Submitted:

02 November 2023

Posted:

03 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

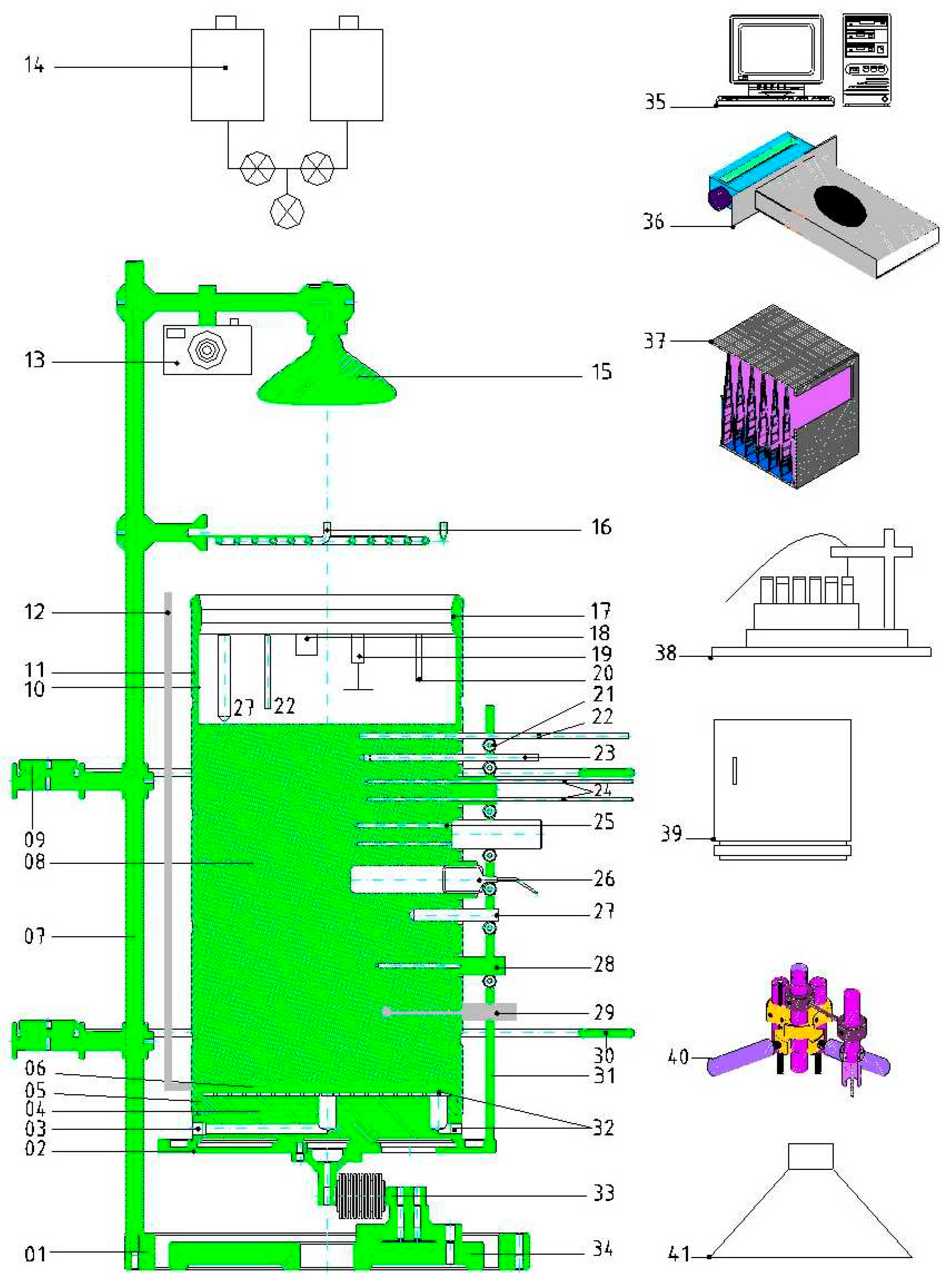

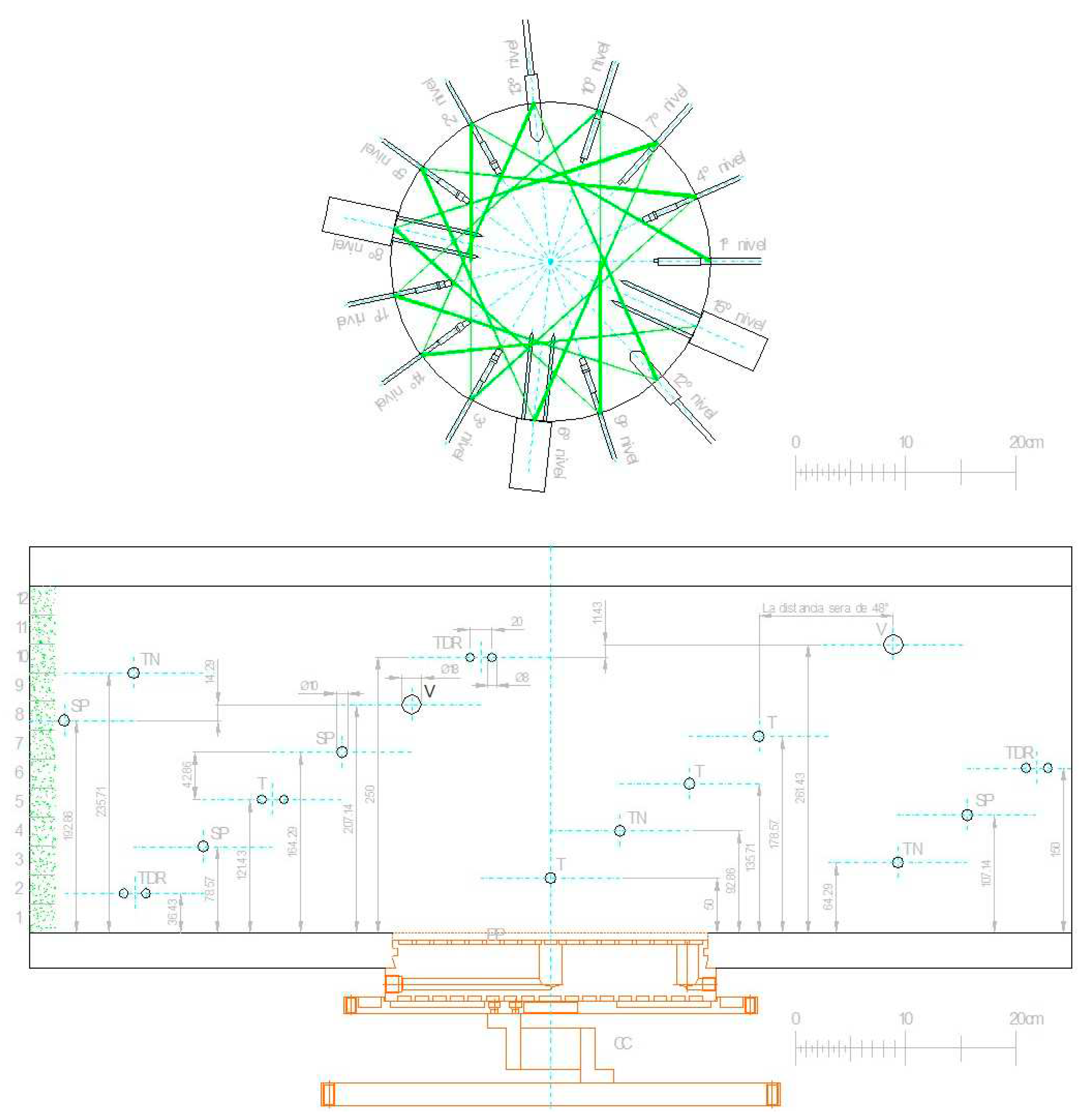

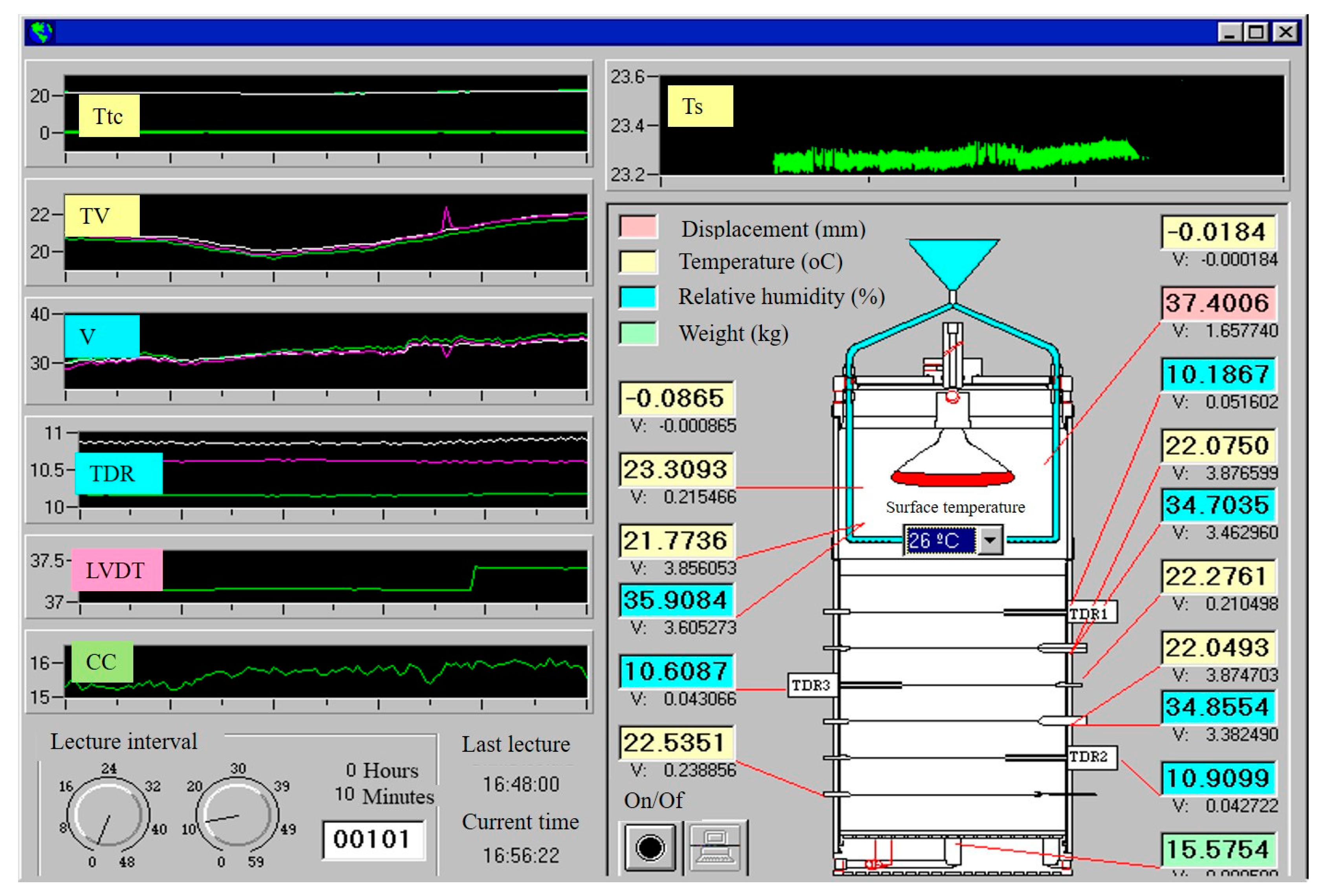

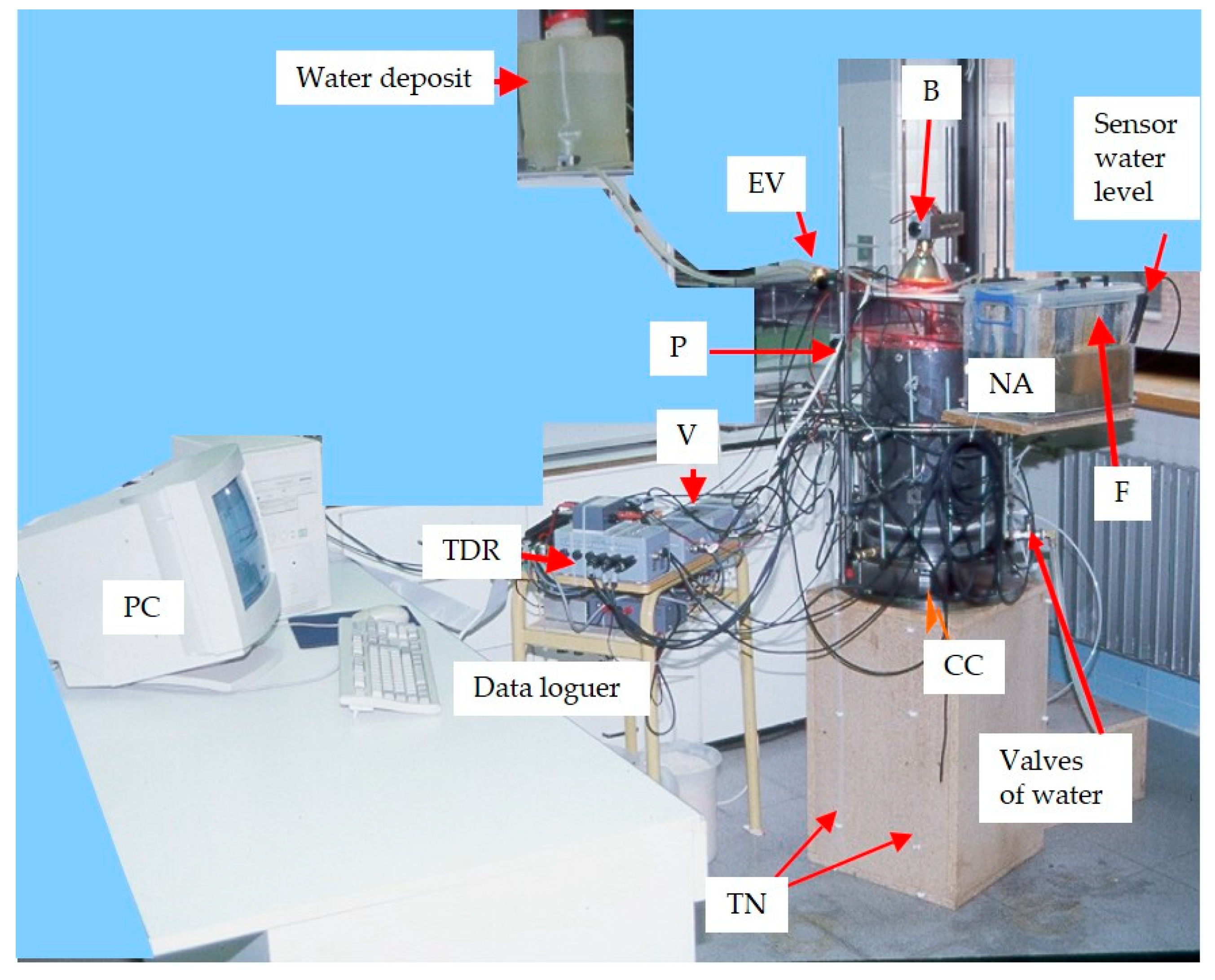

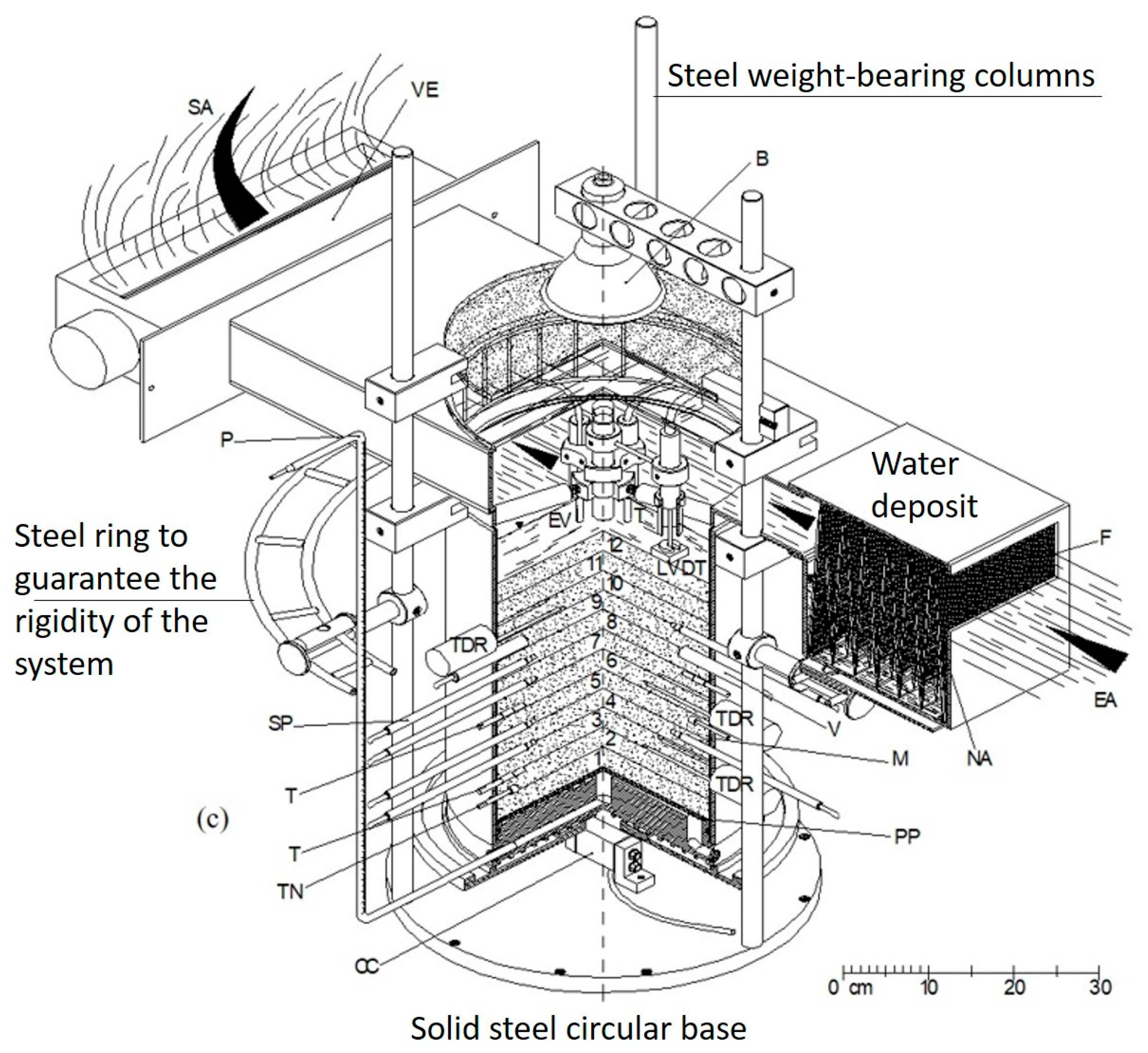

2.1. Description the Main Component of Automatic System

2.2. Materials

| Layers | H (cm) | A (cm2) | V (cm3) | Ws (g) | ρd (g/cm3) | η | Ww (g) | w |

|---|---|---|---|---|---|---|---|---|

| N=3 | ||||||||

| 1 | 2.55 | 637.94 | 1626.75 | 2300 | 1.41 | 0.64 | 1047.40 | 0.46 |

| 2 | 2.58 | 637.94 | 1645.89 | 2300 | 1.40 | 0.65 | 1066.54 | 0.46 |

| 3 | 2.59 | 637.94 | 1652.27 | 2300 | 1.39 | 0.65 | 1072.92 | 0.47 |

| 4 | 2.62 | 637.94 | 1671.41 | 2300 | 1.38 | 0.65 | 1092.06 | 0.47 |

| 5 | 2.63 | 637.94 | 1677.79 | 2300 | 1.37 | 0.65 | 1098.44 | 0.48 |

| 6 | 2.64 | 637.94 | 1684.16 | 2300 | 1.37 | 0.66 | 1104.82 | 0.48 |

| 7 | 2.65 | 637.94 | 1690.54 | 2300 | 1.36 | 0.66 | 1111.20 | 0.48 |

| 8 | 2.66 | 637.94 | 1696.92 | 2300 | 1.36 | 0.66 | 1117.58 | 0.49 |

| 9 | 2.67 | 637.94 | 1703.30 | 2300 | 1.35 | 0.66 | 1123.96 | 0.49 |

| 10 | 2.69 | 637.94 | 1716.06 | 2300 | 1.35 | 0.66 | 1136.72 | 0.49 |

| 11 | 2.68 | 637.94 | 1709.68 | 2300 | 1.34 | 0.66 | 1130.34 | 0.49 |

| 12 | 2.70 | 637.94 | 1722.44 | 2300 | 1.34 | 0.66 | 1143.10 | 0.50 |

2.3. Methods

3. Results

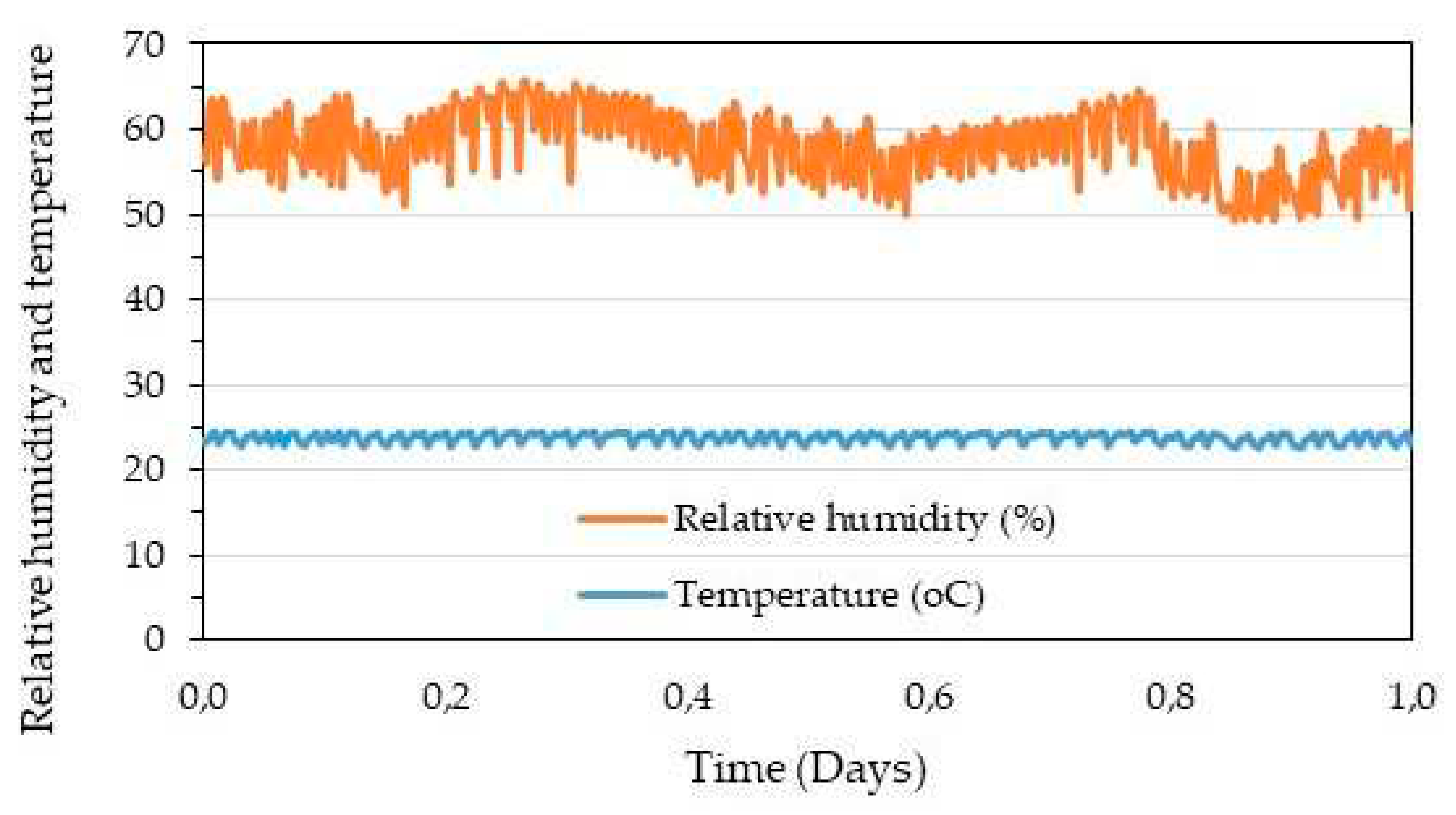

3.1. Espaciotemporal Evolution a Relative Humidity and Temperature

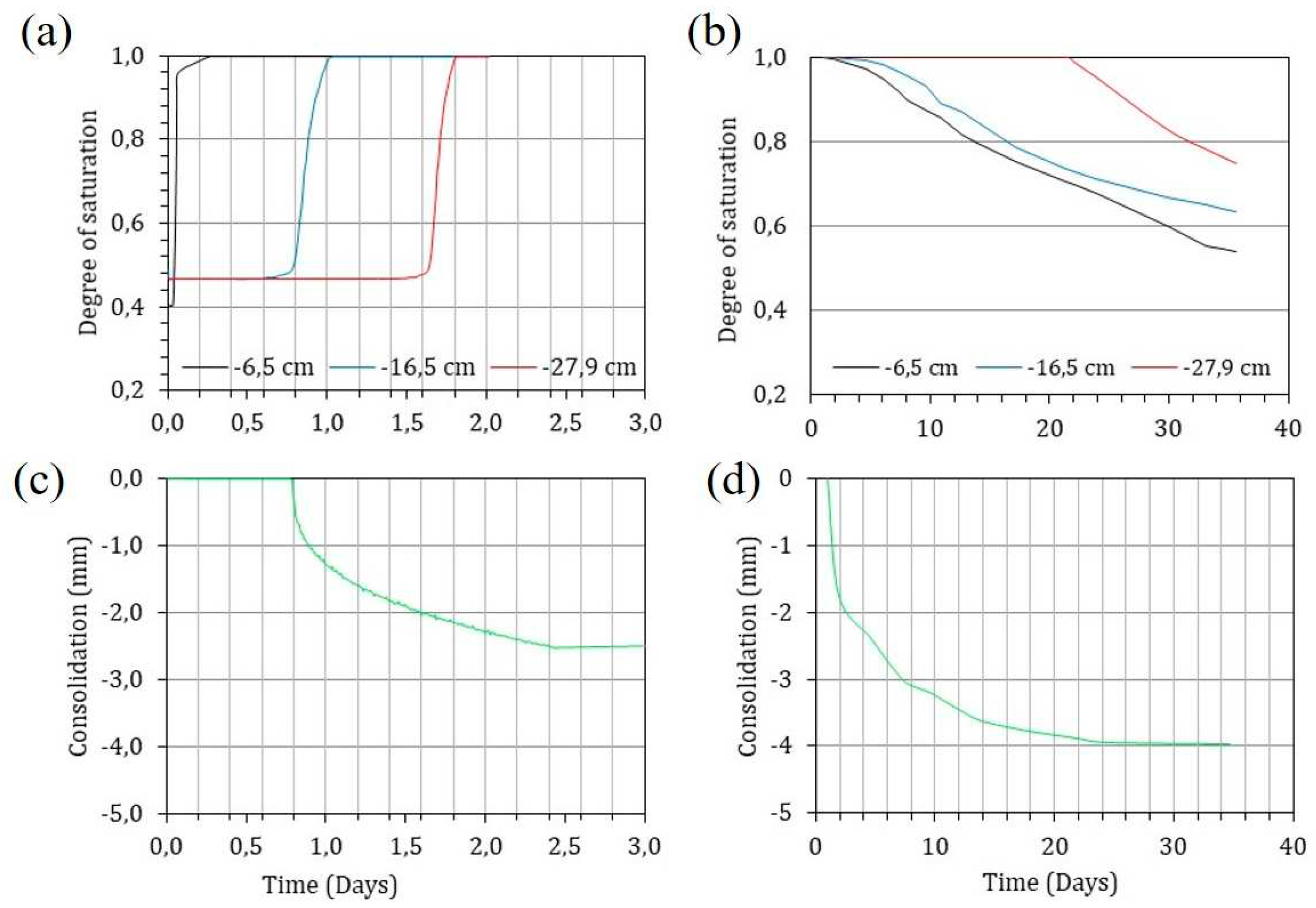

3.2. Espaciotemporal Evolution a Saturation, Dry and Consolidation a Tailings Sample

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Miller, E.D. Physics of swelling and cracking soils. J. Colloid, Interface Sci. 1975, 52, 344–443.

- Blight, G.E. Interactions between the atmosphere and the Earth. Geotechnique 1997, 47, 715–767.

- Rodríguez, R., Estudio Experimental de Flujo y Transporte de Cromo, Níquel y Manganeso en Residuos de la Zona Minera de Moa, Cuba: Influencia del Comportamiento Hidromecánico,” Ph.D. Thesis, University Polytechnic of Catalonia UPC, Barcelona, Spain, 2002.

- Rodríguez, R. Hydrogeotechnical characterization of a metallurgical waste. Can Geotecl J 2006, 43, 1042–1060. [CrossRef]

- Morris, P.H., Graham, J., Williams, D.J. Cracking in drying soils. Can. Geotech. J. 1992, 29, 263–277. [CrossRef]

- Rodríguez, R.; Candela L.; Lloret A. Experimental system for studying the hydromechanicalbehaviour of porous media. Vadose Zone J 4, 345–353.

- Lloret, A., Ledesma, A.; Rodríguez, R.L.; Sánchez, M.J. ; Olivella, S.; and Suriol, J. Crack initiation in drying soils. Proc. Int. Conf. on Unsaturated Soil, 2nd edition, 27–30 Aug. International Academic Publishers, China, Beijing, China. 1998. Vol. I. p. 497–502.

- Rodríguez R, Sánchez M, Ledesma A.; Lloret ,A. Experimental and numerical analysis of desiccation of a mining waste. Can Geotech J. 2007. 44, 644–658. [CrossRef]

- Swarbrick, G.E.; and Fell, R. Modelling desiccating behaviour of mine tailings. J. Geotech. Eng. ASCE. 1992,118, 540–557.

- Corwin, D.L. Evaluation of a simple lysimeter-design modification to minimize sidewall flow. J. Contam. Hydrol. 2000. 42, 35–49. [CrossRef]

- Garino Libardi LM, Oldecop LA, Romero Morales EE and Rodriguez-Pacheco, R.L. Tailings desiccation process studied in environmental chamber experiment. Proceedings of the Institution of Civil Engineers – Geotechnical Engineering, 2021, 1-11. [CrossRef]

- Lakshmikantha, M.R. Experimental and Theoretical Analysis of Cracking in Drying Soils. PhD thesis, Universitat Politècnica de Catalunya, Barcelona, Spain. 2009.

- Rodríguez, R., Lloret, A., Ledesma, A., and Candela, L. Characterization of Mine Tailings in the Cuban Nickel Industry,” Proc. 3rd Intern. Cong. on Environmental Geotechnics, P. S. Seco e Pinto Ed., V-1 Balkema, Rotterdam, 1998, pp. 353–358.

- Rodríguez Pacheco, R.L., Lloret A., Candela L. Pérez, T., Cortés, F. Dispositivo para la caracterización de medios porosos sujetos a diferentes condiciones ambientales y de contorno, 2006. Patent: 2 241 477. [CrossRef]

- Garino L, Rodari G and Oldecop L. Characterization of mine waste materials after 50 years of climate interaction. In PanAm Unsaturated Soils. Applications (Hoyos LR, McCartney JS, Houston SL and Likos WJ (eds)). American Society of Civil Engineers, Reston, VA, USA, GSP 302, 2017. [CrossRef]

- Garino Libardi L and Oldecop L. Evolución de la humedad en presas de relaves mineros ubicadas en climas áridos. Caso de estudio: mina Castaño Viejo, San Juan, República Argentina. Boletín Geológico y Minero de España, Monográfico 2021, 3(132), in press (in Spanish).

- Rodríguez R, Candela L, Lloret A, Apparatus for evaluation of haydomechanicalbehaviour of porous media subjected to environmental changes. Geotech Test J 2006, 29:9–20.

| Physical components | Diameter and height (m) | Function, parameters and range of measure | Accuracy | ||

| Outside | Inside | Height | |||

| Outer column | 0.30 | 0.29 | 0.50 | Avoid deformation of the sample and the shape of the porous medium and the position of the sensors | |

| Latex membrane | 0.29 | 0.285 | 0.50 | Avoid preferential flow through the walls due to separation of the porous medium from the walls | |

| Porous plate | 0.29 | - | 0.05 | Avoid percolation solid particles | |

| Base a porous media | 0.29 | - | 0.10 | Sample and sensor support. It facilitates the entry and exit of water through three different points. Allows the piezometric control in the sample. | |

| Automatic system base | 0.80 | - | 0.10 | Weight of sample, physical component and sensor support | |

| Fan generating air at 2 m/s speed | - | - | 0.10 | Maintain air inlet and outlet at a constant velocity | |

| Wet cotton filter | Humidify inlet air to maintain constant relative humidity | ||||

| Water deposit for cotton filter | Maintain cotton filters to ensure constant relative humidity of incoming air | ||||

| Infrared bulb to impose the temperature in degrees centigrade (oC) | Maintain constant surface temperature of the porous medium | 0-100 | |||

| Solenoid valve | Water flow that maintains the level inside the column and the reservoir where the filters that humidify the inlet air are placed | ||||

| Piezometer | 0.005 | 0.003 | 0.65 | Measuring the water table in the porous medium | |

| Glass | Diffuse light to avoid shadow effect | ||||

| Device for the application of a recharge or irrigation | 0.28 | - | 0.05 | Apply a rainfall of a determined duration and intensity | |

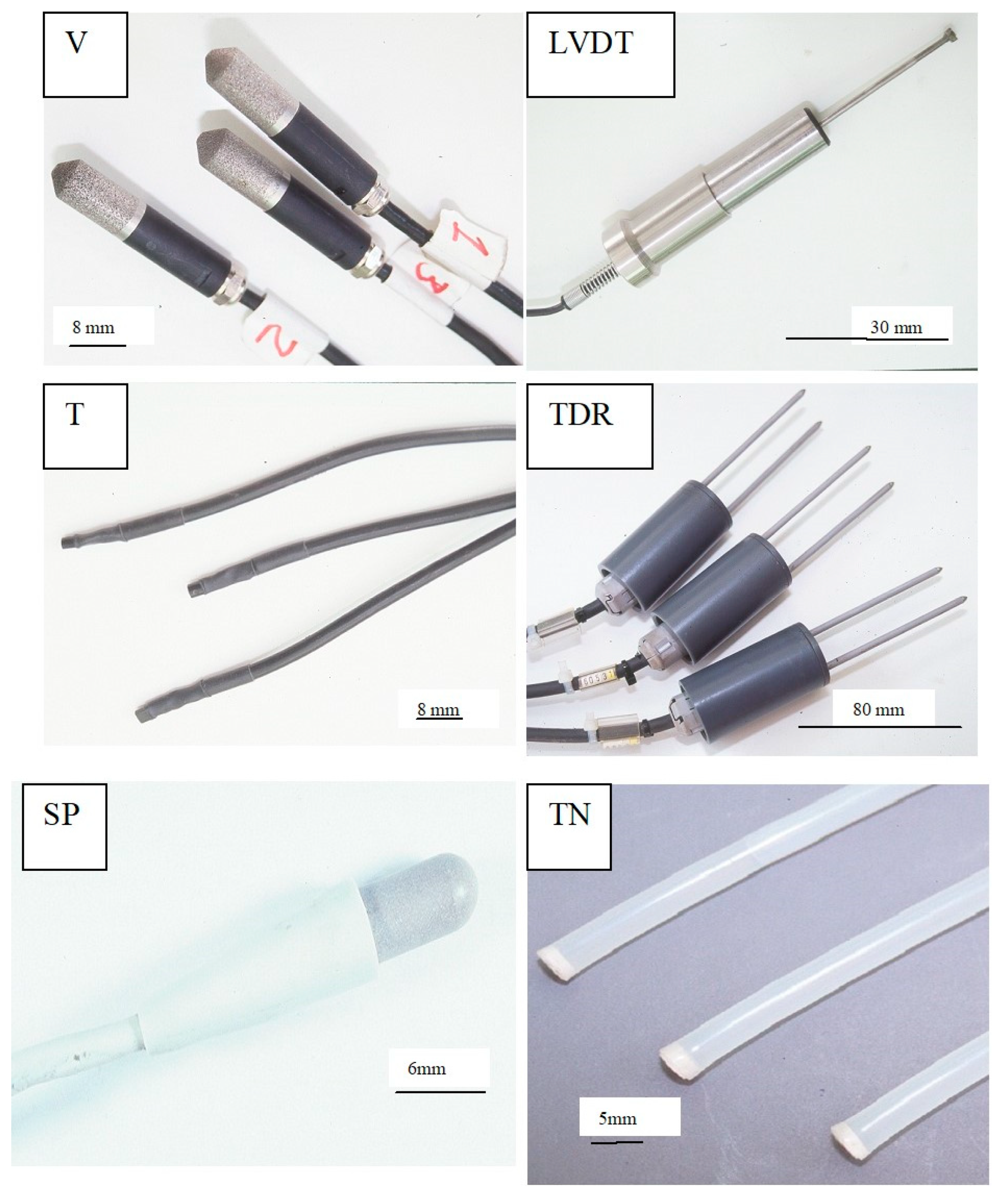

| Sensors, their characteristics and measurement parameters | |||||

| Hygrometers (Vaisala) | 0.012 | 0.50 | Relative humidity 0-99% Temperature 0-100 oC |

1.0 0.05 |

|

| Psychrometers (Wescor) | 0.06 | 0.50 | Suction 0-10 MPa% Temperature 0-100 oC |

0.001 0.2 |

|

| TDR - Time Domain Reflectometry (IMKO) | 0.025 | - | 0.08 | ||

| Thermometer (self-made) | 0.005 | 0.005 | Measurement of temperature at the surface and inside the vertical profile (0-100 oC) | 0.02 | |

| LVDT (Displacement Transducer) | 0.0025 | 0.066 | Measurement of height variation in the sample | 0.02 | |

| Load cell | Measurement of weight change in kilograms (0-100 kg) | ||||

| Tensiometer | 0.005 | Measuring suction in meter of water column (m.w.c.a.) 0.01-1.2 | 0.02 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).