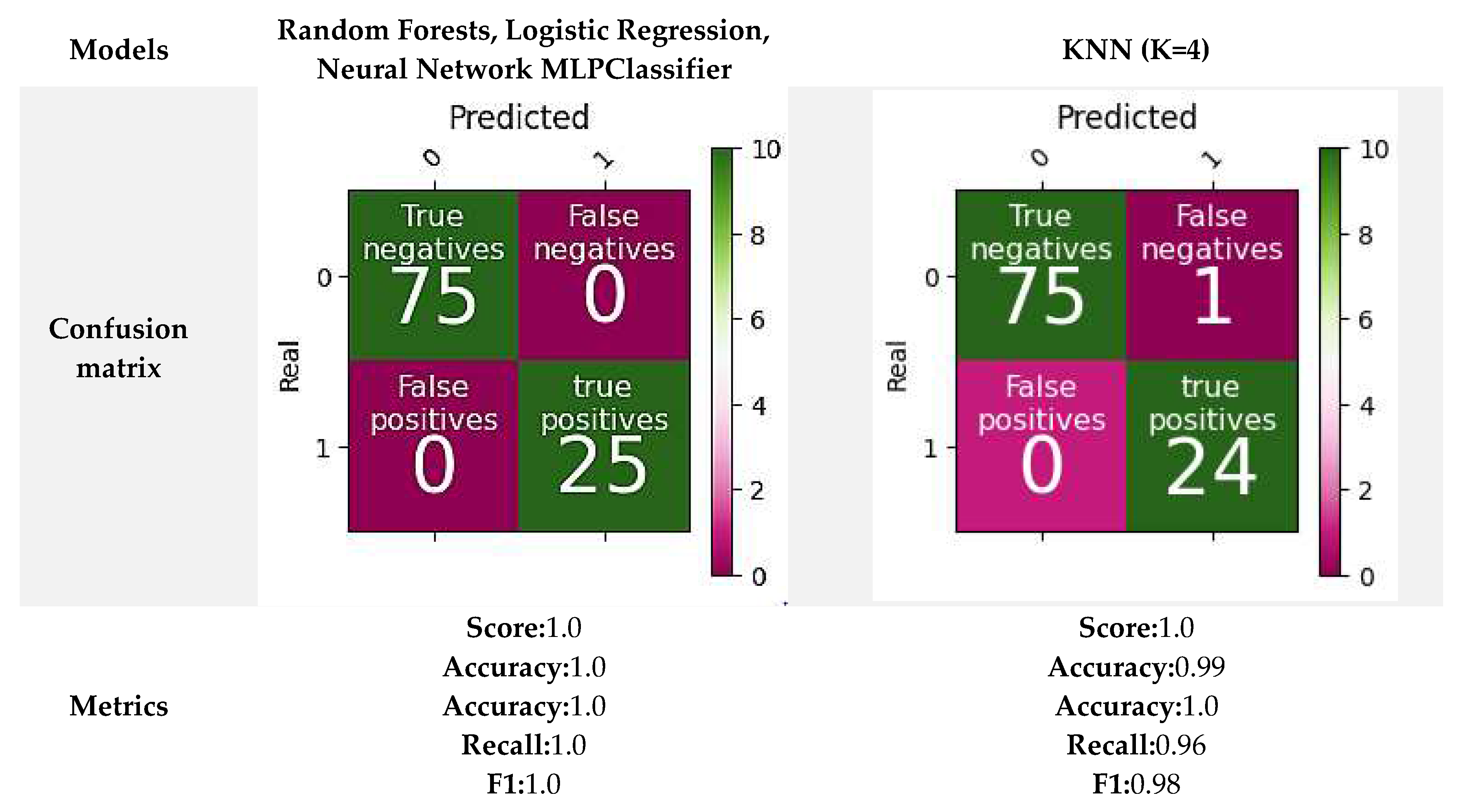

In order to evaluate each algorithm, the confusion matrix was considered, through which it is possible to identify the number of correct or unsuccessful predictions, made by the trained model and compared with the original data through a supervised learning process.

Figure 9 presents the result of the confusion matrix, where it can be seen that for the Random Forests, Logistic Regression and Neural Network MLPClassifier models, The number of “False Positives” and “False Negatives” was “Zero (0.0)”, thereby expressing that no data value was classified incorrectly for each of the proposed classes, accompanied by an adequate classification of each one of the categories, where it is possible to verify through the “True Negatives” and “True Positives” that of the total records that were considered, 75 of them belong to class “0” and 25 to class “1”, being “0”. ” for reusable waste and “1” for organic waste, which is correct. An aspect that did not happen in the same way, although with very similar results for the KNN model where the number of “False Positives” and “True Positives” was 1 and 24 respectively, causing metrics such as Accuracy, Recall and F1 suffered slight changes. The results can be considered favorable considering that they describe a low probability of presenting overfitting processes, in accordance with the values obtained in the Precision, Recall and F1 metrics [

51].

Figure 9 presents the confusion matrix and evaluation metrics for each of the proposed models.

4. Discussion

For the identification of waste or materials through the use of the proposed experimental capacitive sensor, four (4) Machine Learning algorithms were used for the classification of waste (Random Forests, KNN, Logistic Regression and MLP Neural Network), through which the respective training, testing and validation process was carried out, based on the database that was prepared during the sampling campaigns for the MNT sensor, in which the measurement of two characteristics was carried out (Capacitance [pF] and Weight [g]) of each sample, for a total of 100 records, distributed in two classes (0: Reusable waste, 1: Organic waste), and through the classification process and in coherence with the current regulations for the case particular to Colombia, These wastes would be deposited in the “White” and “Green” containers respectively.

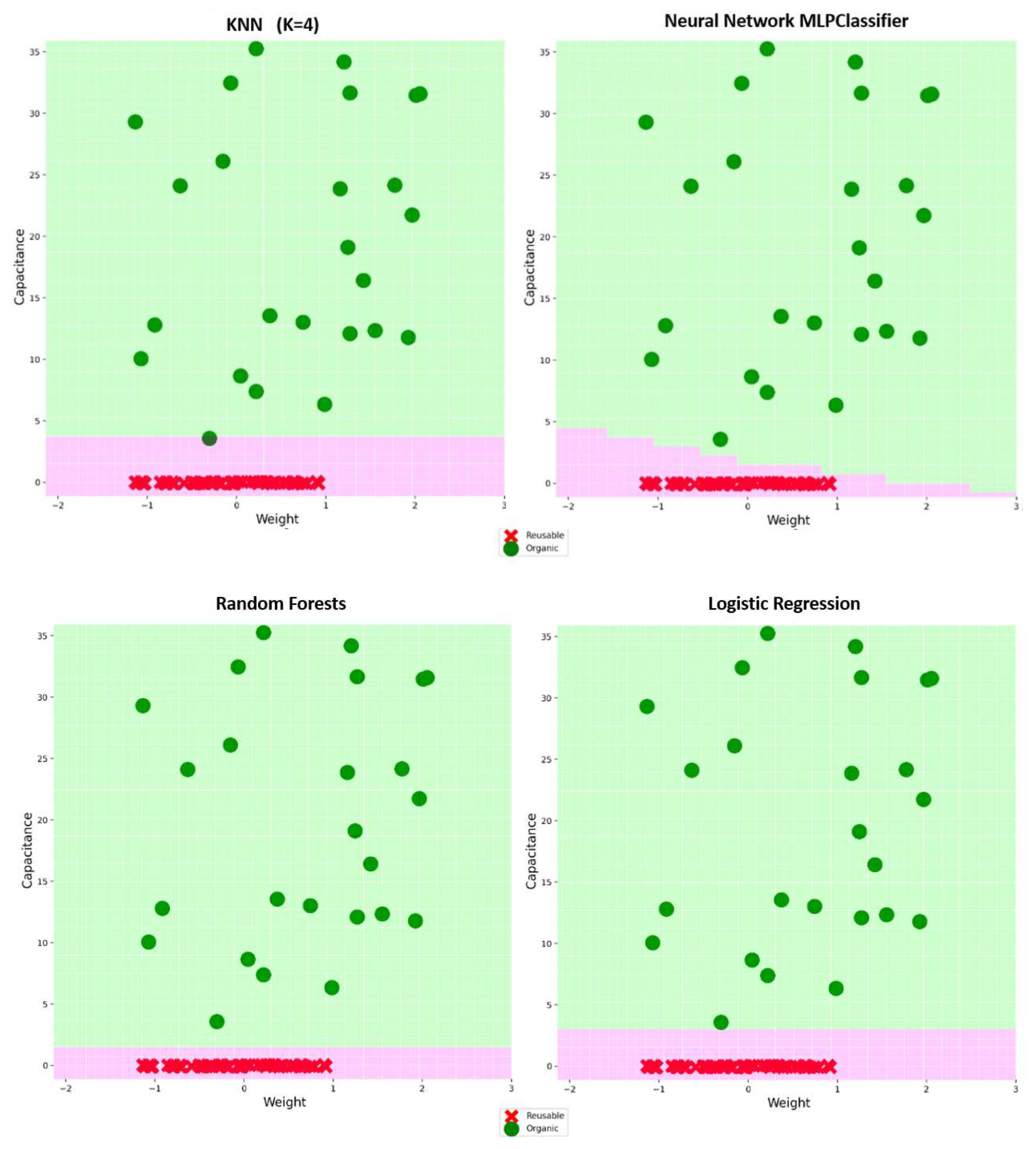

Figure 10 presents graphically the validation of each of the four classification models that were considered as an alternative for the separation of solid waste, where it is possible to identify the straight line or reference line that was estimated by each algorithm for decision making, in relation to the class to which each type of waste belongs, from a statistical point of view. In three (3) of the four (4) models it can be seen that the reference line is completely horizontal, where the standardized capacitance value is less than four (4.0), each of them with a different reference threshold value, although they are very close to each other. However, in the case of the MLP neural network model, the algorithm established a linear reference level with a negative slope and a maximum value less than five (5). In turn, it can be seen that the KNN model presents a very similar behavior in terms of metrics and reference threshold for classification, where although they present high values in terms of metrics such as Recall, Precision and F1 mainly, they perform a inadequate classification process, especially for values in which organic waste describes a low capacitance value and values close to those recorded for reusable waste. On the other hand, the MLP neural network model, although from a graphical point of view it carries out an adequate classification process, accompanied by metric values of 1.0 in all cases, may present the same situation as in the case of the two previous models, because it is possible that situations may arise in which a very low weight organic waste is introduced, where according to the graph obtained it is possible to estimate that in this situation the waste will be classified as reusable waste, which is not correct. In the case of the model supported by logistic regression, it presents, like the previous models, high levels in its metrics and at the same time, establishing a threshold level that allows carrying out an adequate classification process with the data established for its training and testing. However, it is possible to show that the threshold level established for the algorithm is very close to the record of the lowest capacitance value in the case of organic waste, a situation that could generate errors during the process of classifying some organic waste as reusable. because it would present a capacitance value slightly lower than the minimum value used during the training process, which is why the logistic regression model would not be considered ideal for the waste classification process.

Finally, the classification model corresponding to random forests not only presents values of the ideal metrics, but also establishes a threshold level in an intermediate tolerance zone between the maximum and minimum values of capacitance for reusable and organic waste respectively, establishing a tolerance zone in which the possibility of being misclassified between the two types of waste is significantly reduced, in the presence of new records where the capacitance reading is slightly outside the limits established in the model during the training and validation process. Reason why, for the particular case, it would be considered that the model that makes use of the random forest algorithm, given the data that was used during the training, testing and validation process, thereby generating an adequate level of confidence, both for the proposed model and for the MNT sensor designed for use in processes related to the classification of solid waste.