1. Introduction

Global population growth and the development of science and technology have increased the demand for energy. These trends lead to depletion of conventional oil reserves. It is known that in the near future it will be replaced by unconventional hydrocarbon raw materials such as oil sand. World-wide reserves of bitumen and heavy-oil resources estimated 5.6 trillion barrels, which occur in over 70 different countries. Including the Canada, USA, Venezuela, China, Indonesia, Russia, Brazil, Cuba, Trinidad, Jordan, Tobago, Colombia, Madagascar, Romania, Albania, Portugal, Spain, Argentina Nigeria, Kazakhstan and other. The largest oil sands deposits in the world are located in Canada and Venezuela. Oil sand bitumen of the Athabasca deposit is an increasingly important source of synthetic crude oil in the North America. Because of the oil production cost from oil sands is significantly higher than that for conventional crudes, there is an increasing need to develop the resource in a more efficient and cost effective manner. Venezuela also has large amounts of crude oil in the oil sands of Orinoco and they are usually called extra heavy oil, although the hydrocarbons trapped in Orinoco oil sands are more fluid than in Canada. The most common plate-tectonic settings in which the heavy-oil and bitumen are found are in continental multi-cyclic marginal basins and in continental rift basins [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10]. Most deposits of oil sands also called tar sands contain mixtures of bitumen, coarse sand, water, fine solids, small amounts of heavy metals and other contaminants. The complexity of their composition and distribution in the earth’s crust does not allow their production and processing using modern oil refining technology. Due to these difficulties, until now there has been no high industrial interest in this valuable resource [

10,

11,

12].

The organic part separated from the mineral parts of the oil sand is called natural bitumen according to its global name. This type of the hydrocarbon is much heavier and more viscous than conventional oil. In some scientific literature, it is also called “bitumen” together with the term of natural bitumen. Organic part of oil sands close to bitumen by physical and chemical properties. But it does not fully meet the physical and mechanical characteristics of bitumen. Well known bitumen is a complex mixture of high boiling point range of organic liquids compounds that is viscous, black and sticky. Therefore, unprocessed oil sand bitumen is not suitable for using as road construction materials. Thus, these factors indicate the need to find effective ways of processing oil sands based on their unique properties as sustainable materials [

12,

13,

14].

Deposits of oil sands have been investigating all over the world for the production of asphalt concrete for the road construction or for the extraction of natural bitumen for further production of synthetic oil. The term deposit is typically applied to an accumulation of ore in which the ore is part of the rock. Oil sand deposits are loose sand or partially consolidated sandstone containing naturally occurring mixtures of sand, clay, and water, saturated with a dense and extremely viscous hydrocarbonaceous material technically referred to as bitumen. It is colloquially as tar due to its similar appearance, odor, and color to tar produced thermally from coal. The bitumen contained in oil sand deposits exists in the semisolid or solid phase and is typically immobile under deposit conditions of temperature and pressure, unless heated or diluted with low boiling hydrocarbon solvents. Attempts to define oil sand bitumen based on a single property such as API gravity or viscosity are, at best, speculative and subject to inaccuracies [

2,

5]. Natural bitumen fractions varying over a wide range of molecular weights are linked by mutual solubility. Natural bitumen consists of higher content of resin-asphaltene compounds, petroleum acids, sulfur containing compounds and metals, also higher viscosity and density than conventional crude oil. Heavy oil and bitumen resources are largely a result of natural degradation of formerly conventional oil accumulations, with relatively minor accumulations due to immature oil being expelled directly from source rocks. Compared to conventional crude oil, natural bitumen from oil sands have too much carbon and not enough hydrogen. The heavy-oil and bitumen reservoirs are in contact with the atmosphere, shallow groundwater or deeper formation-water aquifers [

11,

15,

16,

17,

18,

19,

20].

Many countries with abundant heavy oil resources are tending to stimulate in fundamental research, test new technologies, and increase heavy oil production to ensure fossil energy supply. In this regarding in the near future, role of natural bitumen in the energy balance expected significantly increase. However, the main obstacle is the difficulty of separating natural bitumen from oil sand [

21,

22].

Kazakhstan has large number of undeveloped reserves of oil sands, actually over 50 fields of oil sands have been discovered in Atyrau, Mangistau and Aqtobe regions. This hydrocarbon raw material has not been developed yet, because it is difficult to refining. Western part of Kazakhstan has more than 1 billion tons of natural bitumen at depths up to 120 m occurs and over 15–20 billion tons of oil sands. However, this is not the final estimate, as different reservation amount are presented in different literature. According to the publication, that Kazakhstan has the second largest oil sands reserves in the world (12.6%), estimated at 420 billion barrels (or 67 billion m

3). Pioneer of complex study on processing oil sands was in 80–90s of last century. The problem of development of oil sands in Kazakhstan in 1980–1985 was conducted in four main areas as following: investigation of geology and geochemistry of mineral and organic components of the oil sand deposits; development of technologies of oil sand and tools for use in road construction; study of organic mineral constituents of the oil sand as an additional source of energy and petrochemical resources [

11,

23,

24,

25]. However, there have been no systematic research or government programs covering oil sands exploration, production and processing. Only some research groups are studying at their own level and publishing their scientific works.

The territory of the oil sand deposits cannot be used for agriculture or other useful directions of the national economy. Nowadays, the human society strongly relies on oil and gas to survive and develop in the world. The survival and development of petroleum industry is determined by four factors as following: resources, market, technology, and social-political-economic environment. Among them, oil and gas resources are the foundation, while technological progress is the most active and critical factor [

26]. We noted that our country has abundant reserves of oil sand. Therefore, it is an urgent problem to study original characteristics of Kazakhstan oil sands and find ways of effective processing them for sustainable application.

Natural bitumen can be processed as crude oil to obtain petrochemical products for various purposes. Therefore, this article aims to show the possibility of using this type of hydrocarbon as a natural resource, comparing its characteristics with the Karazhanbas crude oil.

2. Materials and Methods

In the study, the natural bitumen of Munaily-Mola oil sands and crude oil of Karazhanbas oil field were used. Munaily-Mola oil sand, which belongs to unconventional hydrocarbon type, is located in Atyrau region [

27].

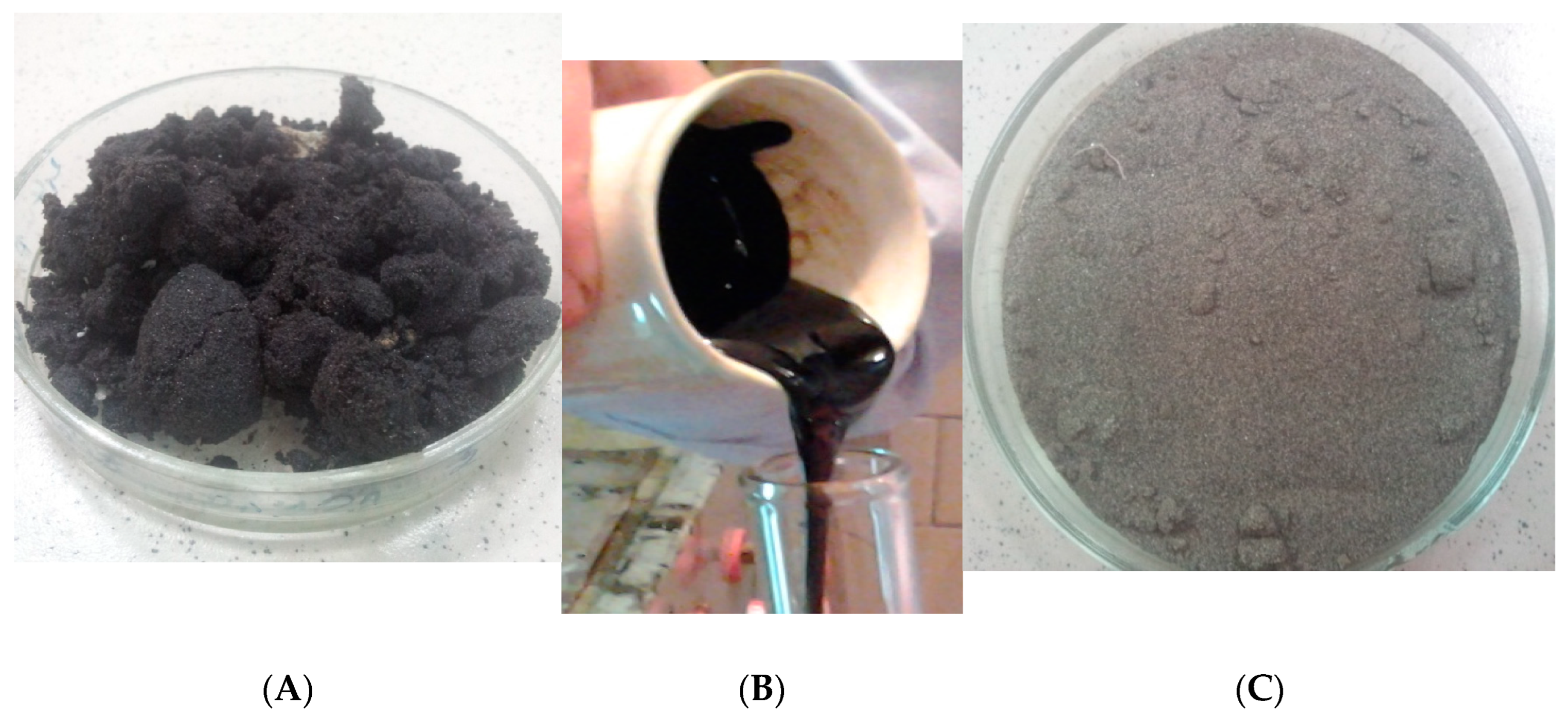

Figure 1 shows a picture of the oil sand samples (

Figure 1A), the natural bitumen extracted from them (

Figure 1B), and mineral part obtained after their extraction (

Figure 1C). It can be seen that natural bitumen is a rich black color, a viscous hydrocarbon. And the mineral part of the oil sand consists of small sandy soil rocks. Karazhanbas oil is considered the heavy oil of the Bozachi peninsula in Mangistau region. Currently, “Karazhanbasmunai” JSC is one of the strategically important companies in the country. Since its establishment in 1974, the company has produced more than 50 million tons of oil [

28]. Both of these oil fields are located in the western part of Kazakhstan, near the Caspian Sea.

Important physical and chemical properties of natural bitumen and crude oil were studied in modern facilities using standard methods. Microscopic analyses of oil sand structure were provided by Leica DM 6000 M optical microscope on optical reflection. It uses visible light and a system of lenses to magnify images of small samples. The images from an optical microscope were captured by normal light-sensitive cameras to generate a micrograph. At experiment pycnometer was used for the density determination of the hydrocarbon samples. Their heating value was tested at IKA oxygen bomb calorimeter C 200. Carbon, hydrogen, nitrogen, oxygen and sulfur analyses were performed using a Elementar Vario EL III. The samples in elemental analysis were sealed in the capsule. Air in the capsule was forced out the capsule via a gas stream of oxygen. The mean blank values of several samples were subtracted for evaluation. Fractional composition of hydrocarbons was performed using the ARN-LAB-11 by gradually heating and condensed vapors in receiving special containers at atmospheric pressure.

Group composition of the natural bitumen of the Munaily-Mola oil sands and crude oil of Karazhanbas were separated by chromatographic method in a Soxhlet apparatus. On the precipitation of asphaltene, the hydrocarbons were added a 40-fold amount of n-hexane in relation to the initial hitch of raw materials and put it to the dark place that it couldn’t reached by light to allow the precipitation of insoluble components. The procedure is repeated several times, and each step eliminates resins. This changes the external appearance of the precipitate from glassy black solid to brownish carbonaceous material. The separation was continued until no more changes in the residue were observed. On the separation of maltenes in oil and resin was used Soxhlet method with activated silica gel. Activation of silica gel carried out at 350 °С temperature for 4 h. Activated silica gel wetted with hexane and prepared maltenes transferred to this silica gel in Soxhlet. Apparatus have been placed on a water bath and extracted oil with 200 ml of hexane until the flask was not drain pure hexane. After extraction of oil, flask replaced to a clean flask with 200 ml benzene-alcohol mixture, which ratio is 1:1. Adsorbed resins on silica gel desorbed by alcohol-benzene mixture. After the separation of oil and resins, all solvents were distilled off on a rotary evaporator. Then the samples were dried at 60 ± 4 °C temperature until a constant weight.

Chemical composition of oil, resin and asphaltene was identified by a Fourier transform infrared spectroscopy Spectrum-65 in cells of KBr and tablets with KBr. It is used to obtain an infrared spectrum of absorption, emission, photoconductivity, or Raman scattering of a solid, liquid, or gas. A spectrometer simultaneously collects spectral data in a wide spectral range. The spectra with 450–4000 cm−1 range were obtained.

3. Results

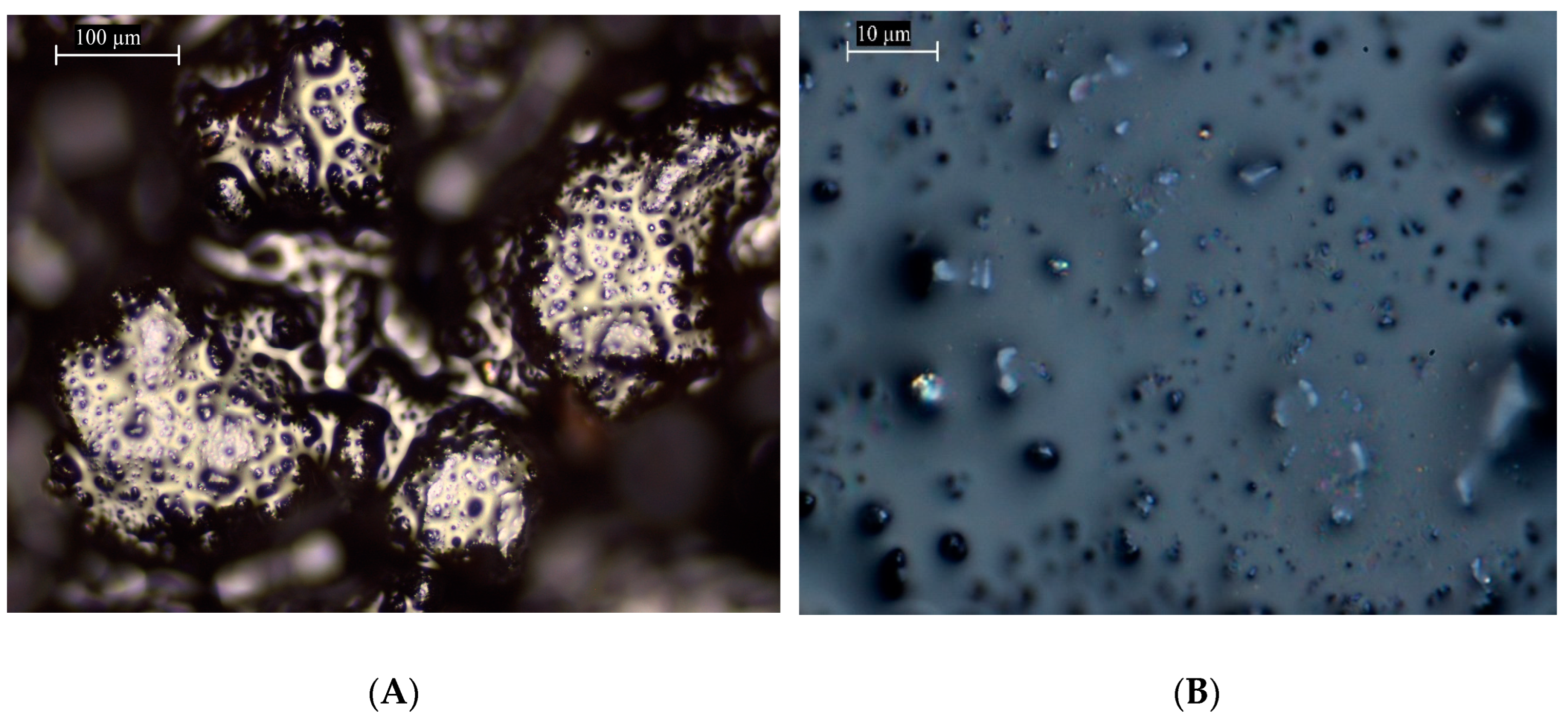

Oil sand has its own natural characteristics. It looks like oil spilled on the ground. To clarify the structure of the oil sand, it was studied using a modern microscope. As a result of the research, the mechanism of mutual connection of the mineral and organic parts in the oil sand was discovered.

Figure 2 is presenting optical microscopic image of oil Munaily-Mola oil sands that

Figure 2A is magnified 20 times and

Figure 2B is 150 times.

The main composition of the mineral part consists of sand, soil and clay. It was found that the organic part of the oil sand completely covers the surface of the mineral part. Due to the organic part is a viscous hydrocarbon that called natural bitumen, it binds the mineral part together. Between this mineral and organic fraction is water moisture composed of very fine clay and other minerals [

5,

11]. This aqueous moisture ensures that the mineral part and the organic part of the oil sand do not separate and stick together. Air voids can also be seen in the oil sand, depending on the size of the sandstones in the mineral particles and the size of the mineral particles around it. In general, the study of such a binding mechanism allows to understand and control the process during the extraction of oil from oil sands.

Petroleum (or oil) is trace amounts of metal-containing valuable organic compounds, which have very complex composition and diverse characteristics. Hydrocarbon raw materials with the general name oil differ from each other depending on their distribution on the globe and their location in the earth’s crust. Therefore, in order to take steps to refine oil, it is necessary to recognize its nature. They are divided into different classes according to their characteristics. The denomination unconventional can refer as geological aspects of the formation, properties of the deposits, and technical necessities for an ecologically acceptable, economic exploitation, and more appropriately to the method of recovery. There are two definitions that need to be addressed which also speak to the difference between petroleum and heavy oil on the one hand and oil sand bitumen on the other. The natural bitumen of oil sands of Munaily-mola used in the article obtained by extraction with organic solvents. Its details are given in the

Table 1 with the comparison characteristics of Karazhanbas crude oil.

Previously published studies reported that the mass fraction of Munaily-mola natural bitumen is 16% in total oil sand. Due to the amount of natural bitumen exceeding 10%, Munaily-Mola belongs to the category of rich oil sand according to the world index [

7]. However, it should be noted that this indicator increases depending on the depth of its distribution in the earth’s crust. The oil sand used in the research was a sample taken from a depth of up to half a meter. It is written in the literature [

29] that this indicator reaches up to 30% at a depth of up to 700 meters. Therefore, it believe that the development of this deposit will be an economically attractive production that will fully justify itself, even if it does not provide as much income as traditional oil processing.

Density of unconventional hydrocarbon is just a little bit heavy (0.987 g/cm

3) than the conventional heavy oil (0.935 g/cm

3). Therefore, both of them are classified as heavy hydrocarbons. The heating value of natural bitumen was 42656 j/g. Considering that the heating value of conventional crude oil is during 42000–44000 j/g, we know that natural bitumen is an excellent source of energy. Elemental compositions of the both hydrocarbons are tabulated in the

Table 2.

According to the data in

Table 2, the ash content of both hydrocarbon raw materials were basically the same. On the other hand, the ash content of natural bitumen may depend on the organic solvent used during its separation from oil sand. It should be noted that benzene is used as a solvent in the process of separation of Munaily-Mola natural bitumen.

For the elemental composition of the research object, it showed that they are very close to each other. Natural bitumen was distinguished by more carbon and hydrogen elements and less sulfur and oxygen than Karazhanbas crude oil. But in general, all the specified elements correspond to the amount of elements characteristic of crude oil. As well as, the fractional composition of natural bitumen was determined in comparison with Karazhanbas crude oil fraction, which is shown in the

Table 3.

In terms of fractional composition, we know that the yield of light fractions of natural bitumen is lower than that of Karazhanbas crude oil. The amount of light fractions of natural bitumen from boiling point to 200 °С is only 0.5%. And its total yield up to 500 °C temperature is 40%. In Karazhanbas crude oil, this indicator reached 90%. The small fraction of light fractions of natural bitumen means that it contains more heavy components.

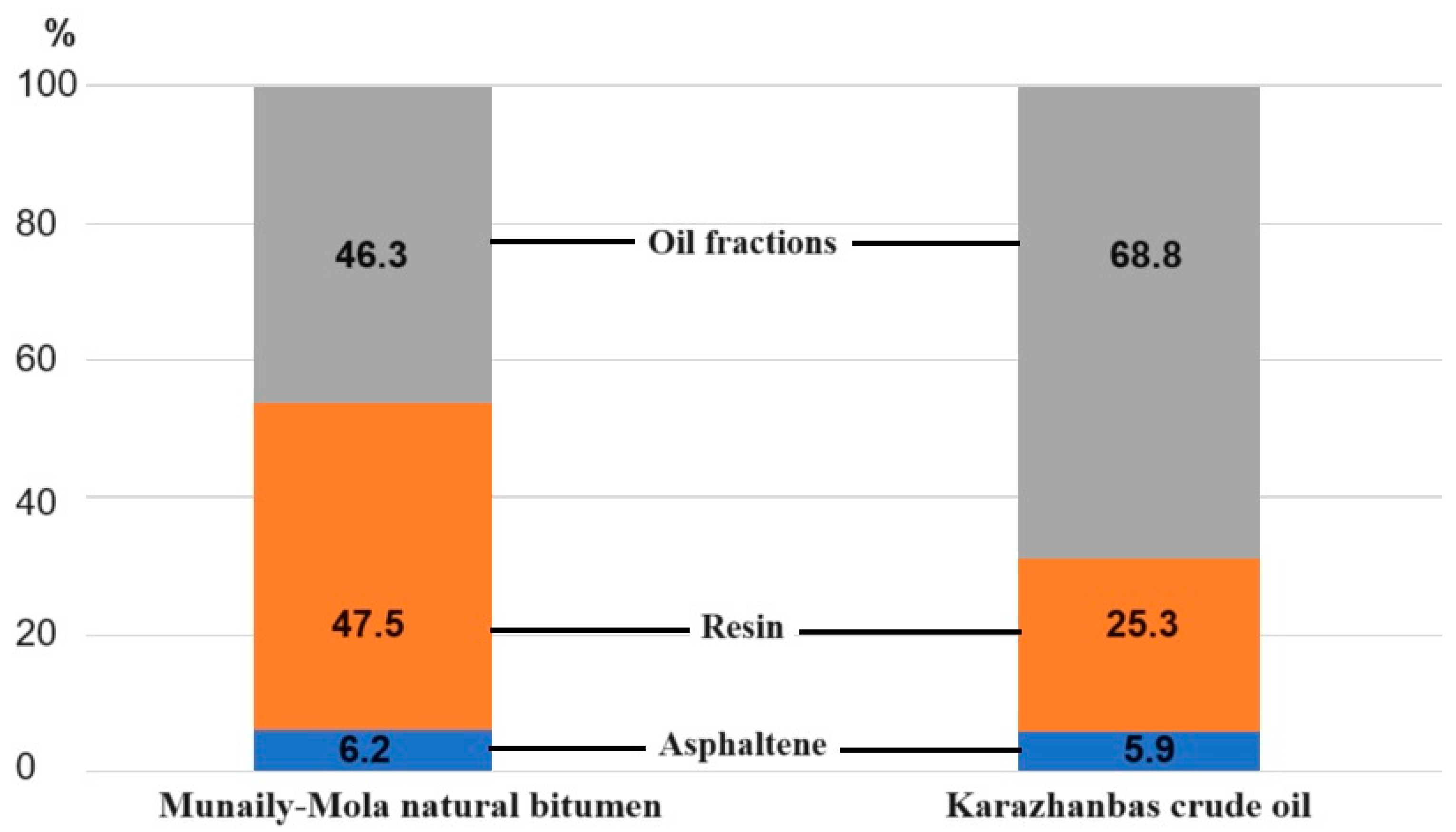

Hydrocarbon fractionations can be separated based on the solubility of the hydrocarbon components in various organic solvents used in analyses. Each fraction of the analyses consists of a solubility class that containing the range of different molecular-weight species. The natural bitumen and Karazhanbas crude oil used as research objects were separated to groups composition such as oil, resin and asphaltene. Their results are presenting in the

Figure 3.

As can be seen in the

Figure 3, there is a significant difference in the oil fractions of natural bitumen and crude oil. The oil fraction of natural bitumen is only 2/3 part of Karazhanbas crude oil. On the contrary, the amount of resin components are much higher than that of Karazhanbas crude oil. However, the asphaltene content of natural bitumen is basically the same as the asphaltene content of the heavy oil being compared. It was 6% in both of them. Therefore, both of the hydrocarbons belong to the highly resin-asphaltene compounds. The composition of the oil fraction consists of saturated hydrocarbons and aromatic hydrocarbons. The results of this group composition are consistent with the results of fractional yield given above.

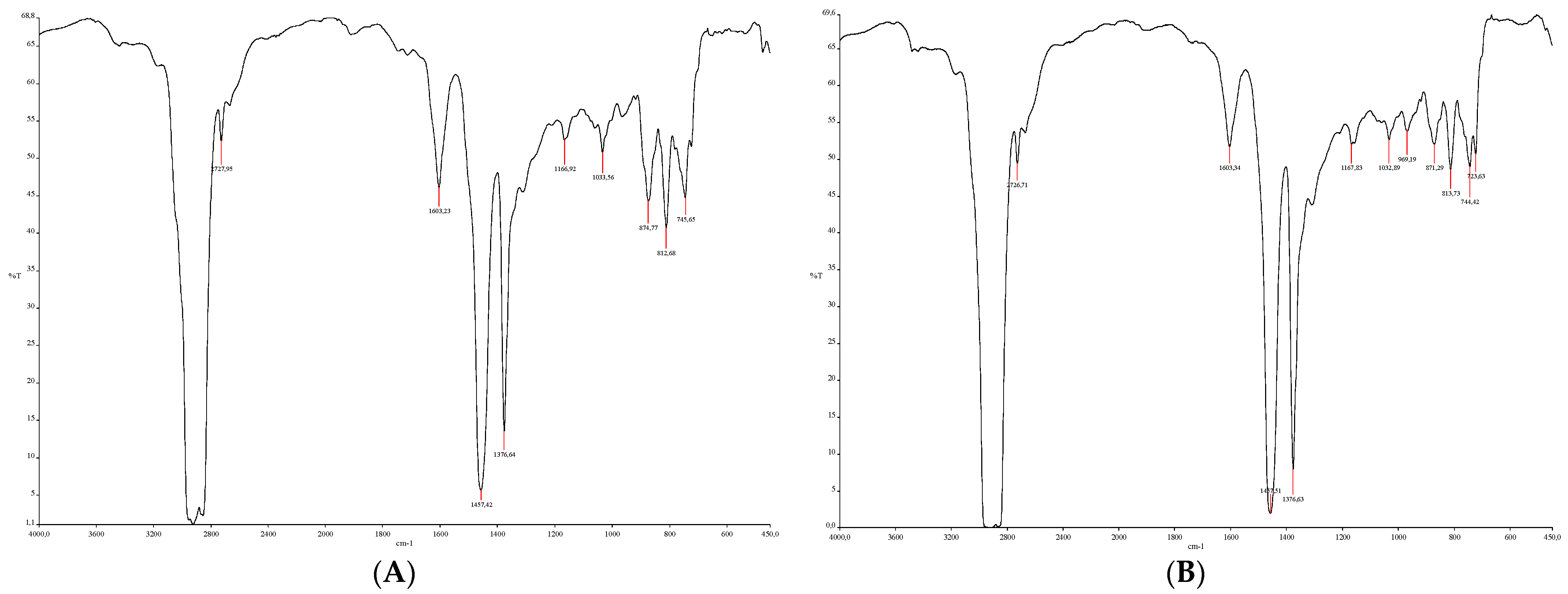

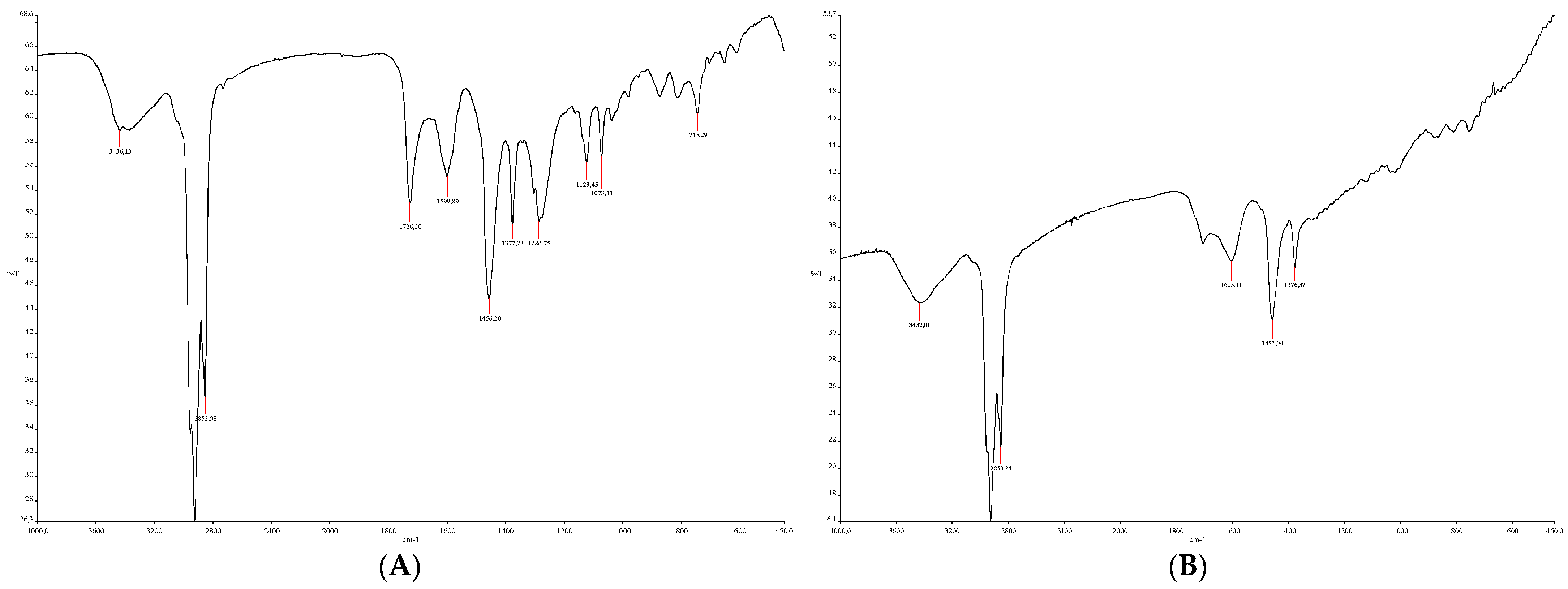

Chemical composition of the oil, resin and asphaltene fractions of the Munaily-Mola bitumen were analyzed at infrared spectroscopy with the comparison group composition of the Karazhanbas crude oil. This type of analysis makes it possible to determine the functional groups of samples and compare its composition. The result of IR spectroscopic analysis of oil fractions separated from the hydrocarbons are shown in the

Figure 4.

According to the results of IR spectroscopic research, the functional groups in the oil fraction of natural bitumen and crude oil were generally similar, only slight differences were observed. Infra-red spectroscopical analysis provided to oil fractions with 450–4000 cm−1 range. Oil fraction of hydrocarbons containing planar and out-of-plane deformation vibrations С-Н of aromatic compounds. Also seen stretching vibrations of the aromatic ring, actually, the band at 1457 cm−1 is overlapped by the band of bending vibrations of CH2. The spectrum contains oxygen, sulfur and nitrogen organic compounds and there are many vibrational waves characteristic of alkanes. However, the aromatic compounds corresponding to 723.63 cm−1, 871.29 cm−1 and alkenes corresponding to 969.19 cm−1 absorption bands, which are not present in natural bitumen, were observed in Karazhanbas crude oil.

The saturated hydrocarbons are non-polar aliphatic compounds with a straight and branched chain. The aromatic compounds cyclic organic compounds, including benzene and its structural derivatives. Most aromatic structures can contain alkyl chains, naphthenic rings, and additional aromatic rings. Therefore, oil is a much lighter hydrocarbon fraction than resin and asphaltene. The result of IR spectroscopic analysis of resin fraction of the natural bitumen and crude oil are presenting in

Figure 5.

In the

Figure 5A IR spectroscopy peaks at 754, 817 and 877.8 cm

−1 present condensed aromatic hydrocarbons. The alkyl groups like CH

3 and CH

2 within long-chain branched structures absorbed at 721.2 cm

−1. The absorption band at 1377 cm

−1 is characterized for compounds with methylbenzene pattern. The acidic hydroxyl group belongs to absorption band at 3355.5 cm

−1. Stretching vibrations of oxygen in carboxyl groups represent absorption bands at 1600.7 and 1703 cm

−1. Structure of heavy crude oil resin peak (

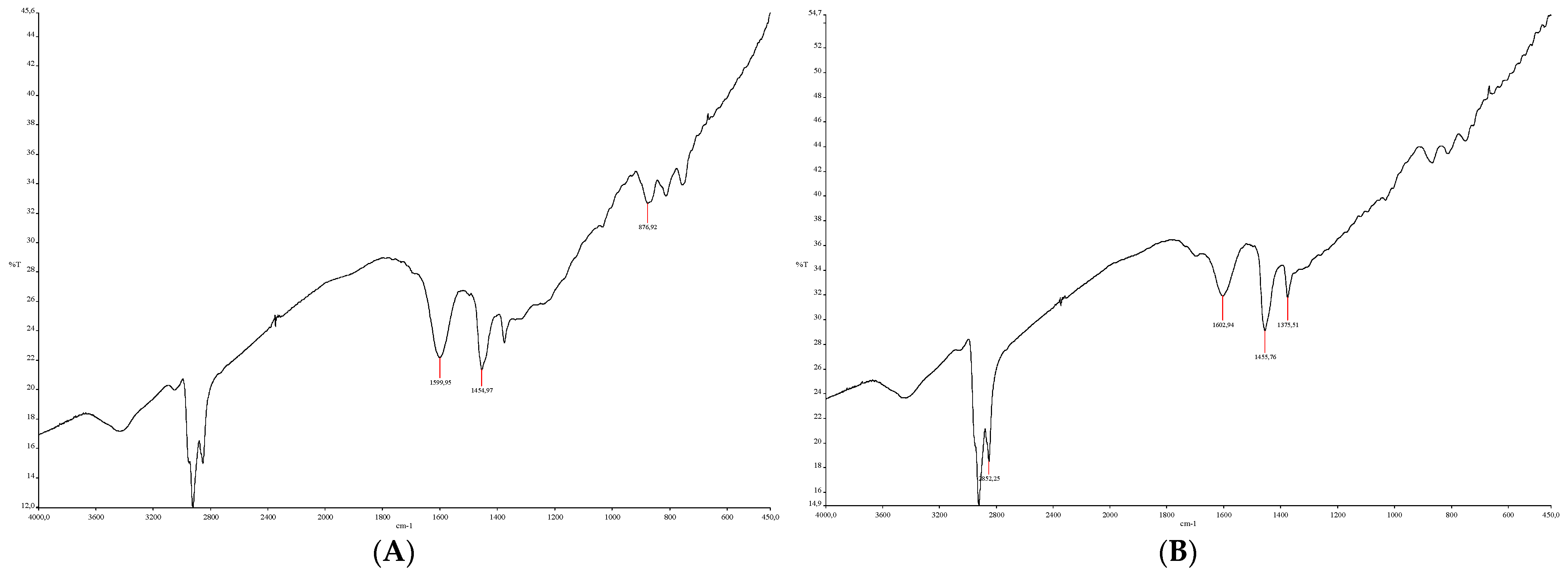

Figure 5B) intensity show the lower content condensed aromatic hydrocarbons compare than natural bitumen of Munaily-Mola oil sands. Most of absorption peak of Karazhanbas crude oil characterize the degree of branching of aliphatic paraffinic chains. Well known the resins are components of an intermediate structure that located between the oil fractions and asphaltenes. They serve to keep the aggregates dispersed in the hydrocarbons. IR spectroscopic result of the asphaltenes deposited from the natural bitumen and crude oil are showing in

Figure 6.

Asphaltenes are the most the heaviest components in the petroleum (or crude oil). They contain highly aromatic and polar of hydrocarbon, therefore the asphaltenes are refractory fractions during the SARA fractions. Natural bitumen and crude oil precipitated asphaltenes were not clearly different from each other, but were similar in many indicators. Only the intensity of the absorption bands of their partial components is little bit different. In the spectrum, it was found that there are heterocyclic compounds with double bonds having oxygen, sulfur and nitrogen compounds (such as R-SO-OH and S-O st). At 2850 and 3055.9 cm−1 absorption bands in both asphaltene structures shows the alkyl substituents (-CH3, =CH2) in long chain. Asphaltenes absorption bands at 1696 cm−1 provides information about the ketones groups with the two aliphatic chains or saturated rings. Lower intensity peak at 912 cm−1 represent oxygenates with higher content of oxygen compounds. Also, asphaltenes contains alkenes with ν-СН2, ν-СН3, O-CH3 bonds and amines with δ-NH2 bonds.

4. Conclusions

Characteristics of the natural bitumen of the Munaily-Mola oil sands were studied with comparison crude oil of Karazhanbas oil field. Microscopic study approved that the organic part of the oil sand completely covers the surface of the its mineral part. Due to the organic parts are viscous hydrocarbon that they bind the mineral part together.

By the density of natural bitumen and crude oil are classified as heavy hydrocarbons. both of them are classified as heavy hydrocarbons. The heating value of natural bitumen with the Karazhanbas crude oil were reached during 42,000–44,000 j/g in accordance with the index for conventional oil.

Elemental composition of the Munaily-Mola natural bitumen and Karazhanbas crude oil were close to each other. Natural bitumen was distinguished by more carbon and hydrogen elements and less sulfur and oxygen than Karazhanbas crude oil. But in general, all the specified elements correspond to the amount of elements characteristic of conventional oil.

The amount of light fractions of natural bitumen from boiling point to 200 °С is only 0.5%. And its total yield up to 500 °C temperature is 40%. In Karazhanbas crude oil, this indicator reached 90%. Yield of the light fractions of natural bitumen is lower than that of Karazhanbas crude oil.

The group composition of these two hydrocarbon raw materials were also studied in comparison with each other. During the experiment, the percentage of their asphaltene, resin and oil were determined and studied by IR spectroscopy. It concluded that natural bitumen belongs to the highly resin-asphaltene compounds as a Karazhanbas crude oil. There is a significant difference in the oil fractions of natural bitumen and crude oil. The oil fraction of natural bitumen is only 2/3 part of Karazhanbas crude oil. On the contrary, the amount of resin components are much higher than that of Karazhanbas crude oil. However, the asphaltene content of natural bitumen is basically the same as the asphaltene content of the heavy oil being compared.

Thus, natural bitumen of Munaily-Mola oil sand corresponds to the general indicators of conventional crude oil in terms of the main physical and chemical characteristics analyzed in the article. It proves that natural bitumen can be used as an excellent sustainable source of the energy.

Author Contributions

Writing—original draft preparation and project administration, Y.T.; writing—review and editing, Y.O.; methodology, Y.I.; investigation and formal analysis, A.Y.; conceptualization, K.Z. and A.S.; validation, A.I.; supervision, Z.M.

Funding

This study was funded by the Scientific Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (AP19175900 “Extraction of liquid fuels from combustible minerals and reuse of waste from this process”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hein, F.J. Geology of Bitumen and Heavy Oil: An overview. J. Pet. Sci. Eng. 2017, 154, 551–563. [Google Scholar] [CrossRef]

- Speight, J.G. Oil sand production processes. Elsevier Inc.: Amsterdam, The Netherlands, 2013; Volume 175. [Google Scholar]

- Wik, S.; Spark, B.D.; Ng, S.; Yu, Y.; Li, Z.; Chung, K.H. Effect of process water chemistry and particulate mineralogy on model. Fuel 2008, 87, 1394–1412. [Google Scholar] [CrossRef]

- Dusseault, M.B. Comparing Venezuelan and Canadian heavy oil and tar sands. www.southportland.org.

- Banerjee, D.K. Oil sands, heavy oil and bitumen. RenWell: Tulsa, USA, 2012; Volume 185. [Google Scholar]

- Imanbayev, Y.; Ongarbayev, Y.; Tileuberdi, Y.; Krivtsov, E.; Golovko, A.; Mansurov, Z. High temperature transformation of tar-asphaltene components of oil sand bitumen. J. Serb. Chem. Soc. 2017, 82, 1063–1073. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, M.; Zhang, Z.; Zhang, D. Pyrolysis of an Indonesian oil sand on a thermogravimetric analyser and a fixed-bed reactor. J. Analy. Appl. Pyr. 2016, 117, 191–198. [Google Scholar] [CrossRef]

- Adebiyi, F.M.; Akhigbe, G.E. Characterization of paraffinic hydrocarbon fraction of Nigerian bitumen using multivariate analytical techniques. J. Uncon. Oil Gas Res. 2015, 12, 34–44. [Google Scholar] [CrossRef]

- Asadzadeha, S.; Souza Filhoa, C.R.; Nannib, M.R.; Batezelli, A. Multi-scale mapping of oil-sands in Anhembi (Brazil) using imaging spectroscopy. Int J Appl Earth Obs Geoinform 2019, 82, 10189. [Google Scholar]

- Abramov, O.V.; Abramov, V.O.; Myasnikov, S.K.; Mullakaev, M.S. Extraction of bitumen, crude oil and its products from tar sand and contaminated sandy soil under effect of ultrasound. Ultras. Sonochem. 2009, 16, 408–416. [Google Scholar] [CrossRef]

- Tileuberdi, Y.; Mansurov, Z.; Ongarbayev, Y.; Tuleutaev, B. Structural study and upgrading of Kazakhstan oil sands. Euras. Chem. Techn. J. 2015, 17, 41–45. [Google Scholar] [CrossRef]

- Yoon, S.; Bhatt, S.D.; Lee, W.; Lee, H.Y.; Jeong, S.Y.; Baeg, J.O.; Lee, C.W. Separation and characterization of bitumen from Athabasca oil sand. Korean J. Chem. Eng. 2009, 26, 64–71. [Google Scholar] [CrossRef]

- Asphalt and Bitumen. Encyclopedia of Chemistry (Ullmann’s) 2012, 4, 273–294. [CrossRef]

- Bergero, C.; Binsted, M.; Younis, O.; Davies, E.G.; Siddiqui, M.S.; Xing, R.; Arbuckle, E.J.; Chiappori, D.V.; Fuhrman, J.; McJeon, H.; Macaluso, N. Technology, technology, technology: An integrated assessment of deep decarbonization pathways for the Canadian oil sands. Ener. Strat. Rev. 2022, 41, 10084. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, C.; Jiang, Q.; Wang, Y.; Deyin, W. Combustion characteristics of Indonesian oil sands. Fuel Proc. Techn. 2012, 99, 110–114. [Google Scholar]

- Wik, S.; Spark, B.D.; Ng, S.; Yu, Y.; Li, Z.; Chung, K.H. Effect of process water chemistry particulate mineralogy on model. Fuel 2008, 87, 1394–1412. [Google Scholar] [CrossRef]

- Barrett, K.R. Reservoir geology of the Grosmont Formation bitumen steam pilot, Saleski, Alberta. Bull. Can. Petr. Geol. 2016, 64, 147–165. [Google Scholar] [CrossRef]

- Parviz, M.R.; Gentzis, T. The chemistry of bitumen and heavy oil processing. In Pratical Advances in Petroleum Processing; Hsu, C.S., Robinson, P.R., Eds.; Springer: New York, NY, USA, 2006; pp. 597–634. [Google Scholar]

- Mullins, O.C.; Sheu, E.Y.; Hammami, A.; Marshall, A.G. (Eds.) Asphaltenes, Heavy Oils and Petroelomics. Springer: New York, NY, USA, 2007; Volume 31. [Google Scholar]

- Wang, Q.; Jia, C.; Jiang, Q.; Wang, Y.; Deyin, W. Combustion characteristics of Indonesian oil sands. Fuel Proc. Techn. 2012, 99, 110. [Google Scholar]

- Cosseya, H.L.; Guigarda, S.E.; Underwooda, E.; Stiver, W.H.; McMillanc, J.; Bhattacharya, S. Supercritical fluid extraction of bitumen using chemically modified carbon dioxide. J. Supercr. Flui. 2019, 54, 104599. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, X.; Li, H.; Li, X.; Gao, X. Understanding the pyrolysis progress physical characteristics of Indonesian oil sands by visual experimental investigation. Fuel 2018, 216, 29–35. [Google Scholar] [CrossRef]

- Tileuberdi, Y.; Ongarbaev, Y.; Tuleutaev, B.; Mansurov, Z.; Behrendt, F. Study of natural bitumen extracted from oil sands. Appl. Mech. Mat. 2014, 467, 8–11. [Google Scholar] [CrossRef]

- Nadirov, N.K. High-viscosity oil and natural bitumen in 5 volumes. Almaty: Science 2001, 5, 337. (In Russian) [Google Scholar]

- Gibson, J.J.; Peters, D.L. Water and environmental management in oil sands regions. J. Hydr. Regi. Stud. 2022, 44, 101274. [Google Scholar] [CrossRef]

- Jia, C.; Pang, X.; Song, Y. The mechanism of unconventional hydrocarbon formation: Hydrocarbon self-sealing and intermolecular forces. Petrol. Explor. Develop. 2021, 48, 507–526. [Google Scholar] [CrossRef]

- Munaily-Mola Field. https://kazakhstan.travel/tourist-spot/en/413/munaily-mola-field.

- Welcome to Corporate Resource of «Karazhanbasmunai» JSC. https://www.kbm.kz/en/index.htm.

- Nadirov, N.K. High-viscosity oil and natural bitumen in 5 volumes. Almaty: Science 2001, 1, 360. (In Russian) [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).