3.1. Hydrodynamic processes. Hydrodynamic cavitation threshold

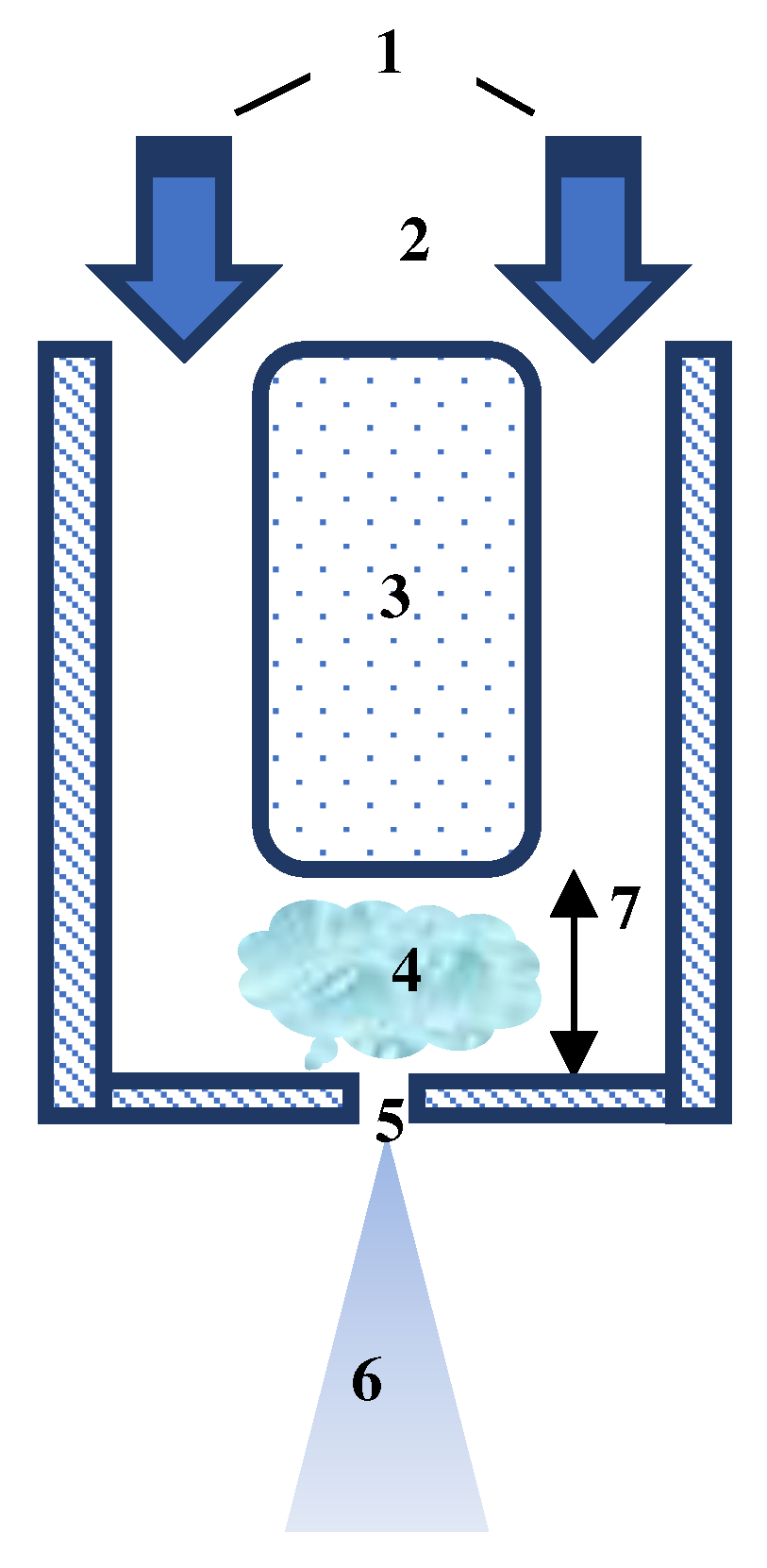

In the system under consideration, processes occur that involve the movement of fluid under the influence of hydrostatic pressure and ultrasonic vibrations. Under certain conditions, both hydrodynamic cavitation and ultrasonic cavitation processes can occur. Let's consider these conditions.

The hydrodynamic cavitation threshold occurs at a certain fluid supply pressure:

where p is the hydrostatic pressure of the liquid flow,

ps is the vapor pressure of the liquid,

pa is the atmospheric pressure, ε =

S2/

S1,

S1 is the cross-sectional area of the cavitation zone,

S2 is the area of the outlet.

This expression was obtained by jointly solving the continuity equation and the Berlulli equation in the inlet section into the cavitation zone:

where

V1 is the flow velocity in the cavitation zone,

Vx is the flow velocity after the outflow, ρ is the density of the liquid.

The hydrodynamic cavitation number is defined as

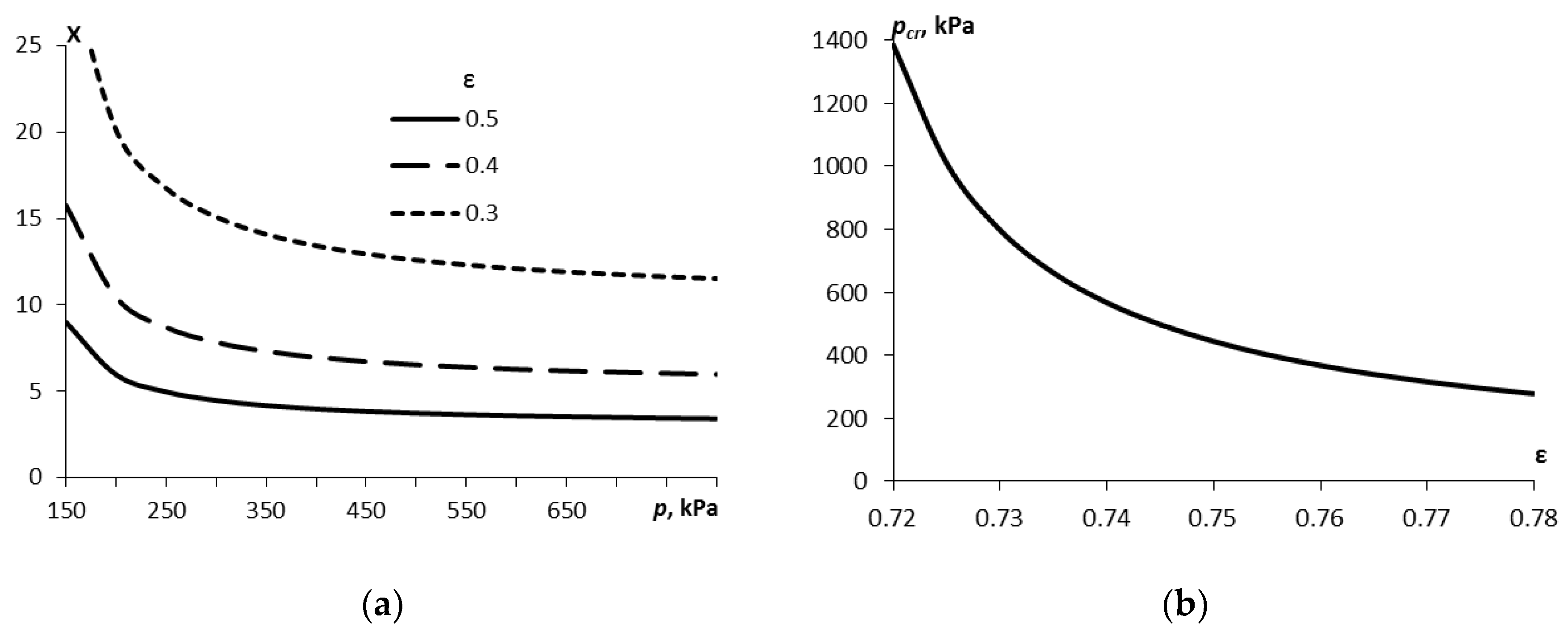

For X > 1, the flow regime is pre-cavitation; for X < 1, developed cavitation is observed. From equation (1) we obtain the cavitation pressure threshold:

where

. At pressures above

pcr, hydrodynamic cavitation occurs.

It should be noted that the pressure

p1 in the cavitation zone differs from the liquid pressure at the inlet to the structure

p. By solving the system of continuity and Bernoulli equations in two sections – at the entrance and exit to the cavitation zone – we obtain an expression for the pressure in the cavitation zone:

where

S0 =

S3 –

S1 is the cross-sectional area of the annular part of the structure (flow area before entering the cavitation zone).

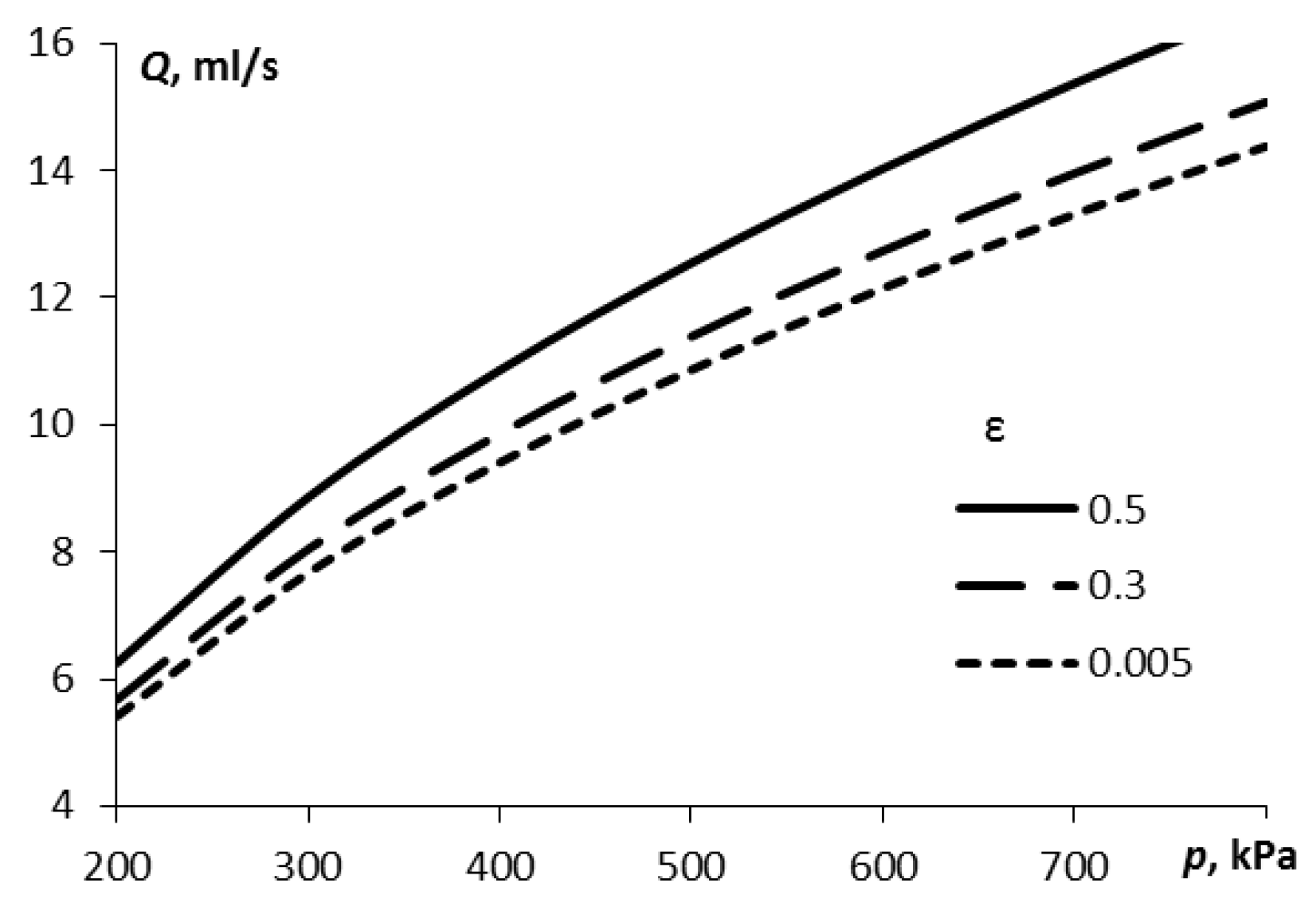

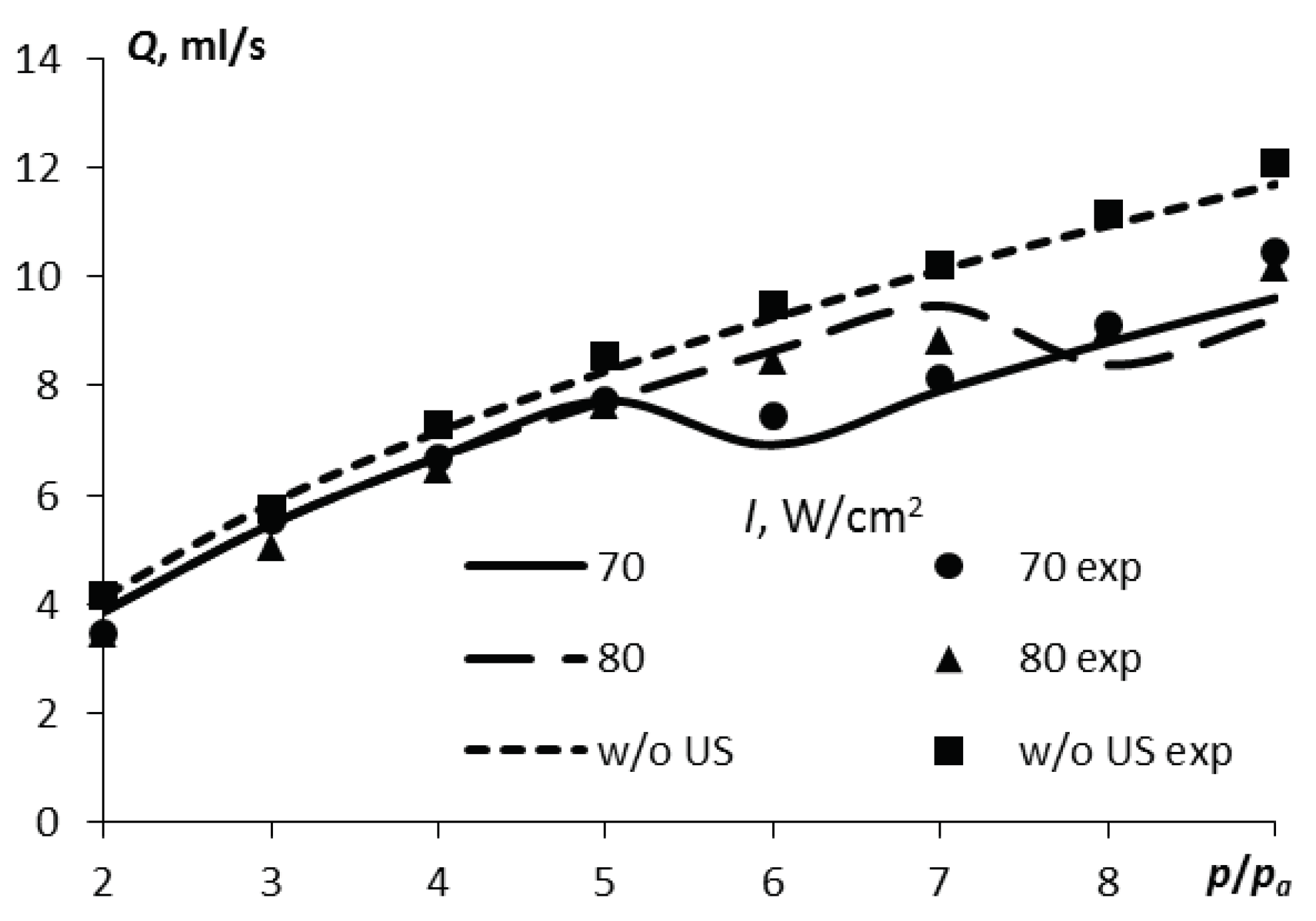

The volumetric flow rate of the liquid is expressed by the equation:

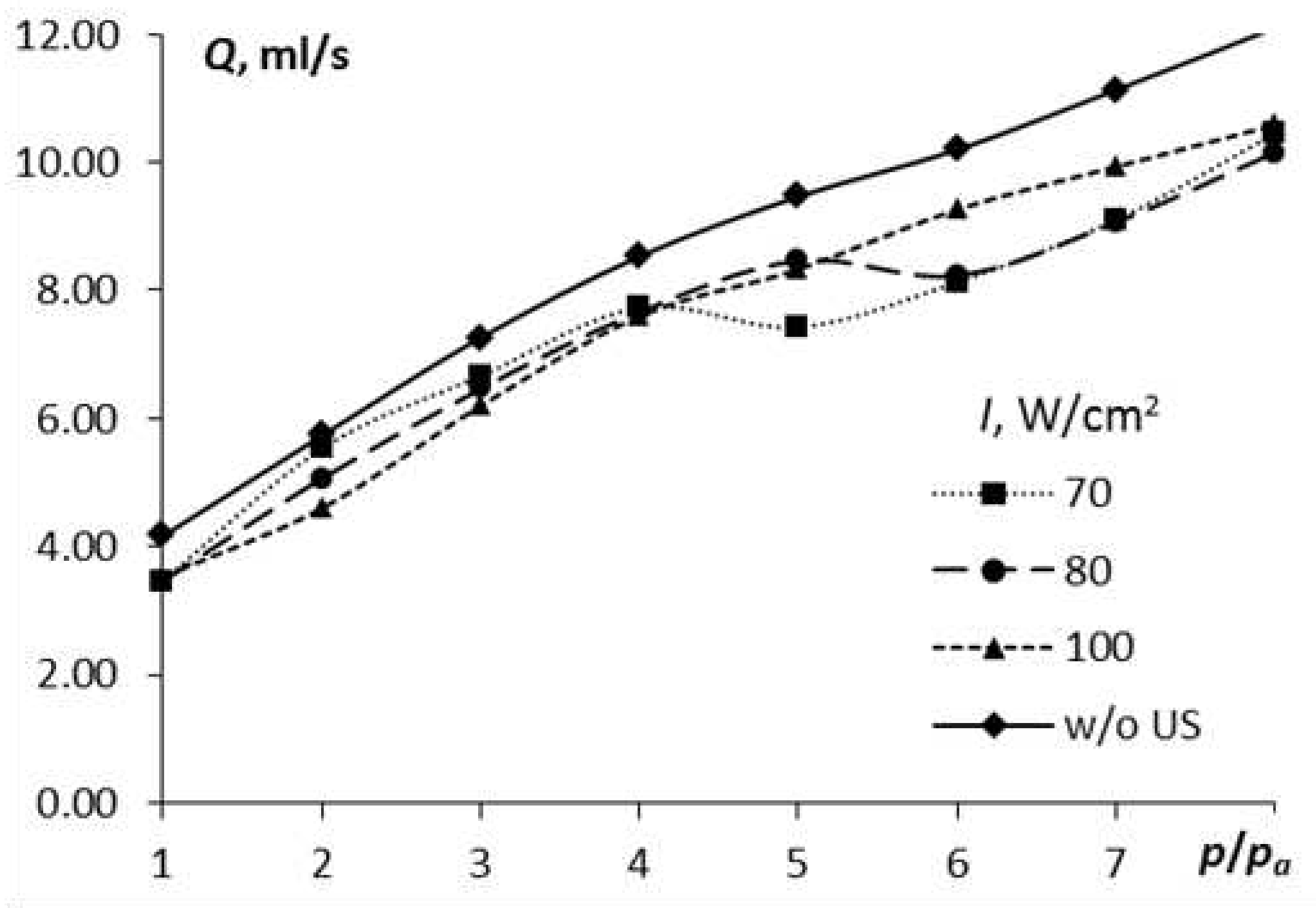

We will evaluate the performance of the nozzle under consideration in accordance with expression (5).

3.2. Ultrasonic exposure. Acoustic cavitation threshold

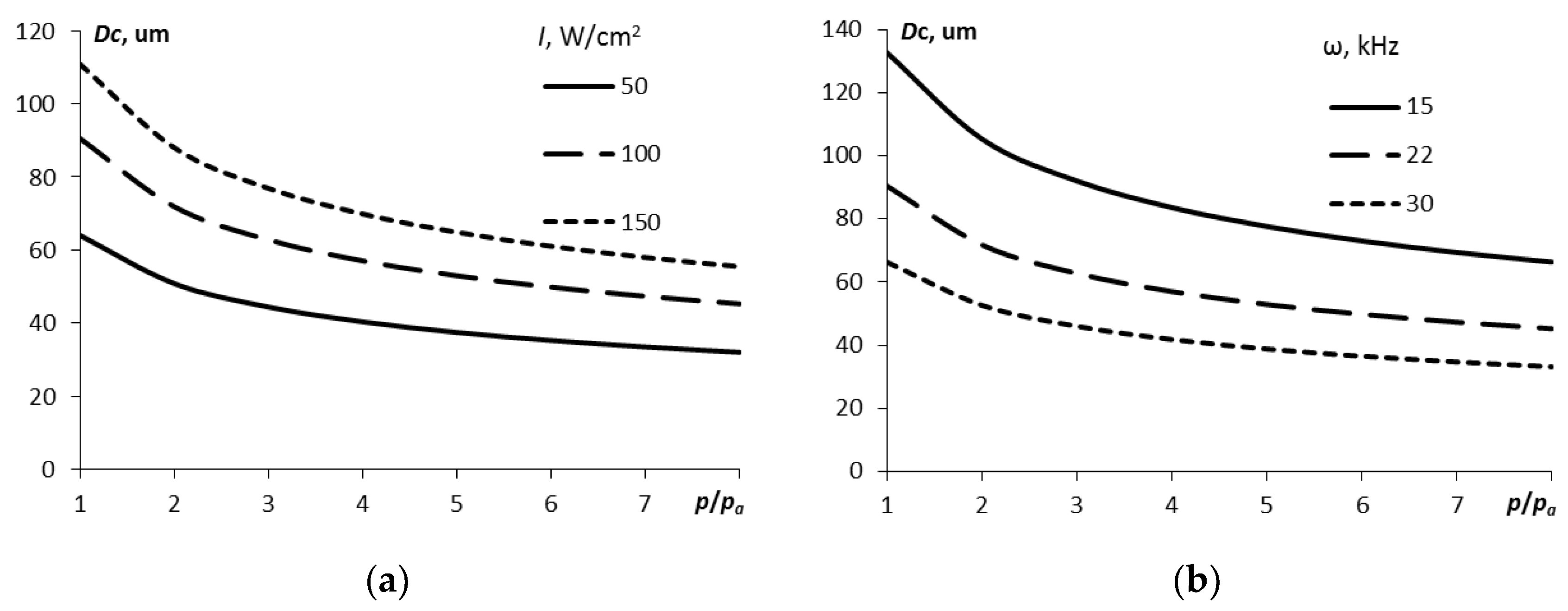

In the cavitation zone of the structure, between the end of the emitter and the outlet, conditions for the development of cavitation are created. Even with a low intensity of ultrasonic exposure, bubbles filled with water vapor appear in the liquid in this area. The size of the bubbles depends significantly on the intensity of the sound field:

This expression is obtained from the following considerations. The amplitude of the displacement of liquid particles in a sound wave A is related to the ultrasound intensity I [W/m2], the speed of sound c and the frequency ω by the known relationship: . When a wave passes through a liquid in the unloading phase, discontinuities of size A are formed in it, and in the compression phase, gas bubbles with a diameter Dc are formed at the site of these discontinuities. The diameter of the cavitation bubble corresponds to the size of the gap A.

From equation (6) it follows that the higher the ultrasound intensity, the larger the diameter of the bubbles formed. In this case, with the development of cavitation, the wave resistance

Wl = ρ·

c decreases significantly in accordance with the increase in the volume fraction of vapors in the liquid [

12], which means that the diameter of the bubbles also increases.

Let us consider the following qualitative physical picture of the development of cavitation. At a minimum intensity of ultrasound of

Imin in the liquid volume, cavitation bubbles in the amount of

N0 are formed on existing inhomogeneities (cavitation nuclei), which, in accordance with (6), will have a minimum size of ~

Imin1/2. Their number does not increase with increasing intensity, but their size, and, accordingly, volume gradually increases. The mode of developed cavitation occurs when a certain bubble size

Dcr is reached. In this case, the volume of bubbles Wg becomes comparable to the volume of liquid

Ww, and the continuity of the medium is disrupted. In the mode of developed cavitation, as confirmed experimentally, the cavitation coefficient K =

Wg /

Ww remains unchanged and corresponds to approximately 0.2 ÷ 0.3 [

13]. This limit is probably determined by the strength properties of the liquid. The volume of liquid in our case is determined as

Ww =

S1·

L. If the ultrasound intensity increases further, the size of the bubbles will continue to increase and their number will decrease. Let us denote the intensity corresponding to the mode of developed cavitation as

Icr. We will define this regime as critical and find the conditions for its occurrence.

With a further increase in intensity at a constant total volume of bubbles, their number N decreases in accordance with a power law with an exponent of 3/2. This means that the number of bubbles drops quickly at first and then weaker. We can conditionally select an intensity value Imax such that the change in the number of bubbles relative to the change in intensity is small. That is, a further increase in intensity practically does not affect the number of bubbles in the liquid. It can be shown that the bubble diameter in this regime will be approximately e times greater than Dcr, and the intensity Imax ~ e2·Icr.

The above considerations correspond to the case of the absence of excess hydrostatic pressure in the liquid. The size of the bubbles, of course, also depends on the pressure in the liquid. According to the Boyle-Mariotte law:

Thus, the critical volume of bubbles will be proportional to the ratio of the critical value of intensity to the power of 3/2 and pressure:

This means that, depending on the hydrostatic pressure, a noticeable cavitation effect from ultrasonic exposure will be observed at different values of ultrasound intensity: the higher the pressure, the higher the ultrasound intensity required for developed cavitation and vice versa.

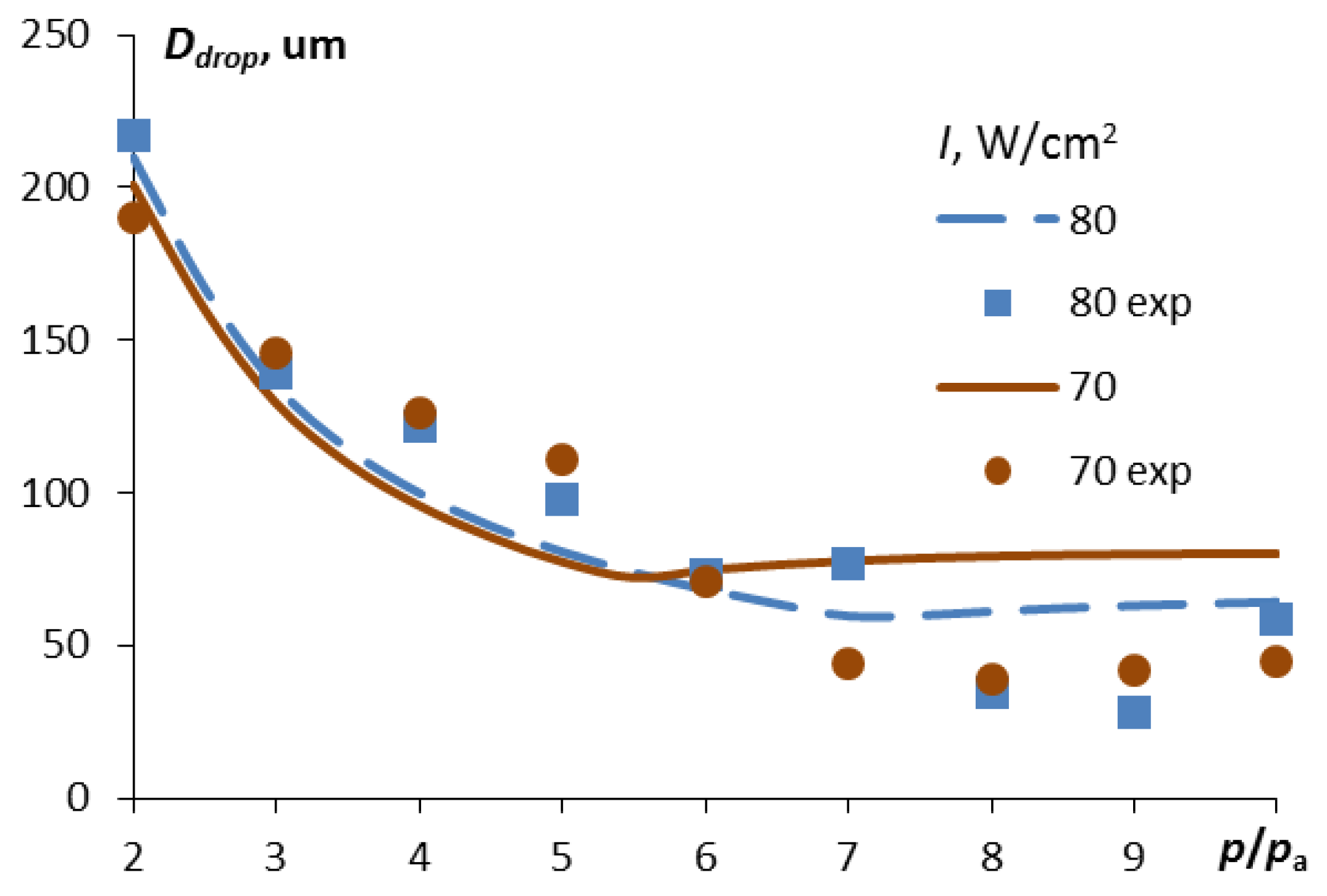

As follows from dependencies (6) and (7), the diameter of the cavitation bubble is proportional to the square root of the ultrasound intensity and inversely proportional to the ultrasound frequency and the cube root of the hydrostatic pressure:

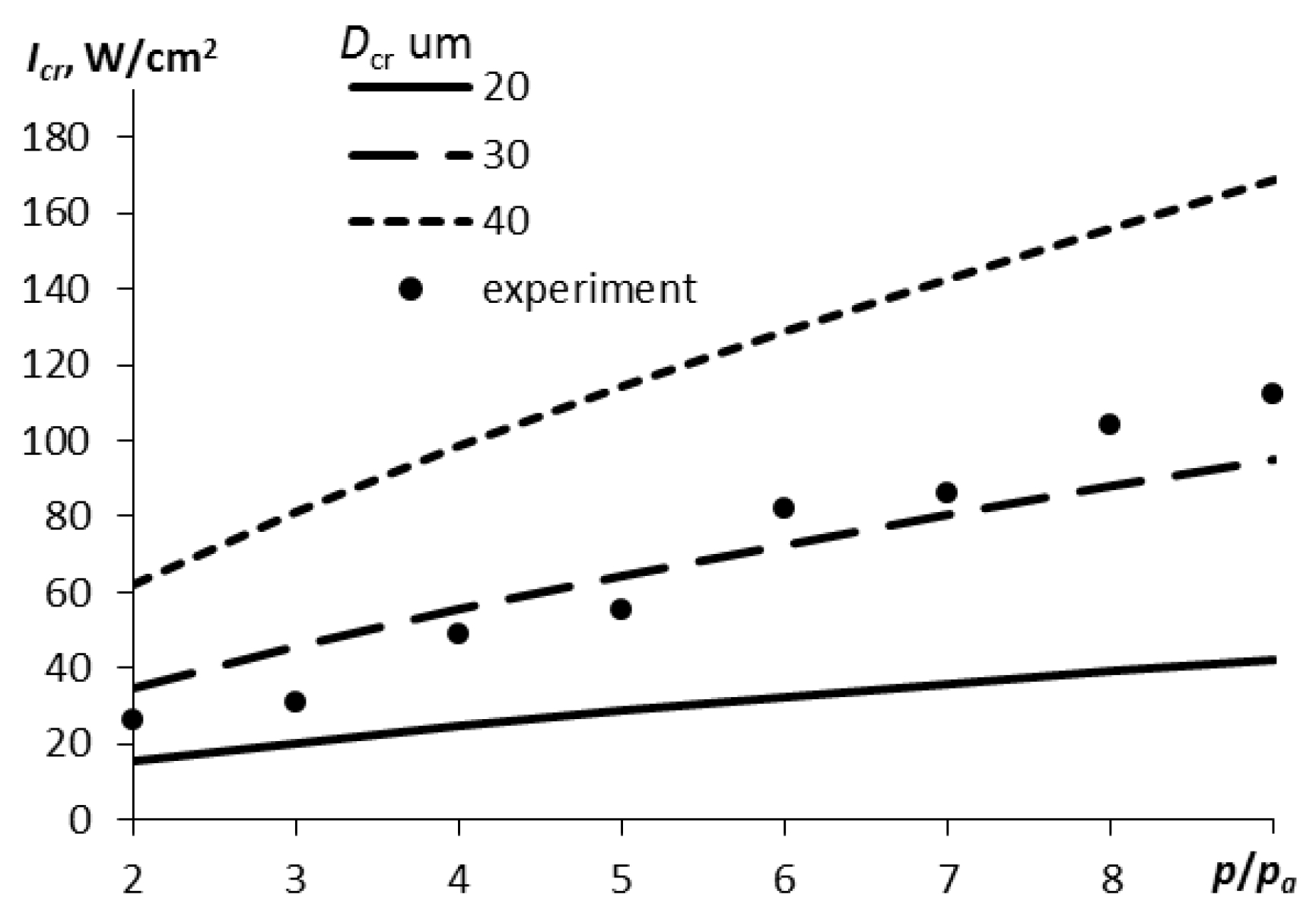

We will consider the critical diameter

Dcr to be a free parameter of the model. In accordance with it, at a given hydrostatic pressure, the critical (threshold) intensity of developed cavitation is determined:

Note that, in accordance with equation (10), the critical intensity will be proportional to the hydrostatic pressure to the power of 2/3. The higher the pressure in the liquid, the higher the required ultrasound intensity for the onset of developed cavitation.

The number of bubbles will be determined as the ratio of the gas volume to the volume of one bubble, calculated according to formula (9):

As will be shown below, the size of the droplets depends significantly on the size of the bubbles and their number.

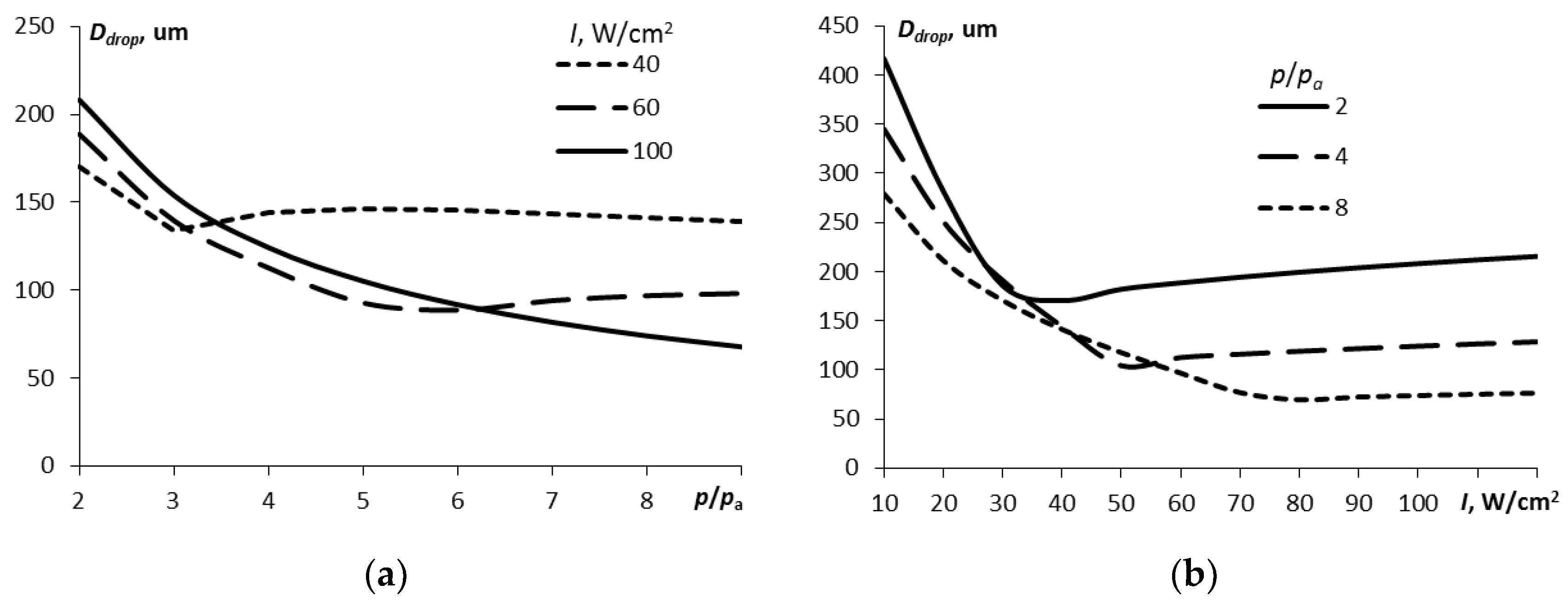

3.3. Droplet size upon expiration of cavitated liquid

What happens to the bubble after its nucleation? As shown in [

13], under conditions of continuous flow, cavitation bubbles do not collapse, but only grow.

It can be assumed that when the cavitated liquid flows into the atmosphere, each bubble will carry with it a layer of liquid, inversely proportional to the number of bubbles:

Ww/

N. This volume will determine the maximum volume of the drop. Then, taking into account (9) and (11), its diameter is:

Thus, the maximum droplet diameter is 1.5-1.7 times larger than the diameter of the cavitation bubble. This model does not take into account the surface energy of the liquid carried by the cavitation bubble. On the other hand, a gas bubble surrounded by liquid, when exposed to atmospheric pressure, will behave like a soap bubble. It will expand to a certain maximum size, determined by surface tension forces, and only then will it collapse into fragments with sizes on the order of the thickness of the liquid layer at that moment [

14]. Let's take a closer look at this model.

Since the outflow occurs quickly, the cavitation expansion can be considered adiabatic:

where γ is the adiabatic index of liquid vapor,

pmin is the minimum pressure in the bubble at the moment of destruction,

Dmax is the maximum diameter of the bubble before destruction. The bubble expands as long as the surface energy of the liquid layer σ·

Sc is greater than the internal energy of the vapor inside it

pminWc, where

Wc is the volume of the cavitation bubble,

Sc is its surface, σ is the surface tension. When these energies become equal, it will collapse. From here we obtain the minimum pressure in the bubble at the moment of destruction:

Solving equations (9, 13, 14) together we obtain the value of the bubble diameter before destruction:

The volume of liquid that the bubble carried with it is

, where the diameter

D0 is determined by expression (12). Let us denote the outer diameter of the bubble before destruction by

Dend. Then from the law of conservation of mass it follows:

. From here

It can be assumed that the minimum droplet size will be equal to the thickness of the liquid layer upon destruction of the cavitation bubble. The thickness of the water layer at the moment of destruction, and therefore the size of the droplets, will be

Ddrop = (

Dend –

Dmax) / 2. Or, taking into account (13):

A joint solution of equations (9), (15) and (17) will give an estimate of the minimum size of droplets formed during spraying, depending on the characteristics of ultrasonic influence, pressure and properties of the liquid. In equation (17), the coefficient k is introduced, which is a free parameter of the model. If k = 1, then equation (17) gives a lower estimate for the droplet size. However, the size of all droplets will not be minimal; a spectrum of particle sizes up to the maximum D0 is realized.

Thus, we proposed a mathematical model of the processes occurring in an acoustic-hydraulic nozzle and theoretically determined the critical modes, productivity and droplet size of the resulting aerosol. The model has two free parameters that need to be determined experimentally – Dcr and k. If our reasoning is correct, then the experimental dependences will have a character corresponding to that described theoretically, including the critical nature of spaying.