Submitted:

17 October 2023

Posted:

18 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Coffee blends: Development and innovative aspects

3.2. Roasting and grindind

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- OIC – Organização Internacional do Café. Estatísticas do Comércio. Available online: http://www.ico.org/pt/trade_statisticsp.asp?section=Estat%EDstica. (accessed on 07 June 2019).

- ABIC – Associação Brasileira da Indústria de Café. Indicadores da Indústria de Café no Brasil. Available online: http://abic.com.br/estatisticas/indicadores-da-industria/indicadores-da-industria-de-cafe-2018/#consint2018. (accessed on 07 June 2019).

- CONAB – Companhia de Nacional de Abastecimento. Acompanhamento de safra brasileira: Café. Available online: https://www.conab.gov.br/component/k2/item/download/24572_0d93c50ad02a492689d26f1319defa39. (accessed on 10 June 2019).

- Cheng, B.; Furtado, A.; Smyth, H.E.; Henry, R.J. Influence of genotype and environment on coffee quality. Trends in Food Sci Technol 2016, 57, 20-30. [CrossRef]

- Paterson, R.R.M.; Lima, N.; Taniwaki, M.H. Coffee, mycotoxins and climate change. Food Res Int 2014, 61, 1–15. [CrossRef]

- Illy, A.; Viani, R. Espresso Coffee: The chemistry of quality, 2nd ed.; Academic press: San Diego, USA, 1996; 253p.

- Wintgens, J.N. Coffee: Growing, Processing, Sustainable Production. Wiley-VCH, 2004.

- Pacetti, D.; Boselli, E.; Balzano, M.; Frega, N.G. Authentication of Italian Espresso coffee blends through the GC peak ratio between kahweol and 16-O-methylcafestol. Food Chem 2012, 135, 1569–1574. [CrossRef]

- Lee, S.J.; Kim, M.K.; Lee, H-G. Effect of reversed coffee grinding and roasting process on physicochemical properties including volatile compound profiles. Innovative Food Sci and Emerging Technol 2017, 44, 97-102. [CrossRef]

- Kim, S-Y; Ko, J-A; Kang, B-S; Park, H-J. Prediction of key aroma development in coffees roasted to different degrees by colorimetric sensor array. Food Chem 2018, 240, 808–816. [CrossRef]

- Lópes-Galilea, I.; Penã, M.P.; Cid, C.I. Correlation of selected constituents with the total antioxidant capacity of coffee beverages: Influence of the brewing procedure. J Agr Food Chem 2007, 55, 6110-6117. [CrossRef]

- Schmidt, C.A.P.; Miglioranza, É.; Prudêncio, S.H. Interação da torra e moagem do café na preferência do consumidor do oeste paranaense. Ciência Rural 2008, 38, 1111-1117. [CrossRef]

- Oliveira, G.H.H.; Corrêa, P.C.; Oliveira, A.P.L.R.; Baptestini, F.M.; Vargas-Elías, G.A. Roasting, grinding, and storage impact on thermodynamic properties and adsorption isotherms of Arabica coffee. J Food Proc Pres 2017, 41, e12779. [CrossRef]

- Corrêa, P.C.; Oliveira, G.H.H.; Oliveira, A.P.L.R.; Vargas-Elías, G.A.; Santos, F.L.; Baptestini, F.M. Preservation of roasted and ground coffee during storage Part 1: Moisture content and repose angle. Ver Bras Eng Agric Amb 2016, 20, 581-587. [CrossRef]

- Baptestini, F.M.; Corrêa, P.C.; Oliveira, G.H.H.; Cecon, P.R.; Soares, N.F.F. Kinetic modeling of water sorption by roasted and ground coffee. Acta Scient Agron 2017, 39, 273-281. [CrossRef]

- Andueza, S.; De Peña, M.P.; Cid, C. Chemical and sensorial characteristics of espresso coffee as affected by grinding and torrefacto roast. J Agric Food Chem 2003, 51, 7034–7039. [CrossRef]

- Galvão, M.C.B.; Ricarte, I.L.M. Revisão Sistemática da Literatura: Conceituação, Produção e Publicação. Logeion: Filosofia da Informação 2019, 6, 57–73. [CrossRef]

- Oliveira, A.P.L.R.; Corrêa, P.C.; Reis, E.L.; Oliveira, G.H.H. Comparative Study of the Physical and Chemical Characteristics of Coffee and Sensorial Analysis by Principal Components. Food Analytical Methods 2015, 8, 1303–1314. [CrossRef]

- Larmond, E. Laboratory methods for sensory evaluation of food. Food Research Institute/Canada Department of Agriculture: Ottawa, 1977; 73 p.

- Alves, R.C.; Soares, C.; Susana Casal, J.O.F.; Oliveira, M.B.P.P. Acrylamide in espresso coffee: Influence of species, roast degree and brew length. Food Chem 2010, 119, 929–934. [CrossRef]

- Santos, E.S.M.; Deliza, R.; Freitas, D.D.G.C.; Corrêa, F.M. Effect of conilon beans on the sensory profile and consumer acceptance of coffee beverages. Semina: Ciencia Agr 2013, 34, 2297-2306. [CrossRef]

- Bakuradze, T.; Parra, G.A.M.; Riedel, A.; Somoza, V.; Lang, R.; Dieminger, N.; Hofmann, T.; Winkler, S.; Hasmann, U.; Marko, D.; Schipp, D.; Raedle, J.; Bytof, G.; Lantz, I.; Stiebitz, H.; Richling, E. Four-week coffee consumption affects energy intake, satiety regulation, body fat, and protects DNA integrity. Food Res Int 2014, 63, 420-427. [CrossRef]

- Liu, C.; Yang, N.; Yang, Q.; Ayed, C.; Linforth, R.; Fisk, I.D. Enhancing Robusta coffee aroma by modifying flavour precursors in the green coffee bean. Food Chem 2019, 281, 8-17. [CrossRef]

- Liu, C.; Yang, Q.; Linforth, R.; Fisk, I.D.; Yang, N. Modifying Robusta coffee aroma by green bean chemical pre-treatment. Food Chem 2019, 272, 251-257. [CrossRef]

- Wongsa, P.; Khampa, N.; Horadee, S.; Chaiwarith, J.; Rattanapanone, N. Quality and bioactive compounds of blends of Arabica and Robusta spray dried coffee. Food Chem 2019, 283, 579-587. [CrossRef]

- Kalschne, D.L.; Biasuz, T.; De Conti, A.J.; Viegas, M.C.; Corso, M.P.; Benassi, M.T. Sensory characterization and acceptance of coffee brews of C. arabica and C. canephora blended with steamed defective coffee. Food Res Int 2019, 124, 234-238. [CrossRef]

- Couto, C.C.; Santos, T.F.; Mamede, A.M.G.N.; Oliveira, T.C.; Souza, A.M.; Freitas-Silva, O.; Oliveira, E.M.M. Coffea arabica and C. canephora discrimination in roasted and ground coffee from reference material candidates by real-time PCR. Food Res Int 2019, 115, 227–233. [CrossRef]

- SAA. Secretaria da Agriculta e Abastecimento do Estado de São Paulo. Resolução SAA 30, Norma de Padrões Mínimos de Qualidade para Café torrado em Grão e Torrado e Moído. Diário Oficial, Brazil, 2007.

- SAA. Secretaria da Agriculta e Abastecimento do Estado de São Paulo. Resolução SAA 31, Norma de Padrões Mínimos de Qualidade para Café torrado em Grão e Torrado e Moído. Diário Oficial, Brazil, 2007.

- Martín, M.J.; Pablos, F.; González, A.G. Characterization of arabica and robusta roasted coffee varieties and mixture resolution according to their metal content. Food Chem 1999, 66, 365-370. [CrossRef]

- Romano, R.; Santini, A.; Grottaglie, L.L.; Manzo, N.; Visconti, A.; Ritieni, A. Identification markers based on fatty acid composition to differentiate between roasted Arabica and Canephora (Robusta) coffee varieties in mixtures. J Food Composition Analysis 2017, 35, 1–9. [CrossRef]

- Colzi, I.; Taiti, C.; Marone, E.; Magnelli, S.; Gonnelli, C.; Mancuso, S. Covering the different steps of the coffee processing: Can headspace VOC emissions be exploited to successfully distinguish between Arabica and Robusta? Food Chem 2017, 237, 257-263. [CrossRef]

- Kalschne, D.L.; Viegas, M.C.; De Conti, A.J.; Corso, M.P.; Benassi, M.T. Steam pressure treatment of defective Coffea canephora beans improves the volatile profile and sensory acceptance of roasted coffee blends. Food Res Int 2018, 105, 393–402. [CrossRef]

- Dias, R.C.E.; Valderrama, P.; Março, P.H.; Scholz, M.B.S.; Edelmann, M.; Yeretzian, C. Quantitative assessment of specific defects in roasted ground coffee via infrared-photoacoustic spectroscopy. Food Chem 2018, 255, 132-138. [CrossRef]

- Ribeiro, V.S.; Leitão, A.E.; Ramalho, J.C.; Lidon, F.C. Chemical characterization and antioxidant properties of a new coffee blend with cocoa, coffee silverskin and green coffee minimally processed. Food Res Int 2014, 61, 39-47. [CrossRef]

- Borrelli, R.C.; Esposito, F.; Napolitano, A.; Ritieni, A.; Fogliano, V. Characterization of a new potential functional ingredient: coffee silverskin. J Agric Food Chem 2004, 52, 1338–1343. [CrossRef]

- Costa, A.S.G.; Alves, R.C.; Vinha, A.F.; Costa, E.; Costa, C.S.G.; Nunes, M.A.; Almeida, A.A.; Santos-Silva, A.; Oliveira, M.B.P.P. Nutritional, chemical and antioxidant/prooxidant profiles of silverskin, a coffee roasting by-product. Food Chem 2018, 267, 28-35, 2018. [CrossRef]

- Jiménez-Zamora, A.; Pastoriza, S.; Rufián-Henares, J.A. Revalorization of coffee byproducts. Prebiotic, antimicrobial and antioxidant properties. LWT Food Sci Technol 2015, 61, 12–18. [CrossRef]

- Bessada, S.M.F.; Alves, R.C.; Costa, A.S.G.; Nunes, M.A.; Oliveira, M.B.P.P. Coffea canephora silverskin from different geographical origins: A comparative study. Sci Total Environ 2018, 645, 1021-2028. [CrossRef]

- Wrigley, G. Coffee. Longman Scientific and Technical, 1988. [CrossRef]

- Lópes-Galilea, I.; Penã, M.P.; Cid, C.I. Correlation of selected constituents with the total antioxidant capacity of coffee beverages: Influence of the brewing procedure. J Agric Food Chem 2007, 55, 6110-6117. [CrossRef]

- Franca, A.S.; Mendonça, J.C.F.; Oliveira, S.D. Composition of green and roasted coffees of different cup qualities. LWT 2005, 38, 709–715. [CrossRef]

- De Maria, C.A.B.; Trugo, L.C.; Aquino Neto, F.R.; Moreira, R.F.A.; Alviano, C.S. Composition of green coffee water soluble fractions and identification of volatiles formed during roasting. Food Chem 1996, 55, 203–207. [CrossRef]

- Bollinger, D. Coffee roasting. Available online: https://en.wikipedia.org/wiki/Coffee_roasting. (accessed on 09 March 2020).

- Specialty Coffee Association of America (SCA). Protocols. Available online: https://sca.coffee/research/protocols-best-practices. (accessed on 09 March 2020).

- Vargas-Elias, G.A. Avaliação das propriedades físicas e qualidade do café em diferentes condições de torrefação. Dissertation, Master in Agriculture Engineering, Universidade Federal de Viçosa, Brazil, 2011.

- Monteiro, M.A.M.; Minim, V.P.R.; Silva, A.F.; Chaves, J.B.P. Influência da torra sobre a aceitação da bebida café. Rev Ceres 2010, 57, 145-150. [CrossRef]

- Bhumiratana, N.; Adhikari, K.; Chambers IV, E. Evolution of sensory aroma attributes from coffee beans to brewed coffee. LWT Food Sci Technol 2011, 44, 2185-2192. [CrossRef]

- Hecimovic, I.; Belscak-Cvitanovic, A.; Horzic, D.; Komes, D. Comparative study of polyphenols and caffeine in different coffee varieties affected by the degree of roasting. Food Chem 2011, 129, 991-1000. [CrossRef]

- Yeretzian, C.; Pascual, E.C.; Goodman, B.A. Effect of roasting conditions and grinding on free radical contents of coffee beans stored in air. Food Chem 2012, 131, 811–816. [CrossRef]

- Vignoli, J.A.; Bassoli, D.G.; Benassi, M.T. Antioxidant activity, polyphenols, caffeine and melanoidins in soluble coffee: The influence of processing conditions and raw material. Food Chem 2011, 124, 863–868. [CrossRef]

- Bell, L.N.; Wetzel, C.R.; Grand, A.N. Caffeine content in coffee as influenced by grinding and brewing techniques. Food Res Int 1996, 29, 185-189. [CrossRef]

- Santos, W.P.C.; Hatje, V.; Lima, L.N.; Trignano, S.V.; Barros, F.; Castro, J.T.; Korn, M.G.A. Evaluation of sample preparation (grinding and sieving) of bivalves, coffee and cowpea beans for multi-element analysis. Microchem J 2008, 89, 123–130. [CrossRef]

- Angeloni, G.; Guerrini, L.; Masella, P.; Bellumori, M.; Daluiso, S.; Parenti, A.; Innocenti, M. What kind of coffee do you drink? An investigation on effects of eight different extraction methods. Food Res Int 2019, 116, 1327–1335. [CrossRef]

- Cordoba, N.; Fernandez-Alduenda, M.; Moreno, F. L.; Ruiz, Y. Coffee extraction: A review of parameters and their influence on the physicochemical characteristics and flavour of coffee brews. Trends in Food Sci Technol 2020, 96, 45–60. [CrossRef]

| Composition | Dry matter range (%) | |

|---|---|---|

| Arabica | Robusta | |

| Kahweol | 0.7 – 1.1 | NA |

| Caffeine | 0.6 – 1.5 | 2.2 – 2.7 |

| Chlorogenic acids | 6.2 – 7.9 | 7.4 – 11.2 |

| Sucrose and reducing sugars | 5.3 – 9.3 | 3.7 – 7.1 |

| Total free amino acids | 0.4 – 2.4 | 0.8 – 0.9 |

| Strecker-active | 0.1 – 0.5 | 0.2 – 0.3 |

| Araban | 9.0 – 13.0 | 6.0 – 8.0 |

| Reserve Mannane | 25.0 – 30.0 | 19.0 – 22.0 |

| Reserve Galactan | 4.0 – 6.0 | 10.0 – 14.0 |

| Other polysaccharides | 8.0 – 10.0 | 8.0 – 10.0 |

| Tryglycerides | 10.0 – 14.0 | 8.0 – 10.0 |

| Proteins | 12.0 | 12.0 |

| Trigonelline | 1.0 | 1.0 |

| Other lipids | 2.0 | 2.0 |

| Other acids | 2.0 | 2.0 |

| Ash | 4.0 | 4.0 |

| Totals* | 90.0 – 114.0 | 86.0 – 107.0 |

| Geographical origin | Nutritional composition | |||||||

| Moisture (%) | Ash (%) | Fat (%) | Protein (%) | Insoluble Fiber (%) | Soluble fiber (%) | Available carbohydrate (%) | Caffeine (mg 100g-1) |

|

| Cameroon | 9.91 | 8.31 | 1.81 | 20.6 | 49.5 | 5.95 | 3.95 | 1154 |

| India | 10.30 | 7.34 | 1.19 | 18.9 | 50.6 | 9.00 | 2.70 | 676 |

| Indonesia | 9.28 | 8.71 | 2.46 | 18.2 | 47.5 | 7.55 | 6.35 | 1100 |

| Brazil | 9.53 | 10.4 | 3.15 | 16.7 | 44.2 | 11.20 | 4.80 | 1215 |

| Vietnam | 9.55 | 9.29 | 2.27 | 20.3 | 47.4 | 10.95 | 0.25 | 1140 |

| Uganda | 9.35 | 10.5 | 1.86 | 19.5 | 45.0 | 7.85 | 5.85 | 709 |

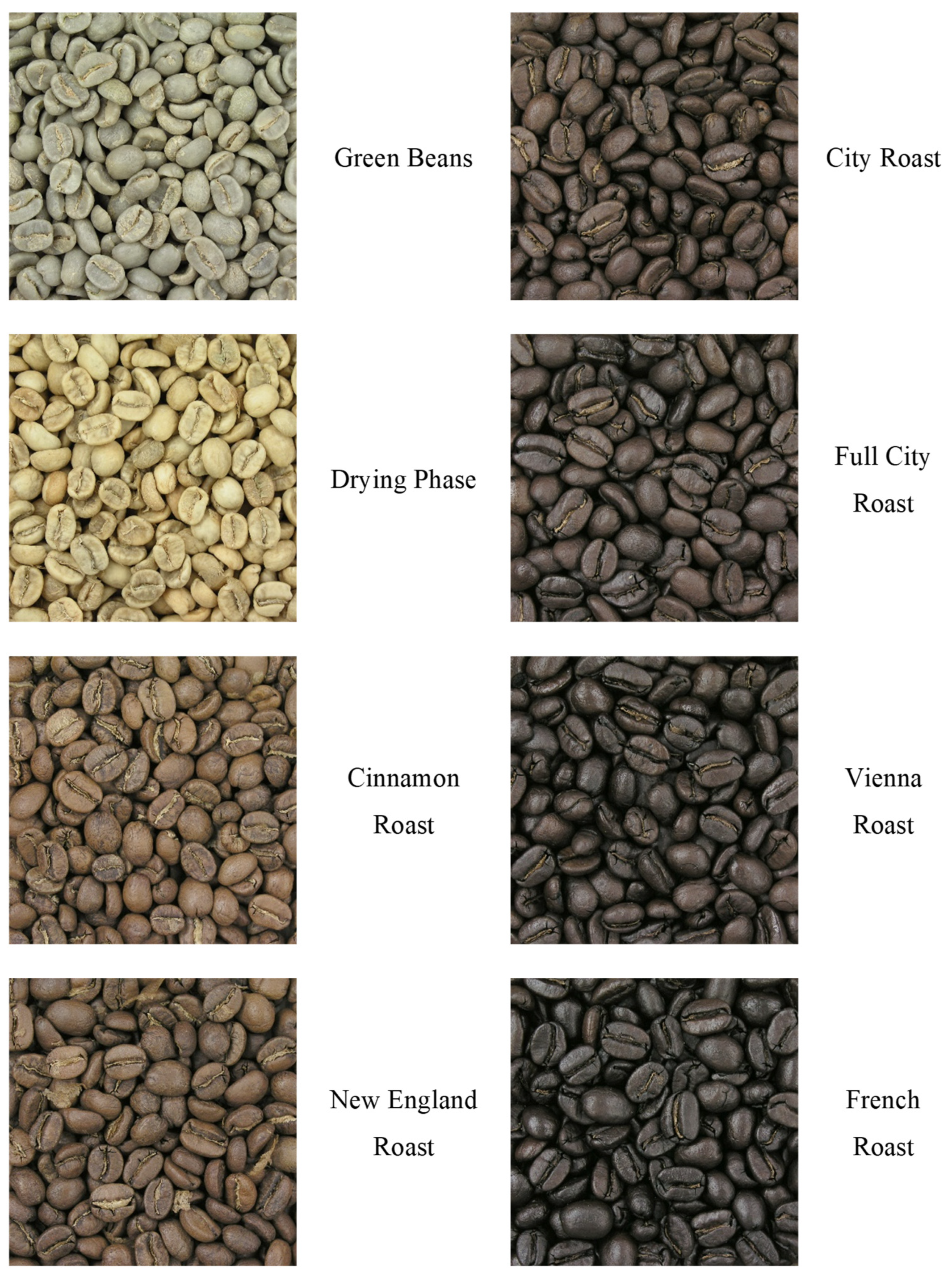

| Roasting | Weight loss (%) | Agtron number | Bean temperature (ºC) | Characteristics |

| Cinnamon | 13.0 | 80-75 | 90-130 | Volatile compounds start to expand the beans |

| American | 14.0 | 74-65 | 170-190 | First crack. Acidity higher than sugar |

| City | 15.0 | 64-60 | 210-220 | First crack ends |

| Full City | 16.5 | 60-50 | 224-230 | Second crack. Balance between acidity and sugar. Oils starts to appear |

| Vienna | 17.0 | 49-45 | 230-235 | Second crack ends. Lower acidity |

| French | 19.0 | 34-25 | 240-246 | Caramelization of sugars. Decrease of acidity. Burn smell |

| Italian | 20.0 | 24-15 | 246-265 | Loss of flavor. Shinny surface (Oil) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).