Submitted:

10 October 2023

Posted:

11 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

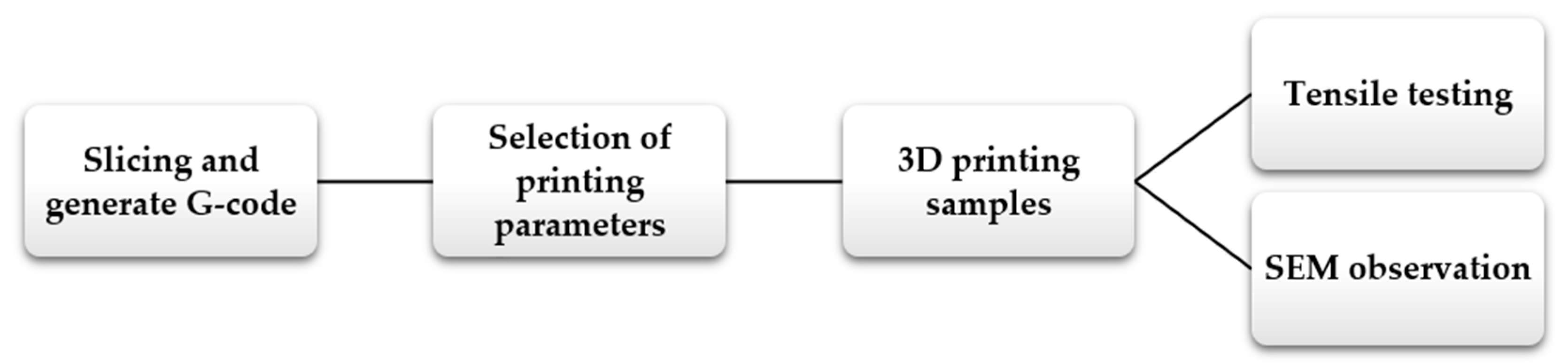

2. Materials and Methods

2.1. Filaments and printing parameters

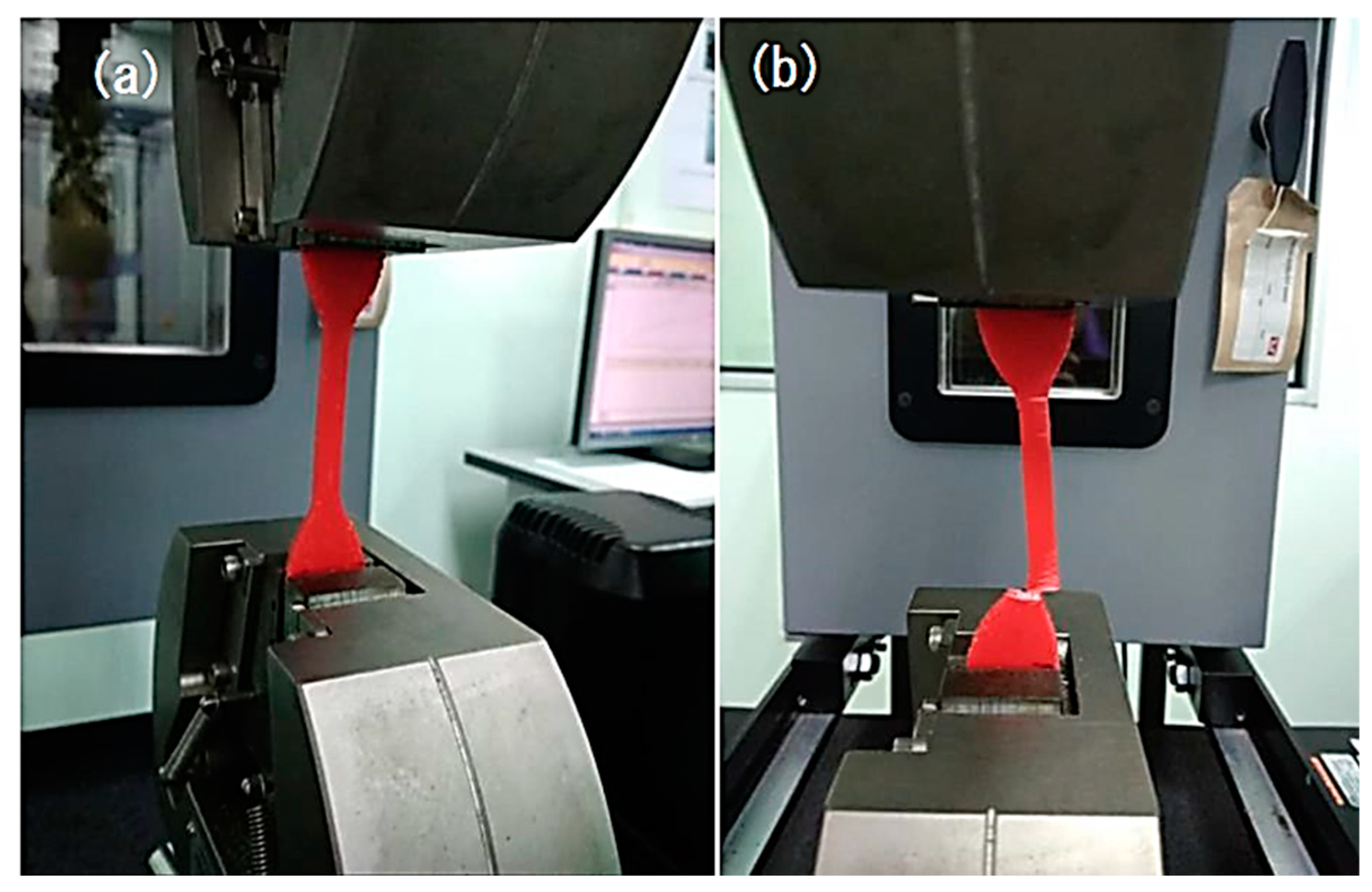

2.2. Tensile testing

2.3. Scanning electron microscope (SEM)

2.4. Analysis of variance (ANOVA)

3. Results and discussion

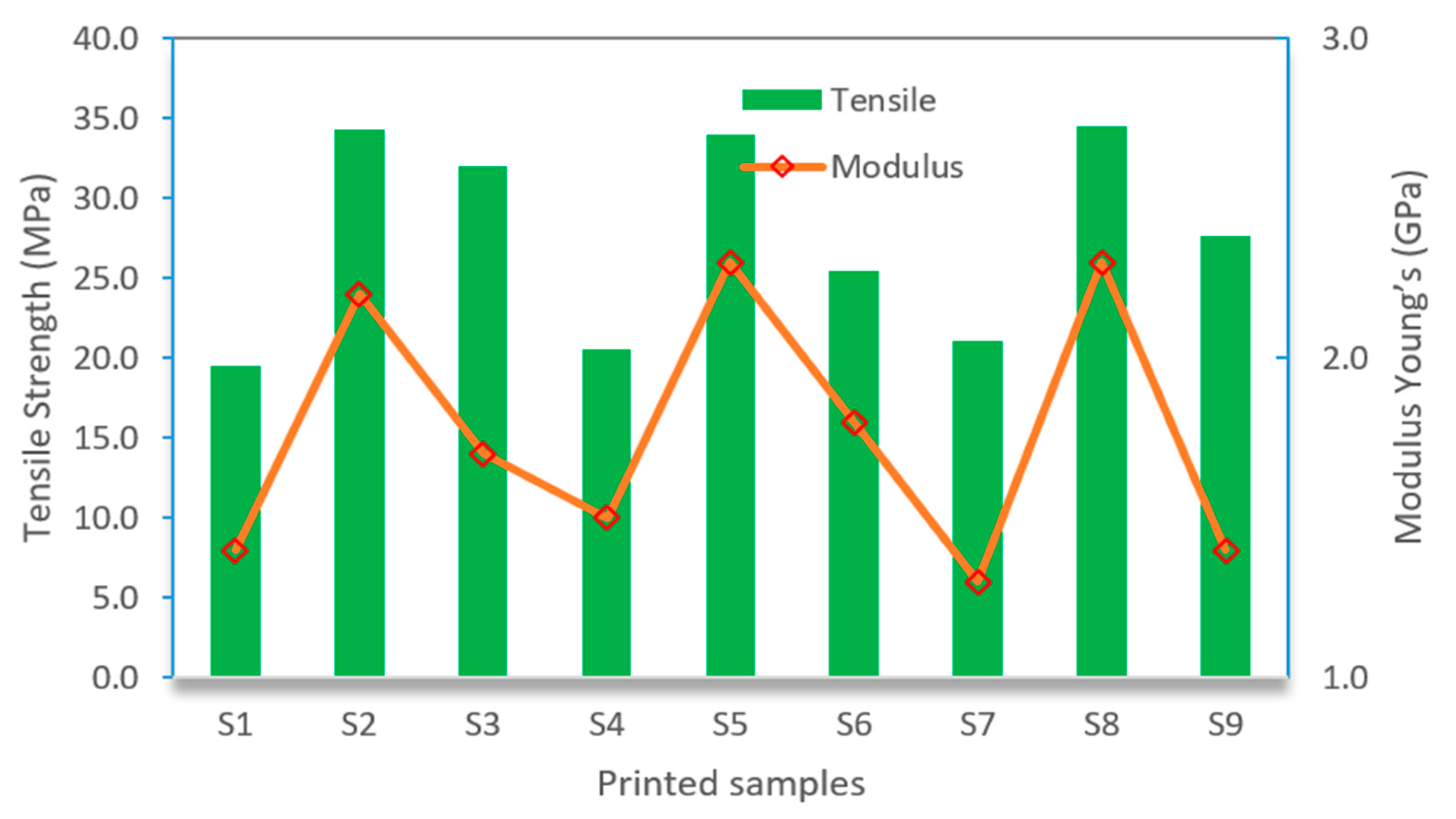

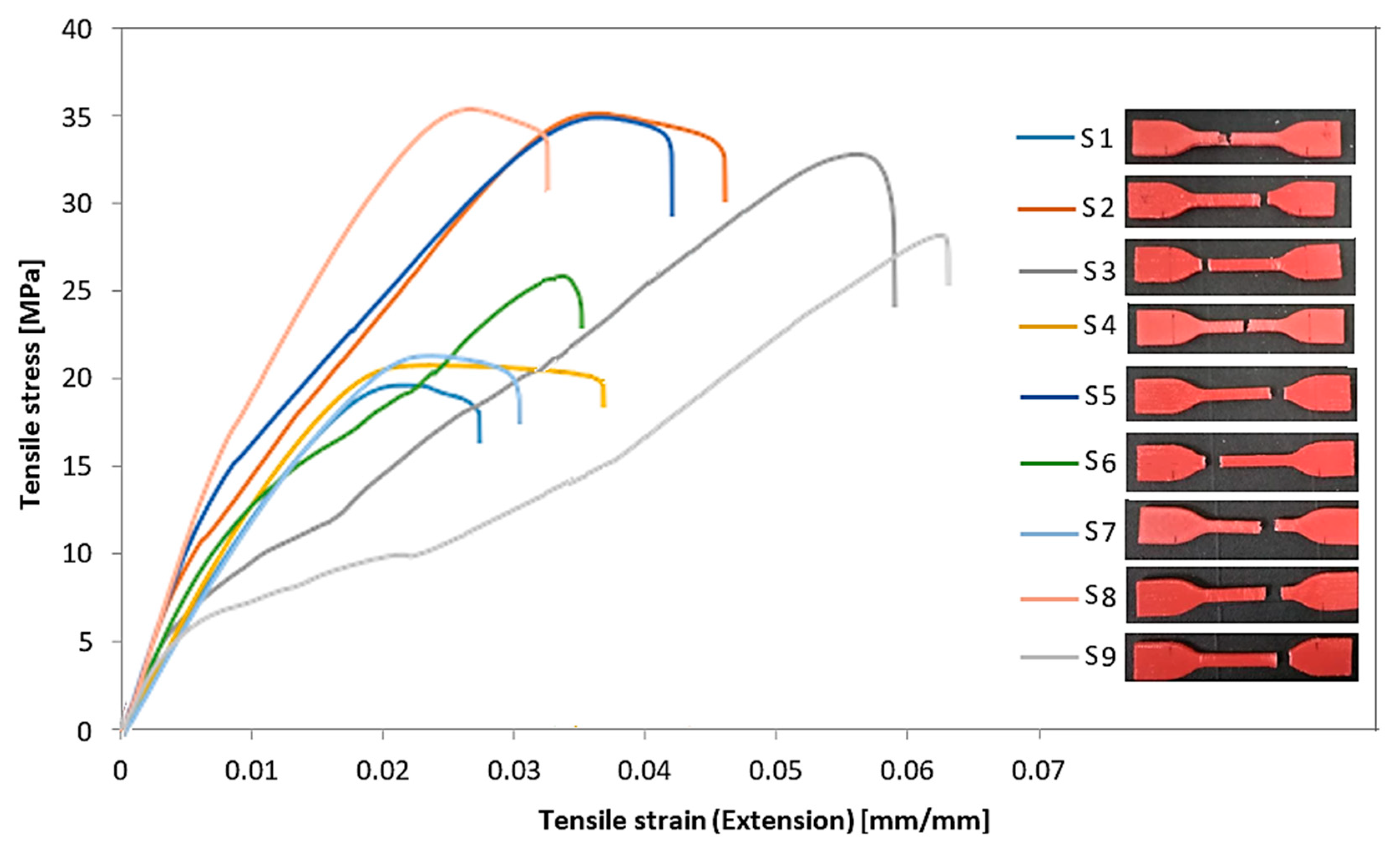

3.1. Mechanical properties

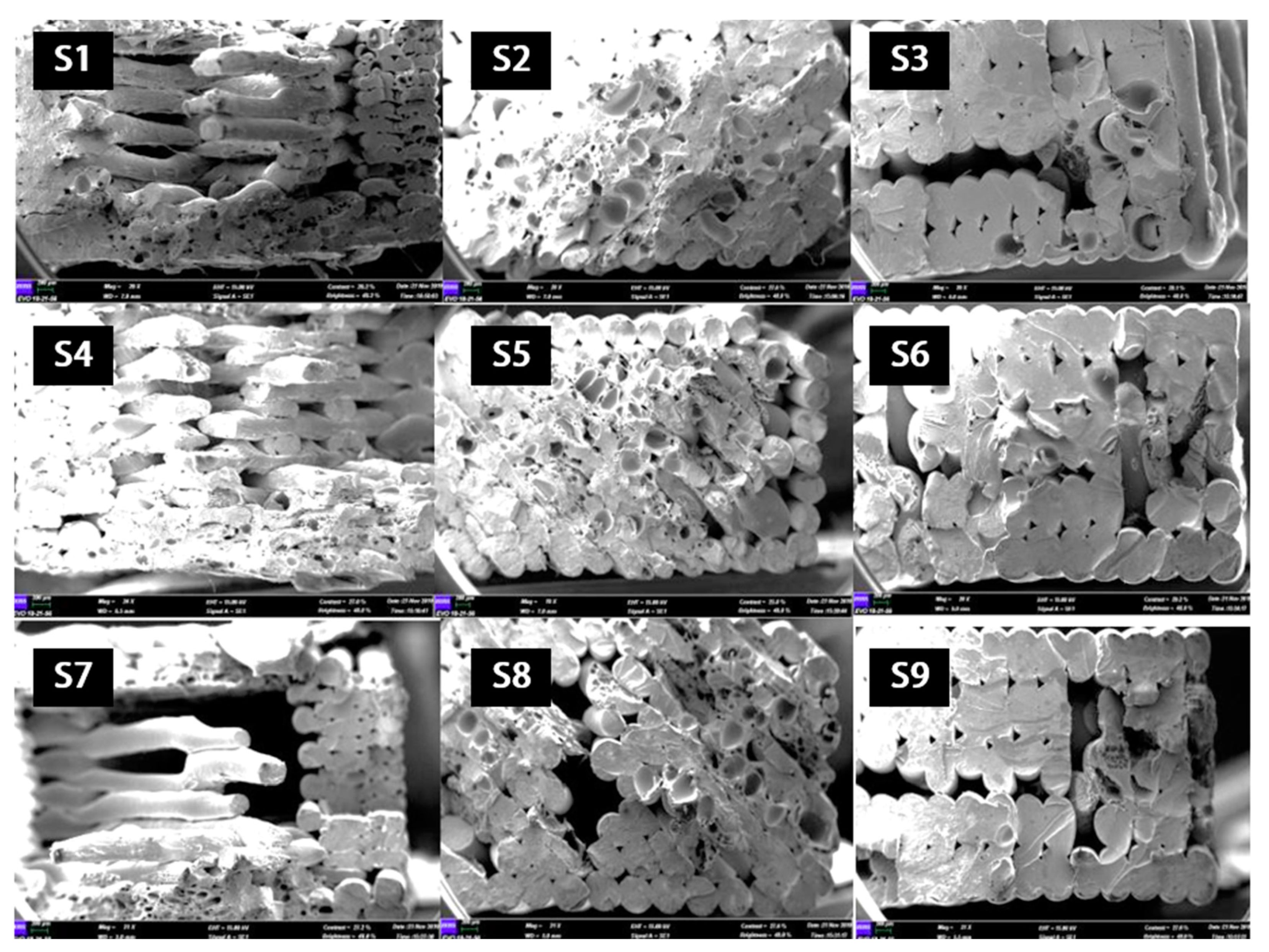

3.2. Morphological analysis

3.3. Analysis of variance (ANOVA)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- G. Liu, et al., ‘‘Additive manufacturing of structural materials,” Materials Science and Engineering R: Reports, vol. 145. Elsevier Ltd, Jul. 01, 2021.

- M. Javaid, A. M. Javaid, A. Haleem, R. P. Singh, R. Suman, and S. Rab, ‘‘Role of additive manufacturing applications towards environmental sustainability,” Advanced Industrial and Engineering Polymer Research, vol. 4, no. 4. KeAi Communications Co., pp. 312–322, Oct. 01, 2021.

- Wang X, Jiang M, Zhou Z, Gou J, Hui D (2017) 3D printing of polymer matrix composites: a review and prospective. Compos Part B Eng 110:442–458.

- Bai X, Wu J, Liu Y, Xu Y, Yang D (2020) Exploring the characteristics of 3D printing global industry chain and value chain innovation network. Inf Dev 36(4):559–575.

- Vialva T (2020) 3D hubs 3D Printing trends report forecasts 24% growth in 3D printing industry over 5 years - 3D printing industry. https:// 3dprinting industry. 1679.

- Jain, A.; Mathur, T.; Pandian, N.K.; Selahi, A. Organ-on-a-chip and 3D printing as preclinical models for medical research and practice. In Precision Medicine for Investigators, Practitioners and Providers; Chapter 9; Elsevier Ltd.: Duxford, UK, 2020; pp. 83–95. [Google Scholar]

- Durfee, K.; Iaizzo, P.A. Medical Applications of 3D Printing. In Engineering in Medicine; Chapter 21; Elsevier Ltd.: Duxford, UK, 2019; pp. 495–509. [Google Scholar]

- Rouf, S.; Malik, A.; Singh, N.; Raina, A.; Naveed, N.; Siddiqui, M.I.H.; Haq, M.I.U. Additive manufacturing technologies: Industrial and medical applications. Sustain. Oper. Comput. 2022, 3, 258–274. [Google Scholar] [CrossRef]

- Ahmad, M. N. , Ishak, M. R., Mohammad Taha, M., Mustapha, F., & Leman, Z. (2023). A Review of Natural Fiber-Based Filaments for 3D Printing: Filament Fabrication and Characterization. Materials, 16(11), 4052.

- Jayawardane H, Davies IJ, Leadbeater G, John M, Biswas WK (2021) 'Techno-eco-efficiency' performance of 3D printed impellers: an application of life cycle assessment. International Journal of Sustainable Manufacturing.

- Maguluri N, Suresh G, Rao KV (2023) Assessing the effect of FDM processing parameters on mechanical properties of PLA parts using Taguchi method. 1: Journal of Thermoplastic Composite Materials 36, 1472.

- Jayawardane H, Davies IJ, Gamage JR, John M, Biswas WK (2022) Investigating the ‘techno-eco-efficiency’ performance of pump impellers: metal 3D printing vs. CNC machining. 6: The International Journal of Advanced Manufacturing Technology 121, 6811.

- Kumaresan, R.; Samykano, M.; Kadirgama, K.; Sharuzi, W.; Harun, W.; Rahman, M. Fused deposition modeling: Process, materials, parameters, properties, and applications. Int. J. Adv. Manuf. Technol. 2022, 120, 1531–1570. [Google Scholar]

- Sabil M, Prabhakar DAP (2022) Optimisation of Extrusion Temperature and Infill Density of PLA material by using L16 Orthogonal Array. 1: Australian Journal of Mechanical Engineering.

- Hikmat M, Rostam S, Ahmed YM (2021) Investigation of tensile property-based Taguchi method of PLA parts fabricated by FDM 3D printing technology. 1: Results in Engineering 11, 1002.

- Ahmad, M. N., Tarmeze, A. A., Rasib, A. H. A. (2020). Capability of 3D printing technology in producing molar teeth prototype. Int. J. Eng. Appl, 8, 64.

- Ahmad, M. N. , & Mohamad, A. R. (2021). Analysis on dimensional accuracy of 3D printed parts by Taguchi approach. In Advances in Mechatronics, Manufacturing, and Mechanical Engineering: Selected articles from MUCET 2019 (pp. 219-231). Springer Singapore.

- M. Heidari-Rarani, N. M. Heidari-Rarani, N. Ezati, P. Sadeghi, Badrossamay M. (2020) Optimization of FDM process parameters for tensile properties of polylactic acid specimens using Taguchi design of experiment method: Journal of Thermoplastic Composite Materials. pp. 2435-2452.

- K. E. Aslani, D. Chaidas, J. Kechagias et al. (2020) Quality Performance Evaluation of Thin Walled PLA 3D Printed Parts Using the Taguchi Method and Grey Relational Analysis: J. Manuf. Mater. Process. 2020, 4, 47.

- Sharma M, Sharma V, Kala P (2019) Optimization of process variables to improve the mechanical properties of FDM structures. 0: J Phys: Conf Ser 1240, 1240.

- Vicente C, Martins T, Leite M, Ribeiro A, Reis L (2019) Influence of fused deposition modeling parameters on the mechanical properties of ABS parts. 5: Polym Adv Technol 31(3).

- Gurrala PK, Regalla SP (2012) Optimization of support material and build time in fused deposition modeling (FDM). 2: Appl Mech Mater 110–116, 2245.

- Nancharaiah T, Raju DR, Raju VR (2010) An experimental investigation on surface quality and dimensional accuracy of FDM components. 1: Int J Emerg Technol 1(2).

- Nabipour M, Akhoundi B, Bagheri Saed A (2019) Manufacturing of polymer/metal composites by fused deposition modeling process with polyethylene. J Appl Polym Sci 48717:1–9.

- Letcher T, Waytashek M (2016) Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer. InASME International Mechanical Engineering Congress and Exposition pp.

- Türk DA, Brenni F, Zogg M, Meboldt M (2017) Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing. Mater Des 118:256–265.

- Shojib Hossain M, Espalin D, Ramos J, Perez M, Wicker R (2014) Improved mechanical properties of fused deposition modeling-manufactured parts through build parameter modifications. J. Manuf. Sci. Eng. Trans.

- Fatimatuzahraa AW, Farahaina B, Yusoff WA (2011) The effect of employing different raster orientations on the mechanical properties and microstructure of Fused Deposition Modeling parts. 2011 IEEE Symposium on Business, Engineering and Industrial Applications (ISBEIA 2011).

- Atakok, G. , Kam, M., & Koc, H. B. (2022). Tensile, three-point bending and impact strength of 3D printed parts using PLA and recycled PLA filaments: A statistical investigation. Journal of Materials Research and Technology, 18, 1542-1554.

- Lyu, Y. , Zhao, H., Wen, X., Lin, L., Schlarb, A. K., & Shi, X. (2021). Optimization of 3D printing parameters for high-performance biodegradable materials. Journal of Applied Polymer Science, 138(32), 50782.

- Retolaza, J., Gondra, K., Ansola, R., Allue, A. (2022). Mechanical research to optimize parameter selection for PPS material processed by FDM. Materials and Manufacturing Processes, 37(11), 1332-1338.

- ASTM D638 (2003) Standard test method for tensile properties of plastics. ASTM International, West Conshohocken, PA.

- Ahmad, M. N. , Ishak, M. R., Mohammad Taha, M., Mustapha, F., Leman, Z., Anak Lukista, D. D. & Ghazali, I. (2022). Application of taguchi method to optimize the parameter of fused deposition modeling (FDM) using oil palm fiber reinforced thermoplastic composites. Polymers, 14(11), 2140.

- Rankouhi B, Javadpour S, Delfanian F, Letcher T (2016) Failure analysis and mechanical characterization of 3D printed ABS with respect to layer thickness and orientation. 4: J Fail Anal Prev 16(3).

- Shergill, K. , Chen, Y., & Bull, S. (2023). An investigation into the layer thickness effect on the mechanical properties of additively manufactured polymers: PLA and ABS. The International Journal of Advanced Manufacturing Technology, 126(7-8), 3651-3665.

- Shashikumar, S. , & Sreekanth, M. S. (2023). The effect of printing parameters on tensile properties of thermoplastics prepared by fused deposition modeling (FDM) based additive manufacturing technique. Materials Today: Proceedings.

- Galeski, strength and toughness of crystalline polymer systems, Progress In Polymer Science (Oxford) 28(12) (Dec.2003)1643–1699. 1643–1699.

- . Owolabi et al., ‘‘Dynamic response of acrylonitrile butadiene styrene under impact loading”, International Journal of Mechanical and Materials, Engineering 11 (1) (2016).

- Casavola, C. , Cazzato, A., Moramarco, V., & Renna, G. (2019). Mechanical behaviour of ABS-Fused Filament Fabrication compounds under impact tensile loadings. Materials, 12(8), 1295.

- Chen, W. H. , Uribe, M. C., Kwon, E. E., Lin, K. Y. A., Park, Y. K., Ding, L., & Saw, L. H. (2022). A comprehensive review of thermoelectric generation optimization by statistical approach: Taguchi method, analysis of variance (ANOVA), and response surface methodology (RSM). Renewable and Sustainable Energy Reviews, 169, 112917.

| No. | Infill pattern | Orientation (°) | Thickness (mm) | Speed (cm3/h) |

| 1 | Loose | 0° | 0.2 | Fine |

| 2 | 45° | 0.3 | Normal | |

| 3 | 90° | 0.4 | Fast | |

| 4 | Solid | 0° | 0.2 | Fine |

| 5 | 45° | 0.3 | Normal | |

| 6 | 90° | 0.4 | Fast | |

| 7 | Hollow | 0° | 0.2 | Fine |

| 8 | 45° | 0.3 | Normal | |

| 9 | 90° | 0.4 | Fast |

| Response | Source | DF | SS | MS | F-value | P-value | Significant (Yes/No) |

|---|---|---|---|---|---|---|---|

| Tensile strength | Infill | 2 | 5.5 | 2.8 | 0.05 | 0.948 | No |

| Orientation | 2 | 290.83 | 145.41 | 36.17 | 0.000 | Yes | |

| Thickness | 2 | 10.2 | 5.1 | 0.10 | 0.906 | No | |

| Speed | 2 | 8.4 | 4.2 | 0,08 | 0.922 | No | |

| Error | 6 | 24.12 | 4.02 | ||||

| Total | 8 | 314.95 | |||||

| Young’s modulus | Infill | 2 | 0.05 | 0.03 | 0.13 | 0.880 | No |

| Orientation | 2 | 1.19 | 0.60 | 32.06 | 0.001 | Yes | |

| Thickness | 2 | 0.03 | 0.01 | 0.07 | 0.937 | No | |

| Speed | 2 | 0.03 | 0.02 | 0.07 | 0.935 | No | |

| Error | 6 | 1.25 | 0.21 | ||||

| Total | 8 | 1.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).