1. Introduction

The global climate crisis is driven by global warming. It has been over seven years since the signing of the Paris Agreement, where the world committed to limiting the rise in the average global temperature to below 2 degrees Celsius compared to pre-industrial levels, with efforts to keep it well below 1.5 degrees Celsius, often hailed as the 'tipping point for the planet'[

1]. However, international efforts to achieve this agreement into action have been sluggish. Additionally, it is very difficult to predict the supply of renewable energy (referred to as alternative energy sources) due to its dependence on environmental conditions. Consequently, there is a shift towards adopting a diversified 'Energy Mix' approach, which encompasses various energy sources including solar and wind power, rather than being reliant on any single form of generation. As of 2021, wind power (6.6%) and solar power (3.6%) collectively exceeded a 10% share of the global total electricity production [

2]. Notably, the offshore wind energy potential in South Korea (annual generation equivalent) is estimated at around 119 TWh/yr, which accounts for more than 20% of the annual consumption strategy (553 TWh/yr in 2021) achievable solely through offshore wind power. The Levelized Cost of Electricity (LCOE) (LCOE(Levelized Cost of Electicty) : Numerical value of all costs incurred during the operation period of the power generation facility. ) for both offshore and onshore wind power generation has already demonstrated economic competitiveness surpassing that of fossil fuels (The LOCE for offshore wind power generation has declined from approximately 162 USD/MWh in 2010 to around 115 USD/MWh in 2019, reaching a level of competitiveness comparable to fossil fuel generation costs (109 USD/MWh))[

3]. Within the context of the 'Energy Mix', it is anticipated that simultaneous and sustainable growth will occur alongside various energy sources.

Offshore wind farms represent one of the most efficient zero-carbon energy production systems, capable of generating substantial and stable electricity in a relatively small area compared to other renewable energy sources. However, despite these advantages, their expansion has been hampered by the high expenses related to design, installation, construction-stage operation, grid connectivity, and the formidable challenges of foundation construction and system operation. Additionally, offshore wind farms tend to incur relatively higher generation costs when compared to onshore wind farms due to the costly offshore infrastructure and grid connection requirements [

4].

2. Literature Review

When reviewing previous research in the offshore wind farm industry, it becomes apparent that the majority of studies have concentrated on the structural efficiency analysis of installation vessels or addressed concerns regarding the installation and operation of offshore wind farms. Notably, there has been a limited number of prior studies dedicated to forecasting the demand for vital resources essential in the actual construction of offshore wind farms.

Walther, L., Münsterberg, T., and Brice, R.J. (2013) underscored the significance of selecting appropriate vessel concepts to streamline the installation process and ensure cost-efficiency. They advocated for a systematic approach to assess different installation vessel concepts, considering predetermined criteria. These criteria are likely to encompass aspects such as vessel capacity, dynamic positioning system, deck space, lifting capabilities, transit speed, weather resilience, and crew accommodations [

5].

On the other hand, Walker, R.T., Sewell, B.J., Morandeau, M., and Boswell, A. (2013) stressed the importance of minimizing installation risks to mitigate costly delays and accidents during offshore wind farm construction. The authors probably introduced various strategies for risk reduction, including enhanced vessel designs, optimized installation procedures, and improved safety measures [

6].

Kaiser, M.J., and Snyder, B.F. (2013), likely introduced a comprehensive model designed to evaluate offshore wind installation costs within the distinctive context of the US Outer Continental Shelf. They are expected to have taken into account a broad spectrum of factors, including sea conditions, seabed characteristics, distance from shore, regulatory requisites, and logistical considerations, all of which have a substantial impact on installation costs [

7].

Jang, B.S., and Choi, J.H. (2013), probably delivered an extensive overview of Wind Turbine Installation Vessels (WTIVs), delving into their design, capabilities, and functions in the context of offshore wind turbine installation. They most likely explored various types of WTIVs, emphasizing their unique attributes and advantages [

8].

Kim B.R., Son M.J., Jang W.S., Kim T.W., and Hong K.W. (2015), primarily concentrated on the development of simulation methodologies to facilitate the planning and optimization of transportation and installation processes for monopile wind turbines in offshore settings. Their study likely encompassed considerations like vessel capacity, weather conditions, distance from shore, and lifting capabilities, with the aim of accurately modeling transportation and installation operations [

9].

Lee S.H., Kim D.H, Choi H.J, Oh Y.J., and Mun S.B. (2023), introduce an innovative approach that harnesses deep learning techniques to forecast wind and sea conditions for an extended timeframe. This model is likely built upon historical data, meteorological patterns, and other pertinent factors to yield precise, long-term predictions [

10].

Upon reviewing prior research, it becomes evident that the majority of preemptive studies have predominantly focused on sector-specific analyses related to a part of offshore wind farm construction and operation. However, when considering the planning of a national energy plan, a broader perspective is necessary to analyze the overall process flow and demand comprehensively. Therefore, it is imperative to attempt a more macro-level analysis encompassing the entire process, aiming to gain insights into the overall demand dynamics. The focal point of this paper lies in predicting the scale and demand for installation and service vessels, which are predicted to be pivotal factors in the offshore wind farm construction process, setting it apart from previous studies. Furthermore, it offers demand forecasts tailored to long-term projects on a national scale, surpassing the scope of typical annual planning. By doing so, its objective is to provide valuable insights that can aid decision-makers in shaping the overall project process and schedule.

3. Prediction of Market on Offshore Wind Farm

The cost of offshore wind power generation has been on a downward trajectory due to technological advancements like larger turbines and the scaling up of individual projects. Consequently, there is a strong expectation that the global demand for offshore wind farms will surge resulting in accelerated growth post-2025. Projections indicate that the global offshore wind market will experience an average annual growth rate of approximately 10% until 2031, with the annual installation capacity surpassing 50 GW by 2030. The global offshore wind market, which stood at a modest 14 GW in 2022, is predicted to reach 53 GW by 2030, 70 GW by 2035, and 110 GW by 2040 [

4].

At the same time, concerning offshore wind farms in the United States, there is an anticipation of reaching a goal of 30 GW by 2030 and 110 GW by 2050. This progress is set to be driven by the commencement of substantial offshore wind projects and the ongoing development of new ventures, supported by initiatives like the Investment Tax Credit (ITC) and Renewable Energy Certificate (REC) programs [

4].

In Europe, specifically in Germany, Denmark, the Netherlands, and Belgium, there are ambitious initiatives to expand their offshore wind power capacity in the North Sea. Their collective aim is to reach 65 GW by 2030 and an impressive 150 GW by 2050. These efforts are aligned with their goals of reducing fossil fuel imports and achieving carbon neutrality through the widespread adoption of renewable energy sources. In parallel, the United Kingdom has unveiled plans to substantially increase its current offshore wind farm capacity, currently at about 13 GW, to nearly quadruple that amount, reaching 50 GW by 2030. This strategic expansion is geared towards advancing energy self-sufficiency and realizing zero-carbon objectives [

4].

In Taiwan, the focus is on reaching an accumulated capacity of 5.6 GW by 2025, followed by plans to add another 15 GW of offshore wind farms between 2026 and 2035. The ultimate goal for Taiwan is to attain an installation capacity of 40-55 GW by 2050. This will be achieved by increasing the size of floating turbines and promoting domestic technological advancements in components and vessels [

4].

Table 1.

Market Status of new and total installations.

Table 1.

Market Status of new and total installations.

| Regions |

Capacity of New

Installations(MW) |

Capacity of Total

Installations(MW) |

Americas

Asia-Pacific

Europe |

0

6,311

2,460 |

42

34,006

30,272 |

| Total Offshore |

8,771 |

64,320 |

In South Korea, the government introduced the Renewable Energy 3020 Implementation Plan in 2017, aiming to achieve 19% of its renewable energy target from offshore wind farms by 2030. To realize this objective, the plan outlines the development of large-scale projects and the construction of offshore wind farms with a cumulative capacity of 12 GW by 2030. The growth of the offshore wind farm sector has also been integrated into the 10th Basic Plan for Electricity Supply and Demand. To meet the 12 GW target by 2030, an expansion of offshore wind power, with a focus on large-scale projects, is expected in areas including Shin-an (8.2 GW), Ulsan (1.4 GW), the South-east region (4.6 GW), Jeju (0.6 GW), and Incheon (0.6 GW). With numerous offshore wind farm projects securing development permits, the domestic expansion of offshore wind farms is anticipated to gain momentum as they progress toward construction [

4].

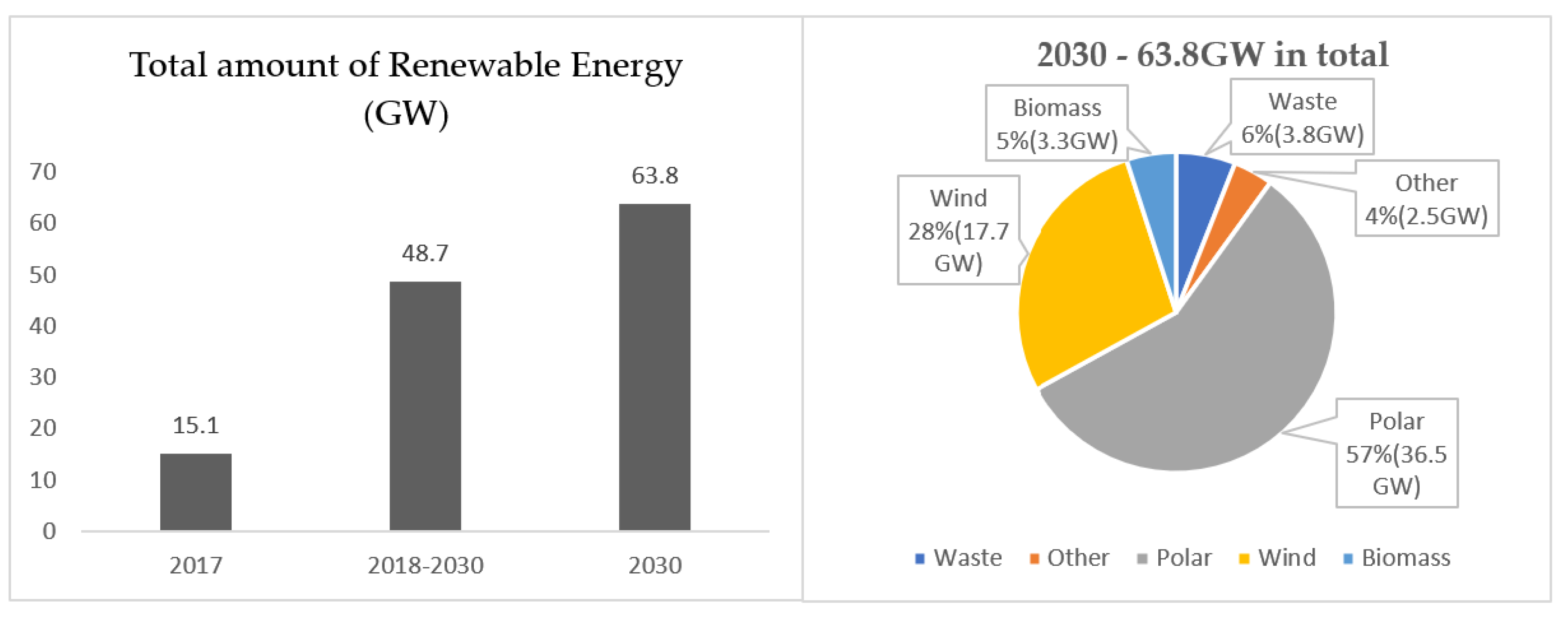

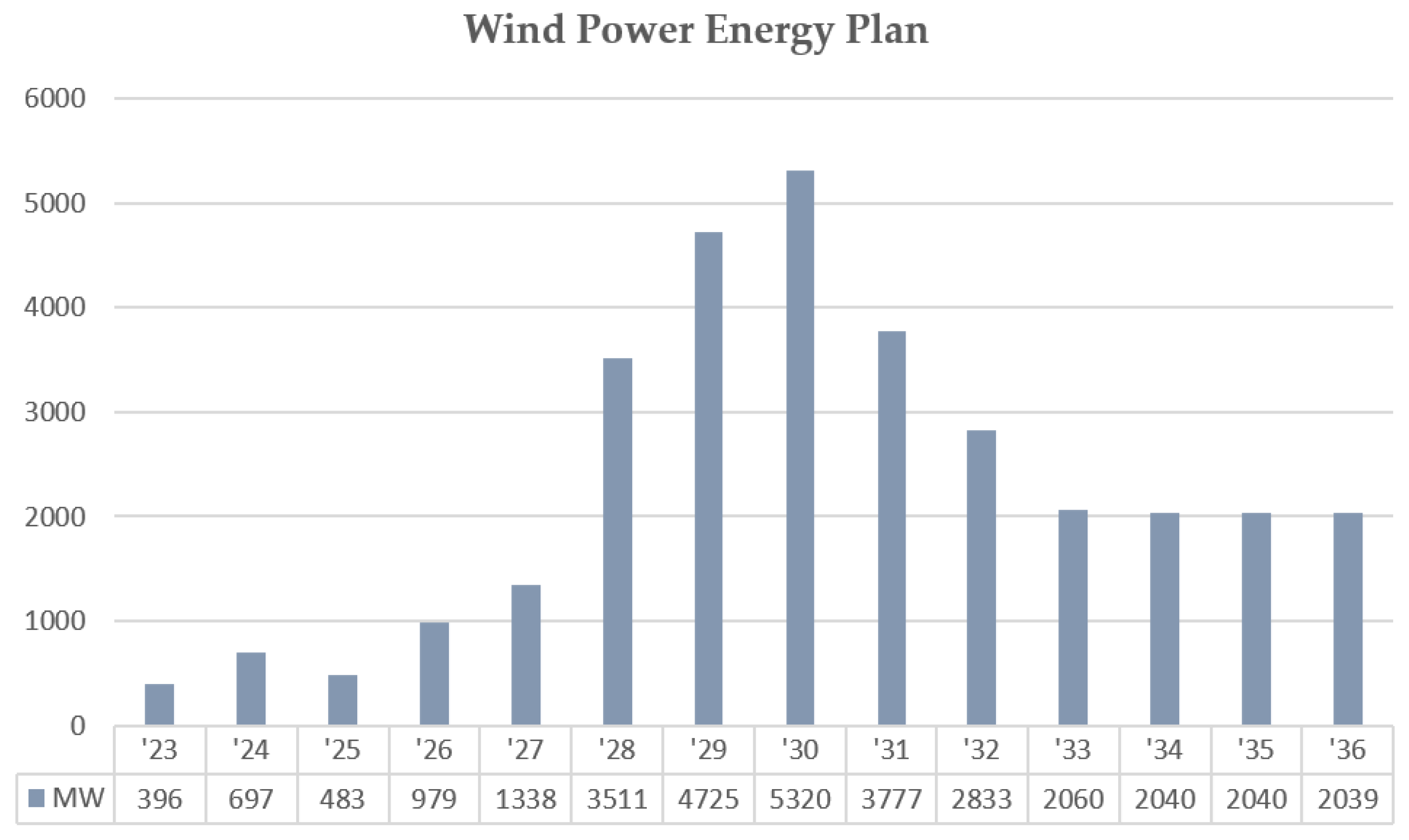

Figure 1.

Renewable Energy 3020 Implementation Plan in South Korea.

Figure 1.

Renewable Energy 3020 Implementation Plan in South Korea.

As a result, offshore wind power is poised for substantial growth and expansion. To facilitate the construction of offshore wind farms, specialized vessels with specific equipment are essential. In particular, the assembly process of towers, nacelles, and blades needs to take place while the vessel is fixed in a specific and certain position and heading. This can be achieved and realized through the use of Dynamic Positioning (DP) systems. In essence, the construction of offshore wind farms necessitates the use of DP vessels and this demand requires a shift from the traditional role of DP vessels which were primarily focused on drilling or production, to a more construction-oriented or cable-laying role, as well as performing service of the Planned Management System (PMS) for offshore wind farms.

The purpose of this study is to develop a predictive model for the specific demand of DP Vessel in the construction of offshore wind farms using System Dynamics (SD) methodology. By employing SD, which examines the evolving nature of a system over time, this study aims to establish and analyze causal relationships through feedback structures to identify factors that influence the demand.

4. Modelling – dDPV-WF Model

4.1. Dynamic Positioning System

In the previous discussion related to offshore wind farm construction, it is described the necessity for specialized types of DP vessels. Currently, the market is witnessing a surge in the popularity of WTIVs (Wind Turbine Installation Vessels) and SOVs (Service Operation Vessels) tailored for offshore wind farm purposes. In this section, it aims to provide a brief overview of DP systems and delve into the technology behind vessels designed for offshore wind energy, specifically WTIVs and SOVs.

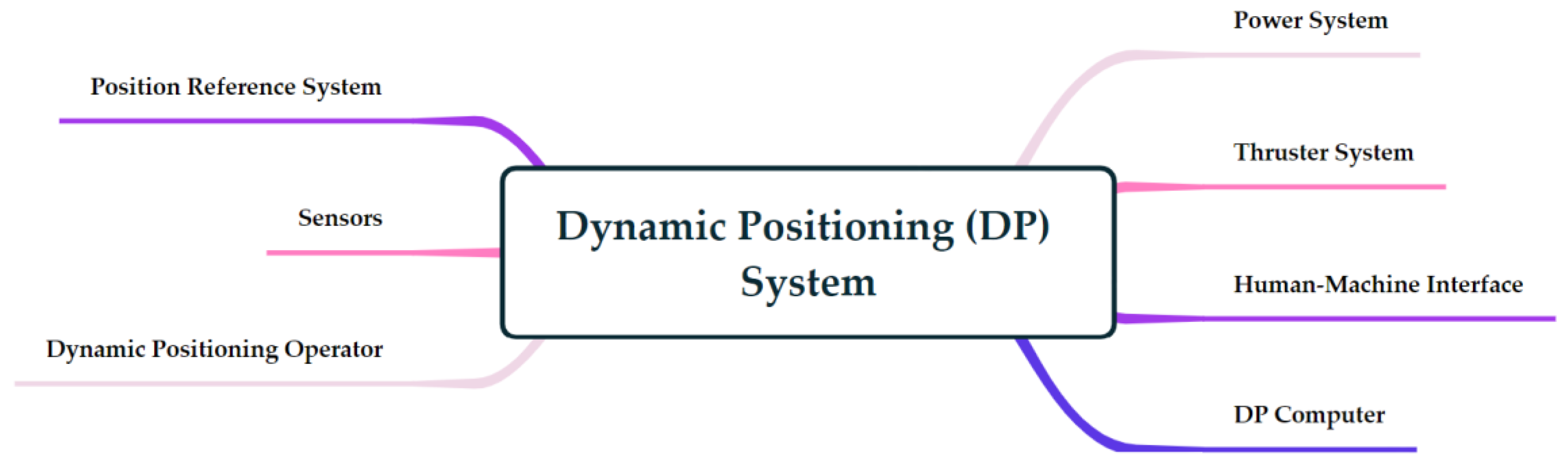

The dynamic positioning (DP) system is a technology developed for various types of vessels, enabling them to maintain their position and heading precisely at sea for various purposes, particularly in offshore plant operations or for automated route following and tracking [

11]. IMO defines the dynamic positioning system as 'a mechanism employing computers, a position reference system, and thrusters to precisely uphold the ship's position and heading within preset boundaries' by MSC.1/Circ.1580 [

11]. In contrast to traditional mooring, the DP system provides vessels with more efficient control and capabilities. For instance, after completing work on one side, it can swiftly transition, under DP control, to the next location, eliminating the time-consuming process of recovering and repositioning anchors [

12].

The DP system consists of main 7 components each of which is vital to the operation in

Figure 2.

The DP computer plays a crucial role in generating set-points for the heading and position of the system, whether generated automatically or input by humans. HMI (Human-Machine Interface) holds significant importance as it enables effective and safe system operation by providing visual aids to DP operators, aiding them in making optimized decisions. PRS (Position Reference System) serves the purpose of providing the DP system with accurate position data using various methods, including global and local approaches. Sensors generally fall into three categories: azimuth reference systems, represented by gyro compasses; motion relative systems, measuring roll, pitch, and heave values; and anemometers, which gauge wind speed and direction using ultrasonic technology. Thrusters are incorporated to control the ship's movements in terms of surge, sway, and yaw. The power system encompasses all components and systems necessary for supplying power to the DP system. DP operators are required to acquire knowledge, understanding, and proficiency in all DP components through an accredited DP certification course.

4.2. WTIVs and SOVs

Although offshore wind farm costs more than twice as much as onshore, it is easier to collect area at sea than on land, and it is possible to obtain continuous and strong winds. Competition among wind energy companies has been intensifying in recent years to the extent that the introduction of 12 MW-class wind power generators has been underway in the world, which has been undergoing industrialization for a short period of time. In particular, the biggest advantage of offshore wind farm is that there are no restrictions on the size enough to compete for capacity and that there are no major obstacles to civil complaints from local residents, so that a larger capacity can be installed compared to onshore.

However, in order to install a wind turbine at sea, a structure including a part of tower must be installed at sea, and it is true that additional cost and weather-related risk factors is arising in maintenance process. Therefore, the development and operation of WTIVs becomes a critical element for the successful establishment of offshore wind farms. Particularly, the costs associated with manufacturing and constructing offshore support structures represent a significant portion, accounting for 25% of the total expenses. Thus, it is crucial to focus on acquiring construction techniques that offer substantial cost savings, reduced construction timetables, and lower installation risks. The operational use of WTIVs is an essential aspect of this effort.

Given that offshore wind farm facilities are larger in scale than their onshore parts, achieving profitability through transportation is challenging. Consequently, the optimal approach is to minimize transportation expenses by directly moving components from the production site to the installation location by sea. As a result, the WTIVs are poised to greatly reduce both transportation and construction costs for companies, ultimately enhancing the profitability of offshore wind farm projects.

SOVs serve as essential offshore bases for the operation and maintenance (O&M) of offshore wind farms located far from the shore. These vessels provide accommodations, meals, and welfare amenities for offshore wind farm technicians and also include workshops and storage for spare parts. SOVs remain stationed at the wind farm for periods of up to four weeks before returning to their home ports for crew changes and restocking. Access to the wind turbines can be facilitated through smaller Crew Transfer Vessels (CTVs), daughter crafts, helicopters, or directly from the SOV using specialized turbine access systems.

SOVs are designed for operational speeds of up to 15 knots and are equipped with DP systems to enhance maneuverability. Efficient maneuvering is crucial for reducing positioning time and, subsequently, operational costs. Due to this requirement, surplus Platform Support Vessels (PSVs) from the oil and gas industry are seldom used in this context. PSVs primarily play a more significant role in supporting installation and commissioning activities. Typically, SOVs can accommodate a crew ranging from 50 to 100 individuals, with up to 50 of them being dedicated to wind farm maintenance tasks.

4.3. Modelling Design and Methods

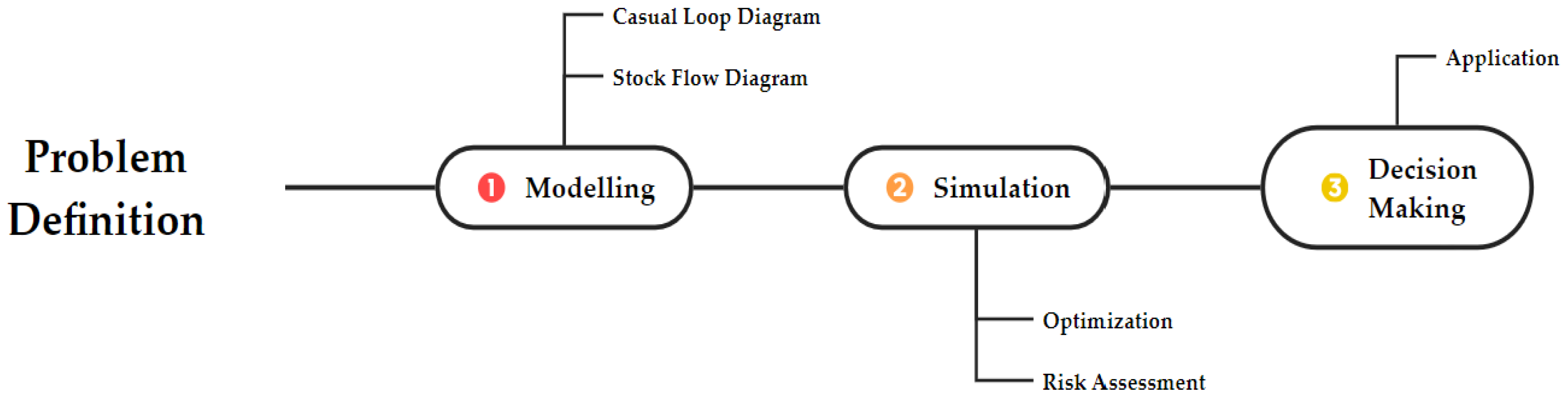

System dynamics is a theoretical tool that explores the changes in a system over time to time and seeks to control the system as desired. In this context, a system encompasses a various range of fields, including machinery and device systems, nations, organizations, individuals, societies, industries, finance, assets, and economics, among others. System

dynamics utilizes both macroscopic system structures and microscopic nodes to regulate the system or to replicate and predict the changes in a phenomenon [

13]. In other words, the system dynamics is an analysis tool which is emphasizes the cyclical causal relationships and feedback structures among problem factors.

Richardson (1995) defined the term of "feedback structure" that refers to a causally closed structure formed by interconnected causal relationships among variables [

13]. To emphasize feedback structures means identifying the causes of the problem within the internal variables and finding solutions to the problem within the overall structure of the system. In other words, system dynamics seeks to explore solutions to problems within the feedback structure by revealing the underlying causal and effect of the problem. The current situation in the system is always influenced by the past one. The procedure involves problem definition, causal loop diagram, modelling, simulation, analysis, evaluation of model validity, and decision-making processes in

Figure 3 [

14].

- (1)

Causal loop diagram is a qualitative logical model that represents the diagram of relationships between factors when approaching a problem [

13]. It involves systematically deconstructing a problem by discovering its underlying variables and interpreting them, and ultimately providing a compelling explanation of the problem's behavior. Therefore, all variables are interconnected through cause-and-effect relationships.

- (2)

Modelling begins with stock-flow diagrams, which consist of stock and auxiliary, illustrating the causal and effect and influences between variables concerning a specific problem. Stocks are variables that change over time, and auxiliaries are variables influenced by certain factors, causing changes that affect the stocks [

14].

A feedback system undergoes changes through variables representing its state and effects caused by actions. These two processes do not occur simultaneously and are separated by a time delay over a specific period. This time delay enables the interaction between the two variables, thereby forming a feedback loop. Mathematically, this can be expressed as follows [

13].

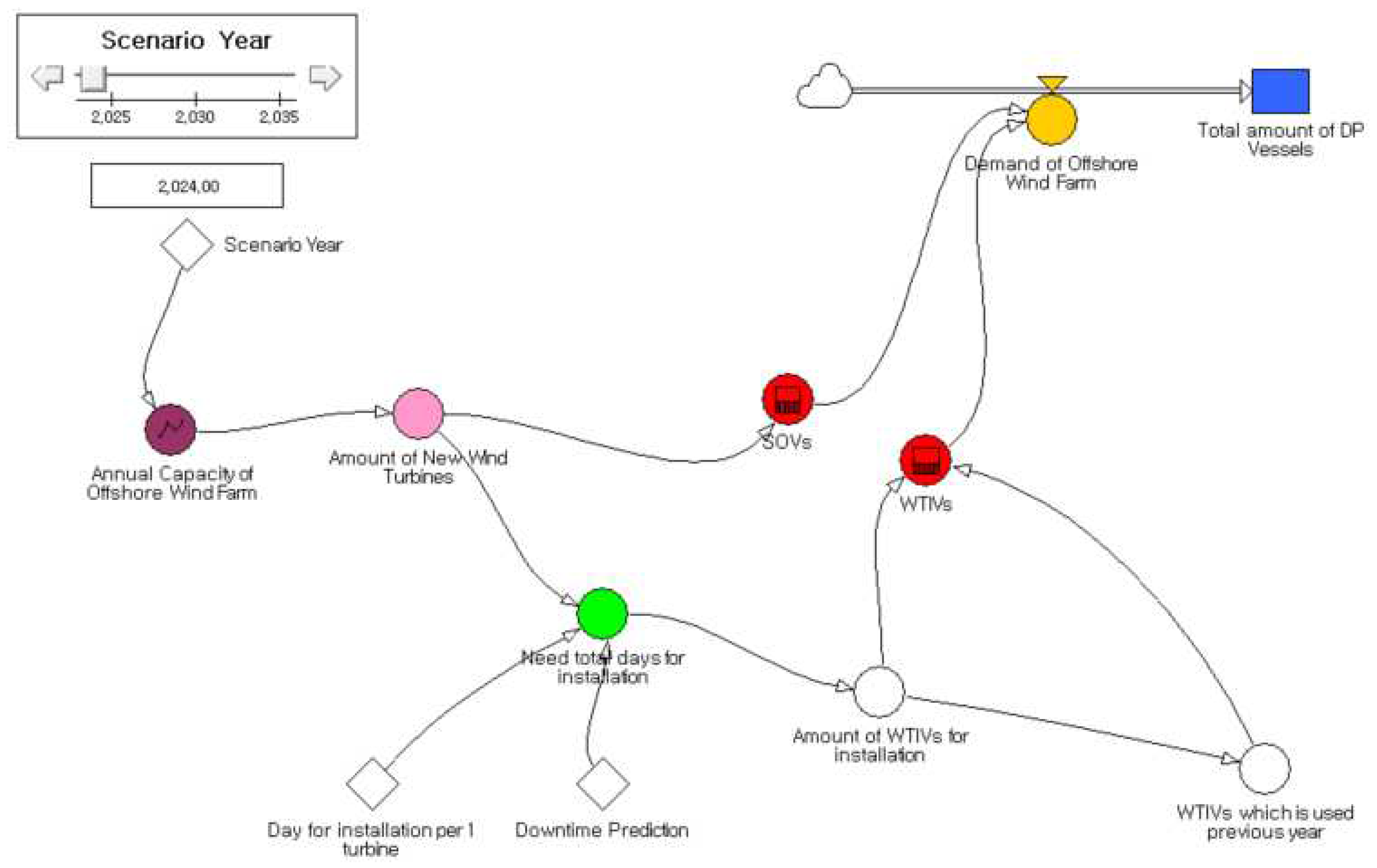

4.4. Diagrams of dDPV-WF Model

4.4.1. Casual Loop Diagram

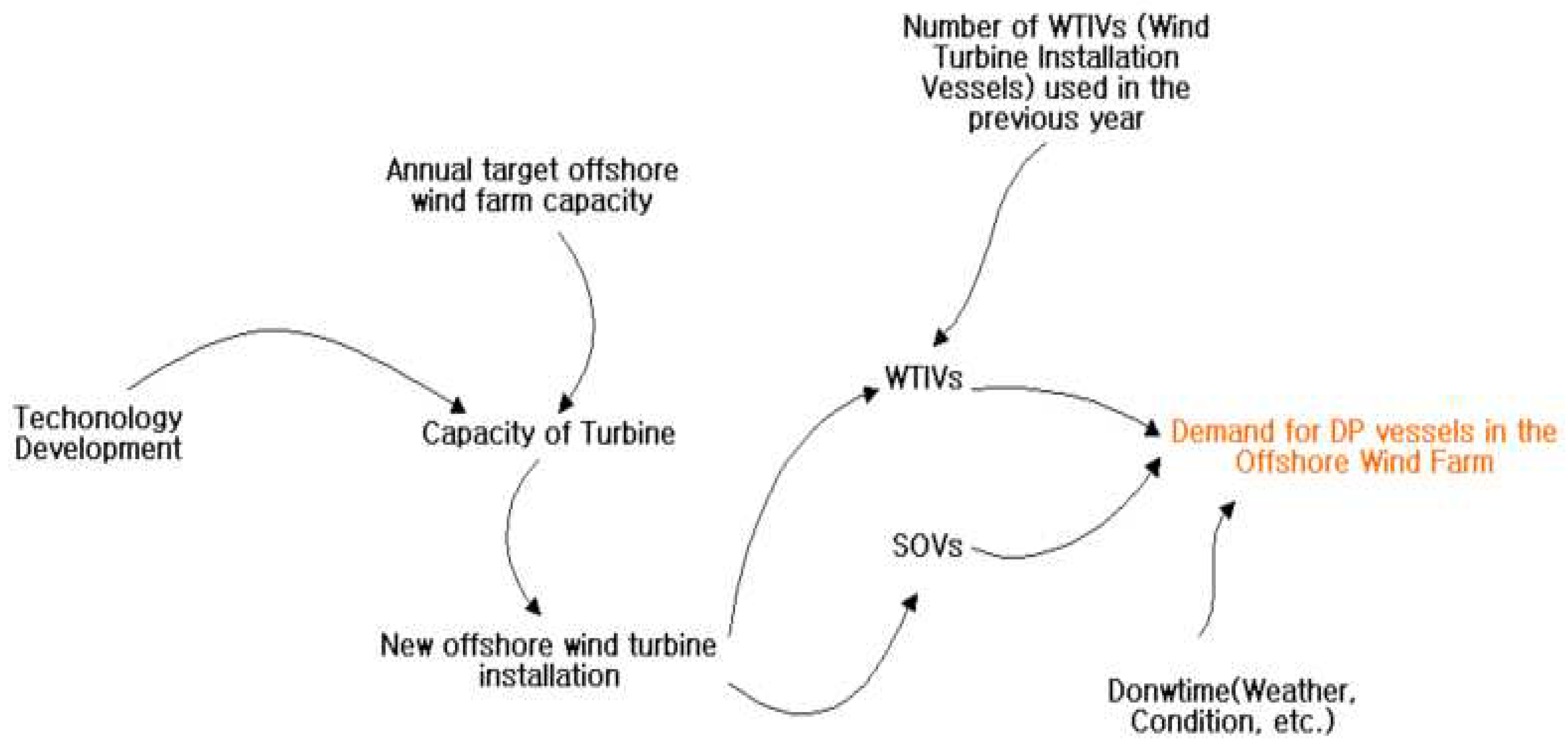

It presents the causal loop diagram designed to examine how the scale and composition of DP vessel operations adapt dynamically in response to the growth of the offshore wind farm industry, which constitutes the primary focus of this paper shown as

Figure 4. This predictive model is referred to as the

dDPV-WF model.

As per the "10th Basic Plan of Long-Term Electricity Supply and Demand," unveiled by the Ministry of Trade, Industry, and Energy in January 2023, there are ambitious goals to substantially boost the share of renewable energy generation, particularly wind power, aiming for a 30.6% contribution by 2036, as depicted in

Figure 5 [

15,

16]. Moreover, while onshore wind power has historically been the primary driver of growth, a significant portion of the wind power expansion outlined in this foundational plan is directed towards offshore wind power projects. The annual installation of offshore wind turbines is determined by the target generation capacity for offshore wind farms, which steadily escalates in accordance with the established plans.

The DP vessels including WTIVs and SOVs in the offshore wind farm industry can anticipate and plan for service demand. In the initial phases, these vessels (WTIVs and SOVs) address the demand by either commissioning new constructions or utilizing existing operational vessels. The number of WTIVs required is linked to the number employed in the previous year and the annual installation capacity of offshore wind turbines for each WTIV. Furthermore, installed offshore wind turbines undergo routine inspections through a PMS to proactively prevent accidents. To support this maintenance process effectively, SOVs play a crucial role. These SOVs operate within a feedback system, with their schedules and demand being determined based on the operational status of offshore wind turbines and the prevailing weather conditions suitable for safe operations.

4.4.2. Stock-Flow Diagram

It is depicted a stock-flow diagram employed to forecast the demand for DP vessels in response to the expansion of the offshore wind farm industry as shown

Figure 6 [

16]. This diagram outlines the anticipated quantity of DP vessels necessary for the construction of offshore wind farms, drawing insights from the energy plan specified earlier, spanning the years 2023 to 2036 [

15]. The analysis takes into consideration feedback loops influenced by factors derived from the causal diagram.

In the offshore wind farm field, efforts are being made to reduce the cost of electricity generation by increasing the capacity of turbines and scaling up key components such as blades and nacelles. As of 2021, the average turbine capacity in European offshore wind farms was 8.5 MW per each turbine, which is more than double the average capacity compared to ten years ago. Due to the significant proportion of the overall system installation and maintenance costs attributed to substructures and undersea cables, it is economically advantageous to construct wind farms with a limited number of large-capacity turbines. Currently, companies like Vestas and Siemens-Gamesa are producing turbines with capacities ranging from 10 MW to over 15 MW, with plans to supply offshore power projects by 2024 [

4]. While the

dDPV-WF model is based on an average turbine capacity of 8.5 MW, it is advisable to enter the target output capacity to accurately estimate future predictions based on technological advancements.

To address periods of downtime, the conventional practice involves allocating approximately 30% of the time to offshore project planning. For the model simulation, the widely used value of 30% has been incorporated. However, the precise information about the specific area and vessel performance should be taken into account for actual planning purposes. Downtime will be primarily influenced by the weather conditions in the offshore wind farm installation area, and the operational envelop limits of the vessels deployed should also be a significant consideration. Additionally, in the future, WTIVs and SOVs are expected to become larger, and the performance of their onboard DP systems and propulsion systems is likely to improve. Therefore, downtime is expected to decrease progressively.

Furthermore, the estimation of installation time is grounded in the 2022 report from H-BLIX, which takes into account the unique characteristics of WTIVs, utilizing a standard of 5 days per turbine, encompassing both installation and transit time. Certainly, this value may also increase or decrease depending on the enlargement of vessels and the size of turbines/towers. However, it is anticipated that the construction speed per tower will gradually and consistently accelerate ultimately as time progresses [

16].

In the case of SOVs, the amount of maintenance required steadily rises and accumulates without the need for additional variables as the number of offshore wind farms under construction increases. However, for WTIVs, their total amount in operation will depend entirely on the number of offshore wind turbines installed in a given year. It will vary depending on whether there is any remaining capacity from the previous year and whether the installation quantity for the current year is greater or smaller than the previous year.

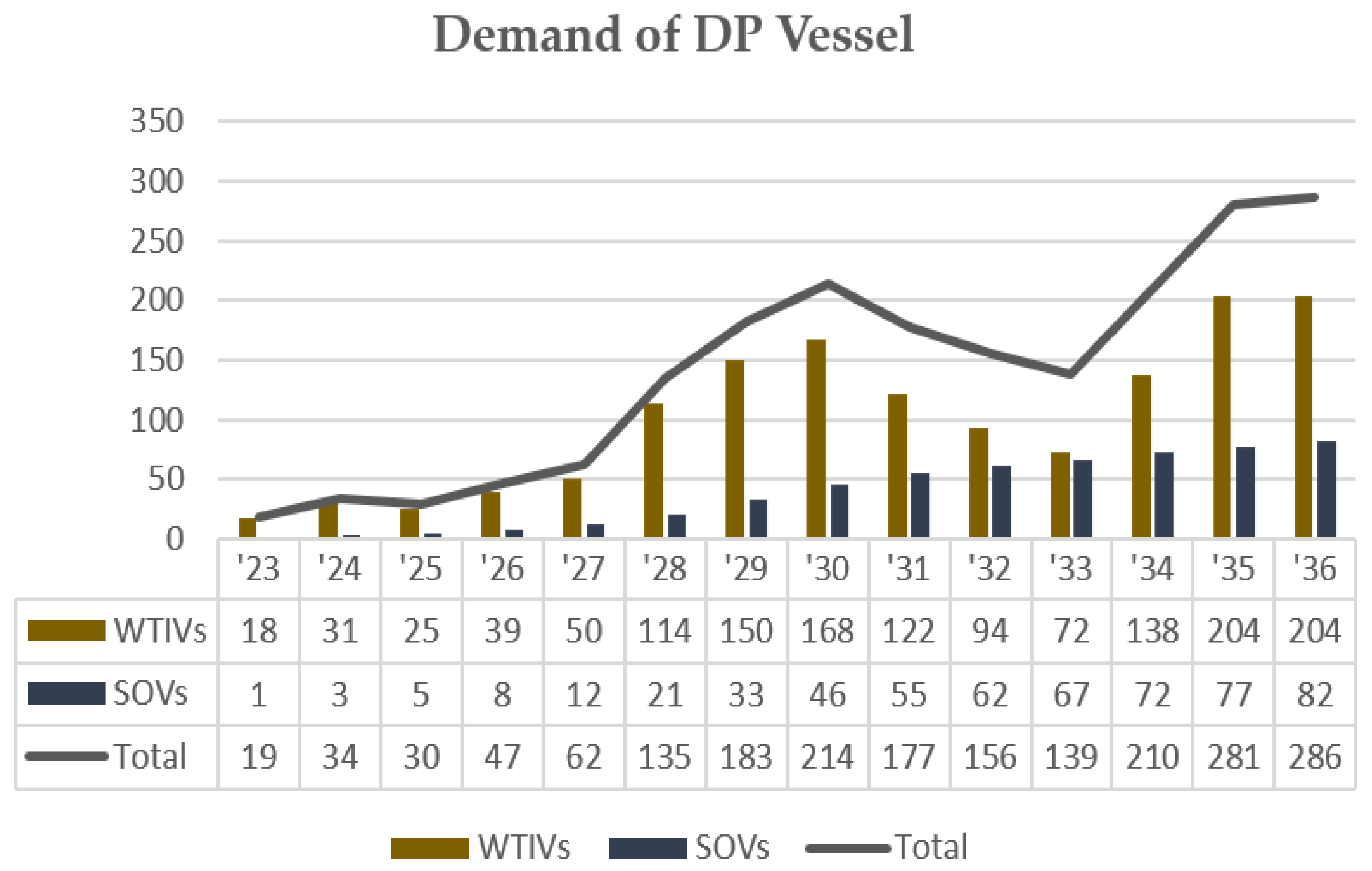

5. Simulation Results of dDPV-WF Model

The simulation results of

dDPV-WF model conducted an analysis of the annual required fleet capacity of WTIVs and SOVs in response to the development of the offshore wind farm industry. The analysis was based on the power generation graph using offshore wind farm presented in the 10th Basic Plan of Long-Term Electricity Supply and Demand [

15]. The results are as

Table 2, and the demand of fleet capacity for type of DP vessel as shown in

Figure 7 [

16].

The annual fleet capacity changes for WTIV and SOV, according to the production plan of offshore wind farm from 2024 to 2036, are presented in

Table 2 and

Figure 5 The demand for WTIVs is directly proportional to the number of turbines to be installed, which is determined by the power generation plan. Therefore, from 2030 to 2034, as the new installation capacity plan decreases, the required number of WTIVs also decreases from 168 to 72. In this case, it may be considered to send WTIVs currently operating in other regions as chartered vessels or to meet the increasing demand from 2027 onwards through short-term charter arrangements to satisfy the demand. On the other hand, for SOV, the fleet capacity steadily increases as the number of offshore wind turbines installed annually rises, leading to a higher number of turbines requiring maintenance based on the PMS.

Through this analysis, it becomes evident that planning offshore wind farms goes beyond merely focusing on power production. By predicting the fleet capacity required for installation and maintenance, it is possible to gain clear insights into the timing of vessel orders and the shipyard cycle, enabling the development of offshore wind farms complexes according to the planned schedule. Moreover, considering that WTIV and SOV are specialized vessels and their global fleet capacity is significantly limited compared to conventional ships, the decision-making process regarding whether to construct new vessels or charter existing ones for operation becomes an urgent task.

6. Conclusion

The wind power industry is expected to sustain continuous growth in line with the global trend of expanding renewable energy production to address the climate crisis. To harness the abundant wind energy resources, there is a shift towards expanding offshore wind farm generation from the previous onshore wind farms.

After 2027, the Asian market with Korea at its center is projected to drive the growth of the global offshore wind farm industry. This trend will involve the enlargement of turbine and power plant sizes, along with optimized maintenance to maximize cost-effectiveness. The government's investment in R&D for offshore wind farm has seen a significant increase, with an average annual growth of 44.1% over the past five years. In 2021, the investment amounted to 55.44 billion won, accounting for 63.2% of the total investment in the entire wind power sector. In the offshore wind farm generation sector, the highest level of investment is particularly directed towards the floating type. This encompasses areas such as turbine system design, critical turbine components, and the transmission and distribution networks, covering the entirety of offshore wind power generation. This sector accounts for the majority of the total investment, with 76.1% (151.18 billion Korean won), and it also boasts a five-year average growth rate of 61.0% [

17].

In order to achieve the zero-carbon in government's goals and secure future energy supply through renewable energy sources, it is essential to expand domestic offshore wind farm generation and implement comprehensive planning and operations for it. Specifically, the installation vessel, known as WTIV, and the maintenance vessel, known as SOV, are high-value ships and the current fleet capacity for these vessels is very limited. Additionally, there may be severe shortages of well-skilled crew and labor force for the operation and maintenance of these ships and their associated tasks. In this regard, the establishment of accurate operational plans for these vessels is considered a crucial factor in the development of offshore wind farm complexes. This paper has conducted predictions on the required fleet capacity based on the plans and power demand of government. However, it is essential to consider variables such as the actual seabed conditions, weather conditions, and scheduling plans that take these factors into account for the operations on the work sites. Furthermore, decisions should be influenced by various factors, such as the availability of personnel qualification and efficiency improvements resulting from technological advancements.

In the future, if more precise data is incorporated into the model based on the dDPV Model, it is expected that the updated model could be used as a decision-making strategy for the wind energy sector of nation.

References

- Conference of the Parties, United Nations Framework Convention on Climate Change, Report of the Conference of the Parties on Its Twenty-First Session, DEC 1/Cp.21, UN Doc FCCC/CP/2015/10/Add.1, 2015.

- Jeong, J.H. , LEE J.S., Report on Offshore Wind Farm Generation, Korea Institute of Science and Technology Evaluation and Planning (KISTEP), Brief No.53, 2022.

- International Renewable Energy Association (IRENA), Renewable Power Generation Cost in 2021, 2022.

- Lee, S.H. , The time for offshore wind power growth is approaching, Hi Investment and Securities Industry Report, 2023, https://m.hiib.com:442/upload/R_E09/2023/03, 02nd Oct. 2023.

- Walther, L. , Münsterberg, T. and Brice, R.J., How to Evaluate Installation Vessel Concepts for Offshore Wind Farms?, Proceedings of EWEA Offshore 2013, Frankfurt, Germany, 2013.

- Walker, R.T. , Sewell, B.J., Morandeau, M. and Boswell, A., Quantifying and Reducing Installation Risk for Offshore Wind Turbine Generators, Proceedings of EWEA Offshore 2013, Frankfurt, Germany, 2013.

- Kaiser, M.J. and Snyder, B.F., Modeling Offshore wind Installation Costs on the US Outer Continental Shelf, Renewable Energy, 50, 2013, pp. 676-691. [CrossRef]

- Jang, B.S. and Choi, J.H., Introduction of Wind Turbine Installation Vessel (WTIV), Computational Structural Engineering, 26(2), 2013, pp.25-30.

- Kim, B.R. , Son M. J., Jang W.S., Kim T.W. and Hong K.W., Scheduling and Cost Estimation Simulation for Transportation and Installation of the Offshore Monopile Wind Turbines. Korean Journal of Computational Design and Engineering, 20(2), 2015, pp.193-209. [CrossRef]

- Lee S., H. , Kim D.H, Choi H.J, Oh Y.J. and Mun S.B., Development of a Deep Learning Based Long-term Prediction Generative Model of Wind and Sea Conditions for Utilization of Offshore Wind Farm Maintenance Optimization, Journal of Wind Energy, 13(2), 2023, pp.42-52.

- International Maritime Organization(IMO), "Guidelines for Vessels and Units with Dynamic Positioning(DP) Systems", MSC.1/Circular.1580, 2017.

- Kim, J.M. , Park H.R., Application of a Dynamic Positioning System to a Maritime Autonomous Surface Ship (MASS), Journal of Navigation and Port Research, Vol.46, No.5, 2022, pp.435-440. [CrossRef]

- Richardson, G.P. , Loop polarity, loop dominance, and the concept of dominant polarity (1984). System Dynamics Review 11(1), 1995, pp. 67-88.

- Kim, C.H. , System Dynamics, Parkyoungsa, 2021.

- Jo, S.H. , A Study on the Change of the Size and Structure of Korean Maritime Manpower by Technological Development of MASS using System Dynamics, Doctoral dissertation, Korea Maritime and Ocean University, Busan, Korea, 2018.

- Kim, J.M. , Lim S.S., Park H.R., Yea B.D., A Study on the Prediction of the Industrial Scale of Dynamic Positioning Systems in the Offshore Wind Farm Industry using System Dynamics., Proceedings of International Logistics and Maritime System (LOGMS) 2023, Busan, South Korea, 2023.

- H-BLIX, “Offshore wind vessel availability until 2030: Baltic Sea and Polish perspective”, 2022.

- Ministry of Trade, Industry and Energy in South Korea, 10th Basic Plan for Electricity Supply and Demand, 2023.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).