1. Introduction

Coal, as a large proportion of consumption energy, is expected to remain irreplaceable for a long time [

1]. With the advancements in coal mining technology, the depth of coal mining continues to increase. However, the common occurrence of rock burst, fire, water inrush and other disasters greatly cast a dark cloud in this field, and thus it is essential for people to provide necessary warning in the face of the increasingly complex coal mining environment to prevent loss of life and property [

2]. Intelligent mining, that is, unmanned mining, is the ultimate goal of coal mine safety production, and research on coal-rock identification is a crucial step in achieving this goal [

3,

4,

5]. Moreover, intelligent identification of coal-rock interface can maximize the efficient utilization of coal resources, replacing the existing manual identification, which not only reduces the safety risk for frontline coal miners but also avoids the waste of coal resources. It is noted that automatic height adjustment of the coal cutter drum is a key aspect of coal-rock interface identification technology. In recent years, various research efforts have been made in the field of coal-rock interface recognition technology, such as image detection, cutting force detection, intelligent sensing technology, ground-penetrating radar (GPR) detection, and infrared detection. [

6]. In 2019, Miao Shuguang et al. [

7] used the finite-difference time-domain method to build models of different coal-rock combinations and conduct numerical simulation to obtain radar detection signals, demonstrating the applicability of radar detection technology in coal-rock interface recognition. In 2020, Liu Zaibin et al. [

8] used dynamic visualization modeling method to characterize the complex structure of coal seams to address the problem of stepwise transparency in coal seams. In 2021, Zhang Ronghua [

9] conducted a comparative study of LSM and RELB-based coal-rock identification methods, explaining their applicability in the field of coal and rock identification. Ju liana et al. [

10] achieved the classification of coal by analyzing coal color and frequency histograms to obtain reflectance distribution. Nazarova et al. [

11] assessed the stress state of coal and rock mass in the coal cutting area and reconstructed the three-dimensional stress field of coal and rock mass through the coal layer tomography and the evaluation of the horizontal component of the external stress field. Shan. et al. [

12] proposed a numerical method for simulating the coupled fluid-solid process during the failure of fractured coal-rock bodies by considering the characteristics of regional stress in the steep coal seam, providing a reliable theoretical basis for the optimizing the roof weakening in steep coal seam mining.

Terahertz (THz) waves, with a frequency range between 0.1 THz and 10 THz, fall between microwaves and infrared waves in the electromagnetic spectrum. Due to their high resolution, non-contact and non-destructive properties, THz waves have been applied in diverse fields such as medical testing, space communication, and non-destructive testing [

13,

14]. In recent years, THz time-domain spectroscopy has been applied to the study of coal-rock interfaces. Researchers such as Takenori Tanno et al. [

15] from Tohoku University and Akita University in Japan measured the transmission spectra of dry and non-dry coal powder and polyethylene mixed with laminated samples in the range of 1 THz~5 THz to estimate the water content in coal. Bao [

16] conducted an analysis of THz wave transmission properties in reservoir layers, revealing the transmission characteristics of THz waves in rocks, which is helpful to improve the efficiency of THz time-domain spectroscopy and enrich oil field exploration methods. In terms of coal and rock identification. In the realm of coal-rock identification, Wang Xin et al. [

17] from China University of Mining and Technology extracted various THz signal parameters from different kinds of coal and rocks, and proposed a classification method based on the absorption characteristics and refractive indices of different coal and rock materials, demonstrating the potential applications of THz technology in coal and rock identification. Subsequently, Yu Jing et al. [

18] used the least squares support vector machine algorithm to analyze and study the THz parameters of the coal-rock mixtures with varying proportions. From previous research on THz applications in coal-rock identification, it is evident that THZ time-domain spectroscopy technology can be applied not only to coal-rock identification but also to more complex situations.

In this study, THz-TDS technology (THz time-domain spectroscopy) is applied to the identification of coal-rock and coal-rock mixtures and for the detection of coal seam thickness. The measurement results on different samples prepared by two kinds of coal (anthracite, lignite) and two kinds of rock (limestone, quartz sandstone), and the extracted optical parameters were used to establish the optical database of multiple kinds of coal and rock mixtures for high-resolution identification of coal and rock mixtures. Additionally, by preparing and analyzing a wider variety of coal-rock mixtures, various interface scenarios and an optical data database for multiple coal-rock mixtures can be established, which provides data support for intelligent identification of multiple coal-rock interfaces by coal mining machines. Based on this, the coal seam thickness detection technology based on THz-TDS is successfully proposed. Through analyzing the THz spectrum detection of 10 anthracite flakes with different thickness and simulating the experimental process using software CST, the relationship between the time domain signal and thickness variation of different coal flakes can be established, thereby verifying the effectiveness and feasibility of this method, which has broader applications in the field of coal-rock interface identification.

2. Experimental Detection

2.1. Experimental Instruments

The experimental setup used in this study is the terahertz time-domain spectrometer (THz-TDS 1008). The working principle of the THz time domain spectrometer involves the generation of laser pulse by the external laser source. These laser pulses are then divided into two parts by the beam splitting mirror, the pump pulse and the probe pulse. After passing through the time delay system, the pumped pulse enters the transmitter to produce THz pulse. These THz pulses propagate free space for a certain distance and then is incident on the THz detector together with the detection pulse to drive the THz detection device for measurement. By controlling the time delay system to adjust the time delay between the pump pulse and the probe pulse, the complete time domain waveform of the THz pulse can be detected. Through Fourier transform, the frequency domain spectrum of the measured sample can be obtained, which can provide essential optical parameters such as absorption coefficient, refractive index, transmittance and other optical parameters [

19,

20,

21]. It is worth noting that the laser source used in this setup has a central wavelength of 800 nm and a pulse duration of 100 fs. In order to ensure experimental conditions closely to the actual environment and avoid the potential effects on the measurement results, the experiments were carried out at room temperature (23 °C) with 5% relative humidity.

2.2. Sample Preparation

In this study, two kinds of coal (anthracite and lignite) and two kinds of rocks (quartz sandstone and limestone) were collected from Datong Coal Mine in Shanxi Province. The sample preparation was done using two methods: the first is the preparation of coal and rock powder mixed laminate, while the second part is the preparation of coal flakes (anthracite) with different thickness. In the first part, coal and rock were individually pressed into certain size pellets with polyethylene. Then, in order to simulate different coal-rock mixtures, four combinations were made (quartz sandstone-Anthracite, limestone-Anthracite, quartz sandstone-Lignite, limestone-Lignite), and each combination was mixed in four different proportions.

Before preparation, we used an agate mortar to grind the coal and rock into powder with a particle size of less than 74 μm, that is, the ground powder must pass through a 200-mesh steel screen. Because of the risk of cracking in some samples with smaller thickness, the coal rock and coal rock mixed powders were mixed with polyethylene in a ratio of 2:1, and each sample laminate weighs 0.2 g. Polyethylene served to bond and dilute the samples and had negligible impact on the absorption rate of THz, with transmission of over 80% in the THz range. Different rock proportions refer to the ratio of coal to coal-rock mixed powders. The mixed samples were placed in a tablet press and pressed at 20 Mpa for 5 minutes, Since the tablet device had a diameter of 5mm, each sample had the same diameter, but different thickness. The specific information for 20 samples is shown in

Table 1 and

Table 2. After that, 0.2 g of polyethylene was weighed and pressed as a reference sample for the experiment.

The second part is the preparation of flake anthracite samples with different thickness to simulate coal seam thickness detection using terahertz waves, which is more suitable to coal-rock identification scenarios in actual coal mines. First, the original anthracite was cut into various thickness samples using a cutting machine. Then, the surface of these plate-like samples was polished using sandpaper to make them relatively smooth and reduce scattering of THz waves on the surface of the sample, minimizing their impact on the test results. The thickness of each sample was measured three times and the average value was taken. The thickness information for10 flaky samples is shown in

Table 3. THz wave passing through an empty sample stage, representing air, were used as a reference in the time-domain spectroscopy.

2.3. Data Processing

Before conducting the experiments, the THz time domain spectrometer should be turned on in advance to ensure the stability. First, measurements were taken separately for pure polyethylene sheets and air, serving as reference THz signal for each sample. After obtaining the time domain spectral signal of each sample, the time domain spectrum was transformed into a frequency domain spectrum by Fourier transform (FFT). Then, optical parameters such as refractive index n(w), extinction coefficient k(w) and absorption coefficient α(w) were obtained by using the optical parameter extraction model [

22,

23,

24]. The formulas for these calculations are as following:

: frequency; : phase difference between the sample signal and the reference signal; ρ (w) is the amplitude ratio between the sample signal and the reference signal; d: sample thickness; c: the speed of light.

3. Results and Discussion

3.1. THz Spectral Properties of Coal-Rock and Coal-Rock Mixtures

3.1.1. THz Spectral Properties of Coal and Rock

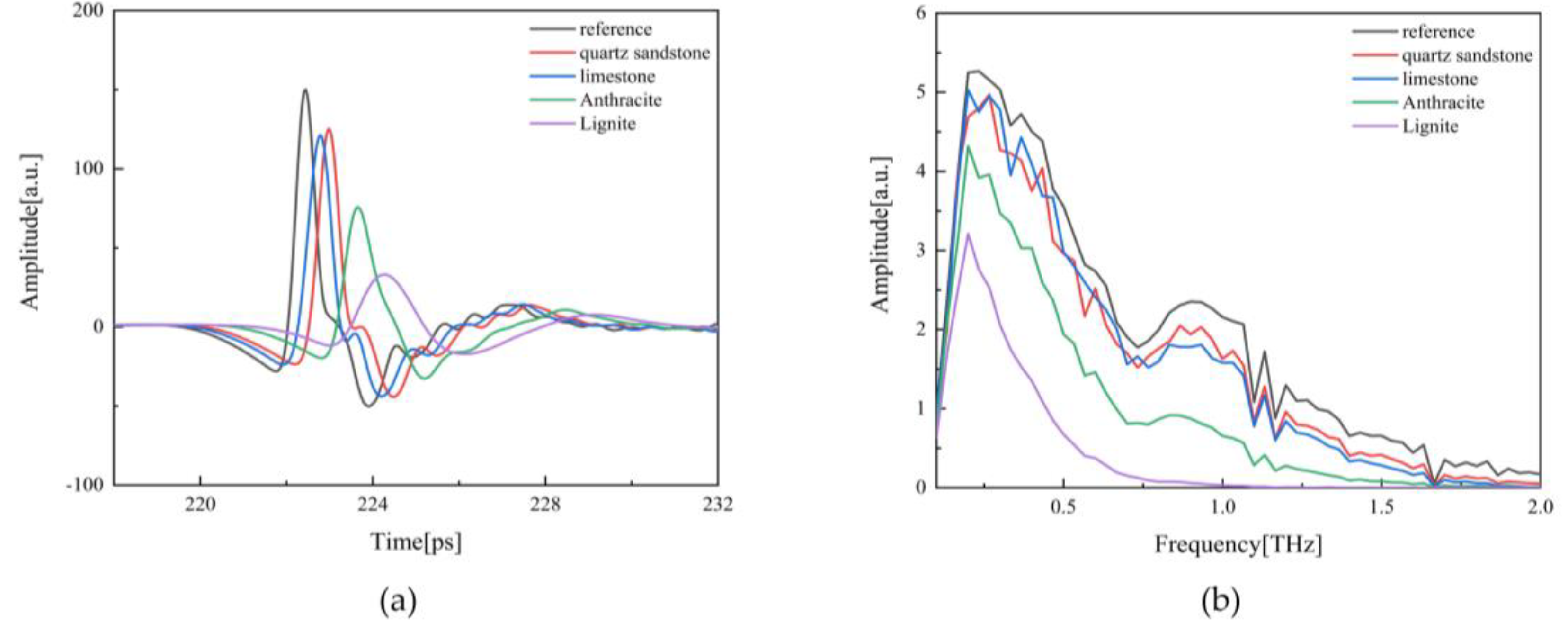

Before starting the sample testing, the pure polyethylene sample was placed on the bench to obtain the reference THz signal. Measurements were conducted on two kinds of coal and two kinds of rock samples (coal/rock powder: polyethylene powder = 2:1) were measured. The THz spectral scan range was 218-232 ps with a step size of 0.02 ps to obtain the time-domain spectrum of the sample as shown in

Figure 1a. It can be observed that the THz amplitudes of coal-rock samples decreases to varying degrees compared with the reference signal due to surface reflection and absorption. Because the four samples have different refractive index, the wave speed and light path of the THz pulse passing through the sample are different, leading to differences in the time delay and the appearance of the at different times [

25]. From the figure, it is evident that the THz amplitude attenuation of the two coal samples is more serious than that of the two rock samples. The peak amplitude for the coal samples is generally lower than 100, indicating more significant reflection and absorption of the THz in coal samples.

Fast Fourier transform (FFT) was used to convert the time-domain signals of coal and rock into the frequency domain to obtain the frequency domain spectrum, as shown in b. From the figure, it can be seen that all samples exhibit peak values in the frequency domain around at 0.25 THz, with the peak values for coal and rock samples being lower than 5, and lignite having the lowest peak value. Rock samples can have higher frequency domain amplitudes than that of the coal samples, primarily due to the differences in the absorption of THz electric field by different components in the coal samples. Subsequently, the frequency domain waveforms of the samples were compared with those of the reference sample to obtain the transmission coefficients for each sample, as depicted in

Figure 1c. The bandwidth of the coal samples in the THz band is about 1.11 THz, and the THz wave fluctuation after 1.11 THz is abnormal, so we study the frequency band of 0.2-1.11 THz to analyze the transmission coefficient, absorption coefficient and refractive index of the sample, and then analyze the optical signal of the coal mixture sample with 0.2-1.11 THz frequency band. It can be seen from the figure that there is a significant difference in transmission coefficients between coal and rock, with rock samples having much higher transmission coefficients than coal samples in the THz waveband. When the frequency is greater than 1.11 THz, the absorption spectral waveform fluctuates significantly and is of limited reference value.

Therefore, the refractive index and absorption coefficient of coal and rock samples can be calculated by using the formula in 2.3. From

Figure 1d, the refractive index of coal and rock samples is relatively stable. In the fixed frequency band, the refractive index of coal samples is higher than that of rock samples, with the refractive index of rock samples being lower than 1.2, and lignite having the highest refractive index.

Figure 1e illustrates the absorption coefficient of coal and rock samples, showing that the absorption coefficient of each coal and rock sample increases steadily with the increase of frequency. The absorption spectrum of each sample exhibits slightly fluctuations due to internal absorption or surface scattering. At the same frequency, the absorption rate of coal samples is higher than that of rock samples. The differences in optical parameters, such as refractive index and absorption coefficient between coal and rock, allow for the accurate identification of coal and rock in the THz band, which also demonstrates that THz time-domain spectroscopy technology can be well applied to coal and rock identification.

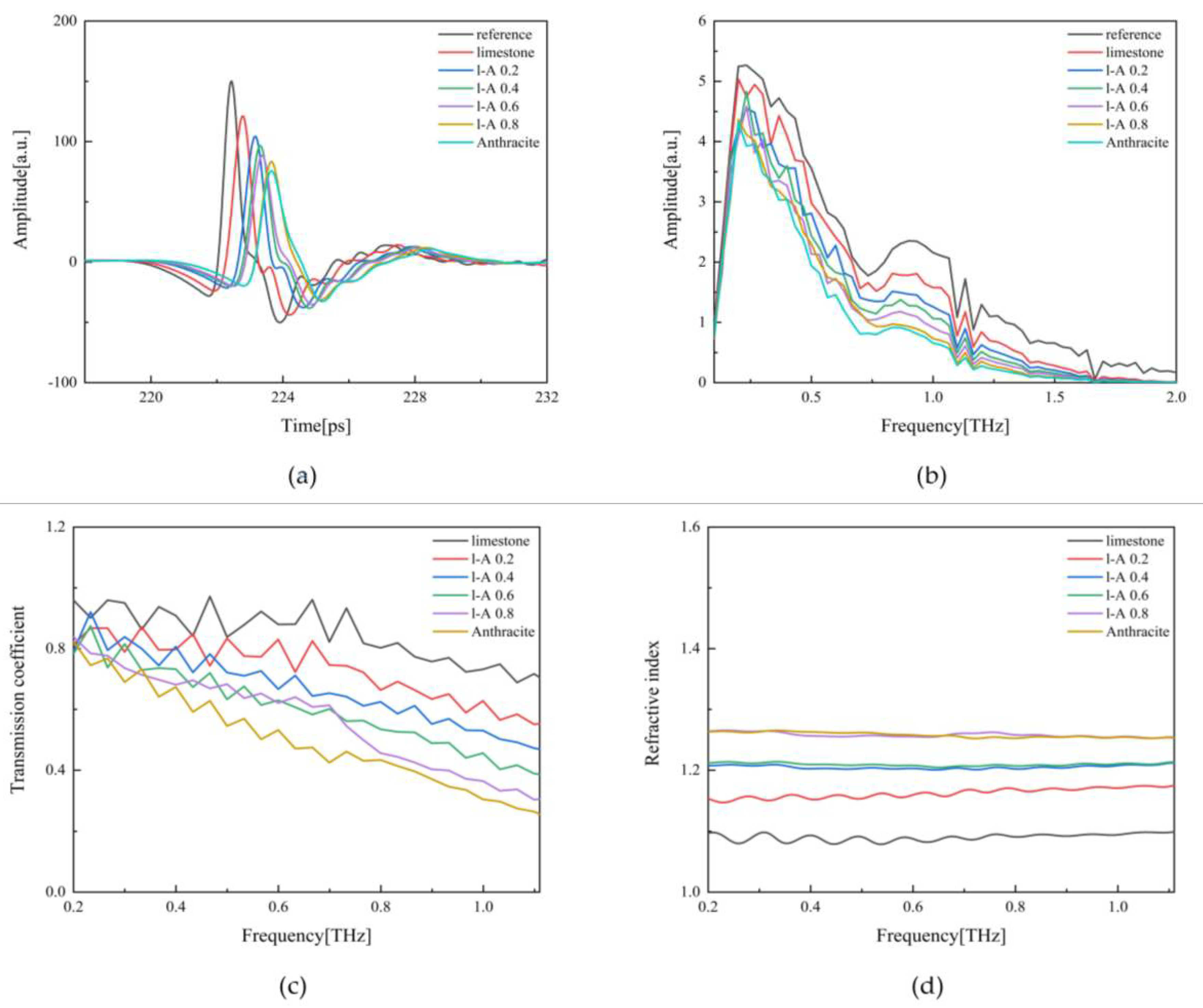

3.1.2. THz Spectral Properties of Coal-Rock Mixtures

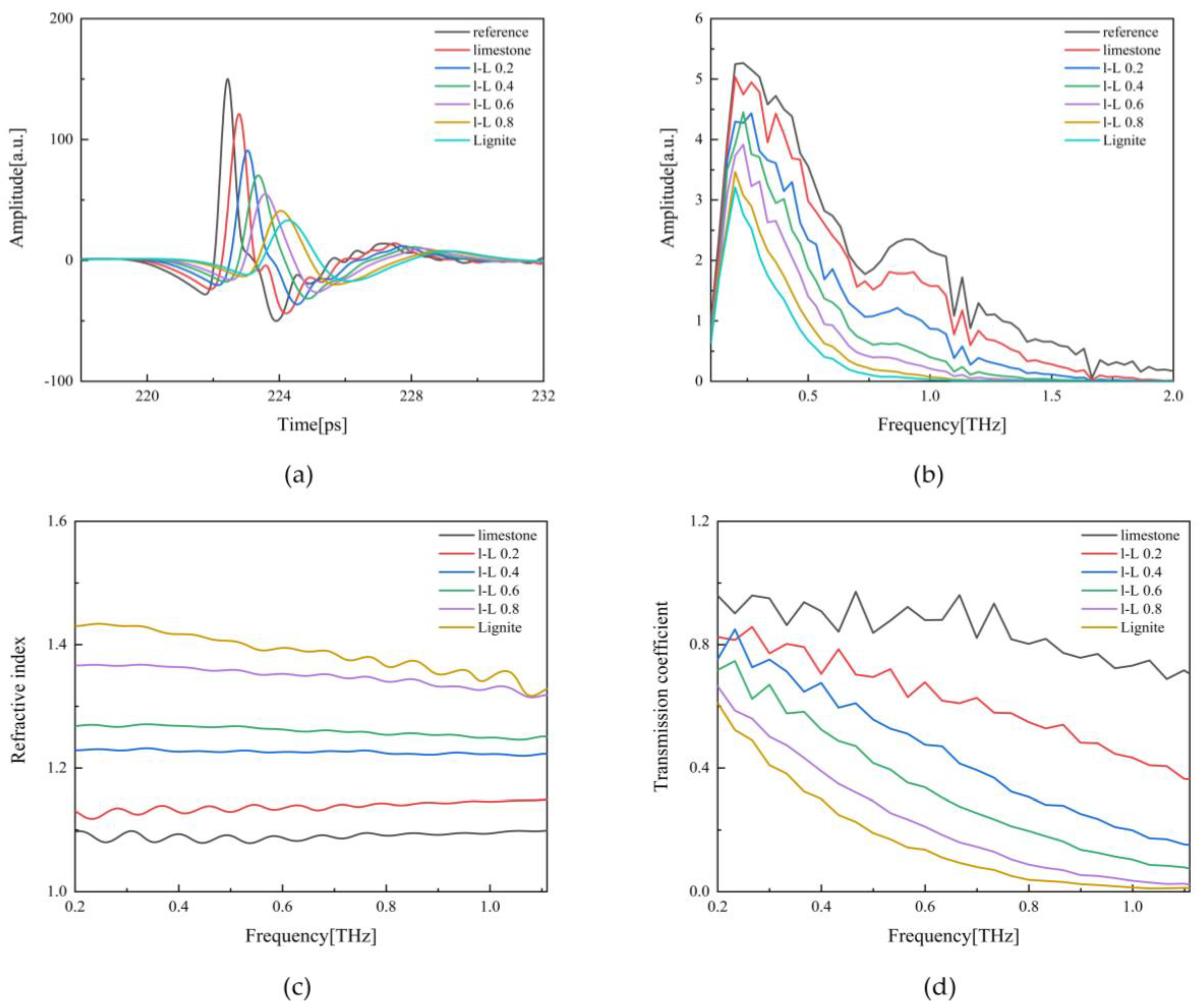

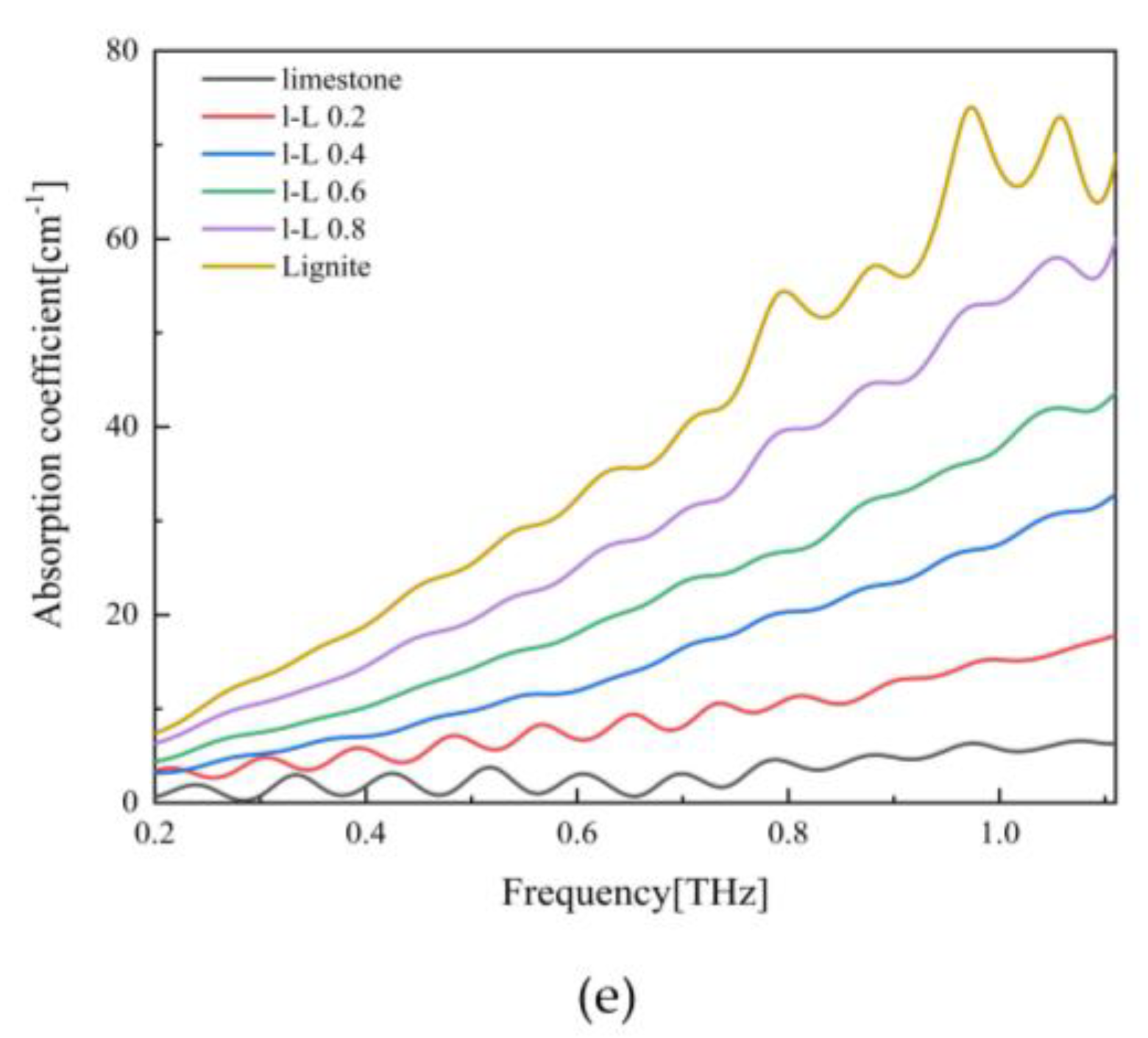

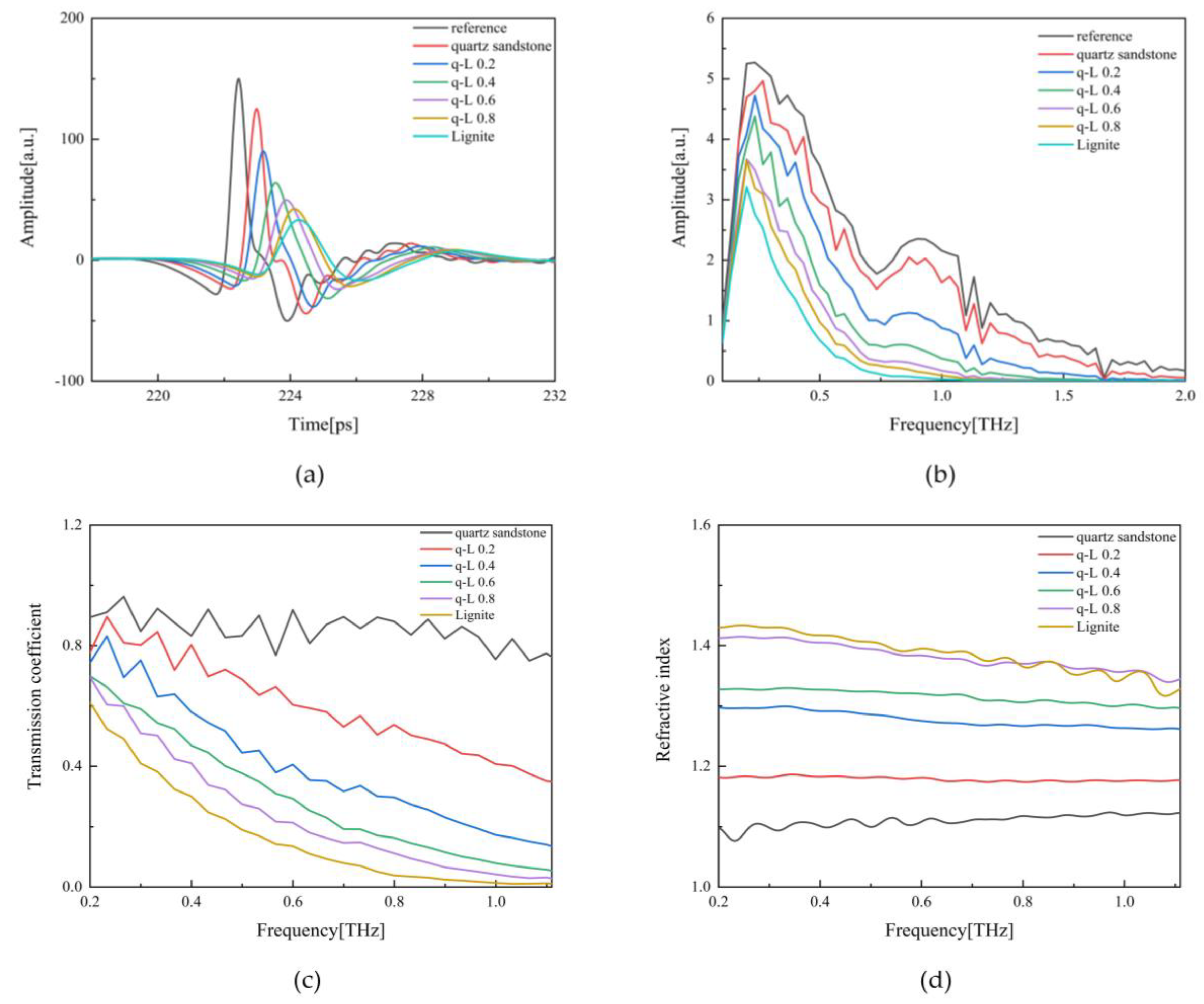

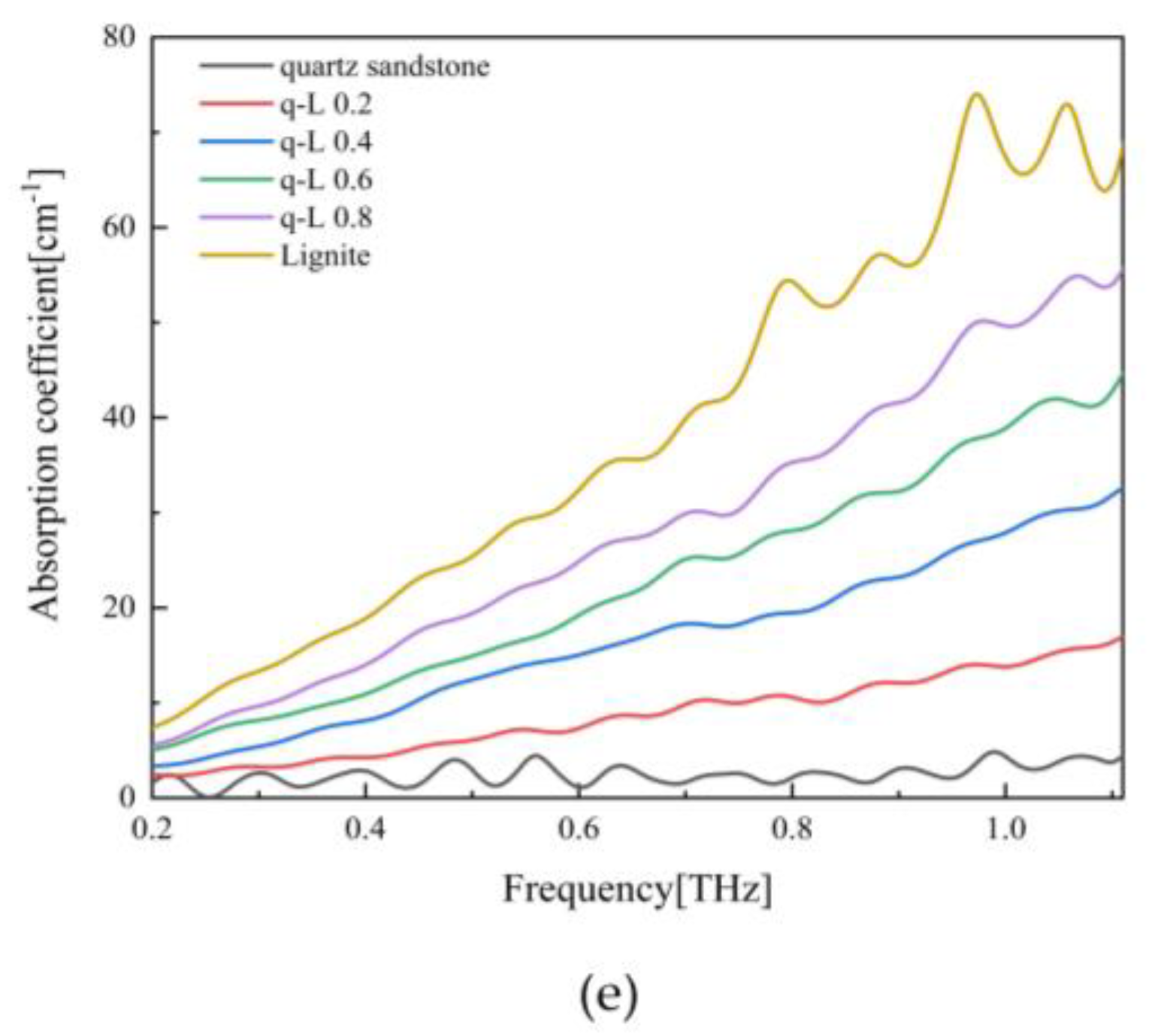

The THz time-domain spectral system is consistent with previous configurations, and the measurement and calculation results for the coal-rock mixture sample (coal-rock powder: polyethylene powder = 2:1) are shown in Figures 2–5: limestone-Lignite mixture sample,

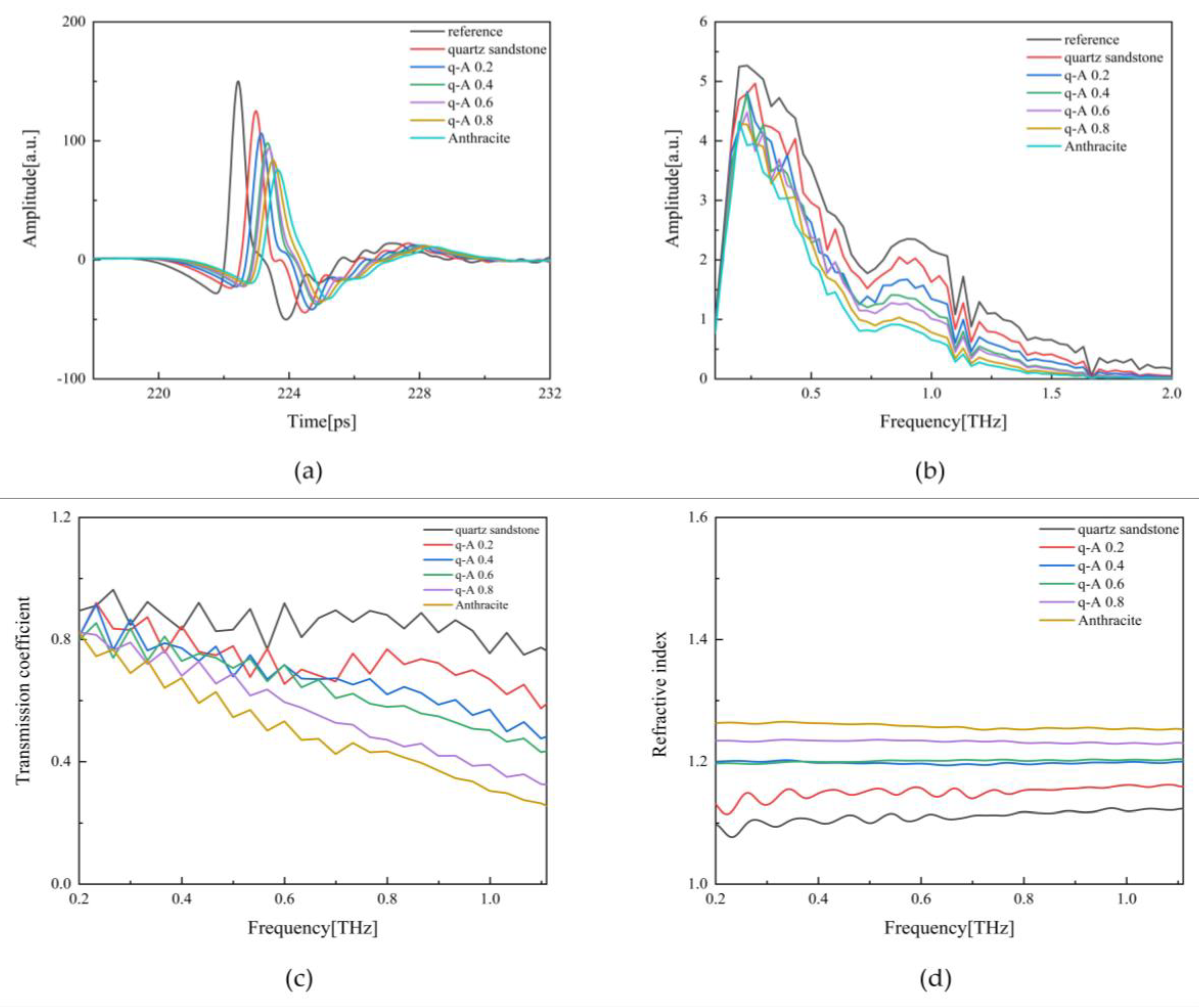

Figure 2; quartz sandstone-Lignite mixture sample, Figure. 3; quartz sandstone-Anthracite mixture sample,

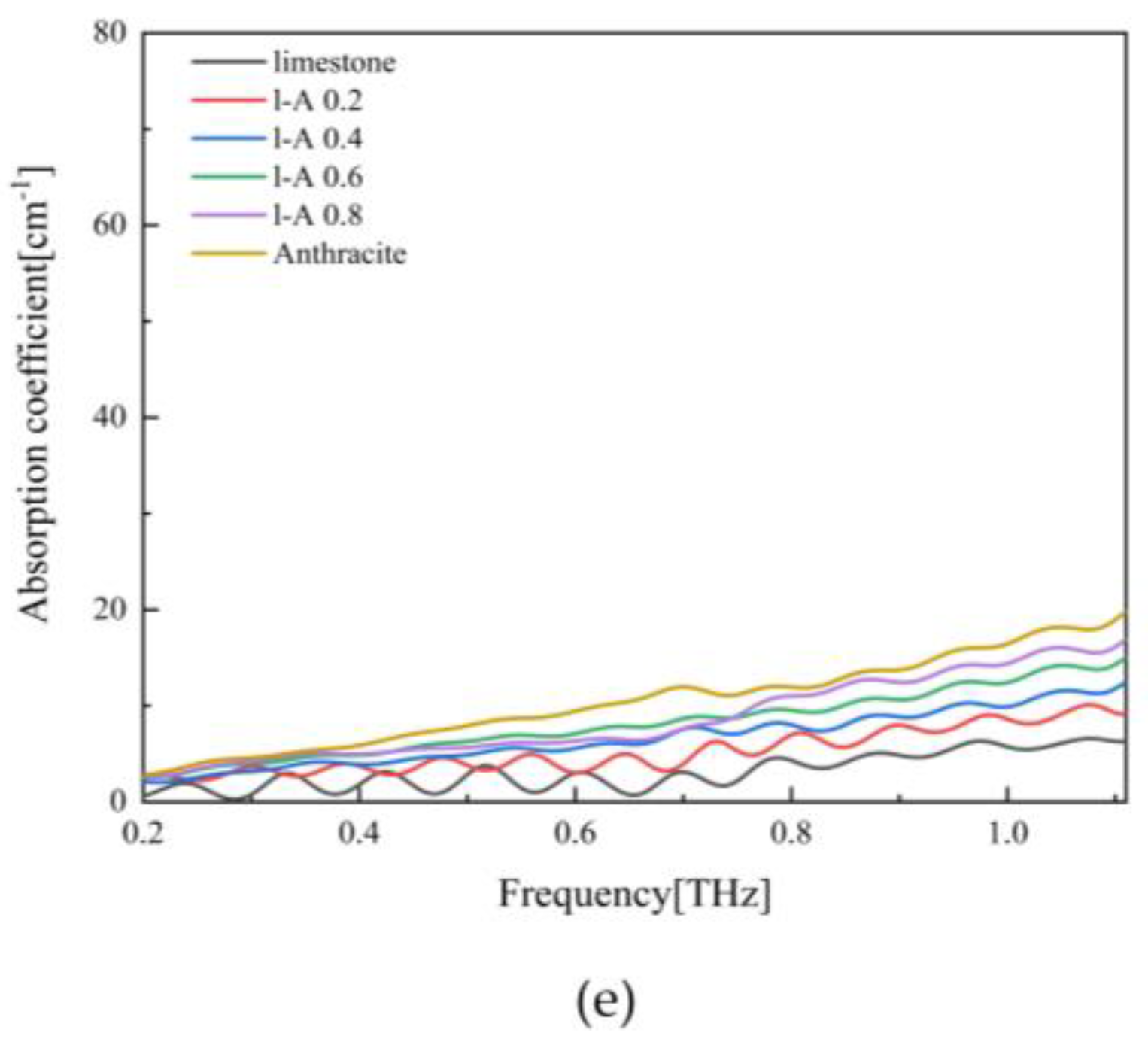

Figure 4; limestone-Anthracite mixture sample,

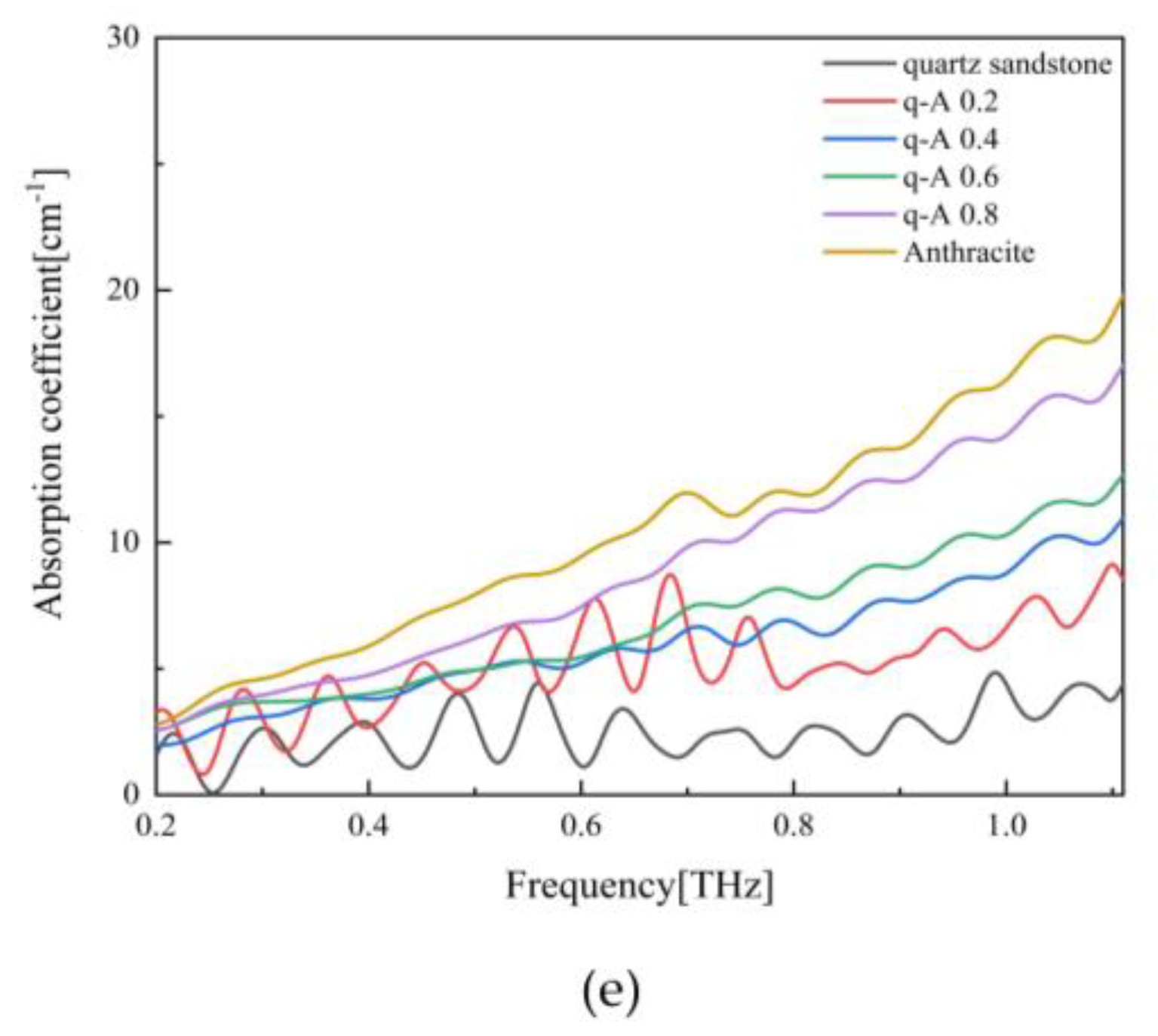

Figure 5. The resulting THz spectra were analyzed using the limestone-Lignite mixture samples, as shown in Figure 2.

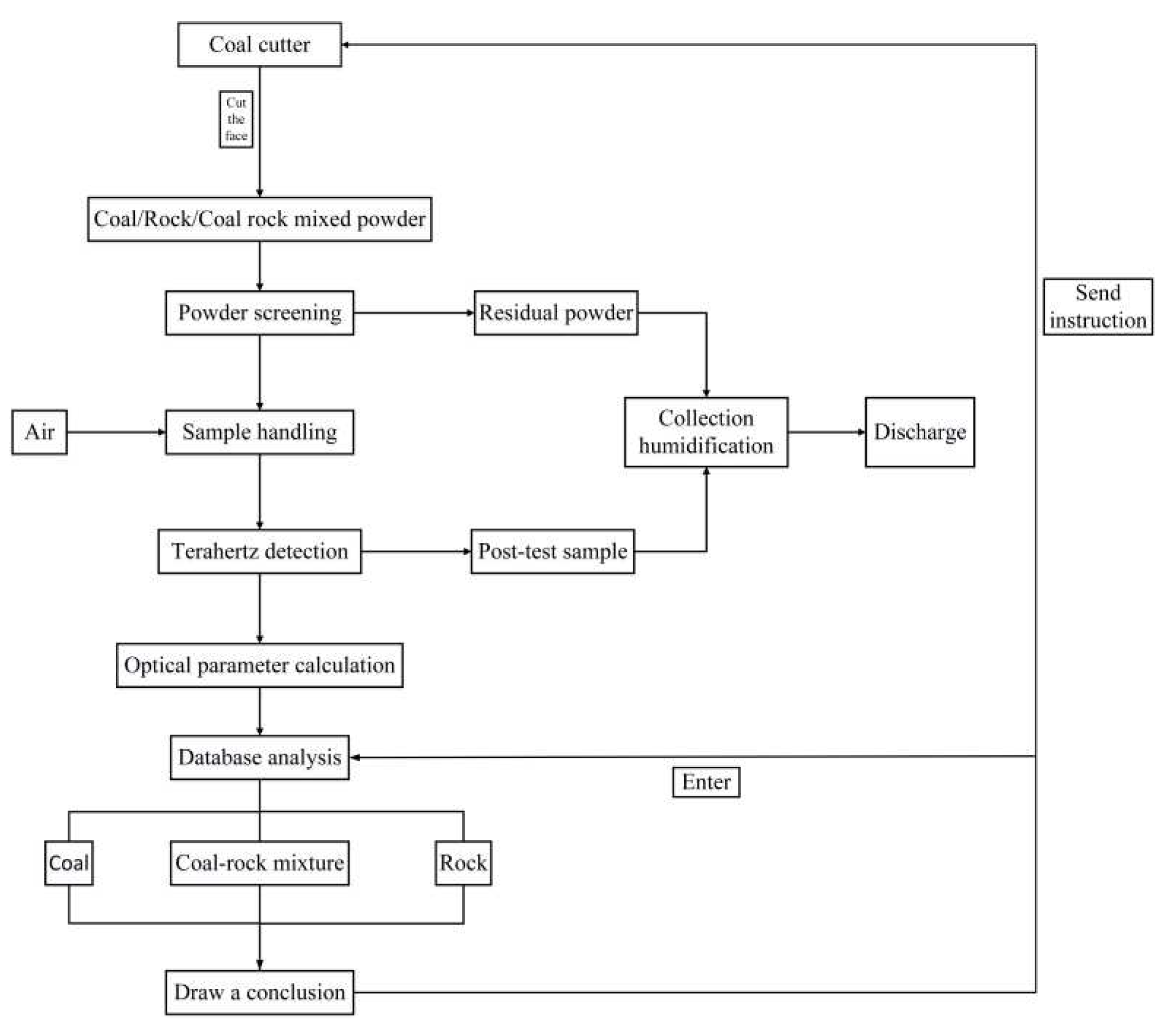

Figure 2a is the THz time-domain signal of 6 samples with the mass ratio of coal powder to coal-rock powder displayed in the upper right corner. The peak value of the reference signal is at 222.626 ps, while the peak value of the other samples occurs after the reference signal. The peak for limestone is at 222.786 ps, and with the increase of coal content in the coal-rock mixed sample, the peak appears progressively later until it becomes a pure coal sample, and the peak time of lignite is at 224.288 ps.

As can be seen from 3.1.1, THz waves experience greater attenuation when passing through coal samples compared with rock samples. Therefore, with the increase of the specific gravity of coal, the attenuation degree of coal-rock mixed samples also increases gradually. The fast Fourier transform was applied to obtain the frequency domain diagram of the coal-rock mixed sample, as shown in

Figure 2b. From the figure, all the coal-rock mixed samples exhibit peaks at 0.2 THz. The peak size decreases gradually with the increase of the mass proportion of coal, which is consistent with the change in the time domain. In addition, the bandwidth of the samples also decreases gradually with the increase of the mass proportion of coal, and the bandwidth of pure lignite sample can have the shortest.

Figure 2c presents the transmission coefficient of the coal-rock mixture. As the mass proportion of coal in the coal-rock mixture samples increases, the transmission coefficient of the sample also gradually decreases. Because this is related to the content of coal and rock substances in the sample, the transmission coefficient of rock is higher than that of coal. The refractive index and absorption coefficient of the coal-rock mixture sample are obtained by calculation.

Figure 2d displays that the refractive indices of the 6 samples remain roughly stable, with a clear difference between pure coal and pure rock samples. With the increase of the proportion of coal mass in the coal-rock mixed samples, the refractive index gradually increases, which can be attributed to the difference main components of coal-rock materials.

Figure 2e is the absorption coefficient diagram for the coal-rock mixture samples. From the figure, the absorption coefficients of all samples increase with the increase of frequency. The increase in absorption becomes more pronounced as the coal content in the sample increases. In the THz band, no obvious absorption peaks are observed in the coal and rock mixed samples. There could be due to two reasons: 1) there is no component that strongly absorbs THz wave in the sample; 2) there are multiple components in the samples to absorb the THz waves in such a way that peak values are not detected. As can be seen from

Figure 2,

Figure 3,

Figure 4 and

Figure 5, the refractive index and absorption coefficient values for the coal-rock mixture samples fall between the values of the pure coal-rock sample. Based on the optical data obtained from the THz detection of coal-rock mixture samples, the refractive index and absorption coefficient of coal-rock mixture and coal-rock mixture can serve as a reference for identifying the coal-rock interface.

Figure 2.

limestone – Lignite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

Figure 2.

limestone – Lignite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

Figure 3.

Quartz sandstone-Lignite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

Figure 3.

Quartz sandstone-Lignite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

Figure 4.

Quartz sandstone-Anthracite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

Figure 4.

Quartz sandstone-Anthracite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

Figure 5.

Limestone-Anthracite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

Figure 5.

Limestone-Anthracite. (a) Time domain spectrum. (b) Frequency domain spectrum. (c) transmission coefficient. (d) Refractive index. (e) Absorption coefficient of coal and rock mixtures samples with different ratio of coal.

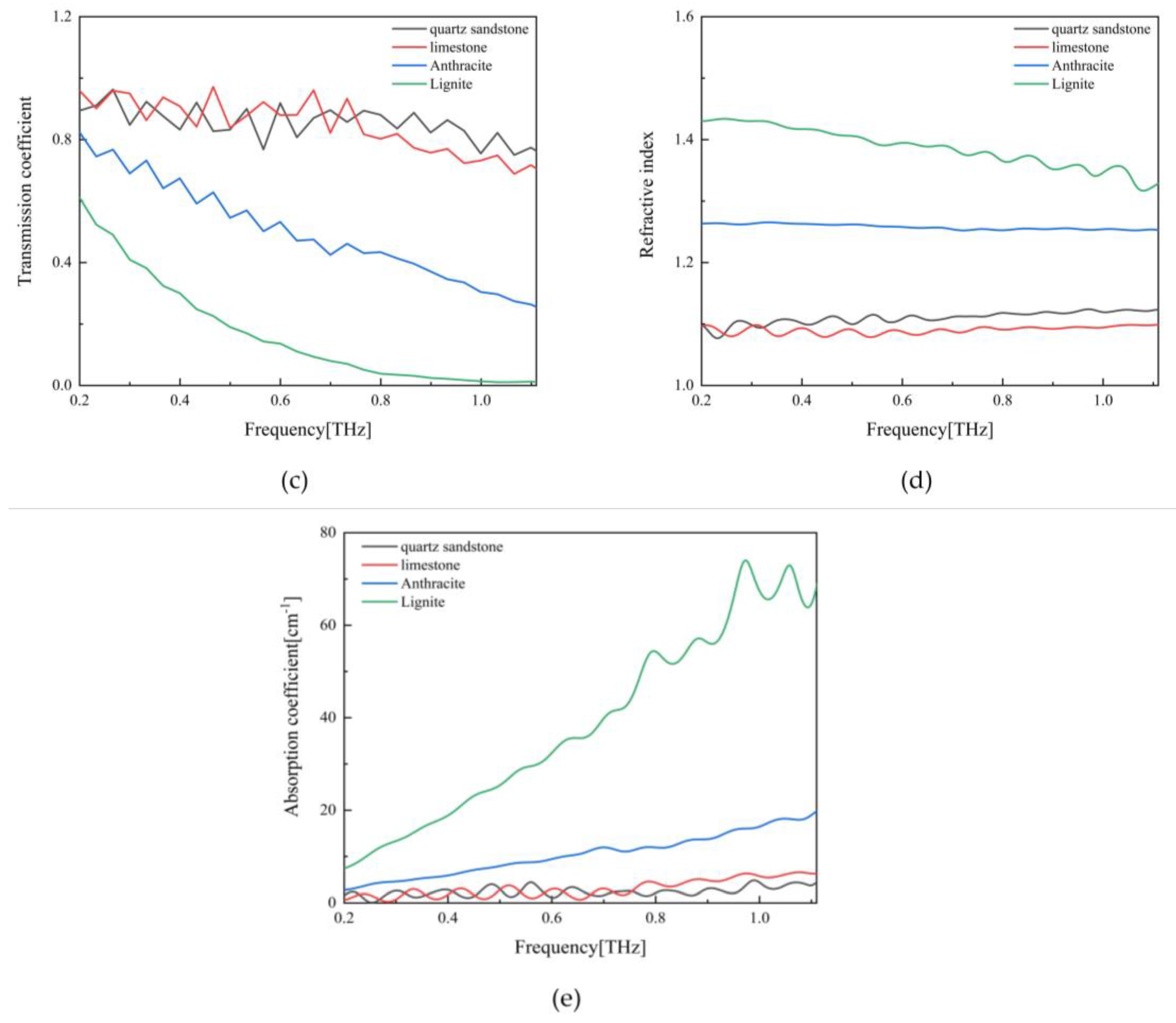

3.1.3. Application of THz-TDS in Coal-Rock Interface Identification

In the actual working environment of coal mine, continuous mining machines need to make timely judgement about the interface while cutting the coal seam. These machines are working underground in coal seams, where the material being cut is general coal. However, when a continuous mining machine encounters a coal-rock working face, it starts cutting a mixture of coal and rock. At this point, it is crucial for the shearer should stop mining the current working face and continue to judge and mining the next working face instead of completely cutting the rock before starting [

26].

In this section, THz time-domain spectroscopy technology is used to assist the continuous mining machine in making real-time assessments of coal-rock working faces, and the flow chart is shown in

Figure 6. When the continuous mining machine cuts the working face, it generates a mixture of coal/rock/coal-rock mixed powder. This powder is collected and sieved with particle size below 74 µm, because only under this condition can the reliability of THz detection be guaranteed. Next, the selected samples are processed, and the ratio of powder to air is controlled. Subsequently, the samples undergo THz testing to obtain the time domain spectrum signal. After testing, the samples are separated from the remaining powder collected earlier, humidified, and the removed. The purpose of this process is to avoid the collected and tested powder from being retested, which could potentially impact the continuous mining machine's real-time assessment of the coal-rock working face and lead to incorrect judgments. Then the time domain spectral signals of the samples are subjected to fast Fourier transform to obtain frequency domain spectra. The optical parameters such as refractive index and absorption coefficient are calculated. All the THz data from the samples are sent to the database for analysis. The analysis database is built by integrating all the time domain signals, frequency domain signals and multiple optical parameters of coal rock and coal rock mixture in 3.1.1 and 3.1.2. In practice, the situation of coal-rock working surface is relatively complex, which requires us to judge a variety of coal-rock combinations in addition to coal and rock. The core function of the database is to assist the continuous mining machine in distinguishing complex coal-rock interface situations, providing a wealth of information. The THz information of the samples is compared and analyzed against the existing information in the database to determine whether the tested sample is coal, rock, or a coal-rock mixture and draw a conclusion. The resulting determination can be first transmitted as instructions to the continuous mining machine, which takes the next steps accordingly. Subsequently, the conclusions can be recorded in the database to provide more abundant data analysis for future tests. Through this process, the THz time-domain spectroscopy technology can be effectively applied to the coal-rock interface identification.

3.2. THz Detection and Simulation of Coal Flakes of Different Thickness

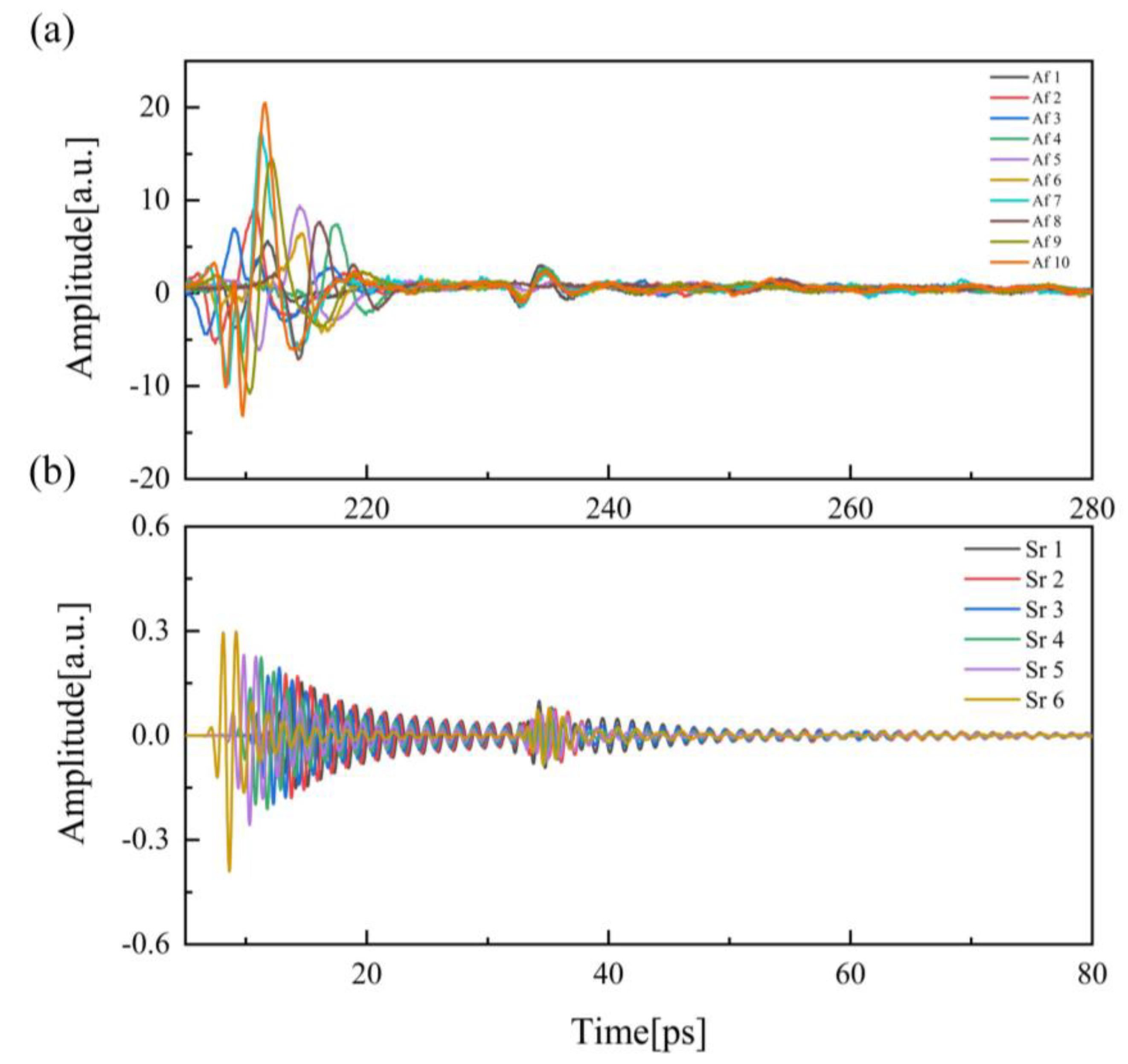

THz testing was carried out on 10 coal samples with different thicknesses, spanning the spectral scanning range of 205-232 ps with a step size was 0.05 ps, as shown in

Figure 7a. After propagating through free space, the THz pulses interact with the flake coal, resulting in phenomena such as transmission, reflection, absorption and scattering. Ideally, if the measured coal flake can meet the absolute ideal conditions: having smooth, parallel surfaces and an internal structure size smaller than the length of the THz wave, then the THz wave cannot scatter on the surface and inside of the coal flake. However, post-processing and preparation of coal flakes obviously cannot meet these ideal conditions, both the surface and interior of the coal flake exhibit scattering, affecting the time domain spectrogram. Usually in the THz measurement, both scattering and absorption of terahertz waves by a substance occur at the same time. When there are components in the material with high absorption of THz waves, the terahertz waves can be partially absorbed when passing through the coal sheet. When the THz pulse incident on the surface of the coal sheet, part of the THz wave can be reflected back by the surface, while the rest can penetrate the coal surface to reach the inside of the coal sheet. During this process, some THz waves can be scattered or absorbed by the coal material. When the remaining THz waves reach the subsequent surface, reflection and transmission occur again, the system detects changes in the time-domain signal of the THz waves between the two surfaces, as shown in

Figure 7a. In order to ensure full interaction between the THz pulse and the coal sheet, all samples are positioned in the same location before testing, securing the second surface's position while the position of the first surface varies with the thickness of each coal slice. Therefore, in

Figure 7a, the peak value of THz waves on the first surface of coal flakes with different thicknesses is mainly in the range of 210 ps-220 ps, and the peak value of the second surface is concentrated around 235 ps. In the time domain signal of the sample, the peak value of the first surface is different in addition to the delay time, and the amplitude of the peak value is also different, which is caused by the different levels of surface smoothness on the coal sheet. Polishing the sample surfaces can make them similarly smooth but not identical, leading to differences in the extent of scattering, resulting in variations in the first peak.

In order to verify the experimental results, we used the simulation software CST to simulate the experimental process of measuring coal seams with different thickness by terahertz time-domain spectroscopy technology, and compared the simulated time-domain spectra with the actual samples. Fourier transform of the time domain signal of the sample is used to obtain the effective spectrum range of the coal slice is 0.2-1.5THz. A transient solver is used with a frequency range set to 0.2-1.5 THz. The rectangular waveguide with short terminal is employed, and the waveguide is filled with dielectric materials. In order to better simulate the experimental process, we divided the waveguide into two parts, the first part is air to simulate the propagation of terahertz pulse in free space, and the last part is anthracite. The waveguide port is applied at the front end of the band, that is, the air material (relative permittivity is 1, conductivity is 0) and the anthracite material (relative permittivity is 3.6, conductivity is 0.00001)[

27]. Changing the air distance is to change the first surface of the coal seam, and the second surface is fixed to achieve the change of the thickness of the coal seam. Set coal seams of the same thickness as multiple samples, and simulate coal seams of different thicknesses. The simulation results (Sr) are shown in

Figure 7b. The peak value of the first surface of the time-domain signal of different thickness coal seams is mainly in the range of 10 ps-20 ps, and the peak value of the second surface is concentrated around 35 ps. Compared with

Figure 7a, it can be seen that the time ranges of the two surface peaks in the samples and simulation results are consistent, and the time domain spectra are the same. Observation of anthracite flakes Af2, Af3, Af6, Af7 and simulation of their obtained simulation results Sr5, Sr6, Sr1, Sr4 were compared.

As can be seen from the figure, the time of occurrence of two peaks in the simulation results is consistent with the experimental results, and the simulation results of coal seams with different thicknesses are accurate. Using the simulation software, we can simulate more coal seams with different thicknesses, and use the simulation results to accurately predict the unknown thickness of coal seams. Although the thickness of the measured coal flakes is relatively small, it is feasible to apply terahertz time-domain spectroscopy technology for coal seam thickness detection in the future based on the 10 different thicknesses of coal flakes and time-domain spectra obtained by CST simulation.

4. Conclusions

In recent years, THz time-domain spectroscopy has developed rapidly, and the research work on its applications in various fields is in progress, Specifically, the research on THz detection system designed for outdoor and severe conditions is underway. The advantage of using THz waves to detect the coal-rock interface is the ability to perform timely, accurate and non-destructive material detection. The analysis of time and frequency domain signals, transmission coefficient, refractive index and absorption coefficient of coal and rock samples and coal and rock mixture samples can accurately identify the detected powders. The establishment of a database can enable the analysis of the shearers judge whether the cutting face is coal, coal or rock. When a coal mining machine encounters a coal-rock interface during cutting, THz time-domain spectroscopy can be employed to assess the working face, thus avoiding cutting into the rock portion. Through the THz testing of 10 kinds of coal flakes with different thickness and the comparative analysis with simulation data, it is evident that despite the relatively small thicknesses, THz wave-based coal layer thickness detection is feasible. The research in this paper contributes to the application of THz time-domain spectroscopy technology in the identification of coal-rock interface, and also provides a reference for the study of THz wave detection of coal seam.

Author Contributions

Conceptualization, Z.J., T.M. and C.Y.; methodology, T.M. and H.L.; software C.Y. and W.H.; validation, L.H., Z.J. and H.L.; formal analysis, Z.J. and W.H.; investigation, W.H. resources, H.L.; data curation, C.Y, H.L. and W.H.; writing-original draft preparation, Z.J., T.M. and L.H.; Writing-review and editing, Z.J. and H.L.; visualization, C.Y.; supervision, H.L.; project administration, W.H; funding acquisition, H.L. and W.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China, grant number 2021YFB3200100, Applied basic research projects of Shanxi Province, grant number 202203021221212, Research Project Supported by Shanxi Scholarship Council of China, grant number 2020-135, the Key R&D Project of Datong City, grant number 2020019, and Special project of Shanxi Datong University, grant number 2020YGZX003, 2020YGZX004, 2021YGZX33, 2022YGZX001.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are included in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Solomon, B.D.; Krishna, K. The coming sustainable energy transition: History, strategies, and outlook. Energy Policy. 2011, 39, 7422–7431. [Google Scholar] [CrossRef]

- Lan, H.; Chen, D.K.; Mao, D.B. Current status of deep mining and disaster prevention in China. Coal Science and Technology. 2016, 44, 39–46. [Google Scholar]

- Huang, S.J.; Liu, J.G. Research of coal-rock recognition technology based on GMM clustering analysis. Journal of China Coal Society. 2015, 40, 576–582. [Google Scholar]

- Wei, R.; Xu, L.J.; Meng, X.Y.; Wu, J.F.; Zhang, K. Coal and Rock Identification Method Based on Hyper Spectral Feature Absorption Peak. Spectrosc. Spectr. Analysis. 2021, 41, 1942–1948. [Google Scholar]

- Ge, S.R. The development history of coal shearer technology (Part six)—Coal-rock interface detection. China Coal. 2020, 46, 10–24. [Google Scholar]

- Sun, J.P.; Chen, B. Coal-rock recognition approach based on CLBP and support vector guided dictionary learning. J.China Coal Society. 2017, 42, 338–3348. [Google Scholar] [CrossRef]

- Miao, S.G. Study of Coal-Rock Characteristics Identification Method Based on GPR and ESR. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2019. [Google Scholar]

- Liu, Z.B.; Liu, C.; Liu, W.M.; LU, Z.Q.; Li, P.; Li, Z.Q. Multi-attribute dynamic modeling technique for transparent working face. Journal of China Coal Society. 2020, 45, 2628–2635. [Google Scholar] [CrossRef]

- Zhang, R.H. Discussion on Coal Rock Identification Method Based on LSM and RELBP. Comput. Technol. Automation. 2021, 40, 109–113. [Google Scholar]

- Galhardi, J. A.; García-Tenorio, R.; Francés, I.D.; Bonotto, D.M.; Marcelli, M.P. Natural radionuclides in lichens, mosses and ferns in a thermal power plant and in an adjacent coal mine area in southern brazil. Journal of Environmental Radioactivity. 2016, 167, 43. [Google Scholar] [CrossRef]

- Nazarova, L.A.; Nazarov, L.A.; Protasov, M.I. Reconstruction of 3D stress field in coal–rock mass by solving inverse problem using tomography data. J Min Sci. 2016, 52, 623–631. [Google Scholar] [CrossRef]

- Shan, P.F.; Lai, X.P. Numerical Simulation of the Fluid–Solid Coupling Process During the Failure of a Fractured Coal–Rock Mass Based on the Regional Geostress. Transport in Porous Media. 2018, 124, 1061–1079. [Google Scholar] [CrossRef]

- Wu, S.; Qu, H.; Tu, H.; Feng, H. Progresses towards the application of terahertz technologies. Appl. Electron. Technique. 2019, 45, 3–7. [Google Scholar]

- Yu, M.; Liu, W.; Wang, K.X.; Wu, Y.H.; Man, R.X. Research on metal surface uniformity detection based on terahertz time domain spectroscopy. Aeronaut. Sci. Technology. 2021, 32, 74–79. [Google Scholar]

- Tanno, T.; Oohashi, T.; Katsumata, I.; Katsumi, N.; Fujiwara, K.; Ogawa, N. Estimation of water content in coal using terahertz spectroscopy. Fuel. 2013, 105, 769–770. [Google Scholar] [CrossRef]

- Bao, R.; Qin, F.; Chen, R.; Chen, S.; Zhan, H.L.; Zhao, K.; Yue, W.Z. Optical detection of oil bearing in reservoir rock: terahertz spectroscopy investigation. IEEE Access. 2019, 7, 121755–121759. [Google Scholar] [CrossRef]

- Wang, X.; Hu, K.X.; Zhang, L.; Yu, X.; Ding, E.J. Characterization and classification of coals and rocks using terahertz time-domain spectroscopy. Journal of Infrared, Millimeter, and Terahertz Waves. 2017, 38, 248–260. [Google Scholar] [CrossRef]

- Yu, J.; Wang, X.; Ding, E.J.; Jing, J.B. A Novel Method of On-Line Coal-Rock Interface Characterization Using THz-TDs. IEEE Access. 2021, 9, 25898–25910. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, L.; Huang, S.; Zhang, C. Terahertz wave generation from noble gas plasmas induced by a wavelength-tunable femtosecond laser. IEEE Trans. THz Sci. Technol. 2018, 8, 299–304. [Google Scholar] [CrossRef]

- Zhan, H.L.; Li, N.; Zhao, K.; Zhang, Z.W.; Zhang, C.L.; Bao, R.M. Terahertz assessment of the atmospheric pollution during the first-ever red alert period in Beijing. Science China Physics, Mechanics & Astronomy. 2017, 60, 1–4. [Google Scholar] [CrossRef]

- Zhan, H.L.; Zhao, K.; Bao, R.; Xiao, L.Z. Monitoring pm2.5 in the atmosphere by using terahertz time-domain spectroscopy. J. Infrared Millim. Terahertz Waves. 2016, 37, 929–938. [Google Scholar] [CrossRef]

- Duvillaret, L.; Garet, F.; Coutaz, J.L. Highly precise determination of optical constants and sample thickness in terahertz time-domain spectroscopy. Appl. Optics. 1999, 38, 409–415. [Google Scholar] [CrossRef]

- Dorney, T.D.; Baraniuk, R.G.; Mittleman, D.M. Material parameter estimation with terahertz time-domain spectroscopy. J. Opt. Soc. America. A Opt. Image Sci. Vis.. 2001, 18, 1562–1571. [Google Scholar] [CrossRef] [PubMed]

- Vieweg, N.; Rettich, F.; Deninger, A.; Roehle, H.; Dietz, R.; Göbel, T.; Schell, M. Terahertz time domain spectrometer with 90 dB peak dynamic range. J Infrared Milli Terahz Waves. 2014, 35, 823–832. [Google Scholar] [CrossRef]

- Deng, J.J. Fundamental Research on Real-time Coal-rock Interface Recognition Using Terahertz Technology. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2021. [Google Scholar]

- Wang, X.; Zhao, R.; Ding, E.J. Coal-rock Identification Method Based on Terahertz Spectroscopy Technology. Coal Min. Technology. 2018, 23, 13–17. [Google Scholar]

- Xu, H.W. Measurement and test of seam electric parameter and study on relationship between seam electric parameter and coal petrology characteristics. Coal Science and Technology. 2005, 3, 42–46. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).