Submitted:

13 October 2023

Posted:

16 October 2023

You are already at the latest version

Abstract

Keywords:

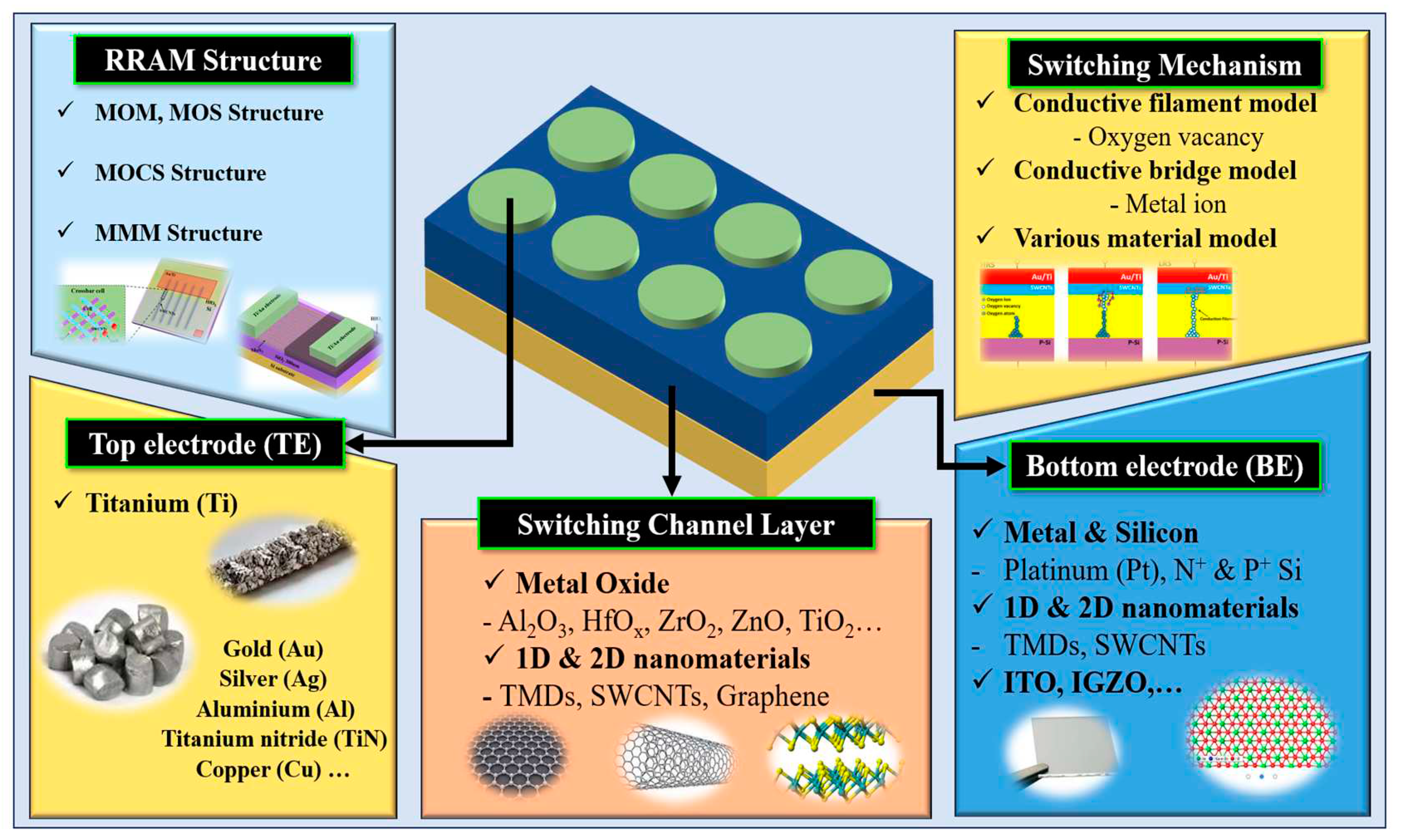

1. Introduction

2. Nanomaterials for Switching Layer

3. Experimental Details

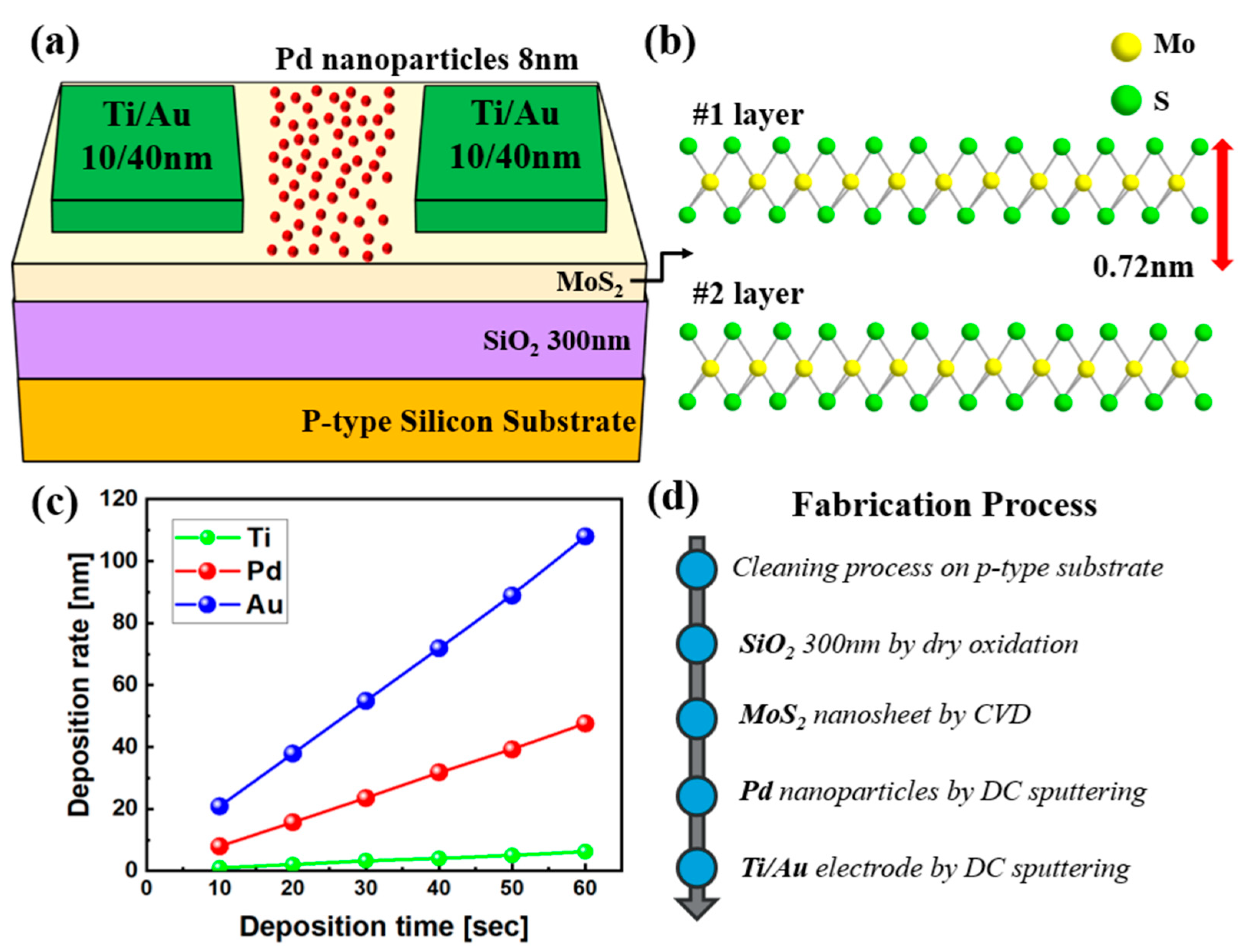

3.1. Fabrication Process

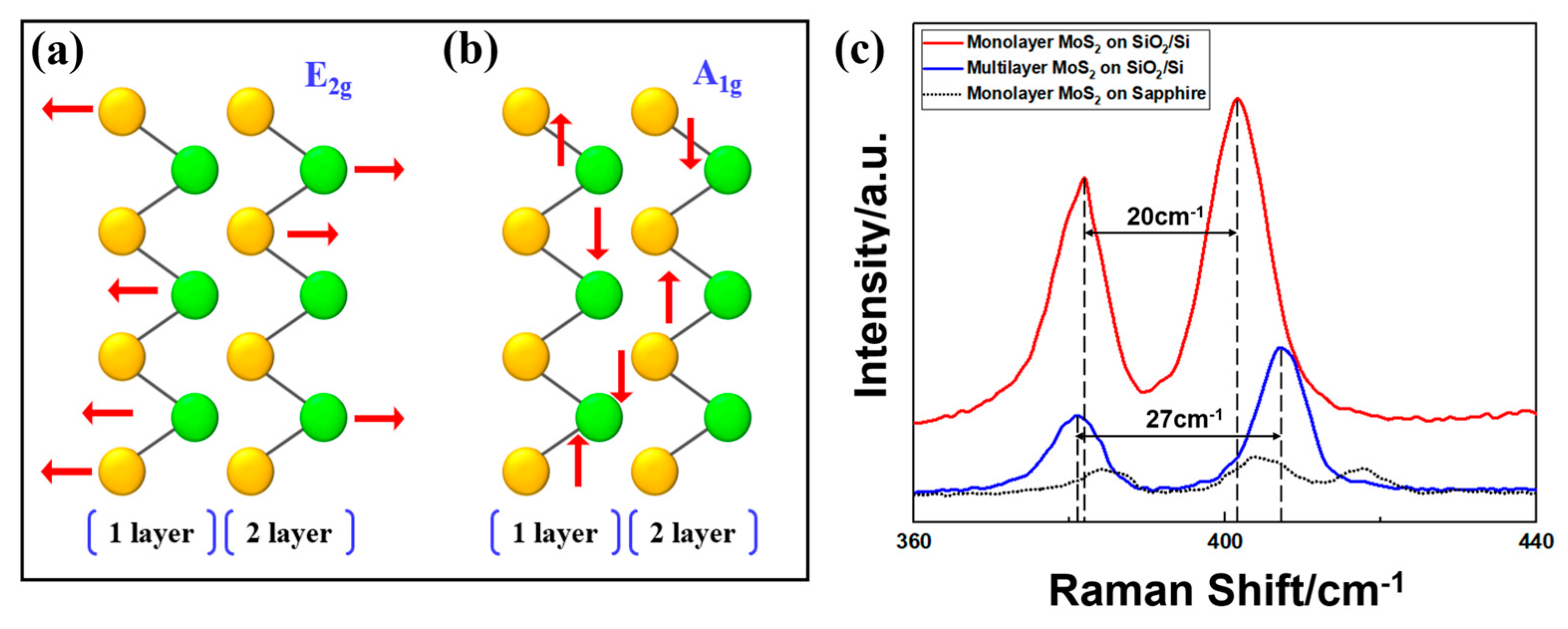

3.2. Raman Spectroscopy

3.3. Photoluminescence Mapping

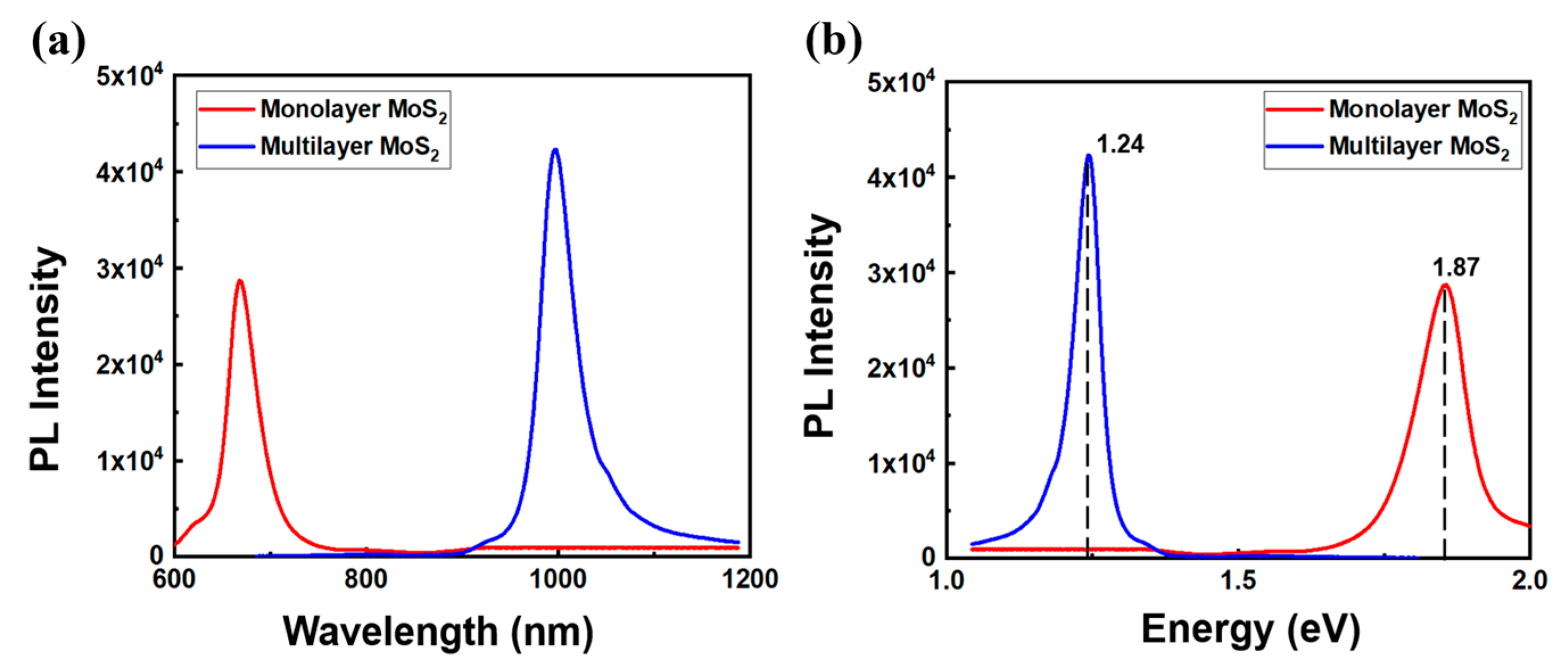

4. Results and Discussions

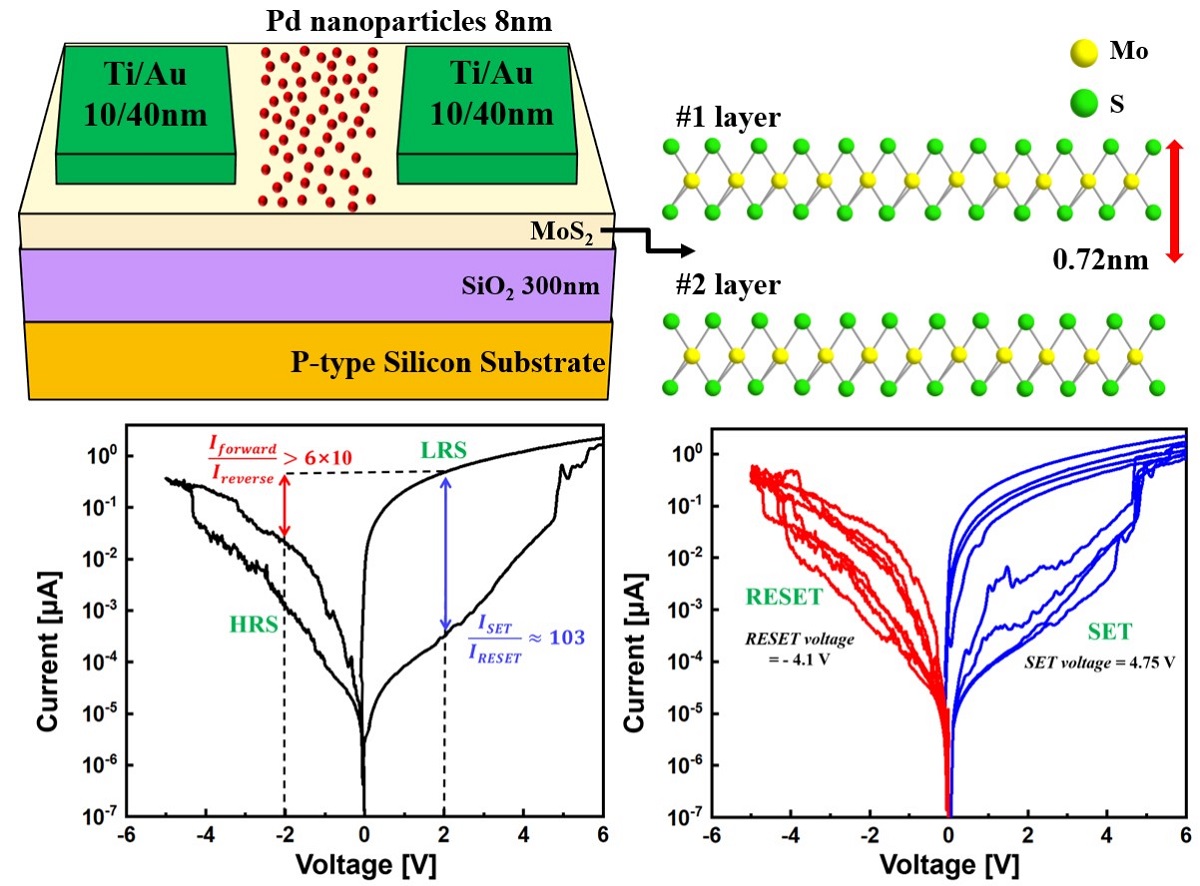

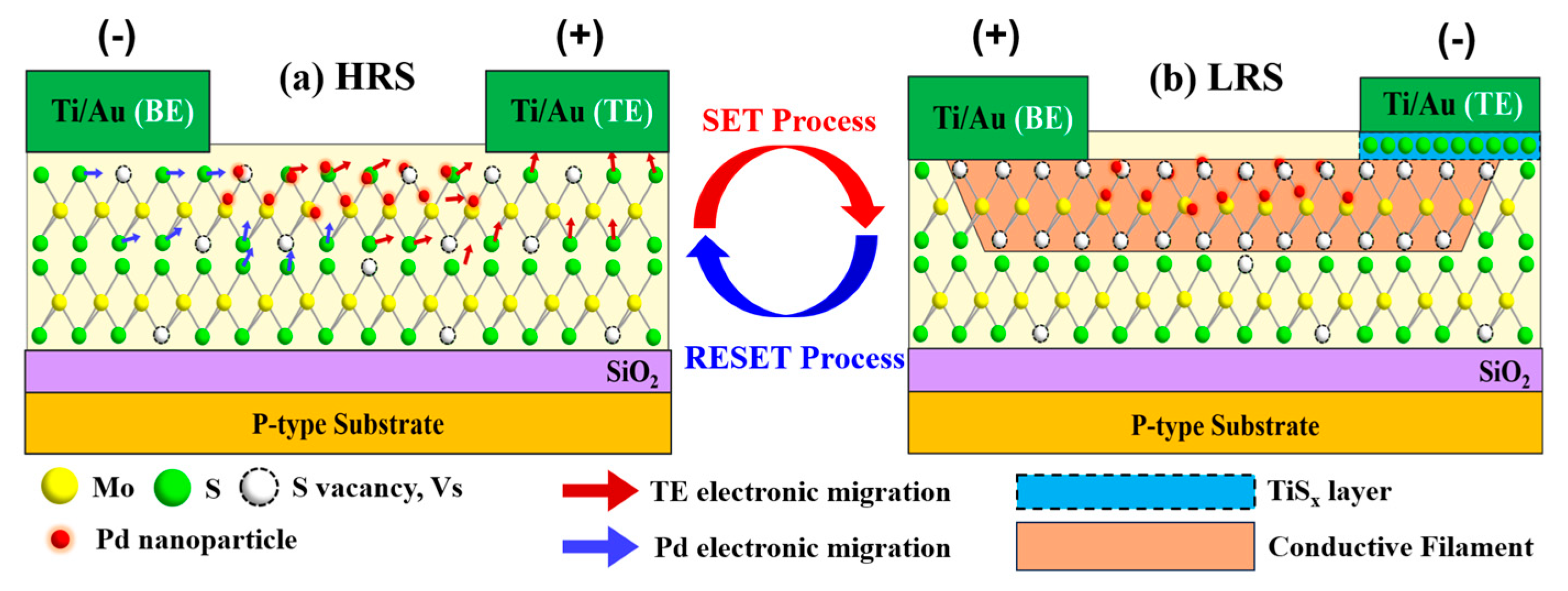

4.1. Resistive Switching Mechanisms

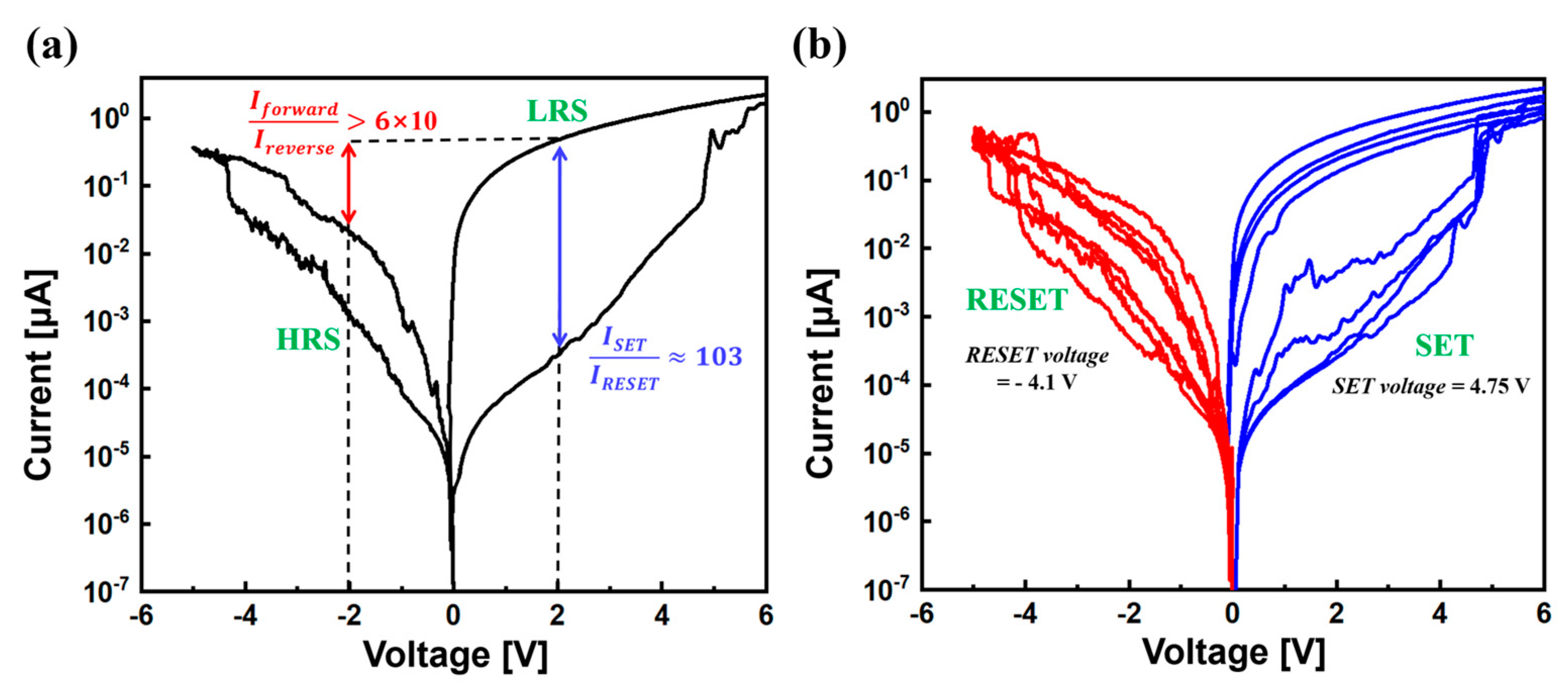

4.2. I-V Measurement

5. Conclusions

Acknowledgments

References

- Zhou, Jiantao, Kuk-Hwan Kim, and Wei Lu. “Crossbar RRAM arrays: Selector device requirements during read operation.” IEEE Transactions on Electron Devices 61.5 (2014): 1369-1376.

- Zhang, Leqi, et al. “On the optimal ON/OFF resistance ratio for resistive switching element in one-selector one-resistor crosspoint arrays.” IEEE Electron Device Letters 36.6 (2015): 570-572.

- Wang, Xue-Feng, et al. “Interface engineering with MoS2–Pd nanoparticles hybrid structure for a low voltage resistive switching memory.” Small 14.2 (2018): 1702525.

- Govoreanu, Bogdan, et al. “A-VMCO: A novel forming-free, self-rectifying, analog memory cell with low-current operation, nonfilamentary switching and excellent variability.” 2015 Symposium on VLSI Technology (VLSI Technology). IEEE, 2015.

- Luo, Qing, et al. “Self-rectifying and forming-free resistive-switching device for embedded memory application.” IEEE Electron Device Letters 39.5 (2018): 664-667.

- Chen, Ying-Chen, et al. “Analog synaptic behaviors in carbon-based self-selective RRAM for in-memory supervised learning.” 2021 IEEE 71st Electronic Components and Technology Conference (ECTC). IEEE, 2021.

- Bai, Yue, et al. “Stacked 3D RRAM array with graphene/CNT as edge electrodes.” Scientific reports 5.1 (2015): 13785.

- Ye, Cong, et al. “Physical mechanism and performance factors of metal oxide based resistive switching memory: a review.” Journal of Materials Science & Technology 32.1 (2016): 1-11.

- Mullani, Navaj, et al. “Improved resistive switching behavior of multiwalled carbon nanotube/TiO2 nanorods composite film by increased oxygen vacancy reservoir.” Materials Science in Semiconductor Processing 108 (2020): 104907.

- Ryu, Ji-Ho, and Sungjun Kim. “Artificial synaptic characteristics of TiO2/HfO2 memristor with self-rectifying switching for brain-inspired computing.” Chaos, Solitons & Fractals 140 (2020): 110236.

- Rodriguez-Fernandez, Alberto, et al. “Resistive switching with self-rectifying tunability and influence of the oxide layer thickness in Ni/HfO2/n+-Si RRAM devices.” IEEE Transactions on Electron Devices 64.8 (2017): 3159-3166.

- Ryu, Hojeong, and Sungjun Kim. “Self-Rectifying Resistive Switching and Short-Term Memory Characteristics in Pt/HfO2/TaO x/TiN Artificial Synaptic Device.” Nanomaterials 10.11 (2020): 2159.

- Chand, Umesh, et al. “Mechanism of nonlinear switching in HfO2-based crossbar RRAM with inserting large bandgap tunneling barrier layer.” IEEE Transactions on Electron Devices 62.11 (2015): 3665-3670.

- Kim, Hee-Dong, Sungho Kim, and Min Ju Yun. “Self-rectifying resistive switching behavior observed in Al2O3-based resistive switching memory devices with p-AlGaN semiconductor bottom electrode.” Journal of Alloys and Compounds 742 (2018): 822-827.

- K. Young Lae, et al. “Voltage-switchable photocurrents in single-walled carbon nanotube silicon junctions for analog and digital optoelectronics,” Nature Photonics, Vol. 8, No. 3, pp. 239-243, 2014.

- Luo, Yifan, and Chao Zhang. “Pt-activated TiO2-MoS2 nanocomposites for H2 detection at low temperature.” Journal of Alloys and Compounds 747 (2018): 550-557.

- Bhattacharjee, Shubhadeep, et al. “Insights into multilevel resistive switching in monolayer MoS2.” ACS applied materials & interfaces 12.5 (2020): 6022-6029.

- Shi, Y. et al. Van der Waals epitaxy of MoS2 layers using graphene as growth templates. Nano letters 12, 2784–2791 (2012).

- Ma, X. & Shi, M. Thermal Evaporation Deposition of Few-layer MoS2 Films. Nano-Micro Letters 5 (2013).

- Lee, Changgu, et al. “Anomalous lattice vibrations of single-and few-layer MoS2.” ACS nano 4.5 (2010): 2695-2700.

- Han, Tao, et al. “Probing the optical properties of MoS2 on SiO2/Si and sapphire substrates.” Nanomaterials 9.5 (2019): 740.

- Chow, Philippe K., et al. “Wetting of mono and few-layered WS2 and MoS2 films supported on Si/SiO2 substrates.” ACS nano 9.3 (2015): 3023-3031.

- Han, Tao, et al. “Probing the optical properties of MoS2 on SiO2/Si and sapphire substrates.” Nanomaterials 9.5 (2019): 740.

- Rehman, Muhammad Muqeet, et al. “Decade of 2D-materials-based RRAM devices: a review.” Science and technology of advanced materials 21.1 (2020): 147-186.

- Ryu, Hojeong, and Sungjun Kim. “Self-Rectifying Resistive Switching and Short-Term Memory Characteristics in Pt/HfO2/TaO x/TiN Artificial Synaptic Device.” Nanomaterials 10.11 (2020): 2159.

- Li, Da, et al. “MoS2 memristors exhibiting variable switching characteristics toward biorealistic synaptic emulation.” ACS nano 12.9 (2018): 9240-9252.

- Liu, Lifu, et al. “Robust resistive switching in MoS2-based memristor with Ti top electrode.” Applied Surface Science 605 (2022): 154698.

- Monama, Nkwe Oscar. Electronic structure studies of pallandium sulphide (PdS) and platinum (pt) ternaries. Diss. University of Limpopo (Turfloop Campus), 2008.

- Bessonov, Alexander A., et al. “Layered memristive and memcapacitive switches for printable electronics.” Nature materials 14.2 (2015): 199-204.

- Sangwan, Vinod K., et al. “Gate-tunable memristive phenomena mediated by grain boundaries in single-layer MoS2.” Nature nanotechnology 10.5 (2015): 403-406.

| TE & BE | Switching layer | On/Off ratio | Rectifying ratio | Ref |

| ITO & ITO | HfOx/Pd-MoS2 | ≈ 102 | - | [3] |

| Au & Au | MoS2 | ≈ 105 | - | [17] |

| Au/Ti & Au/Ti | MoS2 | ≈ 101 | - | [26] |

| Ti & Pt | MoS2 | ≈ 102 | - | [27] |

| Ag & Ag | MoS2/MoOx | ≈ 106 | - | [29] |

| Au & TiN | HfOx/MoS2/TiOx | ≈ 106 | - | [30] |

| Au/Ti & Au/Ti | Pd-MoS2 | ≈ 103 | > 6 × 10 | This work. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).