Introduction

The vast majority of microelectronic devices and photoelectric converters are made on the basis of mono or polycrystalline silicon ingots with a grain size of >300 microns, the production of which at the final stages involves cutting the ingots into wafers, grinding and polishing the wafers and creating p-n junctions on their surface using diffusion and ion implantation methods and epitaxy. This is inevitably accompanied by the appearance of waste in the form of scrub and sludge from operations of cutting plates and chemical-mechanical processing of their surface, as well as waste in the form of scrap, both semi-finished and finished products. The volume of this waste is quite large and, for example, only the return to the production of solar cells (SCs) of silicon extracted from scrub and sludge, even with existing modern, not perfect schemes for their chemical and metallurgical processing, would increase production output by ~25%, and when developing special new technologies—by 38% [

1].

The return of silicon to the production of solar cells within the framework of existing technologies involves the purification and remelting of waste with the production of mono- or polycrystalline silicon ingots with electrophysical characteristics acceptable for the creation of the basic field of solar cells. This naturally limits the range of waste processed for this purpose.

There is another way that makes it possible to usefully utilize a wider range of waste, including those heavily alloyed with small impurities such as P, B, Sb, by remelting followed by casting into molds, into the so-called secondary cast polycrystalline silicon (SCPS) [

2], n

+ or p

+ plates from which it is advisable to use exclusively as a substrate material for deposition from the gas phase of the film base region of a solar cell of n- or p-type conductivity, respectively, with a resistivity of ~1 Ohm*cm [

3].

Such solar cells are characterized by high radiation resistance and are economically competitive, since the gas-phase deposition of the film, which is subsequently used as the basic area of solar cells, is carried out using circulating technologies that are well mastered in the production of raw Si and have made it possible to sharply reduce the cost of solar cells [

4].

However, there are a number of silicon wastes that are difficult or not at all suitable for return for economic reasons, which include scrub, sludge and broken wafers, as well as defective products containing impurities that give deep energy levels in silicon such as Ta, Mo, Zr, W, V, Ti, as well as Cr Fe, Co Mn, the presence of microquantities of which, for example, ~ 10

13 cm

-3 from the first group and ~ 5 * 10

15 cm

-3 from the second, reduces the efficiency of solar cells by ~ 40% [

5,

6].

We propose to use this kind of waste as a raw material for the production of silicon materials used for the manufacture of thermal energy converters (TEC) of natural or man-made origin, including concentrated solar radiation (CSR), in which, under heating conditions, the so-called thermal voltaic effect (TVE) is manifested—the generation process when heating EMF and charge carriers, and this, as will be shown below, is precisely facilitated by the presence of impurities in the used silicon raw materials that give deep energy levels.

Rationale and Methodology of Experiments

TCE was theoretically predicted in [

7] and experimentally discovered on heated p-n structures fabricated by various methods, including structures based on SCPS [

8], then on samples produced by zone melting in a solar furnace of technical silicon [

9], and then even on single-crystalline structures, but subjected to ion implantation of alkali metals or irradiation with fast electrons with E = 1 MeV [

10], without subsequent annealing of radiation-induced defects. Studies have shown that the value of TCE depends on the concentration of defects in the material, which was explained in accordance with [

5] by the generation of charge carriers due to the absorption of subband photons with the participation of deep energy levels caused by structural defects, as well as the presence in it of deep impurities such as Fe, Cu, Mn, Mg, Ti, etc. According to [

5], a necessary condition for the manifestation of TCE is the presence of a critical concentration of deep levels exceeding ~ 4*10

18 cm

-3. Subsequently, when irradiating p-n-film structures Si/Si [

11] and Si-Ge: Ti/Si [

12] with

60Co γ-rays with a dose of 10

9 rad, as well as when treating their surfaces with beams of He

+ ions with an energy of 4 keV up to doses of 10

16 -10

17 cm

-2 [

13], it was shown that the defects that cause the appearance or increase in the concentration of the mentioned deep levels are responsible for the generation of charge carriers [

14,

15].

However, despite the study of defects in silicon and on its surface [

16], it remains unclear which levels of them may be responsible for the occurrence of TVE. From a fundamental point of view, the question of the possible spatial localization of these defects remains open. From a practical point of view, it is very important to assess the possibilities of instrumental influence on the conditions and degree of manifestation of TVE, both for creating relatively inexpensive TEC based on various waste semiconductor materials, and for realizing the possibility of increasing the efficiency of such TEC, the limiting value of which, according to [

5], is ~70%.

In this regard, we, as another method of influencing TVE, studied the influence of neutron treatment on the generation processes of charge carriers in Si-Ge/Si film p-n structures obtained by gas-phase epitaxy, the films in which, like all germanium-silicon alloys, themselves, are considered a promising material for the manufacture of thermoelectric converters [

17].

Experimental studies of the effect of neutron irradiation on TVE were carried out both on silicon-germanium films doped during the growth process with an isovalent Ti impurity to a concentration of ~10

20 cm

-3, and on samples without doping. Si-Ge/Si structures were obtained by gas-phase epitaxy under conditions similar to [

18,

19], in the SiCl

4-GeCl

4-H

2 and SiCl

4-GeCl

4-TiCl

4-H

2 systems on KDB-10 Si substrates with (111) orientation. The conditions for growing Si-Ge layers excluded the ingress of uncontrolled impurities into them, especially those that could, like specially introduced titanium, give deep energy levels [

20,

21].

Microscopic studies using standard techniques of deposited silicon-germanium films show that they are homogeneous and have thicknesses ranging from 8 to 10 microns. Next, we measured the dark currents and voltages generated when these structures were heated in the temperature range of 300–900 K. The measurements were carried out using a method similar to [

22], when placing macroscopic titanium clamping contacts on the free surface of the Si-Ge:Ti film and on the back side Si substrate, from which the heat was supplied. Then these structures were irradiated with thermal neutrons for 600 s until the dose reached 4*10

16 cm

-2. After irradiation, the parameters of these films were measured in the specified temperature range after 38 days.

Results and Discussion

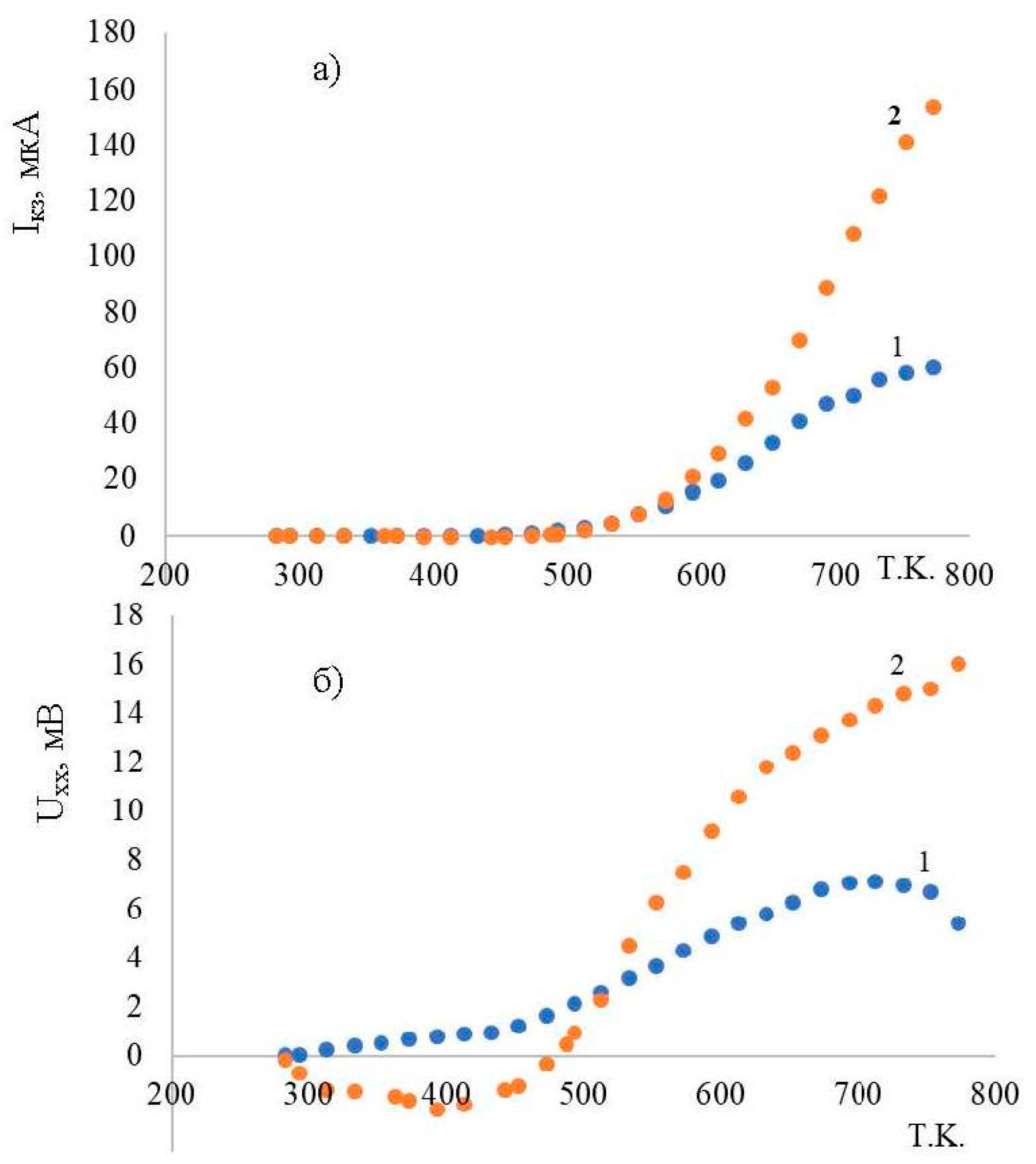

The studies performed show that neutron irradiation significantly affects the magnitude of the dark short circuit current and voltage that occurs during heating, as well as the resistance of structures. As a typical example,

Figure 1 shows graphs of the temperature change in open-circuit voltage (U

oc) and dark short-circuit current (I

sc), which arise when heating, respectively, unirradiated and irradiated samples of Si-Ge:Ti / Si film structures, that is, with films alloyed with titanium.

Analyzing the results obtained and comparing them, including with data from previously conducted studies, we note the following:

1) Neutron irradiation, like irradiation with

60Co γ-quanta [

11,

12] and ion surface treatment [

13], leads to increased generation of currents during heating (

Figure 1a). As in previous cases, this effect for neutron exposure is more pronounced in silicon-germanium films doped with titanium, i.e. those initially containing a greater number of defects in their own structure. This is manifested, in particular, in a clear, from 40% to 2 times, excess of the values of (U

oc) and (I

sc) measured on these heated structures, compared with those observed on similarly heated structures, the films of which are not doped with titanium impurities. This conclusion correlates with previously identified patterns of TVE manifestation. Thus, the effect begins to manifest itself upon the transition from film epitaxial to defective epitaxial, but still single-crystalline p-n structures, clearly intensifies upon transition to film polycrystalline structures, then intensifies when used as substrates for growing wafer structures made from SCPS ingots, characterized by a specific structural defects and (or) containing deep impurities, which can transfer into the growing film due to diffusion and self-doping and are further enhanced by the induction of various radiation defects into them. The effect, as mentioned above, can also manifest itself on single-crystal structures if the latter are subjected to electron irradiation or alkali metal ions are introduced into them by ion implantation, but the defects are not annealed.

2) Neutron irradiation leads to a double change in the open-circuit voltage (U

oc) (

Figure 1b) for heated structures, in contrast to the results obtained on similar structures, but subjected to γ-irradiation [

11,

12] or ion treatment [

13], indicating a very minor effect of heating. Thus, in the heating temperature range up to ~ 500 K, a decrease in (U

oc) is observed, followed by its increase with increasing temperature up to a ~3-fold increase in this parameter for neutron-irradiated structures (2) compared to non-irradiated ones (1) at temperatures above 750 K.

3) Repeated measurements carried out on the same samples 30 days after the first ones showed that the value of the generated current and the resulting emf practically did not change, while for samples subjected to γ-irradiation and ion treatment, after heating in the above temperature range, the values current decreased and actually returned to the original ones, i.e. to those observed before irradiation. In fact, thermal annealing of radiation-induced defects took place.

Conclusions

The results obtained indicate that all types of defects, both structural and associated with doping impurities, as well as with the methods of their introduction into the semiconductor, accompanied by disruption of the crystal structure, contribute to the manifestation of the thermal-voltaic effect, that is, they are responsible for the generation of charge carriers in heated semiconductors with the participation of deep energy levels, the appearance of which in the band gap is precisely due to these defects. In this case, a more significant role in a polycrystalline material is played not by its own structural defects, but by external radiation exposure, which, as a rule, leads to an intensification of the effect, that is, to a significant increase in voltages and dark currents that arise during heating.

From a practical point of view, the results obtained indicate the need for further research on the use of radiation technologies in a much wider range of radiation doses to create effective TECs based on silicon materials that convert the infrared component of solar radiation and thermal energy of natural or man-made origin into electricity.

References

- B.M.Abdurakhmanov, M.KH. B.M.Abdurakhmanov, M.KH.Ashurov, KH.B.Ashurov et al., Problemy i perspektivy kremnievogo proizvodstva v Tsentral’noj Azii [Problems and prospects of silicon production in Central Asia],—Khudzhand: «Nuri ma”rifat», 2016, 420 p. (in Russian).

- A.L.Kadyrov, Poluchenie i svojstva vtorichnogo litogo polikristallicheskogo kremniya [Obtaining and properties of secondary cast polycrystalline silicon],—Khudzhand: «Nuri ma”rifat», 2018, 396 p. (in Russian).

- B.M.Abdurakhmanov, «Modernizatsiya ehlektrodugovogo protsessa vosstanovleniya kremniya i sozdanie ehlektronnykh ustrojstv na ego osnove» [Modernization of the electric arc process of silicon reduction and the creation of electronic devices based on it], PhD thesis,—Tashkent: 2021, 49 p. (in Russian).

- A.V.Naumov, S.I. A.V.Naumov, S.I.Plekhanov, «O syr’evykh ogranicheniyakh razvitiya solnechnoj ehnergetiki v 2012-2020 gg.» [On raw materials limitations for the development of solar energy in 2012-2020], Proceedings of the IX Intern.Conf. “Silicon 2012”,—St. Petersburg, 2012, p 12 (in Russian).

- Abdullin, K.A.; Mukashev, B.N. «Vacancy defects in silicon single crystals bombarded at 77 K». Semiconductors 1995, 29, 169–174. [Google Scholar]

- Watrins, G.D.; Troxell, J.R. Negative-U Properties for Point Defects in Silicon. Phys. Rev. Lett. 1980, 44, 593–595. [Google Scholar] [CrossRef]

- M.S.Saidov, «Vozmozhnye poluprovodnikovye nepreryvnye tverdye rastvory dlya termofotoehlektricheskikh ehlementov» [Possible Semiconductor Continuous Solid Solutions for Thermophotovoltaic Cells], Geliotecjnika (Solar Engineering), No 3, pp. 52–58, 1999. (in Russian).

- Saidov, M.S.; Abdurakhmanov, B.M.; Olimov, L.O. Impurity Thermovoltaic Effect in the Grain Boundaries of a Polycrystalline Silicon Solar Cell. Applied Solar Energy 2007, 43, 203–206. [Google Scholar] [CrossRef]

- Saidov, A.S.; Abakumov, A.A.; Saidov, M.S.; Usmonov, S.N.; Kholikov, K.T. Thermovoltaic Properties of Technical Silicon Melted by Solar Radiation. Applied Solar Energy 2007, 43, 266–267. [Google Scholar] [CrossRef]

- L.O. Olimov, “Granular boundaries in polycrystalline silicon, microstructure, charge states and p-n transitions”, DSc. thesis,—Tashkent: 2017, 52 p. (in Russian).

- Abdurakhmanov, B.M.; Ashurov, M.K.; Ashurov, K.B.; Kuchkanov, S.K.; Maksimov, S.E.; Nimatov, S.J. Defekty i teplovol’taicheskij ehffekt v plyonochnykh kremnievykh p-n strukturakh, poluchennykh vakuumnym osazhdeniem [Defects and thermovoltaic effect in silicon p-n-- film structures obtained by vacuum deposition]. Uzbek Journal of Physics 2014, 16, 219–224. (in Russian).

- Sh.K.Kuchkanov, Kh.B. Sh.K.Kuchkanov, Kh.B.Ashurov, B.M.Abdurakhmanov, M.M.Adilov, S.E.Maksimov, S.Zh.Nimatov, “Defekty struktury i teplovol’taicheskij ehffekt v plyonkakh Si-Ge:Ti/Si, poluchennykh gazofaznoj ehpitaksiej” [Structural defects and thermal voltage effect in Si-Ge:Ti/Si films obtained by gas-phase epitaxy], Eighth International Conference on Physical Electronics IPEC-8 -24, 2021 Tashkent, Uzbekistan. Book of abstracts. pp. 112–113, 2021 (in Russian). 23 September.

- Sh.K.Kuchkanov, M.M. Sh.K.Kuchkanov, M.M.Adilov, A.I.Kamardin, S.E.Maksimov, Sh.T.Khojiev, Kh.B.Ashurov, “Thermal voltaic effect in Si-Ge/Si and Si-Ge/Si film structures subjec.ted to ion treatmen”, Applied Solar Energy, vol.58, No.3, pp.355–359, 2022. [CrossRef]

- Asgerov, E.B.; Beskrovnyy, A.I.; Doroshkevich, N.V.; Mita, C.; Mardare, D.M.; Chicea, D.; Lazar, M.D.; Tatarinova, A.A.; Lyubchyk, S.I.; Lyubchyk, S.B.; Lyubchyk, A.I.; Doroshkevich, A.S. Reversible Martensitic Phase Transition in Yttrium-Stabilized ZrO2 Nanopowders by Adsorption of Water (2022) Nanomaterials, 12(3), 435. [CrossRef]

- A.Lyubchyk, S.A. A.Lyubchyk, S.A. Filonovich, T. Mateus, M.J. Mendes, A. Vicente, J.P. Leitão, B.P. Falcão, E. Fortunato, H. Águas, R. Martins, Nanocrystalline thin film silicon solar cells: A deeper look into p/i interface formation, Thin Solid Films, vol. 591, pp. 25–31, 2015. [CrossRef]

- Vavilov, V.S.; Kiselev, V.F.; Mukashev, B.N. Defekty v kremnii i na ego poverkhnosti [Bulk and Surface Defects in Silicon]; Moscow: Nauka, 1990. (in Russian) [Google Scholar]

- Kuznetsov, B.N. , Chesnokov, N.V., Mikova, N.M., Drozdov, V.A., Shendrik, T.G., Lyubchik, S.B., Fonseca, I.M. Properties of palladium catalysts on carbon supports prepared from chemically modified and activated anthracites. (2004) Reaction Kinetics and Catalysis Letters, 83 (2), pp. 361–367. [CrossRef]

- K.L. Lyutovich, Zh.T. K.L. Lyutovich, Zh.T. Abdurakhmanov, L.L. Lukashevich, I.V. Drachuk, “Issledovanie morfologiya ehpitaksial’nykh sloev tverdykh rastvorov GekhSi1-kh” [Investigation of the morphology of epitaxial layers of GeхSi1-х solid solutions], Uzbek Journal of Physics, No 2, pp. 31–34, 1997 (in Russian).

- Zh.T.Abdurakhmanov, I.V. Zh.T.Abdurakhmanov, I.V.Drachuk, K.L.Lyutovich, “Gazofaznoe osazhdenie ehpitaksial’nykh sloev tverdykh rastvorov GexSi1-x legirovannykh titanom” [Vapour-phase deposition of epitaxial layers of titanium alloyed GexSi1-x solid solutions], Uzbek Journal of Physics, No 5-6, pp. 74–77, 1997 (in Russian).

- Kuznetsov, B.N. , Chesnokov, N.V., Mikova, N.M., Zaikovskii, V.I., Drozdov, V.A., Savos’kin, M.V., Yaroshenko, A.M., Lyubchik, S.B. Texture and catalytic properties of palladium supported on thermally expanded natural graphite (2003) Reaction Kinetics and Catalysis Letters, 80 (2), pp. [CrossRef]

- Lyubchik, S.B. , Perepichka, I.I., Galushko, O.L., Lyubchik, A.I., Lygina, E.S., Fonseca, I.M. Optimization of the conditions for the Cr (III) adsorption on activated carbon (2005) Adsorption, 11 (5-6), pp. 581–593. [CrossRef]

- Sh.K. Kuchkanov, Kh.B. Sh.K. Kuchkanov, Kh.B. Ashurov, “Generation of Charge Carriers in Uniformly Heated Si–Ge Films Heavily Doped with Titanium”, Technical Physics Letters, vol. 44, No. 4, pp. 334–336, 2018. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).