1. Introduction

Asphalt pavement is widely used in highway construction due to its excellent performance such as skid resistance [

1,

2,

3,

4], wear resistance [

5] and driving comfort [

6]. Asphalt mixture is composed of asphalt binder, aggregate and mineral fillers [

7,

8,

9,

10]. Generally, minerals aggregates account for more than 90% in asphalt mixtures [

11,

12,

13,

14]. With the development for highway construction and maintenance, the premium fillers that could be consumed in large quantities [

15,

16]. Therefore, the contradiction between supply and demand is appeared because of tremendous supply pressure on natural resources. Meanwhile, the moisture damage resistance of asphalt mixture which is prepared by ordinary limestone powder is not roundly achieved to requirements. Therefore, it is urgent to achieve substitutable fillers to approach the moisture problems, which has a great significance for environment protection and improving the service life of asphalt pavement.

Steel slag is a typical solid waste material with strong alkalinity [

17,

18,

19], which has the potential to be used in asphalt mixtures. Steel slag has the characteristics of wear resistance, impact resistance and skid resistance [

20]. The asphalt mixture is prepared by using steel slag instead of natural aggregate has obvious advantages to improve the high temperature stability [

21,

22,

23]. Tailing is the section with low useful components in beneficiation [

24]. Statistics showed that the annual cumulative increase of global tailings is 5-7 billion tons [

25]. The main composition of treated tailings is similar to the traditional aggregate, and can be used as aggregates, sand substitutes, cement, etc [

26,

27]. Calcium carbide slag is the waste residue obtained from the hydrolysis of calcium carbide [

28]. In the preparation of cement, the limestone could be replaced by the calcium carbide slag, because there is a large amount of calcium hydroxide in carbide slag, the alkalinity is high which is about 3000 mmo1/L [

29].

The environment will be seriously polluted due to the discharge and accumulation of solid waste [

30]. What’s more, the low price of solid waste material means that the recycling of solid waste could have better economic benefits [

31,

32]. The replacement of solid waste materials such as steel slag with aggregate has been studied [

33]. However, the research on moisture stability of asphalt mixture with different types of solid waste fillers still to be explored.

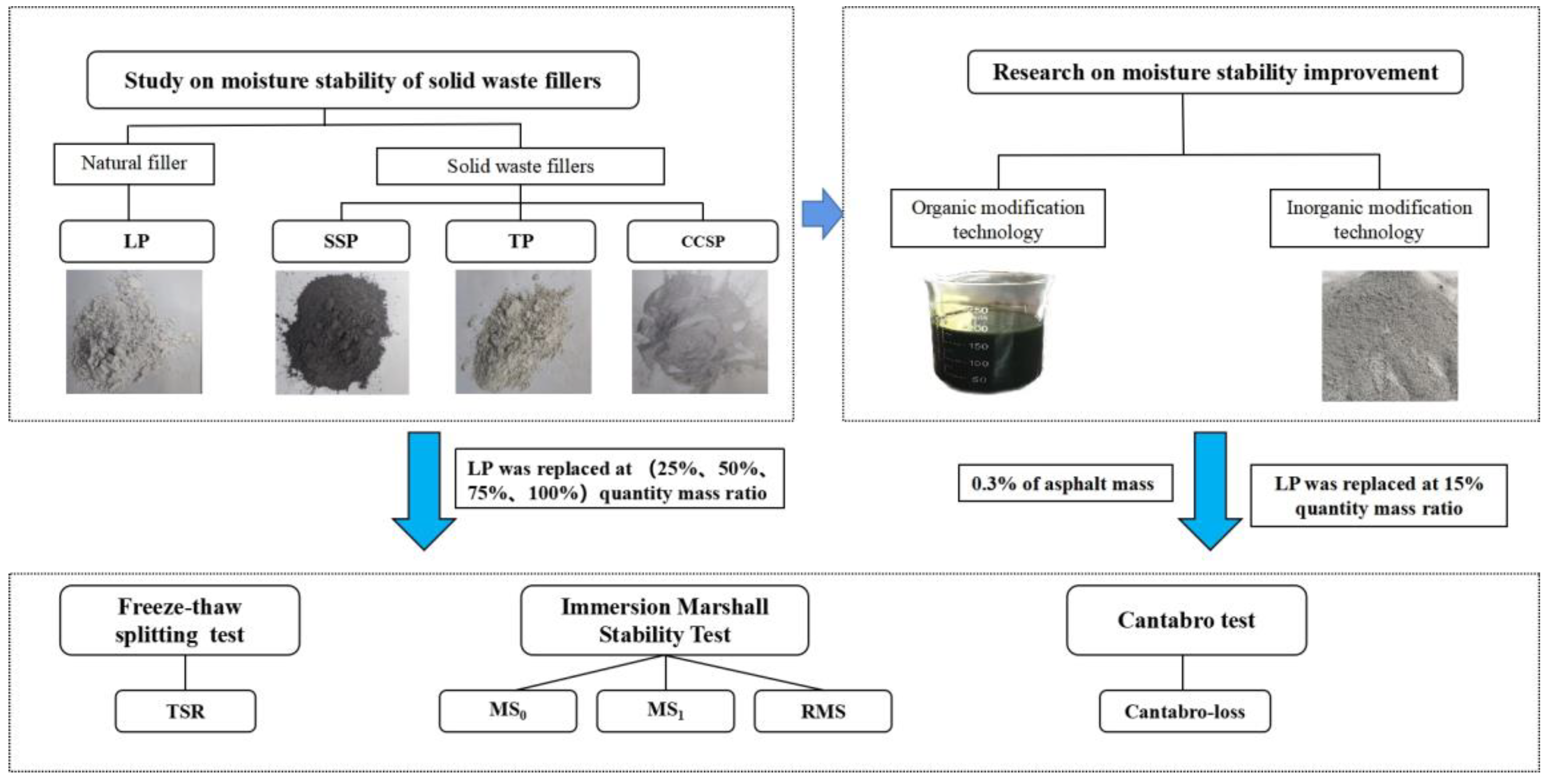

In this research, the limestone powder was replaced by three kinds of solid waste fillers (steel slag powder, tailings powder, calcium carbide slag powder) to prepare the asphalt mixture. The AC-13 and SMA-13 asphalt mixtures were designed to investigate the moisture stability of asphalt mixture with different solid waste fillers. Furthermore, two kinds of anti-stripping agents (non-amine anti-stripping agents and cement) were selected to study the effect of anti-stripping agents on the moisture stability of asphalt mixture. This research mainly focused on the reusing of different solid waste fillers, which provide a reference information for environmental protection and cleaner asphalt pavement construction. The research flowchart was performed as shown in

Figure 1.

2.1. Materials

2.1.1. Asphalt

The Styrene-Butadiene-Styrene (SBS) modified asphalt was adopted. The basic properties are shown in

Table 1.

2.1.2. Aggregates

The aggregates in this article were divided into three categories: coarse aggregate, fine aggregate and filler. In this study, the AC-13 asphalt mixture was prepared by limestone as coarse aggregate and diabase as fine aggregate. The SMA-13 asphalt mixture was prepared by diabase as both coarse aggregate and fine aggregate. What’s more, limestone powder(LP), steel slag powder(SSP), tailings powder(TP), calcium carbide slag powder(CCSP) and cement(CE) were used as different fillers. The basic performance different fillers was shown in

Table 2. Other materials include wood fiber for SMA-13 and non-amine anti-stripping agents, the basic properties of which are shown in

Table 3 and

Table 4.

2.2. Experimental methods

2.2.1. Asphalt mixture design

In this study, the Marshall design method was used to design AC-13 and SMA-13 asphalt mixture. The amount of filler was 3% and 10% of the total mass of mineral aggregate, respectively. Marshall specimens were prepared by adding different fillers (SSP, TP, CCSP) in asphalt mixture according to different substitution amounts (25%, 50%, 75%, 100%) instead of limestone powder. Due to the different density of different fillers, the volume property of Marshall specimens would be different according to the mass ratio. In order to eliminate the influence of volume change, the equal volume method was used to obtain the mass of the mixture by using the density ratio of different fillers.

2.2.2. Moisture damage resistance evaluation

The moisture stabilities of asphalt mixture were evaluated by the immersion Marshall stability test and freeze-thaw splitting test. Retained Marshall Stability (RMS) and Tensile Strength Ratio (TSR) were used to characterize the stability of asphalt mixture moisture respectively [

34]. Besides, the Cantabro-loss was applied to verify the moisture stability of asphalt mixture. All specimens were made according to Marshall specimen forming method.

2.2.2.1. RMS measurement

In RMS test, the Marshall specimens were divided into two groups of 4 in each group. One group was immersed in water at 60℃ for 0.5h, and the other group was immersed in water bath at 60℃ for 48 h. The Marshall stability of two groups were tested, and the following formula was used to calculated the RSM:

where, RMS represents residual Marshall stability (%); MS0 and MS1 are the Marshall stability of immersion in 60°C water for 30 minutes and 60°C water for 48 hours, KN, respectively.

2.2.2.2. TSR measurement

During the TSR test, both sides of the specimens were compacted 50 times. The Marshall specimens were divided into two groups, each group had 6 test blocks. The first group was immersed in 25℃ water bath for 2h. The other group was treated with vacuum water for 15min to extract bubbles, then soaked in room temperature water for 30min. Then frozen in a refrigerator at -18℃ for 16h, then kept in a 60℃ water bath for 24h, and finally immersed in water at 25℃ for 2h. The splitting tensile strength of each specimen was tested, and the following formula was used to measure the TSR:

where, TSR represents the ratio of residual splitting strength of the specimen after freezing and thawing cycles, %; is the average of splitting tensile strength of effective specimens without freeze-thaw cycles, MPa; is the average of splitting tensile strength of effective specimens subjected to freeze-thaw cycles, MPa.

2.2.2.3. Cantabro-loss Measurement

The two sides compaction times of the Cantabro test specimens were 50 times each. Marshall specimens of different fillers types were prepared with 6 in each group. The specimens were put into a 60℃ water tank for 48h, and then placed at room temperature for 24h.The quality of each specimen was tested and the following formula was used to measure the Cantabro-loss:

where, ΔS represents the Cantabro-loss of asphalt mixture, %; m0 is the mass of the specimen before the test, g; m1 is the residual mass of the specimen after the test, g.

Results and discussions

3.1. Chemical compositions of fillers

XRF results of five fillers were presented in

Table 5. It could be concluded that CaO and SiO

2 were the main components of the five fillers studied. The CaO content of the five fillers was CCSP, CE, LP, TP and SSP respectively from high to low. The higher the CaO content, the more alkaline it is. The more the filler particles bond to the asphalt, the better the adhesion to the aggregate. From the higher ignition loss, it could be seen that the main mineral phase of LP was CaCO

3. Since the XRF test was performed at high temperature, CaCO

3 was decomposed at high temperature to generate CO

2 and CaO. However, CaCO

3 pairs improving the adhesion of asphalt to aggregate was ineffective.

The alkalinity of steel slag could be expressed by the alkalinity M, and the formula for calculating the alkalinity:

Steel slag could be divided into three categories according to its value of alkalinity: M value less than 1.8 was low alkalinity steel slag, M value between 1.8 and 2.5 was medium alkalinity steel slag, and M 2.5 was high alkalinity steel slag [

35]. The alkalinities of five fillers in this research were shown in Figure 8. According to the chemical composition analysis table in Table 8, the alkalinity of the steel slag selected in this paper was 1.96. It was a medium alkalinity steel slag. The higher the alkalinity of steel slag, the higher the CaO content it contained. They improved the compatibility between filler particles and weak acid asphalt binder.

3.2. Volume properties of asphalt mixture

3.2.1. The experiment results and analysis of AC-13 asphalt pavement

Different fillers were added to the asphalt mixture in different proportions instead of limestone powder. The number and composition of each asphalt mixture were shown in

Table 6. The volume performance results of each type of asphalt mixture were shown in

Table 7.

The number of test specimens for each group of asphalt mixture was 6. The optimal asphalt content of each group were 5.1%. It could be seen that the test results in

Table 7 meet the requirements for the volumetric properties of the specimens. Subsequent test results of the moisture stability would not be affected by the volume performance of the specimen.

3.2.2. The experiment results and analysis of SMA-13 asphalt pavement

Wood fiber of 0.3% by mass of asphalt mixture was added during the mixing of asphalt mixture. 6 test specimens were prepared with each group of asphalt mixtures. The optimal asphalt content of 100% substitute LP asphalt mixtures were 6.2%. The optimal asphalt content of other groups was 6.1%. The volume properties of various types of asphalt mixtures tested were shown in

Table 8.

According to the test results in

Table 8, the addition of filler did not have effect on the volume performance of asphalt mixture, which ensured the smooth conduct of subsequent experiments.

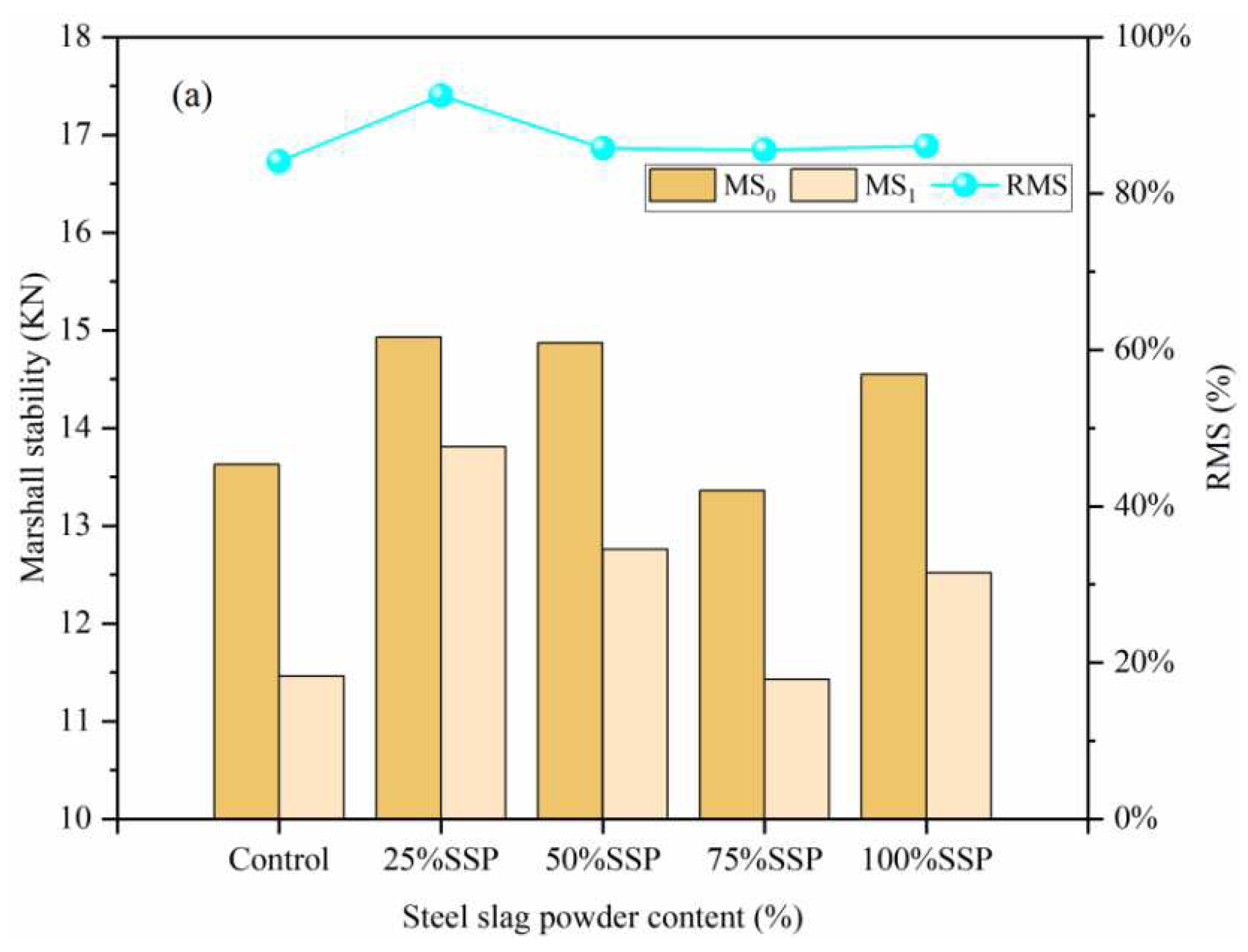

3.3. Moisture damage resistance

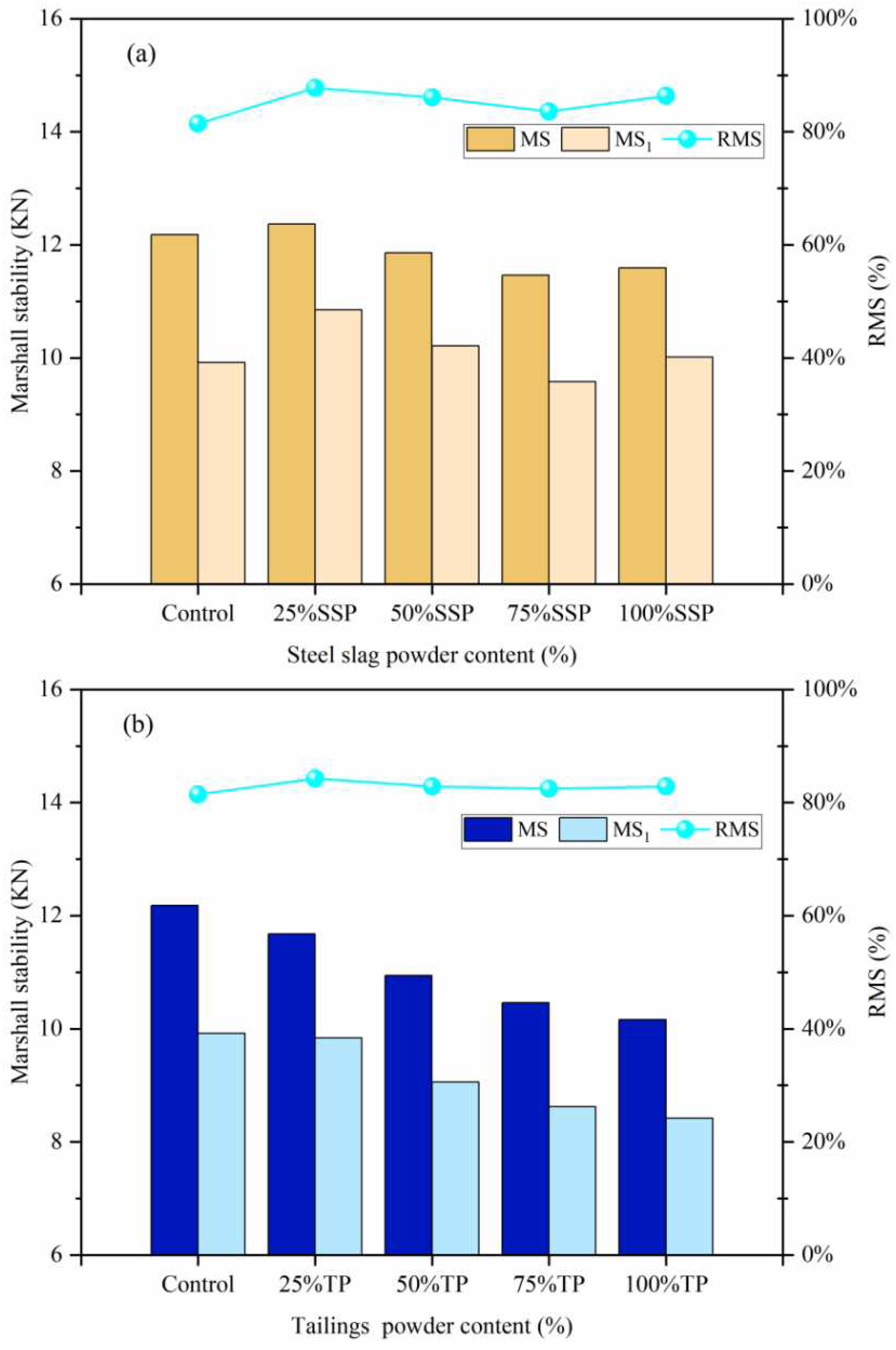

The Marshall stability (MS

0, MS

1) and residual Marshall stability (RMS) of AC-13 asphalt mixture with different replacement amounts of solid waste fillers were shown in

Figure 2. Only 25% of the solid waste filler was substituted, and the Marshall stability and RSM of the asphalt mixture were increased. A small amount of filler improved the adhesion between the asphalt and the aggregate. It had an effect similar to that of an anti-stripping agent. However, as the amount of solid waste filler began to increase, RSM and Marshall stability began to decrease. The reason was that excessive incorporation of solid waste filler increases the void ratio of the mix and the asphalt film on the aggregate surface was more easily removed, allowing water to more easily enter the internal structure of the asphalt mixture. When the substitution rate of solid waste fillers reached 100%, the moisture stability of asphalt mixture improved and RSM and Marshall stability started to increase again due to the reduction of voids on the surface of asphalt mixture and weakening of moisture damage to the structure of asphalt mixture. As could be seen from the figures, the RSM of the specimens increased by 1.97%, 2.26% and 1.2% when the replacement of the solid waste filler reached 100% and also increased when compared to pure limestone powder.

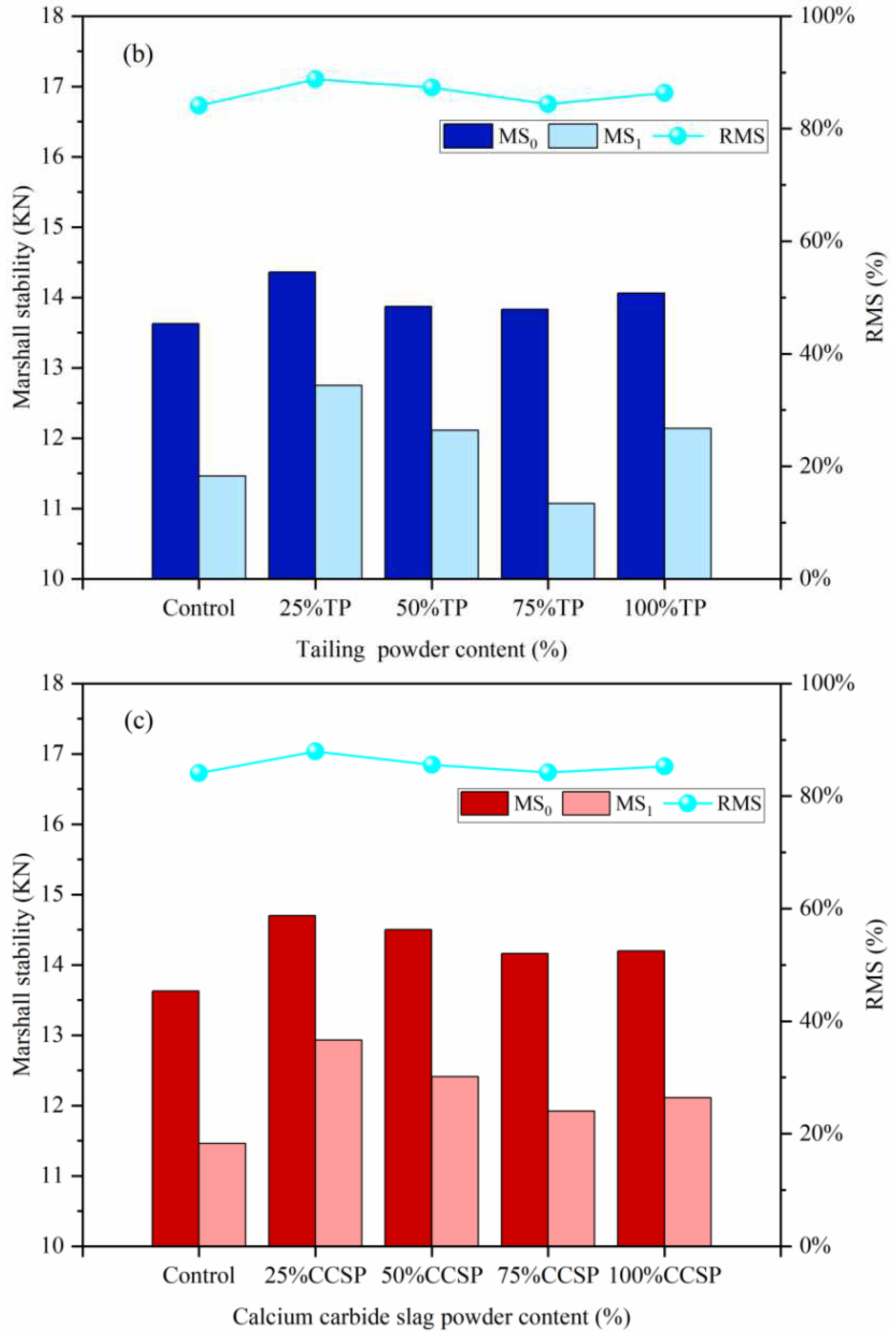

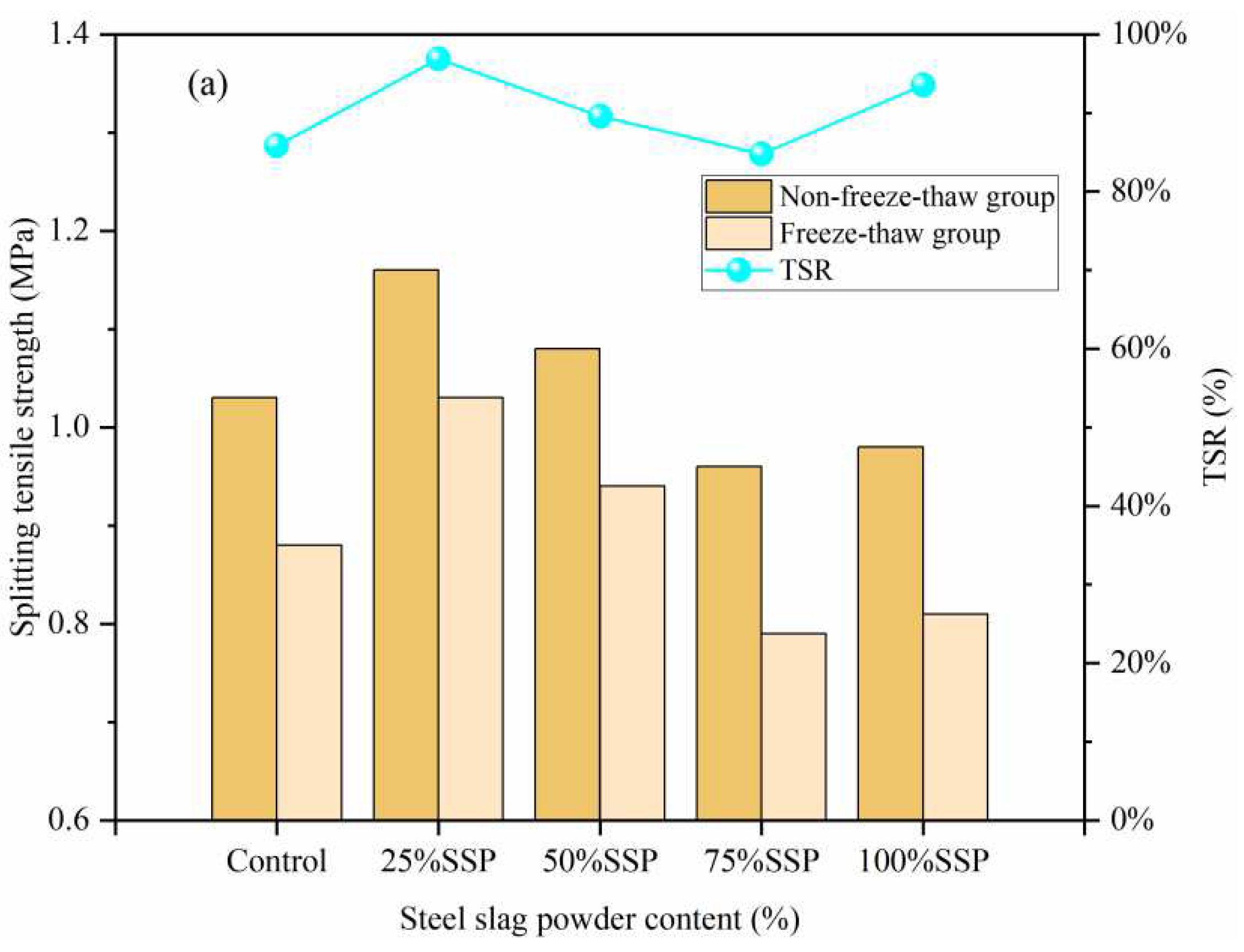

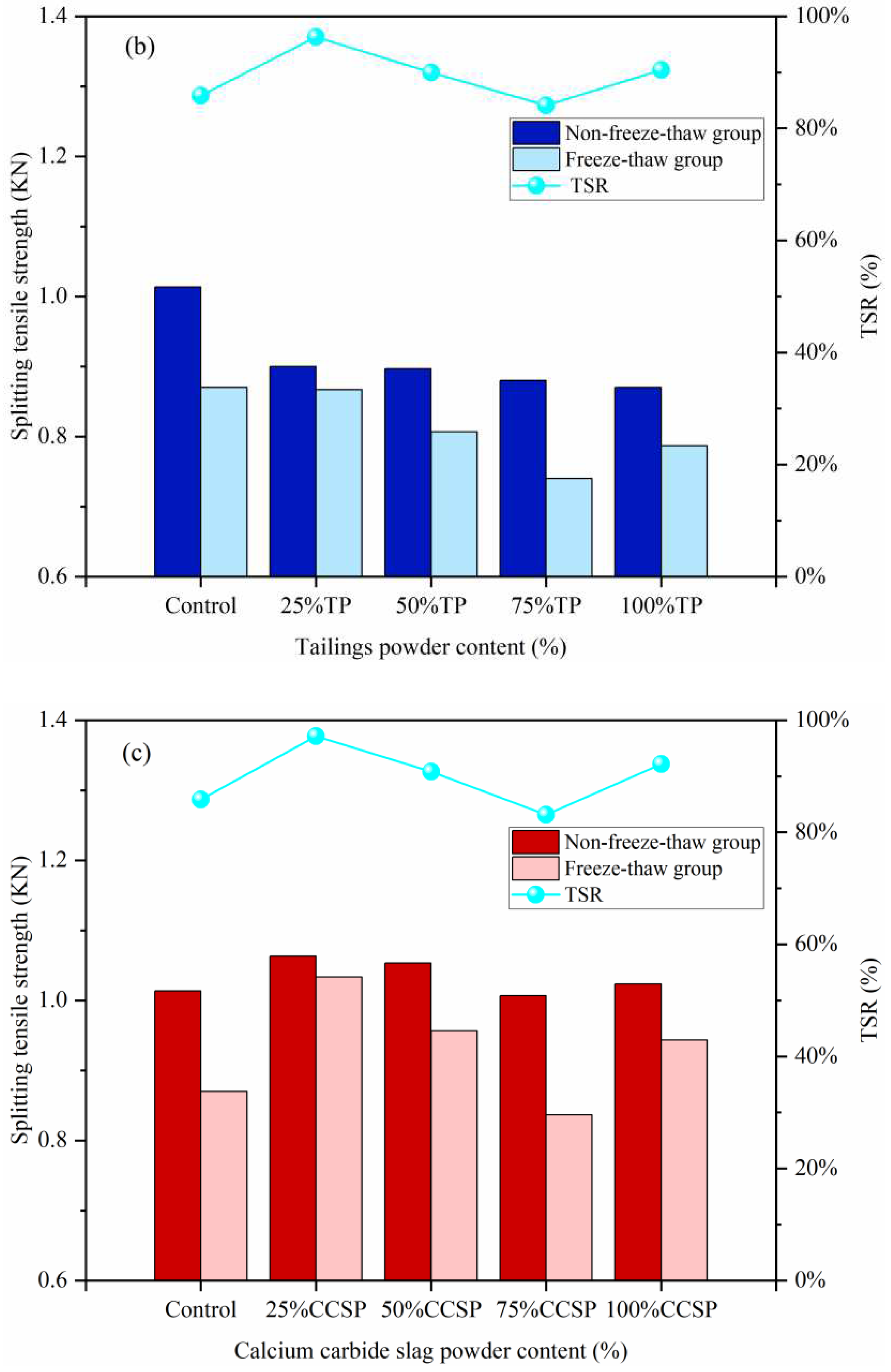

The splitting tensile strength (non-freeze-thaw and freeze-thaw groups) and residual splitting strength ratio (TSR) of AC-13 asphalt mixture with different solid waste filler substitution were shown in

Figure 3. The freeze-thaw splitting test results present a regularity that is generally in agreement with the Marshall stability test results. At 25% LP substitution, the SSP group had higher values of the splitting stretch and TSR than the TP and CCSP groups. It had been shown that SSP was more effective than TP and CCSP in resisting moisture damage to concrete under the same conditions. The TSR of 96.73%, 96.21% and 92.16% for the three groups was significantly higher than the 84.62% for the LP group. The splitting tensile strength and TSR gradually decrease as the admixture of solid waste fillings was gradually increased. The reason was the incorporation of excess solid waste fillers increased the surface void ratio of the mixture and moisture enters the interior of the asphalt mixture, resulting in a decrease in the moisture stability of the asphalt mixture. At 100% LP replacement, the void ratio was reduced, excess solid waste filler was filled into the voids of the mixture, structural damage to the asphalt mixture by water was reduced, and the moisture stability of the asphalt mixture was improved.

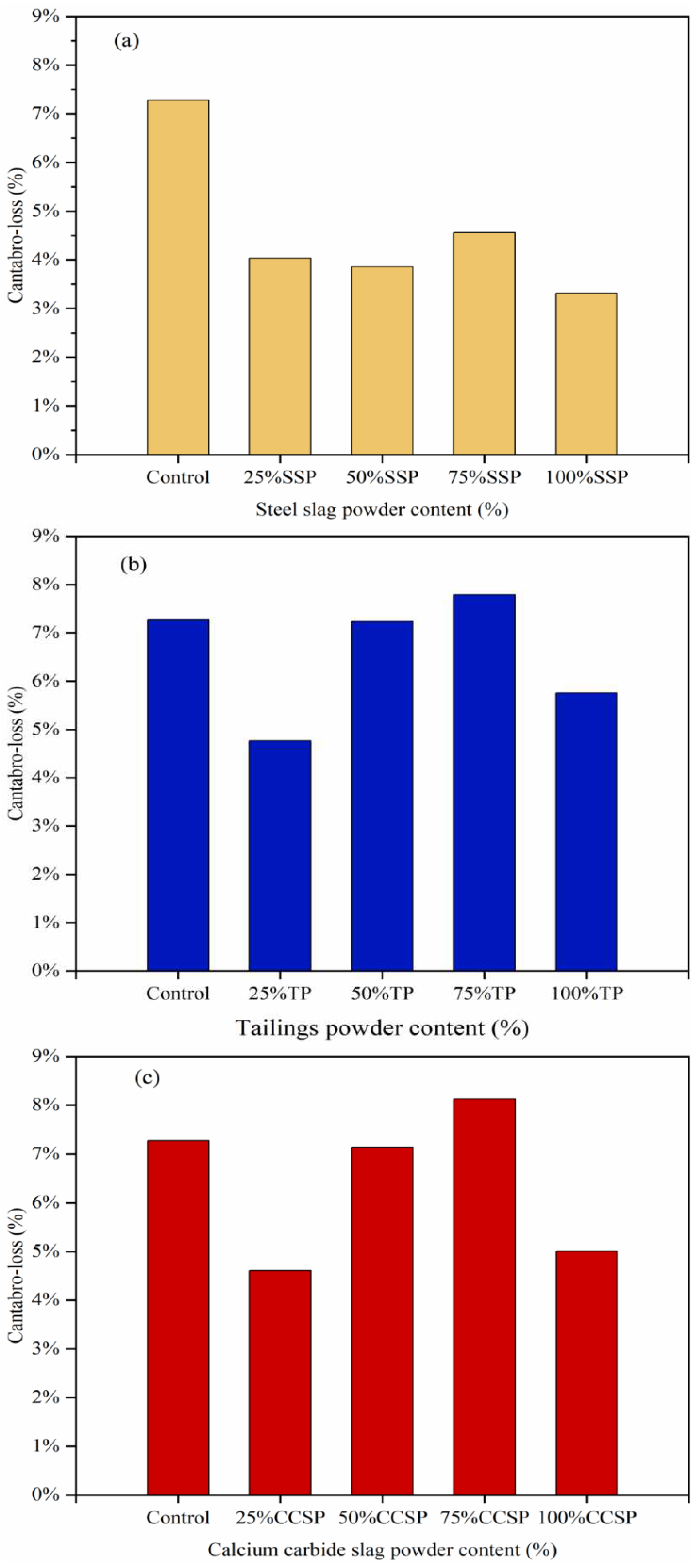

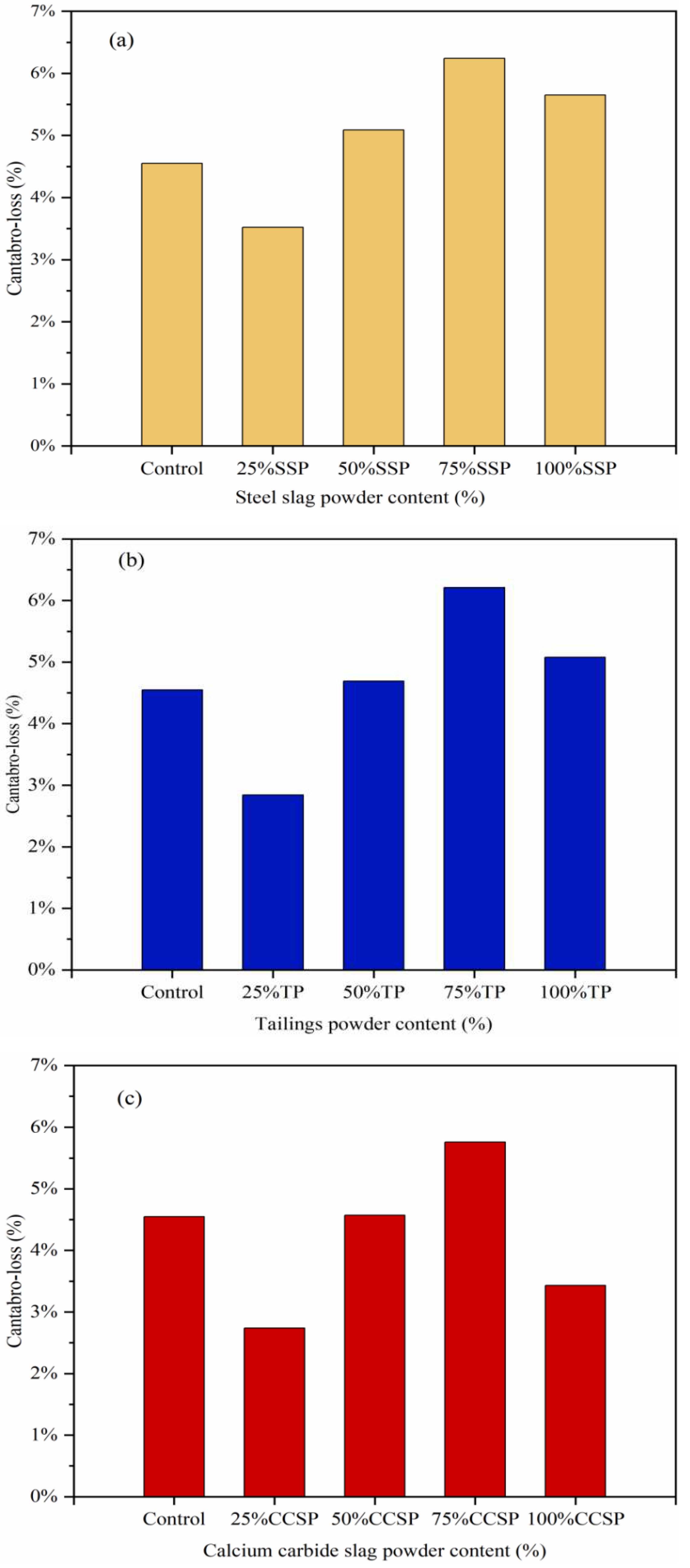

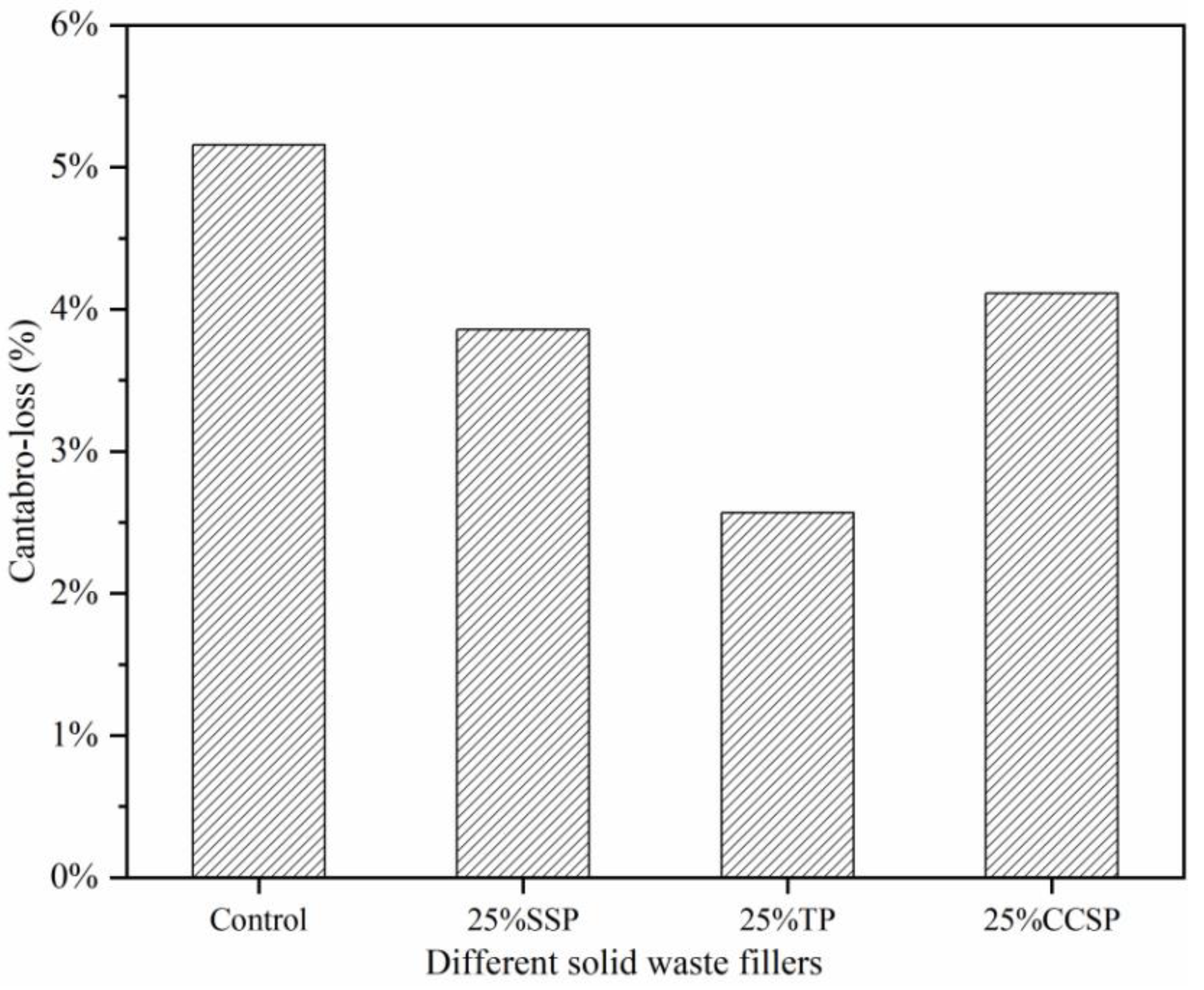

The Cantabro-loss for the AC-13 asphalt mixture with different solid waste fillers were showed in

Figure 4. The Cantabro-loss results were good for each group, where the Cantabro-loss of SSP was kept below 5%. In the TP and CCSP groups, the trends were consistent. At 25% LP substitution, the TP and CCSP groups had a 2.51% and 2.67% reduction in Cantabro-loss, respectively, compared to the LP group. This indicated that the addition of a small amount of solid waste filler could improve the adhesion between asphalt and aggregate. However, as the amount of solid waste filler was increased, the void ratio began to increase and water flowed more easily into the asphalt mixture, resulting in an increase in the amount of water lost from the asphalt mixture. In the case of a 100% solid waste filler ratio, the solid waste filler filled the internal voids, thereby improving the adverse effects of moisture damage and improving the stability of the asphalt mixture.

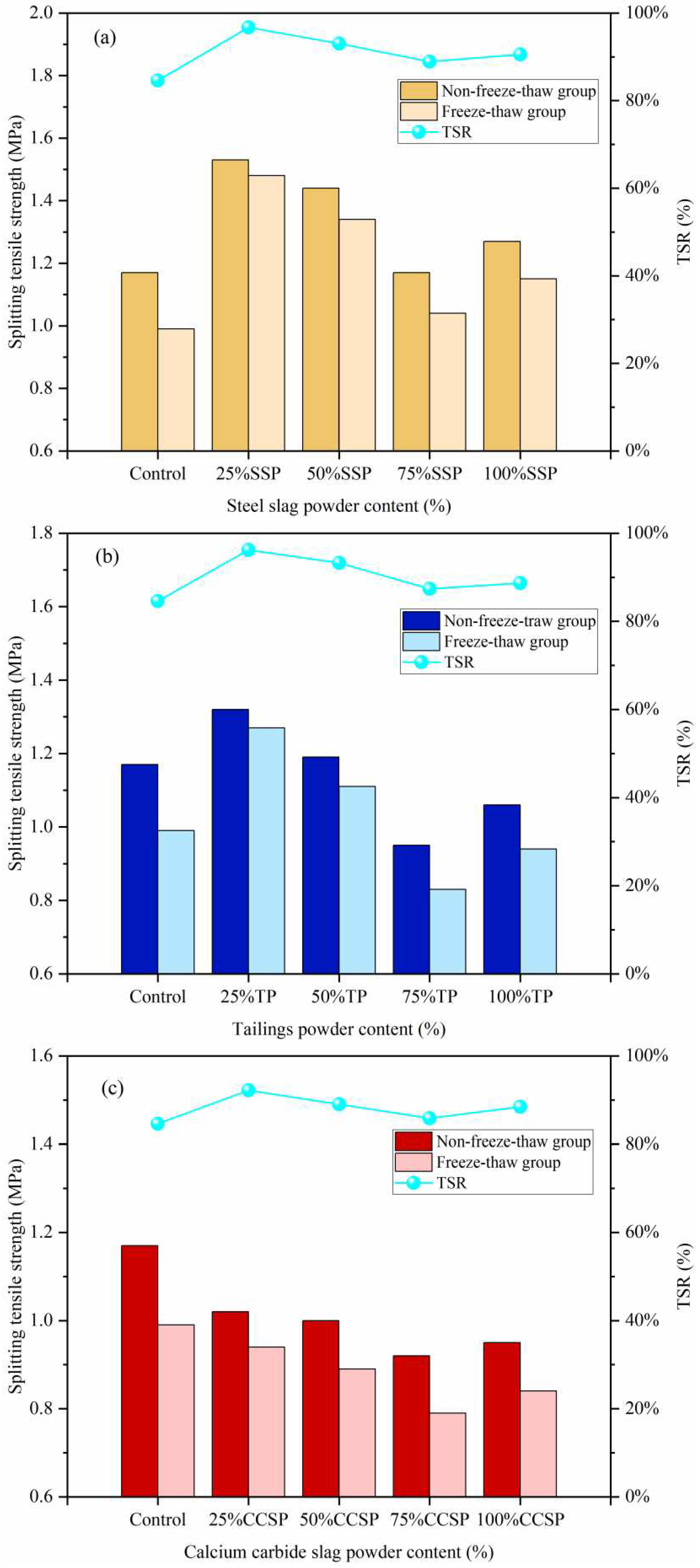

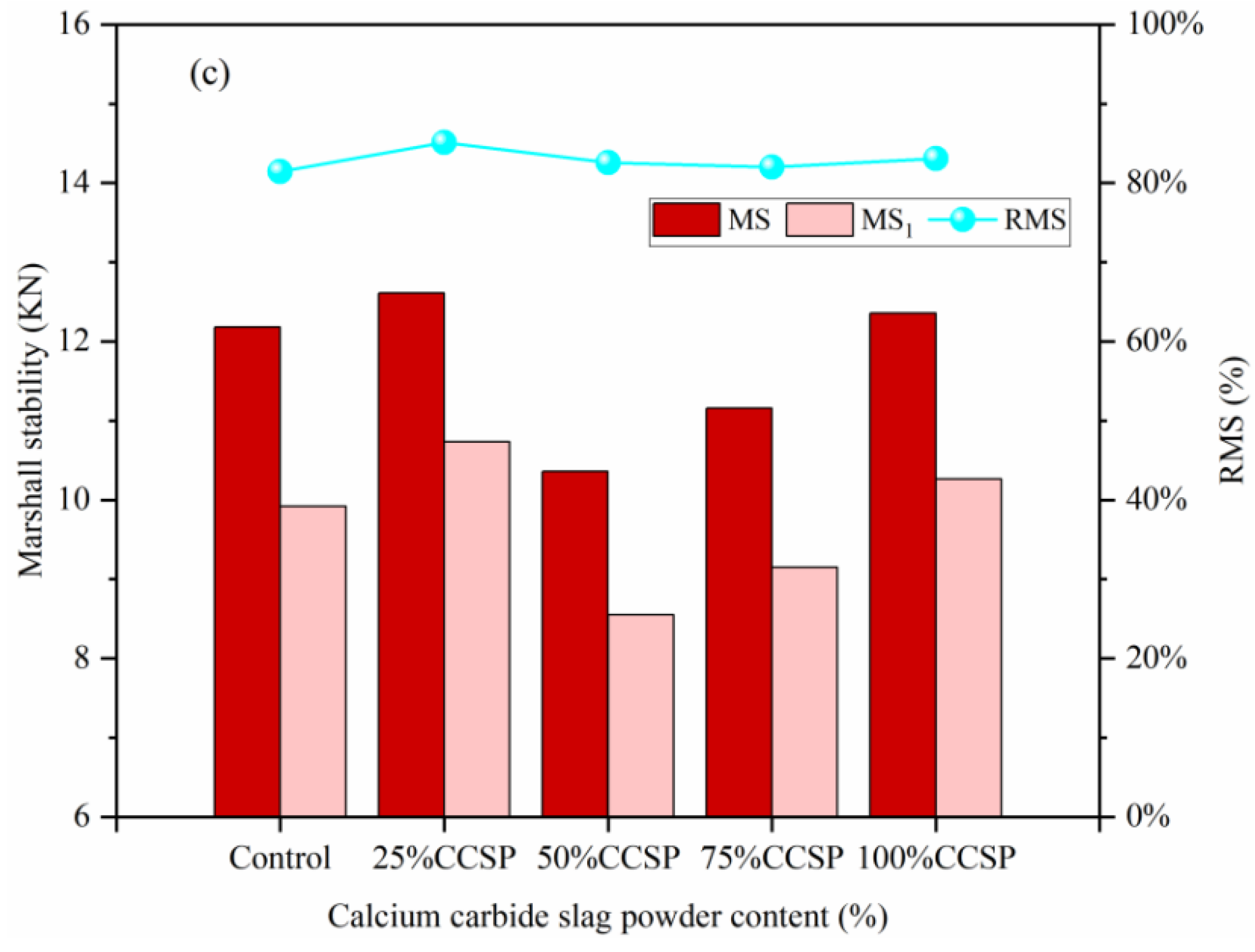

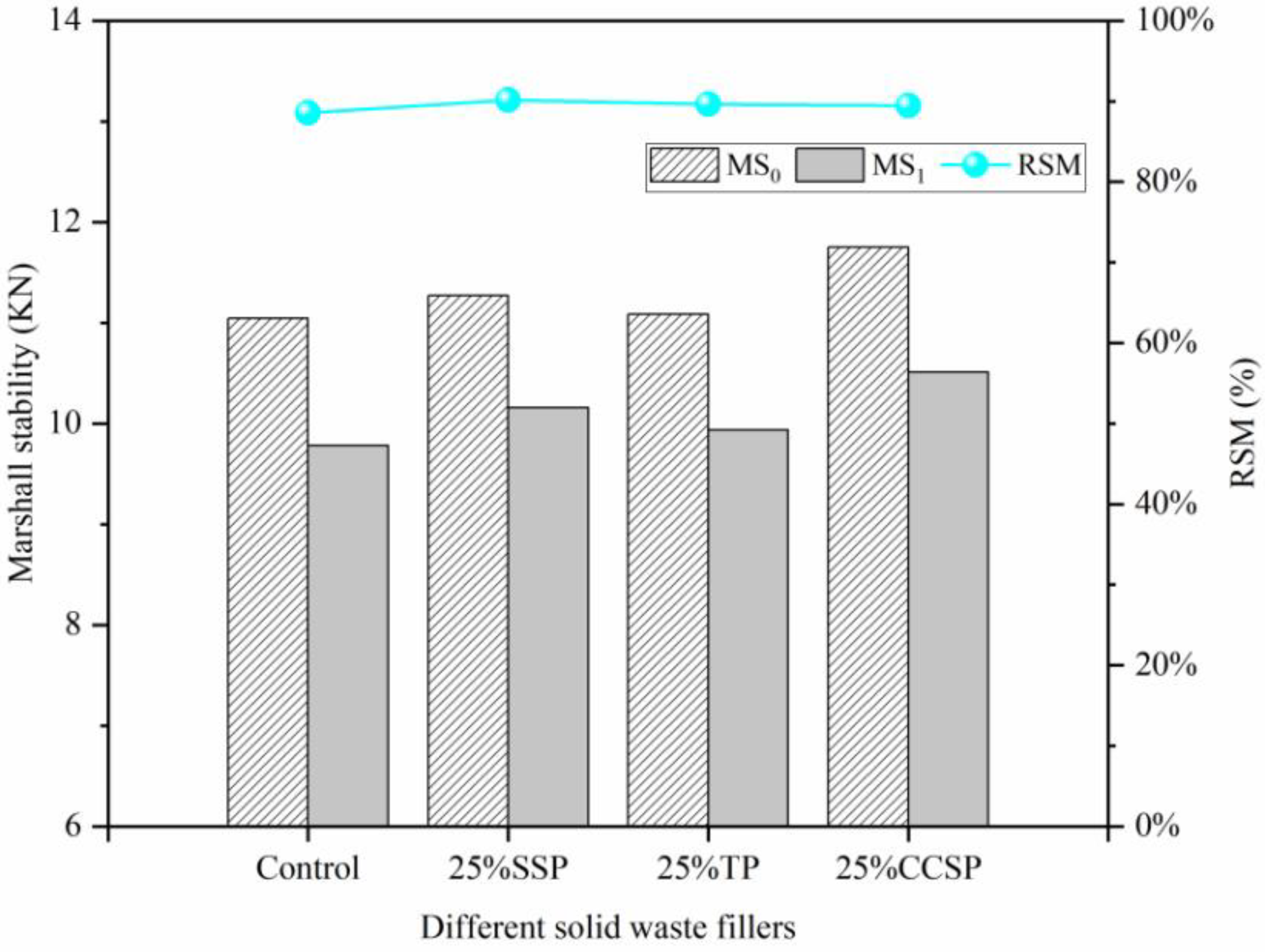

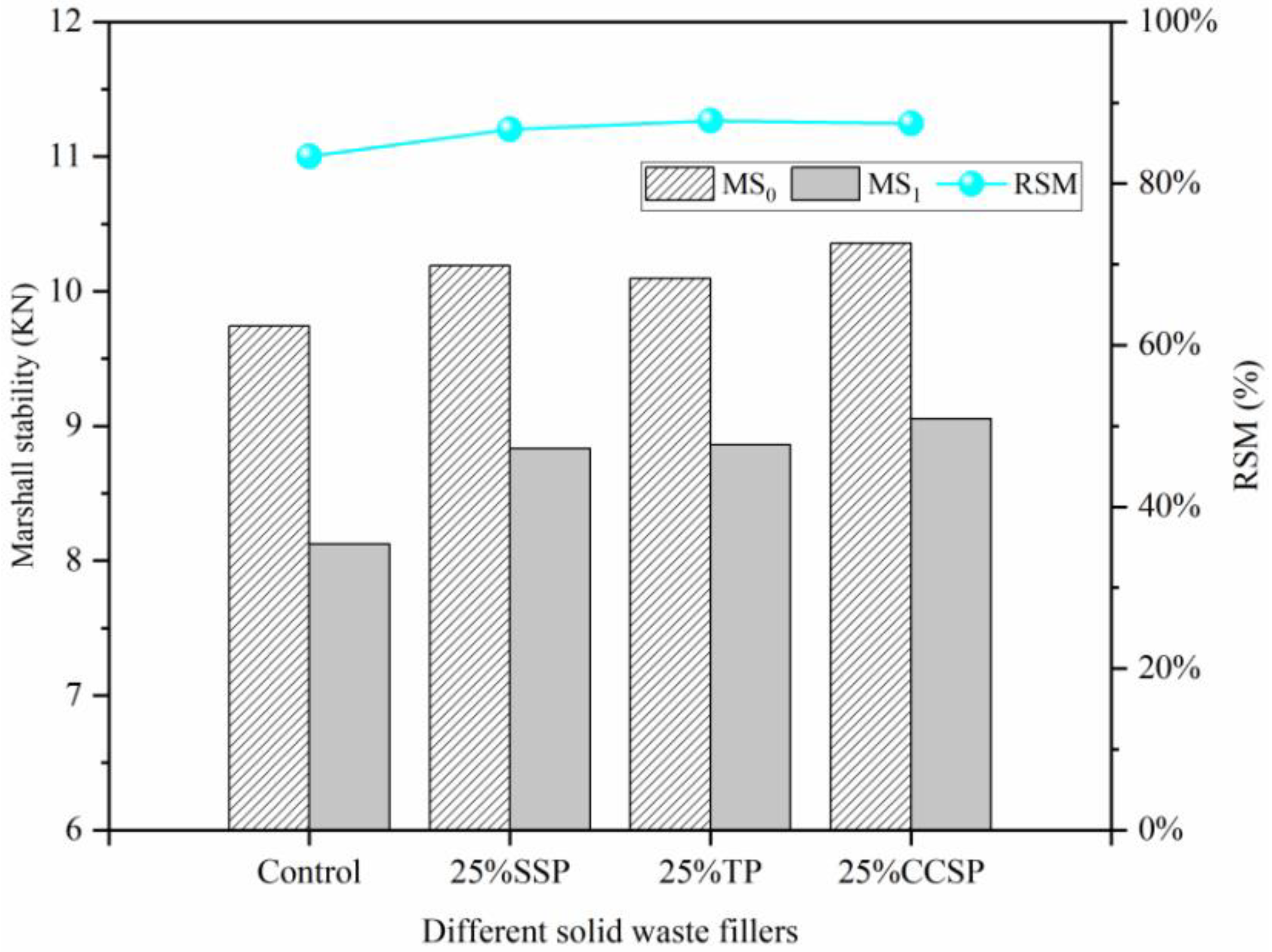

The Marshall stability (MS

0, MS

1) and RMS of SMA-13 asphalt mixture with different solid waste fillers substitution amounts were shown in

Figure 5. The SMA-13 asphalt mixtures showed similar trends as the AC-13 asphalt mixtures. The change in Marshall stability for the SMA mixture was small compared to the AC asphalt mixture. This was especially true for the SSP group, which was similar to the LP group. The reason was that the SMA asphalt mixture had a higher percentage of filler and the asphalt mixture had a smaller void ratio and was less affected by moisture damage. In addition, the excess solid waste filler enhanced the adhesion to the asphalt and the asphalt film spalling area was reduced, so that the TSR is stabilized at a higher level.

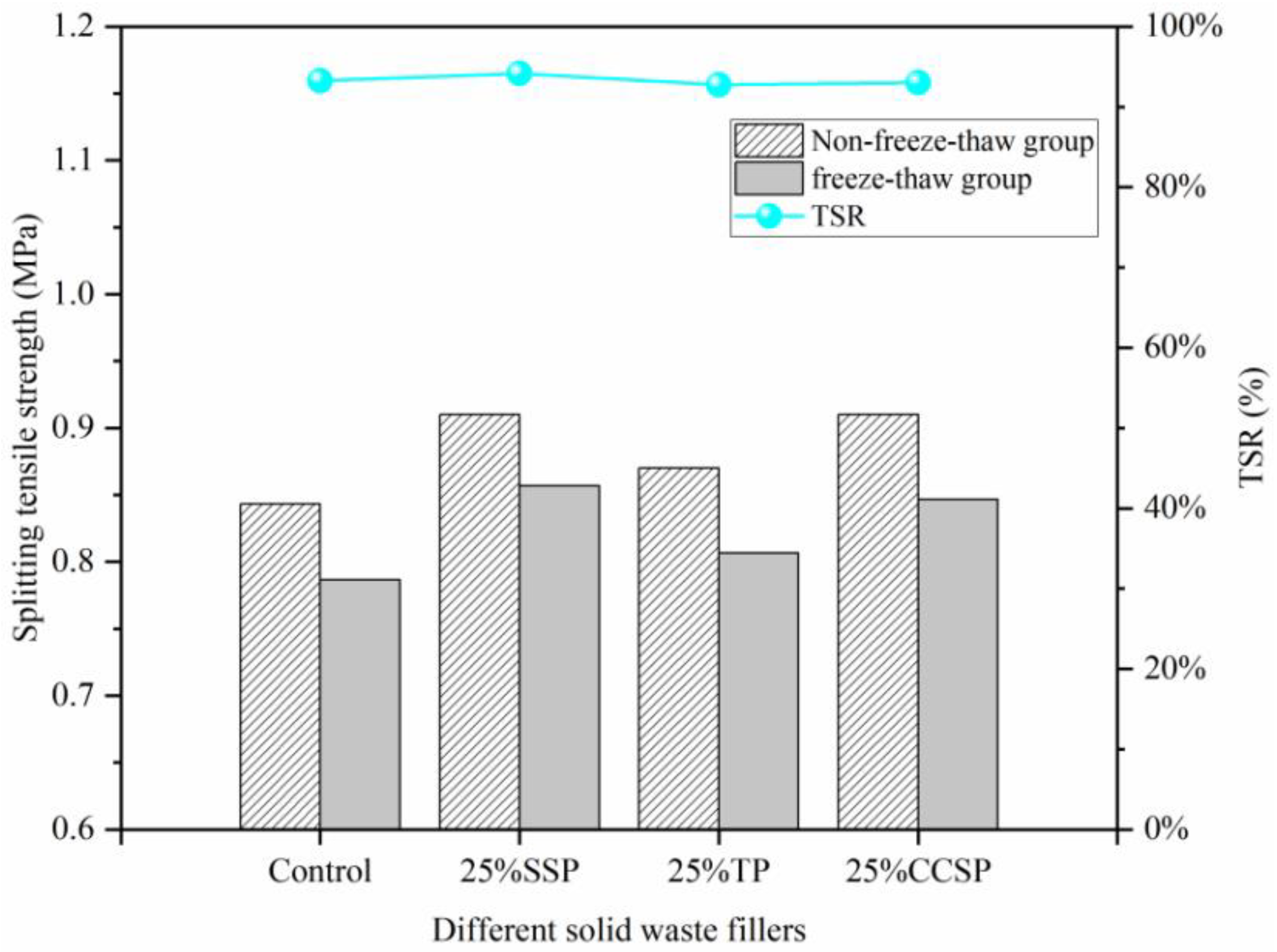

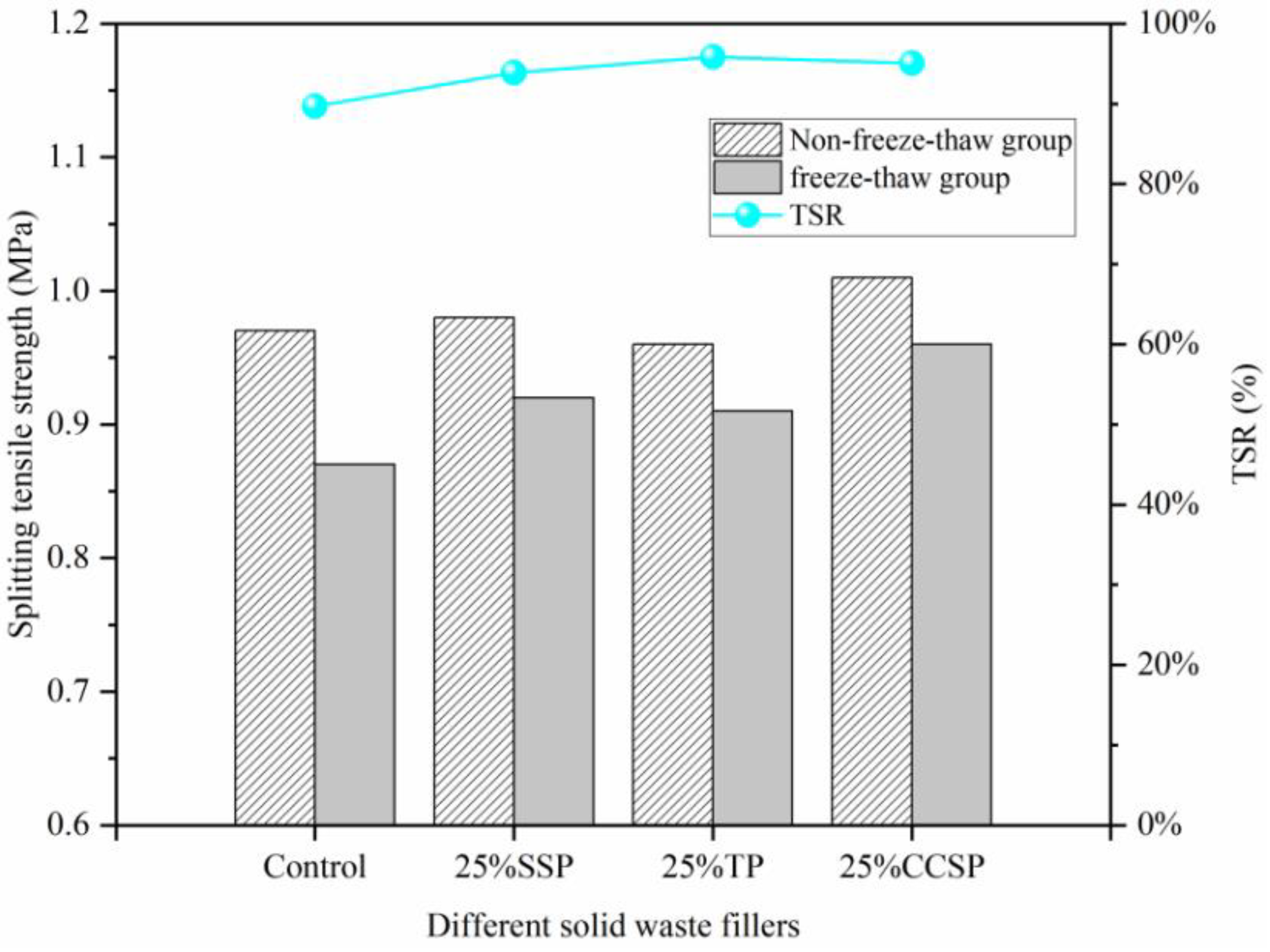

Figure 6 showed the splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual TSR of SMA-13 asphalt mixture with different solid waste fillers substitutes. Figure showed that the splitting tensile strength was not very large for each group. The TSR reaches its maximum at 25% LP substitution. Compared to the LP group, TSR increased by 11.04%, 10.44% and 11.32% respectively. It was suggested that the addition of a small amount of filler could enhance the adhesion between the asphalt and the aggregate and thus improve the moisture stability of the asphalt mixture. As the amount of solid waste filler increased, the splitting tensile strength decreases significantly in the freeze-thaw environment, while it remained essentially constant in the dry environment, leading to a decrease in TSR. At 100% LP substitution, the asphalt mixture was denser internally and more resistant to moisture damage as the duty cycle became smaller.

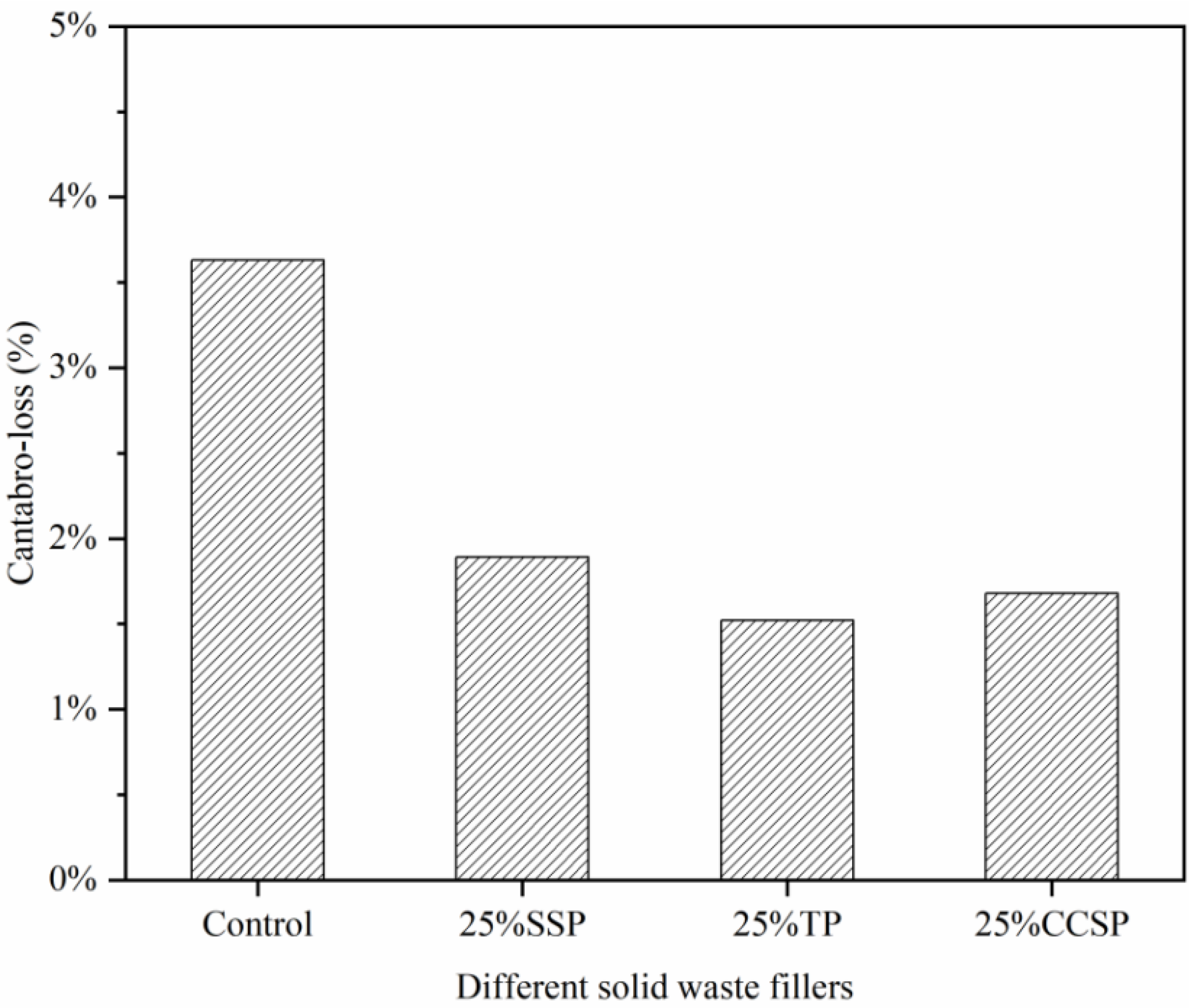

Figure 7 showed the Cantabro-loss for the SMA-13 asphalt mixture with different solid waste fillers. As could be seen from the results in the figure, the type of filler has little effect on the Cantabro-loss results. At 25% solid waste substitution, Cantabro-losses decreased by 1.03%, 1.71% and 1.81% compared to the LP group, respectively. As the amount of solid-waste filler admixture increased, the Cantabro-loss gradually increases and became lower than that of the LP group. The reason was that too much filler reacted with water in the presence of thermal moisture damage, which caused the asphalt mixture to expand in volume and caused a decrease in moisture stability.

3.4. Research on improvement of moisture damage resistance

In this section, organic and inorganic modifiers are mainly used to compare and study the improvement of the moisture resistance of asphalt mixtures. First, organic modifiers were used to mix asphalt and blend with asphalt to form thicker asphalt film. Even if the surface asphalt film was peeled, water erosion of the internal aggregate would not be affected. Second, inorganic modifiers were added to the asphalt mixture instead of limestone powder to enhance the bonding strength of the asphalt aggregate surface, improve the ability of the asphalt mixture to resist moisture damage and achieve the purpose of protecting the aggregate.

3.4.1. Study on modification method

3.4.1.1. Organic modification technology

This section selects the used of a non-amine anti-stripping agent as an organic modifier at a level of 0.3% by mass of the asphalt. SBS modified asphalt was heated to molten state, non-amine anti-stripping agent was added. Stirring while adding, raised the temperature to 180℃ and sheared for 20 minutes, and the shear rate was 3000 r/min.

3.4.1.2. Inorganic modification technology

In this study, PO 42.5 CE was used as an inorganic modifier with a substitution of 15% of the LP mass in the asphalt mixture. The effect of inorganic modifier on the improvement of moisture stability of asphalt mixture was investigated.

3.4.2. Test results

As shown in

Figure 8, it was observed that the addition of non-amine anti-stripping agents did not have almost effect on the Marshall stability of the asphalt mixture. Marshall stability was increased by 7.12% compared to the original asphalt mixture. This indicated that the addition of anti-stripping agent enhanced the adhesion between asphalt and aggregate. As a result, the addition of non-amine anti-stripping agents had little effect on the moisture stability of the solid waste fill asphalt mixture, which could be significantly improved by other solid waste fillers.

As shown in

Figure 9, the addition of non-amine anti-stripping agent did not improve the breaking tensile strength of asphalt mixture. However, the freeze-thaw test showed a 7.42% increase in TSR over the original asphalt mixture. This indicated that the freeze-thaw damage resistance of the asphalt mixture was improved at the TSR index, and that the use of the organic modification non-amine antiperspirant ensures better moisture stability of the asphalt mixture in the freeze-thaw test. The other types of fillers did not show any improvement, indicating that the solid waste fillers were very effective in improving the asphalt mixture and significantly promoting the asphalt mixture.

The Cantabro-loss of the asphalt mixture after organic modification with different solid waste fillers were illustrated in

Figure 10. The addition of non-amine anti-stripping agent did not improve the Cantabro-loss by immersion. This indicated that the improvement of the anti-stripping agent conflicts with the solid waste filler, and that both enhance the moisture stability of the asphalt mixture to the limit.

The Marshall stability (MS

0, MS

1) and residual Marshall stability (RMS) of asphalt mixture after inorganic modification with different solid waste fillers were illustrated in

Figure 11. The addition of cement did not improve the Marshall stability strength of the asphalt mixture, and the RSM was slightly higher than that of the original asphalt mixture. As an inorganic anti-stripping agent, the improvement in CE was less pronounced, increasing by only 1.93%. It indicated that cement and solid waste fillings act similarly, with limited improvement for asphalt mixtures.

From

Figure 12, it could observe that the splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual splitting strength ratio (TSR) of asphalt mixture after inorganic modification with different solid waste fillers. The addition of CE did not improve the splitting tensile strength of the asphalt mixture, but the TSR of the freeze-thaw test was higher than that of the original asphalt mixture. CE improved TSR by 3.83% for the asphalt mixture in the control group, while it had no effect on the other filler groups. The results showed that the freeze-thaw resistance of asphalt mixtures was improved under the TSR index, and the addition of CE could LP group asphalt mixtures with better moisture stability under freeze-thaw test.

Figure 13 given detailed descriptions of the Cantabro-loss of asphalt mixture after inorganic modification with different solid waste fillers. With the addition of CE, the Cantabro-losses of the asphalt mixtures decreased by 0.97%, 1.63%, 1.32% and 1.06%, respectively. It was shown that CE can improve the moisture stability resistance of asphalt mixtures. Therefore, the addition of CE could effectively resist water erosion and improve the moisture stability of asphalt mixtures.

4. Conclusions

From the research results of ceramic fiber modified asphalt binder that were discussed in this research, the following items can be concluded:

Three solid waste fillers with high alkalinity improved the compatibility between filler particles and weak acid asphalt binder, which facilitated the stabilizing bond between the asphalt mastic and the aggregate.

The volumetric property of AC and SMA asphalt mixtures were not affected because the limestone powder is replaced by solid waste fillers.

The moisture stability of asphalt mixtures was improved by different solid waste fillers. What’s more, 25% SSP performed better in improving the moisture stability.

The moisture stability of the original asphalt mixture was improved by the anti-stripping agent. However, it was not effective in improving the moisture stability of solid waste asphalt mixtures. SSP, TP, CCSP could be used as anti-stripping agents.

Author Contributions

Jinxuan Hu, Jie Wu and Meizhu Chen conceived and designed the experiments; Yuyi Chen, Yang Yu and Shiyu Song performed the experiments; Xiantao Qin and Yuyi Chen analyzed the data; Jinxuan Hu contributed reagents/materials/analysis tools; Yuyi Chen wrote the paper.

Acknowledgement

This work was financially supported by the Research and Innovation Initiatives of WHPU (Nos. 2021Y41), the Research Project of Wuhan University of Technology Chongqing Research Institute, YF2021-01. The authors gratefully acknowledge their financial supports.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhao, Z.; Wang, Z.; Wu, S.; et al. Road performance, VOCs emission and economic benefit evaluation of asphalt mixture by incorporating steel slag and SBS/CR composite modified asphalt[J]. Case Studies in Construction Materials, 18 (2023) e01929. [CrossRef]

- Yu, Y.; Tang, S.; Xu, G.; et al. Investigations on the long-term skid resistance of epoxy asphalt mixture based on accelerated loading test[J]. Construction and Building Materials, 365 (2023) 130150. [CrossRef]

- Guo, F.; Pei, J.; Zhang, J.; et al. Study on the skid resistance of asphalt pavement: A state-of-the-art review and future prospective[J]. Construction and Building Materials, 303 (2021) 124411. [CrossRef]

- Zhang, D.; Li, X.; Zhang, Y.; et al. Prediction Method of Asphalt Pavement Performance and Corrosion Based on Grey System Theory[J]. International Journal of Corrosion, 2019 (2019) 1-9. [CrossRef]

- Jiang, Q.; Chen, M.; Zhao, Y.; et al. Comprehensive assessment of the durability deterioration of asphalt pavement in salt environment: A literature review[J]. Case Studies in Construction Materials, 17 (2022) e01706. [CrossRef]

- Sharma, A.; Naga, G.R.R.; Kumar, P.; et al. Mix design development, production and policies of recycled hot mix asphalt: A review[J]. Journal of Traffic and Transportation Engineering (English Edition), 9(5) (2022) 765-794. [CrossRef]

- Guo, M.; Tan, Y. Interaction between asphalt and mineral fillers and its correlation to mastics' viscoelasticity[J]. International Journal of Pavement Engineering, 2019 (2019) 1-10. [CrossRef]

- Fischer, H.R.; Dillingh, E.C.; Hermse, C.G.M. On the interfacial interaction between bituminous binders and mineral surfaces as present in asphalt mixtures[J]. Applied Surface Science, 265 (2013) 495-499. [CrossRef]

- He, Y.; Zhang, J.; Gao, B.; et al. Experimental investigation of the interface interaction between asphalt binder and mineral filler from the aspects of materials properties[J]. Construction and Building Materials, 393 (2023) 132094. [CrossRef]

- Xing, B.; Du, Y.; Fang, C.; et al. Particle morphology of mineral filler and its effects on the asphalt binder-filler interfacial interaction[J]. Construction and Building Materials, 321 (2022) 126292. [CrossRef]

- Al-Hdabi, A. Laboratory investigation on the properties of asphalt concrete mixture with Rice Husk Ash as filler[J]. Construction & Building Materials, 126 (2016) 544-551. [CrossRef]

- Li, J.; Xiao, F.; Zhang, L.; et al. Life cycle assessment and life cycle cost analysis of recycled solid waste materials in highway pavement: A review[J]. Journal of Cleaner Production, 233 (2019) 1182-120. [CrossRef]

- Li, Y.; Hu, X.; Zhao, Y.; et al. Performance evaluation of asphalt mixture using brake pad waste as aggregate[J]. Case Studies in Construction Materials, 17 (2022) e01639. [CrossRef]

- López-Montero, T.; Mañosa, J.; Miró, R.; et al. Sustainable asphalt mixtures by partial replacement of fine aggregates with low-grade magnesium carbonate by-product[J]. Case Studies in Construction Materials, 18 (2023) e01705. [CrossRef]

- Zhao, X.; Sheng, Y.; Lv, H.; et al. Laboratory investigation on road performances of asphalt mixtures using steel slag and granite as aggregate[J]. Construction and Building Materials, 315 (2022) 125655. [CrossRef]

- Tian, Y.; Sun, L.; Li, H.; et al. Laboratory investigation on effects of solid waste filler on mechanical properties of porous asphalt mixture[J]. Construction and Building Materials, 279 (2021) 122436. [CrossRef]

- Tao, G.; Xiao, Y.; Yang, L.; et al. Characteristics of steel slag filler and its influence on rheological properties of asphalt mortar[J]. Construction and Building Materials, 201(MAR.20) (2019) 439-446. [CrossRef]

- Xu, Y.; Lv, Y.; Qian, C. Comprehensive multiphase visualization of steel slag and related research in cement: Detection technology and application[J]. Construction and Building Materials, 386 (2023) 131572. [CrossRef]

- Zhang, Q.; Luo, J.; Yang, Z.; et al. Creep and fatigue properties of asphalt mastic with steel slag powder filler[J]. Case Studies in Construction Materials, 18 (2023) e01743. [CrossRef]

- Liu, J.; Wang, Z.; Li, M.; et al. Microwave heating uniformity, road performance and internal void characteristics of steel slag asphalt mixtures[J]. Construction and Building Materials, 353 (2022) 129155. [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag[J]. Construction & Building Materials, 49 (2013) 611-617. [CrossRef]

- Chen, Z.; Xiao, Y.; Pang, L.; et al. Experimental assessment of flue gas desulfurization residues and basic oxygen furnace slag on fatigue and moisture resistance of HMA[J]. Fatigue & Fracture of Engineering Materials & Structures, 37(11) (2014a) 1242-1253. [CrossRef]

- Chen, Z.; Leng, Z.; Jiao, Y.; et al. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers[J]. Journal of Cleaner Production, 344 (2022) 131124. [CrossRef]

- Wang, C.; David, H.; Liu, Q.; et al. Current state of fine mineral tailings treatment: A critical review on theory and practice[J]. Minerals Engineering, 58 (2014) 113-131. [CrossRef]

- Jiang, P.; Chen, Y.; Wang, W.; et al. Flexural behavior evaluation and energy dissipation mechanisms of modified iron tailings powder incorporating cement and fibers subjected to freeze-thaw cycles[J]. Journal of cleaner production, (Jun.1) 351 (2022) 131527. [CrossRef]

- Cao, L.; Zhou, J.; Zhou, T.; et al. Utilization of iron tailings as aggregates in paving asphalt mixture: A sustainable and eco-friendly solution for mining waste[J]. Journal of Cleaner Production, 375 (2022) 134126. [CrossRef]

- Saedi, A.; Zanjani, A.J.; Khodadadi-Darban, A. A review on different methods of activating tailings to improve their cementitious property as cemented paste and reusability[J]. Journal of Environmental Management, 270 (2020) 110881. [CrossRef]

- Gong, X.; Zhang, T.; Zhang, J.; et al. Recycling and utilization of calcium carbide slag - current status and new opportunities[J]. Renewable and Sustainable Energy Reviews, 159 (2022) 112133. [CrossRef]

- Wang, H.; Xu, W.; Sharif, M.; et al. Resource utilization of solid waste carbide slag: a brief review of application technologies in various scenes[J]. Waste Disposal & Sustainable Energy, 4(1) (2022) 1-16. [CrossRef]

- Osuolale, O.M.; Arinkoola, A.O.; Olawuyi, O.A. Performance evaluation of bamboo leaf ash and steel slag powder as alternative filler in asphaltic mixes[J]. Journal of Engineering Research, 2023 100117. [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Utilization of solid waste materials as alternative fillers in asphalt mixes: A review[J]. Construction and Building Materials, 234[07-18] (2023) 117271. [CrossRef]

- Li, F.; Zhao, X.; Zhang, X. Utilizing original and activated coal gangue wastes as alternative mineral fillers in asphalt binder: Perspectives of rheological properties and asphalt-filler interaction ability[J]. Construction and Building Materials, 365 (2023) 130069. [CrossRef]

- Liu, J.; Wang, W.; Wang, Y.; et al. Towards the sustainable utilization of steel slag in asphalt pavements: A case study of moisture resistance and life cycle assessment[J]. Case Studies in Construction Materials, 18 (2023) e01722. [CrossRef]

- Gan, Y.; Li, C.; Ke, W.; et al. Study on pavement performance of steel slag asphalt mixture based on surface treatment[J]. Case Studies in Construction Materials, 16 (2022) e01131. [CrossRef]

- Wang, Q.; Yan, P.; Han, S. The influence of steel slag on the hydration of cement during the hydration process of complex binder[J]. Science China Technological Sciences, 54(2) (2011) 388-394. [CrossRef]

Figure 1.

The research flowchart of this study.

Figure 1.

The research flowchart of this study.

Figure 2.

Marshall stability (MS0, MS1) and RMS of AC-13 asphalt mixture with different amount of solid waste fillers: (a) SSP; (b) TP; (c) CCSP.

Figure 2.

Marshall stability (MS0, MS1) and RMS of AC-13 asphalt mixture with different amount of solid waste fillers: (a) SSP; (b) TP; (c) CCSP.

Figure 3.

Splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and TSR of AC-13 asphalt mixture with different replacement amounts of solid waste filler: (a) SSP; (b) TP; (c) CCSP.

Figure 3.

Splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and TSR of AC-13 asphalt mixture with different replacement amounts of solid waste filler: (a) SSP; (b) TP; (c) CCSP.

Figure 4.

Cantabro-loss of AC-13 asphalt mixture with different solid waste fillers: (a) SSP; (b) TP; (c) CCSP.

Figure 4.

Cantabro-loss of AC-13 asphalt mixture with different solid waste fillers: (a) SSP; (b) TP; (c) CCSP.

Figure 5.

Marshall stability (MS0, MS1) and RMS of SMA-13 asphalt mixture with different solid waste fillers substitutes: (a) SSP; (b) TP; (c) CCSP.

Figure 5.

Marshall stability (MS0, MS1) and RMS of SMA-13 asphalt mixture with different solid waste fillers substitutes: (a) SSP; (b) TP; (c) CCSP.

Figure 6.

Splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual splitting strength ratio (TSR) of SMA-13 asphalt mixture with different replacement amounts of solid waste filler: (a) SSP; (b) TP; (c) CCSP.

Figure 6.

Splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual splitting strength ratio (TSR) of SMA-13 asphalt mixture with different replacement amounts of solid waste filler: (a) SSP; (b) TP; (c) CCSP.

Figure 7.

Cantabro-loss of SMA-13 asphalt mixture with different solid fillers: (a) SSP; (b) TP; (c) CCSP.

Figure 7.

Cantabro-loss of SMA-13 asphalt mixture with different solid fillers: (a) SSP; (b) TP; (c) CCSP.

Figure 8.

Marshall Stability (MS0,MS1) and residual Marshall stability (RMS) of asphalt mixture after organic modification with different fillers.

Figure 8.

Marshall Stability (MS0,MS1) and residual Marshall stability (RMS) of asphalt mixture after organic modification with different fillers.

Figure 9.

Ratio of splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual splitting strength (TSR) of asphalt mixture after organic modification with different solid fillers.

Figure 9.

Ratio of splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual splitting strength (TSR) of asphalt mixture after organic modification with different solid fillers.

Figure 10.

Cantabro-loss of asphalt mixture after organic modification of different solid waste fillers.

Figure 10.

Cantabro-loss of asphalt mixture after organic modification of different solid waste fillers.

Figure 11.

Marshall Stability (MS0,MS1) and residual Marshall stability (RMS) of asphalt mixture after inorganic modification with different solid waste fillers.

Figure 11.

Marshall Stability (MS0,MS1) and residual Marshall stability (RMS) of asphalt mixture after inorganic modification with different solid waste fillers.

Figure 12.

Ratio of splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual splitting strength (TSR) of asphalt mixture after inorganic modification with different fillers.

Figure 12.

Ratio of splitting tensile strength (non-freeze-thaw group and freeze-thaw group) and residual splitting strength (TSR) of asphalt mixture after inorganic modification with different fillers.

Figure 13.

Cantabro-loss of asphalt mixture after inorganic modification with different solid waste fillers.

Figure 13.

Cantabro-loss of asphalt mixture after inorganic modification with different solid waste fillers.

Table 1.

The basic properties of SBS modified asphalt.

Table 1.

The basic properties of SBS modified asphalt.

| Properties |

Test result |

Indicator |

| Penetration (25 ℃, 0.1mm) |

53.3 |

40-60 |

| Softening point (℃) |

75.3 |

≥60 |

| Ductility (5 cm/min, 5 ℃) |

28.4 |

≥20 |

Table 2.

The basic performance of different fillers.

Table 2.

The basic performance of different fillers.

| Properties |

LP |

SSP |

TP |

CCSP |

CE |

Indicator |

| Apparent specific gravity (t/m3) |

2.71 |

3.68 |

2.90 |

2.31 |

3.11 |

≥2.5 |

| Hydrophilic coefficient |

0.5 |

0.71 |

0.64 |

0.68 |

0.76 |

<1.00 |

| Moisture content (%) |

0.98 |

0.4 |

0.2 |

0.3 |

0.49 |

<1.00 |

Table 3.

The basic properties of lignin fibers.

Table 3.

The basic properties of lignin fibers.

| Properties |

Indicator |

Test result |

| Fiber length (mm) |

≤6 |

4 |

| Ash content (%) |

18±5 |

20 |

| PH value |

7.5±1.0 |

7.4 |

| Oil absorption |

Five times the fiber length |

6 |

| Moisture content |

≤5 |

13.6 |

Table 4.

The basic properties of non-amine anti-stripping agents.

Table 4.

The basic properties of non-amine anti-stripping agents.

| Inspection item |

Standard index |

Measured value |

| Content of active substance |

Not less than 99% |

99.6 |

| Density |

Not less than 0.9 |

0.95 |

| State |

Dark brown liquid |

Dark brown liquid |

| Freezing point |

less than 0℃ |

check out |

Table 5.

The Chemical composition of different fillers.

Table 5.

The Chemical composition of different fillers.

| Compound |

Filler |

CaO |

MgO |

Al2O3

|

SiO2

|

Fe2O3

|

P2O5

|

Others oxides |

Ignition loss |

| content (%) |

LP |

53.771 |

0.884 |

0.283 |

2.791 |

0.401 |

0.017 |

0.013 |

41.84 |

| SSP |

33.26 |

5.68 |

2.9 |

14.52 |

28.53 |

2.41 |

12.44 |

0.26 |

| TP |

36.82 |

11.1 |

19.66 |

26.75 |

0.32 |

- |

4.68 |

0.67 |

| CCSP |

87.363 |

0.109 |

1.049 |

3.109 |

0.264 |

- |

2.64 |

5.466 |

| CE |

57.68 |

2.58 |

6.67 |

20.49 |

3.36 |

- |

5.45 |

3.77 |

Table 6.

Serial number and composition of each group of asphalt concrete specimen.

Table 6.

Serial number and composition of each group of asphalt concrete specimen.

| Number |

Constitute |

| Control |

100% LP |

| 25%SSP |

25% SSP +75% LP |

| 50%SSP |

50% SSP +50% LP |

| 75%SSP |

75% SSP +25% LP |

| 100%SSP |

100% SSP |

| 25%TP |

25% TP +75% LP |

| 50%TP |

50% TP +50% LP |

| 75%TP |

75% TP +25% LP |

| 100%TP |

100% TP |

| 25%CCSP |

25% CCSP+75% LP |

| 50%CCSP |

50% CCSP +50% LP |

| 75%CCSP |

75% CCSP +25% LP |

| 100%CCSP |

100% CCSP |

Table 7.

Volumetric properties of asphalt mixtures with different filler types and substitutes.

Table 7.

Volumetric properties of asphalt mixtures with different filler types and substitutes.

| Mixture type |

Void ratio (%) |

Voids in the Mineral Aggregate (%) |

Effective asphalt saturation (%) |

| Control |

4.8 |

15.1 |

67.8 |

| 25%SSP |

4.7 |

15.8 |

67.6 |

| 50%SSP |

5.0 |

15.9 |

67.8 |

| 75%SSP |

4.9 |

16.0 |

67.9 |

| 100%SSP |

4.9 |

15.8 |

67.6 |

| 25%TP |

4.8 |

15.7 |

67.6 |

| 50%TP |

4.9 |

15.8 |

67.6 |

| 75%TP |

5.1 |

15.8 |

67.7 |

| 100%TP |

4.9 |

15.7 |

67.7 |

| 25%CCSP |

4.8 |

15.7 |

67.8 |

| 50%CCSP |

4.9 |

15.6 |

68.8 |

| 75%CCSP |

4.9 |

15.6 |

69.6 |

| 100%CCSP |

5.0 |

15.5 |

68.4 |

| Reference value |

3-6 |

13.5 |

65-75 |

Table 8.

Volumetric properties of asphalt mixtures with different filler types and substitutes.

Table 8.

Volumetric properties of asphalt mixtures with different filler types and substitutes.

| Mixture type |

Void ratio (%) |

Voids in the Mineral Aggregate (%) |

Effective asphalt saturation (%) |

| Control |

4.2 |

16.9 |

77.1 |

| 25%SSP |

3.8 |

17.1 |

76.1 |

| 50%SSP |

4.1 |

18.1 |

78.3 |

| 75%SSP |

4.3 |

18.6 |

79.4 |

| 100%SSP |

4.0 |

18.2 |

77.9 |

| 25%TP |

4.1 |

17.6 |

78.2 |

| 50%TP |

4.2 |

18.3 |

80 |

| 75%TP |

4.4 |

18.9 |

80.6 |

| 100%TP |

4.3 |

17.8 |

80.1 |

| 25%CCSP |

3.9 |

17.7 |

79.3 |

| 50%CCSP |

4.0 |

18.7 |

79.6 |

| 75%CCSP |

4.2 |

18.9 |

81 |

| 100%CCSP |

4.0 |

18.5 |

79.7 |

| Reference value |

3-4.5 |

16.5 |

75~85 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).