1. Introduction

Urban logistics is essential to the functioning of modern urban economies. Cities are places of consumption relying on frequent deliveries and retail goods, express deliveries to business, and a fast growing home delivery market. For people, urban logistics ensures the supply of goods in stores and for firms it forms a vital link with suppliers and customers [

1]. Under the background of global economic integration, the rapid development of the logistics industry provides new business opportunities for urban construction. Urban logistics distribution, as an important part of overall logistics, has received increasing attention in recent years [

2,

3]. The research content is mainly focused on determining the rational allocation of urban logistics distribution and exploring the sharing and cooperation mode of urban logistics distribution. In terms of optimization and transformation of urban logistics, Szymczyk [

4] made it clear that urban logistics should be transformed into green and intelligent and analyzed new schemes to improve the efficiency of transportation, distribution, and distribution by taking the European Union (EU) logistics operation mode as an example. Because of the low-carbon requirements of advanced logistics mode, Wang [

5] proposed a low-emission closed-loop logistics distribution network model, which verified the feasibility and practicability of urban green logistics distribution. Skultety et al. [

6] used the two-step clustering method to evaluate the development and implementation of logistics measures in each city and explored the effective distribution of urban logistics and the path to reduce environmental pressure and urban congestion. Considering the role of logistics in high-quality urban development and economic transformation, Yue [

7] verified the necessity of expanding the comprehensive logistics distribution system and improving the efficiency of urban logistics under the normalization of epidemic prevention and control. In terms of sharing and cooperation of urban logistics distribution, Cleophas et al. [

8] envisioned an urban multimodal transportation sharing network integrating subway, taxis, and trucks, and evaluated the network performance from the perspectives of the number of operating hubs and the willingness of drivers. Using a heuristic algorithm to select the most appropriate combination of distribution centers and hubs, Hiohi et al. [

9] pointed out that node mergers between suppliers and distribution centers must be accompanied by resource sharing of global logistics participants. Because of the negative impact brought by the development of urban logistics, Yao et al. [

10] explored the actual impact of information-sharing mechanisms on the cooperation of various logistics entities and demonstrated that collaborative logistics is an effective way to reduce distribution costs and improve the environment condition. From the perspective of collaborative transportation and collaborative distribution, Gonzalez et al. [

11] combined the demand generation model with the path optimization algorithm, and constructed a scenario corresponding to the urban logistics distribution pre-evaluation framework.

The physical Internet logistics system may be viewed as a smart logistics system aiming to be socially responsible and environmental friendly by modularizing container transit [

12]. The PI vision is based on the analogy of digital Internet and was first proposed as a solution to major problems of economic, environmental, and social instability in the global logistics network [

13]. Physical Internet logistic model is introduced to replace the traditional logistics model for the following two reasons: (1) To reduce the cost of urban logistics distribution reasonably on the premise of ensuring the stable operation of the logistics distribution system; (2) To reduce the risk and uncertainty of logistics activities with a safe facility layout. Further, It uses the idea of the Internet technology to construct a new logistics network and creates a unified container of public and open transportation modes and intelligent standards so that all kinds of goods are loaded through a unified container and they have the ability of free transmission in the logistics network. Considering the advantages of the sharing and collaboration mode of urban logistics distribution and the public and open characteristics of PI, Crainic [

14] introduced the potential connection between PI and urban logistics and explored the possibility of changing logistics paths and improving economic, environmental, and social efficiency from the perspective of theoretical analysis. Venkatadri [

15] analyzed the impact of PI logistics integration on distribution and inventory costs, established a cost minimization model, and studied the advantages of the PI system over the traditional logistics networks. Based on previous studies, Yang [

16] also evaluated the ability of PI to deal with the interruption between distribution nodes, proposed an optimization model, and proved that PI has greater flexibility and elasticity. Treiblmaier et al. [

17] summarized and analyzed a large number of PI literature to relate with logistics and supply chain management. The PI is anticipated to keep defying conventional supply chain and logistics models going forward while continuing to satisfy environmental and economic development standards.

2. PI Based Urban Logistics Distribution Model

Urban logistics and PI are two significant concepts related to warehouse, distribution centers, and transportation. Urban logistics aims to reduce the negative impact of urban transportation movements within urban region and decreasing environmental impact in terms of congestion without lowering the level of social and economic activities. The principal idea of the PI methodology is a change of the way urban transportation movements within logistics network. Both concepts are complementary and synergy between then could introduce the hyper-connected urban logistics. The establishment of the urban logistics distribution model based on PI needs to be based on the traditional logistics distribution model. In the process of traditional logistics distribution, the limited transportation efficiency and high distribution cost lead to the continuous high cost of urban logistics distribution. However, in the city logistics distribution model based on PI mode, all facilities within the system (including the warehouses, distribution centers, transportation) will be present to each main body (including logistics service providers and consumers) open and sharing, so as to realize point-to-point scenario. Crainic and Montreuil [

14] further improved the efficiency of distribution to reduce the distribution costs received by face to face across the interconnected system. To break the barrier between the distribution node system and the private or relatively fixed logistics distribution line, enterprises achieve sustainable and accurate distribution to complete the effective control of distribution cost.

2.1. Main factors (PI distribution)

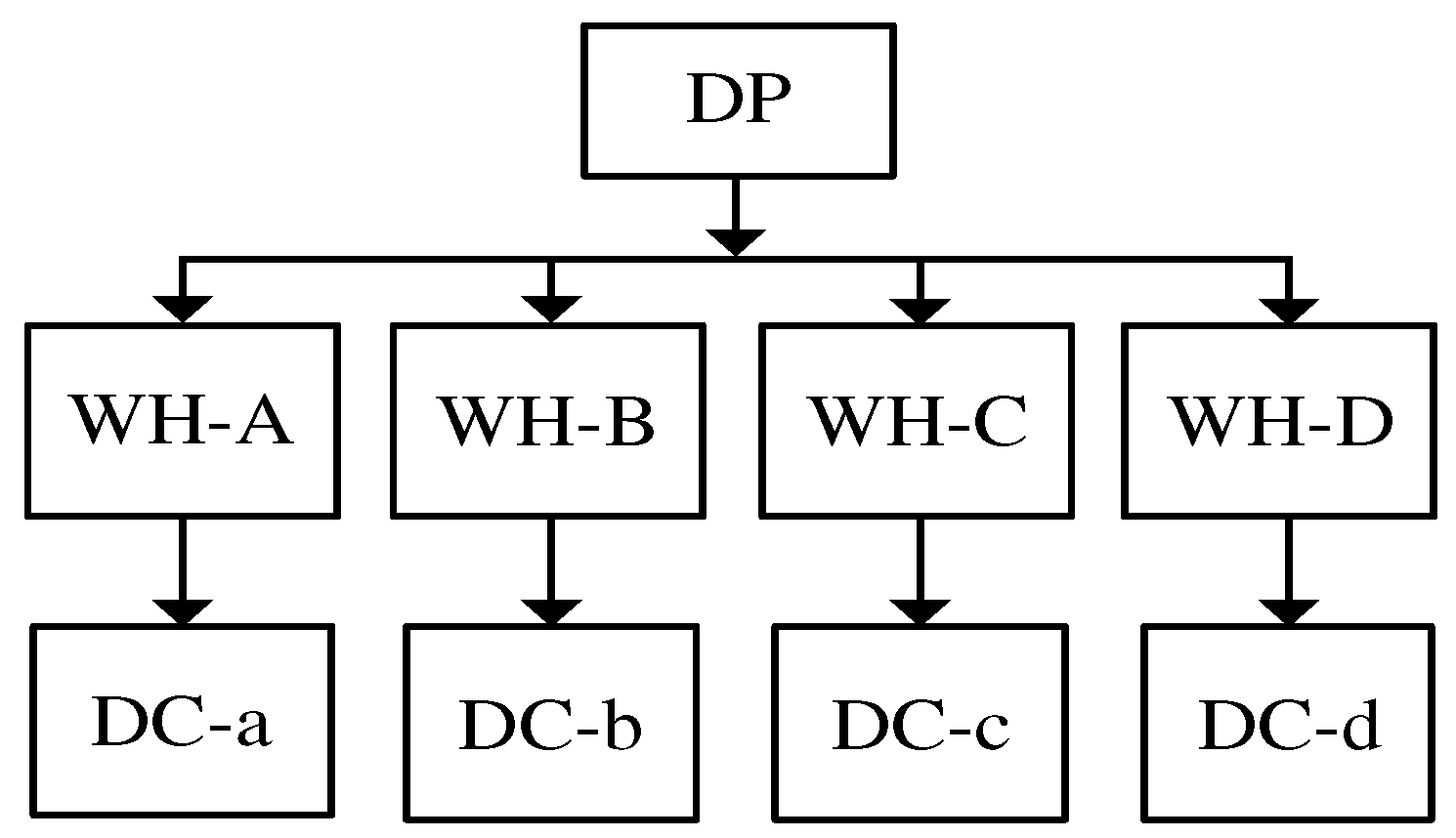

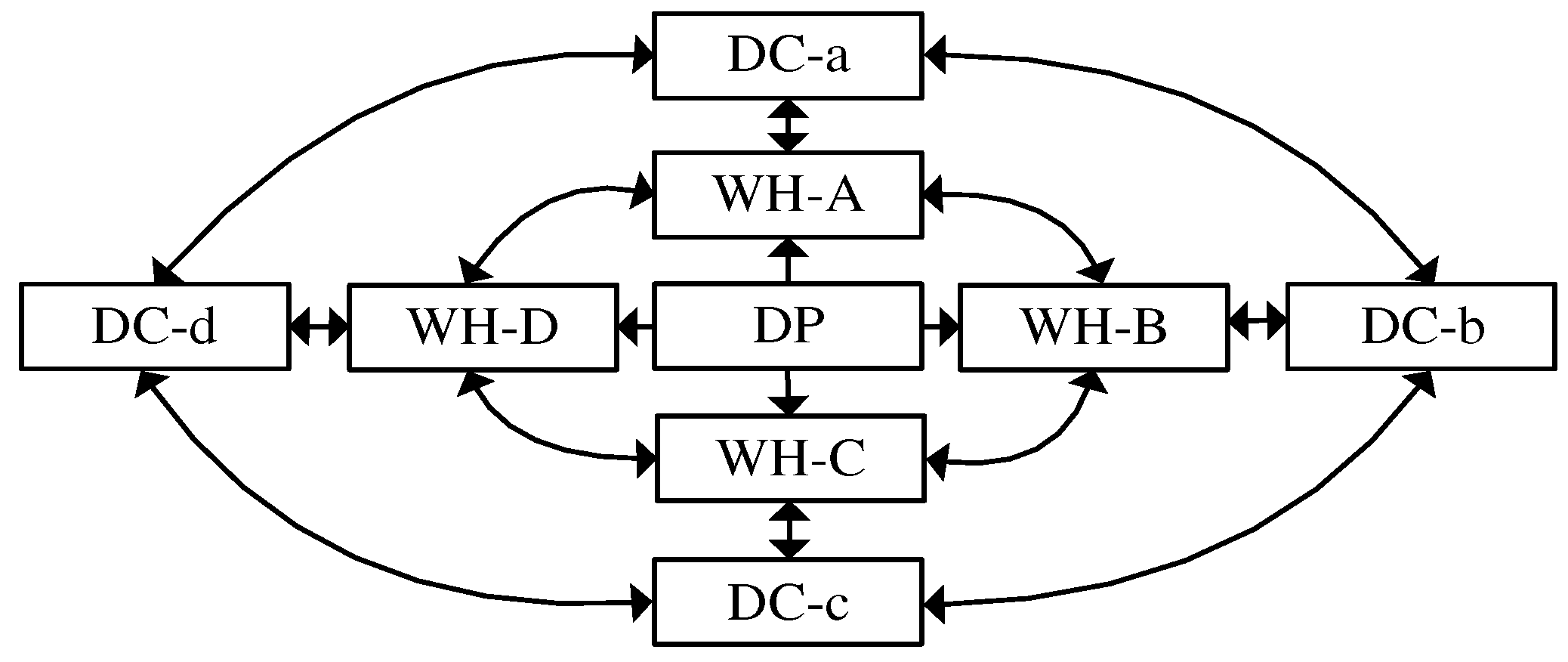

In the traditional logistics distribution network, the distribution mode of goods has been preset prior to entering the logistics network. The source and destination of any transport have experienced advanced planning, and the goods are passed layer by layer from the delivery point (DP), warehouse (WH), distribution center (DC), and terminal node to the consumers. However, the aid of PI data-driven, connectivity, depth of collaborative and efficient features can form a highly efficient logistics distribution model as shown in

Figure 1. Each peer distribution between nodes is closely interconnected, and establishes a widely shared each other’s logistics network environment, and thus has many path selections, the real-time dynamic adjustment of the new key characteristics, and increases the distribution of various possibilities. It helps to explore more flexible distribution solutions to further reduce the waiting time and inventory cost of goods at each node. To explore the best logistics distribution method based on PI, the following three core factors namely PI infrastructure, distribution route, and transshipment standard are analyzed to effectively depict the urban logistics distribution model of PI.

(1) Infrastructure: The classical logistics network layout gave rise to the layout mode known as PI infrastructure layout. The introduction of PI does not change the geographical location of the original node facilities. The PI is a revolutionary logistics system that seeks to level the playing field for the logistics network’s traditional centralized hierarchical structure through hierarchy-based development. The biggest differences of PI with traditional layout are that all nodes are in the network facilities, transportation facilities, and service personnel. The global infrastructure of PI is based on the principles of maximum efficiency within reasonable use. To overcome the initial industrial hurdles, increase distribution efficiency, and reduce distribution costs, PI is incorporated into city logistics.

(2) Distribution route: When Montreuil [

16] initially proposed the concept of PI, it was obvious that the complete path in the PI network could be transformed from private network to open network. Due to delivery lead times and transportation cost restrictions, the shortest route is typically considered to be the best distribution route in a traditional logistics network of distribution. However, if distance is the only criterion used to choose the order of goods in the logistics network, which is predetermined at the starting location, then there is a significant loss of flexibility in the logistics system. However, the transportation and distribution in the PI environment are more dynamic, and the flexible communication between warehouses and distribution centers at all levels gives a higher degree of freedom in route selection. PI considers the distribution distance and the use of network facilities with equal weightage, which helps to realize the uniform distribution of network traffic and improves the general satisfaction of customers.

(3) Transshipment standard: All goods in the PI network are uniformly packaged in standard intelligent green modular containers. Considering the negative impact of long-distance transportation on society and the environment, the ordered goods often need to go through multi-stage combined transportation in PI. In the process of transit at each transport node for the comparative test and research results of Pan et al. [

19] and Yang [

16] et al., it can be seen that the best effect is achieved by direct transfer with the source substitution method, which is based on an intuitive and simple standard. Instead of dividing delivery orders or recombining existing containers, PI selects vehicles that meet the transport capacity and are close enough to the transfer node for transferring the goods.

2.2. Symbol definition (PI distribution)

The urban logistics distribution scheme based on PI should be directly related to the construction layout and logistics level of the city in which it is located. The gap between the layout and logistics capacity of different cities affects the focus of urban logistics distribution decision-making. But regardless of where they are in the PI network. The city logistics distribution follows a set of standards, making it possible to view the city logistics distribution model as a whole at each shipping port, industrial center, and distribution center based on its PI essence. For the reasonable of all varieties of cargo and container transport distribution problems, the need to use the symbol definition comes down as follows:

| Notations |

|

|

: |

collection of dispatching points , |

|

: |

collection of logistics warehouse , |

|

: |

collection of distribution centers , |

|

: |

time of logistics distribution system represented by days, |

|

: |

distance between the delivery point and each logistics warehouse , |

|

: |

distance from each logistics warehouse to each distribution center , |

|

: |

The shipment quantity at pointfollows normal distribution, |

|

: |

fixed cost of opening logistics warehouse and distribution center , |

|

: |

daily unit inventory cost of logistics warehouseand distribution center, |

|

: |

unit transportation cost per kilometer upstream from point to warehouse, |

|

: |

unit transportation cost per kilometer downstream from warehouseto distribution center , |

|

:

|

daily inventory of logistics warehouse and distribution center , |

|

: |

logistics warehouse storage capacity ceiling, |

|

: |

if the warehouse can be used normally, it is 1. If it cannot be used due to warehouse explosion or emergency, it is 0, |

|

: |

if container does not arrive on time, its unit penalty cost is . |

| These are the following decision variables: |

|

: |

select warehouse to receive container sent by point on day , |

|

: |

select distribution centers to receive container sent by warehouse on day , |

|

: |

number of containers A transported from point to warehouseon day , |

|

: |

number of containers transported from warehouseto distribution center on day , |

2.3. Model construction (PI distribution)

The research scope of the urban logistics distribution model based on PI is as follows: after arrival of the goods in a city, the whole level of process is covered from the point of delivery to the logistics warehouse and then to the basic distribution center. The fundamental goal is to minimize the total cost of logistics distribution as much as possible under the premise that accurate goods arrive on time. The proposed model needs to use the traditional logistics distribution model of facilities distribution and operation rules as the template to form its interconnectivity and offer a unique logistics distribution model. Since the composition of urban logistics distribution cost is complex and easily changeable with the characteristics of the city, fixed construction cost , inventory holding cost, transportation and distribution cost and lastly penalty cost can be given priority according to the importance of degree. The fixed construction cost

, inventory holding cost

, transportation, distribution cost

and last penalty cost

that can be given priority according to the importance of degree. The fixed construction cost

given in (1) represents the construction cost of site selection, decoration, acquisition of fixed assets for all warehouses and distribution centers in PI city logistics distribution.

The inventory holding cost

given in (2) is used to represent the cost of daily storage and guarantees the containers to be transferred for from each transport node to other transport node in PI.

Due to the influence of batch economy law, the unit inventory cost of the warehouse and distribution center should be different. The unit inventory cost of the warehouse is slightly lower than that of the distribution center. The transportation and distribution cost

given in (3) is composed of the upstream transportation cost from the delivery point to the warehouse and the downstream transportation cost from the warehouse to the distribution center.

According to the actual logistics and distribution situation, the upstream and downstream transportation cost should also differ. By adding

and

, we get notation

, which is called as penalty cost. The penalty cost

also includes the compensation loss cost

given in (4) caused by consumer complaints if ordered goods do not arrive on time that leads to the loss of invisible potential customers and damage to the company image.

Based on these settings, we present the following proposed PI based city logistics model:

The goal of objective function (5) is to reduce the logistics distribution costs in PI city, taking into account the fixed construction cost of the logistics warehouse and distribution center, the inventory holding cost of the logistics warehouse and distribution center, the full transportation and distribution cost, and the possible penalty cost associated with failing to satisfy customer demand. The constraints (6)-(8) are transport requirements of warehouses and distribution centers, or any transferred orders that cannot be split before arriving at the final destination. The use of the normal operation node as the transport destination helps to ensure that the logistics distribution model accurately reflects the current situation while also making it simple to avoid the logistics warehouse

after incuring a lost function

in the system failure model. The constraint (9) indicates that the upper limit of the storage capacity of the logistics warehouse at a single time should not exceed

is as follows:

The above difference condition (11) is between the accumulated inflow and outflow of containers in any warehouse to prevent the warehouse from exploding or the nearby path from blocking and interrupting due to overload of material flow during operation. The constraint (10) indicates that the number of containers to be distributed in the PI system must be an integer to meet the PI operation standard. The urban logistics distribution problem based on PI is a nonlinear optimization problem. It is difficult to determine an optimal solution directly. Therefore, this paper considers the branch and bound algorithm to obtain satisfactory solutions for decision variables and objective functions.

3. Simulation and result analysis

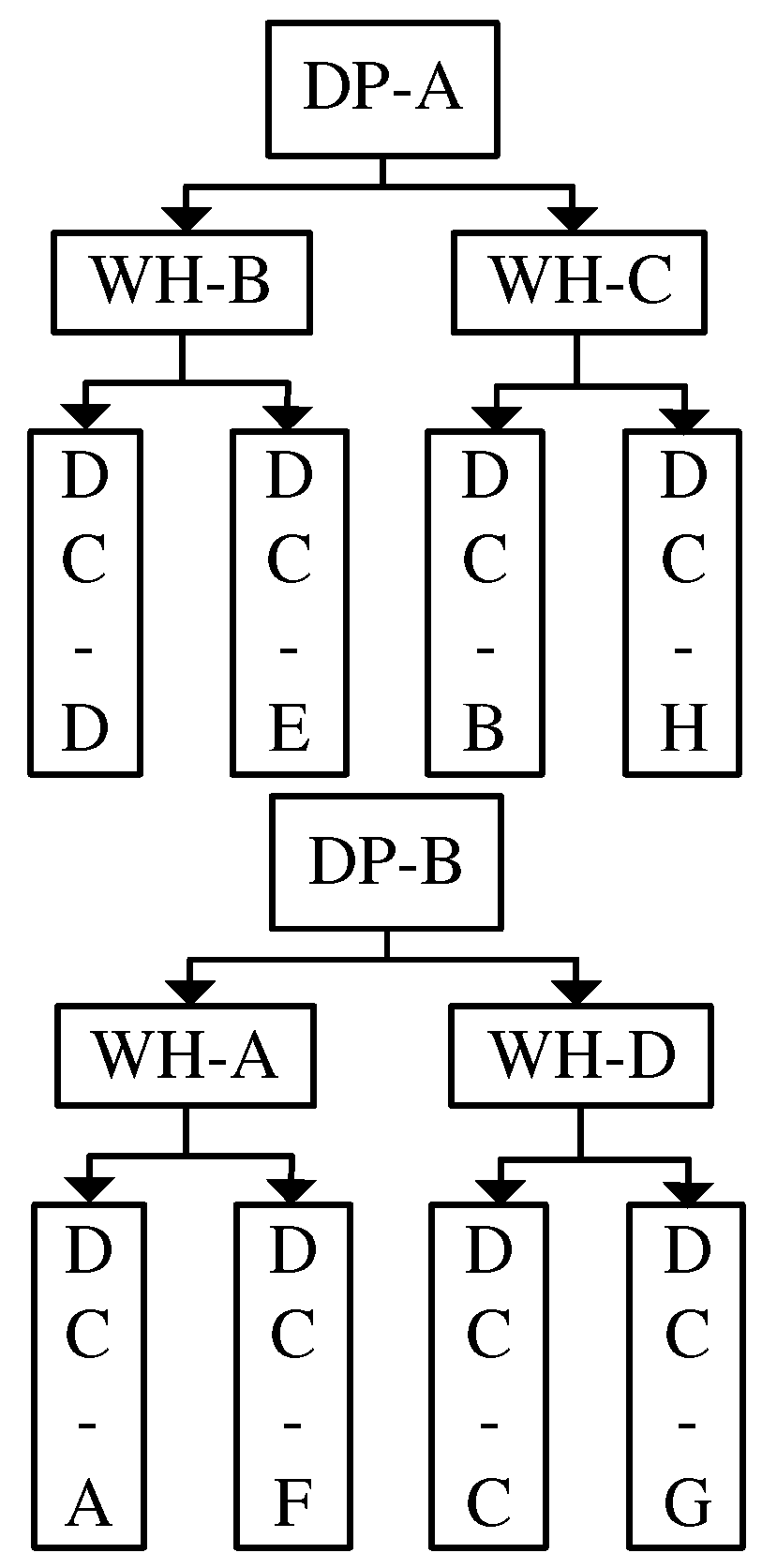

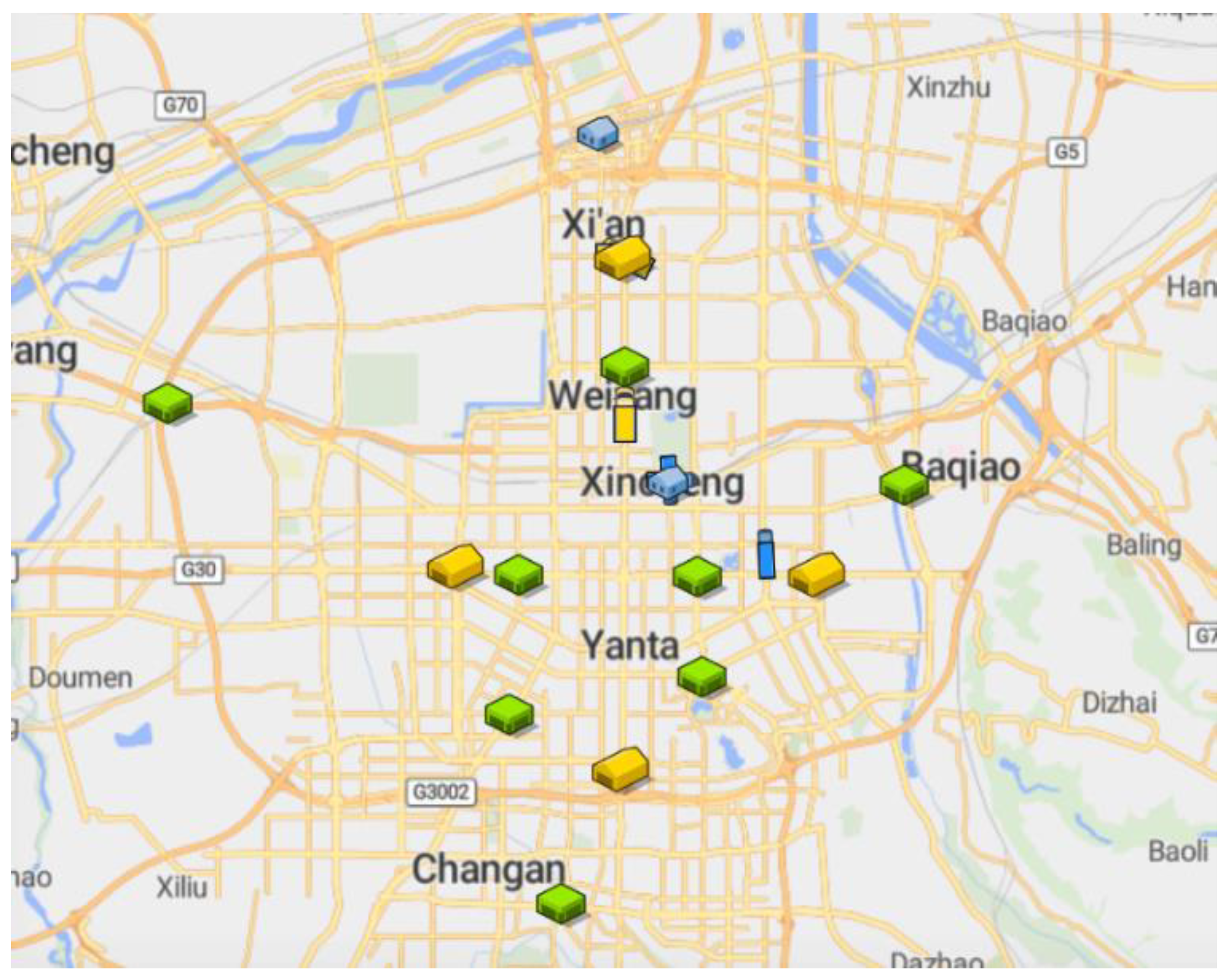

3.1. Simulation example data

We compare the city logistics distribution model based on PI with the traditional logistics model. To make the comparision more effective, this paper takes Xi ‘an city as an example and sets the cover points, warehouse. distribution center logistics distribution network, compared with the traditional logistics model, the introduction of the PI based of maintaining the internal node location, for the network into the open feature of the Internet. The GIS module in the simulation software is used to determine the names and geographical locations of the above nodes as shown in

Table 1. To accurately explore the performance discrepancies between PI and the traditional logistics model in the comparative test process using the traditional logistics model as the reference group, the number of goods delivered daily by PI and the traditional logistics model are consistent with the target locations of all goods. Each cargo has been defined as the target distribution center when the delivery point is generated, and

container is responsible for integrating the goods with the same destination and waiting for the corresponding truck to transport them. In a traditional logistics network, the circulation of goods or container needs to follow the route of man-made rules as shown in

Figure 3. However, in the PI logistics model all fixed routes will be broken and

smart labels on the container for the freedom of choice. The ability to dynamically adjust the goods will be shipped in a single container for adjacent nodes without interrupting all path to choose and form the best distribution route by free combination.

According to the findings about xi ‘an region logistics, the PI distribution system infrastructure construction fixed cost is 27381.13 USD,

container logistics warehouse inventory cost is 2.33 USD per day. In the distribution center level, inventory transportation lost focus size of dividends, so the

container inventory costs rise accordingly to the upstream of the 1.5 times about 3.56 USD per day. At the same time, the upstream (transportation between the delivery point and the warehouse) cost is 1.53 USD per km with a full load, and the downstream (transportation between the warehouse and the distribution center) cost is 2.19 USD per km with a full load. In addition, assume that the maximum total simulated time is T=100 days, the daily containerized quantity to be delivered at the delivery points A and B are respectively 100 pieces, the upper limit of the single transport quantity of the distribution vehicles is 20 pieces, and the random probability interval of daily abnormal use of each warehouse is [0.08,0.10]. As shown in

Figure 4 and

Figure 5, model operation and simulation are carried out on the hardware environment with Intel(R) Core(TM) I5-10210U CPU, 16G memory, and anylogic software. By taking the mean value of 10 simulation results and eliminating the interference of random factors, the total cost changes of the traditional logistics model and PI distribution model under different distribution rules are obtained.

3.2. Analysis and Discussion of Results

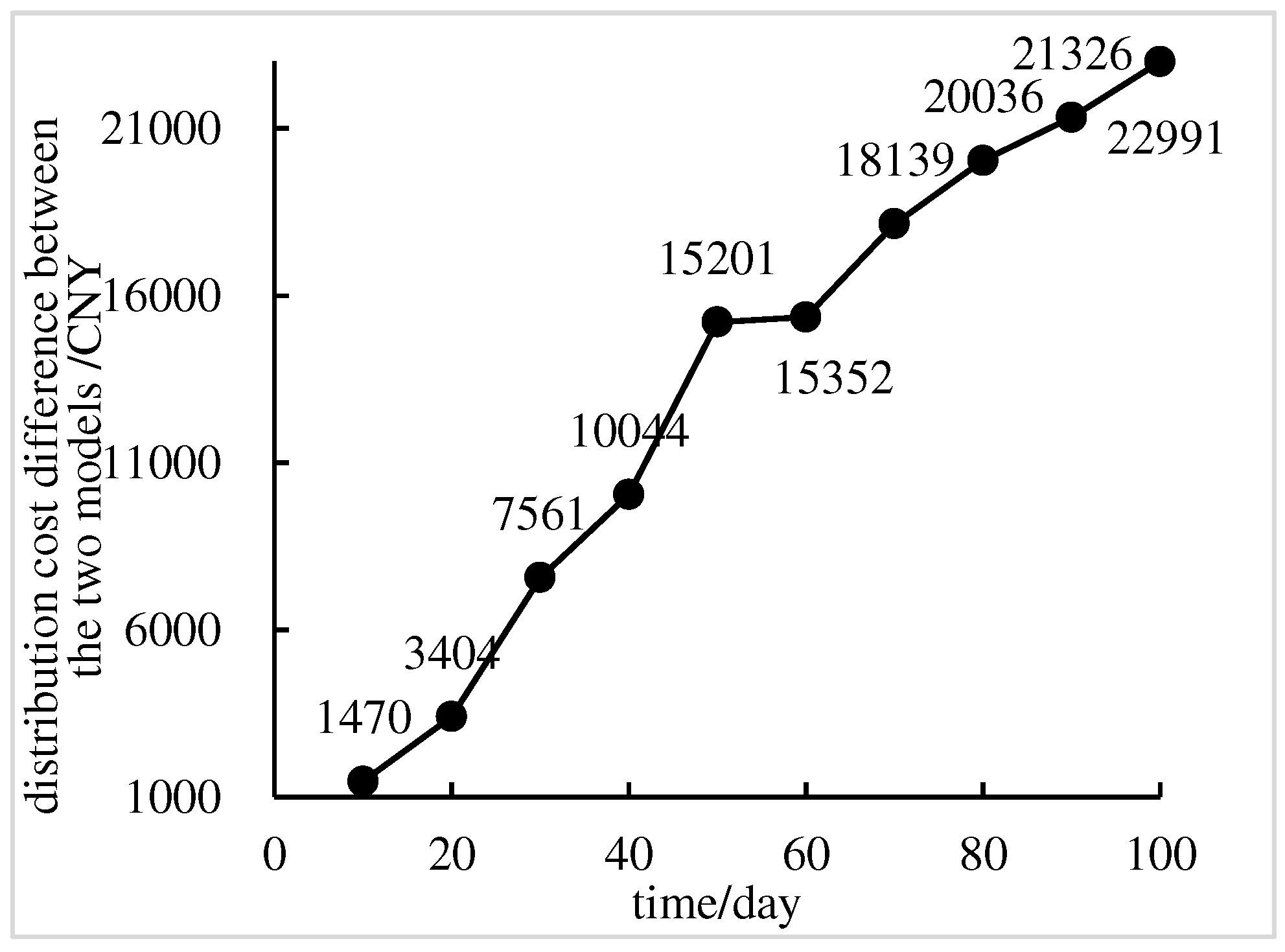

(1

) Comparative Analysis of Distribution models: With given computation, we receive the traditional logistics model and PI logistics model under the condition of the same infrastructure. The total cost of logistics distribution changes over time. From

Figure 6 and

Table 2, it is obvious that the PI logistics model continues to provide the cost advantages over the traditional logistics model in the simulation process, despite the fact that the PI logistics model’s simulation period is less than 20 days. The traditional logistics model and the PI logistics model have similar distribution costs; but, as time goes on, the cumulative logistics cost saved by the PI logistics model keeps growing, and the PI logistics model’s cost advantage progressively becomes apparent. The PI logistics model’s greatest saving value, which is 3147.60 USD on day 100, has an average daily saving rate of 3.96%. This demonstrates that when compared to traditional logistics networks, the PI logistics distribution network is open and interconnection performance can efficiently provide more distribution paths. Additionally, when the scale of local logistics service consumers reaches medium or above and is stable, the cost of the PI logistics distribution network is significantly lower than the cost of traditional logistics. In particular, the trend line of the logistics distribution model based on the PI is not steep, and the growth rate is comparatively stable. It is also difficult for an increase in freight volume to cause a rise in distribution costs. For every 200 containers deployed inside the system, the overall logistics cost rises by 493.82 USD on average. Additionally, because the internal infrastructure of PI serves all demanders in the form of public rental, common third-party logistics companies, and e-commerce activities are exempted from the cost of building basic logistics facilities, further lowering logistics distribution costs and raising customer satisfaction.

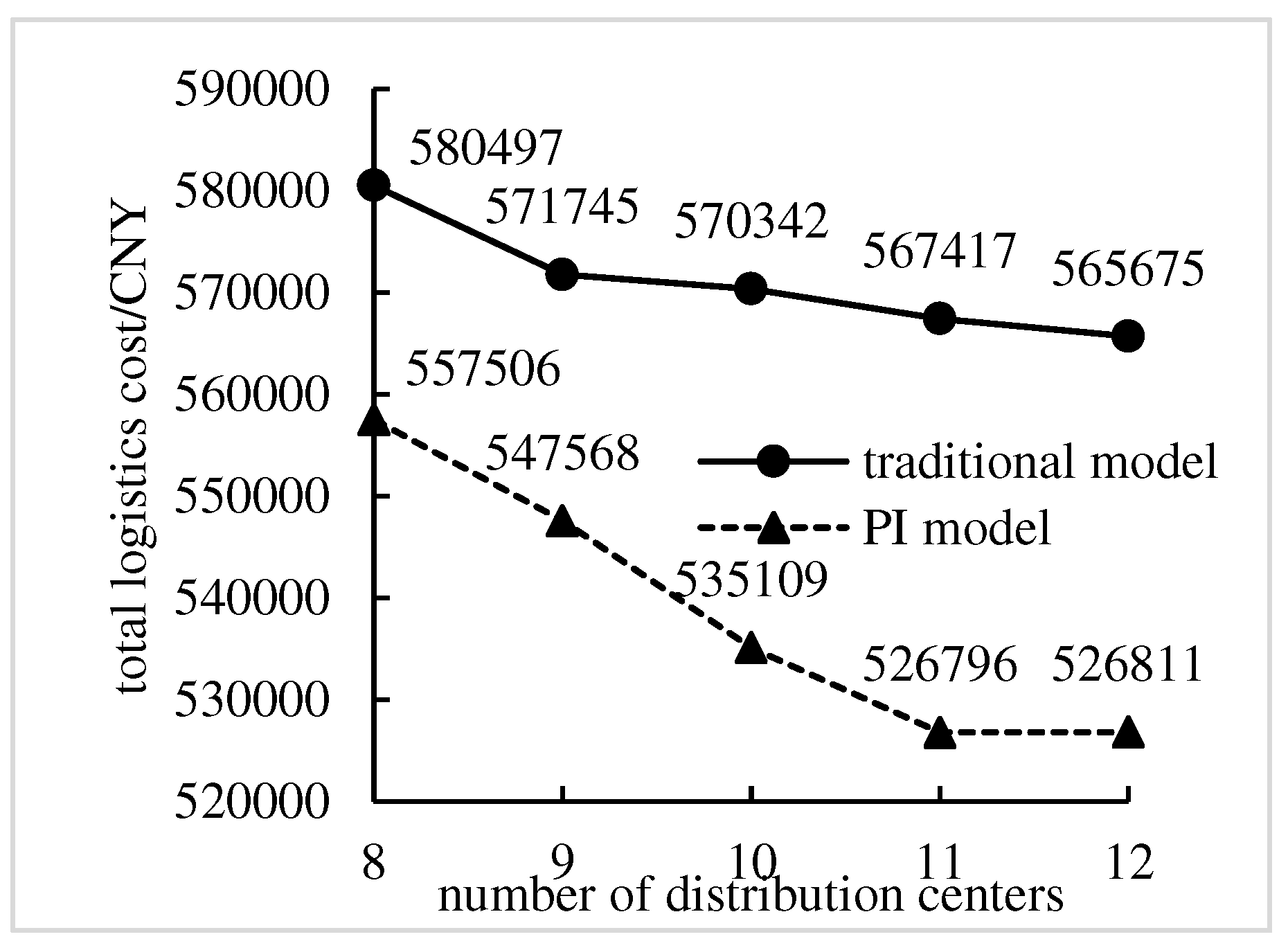

(2)

The Core Factors Analysis: A surge in demand for logistics service providers and consumers has resulted from the gradual replacement of offline retail with online shopping. However, serious challenges have been brought about by “Shopping Day” blowing up and new crown outbreaks, which could cause transportation disruption on the elasticity of the logistics network. Experiments are carried out by gradually increasing the number of distribution centers from 8 to 12 with a step size of 1, while keeping the same parameters in

Table 1 and

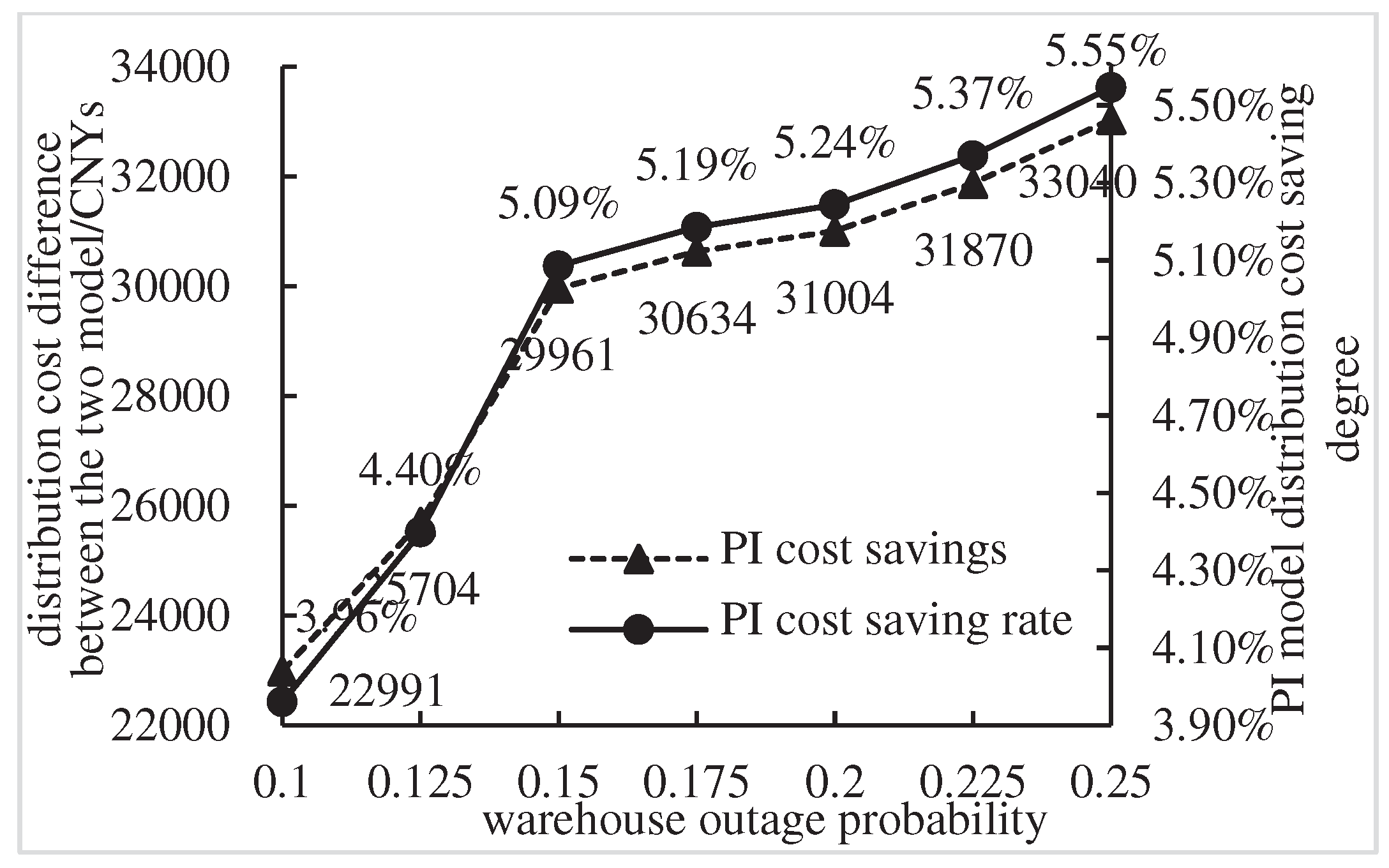

Figure 3, in order to further investigate the impact of the scale of logistics infrastructure and emergency interruption events on the cost advantage of the logistics distribution model in PI cityFor simulation, the random outage chance for each warehouse was incrementally raised from 0.1 to 0.25 with a 0.125 step size. From

Figure 7, it can be seen that the size of the logistics infrastructure for distribution has a positive promoting effect, lowering the total cost of the distribution center to give up the number of PI is higher at the end of the logistics distribution model of flexible selective, so the PI total cost of logistics and distribution center is roughly inversely proportional to the size number, with each increase in a distribution center the cost of distribution costing an average of about 99.12 USD. With the largest decrease in total cost 2029.22 USD, the cost optimization rate was 2.55%, only 48% of the PI logistics model improvement, and the visible PI cost optimization model was significantly higher than that of the traditional logistics model, the expansion of the scale of the distribution center also brought some distribution advantages for the traditional logistics model. It can be seen from

Figure 8 (taking the mean value after 10 simulations) that when the random interruption probability of each warehouse increases, the logistics network risk, and uncertainty increase, and the total cost of PI logistics distribution shows an increasing trend. When the interruption probability increases from 0.10 to 0.25, the total cost increases from 76325.72 USD to 77035.30 USD, but the PI logistics model does not affect the optimization ability of the total cost. This is mainly reflected in that the cost difference value and cost difference rate of the PI logistics model and traditional logistics model continues to rise, especially in the interval of interruption probability [0.10,0.15] optimization increases significantly. Compared with the traditional logistics model, the total distribution cost savings of the PI logistics model is increased by 954.23 USD, and the savings rate is increased by 1.23%. Moreover, the saving rate is consistently higher than 5.00% when the outage probability is greater than 0.15, which shows that PI has good robustness to sudden logistics outage events, while the traditional logistics distribution model has to start emergency response when the interruption occurs and recover the distribution supply through manual allocation, which lacks good fault-tolerance. While comparing with the traditional logistics distribution model, comprehensive

Figure 7 and

Figure 8 show that the distribution of scale expansion and interrupt probability increases when the PI cost savings rate has a high level of the model, the maximum of 6.87% and 5.55% respectively. This further shows that the advantages of PI logistics model in the escalating scale of logistics infrastructure and emergencies that frequently occur are still preserved. The cost and elasticity advantages more magnified under large-scale and highly intrusive external conditions.

4. Conclusions

The traditional logistics model lacks the flexibility, sharing, and interconnection capabilities that PI possesses, making it possible to increase the effectiveness of logistics distribution while lowering the cost of logistical distribution. This research is based on the analyses of the primary PI distribution parameters and makes sure that the logistics process integrity is a requirement in order to explore the PI network of the city logistics distribution system. Based on the city logistics distribution cost minimization model of PI, the model can be PI delivery point in the international, warehouses, distribution centers, and such connectivity to form the open system of distribution network, It improves the flexibility of goods operation and lowers the international cost of logistics distribution.

Author Contributions

Conceptualization, H.F., J.L., K.-K.L. and B.R.; methodology, H.F., J.L., K.-K.L. and B.R.; software, H.F., J.L., K.-K.L. and B.R.; validation, H.F., J.L., K.-K.L. and B.R.; writing—original draft preparation, H.F., J.L., K.-K.L. and B.R.; supervision, K.-K.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is unavailable due to ethical restrictions.

Acknowledgments

We are very gratefully to anonymous reviewers who provided constructive comments to enhance the manuscript. The fourth author acknowledges the support from the Centre of Digital Transformation, Indian Institute of Management Ahmedabad.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Crainic, T.G.; Ricciardi, N.; Storchi, G. Advanced freight transportation systems for congested urban areas. Transp. Res. Part C: Emerg. Technol. 2004, 12, 119–137. [Google Scholar] [CrossRef]

- Behrends, S. Recent Developments in Urban Logistics Research—A Review of the Proceedings of the International Conference on City Logistics 2009—2013. In Proceedings of the Transportation. Research. Procedia; 2016; 278–287; Volume 12. [Google Scholar] [CrossRef]

- Buldeo, R.H.; Dablanc, L. Hunting for treasure: a systematic literature review on urban logistics and e-commerce data. Transp. Rev. 2023, 43, 204–233. [Google Scholar] [CrossRef]

- Szymczyk, K.; Kadłubek, M. Challenges in general cargo distribution strategy in urban logistics—comparative analysis of the biggest logistics operators in EU. Transp. Res. Procedia 2019, 39, 525–533. [Google Scholar] [CrossRef]

- Wang, J.; Lim, M.K.; Tseng, M.-L.; Yang, Y. Promoting low carbon agenda in the urban logistics network distribution system. J. Clean. Prod. 2018, 211, 146–160. [Google Scholar] [CrossRef]

- Škultéty, F.; Beňová, D.; Gnap, J. City Logistics as an Imperative Smart City Mechanism: Scrutiny of Clustered EU27 Capitals. Sustainability 2021, 13, 3641. [Google Scholar] [CrossRef]

- Fatnassi, E.; Chaouachi, J.; Klibi, W. Planning and operating a shared goods and passengers on-demand rapid transit system for sustainable city-logistics. Transp. Res. Part B: Methodol. 2015, 81, 440–460. [Google Scholar] [CrossRef]

- Cleophas, C.; Cottrill, C.; Ehmke, J.F.; Tierney, K. Collaborative urban transportation: Recent advances in theory and practice. Eur. J. Oper. Res. 2019, 273, 801–816. [Google Scholar] [CrossRef]

- Thompson, R.G.; Hassall, K.P. A Collaborative Urban Distribution Network. Procedia—Soc. Behav. Sci. 2012, 39, 230–240. [Google Scholar] [CrossRef]

- Yao, X.; Cheng, Y.; Song, M. Assessment of collaboration in city logistics: From the aspects of profit and CO2 emissions. Int. J. Logist. Res. Appl. 2018, 22, 576–591. [Google Scholar] [CrossRef]

- Gonzalez-Feliu, J. Sustainable urban logistics: Planning and evaluation. John Wiley & Sons, 2018.

- Ben Mohamed, I.; Klibi, W.; Labarthe, O.; Deschamps, J.-C.; Babai, M.Z. Modelling and solution approaches for the interconnected city logistics. Int. J. Prod. Res. 2017, 55, 2664–2684. [Google Scholar] [CrossRef]

- Ambra, T.; Caris, A.; Macharis, C. Towards freight transport system unification: reviewing and combining the advancements in the physical internet and synchromodal transport research. Int. J. Prod. Res. 2018, 57, 1606–1623. [Google Scholar] [CrossRef]

- Crainic, T.G.; Montreuil, B. Physical Internet Enabled Hyperconnected City Logistics. Transp. Res. Procedia 2016, 12, 383–398. [Google Scholar] [CrossRef]

- Venkatadri, U.; Krishna, K.S.; Ulku, M.A. On Physical Internet Logistics: Modeling the Impact of Consolidation on Transportation and Inventory Costs. IEEE Trans. Autom. Sci. Eng. 2016, 13, 1517–1527. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, S.; Ballot, E. Mitigating supply chain disruptions through interconnected logistics services in the Physical Internet. Int. J. Prod. Res. 2016, 55, 3970–3983. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Mirkovski, K.; Lowry, P.B.; Zacharia, Z.G. The physical internet as a new supply chain paradigm: a systematic literature review and a comprehensive framework. Int. J. Logist. Manag. 2020, 31, 239–287. [Google Scholar] [CrossRef]

- Montreuil, B. Toward a Physical Internet: meeting the global logistics sustainability grand challenge. 3, 87. [CrossRef]

- Pan, S.; Nigrelli, M.; Ballot, E.; Sarraj, R.; Yang, Y. Perspectives of inventory control models in the Physical Internet: A simulation study. Comput. Ind. Eng. 2015, 84, 122–132. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).