1. Introduction

Scientific and reasonable road lighting is important for improving road safety [

1,

2,

3] and reducing energy consumption [

4]. The optical reflection characteristics of road surface is one of the important bases for road lighting calculation, and the International Lighting Association CIE recommends the use of reduced brightness coefficient table (r-table) to represent the reflection characteristics of different paving materials and gives some columns of standard r-table [

5], which is used in all kinds of lighting design software calculations, and it provides a great convenience for the design work of road lighting. However, the standard r-tables obtained based on the measurement data in the 1970s do not widely represent the reflectance characteristics of the actual roads today, and the use of the uncorrected r-tables for lighting design will lead to the deviation between the designed and actual brightness of the pavement [

6]. In recent years, more and more research efforts have been devoted to obtaining the reduced brightness coefficient tables representing the actual road reflectance characteristics [

7,

8,

9,

10,

11] or developing various types of test devices for accurately obtaining road reflectance characteristics [

12,

13,

14], to accurately obtain the optical reflectance characteristics of the actual road and improve the accuracy of road lighting design.

However, accurately obtaining data in the form of reduced luminance coefficient requires a lot of cumbersome laboratory measurements, and the instruments to carry out the relevant measurements in the road site have not yet been popularized, and are more in the experimental stage, so the International Illuminating Association, CIE, recommends the use of retro-reflectivity coefficient RL, which is measured in the road site, to indicate the reflective characteristics of the pavement surface [

5].

Pavement surface texture is defined as the deviation of the pavement surface from the true plane [

15]. The International Road Association (PIARC) [

16] classified the surface structure of asphalt pavements into four types: micro-texture, macro-texture, macrostructure and unevenness, based on the wavelength in the horizontal direction, the amplitude in the vertical direction, the power spectral characteristics of asphalt pavements, and their possible impact on road users, where the micro-texture is less than 0.5 mm, and the macro-texture is between 0.5-50.0 mm range [

17]. The pavement texture depends on the composition of the top layer of the pavement material, while the reflectivity of the surface is determined by the micro- and macro-textures [

18].

Macrotexture refers to the irregularities in the rough texture of the road surface and these irregularities are mainly dependent on the nature of the aggregate such as size, grading, shape and distribution, the nominal maximum size of aggregates, and the nature of the asphalt mixture such as asphalt content, mix design and the void ratio [

19,

20,

21]. Macrotexture mainly depends on the roughness of the road surface profile, controls the noise between tires and road surface as well as friction at high speeds, and mainly acts as drainage in rainy weather [

22]. Microtexture refers to the fine structural irregularities on the surface of the aggregate particles, generally reaching the micrometer level, and is mainly related to the mineral composition of the aggregate particles [

23]. Microtexture interacts with rubber tires at the molecular scale and provides adhesion, thus microtexture is important on both wet and dry pavements [

24,

25] and plays an important role in anti-slip [

26].

Moretti [

27] et al. conducted a lighting design and case study for continuously reinforced concrete pavement, plain concrete pavement, and asphalt pavement for the difference in pavement materials, the results showed that the total cost of cement pavement, energy consumption is 29% lower than that of asphalt pavement, and in the use of the period of 5 years, the plain concrete pavement consumes less and has a longer life span than the continuously reinforced cement pavement.

Due to the low accuracy of traditional pavement texture measurement in the past, Huang [

28] and others independently developed a set of ultra-high-speed line laser testing systems based on the image recognition method, which can greatly improve the efficiency and accuracy of asphalt pavement structure, texture morphology three-dimensional data measurement. With the help of high-precision three-dimensional laser scanning technology, Yang et al [

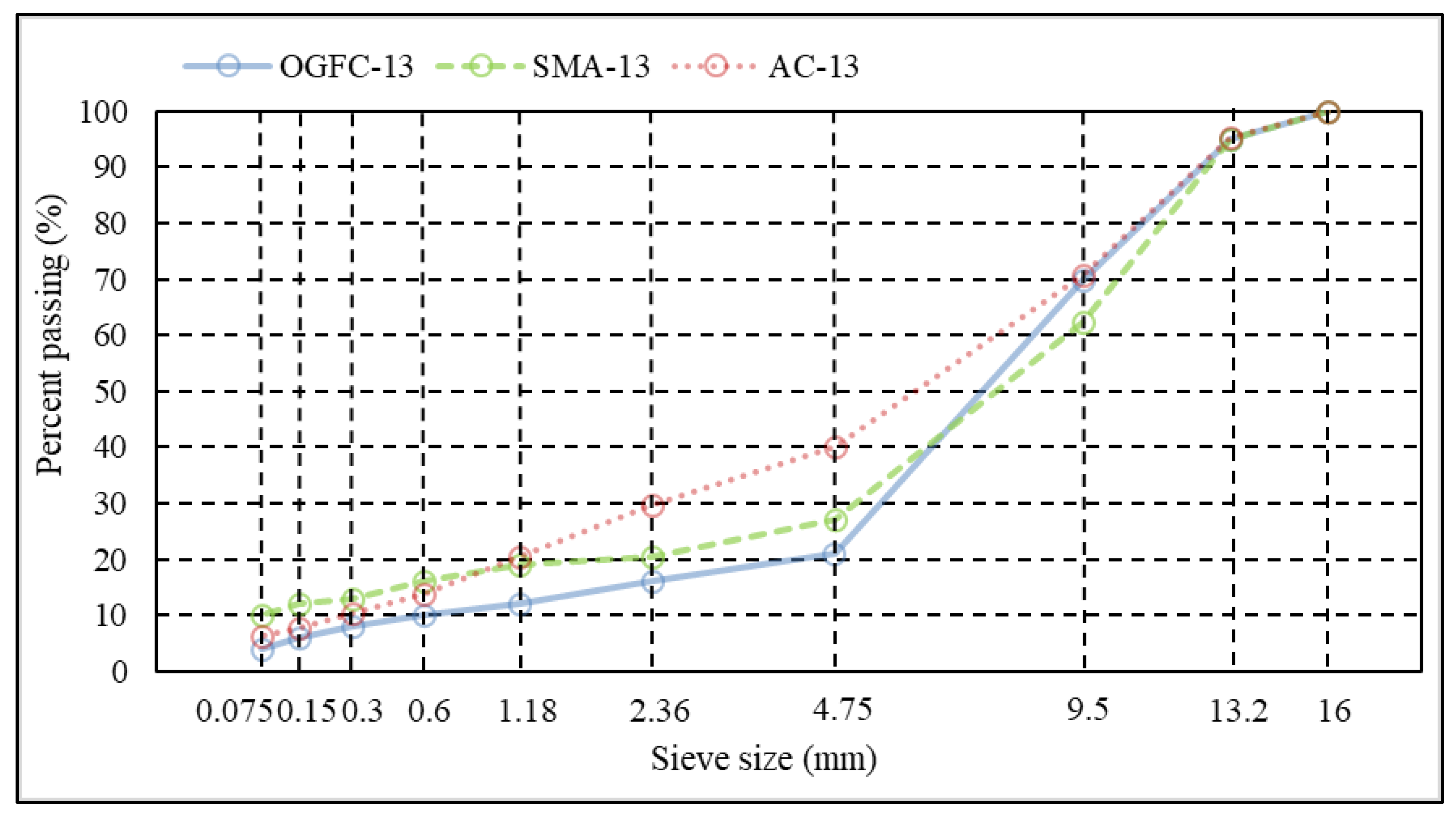

29,

30] measured the surface texture characteristics of three typical grades of asphalt mixture specimens AC, SMA, and OGFC, according to the experimental data to establish a regression model with the mass ratio - the product of particle size and the average depth of the structure of the dependent variable, the model successfully predicted the pavement structure of asphalt specimen plate parameters of the different types of pavements. Weng et al [

31] obtained the pavement texture data with the help of 3D laser scanning, extracted the surface trait parameters based on geometric features and the multi-scale feature parameters based on 2D wavelet transform as the model inputs, and predicted the gradation of asphalt under eight known gradations with the help of the model, and the goodness-of-fit was as high as 0.859. Viktoras [

18] et al. considered that the brightness of pavement is related to the reflective properties of pavement, and different pavements can have different reflective properties. pavements can have different reflective properties depending on the surface texture, material and binder. Therefore, researchers conducted an experimental study on Vilnius city streets, which differed in color and age. The results show that red asphalt pavements have better reflective properties than black asphalt pavements. the simplified brightness factor of asphalt pavements installed in 2021 is about 12% lower than that of asphalt pavements installed 10 years ago.

To summarize, at present, few scholars have explored the light reflection characteristics of roads from the perspective of road surface topographic features and macro- and microstructures. Various studies are aimed at obtaining the reflection coefficient of pavement materials and analyzing the measurement uncertainty, but not enough research on the mechanism of the influence of material surface features on the reflection characteristics. The environmental factors involved in actual road lighting are more complicated, with various types of pavement materials and different three-dimensional morphology structures. Therefore, it is necessary to establish a scientific and reasonable quantitative expression model and choose a suitable and reliable optical research and design method to describe the law of road lighting in China.

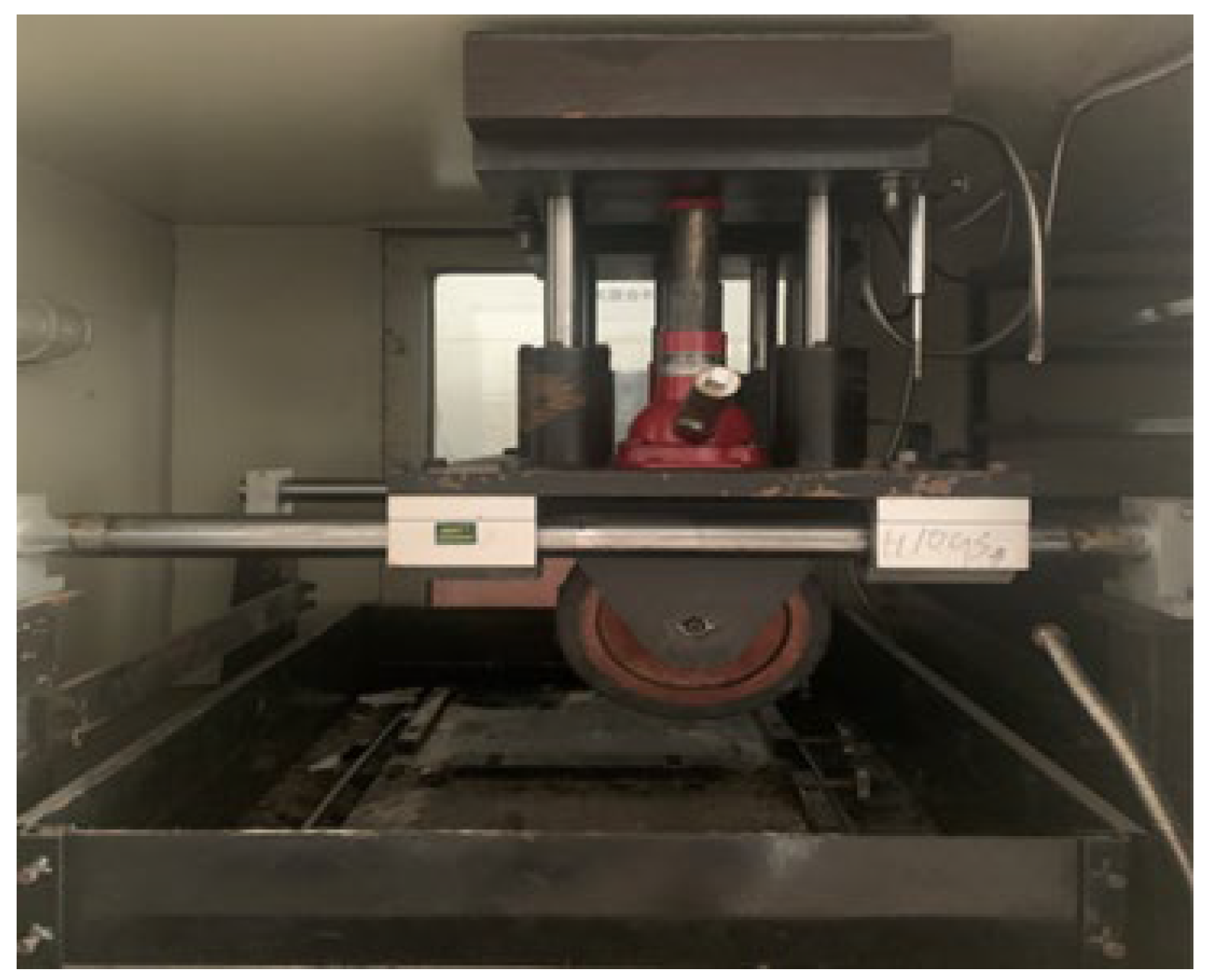

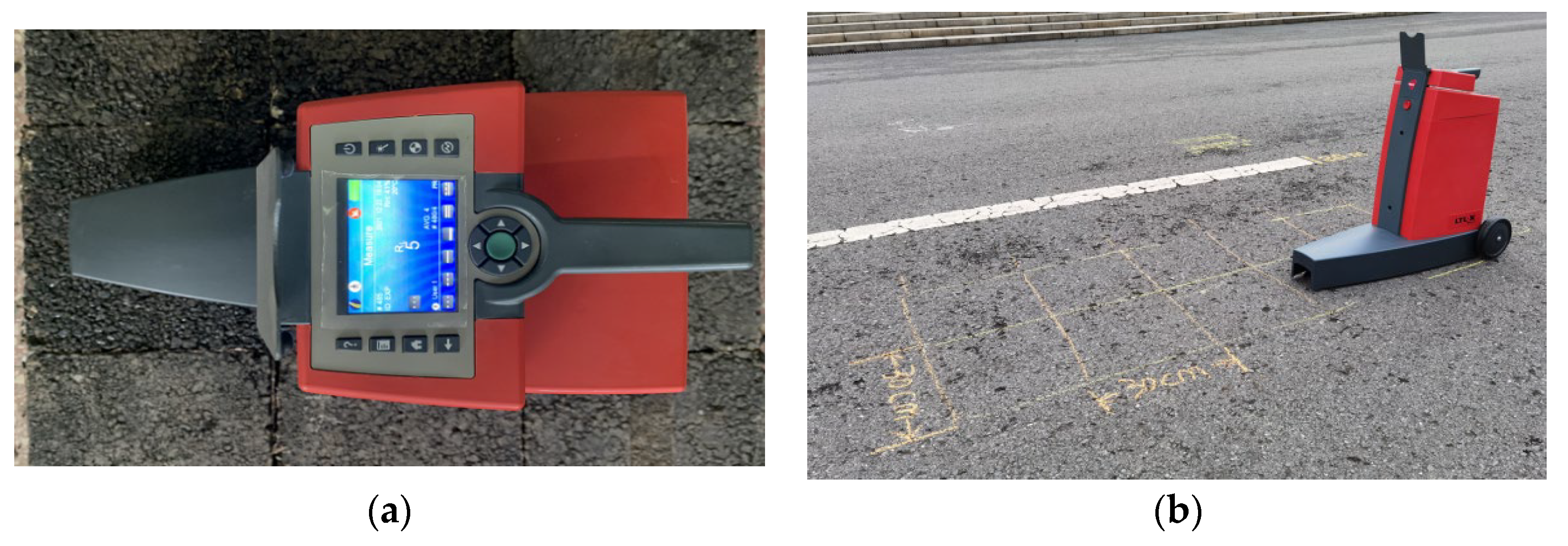

Therefore, in this study, the LTL-XL Mark II retro-reflectometer and PATT-II pavement texture tester were used to obtain the retroreflection coefficient of asphalt mixtures and macro-micro-texture parameters both in the laboratory and on-site. In the labatory, the correlation between the retroreflection coefficient of asphalt mixtures and macro-micro-texture parameters before and after rutting test crushing was determined by measuring the retroreflection coefficient and macro-micro-texture parameters before and after the rutting test crushing, and a single-indicator impact model was established. The correlation between the macro-micro texture index and the retroreflection coefficient was determined by testing the relevant parameters in the field. A quantitative expression model of the retroreflection coefficient influenced by single and multiple texture parameters was established.

Figure 3.

Retroreflection coefficient test: (a) in-house testing and (b) field testing.

Figure 3.

Retroreflection coefficient test: (a) in-house testing and (b) field testing.

Figure 4.

Pavement texture index test: (a) in-house testing,(b) Field testing.

Figure 4.

Pavement texture index test: (a) in-house testing,(b) Field testing.

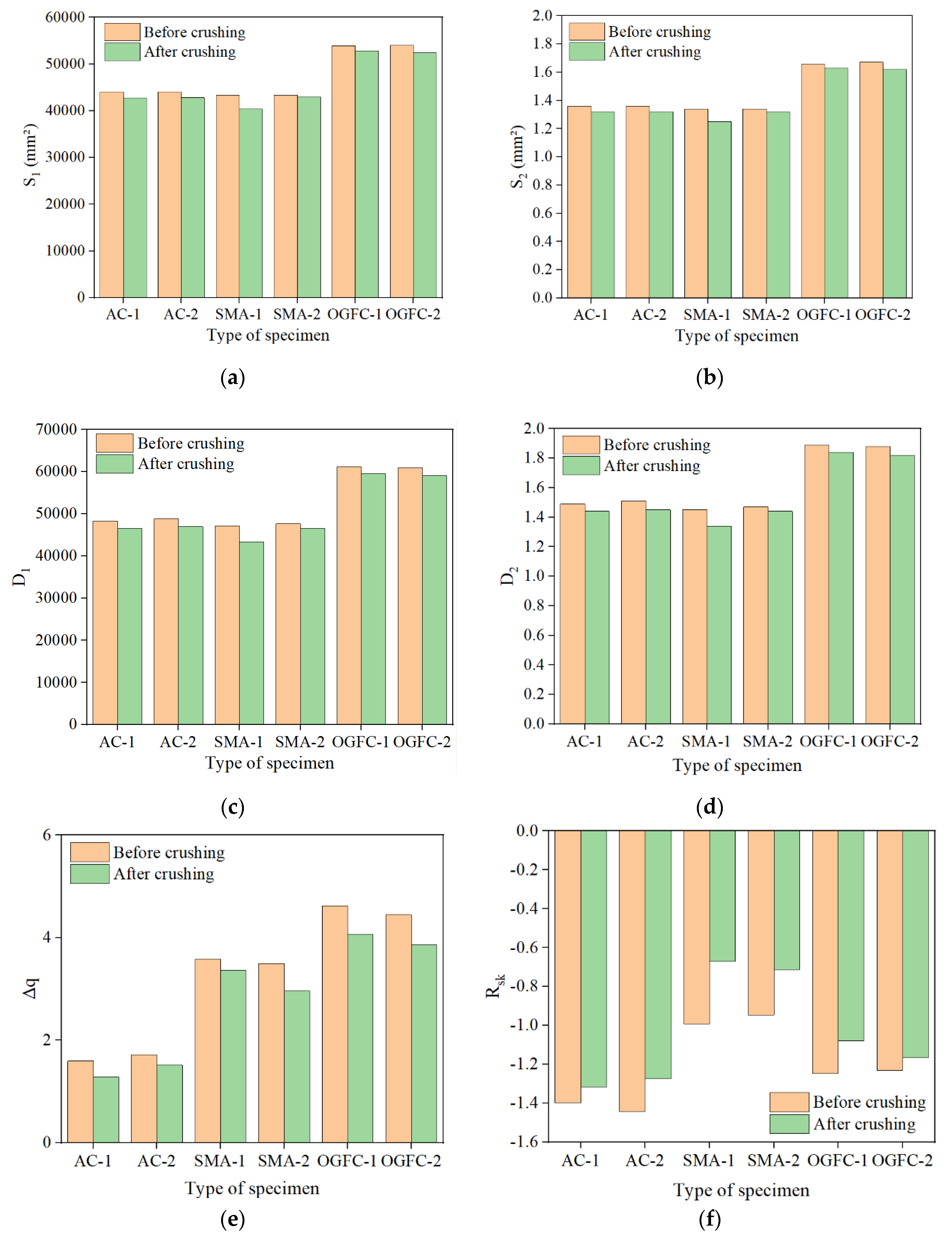

Figure 5.

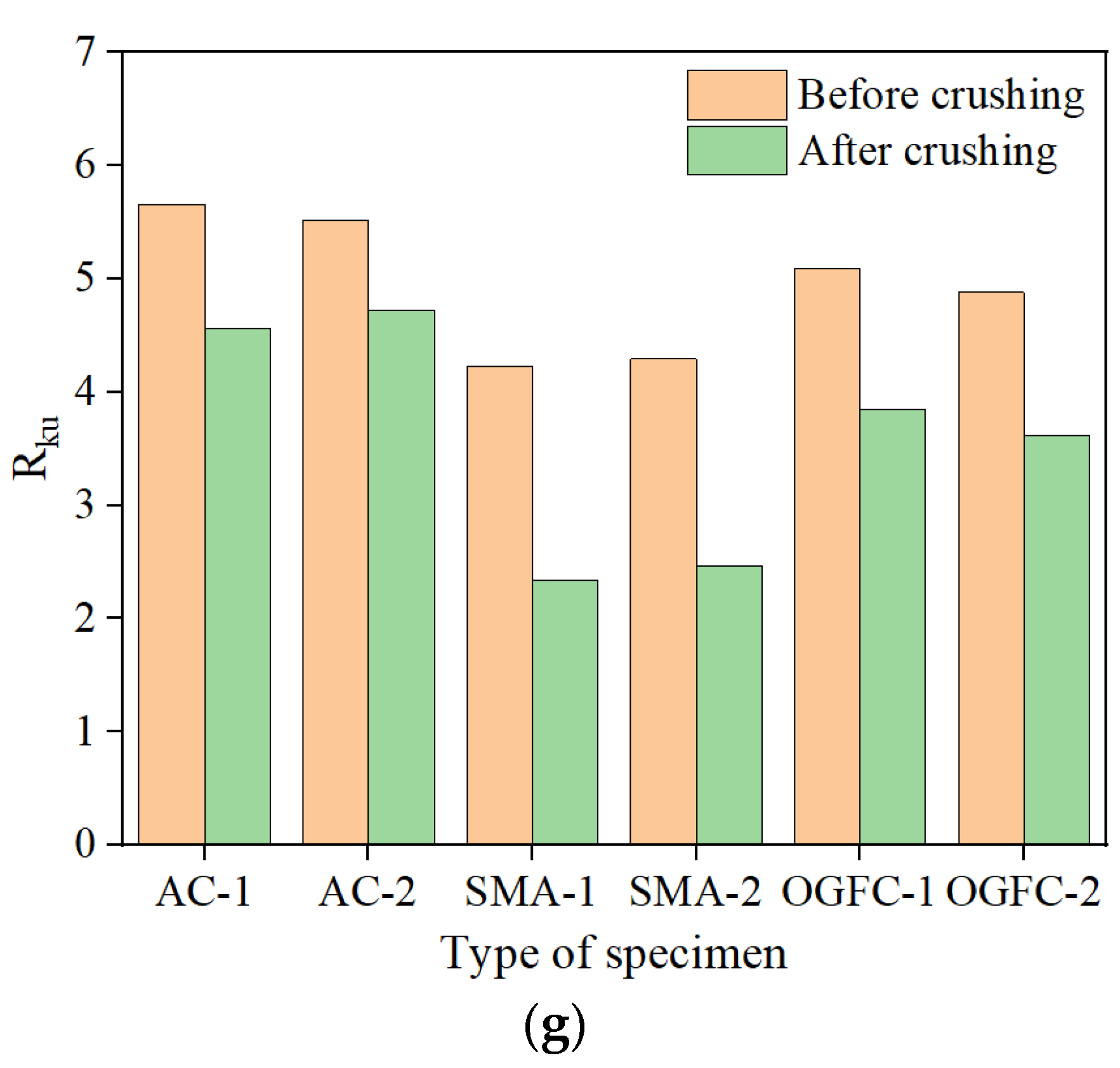

Comparison of texture parameters of different types of rutted specimens before and after crushing in rutting test: (a) Macrotexture surface area comparison, (b) microtexture surface area comparison, (c) macroscopic texture distribution density, (d) microscopic texture, (e) profile slope root mean square, (f) skewness comparison, and (g) kurtosis comparison.

Figure 5.

Comparison of texture parameters of different types of rutted specimens before and after crushing in rutting test: (a) Macrotexture surface area comparison, (b) microtexture surface area comparison, (c) macroscopic texture distribution density, (d) microscopic texture, (e) profile slope root mean square, (f) skewness comparison, and (g) kurtosis comparison.

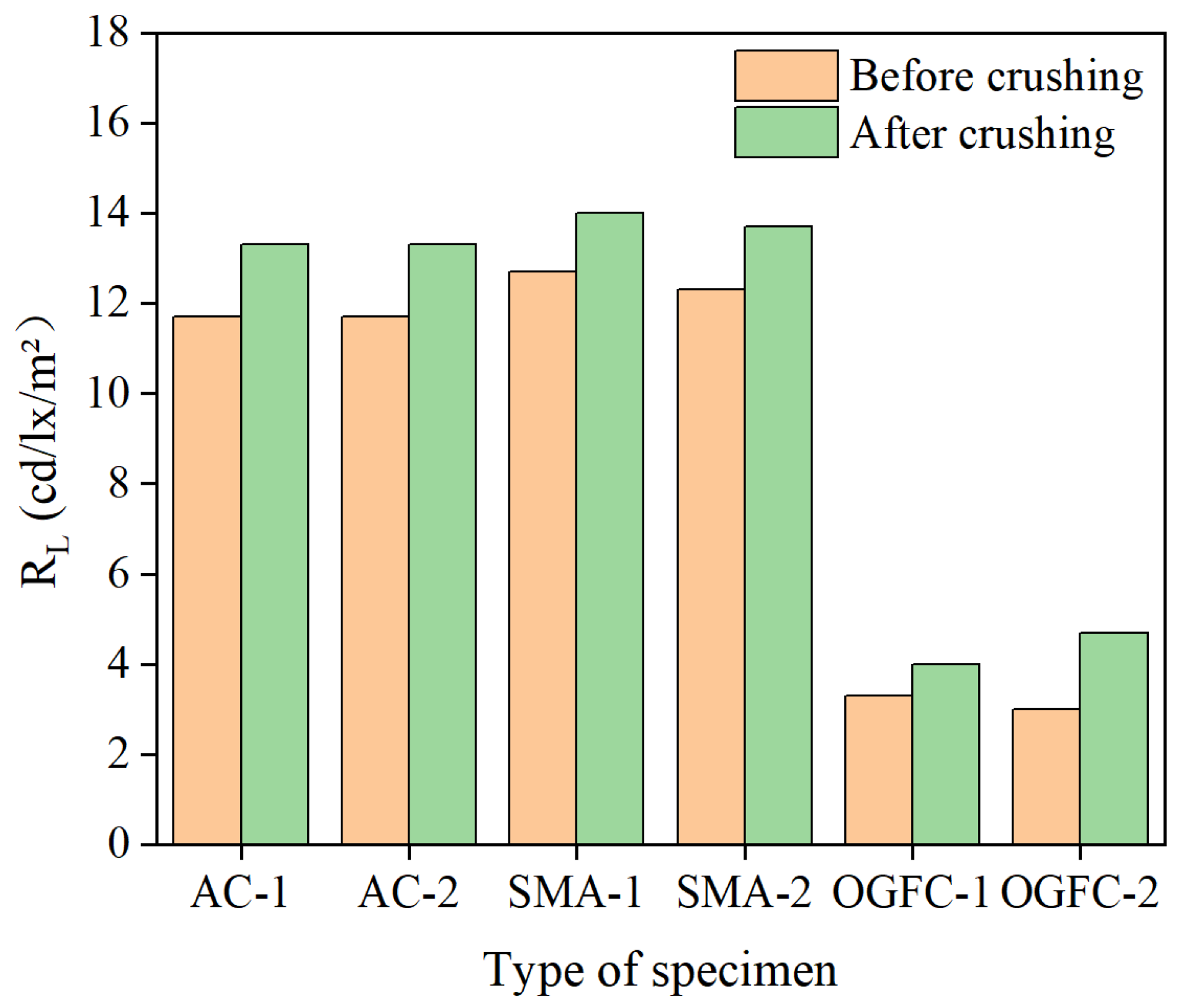

Figure 6.

Reverse reflection coefficients of different types of rutted specimens before and after crushing.

Figure 6.

Reverse reflection coefficients of different types of rutted specimens before and after crushing.

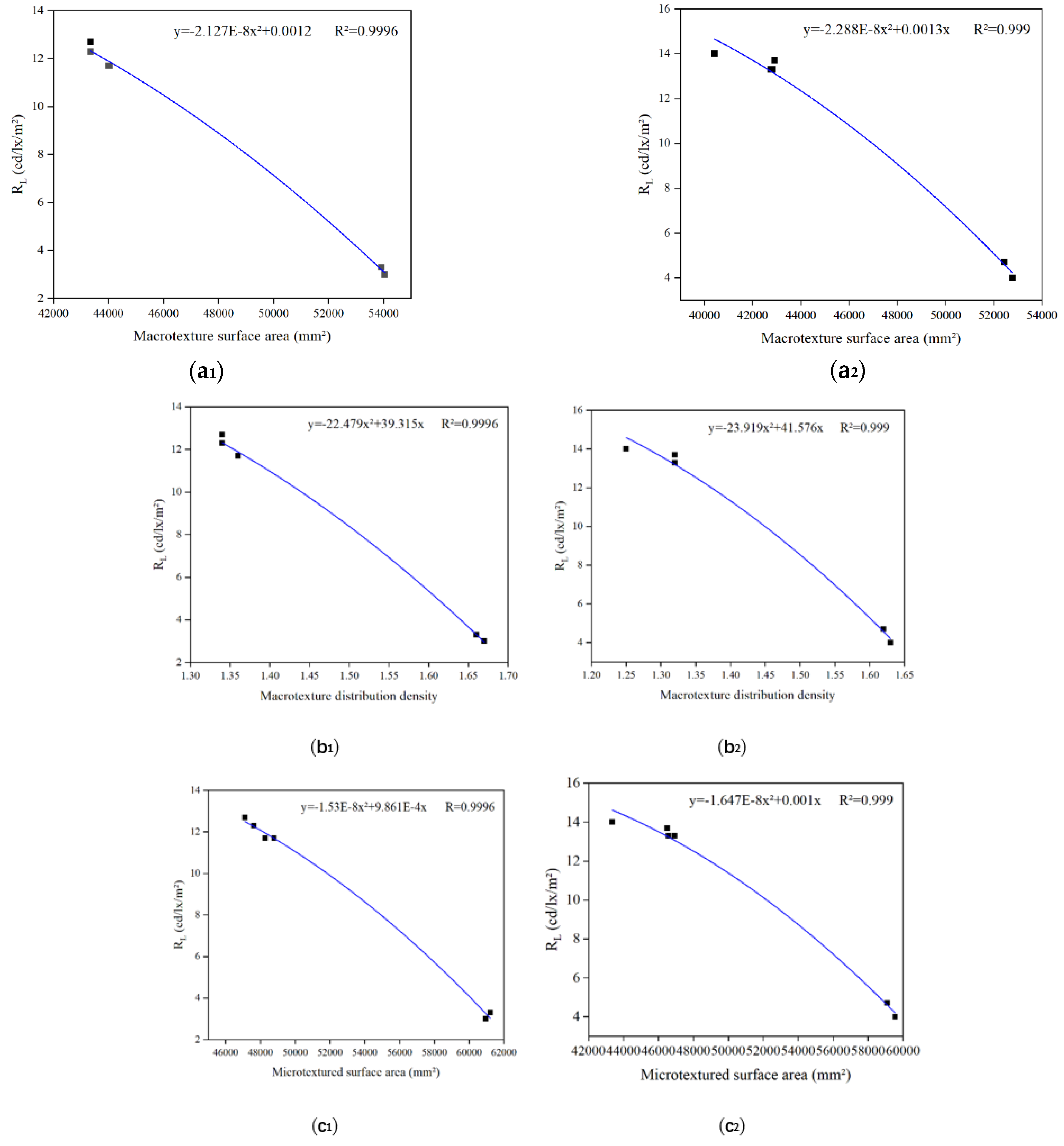

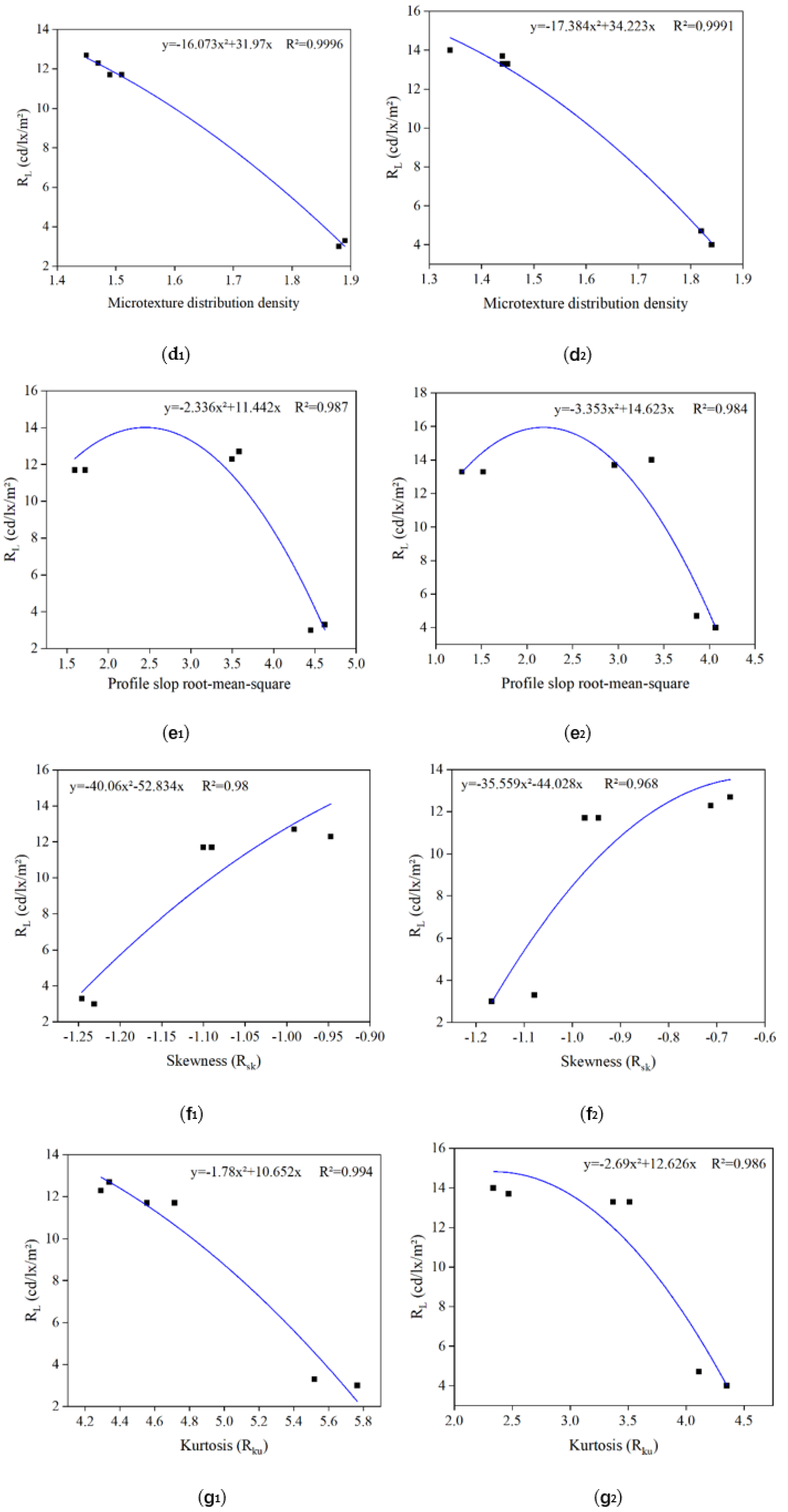

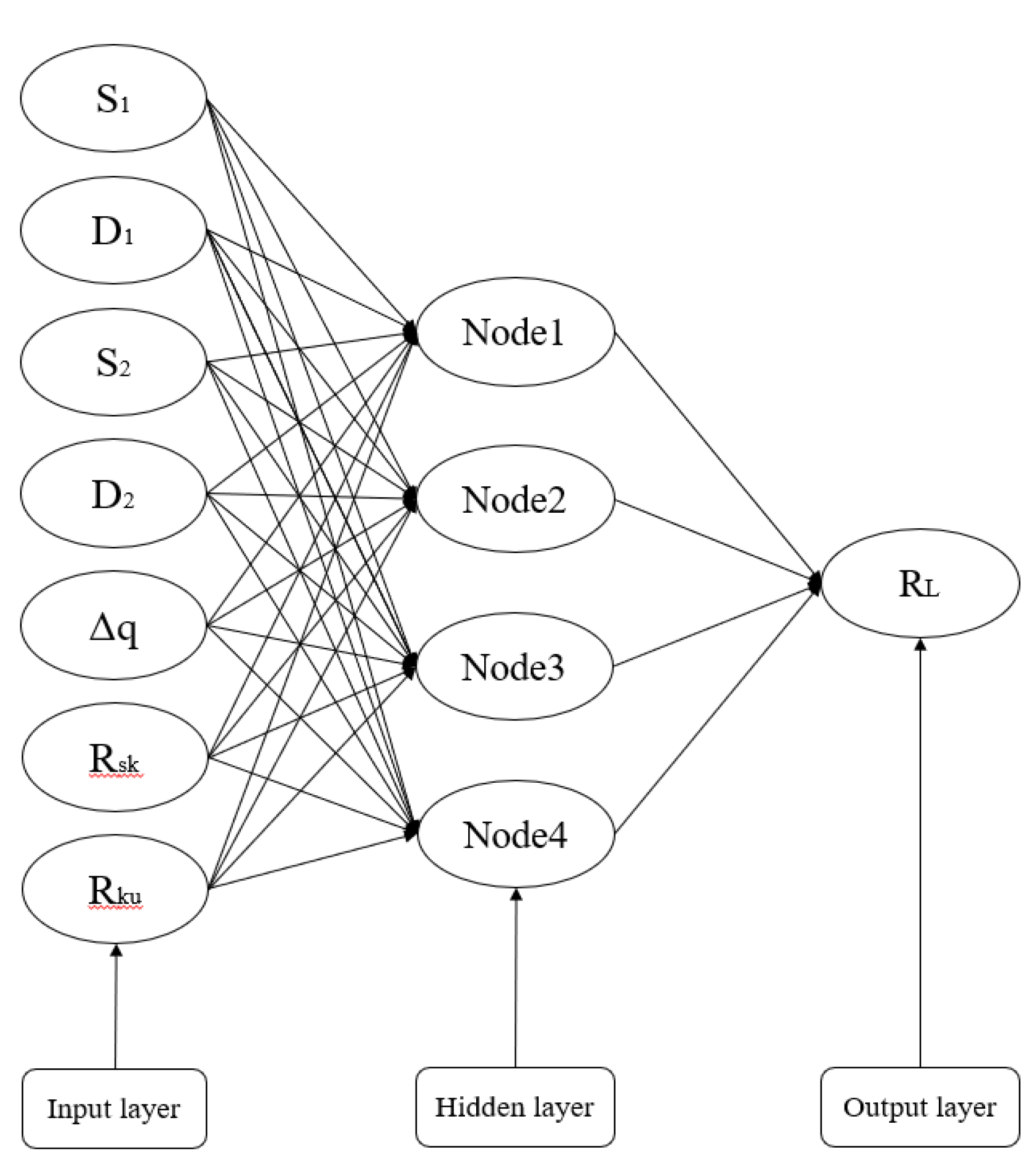

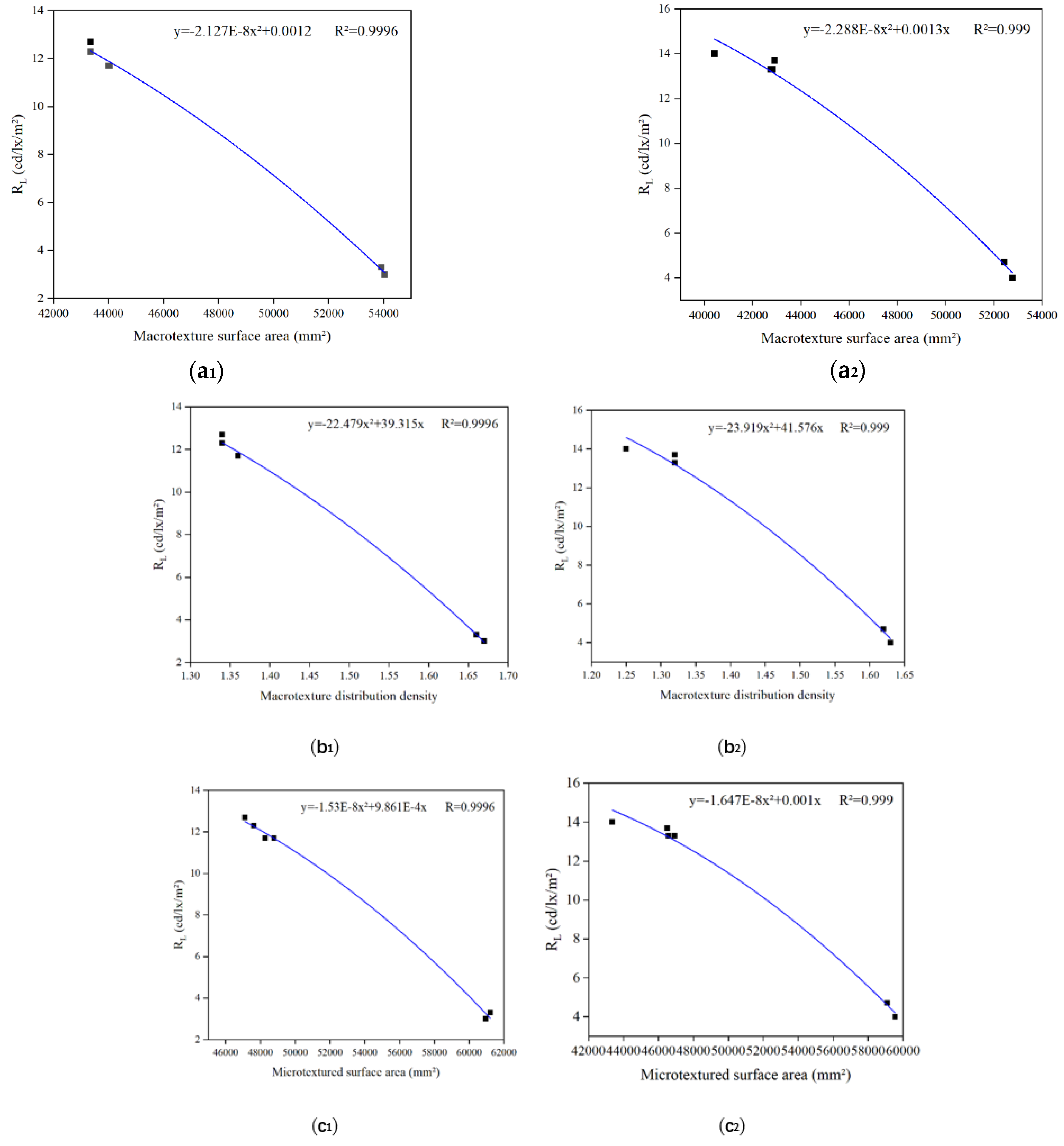

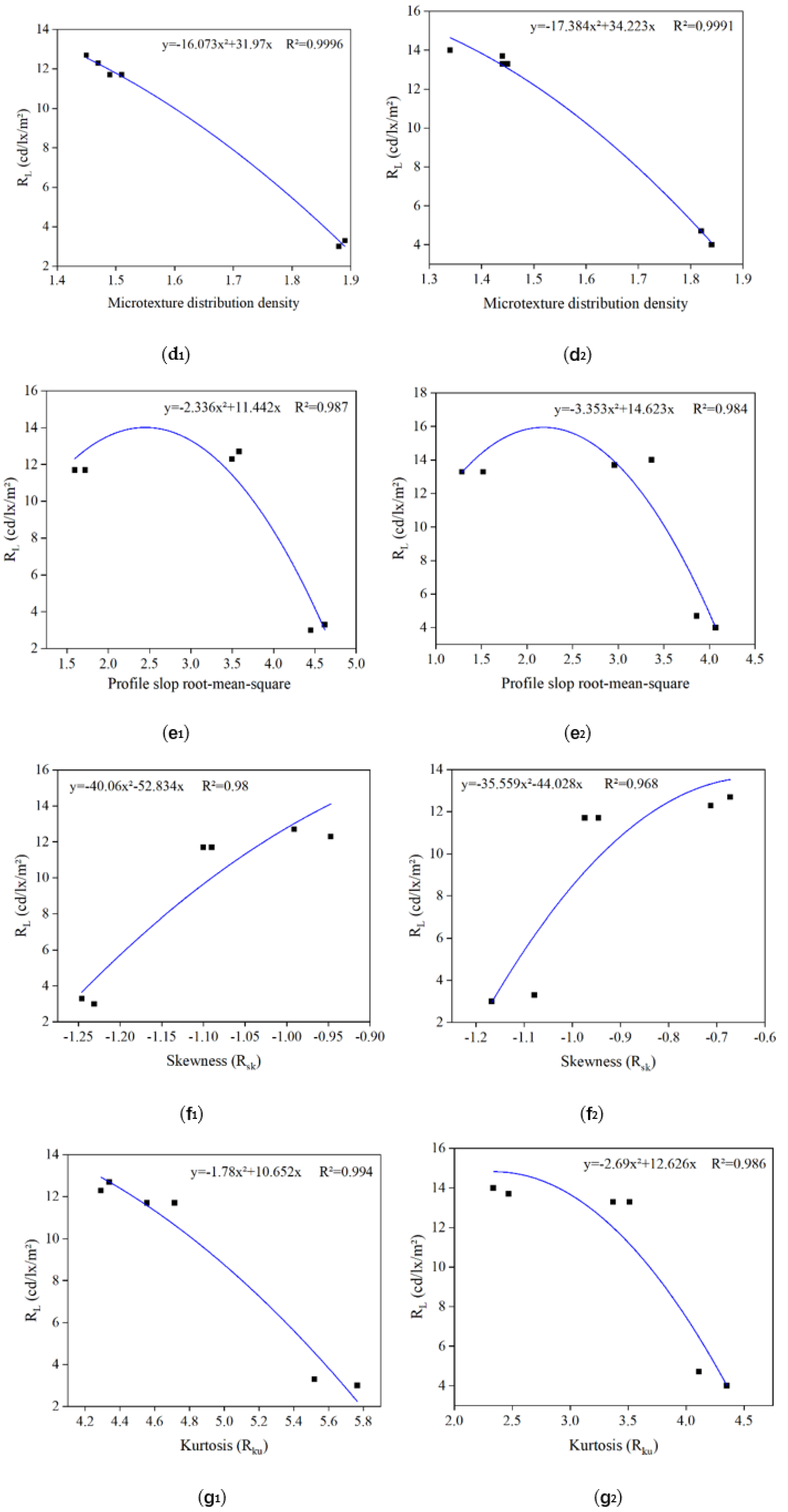

Figure 7.

Model of the correspondence between the retroreflection coefficient RL and the texture index before and after crushing: (a1) Rutted specimen S1 before crushing is correlated with RL, (a2) Rutted specimen S1 after crushing is correlated with RL, (b1) Rutted specimen D1 before crushing is related to RL, (b2) Rutted specimen D1 after crushing is related to RL, (c1) Rutted specimen before crushing S2 Correlation with RL, (c2) Rutted specimen after crushing S2 Correlation with RL, (D1) Rutted specimen D2 before crushing correlates with RL, (d2) Rutted specimen D2 after crushing correlates with RL, (e1) Correlation between Δq and RL for rutted specimens before crushing, (e2) Correlation between Δq and RL for rutted specimens after crushing, (f1) Pre-crush rutted specimen Rsk correlates with RL, (f2) Post-crush rutted specimen Rsk correlates with RL, (g1) Correlation between Rku and RL for rutted specimens before crushing, (g2) Correlation between Rku and RL for rutted specimens after crushing.

Figure 7.

Model of the correspondence between the retroreflection coefficient RL and the texture index before and after crushing: (a1) Rutted specimen S1 before crushing is correlated with RL, (a2) Rutted specimen S1 after crushing is correlated with RL, (b1) Rutted specimen D1 before crushing is related to RL, (b2) Rutted specimen D1 after crushing is related to RL, (c1) Rutted specimen before crushing S2 Correlation with RL, (c2) Rutted specimen after crushing S2 Correlation with RL, (D1) Rutted specimen D2 before crushing correlates with RL, (d2) Rutted specimen D2 after crushing correlates with RL, (e1) Correlation between Δq and RL for rutted specimens before crushing, (e2) Correlation between Δq and RL for rutted specimens after crushing, (f1) Pre-crush rutted specimen Rsk correlates with RL, (f2) Post-crush rutted specimen Rsk correlates with RL, (g1) Correlation between Rku and RL for rutted specimens before crushing, (g2) Correlation between Rku and RL for rutted specimens after crushing.

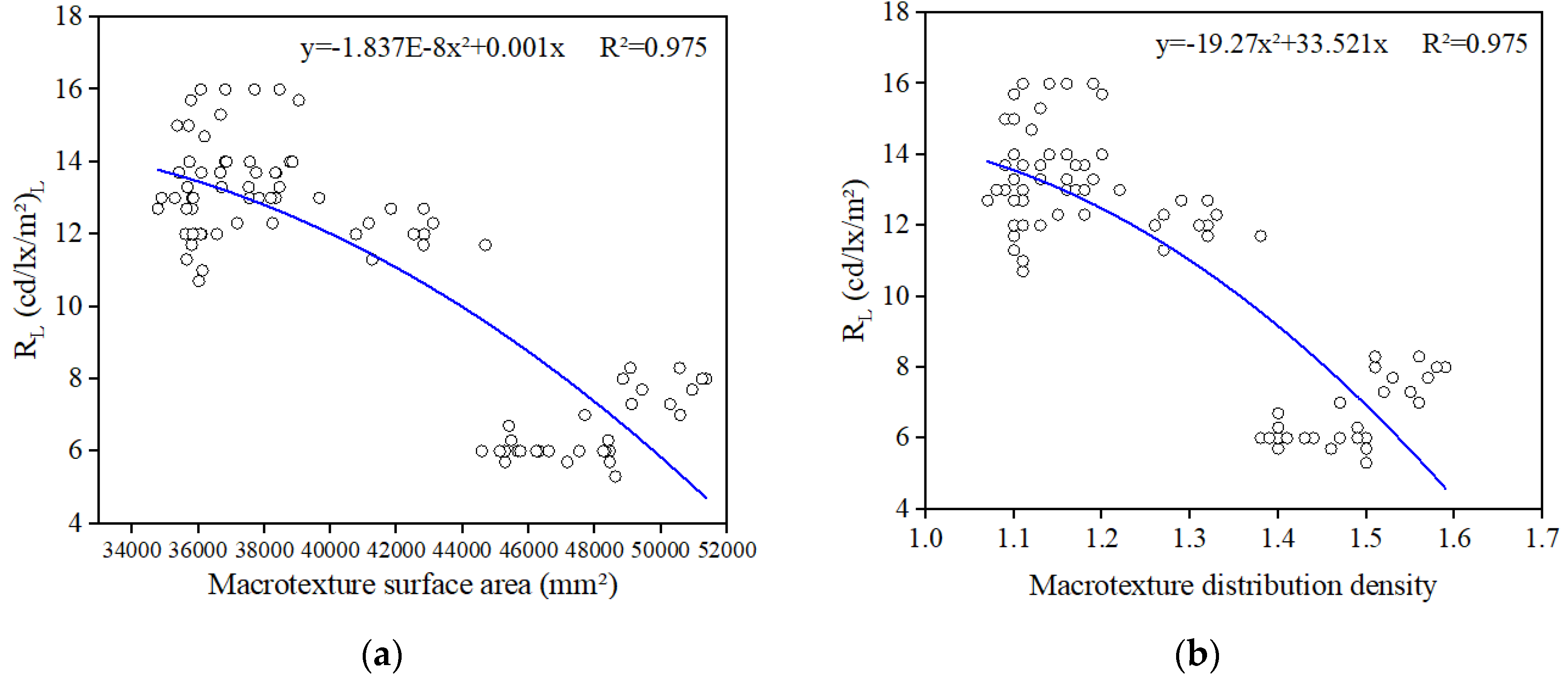

Figure 8.

One-factor modeling of pavement texture index and reverse reflection coefficient: (a) S1 correlates with RL, (b) D1 correlates with RL,(c) S2 correlates with RL, (d) D2 correlates with RL,(e) Δq correlates with RL, (f) Rsk correlates with RL,(g) Rku correlates with RL.

Figure 8.

One-factor modeling of pavement texture index and reverse reflection coefficient: (a) S1 correlates with RL, (b) D1 correlates with RL,(c) S2 correlates with RL, (d) D2 correlates with RL,(e) Δq correlates with RL, (f) Rsk correlates with RL,(g) Rku correlates with RL.

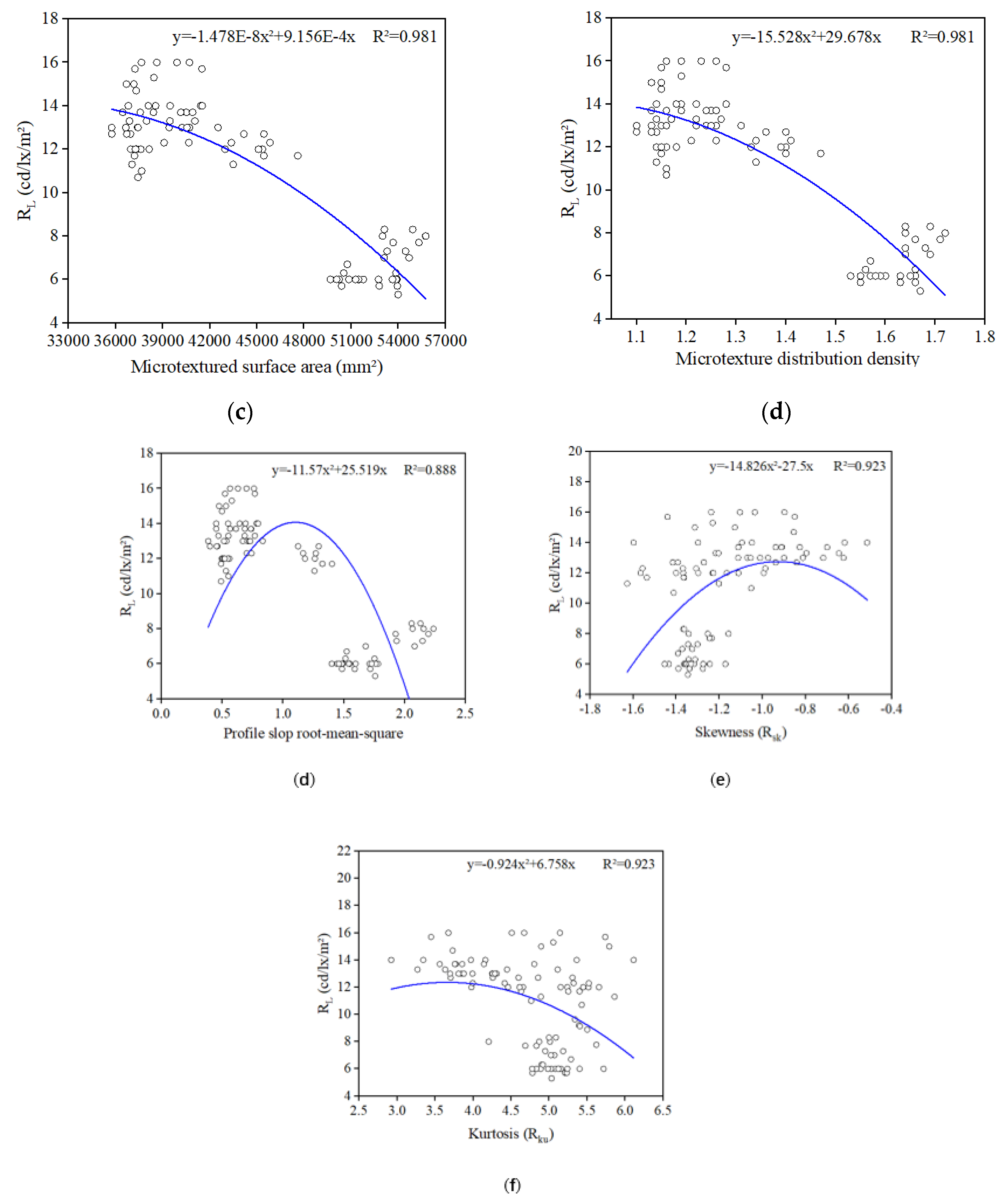

Figure 9.

Multilayer perceptron model.

Figure 9.

Multilayer perceptron model.

Table 1.

Test results for SBS-modified asphalt.

Table 1.

Test results for SBS-modified asphalt.

| Test Project |

Unit |

Technical Requirements |

Test results |

Test Method |

| Softening point (Universal method) |

℃ |

≧55 |

61 |

JTG F40/T4507 |

| Latency |

(5℃,5 cm/min)cm |

≧30 |

34 |

JTG F40/T4508 |

| Needle penetration |

(25℃)1/10mm |

60-80 |

69 |

JTG F40/4509 |

| Needle penetration index (PI) |

― |

≧-0.4 |

-0.25 |

― |

| Flashpoint (open) |

℃ |

≧230 |

280 |

JTG F40/T267 |

| Solubility |

% |

≧99 |

99.6 |

JTG F40/T11148 |

Table 2.

Density of coarse and fine aggregates.

Table 2.

Density of coarse and fine aggregates.

| Coarse aggregate |

Aggregate size |

16–13.2 |

13.2–9.5 |

9.5 – 4.75 |

4.75–2.36 |

- |

| Apparent relative density (g/cm3 ) |

2.75 |

2.79 |

2.75 |

2.92 |

- |

| Fine aggregate |

Aggregate size |

2.36–1.18 |

1.18–0.6 |

0.6–0.3 |

0.3–0.15 |

0.15–0.075 |

| Apparent density (g/cm3 ) |

2.87 |

2.86 |

2.82 |

2.79 |

2.98 |

Table 3.

Limestone mineral powder technical index.

Table 3.

Limestone mineral powder technical index.

| Sports event |

Unit |

stake a claim |

Measurement results |

Test Methods |

| Apparent density |

g/cm3

|

≥2.50 |

2.524 |

T0352 |

| Moisture content |

- |

≦1 |

0.3 |

T0103 |

| Hydrophilicity |

|

<1 |

0.66 |

T0353 |

| Particle size range |

<0.6mm |

% |

100 |

100 |

T0351 |

| <0.15mm |

% |

90-100 |

90.3 |

| <0.075mm |

% |

75-100 |

74.6 |

| Exterior condition |

- |

No agglomeration |

No agglomeration |

- |

Table 4.

Basic properties of lignin fibers.

Table 4.

Basic properties of lignin fibers.

| Pilot project |

Unit |

Technical requirement |

Test results |

Test Methods |

| Fiber length |

mm |

≤6 |

3.6 |

JTG/T533-2004 |

| Ash content |

% |

18% ± 5, no volatiles |

21.4 |

JTG/T533-2004 |

| PH value |

- |

7.5±1.0 |

7.92 |

JTG/T533-2004 |

| Oil absorption |

% |

≥5 times the fiber mass |

846.2 |

JTG/T533-2004 |

| Moisture content |

% |

≤5 |

3.2 |

JTG/T533-2004 |

Table 5.

Basic parameters of the retroreflective tester.

Table 5.

Basic parameters of the retroreflective tester.

| Sports event |

Parameters |

| Measurement range |

45 mm x 200 mm |

| The angle of incidence RL

|

en 1436: 1.24° astm e 1710: 88.76° |

| Observation angle RL

|

en 1436: 2.29° astm e 1710: 1.05° |

| RL Scope |

0 ~ 2000 mcd/(LX -m )2 |

| Equipment length and width |

Length: 573 mm Width: 222 mm |

| Equipment height |

538 mm |

| Equipment weight |

9.7 kg |

| Operating temperature |

0℃~45℃ |

Table 6.

Scanning parameters of the laser sensor.

Table 6.

Scanning parameters of the laser sensor.

| Sports event |

Parameters |

| Scan length |

40 ~ 300 mm |

| Scanning width |

20 ~ 300 mm |

| Travel step |

Integer multiple of scan width |

| Absolute height from the scanned specimen |

80 mm |

Table 7.

Weight relationship between the input and hidden layers.

Table 7.

Weight relationship between the input and hidden layers.

| Weights |

Node1 |

Node2 |

Node3 |

Node4 |

| S1 |

0.576 |

0.249 |

0.121 |

-0.842 |

| D1 |

0.597 |

0.417 |

0.077 |

-0.717 |

| S2 |

-1.419 |

-2.567 |

-0.171 |

-1.113 |

| D2 |

-1.666 |

-2.382 |

-0.184 |

-0.735 |

| Δq |

3.638 |

0.794 |

0.557 |

-1.227 |

| Rsk |

-0.154 |

0.395 |

0.267 |

0.285 |

| Rku |

-1.409 |

-0.367 |

-0.198 |

0.028 |

Table 8.

Weighting relationship between the hiding and output layers.

Table 8.

Weighting relationship between the hiding and output layers.

| Weights |

RL |

| Node1 |

0.856 |

| Node2 |

1.893 |

| Node3 |

0.095 |

| Node4 |

-0.977 |