Submitted:

29 October 2023

Posted:

30 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

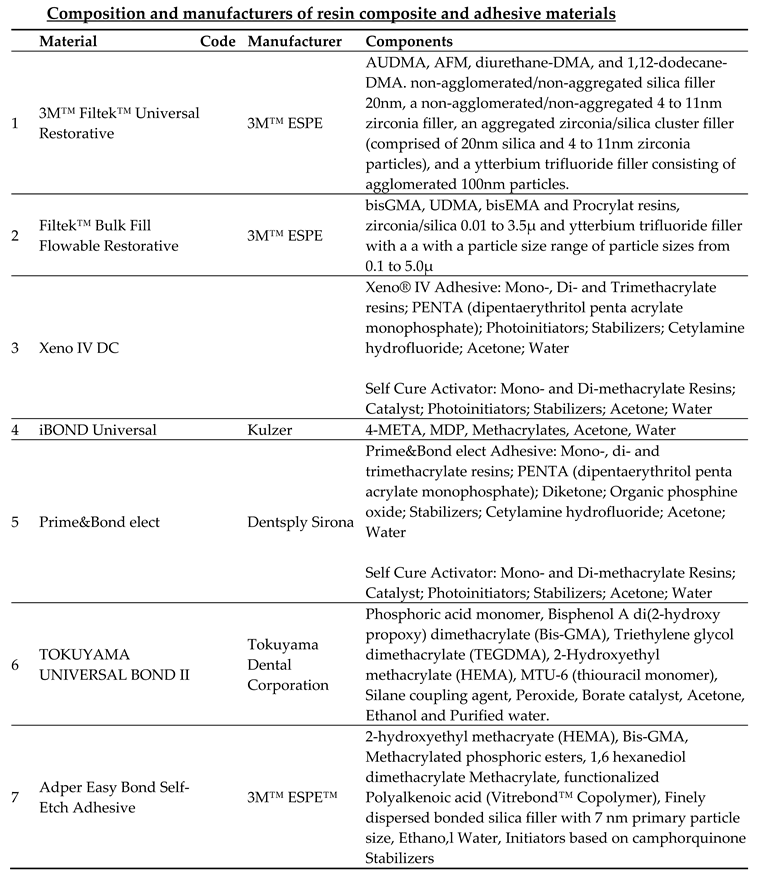

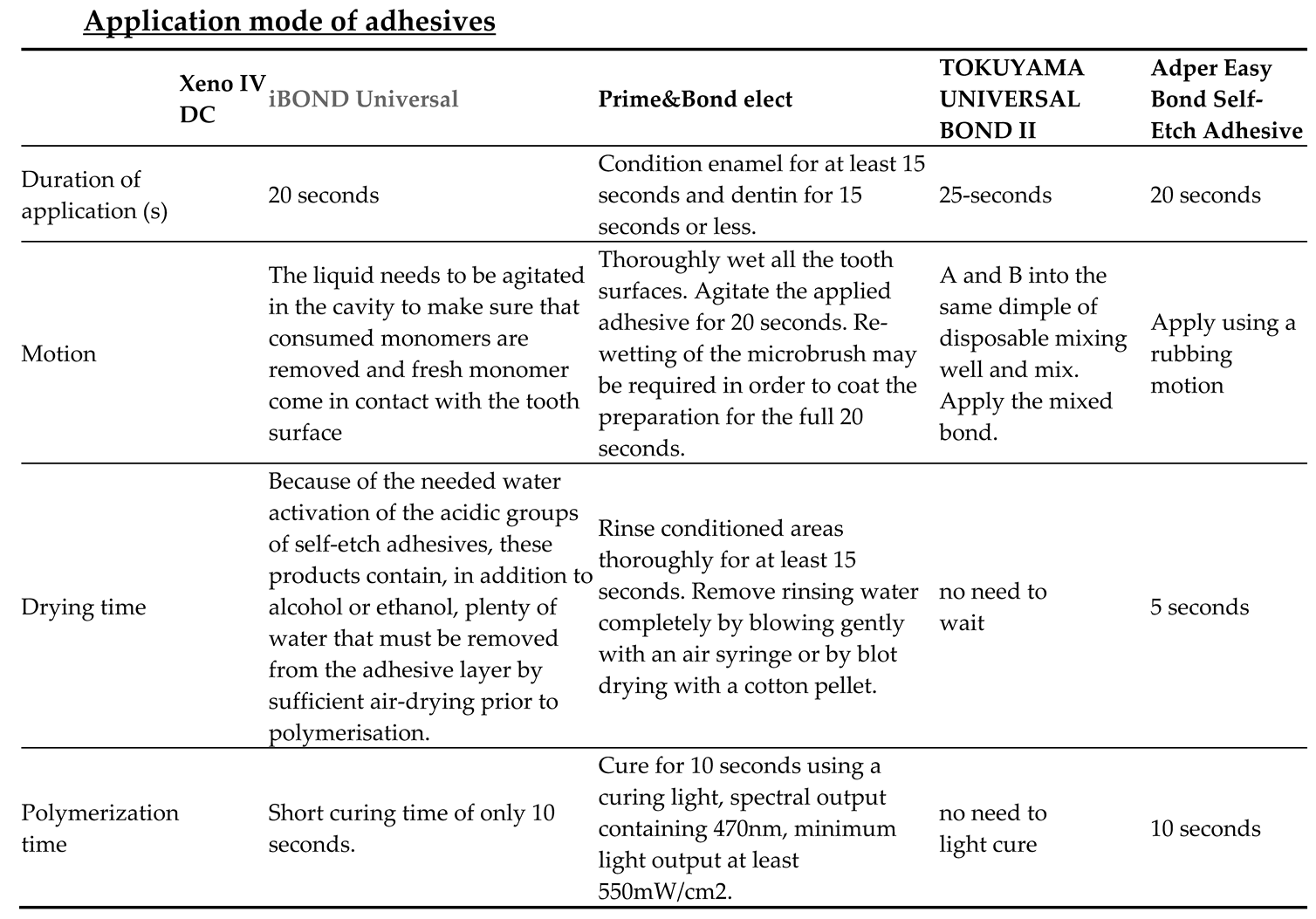

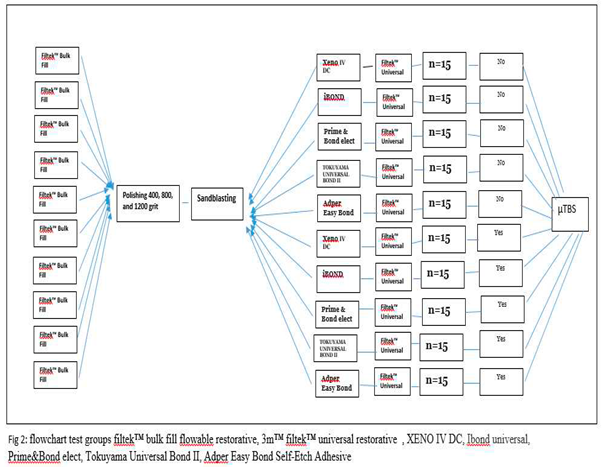

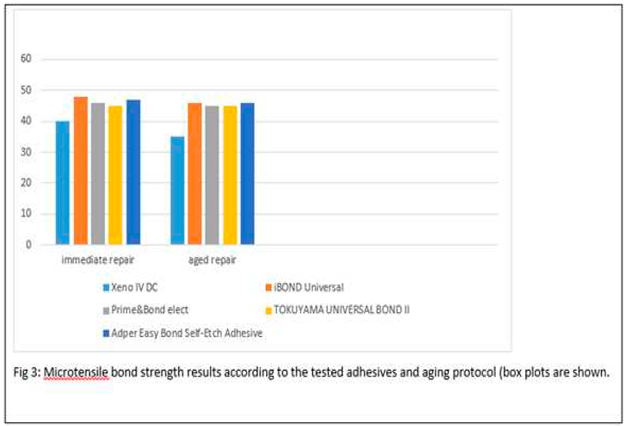

2. Materials and Methods

- Aging of the interface

Acknowledgements

Ethical clearance

References

- Hardan, L.; Bourgi, R.; Cuevas-Suárez, C.E.; Devoto, W.; Zarow, M.; Monteiro, P.; Jakubowicz, N.; El Zoghbi, A.; Skaba, D.; Mancino, D.; et al. Effect of Different Application Modalities on the Bonding Performance of Adhesive Systems to Dentin: A Systematic Review and Meta-Analysis. Cells 2023, 12, 190. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.H.; De Munck, J.; Van Landuyt, K.; Peumans, M.; Yoshihara, K.; Van Meerbeek, B.J. Do Universal Adhesives Benefit from an Extra Bonding Layer? Adhes Dent. 2019, 21, 117–132. [Google Scholar]

- Hurtado, A.; Fuentes, V.; Cura, M.; Tamayo, A.; Ceballos, L. Long-Term In Vitro Adhesive Properties of Two Universal Adhesives to Dentin. Materials 2023, 16, 3458. [Google Scholar] [CrossRef]

- Hardan, L.; Bourgi, R.; Cuevas-Suárez, C.E.; Devoto, W.; Zarow, M.; Monteiro, P.; Jakubowicz, N.; El Zoghbi, A.; Skaba, D.; Mancino, D.; et al. Effect of Different Application Modalities on the Bonding Performance of Adhesive Systems to Dentin: A Systematic Review and Meta-Analysis. Cells 2023, 12, 190. [Google Scholar] [CrossRef] [PubMed]

- Hardan, L.; Bourgi, R.; Kharouf, N.; Mancino, D.; Zarow, M.; Jakubowicz, N.; Haikel, Y.; Cuevas-Suárez, C.E. Bond Strength of Universal Adhesives to Dentin: A Systematic Review and Meta-Analysis. Polymers 2021, 13, 814. [Google Scholar] [CrossRef] [PubMed]

- Fehrenbach, J.; Isolan, C.P.; Münchow, E.A. Is the presence of 10-MDP associated to higher bonding performance for self-etching adhesive systems? A meta-analysis of in vitro studies. Dent Mater. 2021, 37, 1463–1485. [Google Scholar] [CrossRef] [PubMed]

- Cuevas-Suárez, C.E.; da Rosa, W.L.O.; Lund, R.G.; da Silva, A.F.; Piva, E. Bonding Performance of Universal Adhesives: An Updated Systematic Review and Meta-Analysis. J Adhes Dent. 2019, 21, 7–26. [Google Scholar] [PubMed]

- Fehrenbach, J.; Lacerda-Santos, R.; Machado, L.S.; Miotti, L.L.; de Carvalho, F.G.; Münchow, E.A. Which self-etch acidic composition may result in higher dental bonds at the long-term? A network meta-analysis review of in vitro studies. J. Dent. 2022, 126, 104283. [Google Scholar] [CrossRef]

- Wang, R.; Shi, Y.; Li, T.; Pan, Y.; Cui, Y.; Xia, W. Adhesive interfacial characteristics and the related bonding performance of four self-etching adhesives with different functional monomers applied to dentin. J. Dent. 2017, 62, 72–80. [Google Scholar] [CrossRef]

- Nakajima, K.F.; Nikaido, T.; Burrow, M.F.; Iwasaki, T.; Tanimoto, Y.; Hirayama, S.; Nishiyama, N. Effect of the demineralisation efficacy of MDP utilized on the bonding performance of MDP-based all-in-one adhesives. J. Dent. 2018, 77, 59–65. [Google Scholar] [CrossRef]

- Iwai, H.; Fujita, K.; Iwai, H.; Ikemi, T.; Goto, H.; Aida, M.; Nishiyama, N. Development of MDP-based one-step self-etch adhesive--effect of additional 4-META on bonding performance. Dent Mater J. 2013, 32, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Fehrenbach, J.; Lacerda-Santos, R.; Machado, L.S.; Miotti, L.L.; de Carvalho, F.G.; Münchow, E.A. Which self-etch acidic composition may result in higher dental bonds at the long-term? A network meta-analysis review of in vitro studies. J. Dent. 2022, 126, 104283. [Google Scholar] [CrossRef]

- Wendlinger, M.; Pomacondor-Hernandez, C.; Pintado-Palomino, K.; Cochinski, G.D.; Loguercio, A.D. Are universal adhesives in etch-and-rinse mode better than old 2-step etch-and-rinse adhesives? One-year evaluation of bonding properties to dentin. J. Dent. 2023, 132, 104481. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, M.A.; Sezinando, A.; Luque-Martinez, I.; Szesz, A.L.; Reis, A.; Loguercio, A.D.; Bombarda, N.H.; Perdigão, J. Influence of a hydrophobic resin coating on the bonding efficacy of three universal adhesives. J. Dent. 2014, 42, 595–602. [Google Scholar] [CrossRef]

- Moritake, N.; Takamizawa, T.; Ishii, R.; Tsujimoto, A.; Barkmeier, W.; Latta, M.; Miyazaki, M. Effect of active application adhesives. Oper Dent 2019, 44, 188–199. [Google Scholar] [CrossRef] [PubMed]

- Tsujimoto, A.; Fischer, N.G.; Barkmeier, W.W.; Latta, M.A. Bond Durability of Two-Step HEMA-Free Universal Adhesive. J Funct Biomater. 2022, 13, 134. [Google Scholar] [CrossRef] [PubMed]

- Tsujimoto, A.; Barkmeier, W.W.; Hosoya, Y.; Nojiri, K.; Nagura, Y.; Takamizawa, T.; Latta, M.A.; Miyazaki, M. Comparison of enamel bond fatigue durability of universal adhesives and two-step self-etch adhesives in self-etch mode. Am J Dent. 2017, 30, 279–284. [Google Scholar] [PubMed]

- Tsujimoto, A.; Barkmeier, W.W.; Takamizawa, T.; Watanabe, H.; Johnson, W.W.; Latta, M.A.; Miyazaki, M. Comparison between universal adhesives and two-step self-etch adhesives in terms of dentin bond fatigue durability in self-etch mode. Eur. J. Oral Sci. 2017, 125, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, F.; Yazkan, B.; Siso, S.H. Effects of different universal adhesives and surface treatments on repair bond strength between resin composites. J. Esthet. Restor. Dent. 2022, 34, 1068–1076. [Google Scholar] [CrossRef]

- Şişmanoğlu, S.; Gürcan, A.T.; Yıldırım-Bilmez, Z.; Gümüştaş, B. Efficacy of different surface treatments and universal adhesives on the microtensile bond strength of bulk-fill composite repair. J. Adhes. Sci. Technol. 2019, 34, 1–13. [Google Scholar] [CrossRef]

- Solan, C.P.; Moreira, A.G.; Ribeiro, J.S.; Nakanishi, L.; Cuevas-Suárez, C.E. Effect of different adhesive protocols on bond strength between composite resinsfor indirect use and repair materials. J Adhes Sci Technol 2020, 34, 67–75. [Google Scholar]

- Fujiwara, S.; Takamizawa, T.; Barkmeier, W.W.; Tsujimoto, A.; Imai, A.; Watanabe, H.; Erickson, R.L.; Latta, M.A.; Nakatsuka, T.; Miyazaki, M. Effect of double-layer application on bond quality of adhesive systems. J. Mech. Behav. Biomed. Mater. 2018, 77, 501–509. [Google Scholar] [CrossRef] [PubMed]

- Suda, S.; Tsujimoto, A.; Barkmeier, W.W.; Nojiri, K.; Nagura, Y.; Takamizawa, T.; Latta, M.A.; Miyazaki, M. Comparison of enamel bond fatigue durability between universal adhesives and two-step self-etch adhesives: Effect of phosphoric acid pre-etching. Dent. Mater. J. 2018, 37, 244–255. [Google Scholar] [CrossRef] [PubMed]

- Lührs, A.-K.; Guhr, S.; Schilke, R.; Borchers, L.; Geurtsen, W.; Günay, H.; Lührs, S.G.A.-K.; Firat, E.; Unluer, S.; Mcleod, M.E.; et al. Shear Bond Strength of Self-etch Adhesives to Enamel with Additional Phosphoric Acid Etching. Oper. Dent. 2008, 33, 155–162. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, M.; Takamizawa, T.; Hirokane, E.; Ishii, R.; Tsujimoto, A.; Barkmeier, W.W.; Latta, M.A.; Miyazaki, M. Bond durability of universal adhesives to intact enamel surface in different etching modes. Eur. J. Oral Sci. 2021, 129, e12768. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Feng, S.; Jin, Y.; Hou, Y.; Zhu, S. Comparison of bond strength of universal adhesives using different etching modes: A systematic review and meta-analysis. Dent. Mater. J. 2022, 41, 1–10. [Google Scholar] [CrossRef]

- Cruz, J.; Sousa, B.; Coito, C.; Lopes, M.; Vargas, M.; Cavalheiro, A. Microtensile bond strength to dentin and enamel of self-etch vs. etch-and-rinse modes of universal adhesives. Am. J. Dent. 2019, 32, 174–182. [Google Scholar] [PubMed]

- Cruz, J.; Silva, A.; Eira, R.; Sousa, B.; Lopes, M.; Cavalheiro, A. Dentin Permeability and Nanoleakage of Universal Adhesives in Etch-and-rinse vs Self-etch Modes. Oper. Dent. 2021, 46, 293–305. [Google Scholar] [CrossRef]

- Jacker-Guhr, S.; Sander, J.; Luehrs, A.-K. How "Universal" is Adhesion? Shear Bond Strength of Multi-mode Adhesives to Enamel and Dentin. J. Adhes. Dent. 2019, 21, 87–95. [Google Scholar] [CrossRef]

- Ageel, F.A.; Alqahtani, M.Q. Effects of the Contents of Various Solvents in One-step Self-etch Adhesives on Shear Bond Strengths to Enamel and Dentin. J Contemp Dent Pract. 2019, 20, 1260–1268. [Google Scholar] [CrossRef]

- Altinci, P.; Mutluay, M.; Tezvergil-Mutluay, A. Repair bond strength of nanohybrid composite resins with a universal adhesive. Acta Biomater. Odontol. Scand. 2017, 4, 10–19. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.y.; Tian, F.c.; Niu, L.n.; Ochala, K.; Chen, C.; Fu Bp Wang Xy Pashley, D.H.; Tay, F.R. Defying ageing: An expectation for dentine bonding with universal adhesives? J Dent 2016, 45, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Zander-Grande, C.; Loguercio, A.D.; Stanislawczuk, R.; Martins, G.C.; Gomes, O.M.M.; Reis, A. The effect of 6-month water storage on the bond strength of self-etch adhesives bonded to dentin. Am. J. Dent. 2011, 24, 239–244. [Google Scholar]

- Reis, A.; Moura, S.K.; Pellizzaro, A.; Dal-Bianco, K.; Andrade, A.M.; Grande, R.H.M.; Loguercio, A.D. Durability of Enamel Bonding Using One-step Self-etch Systems on Ground and Unground Enamel. Oper. Dent. 2009, 34, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.J.; Kim, J.; Song, J.S.; Chung, S.H.; Hyun, H.K. Shear Bond Strength of Different MDP-Containing Adhesive Systems on Enamel and Dentin from Primary Teeth. J Clin Pediatr Dent. 2021, 45, 186–192. [Google Scholar] [CrossRef] [PubMed]

- Swathy, R.S.; Naidu, J. A Comparative Evaluation of Shear Bond Strength of Embrace WetbondTM Pit and Fissure Sealant with or without the Use of a Universal Dental Adhesive System [ScotchbondTM Universal Adhesive] Using Different Bonding Protocols: A Multiparametric In Vitro Study. Int J Clin Pediatr Dent. 2023, 16, 48–53. [Google Scholar]

- Fang, K.; Chen, K.; Shi, M.; Wang, L. Effect of different adhesive systems on dental defects and sensitivity to teeth in composite resin restoration: A systematic review and meta-analysis. Clin. Oral Investig. 2023, 27, 2495–2511. [Google Scholar] [CrossRef] [PubMed]

- Brkanović, S.; Sever, E.K.; Vukelja, J.; Ivica, A.; Miletić, I.; Krmek, S.J. Comparison of Different Universal Adhesive Systems on Dentin Bond Strength. Materials 2023, 16, 1530. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Tian, F.C.; Niu, L.N.; Ochala, K.; Chen, C.; Fu, B.P.; Wang, X.Y.; Pashley, D.H.; Tay, F.R. Defying ageing: An expectation for dentine bonding with universal adhesives? J Dent. 2016, 45, 43–52. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).